EMBEDDED SYSTEM APPLICATIONS USING PIC18F4550

NORIAH BINTI MUSTAFA SHARMIZA BINTI KAMARUDDIN HELMI BIN JAMALUDIN

Editor PUZIAH BINTI YAHAYA Writer NORIAH BINTI MUSTAFA SHARMIZA BINTI KAMARUDDIN HELMI BIN JAMALUDIN Designer

Application Publishers and Developers Terbitan Edisi 2021

Copyright ©2021, by Politeknik Sultan Haji Ahmad Shah Materials published in this book under the copyright of Politeknik Sultan Haji Ahmad Shah. All rights reserved. No part of this publication may be reproduced or distributed in any form or by means, electronic, mechanical, photocopying, recording, or otherwise or stored in a database or retrieval system without the prior written permission of the publishers

Published by POLITEKNIK SULTAN HAJI AHMAD SHAH SEMAMBU 25350 KUANTAN Embedded System Applications Using PIC18F4550

i

ACKNOWLEDGMENT It is grateful to have a chance to contribute to this e-book project with guidance and countless help in every part of its production process. We like to express our gratitude for the supports of our family and friends.

ABSTRACT This e-book has developed based on a series of lectures notes used in the Embedded System Applications course in the Electrical Engineering Department, Polytechnic Sultan Haji Ahmad Shah (POLISAS). It contains eight chapters that parallel the syllabus of Embedded System Applications for Diploma of Electrical/Electronic Engineering in Polytechnics curriculum. This book covers the basic concept and application of a microcontroller system based on Peripheral Interface Controller (PIC) microcontroller. Students will learn software and hardware development on the PIC18F4550 microcontroller and understand how to do interface with external devices using suitable internal chip features. The variety of examples and review questions in this book may help students to have a better understanding of Embedded System Application using PIC18F4550.

ii

TABLE OF CONTENTS ACKNOWLEGEMENT

ii

ABSTRACT

ii

CHAPTER 1

1

INTRODUCTION TO EMBEDDED SYSTEM

1

1.1 Introduction

1

1.2 Real-Life Applications That Use Embedded System

1

1.3 Microcontroller Versus General-Purpose Microprocessor

2

1.3.1 Microprocessor

2

1.3.2 Microcontroller

3

1.5 The Advantages Of Microcontroller

5

1.6 Disadvantages Of Microcontroller

6

1.7 Microcontrollers Available In The Market

6

REVIEW QUESTIONS

7

CHAPTER 2

8

PIC PROGRAMMING IN C

8

2.1 Introduction

8

2.2 PIC18F4550 Microcontroller

8

2.3 Dual Role Of I/O Ports

9

2.4 Pic Programming In C

11

2.4.1 Compiler For Pic Microcontroller

11

2.4.2 Program Structure

12

2.4.3 C Data Types For The PIC18

13

2.4.4 Declaring Variable

14

2.4.5 Data Format In C

15

2.5 Byte & Bit I/O Programming

15

2.6 I/O PORT SFR Register

15

2.6.1 TRISx Register

17 iii

2.6.2 PORTx Register

18

2.6.3 LATx Register

19

2.7 LED (Light Emitting Diode)

20

2.8 Using Delay Function

23

2.9 Push Button Switch

26

REVIEW QUESTIONS

31

CHAPTER 3

32

PIC TIMER PROGRAMMING IN C

32

3.1 Introduction

32

3.2 PIC18F4550 TIMER

32

3.3 TIMER Register

34

3.3.1 TIMER0 Programming

35

3.3.2 TIMER0 Control Register (T0CON)

35

3.3.3 Prescaler

36

3.3.4 TMR0IF Flag Bit

38

3.4 Program TIMER0 To Generate Time Delay

39

3.4.1 STEPS TO PROGRAM TIMER0 TO GENERATE TIME DELAY

39

3.4.2 FINDING VALUES TO BE LOADED INTO TMR0H AND TMR0L

40

3.4.3 PRESCALER AND GENERATING A LARGE TIME DELAY

41

3.5 Programming TIMER0 As Counter

45

3.6 T0CON In Counter Mode

46

3.7 Step To Programming TIMER0 as Counter

47

REVIEW QUESTIONS

51

CHAPTER 4

52

INTERRUPT PROGRAMMING IN C

52

4.1 Introduction

52

4.2 Interrupt Vs Polling

52

4.3 Interrupt Service Routine (ISR)

53

iv

4.4 Sources Of Interrupts In PIC18

53

4.5 Bits To Control Interrupt Operation

54

4.6 Interrupt Registers

54

4.6.1 RCON - Reset Control Register

54

4.6.2 INTCON – Interrupt Control Register

55

4.6.3 INTCON2 - Interrupt Control Register 2

55

4.6.4 INTCON3 - Interrupt Control Register 3

56

4.7 Programming External Hardware Interrupt 4.7.1 Step To Enable External Hardware Interrupt

56 57

REVIEW QUESTIONS

63

4.8 Programming TIMER0 Interrupt

64

4.8.1 Program TIMER0 Interrupt to Perform Multitasking

65

4.8.2 Program TIMER0 Interrupt for Real Time Applications

68

REVIEW QUESTIONS

70

CHAPTER 5

71

BASIC ELECTRONIC CONNECTION

71

5.1 Minimum Electronics Connection Of Embedded System

71

5.1.1 Power Supply

71

5.1.2 Reset Circuit

72

5.1.3 Clock Signal

72

5.2 Digital Input Output In Pic

73

5.2.1 Digital Input

73

5.2.1.1 Active Low Input (Switch)

74

5.2.1.2 Active High Input (Switch)

74

5.2.2 Digital Output

75

5.2.2.1 LED

75

5.2.2.2 16X2 LCD Display

79

REVIEW QUESTIONS

89

v

CHAPTER 6

90

HARDWARE INTERFACING: ANALOG TO DIGITAL CONVERTER (ADC)

90

6.1 Analogue-To-Digital Converter (ADC)

90

6.2 PIC18F4550 ADC Features

90

6.3 PIC18F4550 ADC Registers

92

6.3.1 ADCON0 Register

92

6.3.2 ADCON1 Register

93

6.3.3 ADCON2 Register

94

6.3.4 ADRESH & ADRESL Register

95

6.4 Calculating A/D Conversion Time

96

6.5 Steps To Program ADC In PIC18

96

6.6 Sensor Interfacing and Signal Conditioning

98

6.6.1 LM35 Temperature Sensor

98

6.7 Reading And Displaying Analogue Value

100

REVIEW QUESTIONS

103

CHAPTER 7

105

HARDWARE INTERFACING: PULSE WIDTH MODULATION (PWM)

105

7.1 Pulse Width Modulation (PWM)

105

7.2 PIC18F4550 PWM

106

7.3 PWM Duty Cycle

106

7.4 PWM Register

108

7.4.1 PR2 Register

108

7.4.2 TIMER2 Control Register (T2CON)

109

7.4.3 CCP Control Register (CCPXCON)

110

7.4.4 CCPRXL Register

111

7.5 Steps For Programming

113

7.6 Application Of PWM

114

7.6.1 Application 1: Generating PWM Signal

114

7.6.2 Application 2: Control The Brightness Of LED Using PWM

116

7.7 DC Motor

117 vi

7.7.1 L293D Motor Driver IC

118

7.7.2 Application 3: Control Dc Motor Speed Using PWM

120

REVIEW QUESTIONS

124

CHAPTER 8

125

HARDWARE INTERFACING: SERIAL COMMUNICATION

125

8.1 Serial Communication

125

8.1.1 PIC18F4550 UART

125

8.2 PIC18F4550 UART Register

126

8.2.1 SPBRG Register

126

8.2.2 BAUD RATE

126

8.2.3 TXSTA (Transmit Status And Control Register)

128

8.2.4 RCSTA (Receive Status And Control Register)

129

8.2.5 PIR1 (Peripheral Interrupt Request Register )

130

8.2.6 BAUDCON (Baud Rate Control Register)

131

8.3 Step To Program The PIC18 To Transmit Data Serially

132

8.4 Step To Program The PIC18 To Receive Data Serially

135

REVIEW QUESTIONS

137

CHAPTER 9

138

MINI PROJECT

138

9.1 Title: Dc Motor Control With PIC18F4550 and L293D (Proteus Simulation)

138

9.2 Circuit Diagram

138

9.3 Flow Chart

139

9.4 Programming

140

REFERENCES

146

vii

CHAPTER 1 INTRODUCTION TO EMBEDDED SYSTEM 1.1 Introduction

Embedded Systems are electronic systems within an equipment that contain a microprocessor or microcontroller, which are directly interfaced with input and output devices designed to perform a particular task.

“Embedded Systems are electronic systems that contain a microprocessor or microcontroller, but we do not think of them as computers – the computer is hidden or embedded in the system.” - Todd D. Morton author of Embedded Microcontrollers. Embedded system cannot be programmed by the user because it is preprogramed within the equipment which it serves.

1.2 Real-Life Applications That Use Embedded System

As consumer we use many applications that use embedded system such as Security system, automatic gate, answering machine, TV, VCR, Remote control, mobile phone, toys, smart cooker, microwave oven, automatic washing machine.

Embedded systems are not always standalone devices. Many embedded systems consist of small, computerized parts within a larger device that serves a more general purpose. Each of these peripherals has a microcontroller inside it that performs only one task.

A Personal Computer (PC) connected to various embedded products such as the keyboard, printer, modem, graphic card, mouse and so on. For example, inside every mouse a microcontroller performs the task of finding the mouse’s position and sending it to the PC. In a car many applications that use embedded systems - automotive safety systems include anti-lock braking system (ABS), Electronic Stability Control (ESC/ESP), traction control (TCS) and automatic four-wheel drive ,air bag, security system, keyless entry.

1

Airplanes contain advanced avionics such as inertial guidance system and GPS. Embedded system also used in RADARs, guided Missile System, automated guns and satellite phones.

1.3 Microcontroller versus general-purpose microprocessor

Processor is the heart of an embedded system. It is the basic unit that takes inputs and produces an output after processing the data. For an embedded system designer, it is necessary to have the knowledge of both microprocessors and microcontrollers.

1.3.1 Microprocessor

A microprocessor is a general-purpose processor with no external components attached to it. A microprocessor can perform various tasks depending on the user requirement. Some of the examples are web browsing, video gaming, sending emails, editing documents, etc. There are many microprocessors available that we use in modern computers and embedded system applications. Figure 1.1 shows different types of microprocessor chips.

Figure 1.1: Different type of microprocessor chips ( https://www.elprocus.com )

Therefore, we need to connect these peripherals with microprocessors according to the user requirement. We need to add I/O ports, serial communication ports, RAM, ROM and timers to a general-purpose processor to make it functional. The addition of these components makes systems more expensive and bulkier but they make a selection of systems more versatile. Because users can select RAM, ROM, input/output ports and other features

2

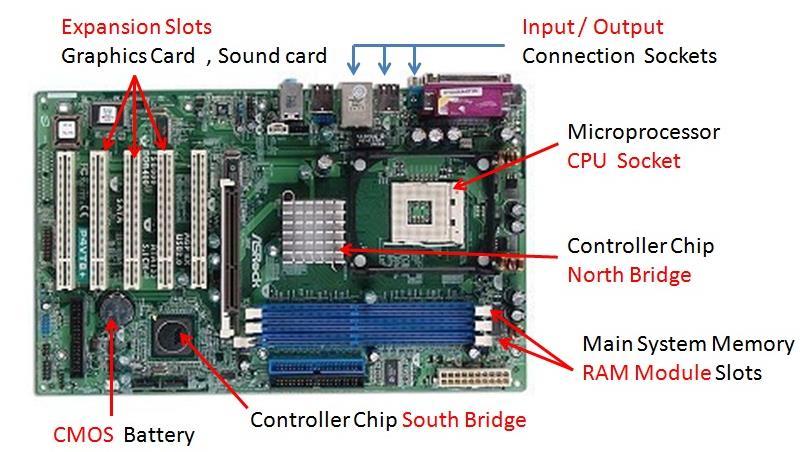

according to their requirement. An example of microprocessor applications is on computer motherboard as shown in Figure 1.2.

Figure 1.2: Component in computer motherboard (https://www.learncomputerscienceonline.com )

1.3.2 Microcontroller

A microcontroller (sometimes abbreviated µC, uC or MCU) is a single integrated circuit containing a processor core, memory, and programmable input/output peripherals. Microcontroller also called computer in chip. The fixed amount of on-chip ROM, RAM, and number of I/O ports in microcontroller makes them ideal for low cost and low space applications. Figure 3 shows the illustrations of inside of a microcontroller.

Figure 3: Inside microcontroller chip (https://www.polytechnichub.com)

3

Components inside microcontroller chip:

a.

CPU – Central Processing Unit (CPU) is the brain of the Microcontroller. A CPU reads, decodes and executes program to perform Arithmetic, Logic and Data Transfer operations.

b.

Memory – two types of Memory: Program Memory and Data Memory. Program Memory is used to store program source codes to be executed by the CPU. Data Memory is used to store temporary data while executing the instructions.

c.

Input/output (I/O) ports – interface for the Microcontroller to the external world. Inputs receive changes in the real-world, from sensor or push buttons, and much more provide information to the CPU. The CPU, upon receiving the data from the input devices, executes appropriate instructions and sends a signal to the output ports.

d.

Serial Ports – to communicate with other device and peripherals (external). Serial Port proves such interface through serial communication.

e.

Timers – provide the operations of Time Delays and counting external events.

f.

ADC (Analog to digital converter) – convert analog signals to digital.

g.

DAC (digital to analog converter) – supervise analog appliances like- DC motors, etc.

A microcontroller can perform only specific predefined tasks. Although a user can program it to perform any task. But once it is programmed, it can perform only specific tasks such as DC motor speed control, remote monitoring systems, etc. Figure 1.3 shows an example of application of microcontroller in embedded system.

Figure 1.3: Microcontroller chip in pen drive (https://steemit.com)

4

1.4 Differences between a microcontroller and microprocessor

The following are the major features to describe the difference between a microprocessor and microcontroller. Based on these aspects, we can clearly summarize the comparison between both digital integrated circuits.

Table 1.1: Differences between a microcontroller and microprocessor Aspect Internal Structure difference

Processing Speed

Microcontroller

Microprocessor

Support devices are

Must add RAM, ROM, I/O ports, and

internal for a

timers externally to make the

microcontroller

microprocessor functional.

Lower speed (in MHz range)

Higher speed (in GHz range)

Power

A microcontroller is used

Due to the high-speed processing

consumption

in low power and low-

requirement, the microprocessor

difference

speed applications

used more power consumption.

Cost Difference

Much cheaper and lower in cost

System more costly

Applications

Performs only one task

Perform various tasks

Software

Microcontrollers offer

Microprocessor based system fails to

protection

software protection

offer software protection system.

1.5 The advantages of microcontroller

a. support devices are internal – small system board b. Program is difficult to copy because of copy protection functions and an emulator will be required to copy it. c. Reduce chip count d. Many applications do not require as much computing power 5

1.6 Disadvantages of microcontroller

a. Can only do a specific task b. Limited amount of memory, I/O port and other internal features such as timers. c. Cannot add any external memory or I/O ports d. Different manufacturer using different internal architecture of microcontroller such as register and internal features

1.7 Microcontrollers available in the market

Today various types of microcontrollers are available in the market with different word lengths such as 4 bit, 8bit, 64 bit and 128-bit microcontrollers. There are several microcontroller architectures and vendors.

Table 1.2: Examples of vendor and microcontroller chips. Vendor ARM core processors (many vendors) Atmel Cypress Semiconductor Freescale Intel

Microchip Technology

Example of microcontroller chip ARM Cortex-M Atmel AVR (8-bit), AVR32 (32-bit), and AT91SAM (32-bit) PSoC (Programmable System-on-Chip) Freescale ColdFire (32-bit) and S08 (8-bit) Freescale 68HC11 (8-bit) Intel 8051 PIC, (8-bit PIC16, PIC18, 16-bit dsPIC33 / PIC24), (32-bit PIC32)

6

REVIEW QUESTIONS

1. Describe the meaning of embedded systems. 2. Describe the advantages of microcontroller application 3. List FOUR (4) common microcontrollers that available in the market 4. Identify THREE (3) examples of embedded system applications that are used in a car electronic system. 5. List THREE (3) embedded products attached to a personal computer.

7

CHAPTER 2 PIC PROGRAMMING IN C 2.1 Introduction

An embedded system is a combination of computer hardware and software designed for a specific function.

Embedded systems vary in complexity but, generally, consist of three main elements:

a. Hardware. The hardware of embedded systems is based around microprocessors and microcontrollers. Microprocessors are very similar to microcontrollers and, typically, refer to a CPU (central processing unit) that is integrated with other basic computing components such as memory chips and digital signal processors. Microcontrollers have those components built into one chip. b. Software and firmware. Software for embedded systems can vary in complexity. However, industrial-grade microcontrollers and embedded IoT systems usually run very simple software that requires little memory. c. Real-time operating system. These are not always included in embedded systems, especially smaller-scale systems. RTOSes define how the system works by supervising the software and setting rules during program execution.

2.2 PIC18F4550 Microcontroller

PIC microcontrollers are a family of specialized microcontroller chips produced by Microchip Technology in Chandler, Arizona. The acronym PIC stands for "peripheral interface controller". PIC18F4550 belongs to pic18f family of microcontrollers. There are different packages like DIP, QPF, and QPN of PIC18F4550 which are currently available as shown in Figure 2.1.

8

40 PIN Package DIP (Dual Inline Package)

44-Pin TQFP (Quad Flat Package)

44-Pin QFN (Quad-Flat No-leads)

Figure 2.1 PIC18F4550 chip Packages (https://www.microchip.com)

The PIC18F4550 is a 40-pins chip. A total of 33 are set aside for five ports: PORTA, PORTB, PORTC, PORTD and PORTE with their alternate functions which can be configured as input or output by setting registers associated with them. The rest of the pins are designated as Vdd, (Vcc), Vss (GND), OSC1, OSC2, MCLR (reset) and another set of Vdd and Vss. Figure 2.2 shows the pin diagram of PIC18F4550.

Figure 2.2: Pin diagrams for PIC18F4550 (https://www.theengineeringprojects.com)

2.3 Dual role of I/O Ports

Dual role of ports of data I/O is where a pin in PIC has more than one function. It can save more pins. In addition to being used as simple I/O, each port has some other functions such as ADC, timers, interrupts and serial communications pins.

By referring pins diagram in Figure 2.3, the port alternate function of each PIC’s pins can be seen next after the symbol “/” at the label.

9

For example, pin RA0/AN0 RA0 – used as input/output terminal for digital data (bit) AN0 – analogue-to-digital converter channel 0 (read analogue signal from external device).

Figure 2.3: Example of dual role I/O pin

Table 2.1 shows an example of I/O port alternate function.

Table 2.1: PORTA I/O Summary (Microchip PIC18F4550 Data sheet)

10

2.4 PIC Programming in C

It is not enough just to connect the microcontroller to other components and turn the power supply on to make it work. There is something else that must be done. The microcontroller needs to be programmed to be capable of performing anything useful. The following are the steps of programming an embedded system:

a. Write a program (example, using C language). b. Compile the program to convert it to machine language (in binary/hex). c. The program will be burned into a microcontroller chip using a special circuit called programmer/burner. d. Finally placed the microcontroller chip on the control circuit of the real application for example robot arm.

The illustration of these steps is shown in Figure 2.4.

Figure 2.4: Steps of programming an embedded system

2.4.1 Compiler for PIC microcontroller

When we write anything, then we write in C language which is a high level language, the computer or controller can’t understand this high-level language because it only understands the machine language. The Compiler, basically used to convert the high-level language into machine language or binary instructions.

11

The manufacturer supplies computer software for development known as MPLAB, assemblers and C/C++ compilers, and programmer/debugger hardware under the MPLAB and PICKit series. Microchip released their own C compilers, C18 and C30, for the line of 18F 24F and 30/33F processors. Other types of PIC compiler are MPLAB XC8 C Compiler, MPLAB XC16 C Compiler, MPLAB XC32 C Compiler, MikroC Compiler and PIC CCS Compiler

2.4.2 Program Structure

The structure of a C program is a protocol (rules) to the programmer, while writing a C program. The general basic structure of the C program is shown in Figure 2.5.

Figure 2.5: General basic structure of C program

There is no specific format in the writing program. Figure 2.6 shows an example of program structure in C language for PIC microcontroller.

12

Comments Include header file Include libraries, function declaration, global variable Main function name Begin of block Comments Local declaration

Function body

Figure 2.6: Example of program structure

End of block

User-defined Function

2.4.3 C Data Types for the PIC18

There are several types of data that can be used in C programming language. Data type is assigned to a variable to determine the size and how the variable is being interpreted as shown in Table 2.2. Table 2.2: Fundamental Data Types Type

Description

Bits

char

single character

8

Int

integer

16

float

single precision floating point number

32

double

double precision floating point number

64

In C programming language, there are various reserved words that can be used to modify the size or signage of an integer. Signed is rarely used because integers are signed by default. We

13

must specify unsigned if we want integers that are only positive. Possible combinations are shown in Table 2.3. Table 2.3: Modified Integer Types Data Type

Size in Bits

Data Range/Usage

unsigned char

8-bit

0 to 255

char

8-bit

-128 to +127

unsigned int

16-bit

0 to 655,535

int

16-bit

-32,768 to +32,767

unsigned short

16-bit

0 to 655,535

short

16-bit

-32,768 to +32,767

unsigned short long

24-bit

0 to 16,777,215

short long

24-bit

-8,388,608 to +8,388,607

unsigned long

32-bit

0 to 4,294,967,295

long

32-bit

-2,147,483,648 to +2,147,483,647

2.4.4 Declaring Variable

A variable must be declared before it can be used. The declaration of a variable consists of two parts:

a. A data types b. An identifier (or name) that will be used to uniquely identify the variable whenever we want to access or modify its contents.

The following are examples of C statement used to declare variable:

14

2.5 Byte & Bit I/O Programming

PIC18 registers are 8-bit registers, meaning that it can store 8-bit binary data. It can be access by 2 methods:

a. Byte-addressable change all 8 bits in the register Format: RegisterX = 0bxxxxxxxx

b. Bit-addressable Change single bit of register without altering the rest Format:

RegisterX = 0;

or

RegisterX = 1;

2.4.5 Data Format in C

The PIC microcontroller has only one data type. It is 8 bits, and the size of each register is also 8 bits. Data format is the way a value is being presented in C language. There are 4 ways to represent a byte of data. The numbers can be in hex, binary, decimal or ASCII formats as shown in Table 2.4.

Table 2.4: Data format Radix

Format

Example

Binary

0bnumber or 0Bnumber

PORTB = 0b01010101;

Octal

Onumber or \number

PORTB = O125;

Decimal

number

PORTB = 105;

Hexadecimal

0xnumber or 0Xnumber

PORTB = 0x55;

ASCII

‘character’

PORTD= ‘K’

15

2.6 I/O port SFR register

Each port of PIC microcontroller has three special function registers (SFR) for its operation. These registers are:

a.

TRISx register (data direction register)

b.

PORTx register (reads the levels on the pins of the device)

c.

LATx register (output latch)

These registers directly associated with the operation of the port, where 'x' is a letter that denotes the particular I/O port which is shown in Figure 2.7

Figure 2.7: PIC18 Special Function Register Map (Microchip PIC18F4550 Data sheet)

For example, for Port B we have PORTA, TRISA and LATA. Each register has 8 bits and each bit has a specific name as shown in Table 2.5 16

Table 2.5: Bits of TRISx, PORTx and LATx registers Bit

B7

B6

B5

B4

B3

B2

B1

B0

TRISA

-

-

TRISA5

TRISA4

TRISA3

TRISA2

TRISA1

TRISD0

PORTA

-

-

RA5

RA4

RA3

RA2

RA1

RD0

LATA

-

-

LATA5

LATA4

LATA3

LATA2

LATA1

LATD0

TRISB

TRISB7

TRISB6

TRISB5

TRISB4

TRISB3

TRISB2

TRISB1

TRISB0

PORTB

RB7

RB6

RB5

RB4

RB3

RB2

RB1

RB0

LATB

LATB7

LATB6

LATB5

LATB4

LATB3

LATB2

LATB1

LATB0

TRISC

TRISC7

TRISC6

PORTC

RC7

RC6

LATC

LATC7

TRISD PORTD

Register

LATD

-

-

-

TRISC2

TRISC1

TRISC0

RC5

RC4

-

RC2

RC1

RC0

LATC6

-

-

-

LATC2

LATC1

LATC0

TRISD7

TRISD6

TRISD5

TRISD4

TRISD3

TRISD2

TRISD1

TRISD0

RD7

RD6

RD5

RD4

RD3

RD2

RD1

RD0

LATD7

LATD6

LATD5

LATD4

LATD3

LATD2

LATD1

LATD0

TRISE

-

-

-

-

-

TRISE2

TRISE1

TRISE0

PORTE

-

-

-

-

-

PORTE2

TRISE1

TRISE0

LATE

-

-

-

-

-

LATE2

LATE1

LATE0

2.6.1 TRISx Register

The TRISx register control bits determine whether each pin associated with the I/O port is an input or an output: a. If the TRIS bit for an I/O pin is ‘1’, then the pin is configured as an Input. b. If the TRIS bit for an I/O pin is ‘0’, then the pin is configured as an Output.

For example, to configure the entire PORTD as input, all pins should be set to HIGH (1) as shown in Figure 2.8.

17

TRISD Value

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

1

1

1

1

1

1

1

1

TRISD = 0b11111111 = 0xFF

Figure 2.8: Bit configuration of TRISD register with PortD as input

Example 2.1 Refer to the circuit diagram in Figure 2.9. Assume the I/O devices are connected to PORTB. Write program statement to configure I/O port as input or output.

Solution: TRISB2 = 0;

//RB2 output

TRISB4 = 1;

//RB4 input

TRISB6 = 0;

//RB6 output

TRISB7 = 0;

//RB7 output Figure 2.9

Or

(https://www.mikroe.com)

TRISB = 0b00010000;

//RB4-input and RB2,RB6, RB7 - output

2.6.2 PORTx Register

PORTx registers hold the current digital state of the I/O pin. It reads the levels on the pins of the device and it assigns logic values (0/1) to the ports. The role of the PORT register is to receive the information from an external source (like a sensor) or to send information to the external elements (like an LCD).

When the port is used as the INPUT. The PIC can read signals from outside through PORT so we can determine which pins are currently HIGH or LOW.

18

When the port is used as the OUTPUT. The PIC can send signals outside through PORT. a. Write Logic 1 - PORTx registers will output 5V b. Write Logic 0 - PORTx registers will output 0V

Example 2.2 Write a program statement to output 5V to RB6 pin, 0V to RC2 pin and 5V to all pins of PortD. Solution: RB6 = 1; //5V to RB6 pin RC2=0; //0V to RC2 pin PORTD = 0b11111111; //5V to PortD. 2.6.3 LATx Register

LATx are the port latch registers. A write to a latch register is same as sending data to the port register PORTx. A read from the latch register, however, reads the data present at the output latch of the port pin, and this may not be same as the actual state of the port pin

The differences between the PORT and LAT registers can be summarized as follows:

A write to the PORTx register writes the data value to the port latch.

A write to the LATx register writes the data value to the port latch.

A read of the PORTx register reads the data value on the I/O pin.

A read of the LATx register reads the data value held in the port latch.

Example 2.3 Write a program code to output 0V to RB0-RB3 and 5V to RB4-RB7. Solution: LATB

bit 7

bit 6

bit 5

bit 4

bit 3

bit 2

bit 1

bit 0

Value

1

1

1

1

0

0

0

0

LATB = 0b11110000;

19

2.7 LED (Light Emitting Diode)

LEDs are a common element of many embedded designs. An LED, with a current limiting resistor, can be wired directly to one of the microcontrollers IO pins. An LED can be interfaced with a microcontroller in two different ways: in current source mode or current sinking mode. Figure 2.10 shows how to connect an LED in either 'sink' or 'source' modes:

a) The LED will light when the PIC pin is LOW.

b) The LED will light when the PIC pin is HIGH.

Figure 2.10: Interfacing of LED (http://www.winpicprog.co.uk)

In current source mode (Figure 2.10(b)), the microcontroller I/O pin is configured in the output direction. So, once the Logic "1" is at the output pin, then an LED will be turned "ON". And when Logic "0" is given the LED will be turned "OFF". See Figure 2.11

Figure 2.11: LED in source mode (https://aticleworld.com)

For LED in sink mode, when Logic "1" at output pin, then an LED will be turned "OFF". And when Logic "0" is given the LED will be turned "ON". 20

Example 2.4 A PIC18 based system interface with a LED which is connected to RD0. See Figure 2.12. Use bit addressable format to write a program code to perform as below: a)

configure RD0 as output pin

b)

On the LED (give Output 5V to RD0)

Solution: a) configure RD0 as output pin TRISD0=0; //RD0 as output pin b) On the LED (give Output 5V to RD0) RD0 = 1; //Output 5V to RD0

Figure 2.12

Example 2.5 A PIC18 based system interface with two LEDs which are connected to RD0 and RD7. See Figure 2.13. Use bit addressable format to write a program code to perform as below: a)

configure RD0 and RD7 as output pins

b)

give Ou tput 5V to RD0

c)

give Output 0V to RD7

Solution: a) configure RD0 and RD7 as output pin TRISD0=0; //RD0 as output pin TRISD7=0; //RD7 as output pin b) give Output 5V to RD0 and RD7 RD0=1; //Output 5V to RD0 OR LATD0=1; //Output 5V to RD0 c) give Output 0V to RD7 RD7=0; //Output 0V to RD7 OR LATD7=0; //Output 0V to RD7

Figure 2.13

21

Example 2.6 Refer to Figure 2.13, PIC18 based system interface with two LEDs which are connected to RD0 and RD7. Use byte addressable format to write a program code to perform as below: a)

configure RD0 and RD7 as output pins

b)

give Output 5V to RD0 and RD7

Solution: a) configure RD0 and RD7 as output pin TRISD0=0b00000000; b) give Output 5V to RD0 and RD7 PORTD=0b10000001;

//Output 5V to RD0 and RD7

OR LATD=0b10000001;

//Output 5V to RD0 and RD7

Example 2.7 By referring Figure 2.12, write a program to turn on the LED which is connected to pin RD0 of PIC18F.

Solution: #include <xc.h> void main(void) { TRISD0 = 0; while(1) { RD0 =1;

//turn on LED

} }

22

2.8 Using Delay function

A time delay is something that is very important when working with embedded applications, because there are times you want a delay before something is begun.

Time delays can also be used for breaks between processes. For example, a time delay in between an LED can make the LED blink on and off, on and off, repeatedly. So time delays can be very useful and important for embedded applications.

A __delay_ms() is not a real function, it is a macro which will expand into in-line assembly instructions or a nested loop of instructions which will consume the specified number of time. So the delay argument must be a constant and can't be changed during runtime. This function is known as the compiler’s in-built delay function.

If you want a real function with a parameter, you had to write it on your own as shown in Figure 2.14.

void delay_ms (unsigned int x) { for(; x>0; x--) __delay_ms(1); //delay 1ms } Figure 2.14: User defined delay function

If an accurate delay is required, or if there are other tasks that can be performed during the delay, then using a timer to generate an interrupt is the best way to proceed. The timer module of PIC will be discussed in the next chapter.

23

Example 2.8 Refer Figure 2.12, write a program to blink the LED which is connected to pin RD0 of PIC18. The LED will turn ON for 500 ms and turn OFF for 500 ms.

Solution: #include <xc.h> #define _XTAL_FREQ 20000000 #define LED RD0 void delay_ms (unsigned int x); void main(void) { TRISD0 = 0; while(1) { LED =1; //turn on LED delay_ms (500); //delay 500ms LED =0; //turn off LED delay_ms (500); //delay 500ms } } void delay_ms (unsigned int x) { for(; x>0; x--) __delay_ms(1); //delay 1ms } Example 2.9 By referring to Figure 2.13, LED1 is connected to RD0 and LED2 is connected to RD7. Write a program to make LED1 and LED2 blink alternately for each 2s continuously.

Solution: #include <xc.h> #define _XTAL_FREQ 20000000 #define LED1 RD0 #define LED2 RD7 24

void delay_ms (unsigned int x); void main(void) { TRISB = 0b00000000; //RD0 and RD7 as output pin while(1) { LED1 =1; //turn on LED1 LED2 =0; //turn off LED2 delay_ms (2000); //delay 2s LED1 =0; //turn off LED1 LED2 =1; //turn on LED2 delay_ms (2000); //delay 2s } } void delay_ms (unsigned int x) { for(; x>0; x--) __delay_ms(1); //delay 1ms } Example 2.10 You are assigned to design a running light using 8 LEDs. Assumed the LED is connected to PORTD as shown in Figure 2.15, write a complete program to make the LEDs turn on and off as below: 11000000 delay 1s 00110000 delay 1s 00001100 delay 1s 00000011 delay 1s

Use byte addressable format for data.

Figure 2.15

25

Solution:

#include <xc.h> #define _XTAL_FREQ 20000000 void delay_ms (unsigned int x); void main(void) { TRISD = 0b00000000; //PortD as output while(1) {

PORTD = 0b11000000; delay_ms(1000); PORTD = 0b00110000; delay_ms(1000); PORTD = 0b00001100; delay_ms(1000); PORTD = 0b00000011; delay_ms(1000);

// or LATD = 0b11000000; //delay 1s We can use shift operation (refer to appendix)

//delay 1s //delay 1s //delay 1s

}

PORTD = 0b11000000; delay_ms(1000); //delay 1s for (int y=0; y<3; y++) //repeat 3x { PORTD=PORTD>>2; // shift right PortD 2x delay-ms (1000); //delay 1s }

} void delay_ms (unsigned int x) { for(; x>0; x--) __delay_ms(1); //delay 1ms }

2.9 Push Button Switch

Push buttons are basic input device in an embedded system seen in very simple to highly complex systems. There two basic interfacing circuits of a push button switch: pull-up mode and pull-down mode.

26

In pull-up mode, the switch will be in active low configuration. See Figure 2.16. That is, the state of the pin is HIGH when the switch not pressed, and LOW when the switch is pressed.

Figure 2.16: Push button interfacing in pull-up mode (https://openlabpro.com)

In pull-down mode, the output acts as an active high. See Figure 2.17. The state of the pin is LOW when the switch not pressed, and HIGH when the switch is pressed.

Figure 2.17: Push button interfacing in pull-down mode (https://openlabpro.com)

27

Example 2.11 You are assigned to design a torchlight using a switch and a LED. The connection of the system is shown in Figure 2.18 Write a complete program for the system

Figure 2.18 Solution: #include <xc.h> #define SW RD1 #define LIGHT RB0 void main(void) { TRISD1 = 1; TRISB0 = 0; while(1) { if (SW == 0) // if SW is pressed { LIGHT = 1; //turn on LED } else { LIGHT = 0; //turn off LED } } }

28

Example 2.12 You are assigned to design a home security system using two switches and two LEDs. The switches is placed at the front door (SW1) and back door (SW2) of the home. The LEDs are used as indicator if the door is closed (switch is released) or open (switch is pressed). The connection of the system is shown in Figure 2.19. When SW1 is pressed, LED GREEN blink for 500ms and when SW2 is pressed, LED RED blink for 500ms. Write a complete program for the system.

Figure 2.19 Solution: #include <xc.h> #define SW1 RD1 #define SW2 RD7 #define LED_RED RB0 #define LED_GREEN RB1

void delay_ms (unsigned int x); void main(void) { TRISD = 0b10000001;

//RD0, RD7 as input pin

TRISB = 0b00000000;

//RB0, RB1 as output pin

PORTB=0;

//for initial – both LEDs off

29

while(1) { if (SW 1== 0)

// if SW1 is pressed

{ // LED GREEN blink for 500ms LED_GREEN = 1; delay_ms(250); LED_GREEN = 0; delay_ms(250); } else if (SW2 == 0) // if SW2 is pressed { // LED RED blink for 500ms LED_RED = 1; delay_ms(250); LED_RED = 0; delay_ms(250); } } } void delay_ms (unsigned int x) { for(; x>0; x--) __delay_ms(1); //delay 1ms }

30

REVIEW QUESTIONS

1. Write program code in C language for the following using byte addressable format: a. Initialize PORTA as an output b. Initialize RB0 and RB1 an input c. Output 5V to PORTD d. Output 0V to RB0 – RB4 and 5V to RB5 – RB7.

2. Write program code in C language for the following using bit addressable format: a. Initialize PORTA as an output b. Initialize RB0 and RB1 an input c. Output 0V to RA3 and RC1 d. Output 5V to RD1 and RB5

3. A programmer decides to make a control system that will control three LEDs and a buzzer. The LEDs and the buzzer were controlled by two digital sensors. Use any pins from PORTB for sensors, PORTC for buzzer and PORTD for LEDs, write program statement to configure pins as an input or output using bit addressable format.

4. A programmer decides to use two DC motors at pin RB6 and RB7. While, the LED at pin RA5 and two digital sensors at pin RB0 and RB1 in his circuit. Write the input output initialization for the program using byte addressable format in C language.

5. Build a C program to make LED1 on pin RD0 and LED2 on pin RD1 blink simultaneously for each 3 second continuously. The time delay function is given below: void Delay_1ms (unsigned int x) { for (; x>0; x--) __delay_ms(1); }

31

CHAPTER 3 PIC TIMER PROGRAMMING IN C 3.1 Introduction

Timers are common features of most microcontrollers. A timer is a register whose value keeps increasing (or decreasing) by a constant rate without the help of the CPU. Timers are used to generate time delay, counting events, generating waveform and also for PWM generation.

3.2 PIC18F4550 Timer

PIC18F4550 has four in-built timers named Timer0, Timer1, Timer2, and Timer3. Timer 2 is an 8-bit timer and all others are 16-bit timers.

The timer increments for each pulse applied to it. The timer counts continuously from 0 to (2n-1) where n is the number of bits. The initial values of the timer register can be set by the user and can be used to generate required counts. PIC18F4550 microcontroller has the following bit length (operation mode) of timer: a.

8 bit mode – count between 0 to 255 (28-1)

b.

16 bit mode – count between 0 to 65535 (216-1)

The timer operations mode for PIC18f4550 was simplified as shown in Table 3.1. while Figure 3.1 shows the Timers in PIC18f4550 block diagram.

Table 3.1: PIC18F4550 Timer Operation Mode Timer

Operation Mode 8-bit

16-bit

0

Yes

Yes

1

No

Yes

2

Yes

No

3

No

Yes

32

Figure 3.1: PIC18F4550 Block Diagram (Microchip PIC18F4550 Datasheet)

33

3.3 TIMER Register

Because the PIC18 has an 8-bit architecture, each 16-bit timer is accessed as two separate registers of low byte (TMRxL) and high byte (TMRxH). For example, Timer1 has TMR1H and TMR1L.

Each timer also has a TxCON (timer control) register for setting modes of operation. For example, T0CON is used to set modes for Timer0. All associated register with Timers in this microcontroller is illustrated in memory map in Figure 3.2.

Figure 3.2: Example of PIC18F4550 Timer Register Memory Map (Microchip PIC18F4550 Datasheet)

34

Embedded System Applications 3.3.1 TIMER0 Programming

Timer0 can be configured as an 8-bit or 16-bit timer or counter. The 16-bit register of Timer0 is accessed as low byte (TMR0L) and high byte (TMR0H) as shown in Figure 3.3. TMR0L

D15 D14

D13

D12

D11

TMR0H

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

Figure 3.3: Timer0 High and Low Registers.

3.3.2 Timer0 Control Register (T0CON)

T0CON register controls the operation of Timer0. T0CON is an 8-bit register used for control of Timer0. The bits for T0CON are shown in Figure 3.4.

Figure 3.4: T0CON (Timer0 Control) Register 35

Embedded System Applications 3.3.3 Prescaler

A prescaler is an electronic counting circuit used to reduce a high frequency electrical signal to a lower frequency. The prescaler in PIC Timer is used to divide the CPU clock (Fosc/4) to obtain a smaller frequency. We can use the prescaler option in the TxCON register to increase the time delay by reducing the period. Figure 3.5 shows the simplified block diagram of Timer 0 module in PIC18.

Figure 3.5: Block diagram of Timer0 ( https://microchipdeveloper.com )

The prescaler is enabled by clearing the PSA bit of the T0CON register. In order to have a 1:1 prescaler value for the Timer0 module, the prescaler must be disabled by setting the PSA bit of the T0CON register. Figure 3.6 shows T0C0N register for PSA bit.

Prescaler Asignment 1: not assign to TMR0 0: assigned to TMR0

Figure 3.6: T0CON Register – PSA bit (Microchip PIC18F4550 Datasheet)

There are eight prescaler options for the Timer0 module ranging from 1:2 to 1:256. These prescaler are illustrated in Figure 3.7.

36

Embedded System Applications

TMR0 PRESCALE

PS2

PS1

PS0

0

0

0

1:2

0

0

1

1:4

0

1

0

1:8

0

1

1

1:16

1

0

0

1:32

1

0

1

1:64

1

1

0

1:128

1

1

1

1:256

VALUE

Figure 3.7: T0CON Register – Prescaler rate select bit (Microchip PIC18F4550 Datasheet)

Example 3.1 Find the value for T0CON if we want to program Timer0 in 16-bit mode, no prescaler. Use PIC’s Fosc/4 crystal oscillator for the clock source, increment on positive-edge. Solution: Refer T0CON register in Figure 3.4. TMR0ON

T08BIT

T0CS

T0SE

PSA

PS2

PS1

PS0

0

0

0

0

1

0

0

0

T0CON = 0000 1000 ;

//16-bit, Fosc/4 clock source, no prescaler, Timer0 off.

Example 3.2 If T0CON = 0b11000100, determine timer operation modes of TIMER0 Solution: 1 Enable TMR0

1 8 bit mode

0

0

0

Internal

Low-high

Use

clock

transition

prescaler

1

0

1

1:32 prescaler

T0CON : operation modes: 8-bit mode (refer bit-6). 37

Embedded System Applications 3.3.4 TMR0IF flag bit

TMR0IF bit (Timer0 interrupt flag) is part of the INTCON (interrupt control) register that will be discuss further on Chapter 4. Figure 3.8 shows the INTCON Register that associated with TMR0IF. 0: Timer0 did not overflow 1: Timer0 has overflowed

Figure 3.8: INTCON Register – Timer0 interrupt flag (Microchip PIC18F4550 Datasheet)

The TMR0IF interrupt is generated when the TMR0 register overflows from FFh to 00h in 8bit mode, or from FFFFh to 0000h in 16-bit mode. For example, when a 16-bit timer has the value 65535 (FFFF H) and receives another clock that will set it to 0 and generate an overflow as illustrated in Figure 3.9.

XTAL OSCILLATO R

TMR0H

÷4

TMR0IF (OVERFLOW FLAG

TMR0L

TMR0ON

FFFF ----- > 0000 TMR0IF = 0---- > TMR0IF = 1

Figure 3.9: TIMER0 Overflow flag

The importance of TMR0IF: a.

In 16-bit mode, when TMR0H:TMR0L overflows from FFFFH to 0000H this flag is raised.

b.

In 8-bit, it is raised when the timer goes from FFH to 00H.

c.

We monitor this flag before we reload the TMR0H:TMR0L registers

The block diagram in Figure 3.10 Figure 3.10 shows the operation of Timer0 16-bit mode: 38

Embedded System Applications

Figure 3.10: Block diagram of Timer0 operation 16 bit mode ( Microchip PIC18F4550 Datasheet)

3.4 Program TIMER0 To Generate Time Delay

To generate a time delay using Timer0, we have to calculate a count of desired time. The following are the steps to program Timer0 to generate time delay.

3.4.1 Steps to program Timer0 to generate time delay

a.

Load the value into theT0CON register indicating which mode (8-bit or 16-bit), internal clock source and the selected prescaler option.

b.

Load initial count value into register TMR0H followed by register TMR0L. (for 8bit mode we can only use TMR0L)

c.

Start the timer with instruction “TMR0ON= 1”

d.

Keep monitoring the timer flag (TMR0IF) to see if it is raised. Get out of the loop when TMR0IF becomes HIGH. Example of instruction, “while (TMR0IF==0);”

e.

Stop the timer with instruction “TMR0ON= 0”

f.

Clear the TMR0IF flag for the next round.(TMR0IF=0)

g.

Go back to Step 2 to load TMR0H and TMR0L again.

39

Embedded System Applications We should load TMR0H first and then load TMR0L because the value for TMR0H is kept in a temporary register and written to TMR0H when TMR0L is loaded. This will prevent any error in counting if the TMR0ON flag is set HIGH.

Program code using Timer0 to generate time delay (16-bit mode): T0CON=0b_____ ; TMR0H=0x_____; TMR0L=0x_____; TMR0ON= 1; while(TMR0IF== 0); TMR0ON= 0; TMR0IF= 0;

// Configure the T0CON register // initial count values (high byte). // initial count values (low byte). // Start the timer // Keep monitoring the TMR0IF to see if it is raised // Stop the timer //Clear TMR0IF

Program code using Timer0 to generate time delay (8-bit mode): T0CON=0b______; TMR0L=0x_____; TMR0ON= 1; while(TMR0IF== 0); TMR0ON= 0; TMR0IF= 0;

// Configure the T0CON register // initial count values // Start the timer // Keep monitoring the TMR0IF to see if it is raised // Stop the timer //Clear TMR0IF

3.4.2 Finding values to be loaded into TMR0H and TMR0L The following are the steps to calculate the values to be loaded into TMR0H and TMR0L registers:

a. Find the time for one clock period (Tc): TC = 1/ (FOSC /4/prescaler) s b. Calculate the number of count (NOC) to get the required time delay: NOC = Time Delay = Td Time Period Tc c. Get the value to be loaded into TMR0: i. TMR0 = 65535 – count + 1 ii. TMR0= 255 – count + 1

(16-bit mode) or TMR0 = 65536 – count (8-bit mode) or TMR0= 256 – count 40

Embedded System Applications d. Convert this value to hexadecimal, we get 0xYYXX e. Load this hex value in the Timer0 : TMR0H = 0xYY TMR0L= 0xXX. **(For 8-bit mode, put the result into TMR0L)

3.4.3 Prescaler and generating a large time delay The time delay generated using Timer depends on two factors. a. The crystal frequency b. The timer’s 16-bit register

Both of these factors are beyond the control of the PIC18 programmer. The largest time delay is achieved by making both TMR0H and TMR0L zero.

We can use the prescaler option in the T0CON register to increase the delay by reducing the period. The prescaler option of T0CON allows us to divide the instruction clock by a factor of 2 to 256.

Example 3.3 Find the largest time delay possible using Timer 0 if the system uses crystal oscillator frequency 10MHz.

Solution: To get the largest time delay, use: 16-bit mode : NOC = 65536 (need 65536 clock pulse to tick) Prescaler: 256 (maximum prescaler)

Fc = Fosc/4 / prescaler

= (10 MHz /4 ) / 256

= 9.766 KHz

Clock period, Tc = 1 / Fc

= 1 / (9.766 KHz)

= 102.4 µs

Time delay = NOC x Tc = 65536 x 102.4 µs = 6.72 s 41

Embedded System Applications In real time applications, we use time delay in seconds or milliseconds or microseconds. The following are examples of how to calculate the real time used.

Example 3.4 Assuming XTAL = 10 MHz and no prescaler . Find the TMR0H and TMR0L registers values if we want to get a time delay 1ms.

Solution:

Timer clock freq,

Fc=Fosc/4= 10MHz/4=2.5MHz.

Timer clock period,

Tc= 1/Fc=1/2.5MHz=0.4us

NOC = Td / Tc = 1ms / 0.4us = 2500 ticks (>255, use 16-bit mode) Value loaded into TMR register

= 65536 – 2500 = 63036 = F63C (hex)

TMR0H =F6 (Hex) TMR0L=3C. (Hex)

Example 3.5 Assuming that XTAL=10 MHz, write a program to generate a square wave with a period of 10ms on pin RB3. The output produce as shown in Figure 3.11.

Figure 3.11 Solution: For square wave with T= 10ms, we must divide period into two for high and low state. Time delay use to produce high and low state:

42

Embedded System Applications Td = T / 2 = 10ms/2 = 5ms Fc = Fosc/2 =10MHz / 2 = 5MHz Tc= 1/Fc = 15MHz = 0.4 µs. NOC = 5ms / 0.4 µs = 12500 ticks. TMR0 register value = 65536 – 12500 = 53036 = CF2C (Hex). Therefore, TMR0H = CF and TMR0L = 2C.

Program: #include <xc.h> void delay_5ms( ); void main (void) { ADCON1=0b00001111; TRISB3=0; while (1) { RB3 =1; delay_5ms( ); RB3 =0; delay_5ms( ); }

// RB3 as output

//output logic HIGH (5V) to RB3 //delay 5ms //output logic LOW (0V) to RB3 //delay 5ms

} //function for time delay 5ms void delay_5ms( ) { T0CON=0b00001000; //Configure timer 10MHz crystal, 16-bit mode, no prescaler TMR0H=0xCF; TMR0L=0x2CF; TMR0ON= 1; // Start the timer while(TMR0IF== 0); // Keep monitoring the TMR0IF to see if it is raised TMR0ON= 0; // Stop the timer TMR0IF= 0; //Clear TMR0IF }

43

Embedded System Applications Example 3.6 Refer to the schematic in Figure 3.12, construct a program to blink LED1 every 500ms. Use Fosc 10MHz and prescaler 1:64.

Figure 3.12 Solution: Fc = Fosc/4/64 = 10MHz /4/64 = 39.0625 kHz Tc = 1/Fc = 1/ 39.0625 kHz = 25.6µs NOC = Td / Tc = 500ms / 25.6µs =19531 ticks TMR0 value = 65536 – 19531 = 46005 = B3B5 (hex) Program: #include <xc.h> #define LED1 RD0 void delay_500ms( ); void main (void) { ADCON1=0b00001111; TRISD0=0; while (1) { LED1 =1; delay_500ms( ); LED1 =0; delay_500ms( ); }

//turn on LED 1 //delay 500ms //turn off LED 1 //delay 500ms

}

44

Embedded System Applications

//function for time delay 500ms void delay_500ms( ) { T0CON=0b00000101; //Configure timer for10MHz crystal, 16-bit mode prescaler 1:64 TMR0H=0xB3; TMR0L=0xB5; TMR0ON= 1; while(TMR0IF== 0); // Keep monitoring the TMR0IF TMR0ON= 0; // Stop the timer TMR0IF= 0; //Clear TMR0IF } 3.5 Programming Timer0 as Counter

Timers are also used as counters to count events happening outside the microcontroller. Example application of counter is Measuring the RPM (speed in revolution per minute) of the rotating wheel. A small magnet is attached in the edge of the wheel as shown in Figure 3.13. Whenever this magnet is exactly below the Magnetic sensor its output becomes high. This output is connected to the T0CKI (Timer0 Clock Input) pin of the MCU. So each time the magnet passes by the sensor the timer register inside the MCU is incremented. These all happen without the help of CPU. CPU can do other task and read the Timer register only when required. The system connected as shown in Figure 3.13.

Figure 3.13: Example application of counter (https://extremeelectronics.co.in)

45

Embedded System Applications 3.6 T0CON in Counter mode

Timer0 will be program as counter by selecting external clock source. mode is selected by setting timer T0CS bit in the T0CON register as in Figure 3.14. TMR0 CLOCK SOURCE SELECT 1: T0CKI 0: FOSC/4

Figure 3.14: Bit T0CS of T0CON register (Microchip PIC18F4550 Datasheet)

In PIC18, the clock pulse is fed through T0CKI (RA4) and T1CKI (RC0) pins. See Figure 3.15. The T0CS bit in the (Timer0 clock source) in the T0CON register decides the source of the clock for the timer. When T0CS=1, the timer is used as a counter and gets its pulse from outside the PIC18.

Figure 3.15: T0CKI (RA4) and T1CKI (RC0) pins

The counter will increment either on rising or falling edge of the clock pulses, which is selectable by the T0SE (Timer0 Source Edge) as in Figure 3.16.

46

Embedded System Applications

SOURCE SELECT EDGE SELECT BIT: 1: INCREMENT HIGH TO LOW 0: INCRTEMENT LOW TO HIGH

Figure 3.16: Bit T0CE of T0CON register (Microchip PIC18F4550 Datasheet)

The range of the counter can be extended by the use of the prescaler. Example 3.7 Find the value for T0CON if we want to program Timer0 as an 8-bit mode counter, no prescaler. Use an external clock for the clock source and increment in the positive edge. Solution: T0CON=0b01101000;

//8-bit, external clock source, n0 prescaler.

3.7 Step to programming Timer0 as counter The following are step to program Timer0 as counter: a.

Configure T0CON register.

b.

Set initial value of counter.

c.

Start timer

d.

Wait for TMR0IF to raised (Timer roll over)

e.

Stop timer

f.

Clear TMR0IF

Finding values to be loaded into TMR0H & TMR0L a.

16-bit mode ( if count value > 255): TMR0 = 65535 – NOC + 1

b.

or

TMR0 = 65536 – NOC

Convert this value to hexadecimal, we get 0xYYXX TMR0H = 0xYY and TMR0L= 0xXX.

c.

8-bit mode ( count value <= 255): TMR0L = 255 – NOC + 1

or

TMR0L = 256 – NOC 47

Embedded System Applications Example 3.8 Assume that a 1 Hz external clock is fed into pin T0CKI (RA4). Referring to Figure 3.17, write a C program for counter0 in 8-bit mode to count up and display the state of TMR0L count on PORTB which is connected to 8 LEDs. Start the count at 0H. PORTB .

PORTB

To all LEDs 1 Hz T0CKI

RA4

Figure 3.17 Solution:

#include <xc.h> void main void { ADCON1=0X0F; TRISA4=1 TRISB=0; T0CON=0x68; TMR0L=0; while (1) { do { TMR0ON=1; PORTB=TMR0L; }

//make RA4/T0CKI an input //counter 0, 8-bit mode, no prescaler //set count to 0 //repeat forever

//turn on T0 //place value on PORTB pins

while (TMR0IF==0); //wait for TF0 to roll over TMR0ON=0; //turn off T0 TMR0IF=0; //clear TF0 } }

48

Embedded System Applications Example 3.9 As a programmer you are assign to develop a counter system to count the number of cars entering to a parking area. The control system use a digital sensor is connected to pin T0CKI and buzzer is connected to pin RB1 as Figure 3.18, Write a program using Timer0 in 8-bit mode to sound the buzzer every time 100 cars enter the parking area.

RB1

BUZZER

RA4

100 Hz

T0CKI

PIC18F

Figure 3.18

Solution: The buzzer will turn on after timer count 100 pulses (overflow). The value needs to put into TMR0L register: to start count N= 255-100 +1 = 156 = 9C (Hex) TMR0L=156; or TMR0L=0x9C; Program:

#include <xc.h> void main void { ADCON1=0X0F; TRISA4=1

//make RA4/T0CKI an input

TRISB1=0; T0CON=0x68;

//counter 0, 8-bit mode, no prescaler

TMR0L=156;

//start count at 156

49

Embedded System Applications while (1)

//repeat forever

{ TMR0ON=1;

//turn on T0

while (TMR0IF==0);

//wait for TF0 to roll over

TMR0ON=0;

//turn off T0

TMR0IF=0;

//clear TF0

RB1= 1;

// turn on the buzzer

delay_ms (100); RB1= 0;

// turn off the buzzer

TMR0L=156;

//reconfigure the counter value

} }

50

Embedded System Applications REVIEW QUESTIONS

1.

Construct a function for void delay (void) in C language to generate a 1 second delay by using 20Mhz Fosc, 16 bit mode and prescale 1:256.

2.

The following is a schematic diagram for a conveyor system for loading tennis ball into a box as in Figure 3.19. Each box can be load NINE (9) tennis balls. A sensor is used to detect the tennis ball that fall into the box. When all the balls fall into the box, the LED will turn on for 2 second. By using Timer0 as counter, write a program to perform the operation.

1st 2nd ball ball

9th ball RA4

RD4

PIC18F 4550

Figure 3.19: Tennis Conveyor system

51

Embedded System Applications

CHAPTER 4 INTERRUPT PROGRAMMING IN C 4.1 Introduction

Interrupt is a signal sent by peripheral or software to a processor that requires the CPU to stop the current program execution and run a specific program to perform some service related to the event. The program associated with the interrupt is called the interrupt service routine (ISR) or interrupt handler.

4.2 Interrupt vs Polling

A single microcontroller can serve several devices. There are two methods by which devices receive service from the microcontroller: Interrupt or polling.

Table 4.1: Comparison between Interrupt and Polling Interrupt

Polling

Whenever any device needs the

Microcontroller continuously monitors the

microcontroller’s service, the device notifies it

status of a given device; when the status

by sending an interrupt signal. Upon receiving

condition is met, it performs the service.

an interrupt signal, the microcontroller stops

After that, it moves to monitor the next

whatever it is doing and serves the device.

device until each one is serviced.

The advantage of interrupt is that the

Polling method cannot assigned priority

microcontroller can serve many devices (not all

because it checks all the devices in round-

at the same time). Each device can get the

robin fashion

attention of the microcontroller based on the priority assigned to it. Interrupts are used to avoid tying down the

Polling method wastes much of

microcontroller.

microcontroller’s time by polling devices that do not need service.

52

Embedded System Applications 4.3 Interrupt Service Routine (ISR)

For every interrupt, there must be an interrupt service routine (ISR) or interrupt handler. ISR tells the processor or controller what to do when the interrupt occurs. When an interrupt is invoked, the microcontroller runs the interrupt service routine.

Figure 4.1: Interrupt Service Routine

4.4 Sources of Interrupts in PIC18

There are many sources of interrupts in the PIC18. The following are some of the most widely used source of interrupts in the PIC18:

1. External hardware interrupt , at pins RB0, RB1 and RB2 for INT0, INT1 and INT2 respectively. 2. The PORTB-Change interrupt 3. Timer interrupt (Timer 0, 1, 2 and 3 ) 4. Serial communication’s USART interrupt, transmit and receive.. 5. The ADC (analog-to-digital converter). 6. The CCP (compare capture pulse-width-modulation)

The PIC18 has many more interrupts than the above list shows.

53

Embedded System Applications 4.5 Bits to Control Interrupt Operation

In general, each interrupt source has the following related bits.

Table 4.2: Bits to Control Interrupt Operation Bits

Function They are suffixed with IE (Interrupt Enable) for example, TMR0IE

Enable Bit

stands for TIMER0 Interrupt Enable. It can be used to enable/disable the related interrupt. When set to ‘1’ it enables the interrupt. It is set automatically by the related hardware when the interrupt condition occurs. It is generally suffixed with IF (Interrupt Fag). When it

Flag Bit

is set to ‘1’ we know that an interrupt has occurred. For example when TMR0IF is set by TIMER0, it indicates that TIMER0 has overflowed. Multiple interrupts could occur at the same time but since our

Priority Bit

microcontroller is single core it can process only one interrupt at a time. Priority bit is used to prioritize some interrupts over others.

GIE

Global interrupt Enable, enable/disable interrupt globally

PEIE

Enable/disable all peripheral interrupt

4.6 Interrupt Registers

PIC18F4550 has ten registers which are used to control interrupt operation. These registers are RCON, INTCON, INTCON2, INTCON3, PIR1, PIR2, PIE1, PIE2, IPR1, IPR2

4.6.1 RCON - Reset Control Register

Table 4.3: Reset Control Register Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 3

Bit 2

Bit 0

IPEN

SBOREN

—

RI

TO

PD

POR

BOR

IPEN: Interrupt Priority Enable bit. Enables priority levels when set. 54

Embedded System Applications 4.6.2 INTCON – Interrupt Control Register

Table 4.4: Interrupt Control Register Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 3

Bit 2

Bit 0

GIE/GIEH

PEIE/GIEL

TMR0IE

INT0IE

RBIE

TMR0IF

INT0IF

RBIF

GIE/GIEH: Global Interrupt Enable bit When IPEN is disabled, GIE enables all interrupts When IPEN is enabled, GIEH enables all high priority interrupts PEIE/GIEL: Peripheral Interrupt Enable bit When IPEN is disabled, PEIE enables all peripheral interrupts When IPEN is enabled, GIEL enables all low priority interrupts TMR0IE: TMR0 Overflow Interrupt Enable bit. Enables the TMR0 overflow interrupt INT0IE: INT0 External Interrupt Enable bit. Enables the INT0 external interrupt RBIE: RB Port Change Interrupt Enable bit. Enables the RB port change interrupt TMR0IF: TMR0 Overflow Interrupt Flag bit. Sets when TMR0 register has overflowed INT0IF: INT0 External Interrupt Flag bit. Sets when INT0 external interrupt occur RBIF: RB Port Change Interrupt Flag bit. Sets when at least one of the RB7: RB4 pins change state

4.6.3 INTCON2 - Interrupt Control Register 2

Table 4.5: Interrupt Control Register 2 Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 3

Bit 2

Bit 0

RBPU

INTEDG0

INTEDG1

INTEDG2

—

TMR0IP

—

RBIP

INTEDGx: External Interrupt x Edge Select bit. If set, the Interrupt flag is set on the rising edge. If cleared Interrupt flag is set on falling edge

55

Embedded System Applications TMR0IP: TMR0 Overflow Interrupt Priority bit. If set, TMRO interrupt is set as a High priority interrupt RBIP: RB Port Change Interrupt Priority bit. If set, RB Port Change Interrupt is set as a High priority interrupt

4.6.4 INTCON3 - Interrupt Control Register 3

Table 4.6: Interrupt Control Register 3 Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 3

Bit 2

Bit 0

INT2IP

INT1IP

—

INT2IE

INT1IE

—

INT2IF

INT1IF

INTxIP: INTx External Interrupt Priority bit. If set, INTx External Interrupt is set as a High priority interrupt INTxIE: INTx External Interrupt Enable bit. Enables the INTx external interrupt INTxIF: INTx External Interrupt Flag bit. The bit sets when INTx external interrupt occurs

4.7 Programming External Hardware Interrupt

There are three external hardware interrupts in PIC18: INT0, INT1 and INT2. They are located on pins RB0, RB1 and RB2, respectively. See Figure 4.2

Figure 4.2: External Hardware Interrupt Pins 56

Embedded System Applications External interrupts pins are edge-triggered. If the corresponding INTEDGx bit in the INTCON2 register is set (= 1), the interrupt is triggered by a rising edge; if the bit is clear, the trigger is on the falling edge. When a valid edge appears on the RBx/INTx pin, the corresponding flag bit, INTxIF, is set. Table 4.7: External Interrupt Register Interrupt

Flag Bit

Register

Enable Bit

Register

INT0 (RB0)

INT0IF

INTCON

INT0IE

INTCON

INT1 (RB1)

INT1IF

INTCON3

INT1IE

INTCON3

INT2 (RB2)

INT2IF

INTCON3

INT2IE

INTCON3

4.7.1 Step to enable External Hardware Interrupt

1. The following are steps to enable External Hardware Interrupt: 2. Enable Global Interrupt Enable bit (GIE) Bit D7 of the INTCON register must be set to HIGH. 3. Enables the INTx external interrupt. 4. Set INTxIF to LOW. 5. Set condition caused interrupt (falling/rising edge). 6. Set interrupt priority for INT1 and INT2. There is no priority bit associated with INT0. It is always a high-priority interrupt source.

Example 4.1 Write program code to enable external hardware interrupt on RB0 (INT0). Assume the interrupt will occur when RB0 changes from HIGH to LOW .

Solution GIE=1;

// Enable Global Interrupt Enable bit (GIE.)

INT0IE=1;

//Enables the INT0 external interrupt

INT0IF=0;

//clear interrupt flag

INTEDG0=1; // interrupt on rising

57

Embedded System Applications Step to write Interrupt Service Routine (ISR):

1. Declare function "void interrupt ISR()“. The words "interrupt" in the function causes it becomes as Interrupt Service Routine (ISR) when an interrupt occurs. 2. Check the related interrupt flag. Example: if (INT0IF==1) //check if INT0 interrupt occurs. 3. Write operation for the related interrupt 4. Clear the related interrupt flag. Example: INT0IF=0; //clear INT0 interrupt flag

Example of ISR:

void interrupt ISR() { if(INT0IF==1) //check if INT0 interrupt occurs { Write operation for the related interrupt } INT0IF=0;

//clear INT0 interrupt flag

}

Example 4.2 A push button (active high) is connected to RB0 (INT0) and a LED is connected to RD0 of PIC18. Write a program so that, every time INT0 is activated, LED is toggled

Solution //Toggled a LED using INTERRUPT #include <xc.h> //Interrupt Service Routine (ISR) void interrupt ISR();

58

Embedded System Applications void main (void) { TRISB0=1; TRISD0=0; ADCON1=0x0F; //Enable Interrupt Register GIE=1;

// Enable Global Interrupt Enable bit (GIE.)

INT0IE=1; //Enables the INT0 external interrupt INT0IF=0;

//clear interrupt flag

INTEDG0=1; // interrupt on rising edge; while(1); //Wait }

void interrupt ISR() { if ( INT0IF==1 ) { LATD0=LATD0^1;

//Toggle LED

} INT0IF=0;

//Clear Interrupt Flag, ready for next interrupt

}

Example 4.3 A control system uses a LED and digital sensor as Figure 4.3. In normal condition, the LED will turn off. If the switch is pressed, the LED on RA2 will blink 3 times. Write a program for the control system using external hardware interrupt.

59

Embedded System Applications

Figure 4.3 Solution #include <xc.h> #define LED RA2 void interrupt ISR(); void main (void) { TRISB1=1; TRISA2=0; ADCON1=0x0F; //Enable Interrupt INT0 GIE=1; INT1IE=1; INT1IF=0; INTEDG1=0; while(1) { LED=0; }

// Enable Global Interrupt Enable bit (GIE.) //Enables the INT0 external interrupt

//loop forever

}

void interrupt ISR() { if ( INT1IF ==1 ) { for(int i=0;i<3;i++) 60

Embedded System Applications { LED= 1; __delay_ms(300); LED= 0; __delay_ms(300);

//Turn on LED //delay 300ms //Turn off LED //delay 300ms

} } INT1IF=0;

//Clear Interrupt Flag, ready for next interrupt

} Example 4.4 Refer to Figure 4.3. TWO (2) switches are connected to RB0 (INT0) and RB1 (INT1). While two LEDs are connected to RB3 and RB4. Write a program using interrupt method to read the status of SW1 and SW2. When the SW1 is pressed, LED1 will turn on and LED will turn off. Otherwise, when SW2 is pressed, LED1 will turn off and LED2 will turn on. The interrupt is triggered by a falling edge of the pulse.

Figure 4.3

Solution #include <xc.h> #define LED1 RB2 #define LED2 RB3 void interrupt ISR();

61

Embedded System Applications void main (void) { TRISB=0B00000011; ADCON1=0x0F;

//Enable Interrupt at INT0 GIE=1;

// Enable Global Interrupt Enable bit (GIE.)

INT0IE=1;

//Enables the INT0 external interrupt

INT0IF=0;

//clear interrupt flag

INTEDG0=0;

// interrupt on falling edge;

//Enable Interrupt at INT1 INT1IE=1;

//Enables the INT1 external interrupt

INT1IF=0;

//clear interrupt flag

INTEDG1=0;

// interrupt on falling edge;

INT1IP=1;

//Enables the INT1 interrupt priority

while(1);

//Wait

}

//Interrupt Service Routine (ISR) void interrupt ISR() { if (INT0IF ==1) { // turn on LED 1 and turn off LED2 LED1= 1; LED2= 0; INT0IF=0;

//Clear INT0IF

}

62

Embedded System Applications if (INT1IF ==1) { // turn off LED1 and turn on LED2 LED1= 0; LED2= 1; INT1IF=0; //Clear INT1IF, } }

REVIEW QUESTIONS

1. List sources of interrupts in the PIC18 microcontroller. 2. Explain the steps to enable External hardware interrupt on RB0 (INT1) 3. Explain the steps to enable External hardware interrupt on RB0 (INT2) 4. PIC microcontroller is connected to a lamp via pin RC0, while LDR is connected to pin RB1. When the voltage across the LDR becomes zero volts, the lamp will turn on. Write a program using an interrupt method.

5. A wood cutting machine in a factory does not have safety features. To improve the safety feature of the machine, you are assigned to develop a safety system using an infrared sensor which is used to detect the presence of the hand. When an object (hand) is detected, the machine will stop immediately. Design the safety system by using a PIC18 microcontroller with suitable I/O devices. Sketch a schematic diagram for the system and write a program for the control system. 63

Embedded System Applications 4.8 Programming Timer0 Interrupt

In the previous chapter we use a timer to generate time delay. The delay loops will pause our program. We have to wait until the timer flag is raised when the timer rolls over. The problem with this method is that the microcontroller is tied down waiting for TMR0IF to be raised, and cannot do anything else.

Using interrupt avoids tying down the controller. The best thing about timer interrupts is that they work in the background and we don’t have to wait for them. When they finish work, they will produce an interrupt. It is like an alarm clock. In this chapter we will use hardware timer interrupt to perform multitasking and real-time application.

Figure 4.4: Timer Interrupt logic diagram

INTCON – Interrupt Control Register

Table 4.8: Interrupt Control Register

Interrupt priority for Timer0 is determined by the value contained in the interrupt priority bit, TMR0IP (INTCON2).

64

Embedded System Applications INTCON – Interrupt Control Register

Table 4.9: Interrupt Control Register 2

a. Step to enable timer interrupt b. Setup T0CON (timer mode, clock source, prescaler) c. Set the TMR0 preload value d. Enable Timer 0 interrupt enable bit e. Clear TMR0IF f. Enable Global Interrupt Enable bit g. Enable Peripheral Interrupt Enable bit for Timer1 and Timer 2.

Example of program code to enable Timer0 interrupt:

T0CON=0b___________; TMR0L=0x_____;

// Configure the T0CON register // preload value TMR0H & TMR0L

TMR0H=0x_____; GIE=1;

// Enable Global Interrupt Enable bit

TMR0IE=1;

// Enable Timer 0 interrupt enable bit

TMR0IF=0

// Clear TMR0IF

PEIE=1;

// Enable Peripheral Interrupt Enable bit for Timer1 and Timer 2.

4.8.1 Program Timer0 Interrupt to Perform Multitasking Using Timer0 interrupt, we can program PIC microcontroller to perform multitasking. In this approach, the delay is provided by loading a count in a timer. When a timer interrupt is generated current execution will move to the ISR to serve the task. But when there is no timer interrupt it will perform another task. 65

Embedded System Applications Example 4.4 Refer to the following Figure 4.5. Write a C program using Timer0 interrupt to turn on and off a buzzer every delay 3 second and LED every delay of 2 second. At the same time, data is being transferred from PORTC to PORTD. Use crystal frequency 8MHz, 16 bit mode and pre-scale of 1:32.

Figure 4.5

Solution:

Fc = 8MHz/4/32 = 62.5 kHz Tc = 1/ 62.5 kHz = 16 us Count = 1s / 16 us = 62500 TMR0 register = 65536- 62500 = 3036 = 0BDC (Hex) TMR0H=0x0B; TMR0L=0xDC;

Program:

#include <xc.h> void interrupt ISR (void); unsigned int tmr_LED, tmr_buz;

66

Embedded System Applications void main (void) { ADCON1=0b00001111; TRISB1=0; TRISB7=0; TRISC=0xFF; TRISD=0x00;

//RB1 : output //RB7 : output //PORTC : input // PORTD : output

//configure timer to activate TMR0IF every 1 s T0CON=0b00000100; //Timer0, 16-bit mode, prescaler 1:32 TMR0H=0x0B; TMR0L=0xDC; //Enable timer 0 Interrupt GIE=1; TMR0IE=1; TMR0IF=0; TMR0ON=1; while(1) { PORTD=PORTC; }

//transfer data from PORTC to PORTD

} //Interrupt Service Routine (ISR) void interrupt ISR (void) { if (TMR0IF==1) { tmr_LED = tmr_LED +1; tmr_buz = tmr_buz +1; if (tmr_LED ==2) { RB1=~RB1; tmr_LED =0; }

// time = 2 x 1s = 2s //toggle LED

67

Embedded System Applications

if (tmr_buz == 3) { RB7=~RB7; tmr_buz =0; }

// time = 3 x 1s = 2s //toggle buzzer

//restore TMR0H & TMR0L value TMR0H=0x0B; TMR0L=0xDC; TMR0IF=0; //clear TMR0IF } }

4.8.2 Program Timer0 Interrupt for Real Time Applications We can use timer interrupt programming to perform real time applications, for example, a counter system.

Example 4.5

A fruit packaging factory wants to install an automatic packaging system. The system used two DC motors to move two conveyor belts. The first conveyer belt is used to carry and drop the fruits into boxes and the second conveyor belt is used to move a box. A sensor is used to detect the fruits that fall into the box. When 50 of the fruits have fallen into the box, the fruit conveyor belt will stop and the second conveyor will move for 2 seconds to place a new empty box.

Sketch the control circuit using PIC18 microcontroller, and write a program using Timer0 Interrupt as a counter to perform the operation. Use any pins as output.

68

Embedded System Applications Solution Schematic diagram

Program : #include <xc.h> #define Motor1 RB3 #define Motor2 RB5 void interrupt ISR (void); void main (void) { ADCON1=0b00001111; TRISA4=0; TRISB3=0; TRISB5=0; //configure timer as counter T0CON=0b01101000; TMR0L=206; //Enable timer 0 Interupt GIE=1; TMR0IE=1; TMR0IF=0; TMR0ON=1; while(1) { Motor1=1; Motor2=0; } }

//RA4 : input //RB3 : output //RB5 : output // 8-bit mode, clock source from RA4, no prescaler //set count value to 50, (255 -50 +1)

//turn on motor 1 // turn off motor 2

69

Embedded System Applications

//Interrupt Service Routine (ISR) void interrupt ISR (void) { if (TMR0IF==1) { Motor1=0; Motor 2=1; delay_ms(2000); TMR0L=206; TMR0IF=0; } }

//turn off motor 1 //turn on motor 2 //restart timer //clear TMR0IF

REVIEW QUESTIONS

1. Explain the steps to enable Timer0 interrupt 2. You are assigned to build a running LED using a PIC microcontroller. Develop a C program using Timer0 interrupt to get the following LED transition: a.

The first LED (RA0) blink every 100ms

b.

Second LED (RA1) blink every 200ms

c.

The third LED (RA2) blink every 400ms

70

Embedded System Applications

CHAPTER 5 BASIC ELECTRONIC CONNECTION 5.1 Minimum electronics connection of embedded system

Minimum hardware connection so that the PIC microcontroller can operate and make microcontroller function is you need to give a DC power supply, a reset circuit and a reset circuit and a quartz crystal (system clock) from external source. The basic connection of embedded system as in Figure 5.1.

POWER SUPPLY

CLOCK SIGNAL

RESET CIRCUIT

Figure 5.1: Basic connection of an embedded system

5.1.1 Power Supply

Microcontroller only need a minimum 3v or 5V DC and this power supplies are commonly used in embedded systems.

71

Embedded System Applications 5.1.2 Reset Circuit

Reset circuit consists of a push button and resistor, connecting the reset pin (MCLR) used to restart the system.

Figure 5.2: Reset Circuit of PIC microcontroller

5.1.3 Clock Signal

Clock signal is used to execute microcontroller instructions. Clock signal is supplied through the external OSC pin of the microcontroller. However modern microcontrollers come with both external and internal ( built-in) oscillators.

Examples of external clock sources are as below and the connection as Figure 5.3: a.

crystal oscillator

b.

Resonator.

c.

RC circuit

Figure 5.3: Clock Signal Circuit

72

Embedded System Applications Table 5.1 : Mode, frequency and capacitor for clock signal circuit MODE LP

XT

HS

FREQUENCY

C1,C2

32KHz

33pF

200KHz

15pF

200KHz

47-68 pF

1 MHz

15pF