Software as a Service can transform business

Software as a Service (SaaS) in the cloud can accelerate in novation, improve scalability and increase agility, according to Rockwell Automation (Booth S-1660). Faster troubleshoot ing, enhanced productivity, on-demand scaling and improved collaboration are real-world benefits of this tool. SD

PACK

International

IS back

Attendance exceeds 40,000.

PACK EXPO International is ending a highly succesful run today with attendance that will exceed the 2018 edition (the previous in-per son show). “The industry has never been busier,” noted Jim Pittas, president and CEO of PMMI, The Association for Packaging and Processing Technologies (Booth N-4550) at a press briefing on Monday, Oct. 24.

Columbia Machine celebrates 85 years

An ambitious 23-year-old, Fred Neth Sr., started Columbia Machine (Booth N-4721) in 1937. At some point, the com pany built a machine to stack concrete blocks on a pallet. At an open house in the early 1960s, the owner of Lucky Brewery saw the machine and asked if the same principle could be used to stack beer on a pallet, and the Palletizer Division was born. SD Kirk returns home

Kirk-Rudy (Booth S-3278) welcomes Caroline Kirk as vice president of Operations. The grand daughter of Kirk-Rudy founder Harry Kirk brings a background in marketing and operations and will focus on those areas as well as employee engagement. She says, “Over the past 55 years, Kirk-Rudy has developed a reputation for offering best-in-class mailing, printing, packaging and RFID solutions. I look forward to continuing the Kirk-Rudy legacy and supporting the next generation of company growth.” SD

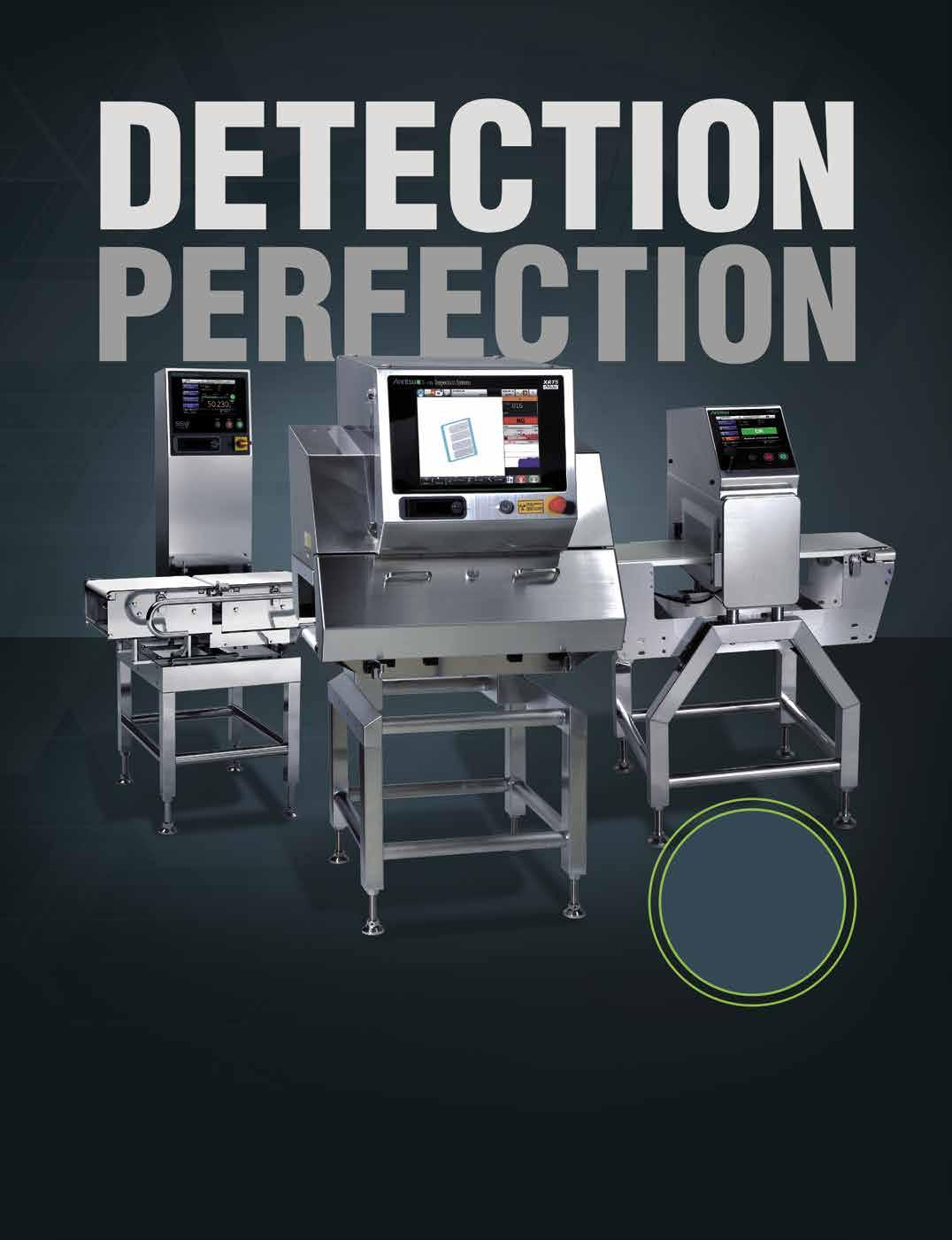

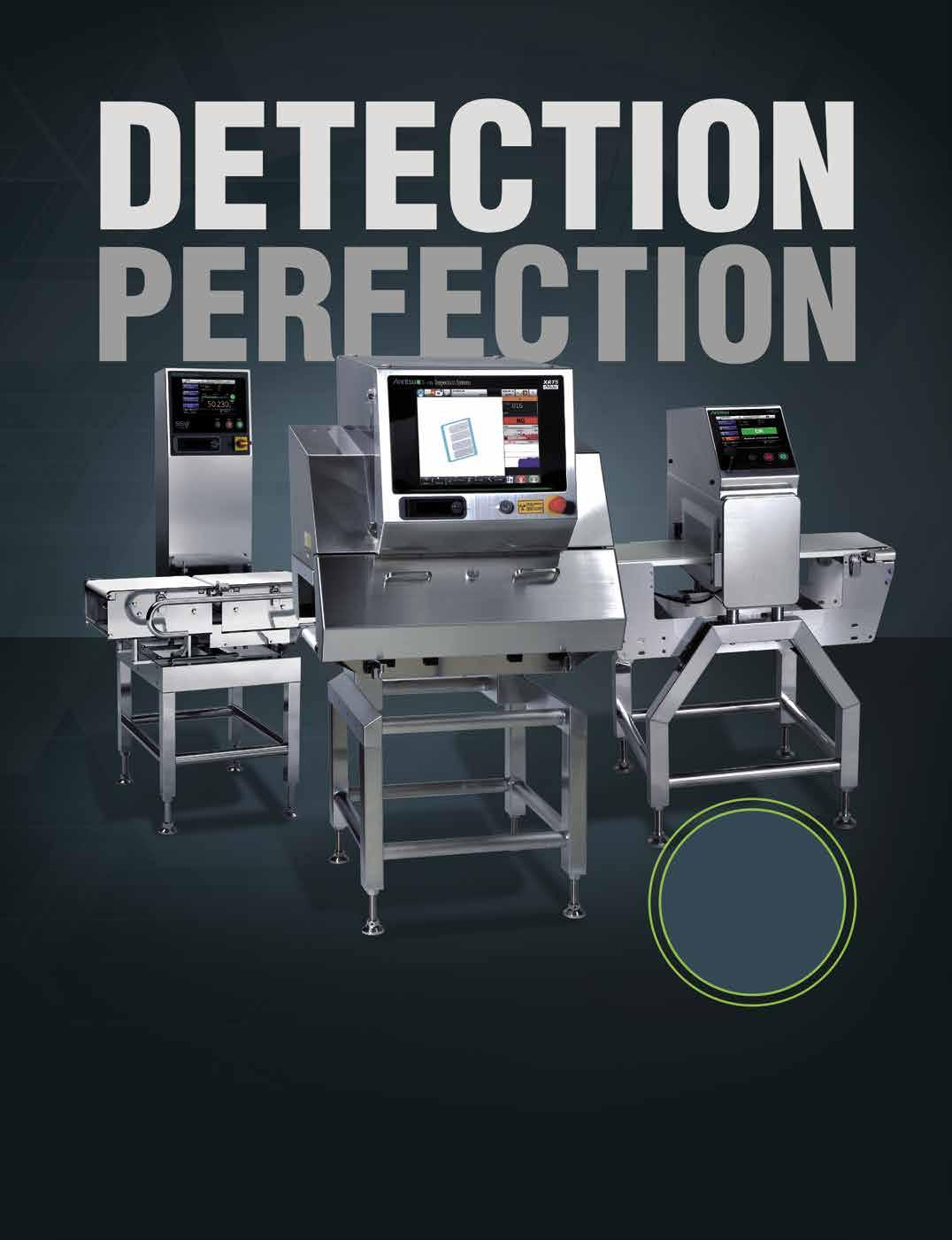

Confirm quality 3 ways

Inspection, weighing and metal detection from Heat and Con trol (Booth N-4704, N-4706) protect product integrity. Sophis ticated image processing of the IX-series x-ray inspection systems reliably detect contaminants, while checkweighers verify package weight or count. THS-Series metal detectors feature superior sensitivity to detect magnetic, non-magnetic and stainless-steel metal contaminants. SD

PACK EXPO International may be winding down, but a full schedule of events lies ahead with EXPO PACK Guadalajara (June 13-15, 2023) and PACK EXPO Las Vegas (Sept. 11-13, 2023).

EXPO PACK Guadalajara offers many tradition al PACK EXPO components including educational sessions on the Innovation Stage. More than 17,000

buyers from Mexico and Latin America are expected to tour the show floor, which houses more than 700 exhibitors.

PACK EXPO Las Vegas will return to the Las Vegas Convention Center and include many ele ments seen in Chicago, including The Processing Zone, The Logistics Pavilion and the Healthcare Packaging Pavilion. Other PACK EXPO Las Ve gas events include a strong educational schedule with the Innovation Stage, the Processing Innova tion Stage, The Forum and the Reusable Packaging Learning Center. Attendees also will be able to enjoy a golf tournament to benefit the PMMI Foundation, a PACK gives BACK fundraiser and a Packaging &

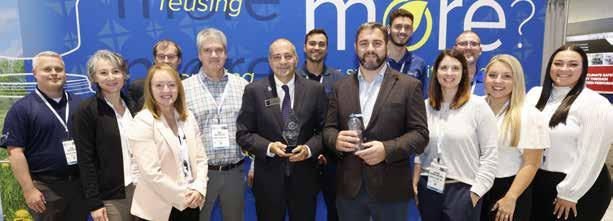

PPWLN draws record crowd

Yesterday’s Packaging & Processing Women’s Leadership Network (PPWLN) Breakfast drew a crowd of more than 1,000.

Tracy Stout, vice president, Marketing at PMMI, The Association of Packaging and Processing Technologies (Booth N-4550), introduced a new resource, the Voices of Women in Packaging and Pro cessing Report, prepared in conjunction with the OpX Leadership Network (Booth N-4550)

Keynote speaker Dawn Hudson, former chief marketing officer at the National Football League (NFL) and CEO of Pepsi Cola North America, talked about her experiences in male-dominated

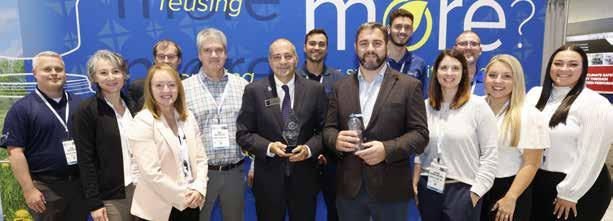

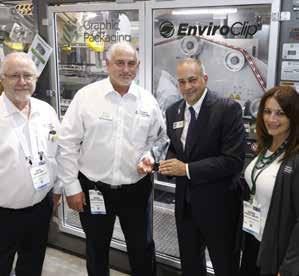

4 exhibitors take home awards

Attendees select Technology Excellence Award winners.

Four exhibitors have won a 2022 Technolo gy Excellence Award. Attendees at PACK EXPO International selected the four from a field of 12 finalists, which were narrowed from a significantly larger field of submissions made by exhibitors.

Winners were named in four categories: Food & Beverage, General Packaging & Processing, Personal Care & Pharma and Sustainability.

The Food & Beverage award was given to Berry Global (Booth N-4727) for its Proxima tethered

NEWS BRIEF INDUSTRY SPEAKS P.20 | PACK TO THE FUTURE P.20 | INNOVATION STAGE P.24 | FORUM P.34

Come and see us in South Hall, Booth # 3514 Syntegon_Corner_ad_ShowDaily_Chicago_2022.indd 1 SHOW DAILY WEDNESDAY, OCTOBER 26, 2022

(Continued on page 4) (Continued on page 4)

EXPO

S M T W packexpolasvegas.com join us for the next show DOWNLOAD THE MOBILE APP Scan to get the app: Search Access Your My Show Planner Navigate Get news Vote in the 2022 Technology Excellence Awards Sponsored by: Booth N-5534 Booth LU-8901 Sponsored by: Complimentary Wi-FI throughout McCormick Place (Continued on page 6)

.

This system WILL dramatically reduce operator touch-time, WILL speed up changeovers beyond your wildest dreams, and WILL eliminate costly downtime on your labeler. Our simple fix to your complex problems.

Nita is the original 100% Servo Labeler that WILL change your production universe forever.

www.NitaLabeling.com | sales@nita.ca | 1.855.668.NITA (6482) COME MEET YOUR NEW SUPER-EFFICIENT “EMPLOYEE” IN BOOTH S-3666. WE KNOW YOU WILL HIT IT OFF RIGHT AWAY.

MEET

YOUR NEW “BEST LABELER OPERATOR EVER” YES, THAT IS CORRECT. WE BUILT YOU A SKILLED WORKER RIGHT INTO THE LABELER . Introducing the ALL-NEW Nita Sentient Labeling Machine with ULTRA-PRECISE FULLY AUTOMATIC CHANGEOVERS.

NEED WE SAY MORE?

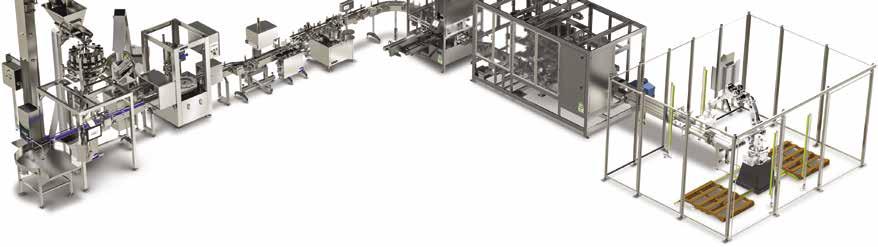

is a leading provider of primary, secondary, and end-of-line packaging machines with more than 30 years of industry expertise. Operating from eight global facilities, with a passionate and focused staff of professionals, we also have a strong national service presence, the ability to provide systems integration, and an installed base that includes more than 7,000 machines across the world. Paxiom. Get more.

Paxiom

Visit us at Booth S-2153

Scan for the Paxiom Xperience™ Center virtual tour.

1.833.4PAXIOM | info@paxiom.com paxiom.com LAS VEGAS | MONTREAL | MIAMI | TORONTO | MILWAUKEE | SCHIO, ITALY WeighingPre-roll Filling BaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing

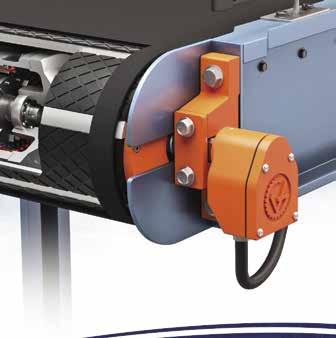

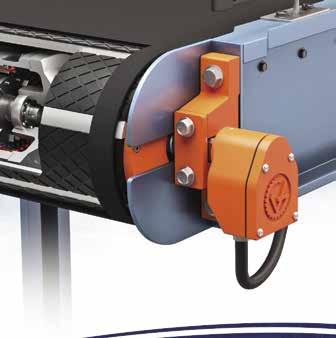

Encoder doesn’t need to go ‘home’

Available in single- and multiturn resolution, the Model A58SB absolute bus encoder from Encoder Products (Booth S-4026) handles applications where an encoder needs to retain position information after power-off scenarios. With absolute positioning, the controller “knows” exactly where the machine is at all times and doesn’t need to rehome. SD

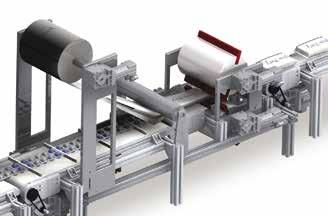

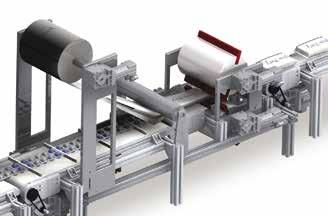

BW Converting brings 5 companies together

The newly aligned BW Converting Solutions platform brings together five Barry-Wehmiller (Booth S-2100) converting companies to serve the tissue, nonwovens, hygiene, bag-converting, mailing and printing indus tries. This group is presenting the Ares 400-SUP standup pouch machine from Hudson-Sharp. SD

Marchesini USA marks 30 years

Marchesini Group USA (Booth W-17005) celebrates its 30th anniversary. Since 1992, the New Jersey-based staff has provided sales and after-sales services to pharmaceutical, nutra ceutical and cosmetics brand owners in the U.S., Canada and Puerto Rico. SD

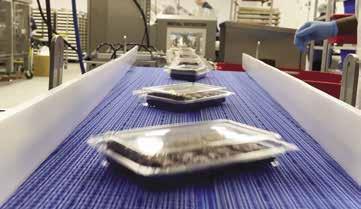

Services support cell and gene therapies

Integrated packaging and distribution services from Thermo Fisher Scientific (Booth N-5706) support the specialized needs of cell and gene therapies. The solution ensures supply chain integrity from storage, serialization, ultracold and cryo genic packaging and global distribution. SD

Sensor receives priority

Firmware advances to Control Station V7.5 from Simco-Ion (Booth N-5020) provide Sensor Priority that accelerates IQ sensor reporting to the unit and instantly posts static measure ments on the human/machine interface. Data and error mes saging also are updated to the PLC. SD

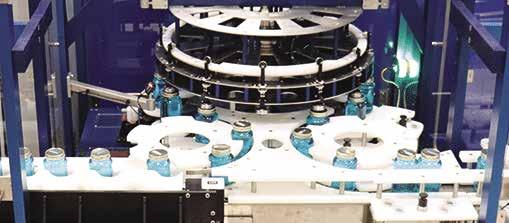

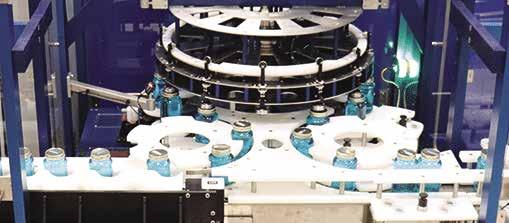

Inspect cased product

The PRO Series Case system from Teledyne TapTone (Booth S-4126) is designed for noncontact, nondestructive, 100% au tomatic container inspection through a sealed corrugated and/ or shrink-wrapped case. Acoustic or proximity technology in spects glass jars with metal closures or metal cans for pressure or vacuum. In many applications, the system will detect other flaws such as missing or damaged containers or lids. SD

Processing Women’s Leadership Network event.

Looking farther into the future, PMMI will launch a new show in 2025, PACK EXPO Southeast (Mar. 10-12, 2025) at the Georgia World Congress Center in Atlanta.

The southeast is home to some of the top manu facturing sectors in the country, and this show will

(Awards continued from page 1) closure.

The General Packaging & Processing award went to IMA North America (Booth S-2514) for the IMA Vegatronic 6400 vertical form/fill/seal machine.

In the Personal Care & Pharma category, the

reach a customer base that is currently untapped by a trade show opportunity. It will laser-focus on the southeast market, as PACK EXPO East does for the northeast concentration of customers.

Stay tuned for details. For more information, visit www.PMMI.org. SD

prize went to Eurotrol (Booth W-13027) for its CueSee Mix dual-chambered device.

The Sustainability award went to Graphic Pack aging International (Booth S-1730) for its Clip Combo™. SD

PACK EXPO International 2022 SHOW DAILY OCTOBER 26, 2022 4NEWS BRIEF

(Look to the Future continued from page 1)

Hygiene, accessibility and efficiency are trademarks of the IMA Ilapak Vegatronic 6400 continuous-motion vertical bagger, developed to meet needs for sanitary design, accessibility, fast changeover and OEE.

The ClipCombo machine can run two different paper-based multipack styles, allows rapid changeovers and delivers high speeds no matter what is running.

The Proxima tethered closure enhances recyclability of the closure while offering consumers a convenient and comfortable drinking experience. The design of the closure includes a special feature on the tamper-evident band ensuring that consumer convenience in not compromised but enabling easy reclosing.

CueSee Mix® is a patented packaging form that is revolutionizing the in vitro diagnostics, pharmaceutical and cosmetic markets. The innovative, dual-chambered device keeps various fractions separated, preventing reactions between components of the desired matrix.

New Solutions VF 1200 Continuous Motion Bagger Up to 180 / minute Hygienic model on display Accurate to 0.01g WeightCheQ 0-250 High Precision Check Weigher PKR Delta Robot Case & Tray Packer BI 600 + BU 600 Bag Inserter & Bag Uncuffer System 1g 1.833.4PAXIOM PaxiomGroup PaxiomXperience Learn more at paxiom.com WeighingPre-roll Filling BaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing NEW NEW NEW NEW I Booth S-2153

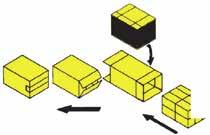

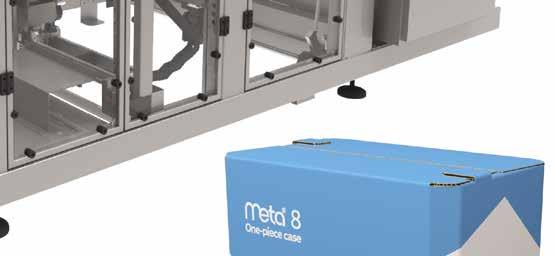

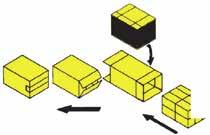

Lock-style forming supports sustainability

Glue-free carton and tray form ing saves energy, maintenance and material cost, according to Syntegon Packaging Technology (Booth S-3514), which debuts its latest Sigpack TTM car toner. A lock-style process accommodates recyclable materials, since it doesn’t require any gluing steps to securely close the carton. SD

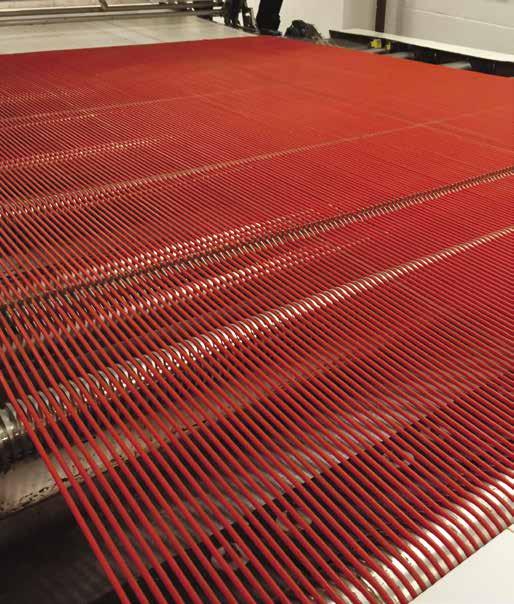

POBCO serves conveyor needs

Conveyor components and fric tion-reducing parts portfolio from POBCO (Booth N-6038) includes roller chain guides, bear ings, guide rails, rollers, sprockets, wear profiles, belt guides and custom-machined parts. Materials include a variety of FDA-compliant plastics, high-temperature-resistant options, lube-filled hardwood and metals. SD

environments beginning with college at Dartmouth, which at the time had a ratio of 10%/90% women to men.

She emphasized the importance of taking a per sonal approach, getting to know people and be ing true to yourself. “You win by leveraging your strengths,” she said. That said, she noted, “When things get tough is when you learn the most.”

She encouraged leaders to be very clear about what the team is trying to achieve. “People that un derstand the goal can bring better solutions.”

She also stressed the need to meet problems head on and described how the NFL, in the aftermath of the Josh Brown elevator assault of his then-fiancé used its forum at the Super Bowl to educate the au dience about domestic abuse. “It was one of the top 10 commercials that year,” she reported, and helped reverse a loss in female fans.

Although improving the status of women in the workplace has been a concern for decades, not much has changed. So Hudson and a group of women business leaders, who were once with PepsiCo, joined forces to educate the workforce. With the advent of the pandemic, speaking events gave way to the group meeting virtually to collect stories about their expe riences. The stories eventually became the book, You Should Smile More: How to Dismantle Gender Bias in the Workplace, to provide advice for young women in 31 situations.

brand (Booth N-5544), Morrison Container Han dling Solutions (Booth N-4906), Plexpack (Booth S-3374), Septimatech Group (Booth N-5934) and SMC Corporation of America (Booth S-3982).

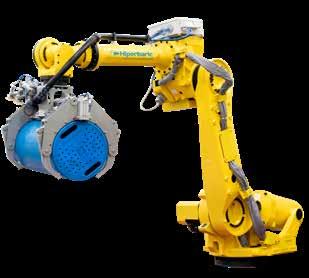

Robotic top loader

The Model IF315 top loader from Cama North America (Booth S-3386) employs a vision-guided RB590 Triaflex deltastyle robot for flexible cartoning, wraparound case packing and tray packing in a monobloc frame. The compact system easily handles flexible or rigid product in secondary and tertiary pack aging. SD

Sponsors of the event include BW Packag ing Systems (Booth S-2100), Emerson (Booth N-4736), ID Technology, a ProMach product

The Packaging & Processing Women’s Leadership Network serves to recruit, retain and advance wom en’s careers in packaging and processing through online and in-person events, information-sharing and networking. Join the Packaging & Processing Women’s Leadership Network group on LinkedIn to connect with peers and learn about upcoming events. For more info, visit www.PMMI.org/ppwln. SD

DAILY

Pregis Receives ISCC

PLUS Certification

The certification, awarded to its Grand Rapids, MI, Perfor mance Flexibles facility, allows Pregis (Booth S-3834) to engi neer certified circular films for food, medical and other perfor mance-critical applications. SD

TE container includes PCR content

The Fresh ‘N Clear® salad container line from Placon (Booth W-24033) combines a tamper-evident (TE) feature with a minimum of 25% EcoStar® post-consumer (PCR) polyeth ylene terephthalate. Ten formats are available, including a me dium and a large footprint clamshell with a dome or flat lid to provide merchandising flexibility. SD

Publisher PMMI Media Group

Editorial Director

Hallie Forcinio

Associate Editors

Kari Moosmann and Barbara Rook

Production Manager

Mary Thorne

Art Director

Debi Friedmann

IT/Production Support

Manny Dominguez

Photographers

Miles Boone, George Burns and Martina Magnusson

Advertising Sales Management

Dave Newcorn, President, PMMI Media Group

Wendy Sawtell, Vice President, Sales, PMMI Media Group

PACK EXPO International 2022 SHOW DAILY OCTOBER 26, 2022 6

PACK EXPO International 2022 SHOW

NEWS BRIEF

(PPWLN continued from

page 1)

“When things get tough is when you learn the most,” said Dawn Hudson, keynote speaker at yesterday’s Packaging & Processing Women’s Leadership Network breakfast.

Jar 1.833.4PAXIOM PaxiomGroup PaxiomXperience WeighingPre-roll Filling BaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing High Performance Check Weigher NEW Turnkey Container Filling & Handling System WeightCheQ 0-250 CONVEYING WEIGHING/ COUNTING FILLING CAPPING LABELING CARTONING PACKING PALLETIZING 10x More Accurate Than Other Check Weighers Accurate to 0.01g. Check weigh all your high value products for the tightest quality control. Learn more at paxiom.com Booth S-2153 Filling System

Sunday – Tuesday: 11:00 am – 3:00 pm Happy hour: 3:00 pm – 5:00 pm Wednesday: 11:00 am – 3:00 pm

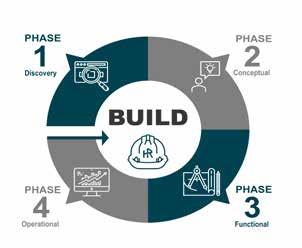

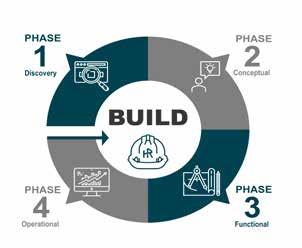

OpX updates FAT guidance

The revised “One Voice Factory Acceptance Tests – Protocols for Capital Equipment in the CPG Industry” work product improves the factory acceptance test (FAT) process.

Developed by the OpX Leadership Network (Booth N-4550), the Factory Acceptance Tests work product is designed to resolve FAT criteria, expectations and miscommunications that often result in unbudgeted travel and material costs, increased timelines and overall confusion for consumer packaged goods (CPG) companies and original equipment manufacturers (OEMs).

This update includes new leadership guidance, additional review of respon sibilities for OEMs and end users, and the integration of the Virtual FAT work product as an appendix rather than a standalone product.

“When conducting an effective FAT, clear communication between all par ties is critical,” says Bryan Griffen, senior director, industry services at PMMI, The Association for Packaging and Processing Technologies (Booth N-4550), convener of the OpX Leadership Network. “This latest update helps streamline that communication and facilitate a more productive FAT, regardless of whether it is virtual or in-person.”

The OpX Leadership Network was founded in 2011 by PMMI to ensure CPG companies and OEMs are connected and well-prepared to solve common opera tional challenges, make smarter decisions and achieve operational excellence.

The revised FAT work product and other operational resources are available for free by downloading at opxleadershipnetwork.org/projects/download.

For more info, visit www.opxleadershipnetwork.org. SD

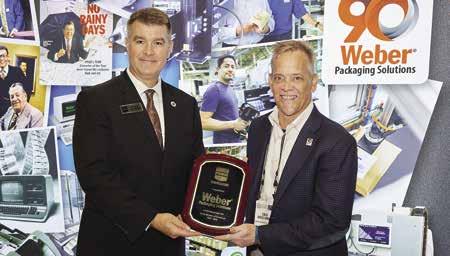

New plants earn awards

Winners in the sixth annual Manufacturing Innovation Awards com petition, sponsored by ProFood World, were honored yesterday at PACK EXPO International. The awards recognize outstanding food and beverage processing and packaging innovation projects involving greenfield plants, expansion and renovation projects or line upgrades.

Mark Anthony Brewing was recognized for its new 1.3-million-sq.-ft. stateof-the-art, fast-track greenfield brewery located in Columbia, SC, which was planned and built in less than a year, a process that typically takes four to six years. The new facility is the largest and most technologically advanced brewery built in the U.S. in the past 28 years.

Sugarlands Distilling, a craft brewer of moonshine, rum, cream liqueurs and rye whiskey, also was honored. Its 32,000-sq.-ft. facility in Kodak, TN, recently under went a $28 million expansion project to support increased production. The highly automated and flexible operation allows for a more streamlined approach to poten tial future expansion and delivers increased throughput, quality and asset utilization.

For more info, visit www.ProFoodWorld.com. SD

SHOW DAILY OCTOBER 26, 2022 8 PACK EXPO International 2022

Open DailyOpen Daily Lakeside Center, Level 2 back of the show floor Sponsored by: Booth LU-8758 Delicious lunch options for under $10 a meal Enjoy fun backyard style games and happy hours. Kick back and dine for leSS!Kick back and dine for leSS! New to the Show? If your badge says “ First-Time Attendee ” stop by and you can: ¤ Ask questions of show staff ¤ Access product locators ¤ Participate in sessions Sponsored by: Booth N-5534 You’re invited to the FIRST-TIMERS LOUNGE! South Building, Level 1, Room S-102 Near the South shuttle bus area

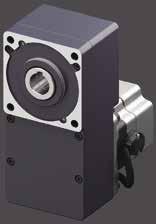

l-r Greg Eidam of Sugarlands Distilling and Dave Blaida of Matrix Technologies (Booth LU-8643) talk about Sugarlands’ award-winning expansion project.

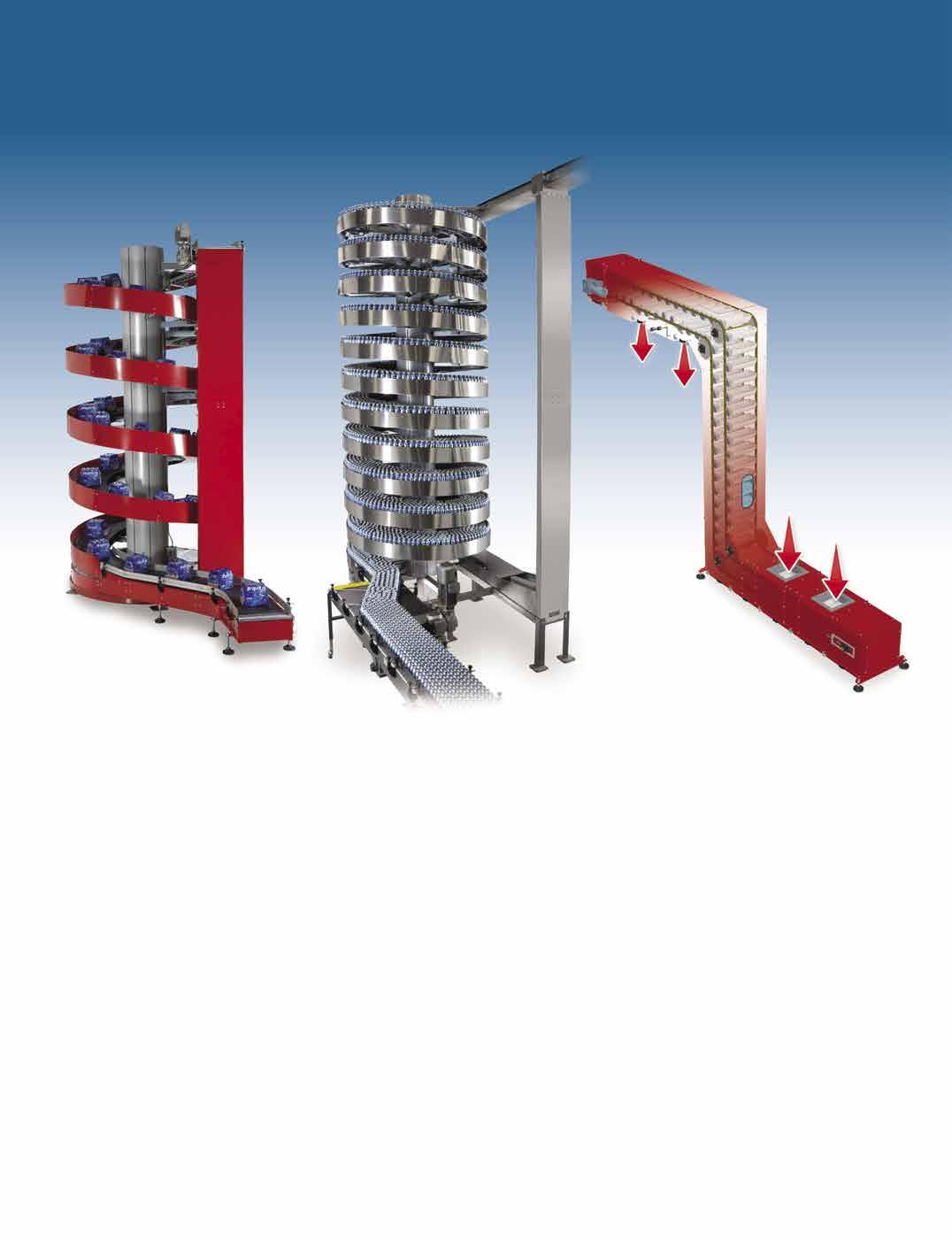

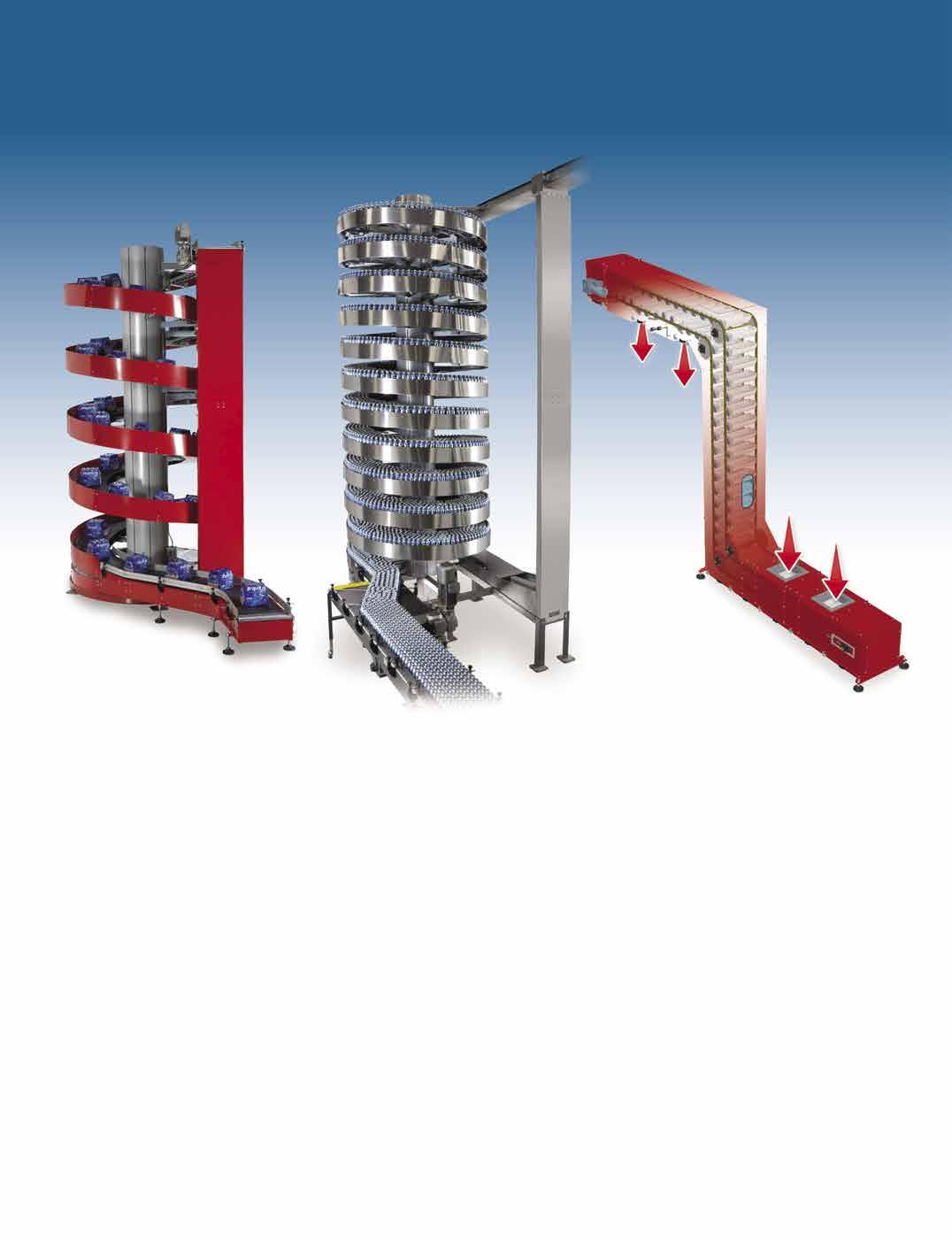

Spiral Conveyors & Bucket Elevators Ryson Vertical Conveying Solutions

Ryson Spiral Conveyors need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Unit Load Spirals convey cases, totes and packaged goods smoothly on our slat style belts and come in 9 standard slat widths ranging from 6” to 30”. Available in powder coated carbon steel, stainless steel, wet environment and freezer versions.

Mass Flow Spirals handle full and empty bottles, cans and jars in mass up to 2000 units per minute. Available in 4 different slat widths ranging from 6” to 20”.

Narrow Trak Spirals are super compact and designed to handle your smaller loads. Our 6” and 9” wide nesting slats can end-transfer small cartons and packages or side-transfer small bottles and containers in a single file or in mass at speeds in excess of 200 FPM.

Ryson’s Bucket Elevators combine vertical and horizontal transportation of bulk materials in one integral unit.

Ryson Bucket Elevators are designed for gentle handling and well-suited to transport a broad range of bulk products. Our signature feature is that they are completely enclosed with overlapping pivoting buckets, that prevent spillage and helps mitigate foreign debris.

Their modular design enables us to customize with ease. They can be configured with multiple inlets or outlets that can be controlled individually. The design makes them easy to install and modify. Available in three standard bucket sizes, yielding capacities up to 300, 700 or 1,800 cubic feet per hour. They can also be delivered in powder-coated carbon-steel, stainless-steel or wet environment versions.

www.ryson.com

Watch our detailed Bucket Elevator Video

Watch our detailed Bucket Elevator Video

All Ryson equipment is modular and built to order. No matter the application, the Ryson team is up to the challenge of finding solutions for your conveying needs. For application assistance or more information, give us a call or visit

300 Newsome Drive • Yorktown, VA 23692 • Phone: (757) 898 1530 • Fax: (757) 898 1580 RYSON INTERNATIONAL, INC. MEMBER OF ROYAL APOLLO GROUP www.ryson.com See our equipment run in the North Hall - Booth N - 5945

PAC Machinery rebrands bag biz

PAC Machinery (Booth S-3314) rebrands Converting Technology, its Rollbag® bags and materials business, as PAC Machinery Bags and Ma terials. The rebranding coincides with the launch of a website, which uni fies all of PAC’s packaging equipment divisions and brands.

THE PARTI IPANT

Packaging

THE M N

PAC Machinery Bags and Materials sells Rollbag pre-opened bags in roll stock or fan-folded formats. The industry-standard bags can be used on virtu ally all brands of automatic baggers. Other products include tubing, coextrud ed poly mailers, poly tubing, side-load bags, medical bags, suffocation warning bags, thermal-transfer ribbon and sustainable packaging options. Products are in stock or available with competitive lead times.

“2022 is a pivotal year for PAC Machinery as bagger sales continue to break . . . records,” says Greg Quinn, GM, PAC Machinery Bags and Materials. “How ever,” he notes, “the most common feedback we hear from customers is that they did not realize we were part of PAC Machinery. Our objective with the rebrand ing is to emphasize that PAC can be a one-stop shop for bags, supplies and for the Rollbag brand of automatic baggers.”

As part of the name change, a new logo is being rolled out for the bags and materials business and a materialsales@pacmachinery.com email has been estab lished. All previously used email addresses remain active.

For more info, visit www.pacmachinery.com. SD

SHOW DAILY OCTOBER 26, 2022 10 PACK EXPO International 2022

Wednesday, Oct. 26 Brought to you by:

and engineering students from across the country.

Tour the PACK EXPO show floor, visit participating exhibitor booths and complete challenges. THE GOAL Learn about new technologies and interact with industry professionals, while earning points for packaging-related challenges. Members of the winning teams will receive cash prizes, courtesy of Emerson. For more information, visit pmmi.org/pmmiu-packexpo Booth N-4736

Bring your product and packaging challenges to Shannon Winans, marketing director.

ORBIS (BOOTH LU-6800) & WESTROCK (BOOTH S-2130) FOR SPONSORING THE PACK EXPO INTERNATIONAL LANYARDS

J Y

CK P C SS

An Interactive Show Floor Must-See!

Service agreements pack in value

Depending on how much support is needed, Syntegon Packaging Tech nology (Booth S-3514) offers a service level to match. From level to level, Syntegon’s commitment increases as your risk decreases. All at a fixed price.

Excellent service and continuous support by Syntegon experts are guaran teed, allowing end users to focus on their core business. Long-term contracts foster a close partnership.

Simply choose the service package that best suits operational needs. Not sure which level is right for you? A Syntegon expert can assist in determining the perfect maintenance strategy.

For more info, visit www.syntegon.com. SD

OMAC updates PackML

New standard will be available from ISA.

At the general meeting of OMAC - The Organization for Machine Au tomation and Control (Booth N-5100), Spencer Cramer of e3, incom ing chair, reported on the update of the PackML standard. It has been defined, documented, printed and submitted to ISA as TR 88.00.02. ISA has approved it, and it is expected to be available for download in November 2022.

Other OMAC publications include the Practical Guide for Remote Access to Plant Equipment, published in January 2021, and Security Considerations for Re mote Access, published in January 2022. The next report in the series from the Digital Transformation Workgroup is devoted to data governance and scheduled to be published in the first quarter of 2023. It will define terminology and discuss ownership, usage and sharing of data.

This spring, the OMAC Board of Directors hammered out and adopted a new strategy document to guide the group, with the overarching goal of making membership stronger. A Technical Advisory Board helps direct the organization, which is further organized into workgroups devoted to Digital Transformation, Packaging and Manufacturing.

The group thanked outgoing chair Ronald MacDonald, senior principal re search engineer at Nestlé, who is retiring; honored the recipient of the 2022 John A. Kowal Memorial Scholarship, Ron Marchionna of the Milwaukee School of Engineering; and welcomed the following nine new members:

(Booth S-4062)

For more info, visit www.omac.org. SD

SHOW DAILY OCTOBER 26, 2022 12 PACK EXPO International 2022

P

Take a tour through this curated exhibit spanning 250 years of historical equipment, materials and photographs. Get a glimpse into the future and attend over 20 free sessions presented on the PACK to the Future Stage exploring: 〉 The circular economy 〉 Smart packaging & Innovative sustainability initiatives 〉 The evolution of pharmaceutical packaging ALSO FEATURED: A corrugated car of the future VR Experience produced by Paper + Packaging Board. Join us in the West Building, Booth W-20001

• Keyence

• Arla Foods • Inovance • MRTEC • Llumin • Skan • Applied Control Engineering • ETT Verpackungstechnik • Cisco

98% Y , M ’ b l y b x . W 98% v ll y y l . M C l l v l x b l y ll v x v l v l . Y , ’ w s roc .com/pac xpo ©2022 W s c ompany. WEST OCK, W s c nd D sign, an h W s c ogo ar ra mar s own d by W s c ompany ll righ s r s rv d. NATURALLY SUSTAINABLE. EFFICIENTLY AUTOMATED. Fas l xibl nd sus ainabl , our n w s ra orm h ac po. Ch u ow his innova iv ac agin quipm produc a aging wi h r wabl ap board. Visi s a Boo h S–2130 o l arn mor . N AT U R A L LY S U S TA I N A B L E . w s roc .com/pac xpo ©2022 W s c ompany. WEST OCK, W s c nd D sign, W s c ogo ar ra mar s own d by W s c ompany

Lanyards keep registration badges close at hand. Aisle banners help attendees navigate the show floor. Both are sponsored by WestRock (Booth S-2130)

Attendees are no doubt grateful for having WiFi access during the show, courtesy of Impackt Packaging Solutions (Booth LU-8901).

Shout out to LAPP USA (Booth LU-8758) for sponsoring the Lake side Backyard Bistro, where attendees can get a quick bite while taking a break from the busy show floor.

At the First Timers’ lounge, sponsored by ProMach (Booth N-5534, N-5540), attendees new to the show can ask questions of show staff, access product locators and more.

The PACK EXPO Exhibitor and Member Lounges, sponsored by Lenze Americas (Booth N-5239), provides an area away from the show floor for exhibitors and members to meet, rest and enjoy refreshments.

PACK EXPO attendees were greeted each morning by eye-opening stair graphics, courtesy of Syntegon Packaging Technologies (S-3514), which also sponsored the Candy Bar Lounge (Booth S-2583)

Lanyards keep registration badges close at hand. Aisle banners help attendees navigate the show floor. Both are sponsored by WestRock (Booth S-2130)

Attendees are no doubt grateful for having WiFi access during the show, courtesy of Impackt Packaging Solutions (Booth LU-8901).

Shout out to LAPP USA (Booth LU-8758) for sponsoring the Lake side Backyard Bistro, where attendees can get a quick bite while taking a break from the busy show floor.

At the First Timers’ lounge, sponsored by ProMach (Booth N-5534, N-5540), attendees new to the show can ask questions of show staff, access product locators and more.

The PACK EXPO Exhibitor and Member Lounges, sponsored by Lenze Americas (Booth N-5239), provides an area away from the show floor for exhibitors and members to meet, rest and enjoy refreshments.

PACK EXPO attendees were greeted each morning by eye-opening stair graphics, courtesy of Syntegon Packaging Technologies (S-3514), which also sponsored the Candy Bar Lounge (Booth S-2583)

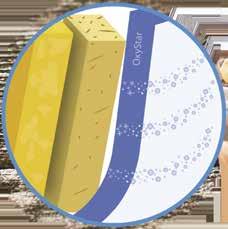

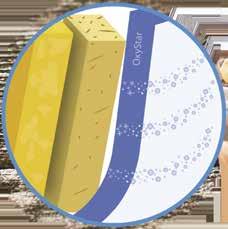

OxyStar barrier material utilizes a multilayer PET with an oxygen scavenging agent. PET has a naturally low oxygen transmission rate (OTR) and this construction slows down the flow of oxygen molecules through the package from the outside. Once the scavenger agent finds an oxygen molecule, it attaches to it and binds the oxygen within the sidewall of the package to keep your product fresh and lasting longer.

RECYCLABLE BARRIER MATERIAL FIRST OF ITS KIND DIRECT FOOD CONTACT FDA COMPLIANT INCREASED SHELF LIFE BLOCKS OXYGEN WATCH OUR PRESENTATION AT THE INNOVATION STAGE WEDNESDAY @ 11AM TO HEAR ABOUT IT

Student teams compete

Amazing Packaging Race returns.

Students will participate in the annual Amazing Packaging Race this morn ing. Coordinated by show producer PMMI, The Association for Pack aging and Processing Technologies (Booth N-4550), and sponsored by Emerson (Booth N-4736), the race brings together 35 teams from 22 high schools and colleges across the U.S. to complete a series of challenges at exhibi tor’s booths spread out across more than 1.2 million net-sq.-ft. of exhibit space.

“This year’s competition was our largest to date,” reports Kate Fiorianti, di rector, Workforce Development, PMMI.

For more info, visit www.PACKEXPOinternational.com. SD

PARTICIPATING EXHIBITOR BOOTH

Allen Field Company LU-8914

B&R Industrial Automation S-3572 Baumer hhs N-4619

Beckhoff Automation S-3882 Belden LU-7058

Packaging Systems S-2100 Daubert Cromwell LU-8608

Dorner N-5725 Duravant

Econocorp

Automation

IV Technologies N-4936 Frazier & Son N-4913 Fresh-lock By Presto Products S-3541

IoPP (Institute of Packaging Professionals) N-4523, W-20052

ITW Hartness N-5132

Americas

USA

Morrison Container Handling Solutions

Group

Machinery

Digital Industries

Packaging Machinery

a ProMach product brand

W-17002

SHOW DAILY OCTOBER 26, 2022 16 PACK EXPO International 2022 WEST HALL | Booth W-20052 Next to the Containers and Materials Pavilion Get inspired by award-winning packaging from around the world—the next great idea for your brand might be on display! Sponsored by: FEATURING ENTRIES FROM: ■ ABRE —Brazilian Packaging Association ■ AIMCAL —Association of International Metallizers, Coaters and Laminators ■ DOW —Packaging Innovation Awards ■ FPA —Flexible Packaging Association ■ FSEA —Foil and Specialty Effects Association ■ IAE —Instituto Argentino del Envase ■ IMDA —In-Mold Decorating Association ■ IoPP —Institute of Packaging Professionals ■ ProFood World’s Sustainability Excellence in Manufacturing Awards ■ RPA —Reusable Packaging Association ■ The Tube Council ■ WPO —World Packaging Organisation

BW

S-3547

S-1630 Fallas

S-3530 FOX

Lenze

N-5239 Linmot

S-2992

N-4906 OMAC N-5100 Pacteon

S-3500 Paper

S-3714 Polypack S-2147 SICK N-5925 Siemens

N-5148 Starview

N-5728 WLS,

N-5650,

Wherever you are and whatever your industry, there’s a PACK EXPO event to provide solutions you need today and the inspiration for tomorrow.

June 13-15, 2023 Guadalajara, Mex.

Sept. 11-13, 2023 Las Vegas, USA

March 18-20, 2024 Philadelphia, USA

June 11-14, 2024 Mexico City, Mex.

Nov. 3-6, 2024 Chicago, USA

®

Visit packexpo.com

Association Partner Program grows

Learn, network at Industry Meets and Industry Speaks.

The PACK EXPO Association Partner Pro gram connects attendees to leading associ ations from all segments of packaging and processing. This year’s program, the largest in PACK EXPO history, offers an unparalleled breadth and depth of industry knowledge to attendees.

The Association Partner Pavilion, in the North Hall, provides a central location for attendees to ac cess these resources. Participants in the 2022 PACK EXPO International Association Partner Program are listed at the bottom of this page.

New this year is the Association Partner Plus des ignation and Industry Meets schedule of ancillary events and meetings hosted by groups listed in the far right column. Events include a hygienic equip ment design seminar, design for recycling training, a fluid power forum and Fundamentals of Medical Device Packaging course. Check the PACK EXPO International App or show website for the latest schedule and pre-registration requirements.

“We are thrilled with the positive response to the Association Partner Program and newly launched In dustry Meets Program,” says Laura Thompson, vice president of Trade Shows at show producer PMMI, The Association for Packaging and Processing Tech nologies (Booth N-4550). “PACK EXPO Interna tional is making a triumphant return to Chicago after four years away, and it is only possible with the strong support of these prestigious associations.”

Another new feature, the Industry Speaks Stage (Booth N-4565), offers educational sessions led by experts from PACK EXPO Partner Associations and focused on hot-button topics and trends across

multiple industry verticals. A schedule of sessions can be found on p. 20, the PACK EXPO Interna tional App or show website.

In addition to the Association Partner Program, PMMI has partnered with industry associations from

PAVILION HOSTS

CCPIT - China Council for the Promotion of International Trade

CFPMA - China Food and Packaging Machinery Industry Association

Confederation of the Danish Industry (Booth LU-7560)

Fundacion Argentina para la Promocion de Inversiones y Comercio Internacional (Booth LU-8755)

INP – Brazilian Plastic Institute/Think Plastic Brazil (Booth W-25011)

Italian Trade Agency (Booth LU-8541)

Korean Packaging Machinery Association

Mouvement Des Enterprises De France International (Booth N-5564)

Switzerland Global Enterprise

UCIMA – Italian Packaging Machinery Manufacturers Association (Booth N-6002)

VDMA – Food Processing and Packaging Machinery Association

across the globe to host pavilions on the show floor. International Pavilion Organizer Partners include the 11 organizations listed under Pavilion Hosts.

For more info, visit www.PACKEXPOinternational.com. SD

INDUSTRY MEETS

3-A Sanitary Standards (Booth N-5901)

Active & Intelligent Packaging Industry Association (Booth N-5802)

Cold Pressure Council (Booth N-4525)

Contract Packaging Association (Booth N-4518)

Flexible Packaging Association (Booth N-4533)

Institute of Packaging Professionals (Booth N-4523)

International Bottled Water Association

MHI Automation Industry Groups (Booth N-5701)

National Fluid Power Association

OMAC – The Organization for Machine Automation and Control (Booth N-5100)

The Association of Plastic Recyclers (Booth N-5902)

INTERNATIONAL PARTNER PROGRAM

AIM (Booth N-5000)

AIMCAL - The Association of International Metallizers, Coaters and Laminators (Booth N-4527)

Asociacion Mexicana de Envase y Embalaje

ASD Turkish Packaging Manufacturers Association (Booth N-4900)

Australian Institute of Packaging

ABRE – Brazilian Packaging Association (Booth N-6003)

CANAINCA

Chicagoland Food & Beverage Network (Booth N-4511)

Composite Can and Tube Institute (Booth N-4512)

Digital Twin Consortium (Booth N-6102)

Foil & Specialty Effects Association (Booth N-4536)

F4SS – Foundation for Supply Solutions

Flexographic Technical Association (Booth N-4510)

In-Mold Decorating Association (Booth N-4534)

IAE - Instituto Argentino del Envase (Booth N-6101)

International Society of Beverage Technologists (Booth N-5702)

ISTA - International Safe Transit Association (Booth N-4537)

Midwest Food Products Association

National Confectioners Association (Candy Bar Lounge, Booth S-2583)

OPC Foundation (Booth N-5001)

PLCopen (Booth N-5002)

Reusable Packaging Association (Booth LU-6737)

SNAC International (Booth N-5801)

The Anuga FoodTec Family

The Australian Packaging and Processing Machinery Association

The Paper and Packaging Board

The Tube Council of North America (Booth W-20052)

UCIMA – Italian Packaging Machinery Manufacturers Association (Booth N-6002)

U.S. Department of Commerce (Booth N-4901)

World Packaging Organisation (Booth N-4902)

SHOW DAILY OCTOBER 26, 2022 18 PACK EXPO International 2022

BO O TH : S-3634 Com p l et e Autom atio n S o lut i o n s F i l li ng & S ealin g Au t o matio n En d- of-Line Pac k a gi n g Au t o matio n

PACK to the Future arrives

Historical exhibit serves as foundation for advancements.

Theinteractive PACK to the Future Exhibit (Booth W-20001) celebrates the role of pack aging and processing throughout history and the impact it is poised to have on the future. The exhibit follows the evolution of modern packaging and pro cessing over 250 years to the present and shifts to ex plore key trends shaping the future in daily live sessions on the PACK to the Future Stage (Booth W-20025)

Launched in 2021 at PACK EXPO Las Vegas, the curated, interactive PACK to the Future exhibit tells the story of packaging and people who saw a better way, solved challenges and provided the foun dation for today’s—and tomorrow’s—innovations.

The exhibit includes:

• 30 historial packaging machines and replicas dating back to the 1800s

• Timeline walls displaying 250 years of history

• An area dedicated to women in packaging and processing

• An interactive display of past, present and future sustainability efforts, including a Corrugated Car of the Future Virtual Reality (VR) Experience. Sponsored by The Paper and Packaging Board, the experience allows attendees to sit in a replica of a futuristic car and use a VR headset to learn about sus

tainable packaging and the industry’s Box to Nature program, an initiative to educate consumers about the importance of recycling corrugated materials and boxes

• An interactive audio tour revealing interesting facts and historical details

• Fun quizzes that test attendees’ knowledge of the industry.

Each day on the PACK to the Future Stage, indus try experts provide 30-minute presentations on cut ting-edge advancements in sustainability, circularity, net-zero goals, returnables and manufacturing trends.

The session schedule is outlined below. PACK EXPO International offers many other free educa tional opportunities, including the long-running In novation Stage (Booth N-4560, N-4580, N-4585) plus the new Processing Innovation Stage (Booth LU-7130) (see schedule, p. 24), The Forum at PACK EXPO (Booth N-4543) (see schedule, p. 34) and the new Industry Speaks (Booth N-4565) (see schedule, at right). The Reusable Packaging Learning Center (Booth LU-6737) also presents educational sessions.

Updated schedules may be found on the PACK EXPO International App or the show website.

For more info, visit www.PACKEXPOinternational.com. SD

WEDNESDAY, OCTOBER 26, 2022

DEVELOPING PRODUCTS FOR A CIRCULAR ECONOMY

9:30-10:00 AM

Urgent focus is being directed at climate change, greener transportation, fresh food, clean water, Circu lar Economy, plastic waste and renewable feedstocks. This presentation relays these challenges through the UN Sustainability Development Goals and outlines solutions to support downstream customers as they set their sustainability and Circular Economy goals.

Matthew Marks

Leader, Circular Economy, Americas SABIC

HEADWINDS, TAILWINDS AND REALISTIC EXPECTATIONS FOR PET RECYCLING IN 2025

10:30-11:00 AM

PET recycling is at a crossroads as the industry drives toward 2025 goals. Brands, consumers, regulatory agencies and NGOs support systemic improvements, while known limitations restrain success. We will con sider what is reasonably possible for increased PET recycling, what changes are needed, and what the rPET industry might look like in 2025.

Steve Lyons

Dir of Strategic Environmental Analysis SBAcci Consulting Group

THE EVOLUTION OF PHARMACEUTICAL PACKAGING

11:30-12:00 PM

An examination of the future of pharmaceutical packaging as it becomes more sustainable and meets the needs for greater convenience, self-administered drugs, reduced hospital stays and serving patients at home. We also will look at how past and present inno vations focused on meeting patient and product needs offer a path for the future.

Ron Yakubison

Exec Dir, Global Technology Packaging Merck

IMPROVING RESIDENTIAL RECYCLING WITH BOX TO NATURE!

12:30-1:00 PM

The paper industry, partnering with the Paper and Packaging Board, is introducing a residential recy cling shipping box messaging initiative called Box to Nature. The partnership is working with customers and large brands to educate consumers about the box with easy instructions on recycling right, every time. Learn about how to become part of this initiative.

Mary Anne Hansan President

Paper and Packaging Board SD

The Industry Speaks Stage (Booth N-4565) offers educational sessions led by experts from PACK EXPO Partner Associations and focused on hot-button topics and industry trends across multiple industry verticals.

WEDNESDAY, OCTOBER 26, 2022

10:30-11:00 AM

CONTRACT PACKAGING ASSOCIATION

WHAT IS DRIVING THE INTEREST IN THE CONTRACT PACKAGING AND MANUFACTURING INDUSTRY?

Using data from our State of the Industry Report, member feedback and our RFQ platform, we will dive into the demands of this dynamically growing indus try. Often a confusing and frustrating segment, these essential providers of capabilities and services are ad dressing the needs of emerging brands as well as lega cy brands seeking to launch new food and CPG retail products. We will explore how CoMans and CoPacks are adding value as consumer- and market-driven needs are moving the packaged goods supply chain. Learn how the newest and innovative products have become key opportunities for CoMans. Understand how brands are adapting to meet new challenges with strategic CoMan and CoPack partnerships and accel erate time to market.

Ron Puvak Exec Dir

Contract Packaging Association

Carl Melville President Melville group on behalf of Contract Packaging Association SD

SEW EURODRIVE (BOOTH LU8105) AND WESTROCK (BOOTH S-2130) FOR SPONSORING THE PACK EXPO INTERNATIONAL HAND SANITIZER STATIONS.

SHOW DAILY OCTOBER 26, 2022 20 PACK EXPO International 2022

READY

THE BEST SOLUTION

TO BE

Ronchi America has started producing an 18 head EXACTA stand-alone fille r that can be easily integrated into new and existing lines. It is proudly and entirely built in Atlanta, Georgia and available in 12 weeks or less. TOTALLY AMERICAN WITH AN ITALIAN HEART www.ronchipackaging.com SEE US AT BOOTH N-6228

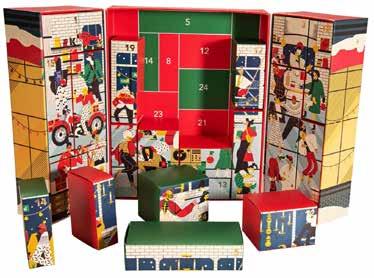

WestRock sponsors Showcase

Exhibit displays award-winning packages from around globe.

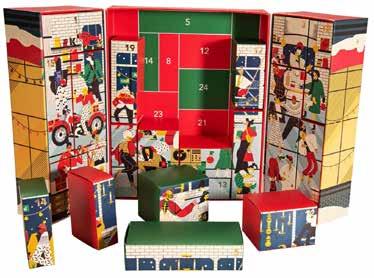

WestRock (Booth S-2130) presents win ning entries from worldwide packaging competitions as the exclusive sponsor of this year’s Showcase of Packaging Innovations® (Booth W-20052).

“At WestRock, we are focused on delivering bold innovation to solve our customers’ biggest challeng es,” says Margaret Herndon, the company’s chief marketing officer. “The Showcase displays the best the industry has to offer in packaging innovation, and we are excited to be part of a program that en gages customers and generates new thinking and new solutions.”

Show producer, PMMI, The Association for Packaging and Processing Technologies (Booth N-4550), is pleased to partner with WestRock on this initiative.

“The Showcase of Packaging Innovations has come to be a show floor favorite at PACK EXPO,” says Jim Pittas, president and CEO, PMMI. “We are thankful for companies like WestRock who seek to inspire the future of our industry and motivate package designers by showcasing packaging that is functional, innovative and sustainable.”

This year’s Showcase participants include 13 or ganizations from around the world. A sampling of the award winners on display is pictured here.

For more info, visit www.PACKEXPOinternational.com, www.westrock. com, www.abre.org.br, www.aimcal.org, www.dow.com, www.flexpack.org, www.fsea.com, www.imdassociation. com, www.packaging.com.ar, iopp.org, www.profood world.com, https://paperbox.org/, www.reusables.org, www.tube.org, www.worldpackaging.org. SD

The Best in Show package in IoPP’s AmeriStar competi tion, Blue Buffalo Tastefuls Spoonless Singles from General Mills and Product Ventures, provides a perfectly portioned split cup with a built-in chopper. The recyclable polypropyl ene split cup separates easily, reducing the need to store opened containers in the refrigerator.

PARTICIPANTS

ABRE - Brazilian Packaging Association (Booth N-6003)

AIMCAL - Association of International Metallizers, Coaters and Laminators (Booth N-4527)

Dow (Booth W-22017) Dow Packaging Innovation Awards

Flexible Packaging Association (Booth N-4533)

Foil & Specialty Effects Association (Booth N-4536)

In-Mold Decorating Association (Booth N-4534)

IAE - Instituto Argentino del Envase (Booth N-6101)

Institute of Packaging Professionals (IoPP) (Booth N-4523)

PMMI Media Group (Booth N-4550)

ProFood World’s 2021 Sustainability Excellence in Manufacturing Awards

Paperboard Packaging Council (Booth W-20052)

Reusable Packaging Association (Booth LU-6737)

Tube Council of North America (Booth W-20052)

World Packaging Organisation (WPO) (Booth N-4902)

Last year,

flip-top

and

with

A

of the

SHOW DAILY OCTOBER 26, 2022 22 PACK EXPO International 2022

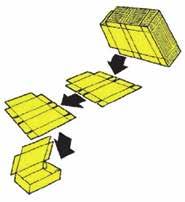

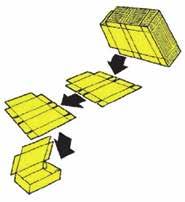

The Package of the Year Award winner in the 2021 North American Paperboard Packaging Competition, the 2020 edition of Kiehl’s Advent Calendar produced by Johnsbyrne, features a storybook display design to deliver a premium unboxing experience while eliminating the use of plastic. A 100% paper-based rigid outer box houses 24 snuggly packed straight-tuck folding cartons containing product.

A capsule dispenser from Germany’s PACKSYS earned a President’s Award in the WPO’s WorldStar competi tion. Designed

for people with limited

motor function,

the

dispenser releases

one

capsule

at a

time

via an easy-topress, lockable

actuator.

The Diamond Award, the top prize in the Dow Packaging Innovation Awards, considers three criteria: sustainability, technological innovation and enhanced user experience. The Brookfarm Roll ‘n’ Recycle curbside-recyclable, high-barrier stand-up pouch from Australia’s OF Packaging earns top honors on each point.

ABRE honored this canister for ease-of-use and ergonomics. Package features waisted silhouette

onepiece,

closure

an induction seal.

pull ring ensures complete removal

seal.

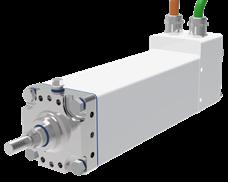

For Filling & Closing of Syringes in a Nest

Ready-to-use (RTU) disposable syringes provide security, hygiene and dosing accuracy for medical injections. The NFL/2, manufactured by Dara and sold in North America by NJM, is a combination of filling and closing equipment for RTU disposable syringes in nests. The syringes are supplied pre-sterilized and ready to be processed, and therefore require no washing, sterilization, or special transportation.

Filling & closing machine for syringes in a nest.

Manual or automatic positioning of the nest, depending on the model of the machine

Dosing through valveless rotary piston pumps or peristaltic pumps

• Automatic infeed and positioning of plungers or stoppers

Production speed: up to 5,200 units per hour

Dara/NJM is at Pack Expo! West Hall / Healthcare Packaging Pavilion...

October 23-26, 2022 McCormick Place Chicago, Illinois USA

FEATURES & BENEFITS 1-800-811-6990 NJMPackaging.com ///////////////////////////////////////////////////////// NFL/2 BOOTH #W-17002

•

•

•

Innovation Stage hosts 60+ sessions

Processing Innovation Stage makes Chicago debut.

Anattendee favorite, the Innovation Stage, returns to PACK EXPO In ternational with more than 50 informative sessions. The free, 30-minute presentations occur throughout each day on three stages (Booth N-4560, N-4580 and N-4585) in the concourse of the North Building near Starbucks.

Topics include sustainability and eCommerce, building a resilient supply chain, automating minimal material operations, cyber resilience, robotics, upgrading from heat sealing to ultrasonic sealing, brand protection and smart sensors.

New this year, after a successful launch at PACK EXPO Las Vegas, the Pro cessing Innovation Stage (Booth LU-7130) in the Lakeside Center concourse featured sessions on Sunday, Monday and Tuesday focused on high-pressure pas teurization, product handling, batching and blending, clean-out-of-place parts washers and sanitary drainage system design.

Innovation Stage presenters rank as subject matter experts and represent a cross-section of exhibitors, including Syntegon Packaging Technology (Booth S-3514), Amcor Rigid Packaging (Booth S-3705, S-3814), Placon

(Booth W-24033), SMAC Moving Coil Actuators (Booth N-5774), Mich igan State University (Booth W-20044), Siemens Digital Industries (Booth N-5148), WestRock (Booth S-2130), Amcor Flexibles North America (Booth S-3705, S-3814), Brenton, a ProMach product brand (Booth N-5546), Emer son (Booth N-4736), Soft Robotics (Booth N-5230) and JBT-Avure (Booth LU-7118)

PACK EXPO International offers many other educational opportunities, in cluding PACK to the Future (Booth W-20025) (see program, p. 20), The Forum at PACK EXPO (Booth N-4543) (see program, p. 34), and the new Industry Speaks (Booth N-4565) (see program, p. 20). The Reusable Packaging Learning Center (Booth LU-6737) also is hosting daily educational sessions.

Updated schedules may be found on the PACK EXPO International App or the show website.

For more info, visit www.PACKEXPOinternational.com. SD

WEDNESDAY, OCTOBER 26, 2022

THE RISE OF SOFTWARE AS A SERVICE

10:00-10:30 AM

Innovation Stage 1|N-4560

Explore what software as a service means for manu facturing or machine-building businesses of any size. Sesssion addresses the “IT won’t let us” challenge and breaks down six real-world ways to can incorporate the cloud for productivity improvement, cost contain ment and workforce support.

Jim Taylor

CPG Industry Consultant Rockwell Automation

CYBERSECURITY BEST PRACTICES IN A CONNECTED IIOT WORLD

10:00-10:30 AM

Innovation Stage 2|N-4580

Being and staying cyber secure in an increasingly dig ital, connected industrial world requires an aggressive, proactive approach. The risks to your operations and brand reputation are palpable. This session provides best practices to establish a strong cybersecurity foun dation and address your organization’s most burning questions: What should you do to proactively defend your operation and ensure ongoing vigilance? What standards and best practices apply to your business? Who is responsible for ensuring cybersecurity at your organization?

Grant Geyer

Chief Product Officer

Claroty

Paula Mott

Cybersecurity Business Consultant

Schneider Electric

PESTS TO WATCH OUT FOR AS MOISTURE LEVELS FLUCTUATE

10:00-10:30 AM

Innovation Stage 3|N-4585

Fungus feeders are extremely common pests in ware houses and can become problematic when moisture levels rise, allowing molds and fungus to grow. These conditions offer pests such as psocids and a few types of beetles the food they need to survive in storage environments. Managing moisture, humidity and air movement is critical to keeping these pests out. Fungus feeders can be found in pallets, on and inside packaging, in supplies and many other places. Learn what fungus feeders are, the risks they pose, proactive measures you can take to avoid them and how an In tegrated Pest Management plan can help proactively manage them in your facility.

Benjamin Hottel

Ph.D., B.C.E, Mgr, Technical Services

Orkin

LEAK TESTING FOR MICROORGANISMS IN MEDICAL/ PHARMA PACKAGING

11:00-11:30 AM

Innovation Stage 1|N-4560

Innovative sensor technologies facilitate non-destruc tive container closure integrity and package leak tests to below the scale that allows microbial ingress to your packages. In this workshop, learn how helium leak testing aids in simple, fast, repeatable, quantitative and non-destructive leak test cycles, providing potential es cape from the archaic dye-penetration tests.

Bill Burnard

General Industrial & Package Integrity Sales & Business Development Mgr - NA INFICON

RECYCLABLE AND RECYCLEREADY PACKAGING FOR THE DAIRY MARKET

11:00-11:30 AM

Innovation Stage 2|N-4580

A void exists in the dairy alternatives, nutritional drinks and ready-to-drink coffee markets for pack aging made from recycled material and recyclable in most markets. ClearCor technology offers significant sustainability benefits compared to aseptic carton packaging, which experiences high damage rates and poses a challenge for convenience stores, where tradi tional refrigerated shelf space is designed for round, rigid, plastic bottles. The ClearCor bottle contains post-consumer recycled (PCR) resin and provides a recyclable packaging solution, as well as easy access to eCommerce and convenience store distribution chan nels. It also delivers a positive drinking experience. A recyclable PET bottle, utilizing the ClearCor technol ogy, offers the same taste and feel as other packaging, delivers a positive drinking experience and extends shelf life.

Terry Patcheak

VP, R&D, Sustainability & PM Excellence Amcor Rigid Packaging

OXYSTAR—THE FIRST RECYCLABLE BARRIER MATERIAL

11:00-11:30 AM

Innovation Stage 3|N-4585

This session explores more sustainable alternatives to barrier materials that achieve the same barrier protec tion. In an economy with limited resources, longer shelf life is a desirable objective for food processors. How do we further promote a Circular Economy where reusing materials reduces reliance on new materials?

SHOW DAILY OCTOBER 26, 2022 24 PACK EXPO International 2022

WEDNESDAY, OCTOBER 26, 2022 (CONT’D)

Ron Haub VP, Sales Placon

FRESH FOOD TO-GO AND THE CIRCULAR ECONOMY

12:00-12:30 PM

Innovation Stage 1|N-4560

This session, including a short case study, takes attendees through existing fresh food to-go packaging in the market, including how flexible packaging and material changes can better support sustainability goals and the Circular Economy.

Nathan Klettinger Dir, Global Marketing ProAmpac

SMART SENSORS: THE BACKBONE OF DIGITAL TRANSFORMATION

12:00-12:30 PM

Innovation Stage 2|N-4580

Discuss Industry 4.0 as it relates to smart sensing technology. Modern manufac turing is saturated with data, even from the most basic sensors. Learn how this data “overload” can be leveraged to make manufacturing smarter and can continue driving the current digital transformation. Learn about trends in using this data and clear, actionable steps to join this new industrial revolution.

Divya Prakash Dir, Business Consulting SICK SD

PAC Machinery rebrands Converting Tech bag biz

New identity unifies divisions and brands.

PAC Machinery (Booth S-3314) rebrands Converting Technology, its Rollbag® bags and materials business, as PAC Machinery Bags and Mate rials. The rebranding coincides with the launch of a website, which unifies all of PAC’s packaging equipment divisions and brands.

PAC Machinery Bags and Materials sells Rollbag pre-opened bags in roll stock or fan-folded formats. The industry-standard bags can be used on virtu ally all brands of automatic baggers. Other products include tubing, coextruded poly mailers, poly tubing, side-load bags, medical bags, suffocation warning bags, thermal-transfer ribbon and sustainable packaging options. Products are in stock or available with competitive lead times.

This year, “2022, is a pivotal year for PAC Machinery as bagger sales continue to break . . . records,” says Greg Quinn, GM, PAC Machinery Bags and Materi als. “However,” he notes, “the most common feedback we hear from customers is that they did not realize we were part of PAC Machinery. Our objective with the rebranding is to emphasize that PAC can be a one-stop shop for bags, supplies and for the Rollbag brand of automatic baggers.”

As part of the name change, a new logo is being rolled out for the bags and materials business and a materialsales@pacmachinery.com email has been estab lished. All previously used email addresses remain active.

For more info, visit www.pacmachinery.com. SD

SHOW DAILY OCTOBER 26, 2022 25 PACK EXPO International 2022

Find your scale at YamatoAmericas.com Always the best way to weigh. WEIGHING & FILLING SOLUTIONS NEW Yama Yama Tray Filling for Leafy Greens Commercial Scales High Speed Bulk Weighing • From napkin drawing to operational equipment • Maximizing productivity, minimizing floor space • OEM communications ... we’ll connect the dots • Immediate solutions designed for future expansion • Agency compliance built directly into your conveyor Accumulate, Rotate, Elevate, Integrate, Lift-gate, Incline, Combine, Decline, Alpine, In-line, Grip, Flip, Split, Invert, Divert, Merge, Twist, Turn, Curves, Transfer, Push, Stack, Hand pack, What’s that?, Serpentine, Sanitary. ki d i t ti l i t Multi-Conveyor ... your best, conveyed better. www.multi-conveyor.com But your secret is always safe!

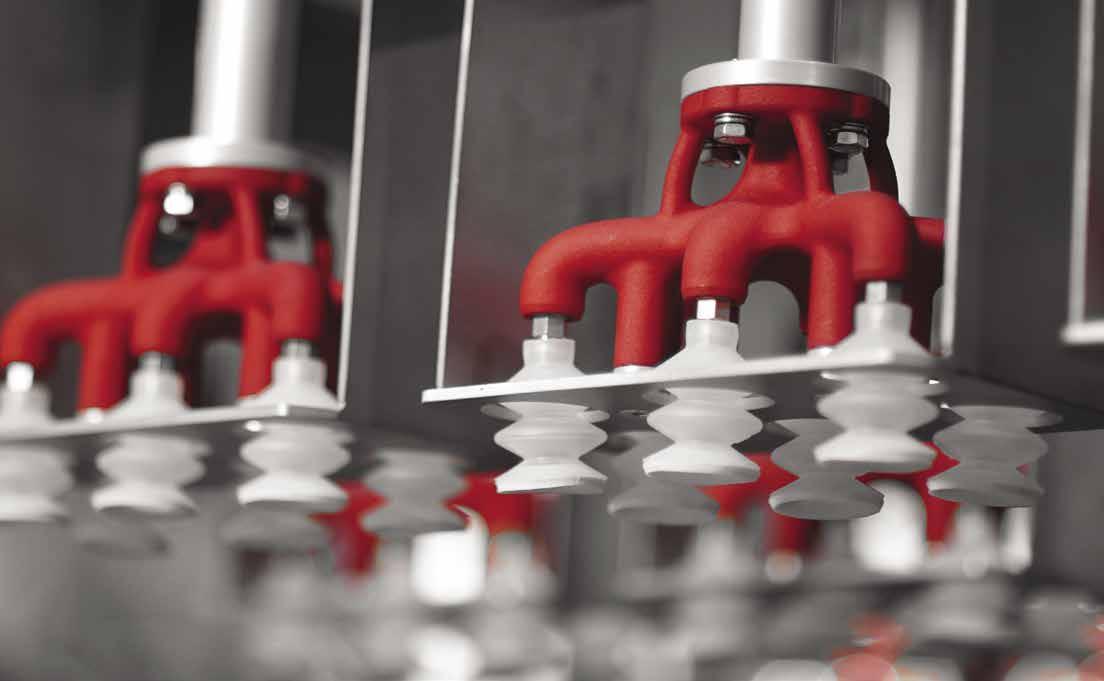

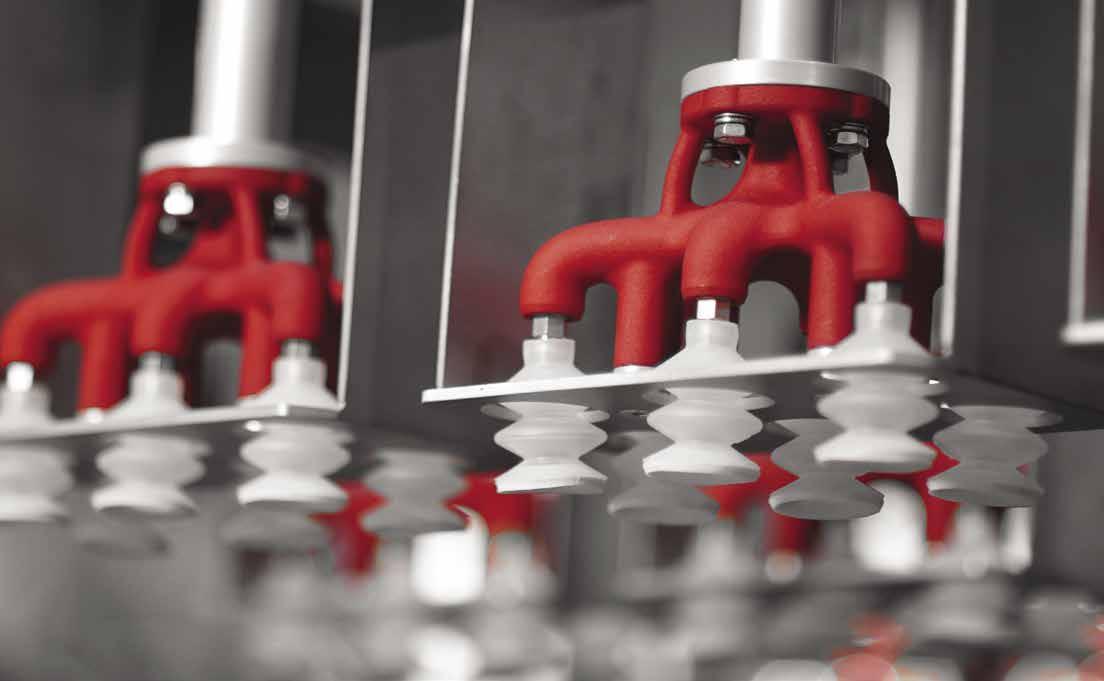

Automation spurs inspection needs

More automated systems raise the risk of contamination.

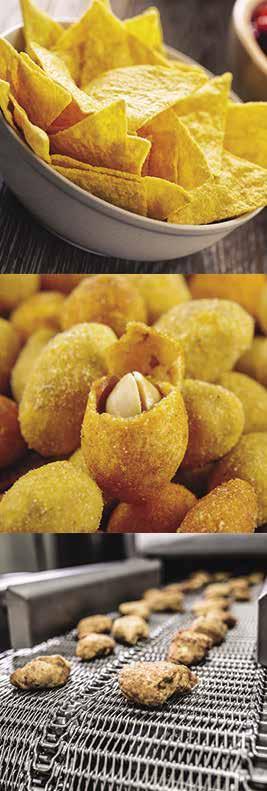

Food plants are accelerating their use of auto mation. Processors, seeking to enhance op erating efficiencies while compensating for reductions in available labor, are leveraging more innovative technologies for functions ranging from washing, cutting and mixing to robotics and the packaging of final products.

While newer machine designs enable production of higher quality food products faster, this increase in automation also brings operating challenges and requires highly effective detection systems. Not only does the greater use of production technologies increase the probability of having machine com ponents, such as bolts and brackets, fall into food during processing, but also smaller labor forces re duce the chances that workers will spot foreign mat ter in products or prevent incidents from occurring.

“The recent push for automation is replacing functions that are easy for humans to execute,” states Michael Ahern, national sales manager for Anrit su - Product Inspection and Detection (Booth N-4730). “When once plant workers had to cut a food product by hand, there are now very sophisti cated machines to perform this role.”

While such machines can be expensive, labor shortages are making the technologies more cost-ef fective. Further, inspection systems are becoming in creasingly valuable by enabling detection of smaller objects while having a range of price points and ca pabilities to support processors of all sizes. That is important, as worker shortages, which were an issue before being exacerbated by the COVID-19 pan demic, are likely to be ongoing.

“The pandemic will continue to spur the move to ward automation because of the reluctance of plant employees to be working close together,” Ahern says. “That means there are fewer hands and eyes exam ining products. Automation is compensating for the lack of workers and to make sure labor is not the issue for not producing products.”

A SYSTEM FOR EVERY SITUATION

X-ray machines and metal detectors remain the two prevalent inspection technologies. X-ray devices transmit energy in the form of a short wavelength x-ray beam through the product. A detector on the opposing side measures the amount of absorption of the x-ray beam passing through to create a den sity graph of the product. Elements denser than the product, including metal, glass, calcified bone, stone and cement, show as dark spots. Objects similar in density to the product, such as wood, paper, fabrics and plastics, are difficult to detect.

“Metal is eight times denser than food or pro teins, so it is very detectible,” Ahern states. “Glass is three to four times as dense, so it is not as easy to detect. Plastic, wood, hair nets and other low-densi ty materials are not typically detectible.”

Metal detectors, on the other hand, have been used in food plants for decades and operation is based on a magnetic field within a tunnel. Metal objects within the field interfere with the magnetic field indicating an unwanted inclusion. Performance of the metal detector varies depending on the size of the aperture and the product.

Metal detectors are commonplace within the food industry and offer economic benefits for the operator. While metal detectors do their job effec tively, they have limitations on product type and packaging. In addition, operators are looking to find nonmetal contaminants, all of which makes x-ray technology more attractive.

Over the past 10 years there have been signifi cant gains in x-ray technology. The launch of newer designs also is resulting in increasingly cost-efficient inspection systems, and that includes previous gen eration models that are dropping in price.

Modern x-ray systems can better detect lessdense contaminants, such as bone and glass, as well as plastics impregnated with x-ray-detectable ma terials. Ahern notes that the top-tier x-ray systems often can detect metals ranging in size between 0.5mm to 0.8mm and that performance level also proves that lower density contaminants are detected at smaller sizes as well.

Nevertheless, he states that processors will benefit from using both x-ray and metal detectors on their lines, as “there still will be instances in which a metal

detector will find matter that an x-ray system cannot.” Such detection may include clusters of metal particles, which typically are too small for x-ray to locate, and thinner material, including aluminum foil.

There is a school of thought that x-ray devices are most effective when inspecting products that are uniform in size and shape, but evolving technologies are enabling processors to better detect foreign mat ter in non-uniform products as well.

He notes, for instance, that while it is easier to locate objects in food of consistent sizes lying flat on a conveyor belt, upgrades are enabling better inspection of various-size products that processors might randomly deposit on a line. Today, “We can deal with the natural variations of the production load and still find the contaminants,” reports Ahern.

DEVICE POSITIONING

The optimal locations for inspection devices on processing lines, and the technologies that are most effective, can vary in accordance with such factors as space availability; product temperature, as some devices are more effective on frozen food; and the size of the product undergoing inspection.

Equipment selection and placement also will differ in accordance with a processor’s inspection objectives, and can include the use of multiple tech nologies in different sections of the processing line to support functions ranging from bulk inspection of raw ingredients to case inspection prior to pallet izing. Earlier placement, however, can help prevent damage to processing equipment by enabling oper ators to detect dense matter before the objects have contact with processing machinery.

In addition, inspecting products at the head of the process can help ensure that larger objects are not re duced into smaller, harder-to-detect pieces, while end-of-the-line inspection re duces the chance that foreign matter will elude monitoring.

“Placement becomes more critical when the primary goal is finding low-den sity contami nants like bones,

SHOW DAILY OCTOBER 26, 2022 26 PACK EXPO International 2022

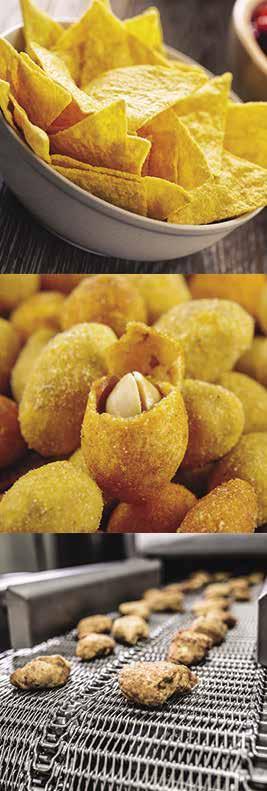

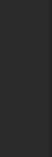

M6 Free-fall metal detector inspects dry food products like candies, snacks, pet food, cereals, grains and nuts. Ideal for gravity-fed vertical form/fill/seal packaging lines, the head is available in 4-, 6- and 8-in. tube diameters

IP69K-rated sanitary x-ray system withstands harsh washdown conditions and combines reliability, ease of use and low cost in a rugged, compact footprint.

A CONFECTIONERY

JUNGLE PACKAGED AUTOMATICALLY. BROUGHT TO

LIFE

WITH SCHUBERT.

How can you package confectionery and baked goods flexibly in a wide variety of pack formats? With pick & place robots that accurately position each product and systems that effortlessly switch between different packaging materials. Saving precious resources –with virtually no waste. This is our Mission Blue. A true benefit for the climate and the many FMCG manufacturers who have been relying on us since 1 66. And for you too. www.schubert.group/en/confectionery-snacks.html PACK EXPO CHICAGO OCTOBER 23 – 26, 2022 BOOTH # 8730 WELCOME

glass or stones,” Ahern notes. “Often this dictates upstream placement where product thickness is low and consistent and creates more-ideal conditions for detecting the matter.”

X-ray inspection systems can consist of single- or dual-energy technologies. Single energy x-ray is the traditional technology used by most facilities and excels at detecting metals, stone and glass and bones in certain applications. Dual energy is an upgrade in technology that uses two energy levels to identify the difference between organic and inorganic mate rial and is better able to detect low-density matter such as glass, stone, rubber and bone.

Dual energy also can better “tune out” product effect when detecting foreign matter and is ideal for inspecting products consisting of layers and overlap ping pieces. Product effect refers to food character istics that can alter inspection device readings and cause false rejects.

MINIMIZING FALSE REJECTS

Because false reject readings often result in prod uct waste and mistrust of the detection system, it is critical that processors leverage devices that mini mize occurrences. Indeed, frequent false reject read ings may cause operators to question whether an ac curate positive reading is legitimate. False rejects not only cost money, but the plant’s quality department is more likely to say, “Here we go again” rather than “I have a reject, let me find out what it is,” Ahern

explains. “It is important to minimize false rejects because you want everyone in the plant to trust the detection technology.”

Higher false reject rates are more likely to occur if the producer’s inspection goal is too close to the detection device’s performance limit. For instance, metal detectors are subject to performance changes based on product and plant temperatures. So, if the device is tuned to the edge of performance, they are subject to a high reject rate if the product tempera ture changes. “On the other hand, having perfor mance headroom allows producers to run with much lower false reject rates and that is an advantage with x-ray technology,” says Ahern.

Such headroom is available with x-ray technology that can detect 0.6mm metal where the customer’s specification is 0.8mm. “Having a two-rank margin against the specification will reduce false reject rates and that can have a dramatic financial upside when there is less interruption of high-speed lines that are processing high-value products,” he notes.

The technology evolution adds ease and efficien cies Along with greater detection capabilities, x-ray equipment and metal detectors are becoming easier for processors to implement. “The auto setup routine is more intuitive and no longer requires technical skills or the services of an electrician or engineer,” Ahern says. Indeed, operators typically perform simple functions such as inputting product information and the con veyor belt speed before running products through the

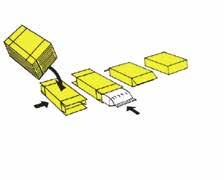

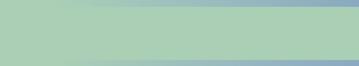

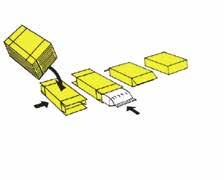

From filling to palletizing Multiple machines, converting group make debut.

Under the theme “Conversations to Inno vations,” BW Packaging Systems (Booth S-2100) showcases equipment from Ac craply, BW Flexible Systems (Booth S-2406), BW Integrated Systems (Booth S-2106), Pneumatic Scale Angelus and Synerlink.

The Maximus mid-speed case palletizer from BW Integrated Systems debuts to meet demand for a flexible high-level palletizer. Designed for simple maintenance, this machine includes a split-for-ship feature for a quicker vertical startup.

Also at the front of the booth, the Hayssen ISB vertical form/fill/seal bagger from BW Flexible Sys tems includes several improvements added since its launch last year at PACK EXPO Las Vegas. Its hy gienic design targets the food industry.

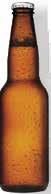

Building on the capabilities of the innovative CB50C counter-pressure canning line, also intro duced last year, Pneumatic Scale Angelus exhibits the new CB100C counter-pressure canning line. It allows craft brewers to increase throughput to more than 100 cans/min., leveraging a 12-head rotary fill ing turret design, coupled with a dual-station seamer.

Synerlink team members guide booth visitors through an immersive 3D view of the Versatech filler

for food and dairy products. Modular design allows end users to realign this machine as needs change and addresses the desire for a filler that can outlast the standard 20-to-30-year life cycle.

Another new machine, Accraply’s MK6 pres sure-sensitive labeler/tamper-evident (TE) bander integrates labeling with TE sleeving and features Accraply’s SmartLink human/machine interface.

devices multiple times to set the detection signal.

“Systems can be operating within a couple min utes,” he reports, adding that common user interfac es on equipment from a single supplier can reduce the need to train workers to use different technol ogies within a plant, including x-ray systems, metal detectors and checkweighers.

The inspection equipment itself is already mostly automatic and requires very little input from oper ators. The human/machine interfaces are becoming more usable and efficient by simplifying and speed ing product setup and easing adjustments.

Inspection technologies, meanwhile, continue to evolve with advances to x-ray sensors set to provide even better detection of low-density contaminants, offering higher resolution imaging with more con trast. In addition, improvements to single-energy x-ray equipment are increasing efficiencies and re ducing ownership costs.

Inspection technologies also are incorporating deep learning, a subset of machine learning that contains algorithms that are intended to work like the human brain to optimize detection.

“The goal is to find as many contaminants as are rea sonable to find with x-ray systems,” concludes Ahern.

For more info, visit www.anritsu.com/infivis. SD

Editor’s Note: This article was written by Mi chael Ahern, national sales manager at AnritsuProduct Inspection and Dectection.

The newly aligned BW Converting Solutions brings together five Barry-Wehmiller converting companies to serve the tissue, nonwovens, hygiene, bag-converting, mailing and printing industries. This group is presenting the Ares 400-SUP stand-up pouch machine from Hudson-Sharp.

For more info, visit www.bwpackagingsystems.com. SD

SHOW DAILY OCTOBER 26, 2022 28 PACK EXPO International 2022

BW Packaging Systems presents a new palletizer, vertical form/fill/seal bagger, canning line, food/dairy filler, integrated labeler/bander and stand-up pouch machine.

Press runs MDO-PE film

Sensor tracking and material control overcome variability.

The Heliostar II gravure press from Wind moeller & Hoelscher (W&H) (Booth LU7919) combines faster speeds (up to 600 m/ min.) with tighter control. It’s also designed to effi ciently print sustainable films made of machine-di rection-oriented polyethylene (MDO-PE).

A new sensor-tracking system and Supergrip idler rollers provide stability and control even at top speeds. The former ensures extremely fast register control, which is no longer pneumatically governed but motor ized, thus ensuring a faster response to material move ments in the press. The Supergrip idler roller, a com pletely new technology, guides the material through the machine in a much more stable manner.

The updated gravure printing press also breaks new ground in automa tion: simple, intuitive machine operation and handling are guaranteed by the central Procontrol panel with direct access to all machine functions and quality parameters.

A deeply integrated vi sion control system gives the operator detailed and precise job control for best machine performance and job quality. All production parameters are recorded and can be used for further downstream processes via W&H’s Ruby Internet of Things system.

BEST EQUIPPED TO PRINT MDO-PE

The new Heliostar II press addresses growing demand for sustainable materials and trends toward shorter print jobs (and frequent job changes). The register control and Supergrip technology are espe cially important in handling the stretched MDOPE, which does not run homogeneously over the entire working width of the press.

The Heliostar II Series includes S and A mod els. The Heliostar II S press is extremely flexible and can be configured for all packaging films, laminates and papers and special customer requirements. The Heliostar II A, with up to 10 printing units, is po sitioned to serve the core flexible packaging market.

For more info, visit www.whcorp.com. SD

Go performance.

Emerson is redefining interactions between people and machines. Immediate, real-time access to machine settings, status and performance enables you to make faster decisions and keep processes under control.

Learn more at Emerson.com/movicon

Visit us at Pack Expo 2022.

Hall – Booth N4736

PACK EXPO International 2022 OCTOBER 26, 2022 29 SHOW DAILY

North

The Heliostar II gravure press maintains control to compensate for the inconsistencies presented by recyclable MDO-PE film.

GET IN THE L P WINDMOELLER & HOELSCHER PASSION FOR INNOVATION Upper Lakeside Booth 7919

Clean laser coder applies crisp codes

Fibre laser codes through condensate, reduces consummables.

In a warm, wet and very challenging coding en vironment, Pepsi Bottling Ventures counts on the F720i fibre laser coder from Domino, par ent company of Domino Amjet (Booth S-3506), to serve up crisp, refreshing, readable codes, day-afterday, can-after-can.

“Why does Pepsi use Domino laser coding? Be cause it works!” exclaims Pepsi Bottling Ventures GM Mike Collins.

BACKGROUND

As North America’s largest independent Pepsi Co. product bottler, Pepsi Bottling Ventures serves 8 million customers from 16 production facilities located in five eastern states: Delaware, Maryland, North Carolina, South Carolina and Virginia. Lines run at lightning speed and there’s no time for down time, so quality coding is both a significant under taking and challenge for the company.

coding with fibre technology, but when Domino pre sented the fibre technology for can coding we didn’t hesitate . . . and, at the end, we have a great technol ogy working for us.”

The F720i fibre laser coder uses short, intense pulses, which significantly increase its marking speed and allow it to deliver high-quality codes at speeds up to 120,000 cans/hr. The result is a high-resolu tion, durable mark on even the most challenging sur faces—such as the concave base of a can. Total cost of ownership is reduced through the removal of inks and solvents, minimal setup or adjustment needs, uninterrupted production runs and a lack of waste typically associated with can printing.

to put in a lot of hot air to get it to where [the can is] dry. With laser coding, there can be a little bit of condensate, it really doesn’t matter. . . . It’s power ful enough, it’s going to etch the bottom of that can with the code . . . a very crisp code.

“The other thing I will tell you . . . with inkjet cod ing, the ink doesn’t always land where you want it. If you were to look under an inkjet coder, you’d likely see where an alien died,” jokes Collins, referring to the inky mess often found under an inkjet printer.

“With the laser coder, there’s none of that,” he adds.

SITUATION

In the past, Pepsi Bottling Ventures used ink jet printers to code the bottom of its cans, but they were dissatisfied with the resulting code quality. Dis cussing the company’s switch from inkjet coding to Domino’s high-speed fibre laser system, Daryl Beel er, production supervisor at Pepsi Bottling Ventures, reports, “From a production standpoint, we love it. When a can comes through, we don’t have to con stantly check the code date . . . with the inkjet system, we constantly had to check.”

SOLUTION