Honor Hall of Famers this afternoon

The late Jean-Jacques Graffin, Rebecca Oesterle, Pierre Pienaar and E. Jeffrey Rho dehamel, Ph.D., will be inducted into the Packaging & Processing Hall of Fame today at 3:30 p.m. in a ceremo ny at the Industry Speaks Stage (Booth N-4565) SD

4th generation continues POBCO tradition

As POBCO (Booth N-6038) approaches its 100th anniver sary, the fourth-generation, family-owned manufacturer and distributor of conveyor components and friction-reducing parts continues adding employees and maintains the work ethic and dedication of its founders. Products include roller chain guides, bearings, guide rails, rollers, sprockets, wear profiles, belt guides and custom-machined parts. SD

Choose TEA winners

Vote now for your favorite finalists in the 2022 Technology Excellence Award competition (see story, p. 54). Winners will be announced Tuesday afternoon (Oct. 25). Vote onsite at the Attendee Solu tions Center in the North Hall Concourse or Lakeside Upper Hall Lobby; via the PACK EXPO International mobile App, sponsored by ProMach (Booth N-5534, N-5540); or online. SD Marchesini USA marks 30 years

Marchesini Group USA (Booth W-17005) celebrates its 30th anniversary. Since 1992, the New Jersey-based staff has provided sales and after-sales services to pharmaceutical, nutraceutical and cosmetics brand owners in the U.S., Canada and Puerto Rico. SD

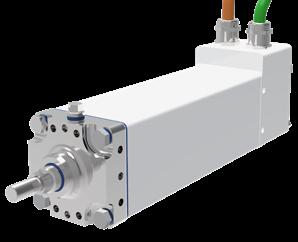

Heat-sealing basics

Heat Sealing-Art or Science? white paper written by Charles Trillich, co-founder of TOSS Machine Components (Booth N-5913), describes heat-sealing technologies and the evolution of precision heat-sealing. SD

Styx plays at PACK gives BACK Event raises funds for PMMI Foundation, supports education and training for packaging and processing industry.

The multi-megamillion-selling rock band, Styx, will play this afternoon at PACK gives BACK (West Ballroom, Level 3), a fund raiser for the PMMI Foundation.

Doors open at 4:30 p.m. for the event, sponsored by Rockwell Automation (Booth S-1660), the Contract Packaging Association (Booth N-4518), Hoosier Feeder (Booth N-6136), the Institute of Packaging Professionals (Booth N-4523, W-20052) and OMAC - The Organization for Machine Automation and Control (Booth N-5100). Attendees may enjoy a preshow networking reception with refreshments and ap petizers before the concert begins at 5:30 p.m.

Pre-concert festivities include a video highlight ing recent scholarship winners along with the mem bers of the Packaging Hall of Fame Class of 2022: Jean-Jacques Graffin, Rebecca Oesterle, Pierre Pie naar and E. Jeffrey Rhodehamel, Ph.D.

The schedule also includes time for the band to sign guitars won in the Silent Auction at the An

PPWLN hosts breakfast

Dawn Hudson, former chief marketing of ficer at the National Football League and CEO of Pepsi Cola North America, key notes the Packaging & Processing Women’s Leader ship Network (PPWLN) breakfast, 7:30–9:00 a.m. on Tuesday, Oct. 25, in Room S-100. The event is free to show attendees, but you must pre-register.

Sponsors of the event include Emerson (Booth N-4736), ID Technology (Booth N-5544), Mor rison Container Handling Solutions (Booth N-4906), PlexPack (Booth S-3374), Septimatech Group (Booth N-5934) and SMC Corporation of America (Booth S-3982)

“We are proud to be a part of the event and the women’s leadership network as a whole,” says Kelley

nual Meeting of PMMI, The Association for Packaging and Processing Technologies (Booth N-4550). High bidders for the guitars were Bri an McCann, global accounts manager at Polypack (Booth S-2147) and Emmanuel Cerf, vice president at Polypack and PMMI Board chair.

PACK Challenge Accepted

High school teams design and build a filling machine.

PepsiCo

is the official title sponsor of PACK Challenge, the first of its kind end-to-end packaging competition bringing together six high school teams for a machine-building challenge at PACK EXPO International. PepsiCo’s sponsor ship represents its commitment to advancing the packaging and processing workforce.

“The packaging and processing industries are critical to delivering safe products to consumers that meets their needs and that have minimal im pact on the planet,” says Ron Khan, vice president, Packaging, Beverages, PepsiCo. “We are pleased to

Scan to get the app:

Complimentary Wi-FI throughout McCormick Place

NEWS BRIEF PACK TO THE FUTURE P.18 | INDUSTRY SPEAKS P.24 | INNOVATION STAGE P.28 | FORUM P.44

Come and see us in South Hall, Booth # 3514 Syntegon_Corner_ad_ShowDaily_Chicago_2022.indd 1 SHOW DAILY MONDAY OCTOBER 24, 2022

(Continued on page 8)

packexpolasvegas.com join us for the next show DOWNLOAD THE MOBILE APP

Search Access Your My Show Planner Navigate Get news Vote in the 2022 Technology Excellence Awards Sponsored by: Booth N-5534 Booth LU-8901 Sponsored by:

S M T W

(Continued on

page 8)

Styx performs in the West Ballroom this afternoon to benefit the PMMI Foundation.

(Continued on

page 8)

.

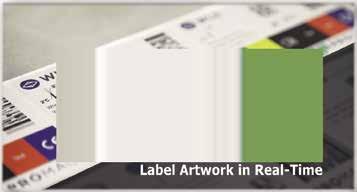

This system WILL dramatically reduce operator touch-time, WILL speed up changeovers beyond your wildest dreams, and WILL eliminate costly downtime on your labeler. Our simple fix to your complex problems.

Nita is the original 100% Servo Labeler that WILL change your production universe forever.

www.NitaLabeling.com | sales@nita.ca | 1.855.668.NITA (6482) COME MEET YOUR NEW SUPER-EFFICIENT “EMPLOYEE” IN BOOTH S-3666. WE KNOW YOU WILL HIT IT OFF RIGHT AWAY.

MEET

YOUR NEW “BEST LABELER OPERATOR EVER” YES, THAT IS CORRECT. WE BUILT YOU A SKILLED WORKER RIGHT INTO THE LABELER . Introducing the ALL-NEW Nita Sentient Labeling Machine with ULTRA-PRECISE FULLY AUTOMATIC CHANGEOVERS.

“MORE” IS A FOUR-LETTER WORD WE CAN GET BEHIND.

is a

years

an

a

from eight

that includes more than 7,000

with a

the

to

with more

and

the world.

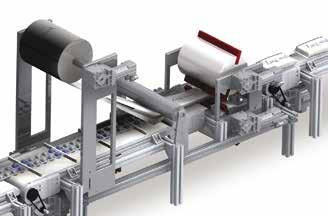

Paxiom

leading provider of primary, secondary, and end-of-line packaging machines

than 30

of industry expertise. Operating

global facilities,

passionate

focused staff of professionals, we also have

strong national service presence,

ability

provide systems integration, and

installed base

machines across

Paxiom. Get more. Visit us at Booth S-2153

Scan for the Paxiom Xperience™ Center virtual tour.

1.833.4PAXIOM | info@paxiom.com paxiom.com LAS VEGAS | MONTREAL | MIAMI | TORONTO | MILWAUKEE | SCHIO, ITALY WeighingPre-roll Filling BaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing

Yamato debuts bulk weigher

Among its other offerings, Yamato (Booth S-3783) debuts the Gravimetric Flex weigh er with four weigh heads supporting target weights between 5–20kg. At 5kg, this scale can operate at up to 60 weighments/min., ±5g. Also at the Yam ato booth: an automatic diving funnel and semiautomatic scale for fixed-weight packaging. SD

Case packer for gentle product handling

Bottom-loading products via Schneider Packaging Equip ment’s (Booth S-3500) Everest case packer means no machin ery touches the top of your products. The machine—a conven tional alternative to pick-and-place systems—is well suited for rectangular or lay-flat cartons; delicate or sensitive products; gabletop cartons; shrink wrap or transparent film on top; indus trial cans or bottles. SD

Airflow sensor improves energy efficiency

The AVENTICS Series AF2 airflow sensor from Emerson (Booth N-4736) monitors air consump tion in pneumatic pipe systems, providing action able machine data, including flow, pressure and temperature. Detecting leaks in real time allows op erators to react quickly, saving downtime. SD

Dutch king honors Ryson parent

Apollo Group, the parent company of Ryson Internation al (Booth N-5945), has been honored by the King of Holland as it celebrates its 175th birthday. Firm is now known as Royal Apollo Group and may add a crown to its logo. The recognition acknowledges the company’s good reputation and symbolizes the respect, valuation and trust of the sovereign. SD

Filler meets dairy standards

Hygienic rotary and straight-line machine from ATS Engi neering (Booth S-3274) fills liquid or viscous food products, seals containers and then applies overcaps. Machine, configured in up to eight lanes, offers easy changeover between cup sizes and no-cup/no-fill feature. Options include multi-fill capability, bottom-up fill and gas flushing. SD

Air stream cleans

Specially designed, four-position nozzle on Cleanflex Easy Gun from Simco-Ion (Booth N-5020) cleans electrostatical ly charged surfaces with compact air stream. Built-in 24V DC power supply eliminates cumbersome high-voltage cables and separate power supply unit. Ergonomic, full-hand trigger reduces finger strain. Ionization begins only when the trigger is active and enough air pressure has been measured by an internal sensor. SD

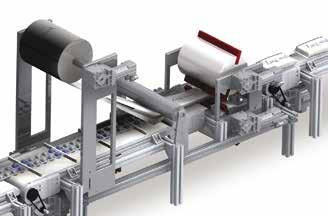

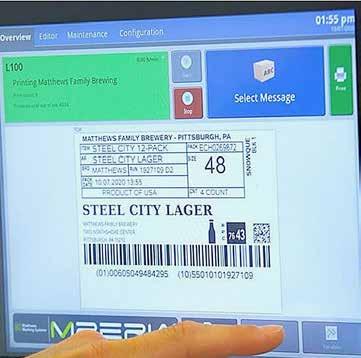

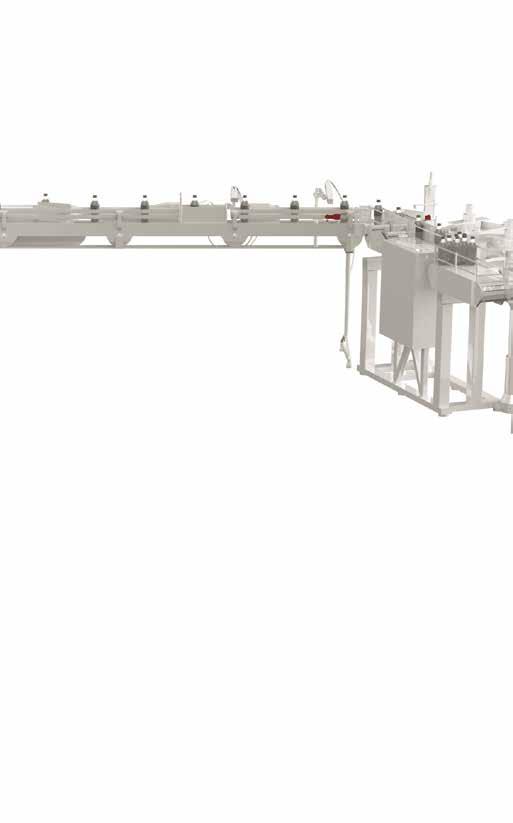

ProMach Pharma integrates lines

Integration services provide single-source responsibility.

ProMach’s Pharma business unit (Booth W-17002) demonstrates its integration ca pabilities with a turnkey packaging line for an aseptic kit that contains both a prefilled syringe and a vial. A schedule of demonstration times will be posted daily.

Located in the Healthcare Packaging Pavilion, the line includes all equipment from vial and syringe fill ing through labeling, blister packaging, cartoning and case packing. Integrating solutions from ProMach Pharma brands—NJM (Booth N-5650, W-17002), Pharmaworks, (Booth N-5650, W-17002), Serpa Packaging Solutions (Booth N-5548, W-17002) and WLS (Booth N-5650, W-17002)—and systems from partners and third-party OEMs as needed, ProMach Pharma provides best-of-class technologies and seam less integration with single-source responsibility to customers worldwide.

“There is growing demand for our integration services as many manufacturers and contract packers with pharma, nutra, ophthalmic and animal health products have fewer resources in-house to manage line integration. There is also growing interest from personal care and other non-pharma companies looking for high quality and precision within their packaging lines,” says Tom McDaniel, president of ProMach Pharma. “We’re uniquely positioned to give

customers the deep expertise that comes from each of our brands and their core competencies, collaborat ing as one company under ProMach Pharma as the total solution provider and single point of contact.”

Focused on packaging lines that fill liquids, pow ders and solid doses into vials, syringes, bottles, blister packs and other primary packages, ProMach Pharma can take responsibility for an entire line or a portion of a line. Offerings include standalone machines, in tegrated mini lines that combine a few systems and complete turnkey packaging lines from filling to case packing, including serialization, aggregation, radio frequency identification labeling and/or fully inte grated controls. Full-service integration includes pre-engineering and design to plant startup and site acceptance test, while a network of local service tech nicians provide world-class aftersales support.

As drugs become more personalized and small er batches become more commonplace, “Integration has taken on greater importance,” says Adam Rosen thal, director, Marketing - Pharma for ProMach Pharma. He explains, “End users want to be able to work with a single source to manage the project and eliminate multiple purchase orders, multiple organi zations and multiple deadlines.

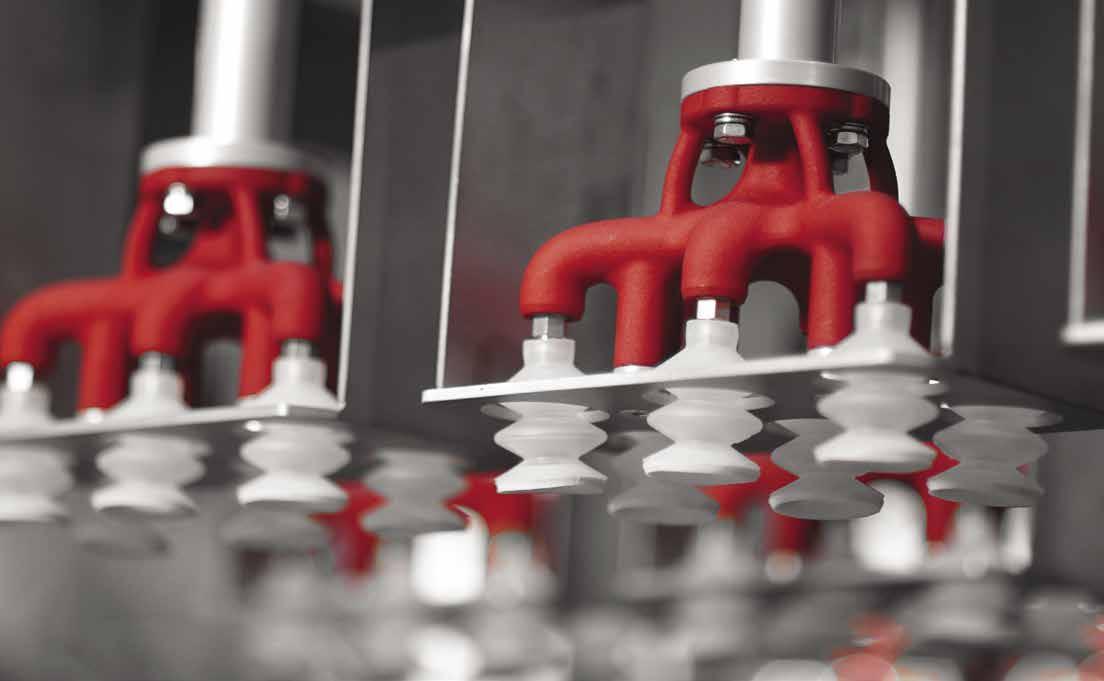

ProMach Pharma’s turnkey blister packaging line

PACK EXPO International 2022 SHOW DAILY OCTOBER 24, 2022 4

NEWS BRIEF

An integrated line demonstrates the filling and assembly of an aseptic kit that contains a pre-filled syringe and vial. This portion of the line shows blister forming, loading of the vial and syringe, blister sealing, cartoning and case packing.

(Continued on

page 6)

New Solutions VF 1200 Continuous Motion Bagger Up to 180 / minute Hygienic model on display Accurate to 0.01g WeightCheQ 0-250 High Precision Check Weigher PKR Delta Robot Case & Tray Packer BI 600 + BU 600 Bag Inserter & Bag Uncuffer System 1g 1.833.4PAXIOM PaxiomGroup PaxiomXperience Learn more at paxiom.com WeighingPre-roll Filling BaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing NEW NEW NEW NEW I Booth S-2153

Shaft encoder offers many configurations

Model 25SP Accu-CoderPro® Size 25 (2.5-in.) shaft encoder from Encoder Products (Booth S-4026) offers high flexibili ty with 32 waveform choices, six output types, servo or flange mounting. Unit can be factory-configured or programmed via an optional USB module. IP67 sealing is available and some configurations offer same-day shipping. SD

Stretch hood stabilizes loads

Stretch hood® system from BEUMER (Booth N-5832) utilizes vertical and horizontal contraction to ensure maximum load stability. Single layer of high-flexibility film minimizes resources, increases efficiency and allows different product sizes to be packaged on the same pallet. Process requires no heat. SD

Cobot palletizes in less space

The compact RC10 collaborative ro bot (cobot) cell from FlexLink (Booth S-2501) installs and configures easily and cuts floor space re quirements by more than 50% compared to cell equpped with an industrial robot. Offerings include four standard configura tions. SD

NCA hosts lounge

The Candy Bar Lounge (Booth S-2583), sponsored by Syntegon Packaging Technology (Booth S-3514) and hosted by the National Confectioners Association (Booth S-2583), provides a spot for confection ery industry attendees to network, gain insights and recharge during the show. SD

Cartoner automates

Spartan cartoner from Econocorp (Booth S-1630) automates case/tray erecting and packing on beer lines. The rugged, mechan ical, automatic horizontal cartoner operates at speeds of up to 40 cartons/minute. Endload cartons can be loaded manually or automatically. Closing options include tuck or sealing with hot melt or hot air. SD

Match service to needs

Service packages from Syntegon (Booth S-3514) provide sup port at the level that best suits needs. Fixed-rate plans decrease risk and allow end users to focus attention on core business. SD

Need project advice?

Industry veterans at the “Ask the Experts” Station (N-4552, LU7000) stand ready to answer packaging and processing questions. Attendees can stop by for guidance on narrowing their search for suppliers and navigating the show. SD

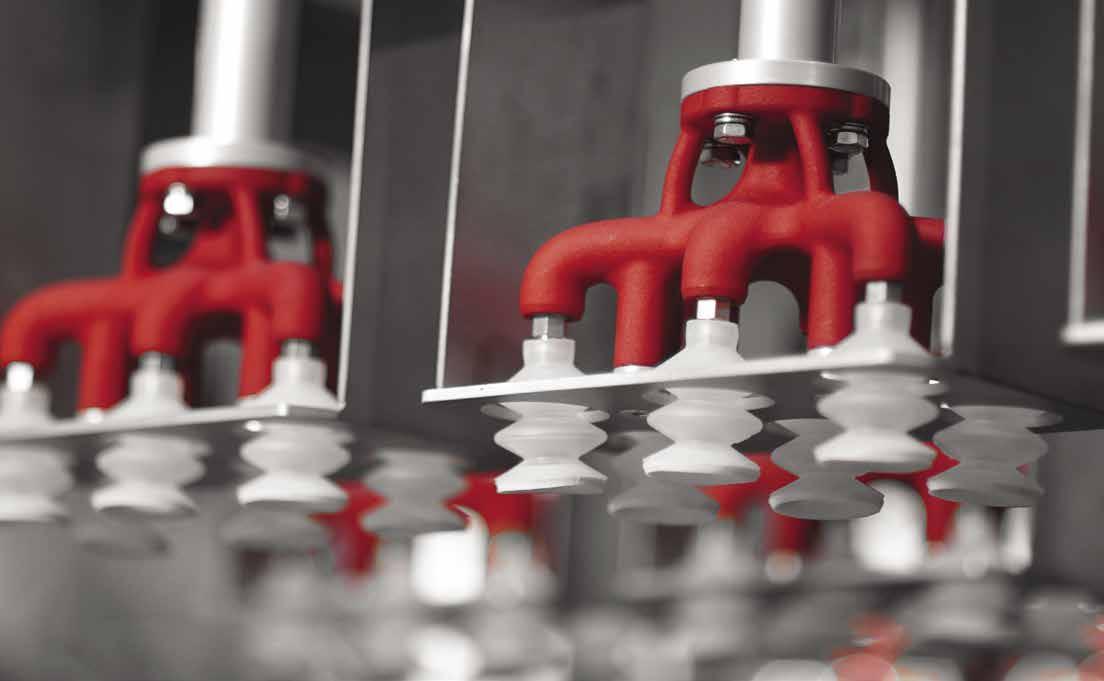

for aseptic kits begins with Dara’s NFL/2 system filling and closing ready-to-use syringes and vials. NJM’s Courser 230 labels the syringes and WLS’ VR-72 labels the vials. A robotic pick-and-place from PharmaMed (Booth W-14028) feeds one sy ringe and one vial per cycle to Pharmaworks’ TF2 blister machine.

These blister-packed kits are then conveyed on a linear transport from Beckhoff Automation (Booth S-3882), which synchronizes speeds between the blister machine and Serpa P100 horizontal cartoner, which is followed by a Serpa P200 case packer. La bels for syringes and vials are printed off-line on an Autonomy digital label printer from WLS.

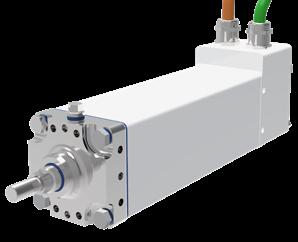

The Dara NFL/2 aseptic filling and closing ma chine can handle nests of ready-to-use syringes, vi als and cartridges. Simplifying small-scale produc tion, this fully servo-driven system reduces capital costs, minimizes floorspace requirements and speeds changeover.

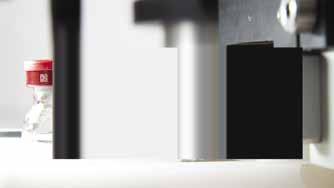

NJM’s Courser 230 labeler features a trunnion starwheel for positive handling of small containers at speeds up to 250 containers/min. (cpm). Achieving

quick changeover to handle syringes and vials, the Courser 230 pressure-sensitive labeler maximizes production versatility and saves floor space.

WLS’ VR-72 pressure-sensitive labeler handles vials, syringes and bottles at speeds up to 700 cpm. The fully servo-driven labeler provides high-speed operation, accurate and repeatable label placement, low maintenance and quick changeovers.

Pharmawork’s TF2 blister machine is a medi um- to high-output, large-format system ideal for a wide range of blister applications including standard HUD (hospital unit dose) blister packs, bingo-style cards, medical devices and tray packaging.

Serpa’s P100 horizontal cartoner is a compact, state-of-the-art cartoner that reaches speeds up to 330 cartons/min. Its balcony-design provides maxi mum access to all drive components from one side of the machine and its fall-through construction meets all sanitary and FDA validation requirements.

Serpa’s P200 side-load case packer picks, erects and packs both cases and trays at speeds up to 20 cases/min. Featuring first-of-its-kind versatility, the P200 unit can apply a tape closure on cases and change over to seal trays with hot glue. Its “Easy Case Clear-out” feature allows for problem cases to be released with ease to maximize machine uptime.

WLS’ Autonomy is a high-speed, full-color, standalone, digital label printer with an integrated full-label inspection capability. Printing variable and serialized data along with label artwork, the machine delivers inhouse, on-demand labels, ready for application, to max imize label quality and production flexibility.

For more info, visit www.njmpackaging.com, www. pharmaworks.com, www.serpapackaging.com, www.weiler ls.com, www.pharmamedinc.com, www.beckhoff.com. SD

SHOW DAILY

Publisher PMMI Media Group

Editorial Director

Hallie Forcinio

Associate Editors

Kari Moosmann and Barbara Rook

Production Manager

Mary Thorne

Art Director

Debi Friedmann

IT/Production Support Manny Dominguez

Photographers

Miles Boone, George Burns and Martina Magnusson

Advertising Sales Management

Dave Newcorn, President, PMMI Media Group

Wendy Sawtell, Vice President, Sales, PMMI Media Group

NEWS BRIEF PACK EXPO International 2022 SHOW DAILY OCTOBER 24, 2022 6

PACK EXPO International 2022

NEWS BRIEF

(ProMach Pharma Continued from page 4)

ProMach Pharma’s integrated line begins with primary packaging and ends with distribution packaging.

Jar 1.833.4PAXIOM PaxiomGroup PaxiomXperience WeighingPre-roll Filling BaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing High Performance Check Weigher NEW Turnkey Container Filling & Handling System WeightCheQ 0-250 CONVEYING WEIGHING/ COUNTING FILLING CAPPING LABELING CARTONING PACKING PALLETIZING 10x More Accurate Than Other Check Weighers Accurate to 0.01g. Check weigh all your high value products for the tightest quality control. Learn more at paxiom.com Booth S-2153 Filling System

Sunday – Tuesday: 11:00 am – 3:00 pm Happy hour: 3:00 pm – 5:00 pm Wednesday: 11:00 am – 3:00 pm

Founded in 1972 in Chicago, Styx draws on five decades of barn-burning chart hits, joyous singalongs and hard-driving deep cuts such as Renegade, Come Sail Away, Lady, Blue Collar Man, Too Much Time on My Hands, Mr. Roboto, Fooling Yourself and The Grand Illusion.

Tickets are $95 each and may be purchased by logging into your PACK EXPO registration record. Purchase nine tickets, and the 10th is free.

The PMMI Foundation provides financial support for packaging and pro cessing education throughout the U.S and Canada. Programs include summer manufacturing camps, scholarships, tuition reimbursement and training via the PMMI Skills Fund.

For more info, visit www.PACKEXPOinternational.com, www.PMMI.org/foundation. SD

Stacy, president and CEO of SMC Corporation of America, a recurring sponsor of PPWLN events. As one of the 1.3% of manufacturing companies led by a female CEO, empowering women’s presence in the world of manufacturing and automation comes as a natural initiative.

Twice named to Fortune magazine’s annual “50 Most Powerful Women in Busi ness” list, Hudson’s career has included high-level positions in media, retail, consum er goods, consulting and healthcare at some of the biggest corporations in the world.

She is an authority on brand power, turning adversity into advantage, the im portance of innovation and embracing change and the need for strong, inclusive leadership. Using personal experiences, she provides audience members with tools to be better leaders, more engaged team players and stronger additions to high-functioning teams.

As co-author of You Should Smile More: How to Dismantle Gender Bias in the Workplace, she helps women navigate everyday corporate life, while educating and including men in the conversation.

The Packaging & Processing Women’s Leadership Network serves to recruit, retain and advance women’s careers in packaging and processing through online and in-person events, information-sharing and networking. Join the Packag ing & Processing Women’s Leadership Network group on LinkedIn to connect with peers and learn about upcoming events.

For more info, visit www.PACKEXPOinternational.com, www.PMMI.org/ppwln. SD

support the . . . development of this . . . industry and its emerging workforce.”

PACK EXPO International show producer, PMMI, The Association for Packaging and Processing Technologies (Booth N-4550), introduced this competition to involve students in the machine-building process, provide realworld, hands-on experience, and demonstrate the benefits and opportunities available in a career in manufacturing.

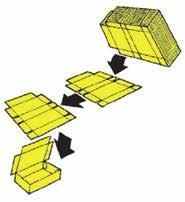

PACK Challenge supplied six Chicago-area high schools with pre-crated kits that contained all the components necessary to build a machine that fills the specified product into the provided container on a mock production line. These teams designed and built their machines in time to be crated and shipped to the show, where they will assemble their machine and conduct multiple pre sentations as part of the competition. Judges will consider multiple aspects of the project, including design, operator training, changeover and sales/marketing.

The overall best-in-show team will be awarded $6,000 with second and third place receiving $3,000 and $1,000, respectively.

“We are very excited about PACK Challenge and the opportunity this expe rience presents to show students what a career in this industry looks like,” says Jim Pittas, president and CEO of PMMI. “We thank PepsiCo for recognizing the importance of our future workforce and partnering with us to educate and inspire the next generation of leaders and innovators.”

In addition to PepsiCo’s title sponsorship, PMMI is pleased to recognize Belden (Booth LU-7058) as the sponsor of the PACK Challenge Friends & Family Reception, held on Sunday, Oct. 23.

PACK EXPO International offers other student activities to generate ex citement about careers in packaging and processing and connect with profes sional mentors in the industry. This includes the Amazing Packaging Race on Wednesday, Oct. 26, and the Future Innovators - Robotics Showcase (Booth W-21028) where teams from area high schools demonstrate their creations.

For more info, visit www.PACKEXPOinternational.com. SD

SHOW DAILY OCTOBER 24, 2022 8 PACK EXPO International 2022

Open DailyOpen Daily Lakeside Center, Level 2 back of the show floor Sponsored by: Booth LU-8758 Delicious lunch options for under $10 a meal Enjoy fun backyard style games and happy hours. Kick back and dine for leSS!Kick back and dine for leSS! New to the Show? If your badge says “ First-Time Attendee ” stop by and you can: ¤ Ask questions of show staff ¤ Access product locators ¤ Participate in sessions Sponsored by: Booth N-5534 You’re invited to the FIRST-TIMERS LOUNGE! South Building, Level 1, Room S-102 Near the South shuttle bus area

(PPWLN Continued from page 1)

(PACK gives BACK Continued from page 1)

(PACK Challenge Continued from page 1)

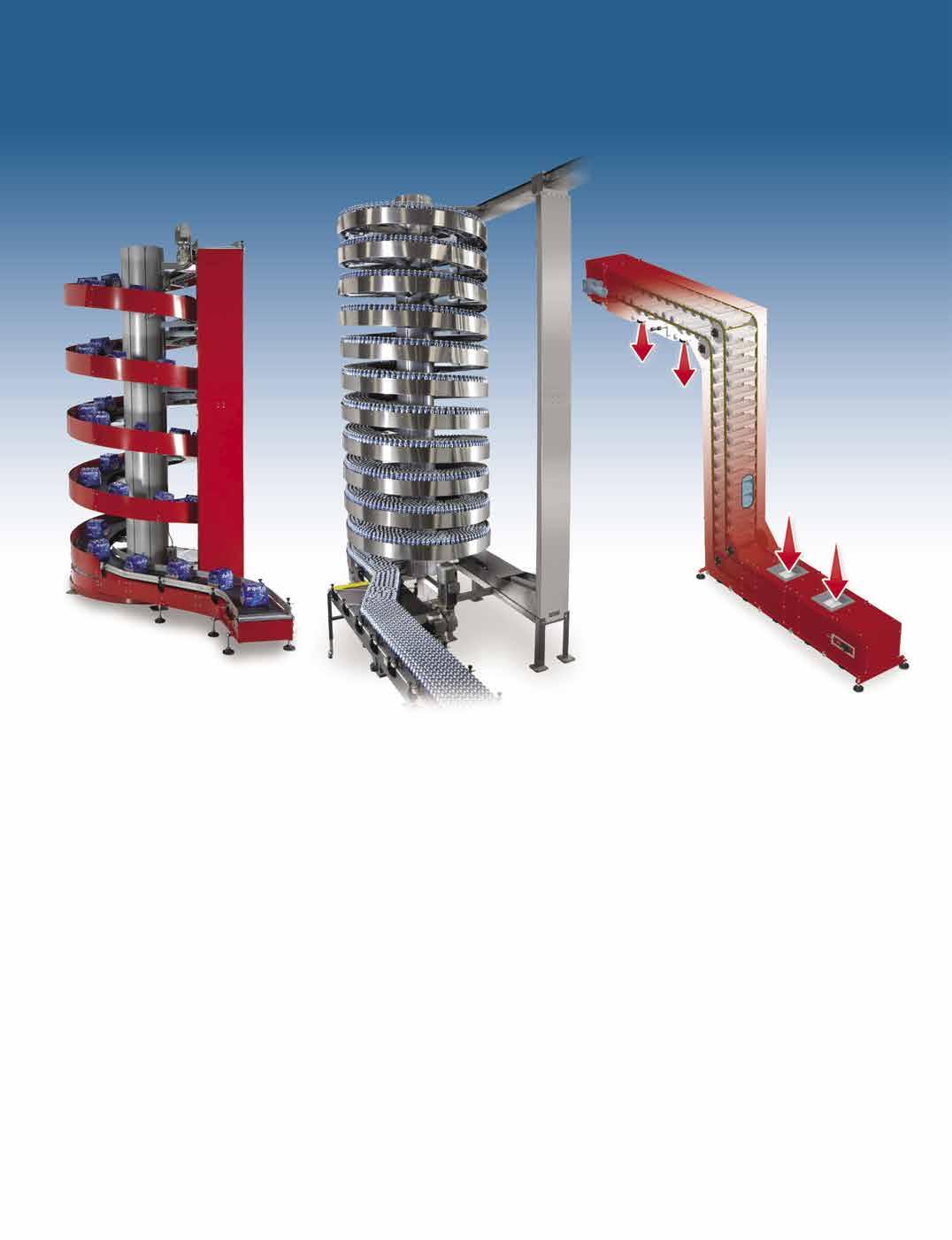

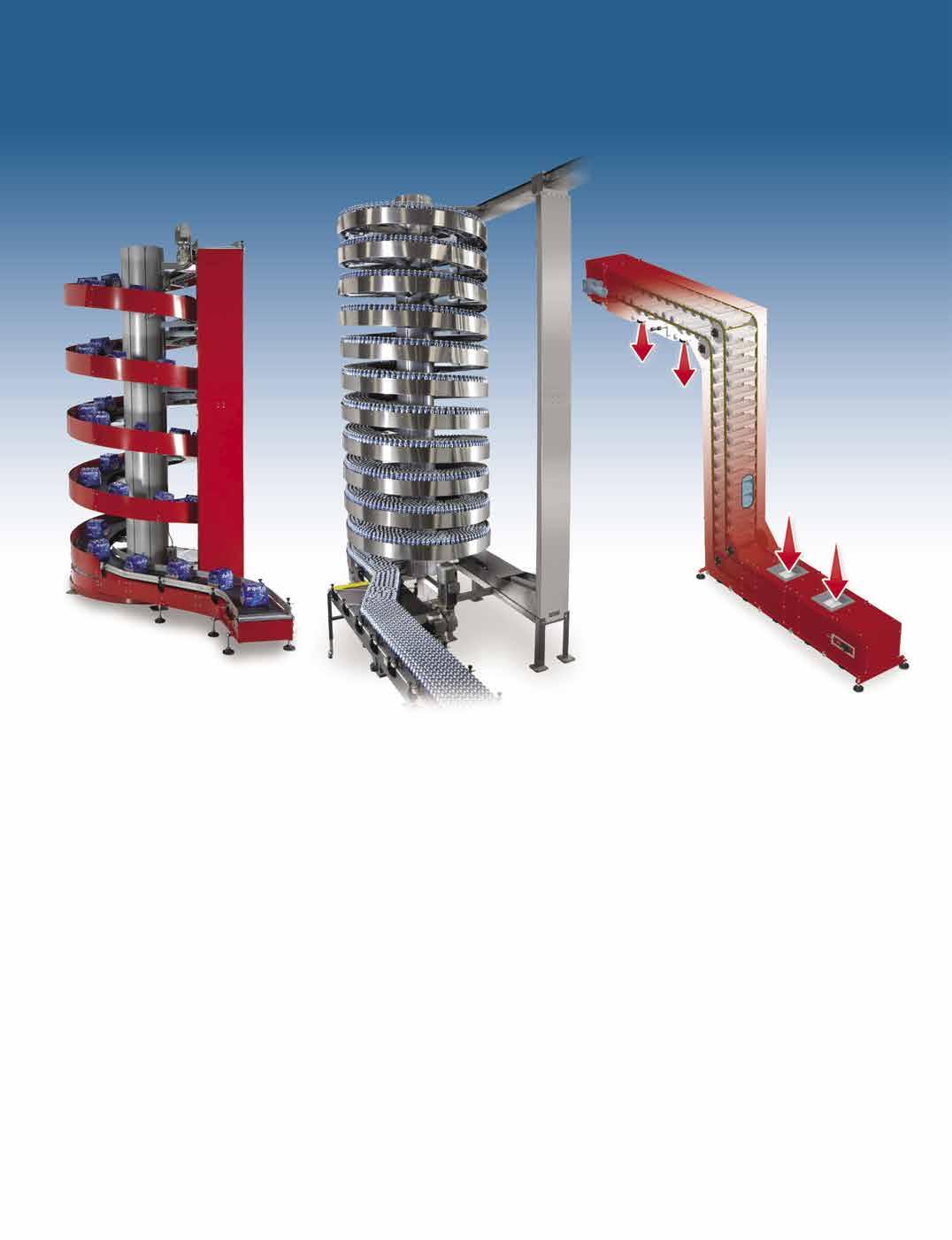

Spiral Conveyors & Bucket Elevators Ryson Vertical Conveying Solutions

Ryson Spiral Conveyors need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Unit Load Spirals convey cases, totes and packaged goods smoothly on our slat style belts and come in 9 standard slat widths ranging from 6” to 30”. Available in powder coated carbon steel, stainless steel, wet environment and freezer versions.

Mass Flow Spirals handle full and empty bottles, cans and jars in mass up to 2000 units per minute. Available in 4 different slat widths ranging from 6” to 20”.

Narrow Trak Spirals are super compact and designed to handle your smaller loads. Our 6” and 9” wide nesting slats can end-transfer small cartons and packages or side-transfer small bottles and containers in a single file or in mass at speeds in excess of 200 FPM.

Ryson’s Bucket Elevators combine vertical and horizontal transportation of bulk materials in one integral unit.

Ryson Bucket Elevators are designed for gentle handling and well-suited to transport a broad range of bulk products. Our signature feature is that they are completely enclosed with overlapping pivoting buckets, that prevent spillage and helps mitigate foreign debris.

Their modular design enables us to customize with ease. They can be configured with multiple inlets or outlets that can be controlled individually. The design makes them easy to install and modify. Available in three standard bucket sizes, yielding capacities up to 300, 700 or 1,800 cubic feet per hour. They can also be delivered in powder-coated carbon-steel, stainless-steel or wet environment versions.

www.ryson.com

Watch our detailed Bucket Elevator Video

Watch our detailed Bucket Elevator Video

All Ryson equipment is modular and built to order. No matter the application, the Ryson team is up to the challenge of finding solutions for your conveying needs. For application assistance or more information, give us a call or visit

300 Newsome Drive • Yorktown, VA 23692 • Phone: (757) 898 1530 • Fax: (757) 898 1580 RYSON INTERNATIONAL, INC. MEMBER OF ROYAL APOLLO GROUP www.ryson.com See our equipment run in the North Hall - Booth N - 5945

Nordson and PMMI team up Contribute funds to support research to fight breast cancer.

Nordson Adhesive Dispensing Systems, a division of Nordson (Booth S-2030) has raised $8,000 for the Breast Cancer Re search Foundation (BCRF). Show producer, PMMI, The Association for Packaging and Processing Technologies (Booth N-4550), has added $5,000 for a total donation of $13,000.

“At PMMI, we strive to support our members in all that they do, and we are honored to be a part of

Nordson’s initiative to raise money for BCRF,” says Jim Pittas, president and CEO of PMMI. “PMMI is proud to have member companies like Nordson that work to make a positive impact in their communi ties, and we are happy to be able to contribute.”

An official check presentation will take place at 1:30 p.m. on Tuesday, Oct. 25, at the Nordson booth. The $13,000 donation will fund 260 hours of work by researchers who have been deeply involved in every

major breakthrough in breast cancer prevention, di agnosis, treatment, survivorship and metastasis.

“The Nordson Corporation places a great amount of effort into our Nordson Impact giving programs; we see it as an investment that’s improving the lives of others,” explains Cindy Baumgardner, manager of the Nordson Corporation Foundation and Community Affairs. She adds, “The research that BCRF funds is transformative for so many people, families and communities. In addi tion, we are always elated when partners, such as PMMI, join forces with us to make an impact.”

Nordson has given back for more than 60 years through The Nordson Impact, a set of outreach pro grams that help improve the quality of life in Nord son communities through volunteering, donations, scholarships, educational opportunities and fund raising campaigns.

For more info, visit www.nordsonadhesive.com, www.PMMI.org. SD

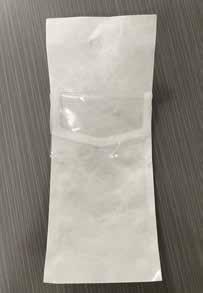

Partners develop barrier coating Resulting monomaterial substrate is certified recyclable.

An oxygen-barrier coating, developed by Henkel (Booth S-2172) and Siegwerk, makes it possible to produce recyclable, monomaterial flexible packaging for food products.

The more sustainable alternative to current multi-material substrates offers the potential to ac celerate the transition to a Circular Economy and has been recognized as compatible with recycling by The Association of Plastics Recyclers’ (Booth N-5902) APR Critical Guidance.

The development dates to 2019 when Henkel and Siegwerk met at K in Düsseldorf, Germany, and agreed to co-develop an oxygen barrier coating for more recyclable food packaging. Working in close partnership, Henkel and Siegwerk shared knowledge and explored ideas for how to create film laminates with barrier properties without compromising shelf life. The result? An industrially validated oxygen bar rier coating that enables monomaterial flexible pack aging for dry food products, setting recyclers free from the headache of mixed materials.

For more info, visit www.henkel.com. SD

SHOW DAILY OCTOBER 24, 2022 10 PACK EXPO International 2022 Title Sponsor: Bronze Sponors: Proceeds benefit the Booth S-1660 A NETWORKING EVENT THAT ROCKS! MONDAY, OCTOBER 24 WEST BALLROOM, LEVEL 3 Reception: 4:30 pm Performance: 5:30 pm Tickets: $95 (Purchase in Registration)

Interactive Show Floor Must-See!

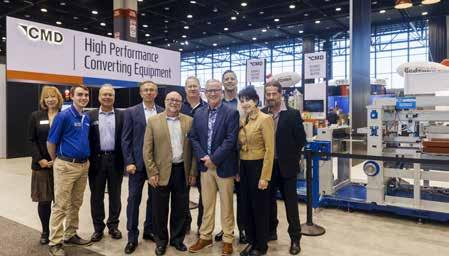

Newcorn leads PMMI Media Group

Incoming president focuses on digital media, events, conferences.

David Newcorn, the new president of PMMI Media Group (Booth N-4550), is taking the reins from Joe Angel, nearly 30 years after An gel co-founded the company. Newcorn joined PMMI Media Group in 1995 as staff editor on Packaging World and was quickly promoted to develop a digital strategy for the company. His focus on digital media continues, with plans to offer new and innovative ways to engage audiences with critical infor mation about packaging, processing and automation technologies.

Newcorn created PMMI Media Group’s signature digital platform, LeadWorks, along with a host of unique digital market ing products such as Game Plan, Second Look and the digital platform for Leaders in Packaging that is a mainstay in the in dustry. During the past 25+ years, Newcorn has held various leadership roles at the com pany in editorial, operations, audience, web site and product strategy. In his new role, he will be backed by a highly seasoned senior leadership team that collectively has nearly 80 years of experience at the company.

“When I announced I was stepping down as PMMI Media Group president, there was only one person I entrusted to take the helm, and that was Dave,” says Angel, who remains with PMMI, The Association for Packaging and Process ing Technologies (Booth N-4550), moving into a new role as executive vice president, Industry Outreach. “After hiring Dave in 1995, his value increased over the years as our digital platform unfolded. He became a trusted advisor and an integral part of our senior leadership team. I have every confidence in Dave’s leadership and am excited for what lies ahead for the media group.”

PMMI Media Group has several initiatives in the works to usher in a new era of media and marketing solutions. The company is expanding into a series of events and conferences in several high-interest topical areas and is doubling down on digital media as the most effective way to deliver crucial industry and business insights to key audiences.

“The two most important elements of this leadership transition are continu ity and transformation,” says Jim Pittas, president and CEO, PMMI. “Dave’s proven track record and broad and deep experience in the industry will assure continuity while also leading the media group into an exciting new era. With Dave at the helm, the senior leadership team will continue transforming PMMI Media Group for the next 30 years.”

In his new role as PMMI’s executive vice president, Industry Outreach, An gel will focus on building relationships that support the packaging and process ing industry and add value to PMMI Media Group and the association.

A market-leading B2B media company, PMMI Media Group produces in formation for packaging, processing and automation professionals, bringing to gether solution providers and end-users and facilitating connectivity throughout the supply chain. Its media brands—Packaging World, ProFood World, Automa tion World, Healthcare Packaging, OEM, Contract Manufacturing and Packaging and Mundo PMMI—are proven leaders in covering this diverse and dynamic marketplace, and its digital products incorporate leading-edge media technolo gies to deliver informed, actionable business intelligence to the industry.

For more info, visit www.PMMImediagroup.com, PMMI.org. SD

SHOW DAILY OCTOBER 24, 2022 12 PACK EXPO International 2022 J Y P CK P C SS An

Take a tour through this curated exhibit spanning 250 years of historical equipment, materials and photographs. Get a glimpse into the future and attend over 20 free sessions presented on the PACK to the Future Stage exploring: 〉 The circular economy 〉 Smart packaging & Innovative sustainability initiatives 〉 The evolution of pharmaceutical packaging ALSO FEATURED: A corrugated car of the future VR Experience produced by Paper + Packaging Board. Join us in the West Building, Booth W-20001

David Newcorn, president, PMMI Media Group.

NATURALLY SUSTAINABLE. EFFICIENTLY AUTOMATED. Fas l xibl nd sus ainabl , our n w s ra orm h SF 2500, will b n display a ac po. Ch u ow his innova iv ac agin quipm an h lp you r lac las ic produc a aging wi h r wabl ap board. Visi s a Boo h S–2130 o l arn mor . N AT U R A L LY S U S TA I N A B L E . w s roc .com/pac xpo ©2022 W s c ompany. WEST OCK, W s c nd D sign, an h W s c ogo ar ra mar s own d by W s c ompany ll righ s r s rv d.

Domino Amjet (Booth S-3506) reminds everyone to think about coding improvements as they travel on the escalator in the Grand Concourse.

Festo (Booth N-6213) provided the aisle banners to help everyone find their way around the show floor.

Thanks to SEW Eurodrive (Booth LU-8105) for sponsoring hand sanitizer stations throughout the show floor.

WestRock (Booth S-2130) again is sponsoring the Showcase of Packaging Innova tions® (Booth W-20052), a show favorite.

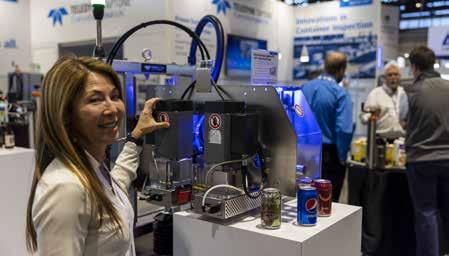

Stop by the Confectionery Pavilion and visit the Candy Bar Lounge, hosted by the National Confectioners Asso ciation (Booth S-2583) and sponsored by Syntegon Packaging Technology (Booth S-3514). You’ll be greeted by (l-r) Lee Anne Pirrello, Joni Wisner, Mandie Middleton and others from the Association.

Domino Amjet (Booth S-3506) reminds everyone to think about coding improvements as they travel on the escalator in the Grand Concourse.

Festo (Booth N-6213) provided the aisle banners to help everyone find their way around the show floor.

Thanks to SEW Eurodrive (Booth LU-8105) for sponsoring hand sanitizer stations throughout the show floor.

WestRock (Booth S-2130) again is sponsoring the Showcase of Packaging Innova tions® (Booth W-20052), a show favorite.

Stop by the Confectionery Pavilion and visit the Candy Bar Lounge, hosted by the National Confectioners Asso ciation (Booth S-2583) and sponsored by Syntegon Packaging Technology (Booth S-3514). You’ll be greeted by (l-r) Lee Anne Pirrello, Joni Wisner, Mandie Middleton and others from the Association.

Love your lanyard? Thank a member of the ORBIS (Booth

LU-6800)

team for sponsoring these handy accessories.

OxyStar barrier material utilizes a multilayer PET with an oxygen scavenging agent. PET has a naturally low oxygen transmission rate (OTR) and this construction slows down the flow of oxygen molecules through the package from the outside. Once the scavenger agent finds an oxygen molecule, it attaches to it and binds the oxygen within the sidewall of the package to keep your product fresh and lasting longer.

RECYCLABLE BARRIER MATERIAL FIRST OF ITS KIND DIRECT FOOD CONTACT FDA COMPLIANT INCREASED SHELF LIFE BLOCKS OXYGEN WATCH OUR PRESENTATION AT THE INNOVATION STAGE WEDNESDAY @ 11AM TO HEAR ABOUT IT

Food firms earn awards

Sustainability competition recognizes Program and Project Category winners.

ProFood World (Booth N-4550) honored recipients of its Sustainabili ty Excellence in Manufacturing Awards (SEMAs), yesterday afternoon. Winners were recognized in Program and Project Categories. These an nual peer-reviewed awards recognize manufacturing plants for their efforts in driving improved performance through sustainability. This year’s winners in clude Conagra Brands, Bob’s Red Mill Natural Products and Smithfield Foods.

First place in the Program Category honored a Conagra Brands plant in Oakland, CA, that implemented a no-cost project that yielded a $1 million payback. Over the past year, the facility’s cross-functional team made excellent progress in reducing food waste. The team implemented a program to eliminate ingredient loss for jalapeños and tomatoes. Savings were strictly through better use of available equipment resources and process improvements.

The second-place award winner in the Program Category, Bob’s Red Mill Natural Products, focused on wasted food rescue and materials management to prevent downstream climate emissions. Last year, Bob’s Red Mill kept more than 385,000 lb. of edible food from going to waste, upcycling 2,000 tons as animal feed instead of landfill or compost waste, and recycling more than 1,600 tons of materials, such as paperboard, plastic, metal and wood. In addition, food donations provided 161,000 meals to those experiencing hunger in 2021.

Third place in the Program Category goes to a yield improvement project at Conagra Brands. The company’s Troy, OH, team implemented a continuous im provement program when running pizza. Ongoing efforts are expected to save more than $325,000 by improving yield loss by 13.4% and eliminating 267,000 lb. of meat, cheese and breading waste.

The first-place award in the Project Category goes to a Conagra Brands fa cility in Irapuato, Mexico, that saved nearly 9 million gallons of water by iden tifying leaks, improving the sweet corn process and canning process equipment and sanitizing more efficiently. The latter reduced the consumption of cleaning chemicals and resulted in greater production line availability.

A switch to plastic combos at Smithfield Foods is the second-place Project Category winner. Early in 2021, Smithfield Foods’ Milan, MO, plant started sending out hams for further processing, using corrugated combos. A switch to reusable plastic combos is expected to save more than $1 million while reducing greenhouse gas emissions, water usage, energy and landfill. The project is expect ed to save more than $1 million.

Third place in the Project Category goes to a blast cell air optimization proj ect. Degradation of freezer blast cells was resulting in improper air flow and inefficiency of the blast cell function at Conagra Brands’ Marshall, MO, facility. Repairs were made to air segregation, and baffle design was changed to reduce potential damage from forklift loading. The project will reduce electricity con sumption by 5.7% and reduce the plant’s Scope 2 greenhouse gas emissions footprint by almost 1,300 MT. This project paid for itself in less than one year.

For more info, visit www.PACKEXPOinternational.com, www.profoodworld.com. SD

SHOW DAILY OCTOBER 24, 2022 16 PACK EXPO International 2022 WEST HALL | Booth W-20052 Next to the Containers and Materials Pavilion Get inspired by award-winning packaging from around the world—the next great idea for your brand might be on display! Sponsored by: FEATURING ENTRIES FROM: ■ ABRE —Brazilian Packaging Association ■ AIMCAL —Association of International Metallizers, Coaters and Laminators ■ DOW —Packaging Innovation Awards ■ FPA —Flexible Packaging Association ■ FSEA —Foil and Specialty Effects Association ■ IAE —Instituto Argentino del Envase ■ IMDA —In-Mold Decorating Association ■ IoPP —Institute of Packaging Professionals ■ ProFood World’s Sustainability Excellence in Manufacturing Awards ■ RPA —Reusable Packaging Association ■ The Tube Council ■ WPO —World Packaging Organisation

Joyce Fassl of ProFood World (right) presents SEMAs to (l-r) Wes Maulsby of Smithfield Foods, Nick Chow of Bob’s Red Mill and David Bauman of Conagra Brands.

Wherever you are and whatever your industry, there’s a PACK EXPO event to provide solutions you need today and the inspiration for tomorrow.

June 13-15, 2023 Guadalajara, Mex.

Sept. 11-13, 2023 Las Vegas, USA

March 18-20, 2024 Philadelphia, USA

June 11-14, 2024 Mexico City, Mex.

Nov. 3-6, 2024 Chicago, USA

®

Visit packexpo.com

PACK to the Future arrives

Historical exhibit serves as foundation for advancements.

The interactive PACK to the Future Exhib it (Booth W-20001) celebrates the role of packaging and processing throughout histo ry and the impact it is poised to have on the future. The exhibit follows the evolution of modern pack aging and processing over 250 years to the present and shifts to explore key trends shaping the future in daily live sessions on the PACK to the Future Stage (Booth W-20025).

Launched in 2021 at PACK EXPO Las Vegas, the curated, interactive PACK to the Future exhibit tells the story of packaging and people who saw a better way, solved challenges and provided the foun dation for today’s—and tomorrow’s—innovations.

The exhibit includes:

• 30 historial packaging machines and replicas dating back to the 1800s

• Timeline walls displaying 250 years of history

MONDAY, OCTOBER 24, 2022

CONCEPT TO MANUFACTURING IN 5 DAYS: UTILIZING ADVANCED CAPABILITIES

9:30-10:00 AM

By leveraging advanced capabilities, such as virtu al analysis and advanced rapid prototyping, PepsiCo aims to dramatically accelerate the time required to go from concept to final product, within five days.

Max Rodriguez Sr Mgr, Global Beverages R&D Thangthip Tekanil R&D Packaging Engineer PepsiCo

THE EVOLUTION OF PHARMACEUTICAL PACKAGING

10:30-11:00 AM

Examine the future of pharmaceutical packaging as it becomes more sustainable and meets the needs for greater convenience, self-administered drugs, reduced hospital stays and serving patients at home. Review how past and present innovations, focused on meeting patient and product needs, offer a path for the future.

Ron Yakubison

Exec Dir, Global Technology Packaging

Merck

ADVANCED RECYCLING MAKES PLASTIC PACKAGING CIRCULAR

11:30-12:00 PM

No material is inherently sustainable. To achieve true Circular Economy sustainability for plastic packaging, all plastic packaging must be captured without the re quirement to sort. Regenerative Robust Gasification can accept all plastic packaging, including metallized, multilayer, chlorine, foils, fitments, filth, etc. New plas tic resins can be made via the syngas-methanol-plas

• An area dedicated to women in packaging and processing

• An interactive display of past, present and future sustainability efforts, including a Corrugated Car of the Future Virtual Reality (VR) Experience. Sponsored by The Paper and Packaging Board, the experience allows attendees to sit in a replica of a futuristic car and use a VR headset to learn about sus tainable packaging and the industry’s Box to Nature program, an initiative to educate consumers about the importance of recycling corrugated materials and boxes

• An interactive audio tour revealing interesting facts and historical details

• Fun quizzes that test attendees’ knowledge of the industry.

Each day on the PACK to the Future Stage, in

tics route, which already exists commercially. By co-lo cating at landfills, using renewable process power and simplifying collection and sorting, GWP is favorable relative to traditional virgin plastics. The Consortium for Waste Circularity is organizing Robust Advanced Recycling projects in which packaging industry stake holders can participate.

Bruce Welt Professor University of Florida - Packaging Engineering

THE SCIENCE OF CIRCULARITY— HOW MATERIAL INNOVATIONS CREATE NEW OPPORTUNITIES TO CATALYZE A CIRCULAR VALUE CHAIN

12:30-1:00 PM

Brands are making ambitious sustainable packaging goals that are driving demand for material innovations to reduce the use of virgin plastic, improve environ mental impact and increase recyclability to enable package circularity. Sustainable packaging brings chal lenges that go beyond materials and packaging design such as the infrastructure needed to increase collec tion, equipment to improve sortation and technolo gy to recycle a wider range of plastic waste. Procter & Gamble (P&G) and Eastman share experiences bringing sustainable materials to market. Both are founding members of the new PET Recycling Co alition, a initiative of The Recycling Partnership. This group of stakeholders is developing scalable solutions to improve the circularity of polyethylene terephthal ate (PET) packaging through a more robust recycling system. Learn about the PET Recycling Coalition’s goals and approach, including ways to get involved.

Matt Storey Segment Mgr, Circular Packaging Eastman

dustry experts provide 30-minute presentations on cutting-edge advancements in sustainability, circu larity, net-zero goals, returnables and manufacturing trends.

The session schedule is outlined below. PACK EXPO International offers many other free educa tional opportunities, including the long-running In novation Stage (N-4560, N-4580, N-4585) plus the new Processing Innovation Stage (Booth LU-7130) (see schedule, p. 28), The Forum at PACK EXPO (Booth N-4543) (see schedule, p. 44) and the new In dustry Speaks (Booth N-4565) (see schedule, p. 24). The Reusable Packaging Learning Center (Booth LU-6737) also will present educational sessions.

Updated schedules may be found on the PACK EXPO International App or the show website.

For more info, visit www.PACKEXPOinternational.com. SD

John M. Layman, Ph.D. Sr Dir, Corporate R&D Procter & Gamble

RACE TO NET-ZERO: HOW TO DRIVE ESG IN A FRAGILE WORLD

1:30-2:00 PM

How to drive ESG in a fragile world Michael Okoroafor, Ph.D.

Chief Sustainability Officer McCormick & Company

THE 10-YEAR PACKAGING MATERIALS AND SUSTAINABILITY COMPASS

2:30-3:00 PM

PMMI, producer of the PACK EXPO portfolio of trade shows, has partnered with AMERIPEN, the American Institute for Packaging and the Environ ment, to create the 10-Year Packaging Materials and Sustainability Compass, a collaboration report on the future of materials usage and replacement for CPG companies, OEMs, materials suppliers and recovery professionals. The research seeks to uncover what ma terials are projected to be replaced, what new materi als are on the packaging horizon and how the legisla tive landscape will be shaped during the next decade.

Findings provide comprehensive guidance to packag ing value chain professionals on materials usage over the next three, five and 10 years; expected changes to sustainability legislation, including EPR; and key drivers of those changes.

Rebecca Marquez

Mgr, PMMI Business Intelligence PMMI Dan Felton Exec Dir AMERIPEN

SHOW DAILY OCTOBER 24, 2022 18 PACK EXPO International 2022

BO O TH : S-3634 Com p l et e Autom atio n S o lut i o n s F i l li ng & S ealin g Au t o matio n En d- of-Line Pac k a gi n g Au t o matio n

DESIGNING BREAKTHROUGH PACKAGING WITH SUSTAINABILITY IN MIND

3:30-4:00 PM

This session, describes Procter & Gamble’s sustainabil ity goals and how it brings those to life in designing new-to-the-world packaging for its products.

Ken McGuire Research Fellow Procter & Gamble

TUESDAY, OCTOBER 25, 2022

LIVING CARBON SMART

9:30-10:00 AM

To achieve climate goals and deliver to consumers, we need a systems-level view and solutions that can draw on multiple sources of waste carbon. Advances in technology and a global momentum to avert the deepening climate crisis have brought us to the cusp of a new industrial era. Recycled CO₂ will be the feed stock and clean electricity the energy source to pro duce the climate-safe materials and fuels that are to day made from oil. Hear examples of carbon recycling and how to rethink carbon as a liability. Opportunities exist to create a new carbon economy and develop ma terials for consumer goods, from packaging to textiles.

Dr. Sean Simpson Chief Science Officer & Founder LanzaTech

CHALLENGES AND DEMANDS OF A GLOBAL FOOTPRINT

10:30-11:00 AM

There are many parameters to take into consideration when choosing the right packaging for the job, in cluding product needs and legislative, investment and consumer considerations. This session touches on ele ments that make this such a topical, challenging and interesting field, including where focus could be spent in the future.

Graeme Smith Global Sustainable Packaging Dir Mars Petcare

BEYOND PEAK PLASTIC: ENGINEERING AN AFFORDABLE HIGH-PERFORMANCE FUTURE

11:30-12:00 PM

According to McKinsey, more than 75% of millen nials say they think about sustainability when they make their purchases. The packaging industry has long accepted ubiquitous plastic use; however, chang ing consumer preferences no longer make unsustain able materials a viable option. Learn about how plastic alternatives like molded fiber can be an economically viable solution to help brands and packaging manufacturers reach their sustainability commitments.

Alex Garden Chairman & CEO Zume

THE RETURNITY PACKAGE DEAL: LESS WASTE, LOWER COSTS

12:30-1:00 PM

With 100 billion global parcel deliveries a year and more than 200 billion by 2026, the environmental impact is undeniable. U.S. packaging alone can pave a mile-wide cardboard road from New York City to Los Angeles and back—three times over. Returnity re places single-use shipping and delivery packaging by designing, manufacturing and implementing cost-ef fective reusable packaging and circular logistics sys tems for companies like Walmart, Estée Lauder, New Balance, Rent the Runway and others. Our packaging is now used for more than 2 million shipments and deliveries a month. Focused on identifying high-re turn rate opportunities, Returnity is especially pas sionate about educating businesses and consumers on the value of the package return rate. Rates below 75% are actually worse for the planet. The average Retur nity bag or box can be used for 20 customer shipment cycles (40 total) with a 95.5% return rate.

Mike Newman CEO

Returnity INNOVATING PACKAGE PORTFOLIOS THROUGH A POSTPANDEMIC DEMAND

1:30-2:00 PM

Learn about innovating package portfolios through a post-pandemic demand via holistic packaging design and engineering approach.

Kory Nook VP, Packaging R&I DANONE

PET PACKAGING TRENDS AND COMPARATIVE LCA RESULTS

2:30-3:00 PM

PET is the perfect material for numerous applications and achieves both legislative and brand commitments. This session on all things PET covers trends, debunks myths and describes a new comparative life cycle as sessment that evaluates environmental impacts for widely used types and sizes of containers.

Laura Stewart Dir, Operations National Association for PET Container Resources (NAPCOR)

LOOP’S ROLE IN THE FUTURE OF REUSABLE PACKAGING

3:30-4:00 PM

Learn how Loop works with CPG brands, retailers and quick-serve restaurants to build a network of reusability. Discussion points include: approaches to reusable packaging including design, material type, labeling and dispensers/closures; Loop as a “pre-fill” platform; and Loop’s growth somce mid-2019.

Tony Rossi

EVP Business Development TerraCycle

WEDNESDAY, OCTOBER 26, 2022

DEVELOPING PRODUCTS AND SOLUTIONS TO SUPPORT A CIRCULAR ECONOMY

9:30-10:00 AM

Urgent focus is being directed at climate change, greener transportation, fresh food, personal care, clean water, circular economy, plastic waste and renewable feedstocks. This presentation addresses these challeng es, relays them through the UN Sustainability Devel opment Goals and outlines a portfolio of solutions to support downstream customers as they set their sus tainability and Circular Economy goals.

Matthew Marks

Leader, Circular Economy, Americas SABIC

REALISTIC EXPECTATIONS FOR PET RECYCLING IN 2025

10:30-11:00 AM

PET recycling is at a crossroads as the industry drives toward 2025 goals. Brands, consumers, regulatory agencies and NGOs support systemic improvements, while known limitations restrain success. Learn about what is reasonably possible for increased PET recy cling, what changes are needed and what the rPET industry might look like in 2025.

Steve Lyons

Dir of Strategic Environmental Analysis

SBAcci Consulting Group

THE EVOLUTION OF PHARMACEUTICAL PACKAGING

11:30-12:00 PM

An examination of the future of pharmaceutical packaging as it becomes more sustainable and meets the needs for greater convenience, self-administered drugs, reduced hospital stays and serving patients at home. We also will look at how past and present inno vations focused on meeting patient and product needs offer a path for the future.

Ron Yakubison

Exec Dir Global Technology Packaging Merck

IMPROVING RESIDENTIAL RECYCLING WITH BOX TO NATURE!

12:30-1:00 PM

The paper industry, partnering with the Paper and Packaging Board, is introducing a residential recycling shipping box messaging initiative called Box to Na ture. The partnership is working with customers and large brands to educate consumers about the box with easy instructions on recycling right, every time. Learn how to become part of this important initiative.

Mary Anne Hansan President

Paper and Packaging Board SD

SHOW DAILY OCTOBER 24, 2022 20 PACK EXPO International 2022

Ronchi America proudly presents the SIRIO/S capper, built in Atlanta, GA. This SIRIO/S capper includes all of the Ronchi features and is FAT ready within 12 weeks or less. The SIRIO/S capper is also capable of being synchronized with the US built Ronchi EXACTA/R 18 filler. TOTALLY AMERICAN WITH AN ITALIAN HEART www.ronchipackaging.com NEVER BEEN SO EASY SEE US AT BOOTH N-6228

Association Partner Program grows Learn, network at Industry Meets and Industry Speaks.

The PACK EXPO Association Partner Pro gram connects attendees to leading associ ations from all segments of packaging and processing. This year’s program, the largest in PACK EXPO history, offers an unparalleled breadth and depth of industry knowledge to attendees.

The Association Partner Pavilion, in the North Hall, provides a central location for attendees to ac cess these resources. Participants in the 2022 PACK EXPO International Association Partner Program are listed at the bottom of this page.

New this year is the Association Partner Plus des ignation and Industry Meets schedule of ancillary events and meetings hosted by groups listed in the far right column. Events include a hygienic equip ment design seminar, design for recycling training, a fluid power forum and Fundamentals of Medical Device Packaging course. Check the PACK EXPO International App or show website for the latest schedule and pre-registration requirements.

“We are thrilled with the positive response to the As sociation Partner Program and newly launched Industry Meets Program at PACK EXPO International,” says Laura Thompson, vice president of trade shows at show producer PMMI, The Association for Packaging and Processing Technologies (Booth N-4550). “PACK EXPO International is making a triumphant return to Chicago after four years away, and it is only possible with the strong support of these prestigious associations.”

Another new feature, the Industry Speaks Stage (Booth N-4565), offers educational sessions led by experts from PACK EXPO Partner Associations and focused on hot-button topics and industry

trends across multiple industry verticals. A schedule of sessions may be found on page 24 or on the PACK EXPO International App or show website.

In addition to the Association Partner Program, PMMI has partnered with industry associations from

PAVILION HOSTS

CCPIT - China Council for the Promotion of International Trade

CFPMA - China Food and Packaging Machinery Industry Association

Confederation of the Danish Industry (LU-7560)

Fundacion Argentina para la Promocion de Inversiones y Comercio Internacional (Booth LU-8755)

INP – Brazilian Plastic Institute/Think Plastic Brazil (Booth W-25011)

Italian Trade Agency (Booth LU-8541)

Korean Packaging Machinery Association

Mouvement Des Enterprises De France International (Booth N-5564)

Switzerland Global Enterprise

UCIMA – Italian Packaging Machinery Manufacturers Association (Booth N-6002)

VDMA – Food Processing and Packaging Machinery Association

across the globe to host pavilions on the show floor. International Pavilion Organizer Partners include the 11 organizations listed under Pavilion Hosts. For more info, visit www.PACKEXPOinternational.com. SD

INDUSTRY MEETS

3-A Sanitary Standards (Booth N-5901)

Active & Intelligent Packaging Industry Association (Booth N-5802)

Cold Pressure Council (Booth N-4525)

Contract Packaging Association (Booth N-4518)

Flexible Packaging Association (Booth N-4533)

Institute of Packaging Professionals (Booth N-4523)

International Bottled Water Association

MHI Automation Industry Groups (Booth N-5701)

National Fluid Power Association

OMAC – The Organization for Machine Automation and Control (Booth N-5100)

The Association of Plastic Recyclers (Booth N-5902)

INTERNATIONAL PARTNER PROGRAM

(Booth N-5000)

AIMCAL - The Association of International Metallizers, Coaters and Laminators (Booth N-4527)

Asociacion Mexicana de Envase y Embalaje

ASD Turkish Packaging Manufacturers Association (Booth N-4900)

Australian Institute of Packaging

ABRE – Brazilian Packaging Association (Booth N-6003)

CANAINCA

Chicagoland Food & Beverage Network (N-4511)

Composite Can and Tube Institute (Booth N-4512)

Digital Twin Consortium (Booth N-6102)

Foil & Specialty Effects Association (Booth N-4536)

F4SS – Foundation for Supply Solutions

Flexographic Technical Association (Booth N-4510)

In-Mold Decorating Association (Booth N-4534)

IAE - Instituto Argentino del Envase (Booth N-6101)

International Society of Beverage Technologists (Booth N-5702)

ISTA - International Safe Transit Association (Booth N-4537)

Midwest Food Products Association

National Confectioner’s Association (Candy Bar Lounge, Booth S-2583)

OPC Foundation (Booth N-5001)

PLCopen (Booth N-5002)

Reusable Packaging Association (Booth LU-6737)

SNAC International (Booth N-5801)

The Anuga FoodTec Family

The Australian Packaging and Processing Machinery Association

The Paper and Packaging Board

The Tube Council of North America (Booth W-20052)

UCIMA – Italian Packaging Machinery Manufacturers Association (Booth N-6002)

U.S. Department of Commerce (Booth N-4901)

World Packaging Organisation (Booth N-4902)

SHOW DAILY OCTOBER 24, 2022 22 PACK EXPO International 2022

AIM

+1 (856) 273-3377 www.WeilerLS.com WLS Labeling Equipment Tailored for... - Pharmaceuticals - Nutraceuticals - Cosmetics - Personal Care Products - Food & Beverage WLS is in TWO BOOTHS at Pack Expo! Healthcare Packaging Pavilion #W-17002 & North Hall #N-5650 For over 30 years, WLS (Weiler Labeling Systems) has produced the most sophisticated and advanced pressure sensitive labeling solutions in the marketplace, kno wn for Simple & Efficient Changeovers and World Class Service & Support . ) h d d t h t h i t i VR VR In-Line Labelers for High-Speed Round ProductsIn-Line Labelers for Round Products////////////////////////////////////// //////////////////////////////////// RL RL Rotary Labelers for Any ProductRotary Labelers for Any Product HR HR In-Line Labelers for Medical DevicesIn-Line Devices //////////////////////////////////// ///////// Vial Coders for Identification Label Printers & Coders for Serialization /////////////////////////////////////// ///////////// October 23-26, 2022 McCormick Place Chicago, Illinois USA

The Industry Speaks Stage (Booth N-4565) offers educational sessions led by experts from PACK EXPO Partner Associations and focused on hot-button topics and industry trends across multiple industry verticals.

MONDAY, OCTOBER 24, 2022

10:30-11:00 AM

OMAC - THE ORGANIZATION FOR MACHINE AUTOMATION AND CONTROL

INTRODUCING PACKML-2022, AN UPDATE TO ANSI/ISA-TR88.00.02

FOR DISCRETE MACHINE CONTROL

A team from the OMAC Packaging Workgroup has won approval from ISA on several updates to ANSI/ ISA-TR88.00.02-2015 that improve the PackML State Model and expand/clarify the associated Pack Tags and data types for greater accessibility and su pervisory control across a variety of vendor platforms.

Doug Meyer Sr Mgr, Motion Yaskawa America

11:30-12:00 PM

MHI CONVEYOR & SORTATION SYSTEMS INDUSTRY GROUP

2022 DELOITTE/MATERIAL HANDLING INDUSTRY ANNUAL REPORT

Access to the latest report on trends and digital tech nologies that are transforming supply chains. MHI’s Conveyor and Sortation Systems (CSS) Industry Group present report findings, the effect on the pack aging industry as a whole and how specific packaging automation technologies will aid in the future. CSS is a 50-year-old industry group under the MHI umbrel la with a collective deep understanding of the market. Come for the presentation and stay for the Q&A. Be sure to bring your own challenges and application curiosities for this energized group to address. Key takeaways: a review of the digital technologies trans forming supply chain; the latest data around materi al-handling market growth; potential threats and op portunities within the packaging industry.

Mike Drolet Development Mgr

Murrelektronik

Allison Meyers

Marketing & Communications Mgr

Fives Intralogistics

12:30-1:00 PM

MHI’S SLAM INDUSTRY GROUP

ECOMMERCE FULFILLMENT— BUSINESS CASE FOR A SLAM SOLUTION

MHI’s SLAM Industry Group is made up of the companies that provide the software, hardware and

integrated solutions that go into the last 100 ft. To gether these companies collaborate to provide thought leadership and education on best practices in this crit ical area of your operation. Key takeaways: What is a SLAM system? (It stands for scan, label, apply, and manifest, but it is so much more.); core components of SLAM (what you see and what you don’t); how to mitigate risk in your fulfillment operation.

Gina Barrieau

Banding Sales Mgr, eCommerce

Felins

Greg Berguig

VP, Sales and Marketing Pac Machinery

Justin Garski Packaging OEM Mgr Rockwell Automation

1:30-2:00 PM

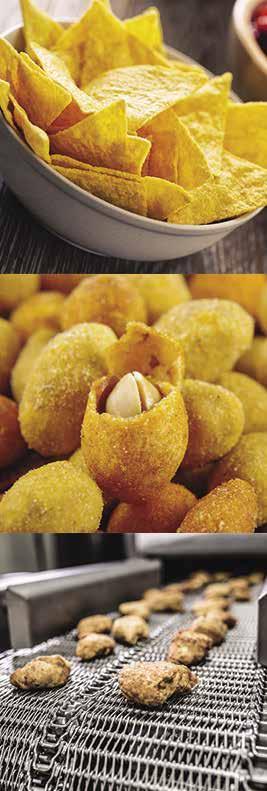

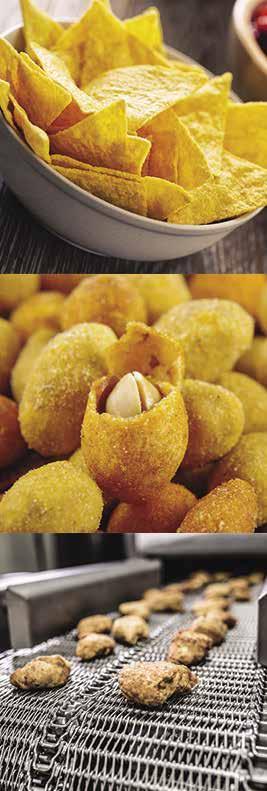

SNAC INTERNATIONAL STATE OF SNACKING: OPPORTUNITY AND INNOVATION ABOUND

As consumers turned to snacking as a source of fun and comfort during the pandemic, they also became increas ingly focused on holistic health and wellness goals. With the return to more active lifestyles, shoppers continue to value added benefits beyond nutrition in the snacks they choose. During the next year, innovation is set to explode in a snack category that continues to grow by provid ing new, healthful and tasty options, as well as reaches consumers faster than ever before through eCommerce. Learn which snack categories are growing, why they are growing, and how snack makers are capturing opportu nity for one of the fastest-growing categories in CPG.

David Walsh

VP, Membership and Communications SNAC International

2:30-3:00 PM

INTERNATIONAL SOCIETY OF BEVERAGE TECHNOLOGISTS EVOLUTION, TRENDS, AND ISSUES FOR BEVERAGES

Beverages have been available since the beginning of mankind. As mankind progressed and new tech nologies became available, the evolution of beverages progressed. The number and types of beverages grew as time passed until today where more than 20,000 foods and beverages are introduced each year. Tech nology advances and consumer preference can change the beverage world rapidly. Trends in total market, beverage groups and emerging markets can be iden tified. Changing markets, industry challenges and world events can create issues for the beverage indus try. COVID-19, The Great Disruption (supply chain

problems), sustainability, green, legalized cannabis, and other issues have impacted the industry.

Tom Reimer

Dir of Education

International Society of Beverage Technologists

TUESDAY, OCTOBER 25, 2022

10:30-11:00 AM

DIGITAL TWIN CONSORTIUM APPLICATIONS OF DIGITAL TWIN FOR THE PACKAGING SECTOR

The Digital Twin Consortium presents its activities for the development of Digital Twin technologies and specific pilot projects in the packaging sector. Learn how the use of Digital Twin technologies, both real time and offline, improve the efficiency and effective ness of the traditional process, in terms of costs, qual ity, time, OEE and improving ESG factors (environ mental, social and governance).

Dan Isaacs

Chief Technology Officer

Giuseppe Padula

Regional Branch Organizer

Digital Twin Consortium

11:30-12:00 PM

INTERNATIONAL SOCIETY OF BEVERAGE TECHNOLOGISTS

WHAT IS THE PROCESS TO CREATE A NEW PRODUCT?

New product innovation (NPI) creates, produces, sells and delivers a new product to the consumer. The definition of an NPI process is to define, estab lish and provide standardized methodology to ensure cross-functional alignment through a product’s devel opment lifecycle, delivering on-time and on-budget. There are three phases: ideation (concept or creation), design (development) and execution (commercial ization). Each phase has a series of gates to complete before moving to the next phase. Learn the total NPI process and the roles of different departmental func tions. Understand where your function fits in and what is needed to ensure a successful product launch.

Brian Stegman

Exec Dir

International Society of Beverage Technologists

2:30-3:00 PM

AMERIPEN

PACKAGING POLICY FOR NOW AND THE FUTURE

We are standing at a critical precipice on packaging and environment policy proposals and implementation here in the United States, with new laws coming

SHOW DAILY OCTOBER 24, 2022 24 PACK EXPO International 2022

at us fast and furious on packaging producer responsibility, labeling and recy cled-content mandates. Participate in a lively discussion about what’s happening and how this will impact the entire packaging value chain now and in the future.

Dan Felton Exec Dir

AMERIPEN - American Institute for Packaging and the Environment

3:30-4:15 PM

CHICAGOLAND FOOD & BEVERAGE NETWORK

WHAT IS THE FOOD MANUFACTURING FACILITY OF THE FUTURE?

The last two years have transformed our lives and businesses. How has it changed what is needed in a food manufacturing facility? How are supply chain disruptions, labor challenges, including the Great Resignation, and evolving customer and con sumer expectations changing how we manufacture food and beverage? How have food and beverage industry expectations changed? And how will we adjust our manufacturing processes, strategies, tactics and teams to best meet these evolving expectations? Join our panel of experts to learn how they are adjusting their ap proaches and playbooks to deal with the new realities of business today and what they see as the implications for imagining and creating the Food Manufacturing Facility of the Future.

Alan Reed - Moderator Exec Dir

Chicagoland Food & Beverage Network

WEDNESDAY, OCTOBER 26, 2002

10:30-11:00 AM

CONTRACT PACKAGING ASSOCIATION

WHAT IS DRIVING THE INTEREST IN THE CONTRACT PACKAGING AND MANUFACTURING INDUSTRY?

Using data from our State of the Industry Report, member feedback and our RFQ platform, we will take a dive into the demands of this dynamically growing indus try. Often a confusng and frustrating segment these essential providers of capa bilities and services are addressing the needs of emerging brands as well as legacy brands seeking to launch new food and CPG retail products. We will explore how CoMans and CoPacks are adding value as the consumers and market-driven needs are moving the packaged goods supply chain. Learn how the newest and innova tive products have become the key opportunities for CoMans. Understand how brands are adapting to meet new challenges with strategic CoMan and CoPack partnerships and accelerate time to market.

Carl Melville President

Melville group on behalf of Contract Packaging Ron Puvak Exec Dir

Contract Packaging Association SD

(BOOTH LU-6800) & WESTROCK (BOOTH S-2130) FOR SPONSORING THE PACK EXPO INTERNATIONAL LANYARDS

Yama

SHOW DAILY OCTOBER 24, 2022 25 PACK EXPO International 2022 Find your scale at YamatoAmericas.com Always the best way to weigh. WEIGHING & FILLING SOLUTIONS NEW Yama

Tray Filling for Leafy Greens

Commercial Scales

High Speed Bulk Weighing

• From napkin drawing to operational equipment • Maximizing productivity, minimizing floor space • OEM communications ... we’ll connect the dots • Immediate solutions designed for future expansion • Agency compliance built directly into your conveyor Accumulate, Rotate, Elevate, Integrate, Lift-gate, Incline, Combine, Decline, Alpine, In-line, Grip, Flip, Split, Invert, Divert, Merge, Twist, Turn, Curves, Transfer, Push, Stack, Hand pack, What’s that?, Serpentine, Sanitary. ki d i t ti l i t Multi-Conveyor ... your best, conveyed better. www.multi-conveyor.com But your secret is always safe!

ORBIS

WestRock sponsors Showcase

Exhibit displays award-winning packages from around globe.

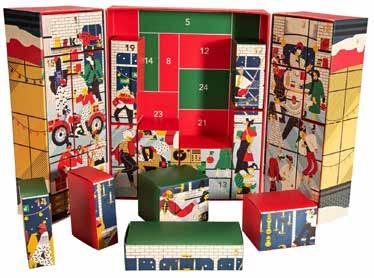

WestRock (Booth S-2130) presents win ning entries from worldwide packaging competitions as the exclusive sponsor of this year’s Showcase of Packaging Innovations® (Booth W-20052).

“At WestRock, we are focused on delivering bold innovation to solve our customers’ biggest challeng es,” says Margaret Herndon, the company’s chief marketing officer. “The Showcase displays the best the industry has to offer in packaging innovation, and we are excited to be part of a program that en gages customers and generates new thinking and new solutions.”

Show producer, PMMI, The Association for Packaging and Processing Technologies (Booth N-4550), is pleased to partner with WestRock on this initiative.

“The Showcase of Packaging Innovations has come to be a show floor favorite at PACK EXPO,” says Jim Pittas, president and CEO, PMMI. “We are thankful for companies like WestRock who seek to inspire the future of our industry and motivate package designers by showcasing packaging that is functional, innovative and sustainable.”

This year’s Showcase participants include 13 or ganizations from around the world. A sampling of the award winners on display is pictured here.

For more info, visit www.PACKEXPOinternational.com, www.westrock. com, www.abre.org.br, www.aimcal.org, www.dow.com, www.flexpack.org, www.fsea.com, www.imdassociation. com, www.packaging.com.ar, iopp.org, www.profood world.com, https://paperbox.org/, www.reusables.org, www.tube.org, www.worldpackaging.org. SD

The Best in Show package in IoPP’s AmeriStar competi tion, Blue Buffalo Tastefuls Spoonless Singles from General Mills and Product Ventures, provides a perfectly portioned split cup with a built-in chopper. The recyclable polypropyl ene split cup separates easily, reducing the need to store opened containers in the refrigerator.

INDUSTRY MEETS

ABRE - Brazilian Packaging Association (Booth N-6003)

AIMCAL - Association of International Metallizers, Coaters and Laminators (Booth N-4527)

Dow (Booth W-22017) Dow Packaging Innovation Awards

Flexible Packaging Association (Booth N-4533)

Foil & Specialty Effects Association (Booth N-4536)

In-Mold Decorating Association (Booth N-4534)

IAE - Instituto Argentino del Envase (Booth N-6101)

Institute of Packaging Professionals (IoPP) (Booth N-4523)

PMMI Media Group (Booth N-4550)

ProFood World’s 2021 Sustainability Excellence in Manufacturing Awards

Paperboard Packaging Council (Booth W-20052)

Reusable Packaging Association (Booth LU-6737)

Tube Council of North America (Booth W-20052)

World Packaging Organisation (WPO) (Booth N-4902)

Last year,

A

and

of

SHOW DAILY OCTOBER 24, 2022 26 PACK EXPO International 2022

The Package of the Year Award winner in the 2021 North American Paperboard Packaging Competition, the 2020 edition of Kiehl’s Advent Calendar produced by Johnsbyrne, features a storybook display design to deliver a premium unboxing experience while eliminating the use of plastic. A 100% paper-based rigid outer box houses 24 snuggly packed straight-tuck folding cartons containing product.

A capsule dispenser from Germany’s PACKSYS earned a President’s Award in the WPO’s WorldStar competi tion.

Designed for people with limited motor

function,

the dispenser

releases

one capsule at a time via an easy-topress, lockable actuator.

The Diamond Award, the top prize in the Dow Packaging Innovation Awards, considers three criteria: sustainability, technological innovation and enhanced user experience. The Brookfarm Roll ‘n’ Recycle curbside-recyclable, high-barrier stand-up pouch from Australia’s OF Packaging earns top honors on each point.

ABRE honored the 3 Corações cappuccino canis ter for ease-of-use and ergonomics. Package features waist ed silhouette

one-piece, flip-top closure with an induction seal.

pull ring ensures complete removal

the seal.

H LIGH LI FL W CK

I IC .

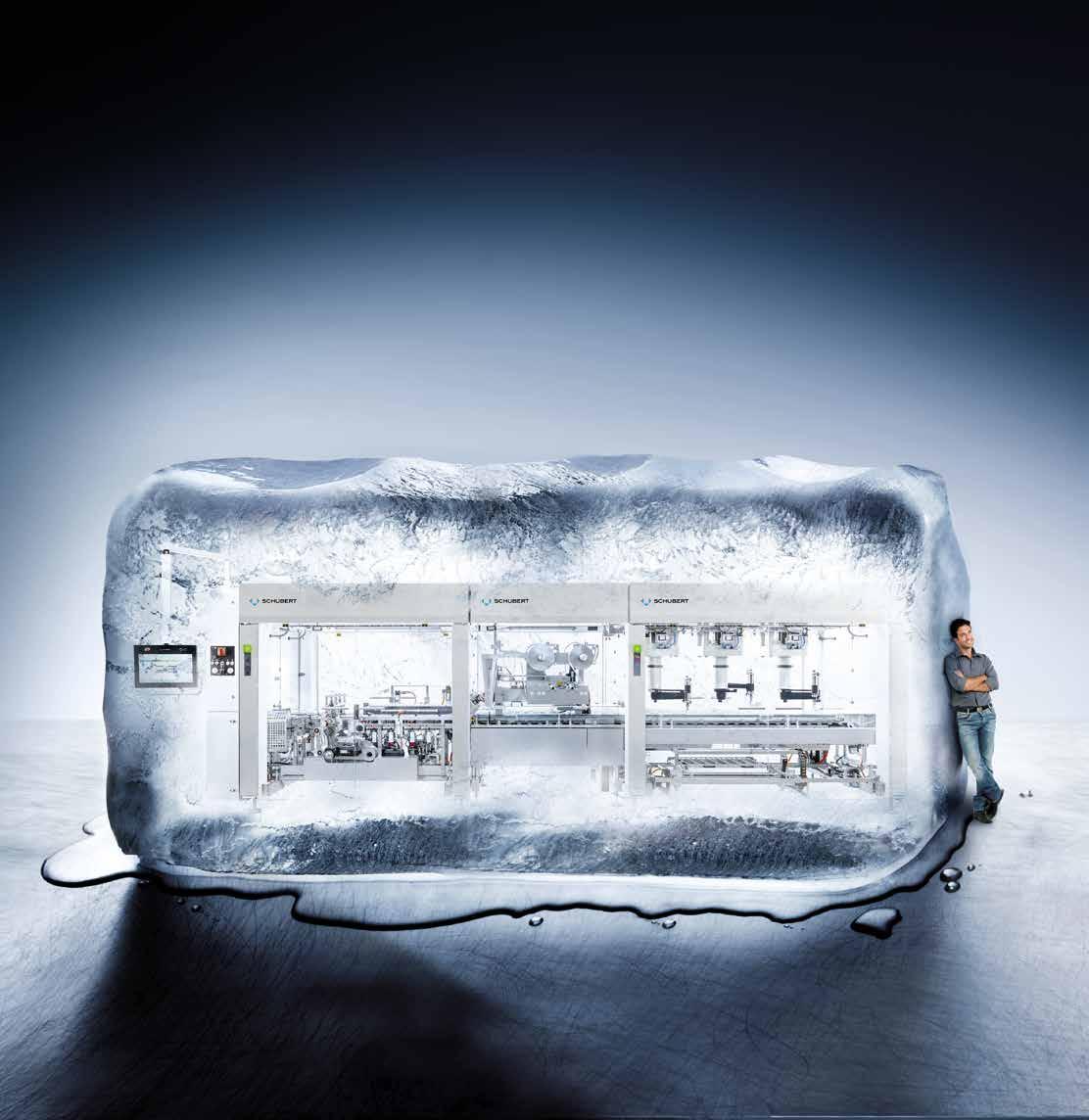

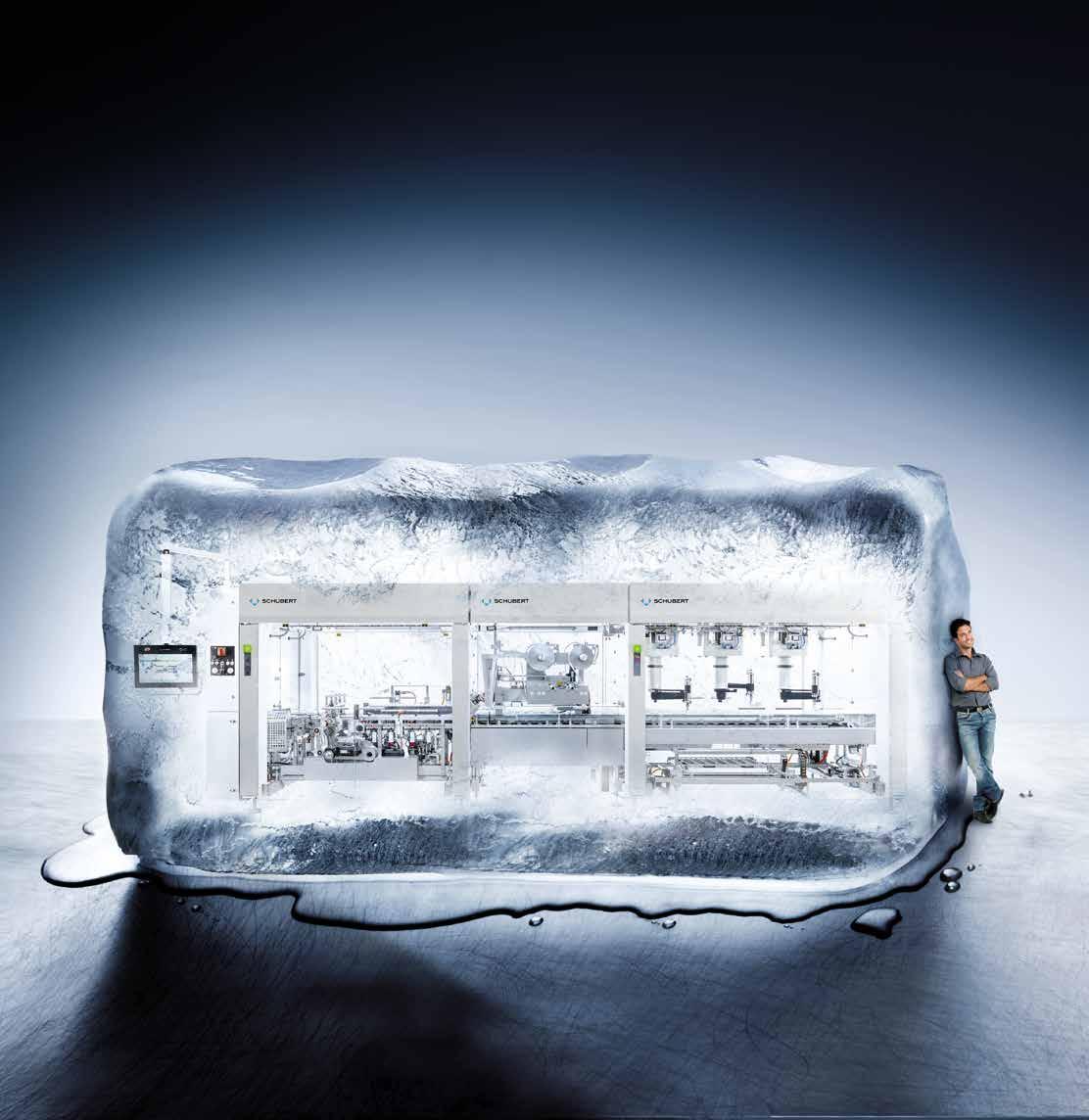

The lightline machines from Schubert can be delivered quickly and are especially attractive in terms of price . With the preconfi gured machines, customers can adapt more fl exibly to market trends and signifi cantly speed up their time-to-market.

The LIGH LI FL W CK is a flow-wrapping machine with robot-supported pick & place infeed and packs a wide variety of products in conventional and sustainable fi lms. It offers an affordable and highly fl exible way to automate packaging processes with the most effi cient technology on the market while ensuring the highest availability and packaging quality.

The world’s leading FMCG and private label manufacturers rely on Schubert. www.schubert.group

D CI

F

CK GI G D C Y I FL W CK .

CK

X

CHIC G

OCTOBER

23 – 26, 2022

BOOTH # 8730

WELCOME

Innovation Stage hosts 60+ sessions

Processing Innovation Stage makes Chicago debut.

Anattendee favorite, the Innovation Stage, returns to PACK EXPO In ternational with more than 50 informative sessions. The free, 30-minute presentations occur throughout each day on three stages (Booths N-4560, N-4580 and N-4585) in the concourse of the North Building near Starbucks.

Topics include sustainability and eCommerce, building a resilient supply chain, automating minimal material operations, cyber resilience, robotics, upgrading from heat sealing to ultrasonic sealing, brand protection and smart sensors.

New this year, after a successful launch at PACK EXPO Las Vegas, the Pro cessing Innovation Stage (Booth LU-7130) in the Lakeside Center concourse will feature sessions on Sunday, Monday and Tuesday focused on high-pressure pasteurization, product handling, batching and blending, clean-out-of-place parts washers and sanitary drainage system design.

Innovation Stage presenters are subject matter experts and represent a cross-section of exhibitors, including Syntegon Packaging Technology

(S-3514), Amcor Rigid Packaging (S-3705, S-3814), Placon (W-24033), SMAC Moving Coil Actuators (N-5774), Michigan State University (W-20044), Siemens Digital Industries (N-5148), WestRock (S-2130), Am cor Flexibles North America (S-3705, S-3814), Brenton, a ProMach product brand (N-5546), Emerson (N-4736), Soft Robotics (N-5230) and JBT-Avure (LU-7118).

The full Innovation Stage schedule is listed on the following pages. Check the PACK EXPO International App or the show website for the latest updates.

PACK EXPO International offers many other educational opportunities, including PACK to the Future (Booth W-20025) (see program on p. 18), The Forum at PACK EXPO (Booth N-4543) (see program on p. 44), and the new In dustry Speaks (Booth N-4565) (see program on p. 24). The Reusable Packaging Learning Center (Booth (LU-6737) also is hosting daily educational sessions.

For more info, visit www.PACKEXPOinternational.com. SD

MONDAY, OCTOBER 24, 2022

LOOKING BEYOND XR FOR A COMPLETE WORKFORCE STRATEGY

10:00-10:30 AM

Innovation Stage 1|N-4560

While much as been said about augmented reality/ virtual reality in recent years, it is just a piece of the multi-faceted workforce puzzle. Explore six ways to augment today’s workforce, from simulation and pre dictive control to automated changeovers and attract ing the next generation.

Steve Mulder

Americas OEM Mgr Rockwell Automation

THE PATH TO BECOMING A GREEN SMART FACTORY

10:00-10:30 AM

Innovation Stage 2|N-4580

Plant operators today are tasked with driving great er operational efficiency through digitalization while achieving ambitious corporate sustainability targets. Thankfully, these outcomes are not mutually exclusive. During this session, learn from Schneider Electric’s smart factory journey and the step-by-step approach the company took to convert its 60-year-old brown field site in Lexington, KY, into the world’s first Sus tainability Lighthouse Smart Factory as designated by the World Economic Forum.

Kenneth Labhart

Smart Factory Leader

Schneider Electric

INTELLIGENT PLASTIC FOR THE 21ST CENTURY

10:00-10:30 AM

Innovation Stage 3|N-4585

Discussion centers on how to significantly impact the sustainability of plastic. Topics include leveraging life cycle analyses and carbon credits; improving pack

aging design and the use of homogeneous materials; enhancing recycling and waste management systems; transitioning to bio-based plastics; and tackling food/ plastic waste by using end-of-life and shelf-life-exten sion technologies.