JAN2023 packworld.com 38 2023 Packaging Policy Update from AMERIPEN 44 Tropicana’s Spray Bottle Goes Viral 92 Dot’s Pretzels Doubles Down on Robotics 104 Smart Packaging Shines During Pandemic Era 128 PACK EXPO International 2022 Innovations Report 54 Brands Embrace Re ll-at-home Strategies Learn more about our automation solutions at www.westrock.com/ automation

Many players, one team.

Many players working hard to ensure the productivity, safety, and sustainability of our machines are always at their best. One team dedicated to providing exemplary service — every time.

www.syntegon.com

As consumers seek more sustainable products and packages, direct-toconsumer and consumer packaged goods companies in a range of industries—household cleaning, personal care, and luxury goods, among them— develop reusable packaging systems that can be re lled at home.

44

Buzz-Worthy Spray Closures Go Viral for Tropicana Campaign

In a social media campaign targeting TikTok, Instagram, and Facebook in uencers who are pushing the tongue-in-cheek #ThePerfectMimosa trend, Tropicana scored big-time buzz.

54 COVER STORY/SPECIAL REPORT Re ll-at-Home Packaging Takes Off Across Categories

Beginning with innovative at-home re ll solutions from Direct-to-Consumer startups, reusable/ re llable packaging has found its way into retail, in markets that include household cleaning, personal and oral care, lawn care, and luxury brands, to name a few.

92 AUTOMATION

Robotic Automation Doubles Capacity for Dot’s Pretzels

With no perceivable impediment to its growth other than capacity, Dot’s Pretzels, now a Hershey Co. brand, opened a new facility with a special focus on robotic packaging automation.

104

Smart Packaging Provides a Glimpse of the Ongoing Industrial Revolution

The AIPIA World Congress proves that smart packaging holds great promise for a host of near-universal brand objectives, including traceability, recyclability, consumer engagement, food waste reduction, and better supply chain logistics. Can tech suppliers in this sector band together to create ecosystems that deliver total solutions to brands?

2 PW JAN2023

FEATURES

VOL30 NO1 54 44 104 92 128 PACK EXPO International 2022 Innovations Report PMMI Media Group editors scoured the exhibits at PACK EXPO International 2022 to report on the latest and greatest packaging breakthroughs. 132 MACHINERY 176 FOOD PROCESSING & PACKAGING 202 SUSTAINABLE PACKAGING 226 ROBOTICS 250 CONTROLS

• Magnetic levitating shuttles • Ideal for small-batch production • Six degrees of motion control freedom • Fully integrated into the B&R ecosystem ACOPOS 6D Versatile. Levitating. Adaptive. br-automation.com B&R | A member of the ABB Group

4 PW JAN2023 Packaging World® (ISSN # 1073-7367) is a registered trademark of PMMI, The Association for Packaging and Processing Technologies. Packaging World® is published monthly by PMMI with its publishing of ce, PMMI Media Group, located at 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611; 312.222.1010; Fax: 312.222.1310. Periodicals postage paid at Chicago, IL, and additional mailing of ces. Copyright 2023 by PMMI. All rights reserved. Materials in this publication must not be reproduced in any form without written permission of the publisher. Applications for a free subscription may be made online at www.packworld.com/subscribe. Paid subscription rates per year are $254 in the U.S., $363 Canada and Mexico by surface mail; $605 Europe and South America; $907 Far East, Australia, and other countries by air mail. Single copy price in U.S. is $20. To subscribe or manage your subscription to Packaging World, visit Packworld.com/subscribe. Free digital edition available to quali ed individuals outside the United States. POSTMASTER; Send address changes to Packaging World®, 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611. PRINTED IN USA by Quad. The opinions expressed in articles are those of the authors and not necessarily those of PMMI. Comments, questions and letters to the editor are welcome and can be sent to: editors@packworld.com. Mailing List: We make a portion of our mailing list available to reputable rms. If you would prefer that we don’t include your name, please write us at the Chicago, IL address. DEPARTMENTS Connect with us: VIDEO Dot’s Pretzels’ Robotic Revolution pwgo.to/7870 VIDEO HomeRe llable Lip Balm Pack pwgo.to/7857 PODCAST PACK EXPO Trends Driving Healthcare pwgo.to/7871 AWARDS SUBMISSION Submit Your Innovative Pack Design pwgo.to/7872 packworld.com COLUMNS 7 Lead Off 34 The Legal Side 36 The Big Picture 38 Sustainable Packaging 266 Shelf Impact! 276 Professional Perspective NEWS/EVENTS 8 News 24 Quotables/By the Numbers 270 Industry Watch INTERVIEW 26 First Person PRODUCTS 272 Technology ADVERTISING 274 Advertiser Index Connect with a Leaders in Packaging supplier and support packaging education! www.packworld.com/leaders 10 26 EDITORIAL ADVISORY BOARD Aladin Alkhawam Director, Packaging Operations, Par Pharmaceutical Jan Brücklmeier Technical Application Group Packaging Technology Expert, Nestlé M. Shawn French Director – Innovation & Packaging Engineering (Beverage), Danone North America Patrick Keenan R&D Packaging Engineer, General Mills/Annie’s Organic Snacks Mike Marcinkowski Global R&D Of cer, GPA Global & Hub Folding Box Co. Paul Schaum Chief Operations Of cer, Pretzels Inc. David Smith, PhD Principal, David S. Smith & Associates Brian Stepowany Packaging R&D, Senior Manager, B&G Foods, Inc. Jasmine Sutherland President, Texas Food Solutions; Vice President, Perfect Fit Meals

'LDJUDSK�0DUNLQJ� �&RGLQJ�KDV�EHHQ�SURYLGLQJ�SURGXFW�LGHQWLÀFDWLRQ�VROXWLRQV�IRU�����\HDUV� WKDW�PDNH�LW�HDV\�IRU�PDQXIDFWXUHUV�WKURXJKRXW�WKH�ZRUOG�WR�PDNH�WKH�SHUIHFW�PDUN�³�SULQW� DIWHU�SULQW�DIWHU�SULQW��:H�IRFXV�RQ�SDUWQHULQJ�ZLWK�FXVWRPHUV�LQ�HYHU\�DVSHFW�RI�WKHLU�FRGLQJ� DQG�ODEHOLQJ�RSHUDWLRQV�WR�PD[LPL]H�HIÀFLHQFLHV�IRU�RXU�FXVWRPHUV�DQG�GULYH�WDQJLEOH�YDOXH� WKURXJKRXW�D�ORQJ�WHUP�SDUWQHUVKLS� TRAY PACK CODING CASE CODING CASE LABELING PALLET LABELING PACKAGE CODING PALLET PRIMARY SECONDARY ��5HVHDUFK�3DUN�'ULYH 6W��&KDUOHV��02����������� ������������� GLDJUDSK�FRP • VDOHV#GLDJUDSK�FRP &RQWDFW�'LDJUDSK�WRGD\�WR�GLVFXVV� WKH�EHVW�RSWLRQV�IRU�\RXU�RSHUDWLRQ� An ITW Company

CONTENT

Matt Reynolds Chief Editor Anne Marie Mohan Senior Editor @PackagingTrends Iris Zavala Managing Editor Sean Riley Senior News Director Pat Reynolds, Sterling Anthony, Eric F. Greenberg, Ben Miyares Contributing Editors David Bacho Creative Director

ADVERTISING

Wendy Sawtell Vice President, Sales wsawtell@pmmimediagroup.com

Lara Krieger Production Manager lkrieger@pmmimediagroup.com

Janet Fabiano Financial Services Manager jfabiano@pmmimediagroup.com

PMMI MEDIA GROUP

David Newcorn President

Elizabeth Kachoris Vice President, Digital Kelly Greeby Senior Director, Client Success & Media Operations Jen Krepelka Director, Digital Media

Mike Prokopeak Senior Director, Content & Brand Growth Trey Smith Senior Director, Events Sharon Taylor Director, Marketing Joseph Angel Founding Partner and Executive Vice President, Industry Outreach, PMMI Lloyd Ferguson Founding Partner

Packaging World • PMMI Media Group 401 N. Michigan Ave., Suite 1700, Chicago, IL 60611

Phone: 312/222-1010 • Fax: 312/222-1310

E-Mail: info@packworld.com • Web: www.packworld.com

PMMI The Association for Packaging and Processing Technologies 12930 Worldgate Dr., Suite 200, Herndon VA, 20170 Phone: 571/612-3200 • Fax: 703/243-8556 • Web: www.pmmi.org

Staff at PMMI Media Group can be contacted at info@pmmimediagroup.com

Questions about your subscription or wish to renew? Contact circulation@pmmimediagroup.com.

6 PW JAN2023

Follow us on twitter @PackagingWorld

Paper Pack Pragmatism

We’ve been keeping an eye on a localized spate of big confectionery brands in Australia swapping out traditional mixed-plastic flow-wrap film for what they say is curbside recyclable paper-based material. Mars Wrigley Australia’s new pack film format (more on page 16) consists of 86% sustainably sourced FSC-certified paper, plus a thin (enough) plastic liner as a barrier layer. Not to be outdone, Nestlé Oceania’s KitKat is trialing a paper-based material (pwgo.to/7873) using an on-pack QR code to invite consumer feedback on disposal habits for the curbside recyclable pack. These recent announcements follow similar Nestlé and Mars Wrigley paperbased confectionery pack rollouts in Europe over the past few years.

Are you sensing a trend? So is Bob Lilienfeld, a packaging consultant and executive director of SPRING (Sustainable Packaging Research, Information, and Networking Group), an online community of experienced, science- and fact-based packaging professionals pushing for a more circular, sustainable packaging future.

Lilienfeld posted the Mars Australia article on his popular LinkedIn page, predictably garnering a flurry of follower reaction ranging from praise to consternation. Seeing this activity unfolding online, I asked Lilienfeld about it. For his part, he’s taking an interested, but even-keeled approach.

“I’m a skeptic,” he told me. “Before I say ‘hey, this is a great move,’ tell me what the greenhouse gas savings are. Let’s see whether it actually improves—not the recyclability per se—but the actual collection, and then the actual conversion of these wrappers back into new materials … In my ideal world, the switch to this substrate would reduce the greenhouse gas generation over its entire lifecycle, versus having that package made out of plastic. And that’s whether or not the plastic is recycled.”

Variables that factor into this ideal-world preference are numerous, making a life cycle analysis (LCA) a complex endeavor (much less two LCAs to compare the new paper pack with the legacy plastic film). But Lilienfeld looks to two primary considerations. First is the LCA information “from cradle to cupboard; or more appropriately for a candy bar that’s immediately consumed, from cradle to conversion,” he says, possibly coining a new phrase. That involves everything from extracting materials from the earth—either as trees for paper or fossil fuels for plastic—to the actual conversion of the material into a printed roll of candy bar wrapper film.

Assuming differences between packaging, supply chain, and consumption variables of the two pack formats are negligible, the next consideration is disposal of the pack after the candy bar has been eaten. “What happens if it goes into a landfill?” he asks. “You can claim all the recyclability you want here, but a significant amount of these are going to landfill … And even if they do go into a recycling bin, is the paper material recovered and converted into a new material? Is the plastic liner removed? Used as waste to energy? There are a lot of possibilities, but from the point of diversion forward, what does the environmental profile look like for the plastic format versus this package?”

A couple of other notable observations Lilienfeld shared got me looking at the several paper-based candy bar packaging projects in a new light. For one, on-pack brand presence is reduced on the paperbased Mars bars. “Only a company like Mars, which has incredible brand equity, could actually pull something like that off,” he says. In a way that a newcomer to a crowded, vibrantly colored candy aisle couldn’t, Mars has the luxury of being able to sacrifice some on-pack branding space in favor of building a family of products (Mars, Snickers, and Milky Way) that all signal “sustainability” to consumers via a natural, kraft paper appearance.

Also, candy has a unique quality that it perhaps only shares with beer and spirits—food waste is negligible and doesn’t come into play in an LCA. As long as the candy bars aren’t sitting for months in inventory outside of temperature exclusion ranges, they move fast off of shelves, and are quickly and entirely consumed, often before the consumer even gets home.

And given candy bars’ quick and on-the-go consumption quality, I wonder if waste disposal becomes more a function of available recycling receptacles? If I’m buying a Snickers bar in a recyclable flow wrapper, it’s never making it to my home curbside recycling bin since it’s not making it home with me to begin with.

I’m with Bob. It’s interesting to follow these big brand decisions, but let’s wait and see. PW

mreynolds@pmmimediagroup.com

7 ÀȌ�˛ȁƮ�Ȍɐ �ǿȌ Ƶة� ƵƵ ɩɩɩخ ǿǞDzɯȌ ȌخƧȌǿ Ȍ ƵǿƊǞ �ɐ �Ɗ � Ɗ Ƶ ǿǞDzɯȌ ȌخƧȌǿ

NEW TOP LOAD CASE PACKER

Introduced

at PACK EXPO 2022, the KTB-100 has been well-received for its small footprint, robust design, and simple integration. This unique vertical case packer can pack all of these and more!

KTB-100

LEAD OFF

Coca-Cola’s ‘Recycled Records’ Highlights

Music Sampling & Recycling’s Shared Values

The Coca-Cola Company teamed up with two legendary names in music sampling, Mark Ronson and Madlib, to bring a bold musical experiment to life with the launch of “Recycled Records.”

“A great sample doesn’t have to come from other music, it just has to make you move. Your ear is your greatest asset when it comes to nding unique sounds and chopping them together,” says beatmaker and rapper Madlib. “The thud of a plastic bottle going through a recycling facility is, in its own way, a piece of art. Being able to take sounds so different from what I’ve used in the past and ip it into a whole new format is a great example of the versatility of sound— and clear plastic. Now fans of The Coca-Cola Company will get the opportunity to listen to my tracks and make some dope sounds of their own.”

To learn more, fans can look to acclaimed artist and female rap pioneer MC Lyte, who narrates a documentary-style short lm that draws a clear connection between the heritage and spirit of music sampling and the closed-loop recycling process. The company says this lm, lled with rich soundscapes, imaginative beats, and riveting visuals, showcases the creative process behind Recycled Records including extensive sound recordings at recycling facilities nationwide and a fascinating glimpse into the studios of Mark Ronson and Madlib.

The campaign introduces an original EP made up of the sounds taken from the bottle-to-bottle recycling process, alongside a versatile sound library and engaging short lm. Not only will fans be able to listen to these uniquely made tracks, but they’ll also have the ability to re-mix the very same sound library used by the two musical legends into innovative compositions of their own through an interactive digital beat machine.

Creative masters Mark Ronson and Madlib chopped, looped, and distorted recycled sounds, vocals, and ambient noises into an imaginative collection of six one-of-a-kind tracks to celebrate Sprite, Fresca, and Seagram’s transition from green to clear packaging. From the percussion of a forklift beeping to the tonal beat of a conveyor belt to the hi-hat of air blown into a plastic bottle, the EP brings to life the magic of multiple reuses.

“Sound sampling is constantly regenerating. Sampling is what my heroes did, and it’s now become an integral part of my own work,” says Grammy award-winning producer and sampling master Mark Ronson. “The creative process is lled with happy accidents...creators will nd, you play with this beat pack a million ways and no composition will be the same. Now it’s time for the fans to recycle the sounds of recycling itself. After all, some of the most inspiring sounds we can use in music creation are from our everyday lives.”

A sound sample is to music as clear plastic is to recycling. The process of music sampling is ongoing; an old sound is used in a new track, which is ipped again into a newer track, and so on. When green plastic is recycled, it is usually turned into single-use items that do not get recycled again—so, it was time for a moment of clarity, the company says. Now Sprite, Fresca and Seagram’s clear plastic bottles increase the likelihood of them being remade into new bottles many times.

“The Coca-Cola Company is thrilled to have teamed up with Mark Ronson and to celebrate our portfolio’s transition from green to clear. This sonic partnership is part of The Coca-Cola Company’s broader World Without Waste goals,” says Kurt Ritter, VP and general manager of sustainability, North America at Coca-Cola. “We’re excited about the switch because it increases the amount of high-quality, food-grade recycled plastic available in the marketplace and ultimately allows our brands to use more recycled plastic in their packaging.”

Consumers can watch the lm and take the Recycled Records beat machine for a spin to create their own musical compositions at greentoclear. com. —Matt Reynolds

Getting Started with Sustainable Packaging

Looking for information on how to get started with sustainable packaging? This Packaging World primer provides an overview on what sustainable packaging is, what’s driving the push for more sustainable packaging, and how to reduce the environmental impact of packaging. It also includes links to resources. Download this free PDF today at pwgo.to/7345

8 PW JAN2023 NEWS

800.835.2526 or 316-284-2020 Newton@BuntingMagnetics.com BUNTINGMAGNETICS.COM Two inspection devices. One easy to use product. With one common interface, Bunting’s Metal Detector Checkweigher Combo is easy to operate and requires less space on your line. Detect and reject metal contaminants and ensure the desired weight of your product. It’s Simple Assurance toward the highest quality. • Fully integrated metal detector and weigh cell with single point operation • Rates up to 250 PPM up to +/- .1 gram repeatability • Audit logging of all events

Pantone Color of the Year 2023 Celebrates the Natural World, Verve for Life

A vast departure from 2022’s soothing blue and violet Veri Peri Color of the Year, Pantone’s choice for Color of the Year 2023, Viva Magenta 18-750, “vibrates with vim and vigor,” says the brand. Explains Pantone, Viva Magenta is a shade rooted in nature—more speci cally, it originates from a beetle found in tropical and sub-tropical environments—descending from the red family, and expressive of a new signal of strength. “Viva Magenta is brave and fearless, a pulsating color whose exuberance promotes a joyous and optimistic celebration, writing a new narrative,” Pantone says.

Expanding on the nature of Viva Magenta, the brand states that it is powerful and empowering, an animated red that revels in pure joy, encouraging experimentation and self-expression without restraint, an electrifying and a boundless shade that is manifesting as a stand-out statement. “PANTONE 18-1750 Viva Magenta welcomes anyone and everyone with the same verve for life and rebellious spirit,” it says. “It is a color that is audacious, full of wit, and inclusive of all.”

Furthermore, Viva Magenta is described as a nuanced, crimson-red tone that presents a balance between warm and cool; it is a hybrid color, one that comfortably straddles the physical and virtual in our multi-dimensional world. “It is assertive, but not aggressive, a carmine red that does not boldly dominate but instead takes a ‘ st in a velvet glove’ approach,” says Pantone. “Exuding dynamism, PANTONE 18-1750 Viva Magenta is a transformative red tone capable of driving design to create a more positive future.”

Viva Magenta is the 24th color in Pantone’s Color of the Year series, which was rst launched in 1999 by the Pantone Color Institute. The Color of the Year is described as being “one moment in time” that provides strategic direction for the world of trend and design. It is a culmination of institute’s year-round work forecasting trends, based on all aspects of society, including fashion, marketing, social media, and politics, and developing color palettes for its clients.

In explaining the reasoning behind its choice of Viva Magenta for 2023, Pantone says, “As we balance our digital and physical lives, we continue to grow our appreciation for the natural world. The Color of the Year 2023 acknowledges our gravitational pull towards natural colors as movements swell around climate change, sustainability, and land protection.”

In this year’s Color of the Year selection process, Pantone says it observed a heightened appreciation and awareness of nature represented by countless lifestyle trends. “We’re incorporating more living things into our homes, such as plants, orals, living walls, and restorative outdoor spaces,” it notes. “We’re nding newfound enjoyment in travel, sports, and outdoor recreation after pausing these activities during the pandemic. We’re more careful to protect our bodies as a result of the public health crises—we look to apply and ingest trusted, life-giving ingredients. All of these lifestyle trends speak to the heartiness of natural forces.”

Viva Magenta’s organic origins hail from the cochineal beetle, an insect that produces carmine dye, which, according to Pantone,

is one of the most precious, strongest, and brightest of the natural dye family. As a result, the company says that “the red tone of Viva Magenta connects us to original matter, imbibing us with a primordial signal of strength.”

“The Color of the Year 2023 merges the richness, warmth, and strength of natural matters with the rich, open horizons of the digital world,” says Pantone. “The result is a shade of red that expands our horizons of authenticity. The metaverse creates new opportunities for us to express ourselves, and the raw fortitude of Viva Magenta inspires us to do so with con dence and bravery.”

Along with Pantone’s designation of the Color of the Year, it provides a number of tools for designers in fashion, beauty, home and interiors, graphic arts, and packaging and plastics that provide direction on how to effectively incorporate the color into their designs and to what end. For those designing packaging and plastics, Pantone says that brands wanting to appear animated and passionate can use Viva Magenta to elicit a strong consumer reaction. “Because reds are advancing colors, they draw the eye and muscle out the colors surrounding them,” it says. “Whether consumers are scrolling on their phones or browsing the aisles, tapping into the Color of the Year 2023 will ensure you stand out.” —Anne Marie Mohan

10 PW JAN2023 NEWS

We are here to help you protect: Profits Decrease labor costs. Increase productivity. Environment Prevent damage. Protect the planet. Brand Elevate customer experience. Increase brand loyalty. Learn more about the complete portfolio of protective solutions: Inside the box protection Sustainable packaging solutions Mailing & bagging solutions Temporary surface protection films Performance films for flexible packaging Products worth protecting deserve Pregis. Schedule a consultation today to protect what matters most to your business. www.pregis.com/contact-us

Clemson Announces Fall 2022 Packaging Science Award Winners

From Clemson University comes news about two Fall 2022 awards. Rebekah Pereira was named the Robert Testin Outstanding Packaging Science Senior Award winner, and Sophie Owen was the Packaging World Outstanding Packaging Science Senior nominee.

Clemson University Robert Testin Outstanding Senior in Packaging Science winner for Fall 2022

Rebekah Pereira, a Packaging Science major with an emphasis in materials, graduated December 2022 from Clemson University Honors College. Throughout her years at Clemson, she has become very involved in the Packaging program. As a sophomore, she attended PACK EXPO, where she found a great interest in this major. From there she participated in her rst coop at Unilever during the spring of her sophomore year, returning a year later to complete a second rotation. She was Vice President of the Packaging Science Club for an entire year and participated in the nationwide 48HR Repack Student Packaging Design Competition, where her team won rst place. During her nal year, she has been working at The Sonoco Institute of Packaging Design and Graphics as an intern and has participated in a Creative Inquiry Undergraduate Research project designing football photo displays for recruits. Pereira says she hopes to continue her Clemson legacy well beyond these accomplishments.

Packaging World

Outstanding Packaging Science

Senior winner for Fall 2022

Sophie Owen graduated in December of 2022 with a bachelor’s in Packaging Science, an emphasis in Food and Healthcare Packaging, and a minor in Sustainability. In 2020, she completed her cooperative education requirement with Arthrex and gained invaluable experience in medical device manufacturing and regulatory practices. During her time at Clemson, Owen was part of the team that submitted and won a bid for a PMMI PACK EXPO booth, which focused on sustainable packaging alternatives, research, and initiatives. Additionally, Owen took part in creating and presenting packaging for the FRESH 2022 Food, Packaging & Sustainability Summit. She says she is extremely grateful for all the opportunities that the Packaging Science faculty at Clemson have given her and will cherish these experiences for a lifetime. —Matt Reynolds

PACK EXPO Southeast Debuts Spring 2025 in Atlanta

PACK EXPO Southeast will debut spring 2025 in Atlanta (March 10-12; Georgia World Congress Center) bringing packaging and processing machinery, materials, and technology all under one roof to a growing manufacturing corridor.

The newest show in the PACK EXPO portfolio, produced by PMMI, will offer solutions for over 40 vertical markets to address the packaging and processing needs of southeast manufacturers.

“This show represents a big opportunity to bring the industry together in a region of the country that is not currently served by a trade show focused on packaging and processing,” says Jim Pittas, president and CEO, PMMI. “PACK EXPO Southeast in Atlanta is the perfect location to focus on targeted opportunities in this robust market, which is home to some of the top manufacturing industries in the region.”

Located within driving distance of key manufacturing cities and a mere two-hour ight from 80 percent of the U.S. population, PACK EXPO Southeast will harness all the power of the PACK EXPO portfolio of trade shows, directed at the robust southeast market.

“PACK EXPO Southeast 2025 will provide a prime opportunity for exhibitors to reach a new, untapped customerbase in this region,” says Laura Thompson, vice president, PMMI. “And attendees will have the chance to experience new kinds of machinery, materials, and other innovations live and in-person, while forging critical relationships with their peers and suppliers.”

As PACK EXPO East does for the northeast market, PACK EXPO Southeast will laser focus and target the southeast market and offer a depth and breadth of exhibits not provided by any other events in the region.

Exhibitor booth sales for PACK EXPO Southeast 2025 start in September 2023. Attendee registration will open during PACK EXPO International 2024. Request information and learn more at packexposoutheast.com —Sean Riley

12 PW JAN2023 NEWS

XTS: Agile transport for pitchless, asynchronous packaging

XTSTEP

The XTS advantage

infinitely flexible dramatically reduces machine size faster time to market

Mechanical flexibility

embed XTS directly into machines configure for any track geometry install flat, vertical or at angles repeat or stack XTS tracks 30–50% reduction in machine footprint

Manufacturers around the world need to offer increasingly customized products – with machines that deliver reduced footprint and improved productivity. Available now in the U.S., the eXtended Transport System (XTS) from Beckhoff answers these machine design challenges and more. In combination with PC- and EtherCAT-based control technology, the XTS features a high level of design freedom for machine builders to develop game-changing concepts for product transport, handling and assembly. A stainless steel hygienic XTS version is ideal for use in the pharmaceutical and food industries. Take your next step in machine design with XTS: total freedom of installation position compact design integrates directly into machinery freely selectable track geometries few mechanical parts and system components

NE

Scan and learn all about the XTS

Walkers Multipacks Get Paper Cartons; Stretch Film Made with Nanotechnology

PepsiCo has announced that it has invested approximately $18 million in new sustainable food packaging innovations for its Walkers UK potato chip snack brand. The new packaging, part of the company’s PepsiCo Positive (pep+) sustainability strategy, is expected to remove 250 million tons of virgin plastic across the brand’s supply chain annually.

As part of the move, the outer plastic packaging on millions of Walkers 22- and 24-bag multipacks will be replaced with a new paperboard carton design. After a successful trial with Tesco, the new and improved multipack outer packaging launched on shelves in all major supermarkets in the U.K. following the October announcement.

Alongside the new packaging design, Walkers has invested in a new pallet stretch lm. The lm, from a proprietary supplier, is produced using nanotechnology, which puts tiny air bubbles into the lm to reduce the amount of plastic used while retaining the same strength and stretch needed to protect the snacks as they travel to stores across the country. The use of this new technology will lead to a 40% reduction in virgin plastic year on year, compared to the previous lm. Reducing the amount of fossil

fuel-based virgin plastic in the shrink wrap will also reduce the company’s annual carbon emissions by 465 metric tonnes.

Says Simon Devaney, sustainable packaging director, PepsiCo UK & Ireland, “We are constantly exploring new scalable solutions, and this investment marks an important step forward, delivering a huge reduction in virgin plastic across some of our best-selling ranges, while also helping to tackle our carbon footprint.

“Reducing virgin plastic across our supply chain is a key part of our commitment to creating a world where packaging never becomes waste.” —Anne Marie Mohan

Erewhon, the Los Angeles premium organic grocer, announced a partnership with Cove, a California-based material innovation company, making it the rst retailer of Cove’s fully biodegradable water bottles.

“Erewhon has celebrated the amazing bene ts of naturally grown foods and the importance of preserving the earth for more than 50 years

and continues to lead the way in conscious consumption today,” says Vito Antoci, executive vice president of Erewhon Markets. “When we were introduced to Cove, we were incredibly excited to be part of this innovative and potentially world-changing moment for CPG—the world’s rst fully biodegradable water bottle is something we are very proud to be launching at Erewhon.”

The company says that Cove bottles are plastic-free, biodegradable, renewable, non-toxic, and compostable. They are made with polyhydroxyalkanoate (PHA) a sustainably sourced, naturally occurring biopolymer.

PHA is produced and consumed by microorganisms that occur all over the world, including soil-inhabiting and marine microorganisms. It biodegrades in all natural environments–fresh water, soil, and marine environments–and breaks down without producing any toxic waste. It is broadly biodegradable at a rate comparable to cellulose, the building block of plant life and the primary component of paper, the company says.

“Cove entering retail is a signi cant milestone for the company and it was important for us to nd a mission-aligned retail partner to debut Cove. We’ve found that in Erewhon and are excited to take a big step forward in our mission to create a sustainable material world,” says Alex Totterman, founder and CEO of Cove.

The water bottles, named the Plastic-Free Innovation of The Year in 2019 by Dieline, will be available at Erewhon stores throughout Los Angeles, as well as online at cove.co. Cove says it will announce new retail partners in coming months as they scale up manufacturing at their production facility in Los Angeles. —Matt Reynolds

14 PW JAN2023 NEWS

Biodegradable PHA Water Bottles Make Retail Debut

Mars Wrigley to Switch to Paper-Based Packaging in Australia

Article rst appeared in Australia’s PKN Packaging News on Nov. 28, 2022. Coverage courtesy of Lindy Hughson, Managing Editor & Publisher.

Mars Wrigley Australia’s move to paper-based wrappers for its chocolate bar lines marks a world- rst for the company and is in line with the growing global trend for brands to switch from single-use plastics and adopt ber-based packaging materials that it says are curbside recyclable.

The company will roll out the new paper-based packaging for its Mars Bar, Snickers, and Milky Way chocolate bar lines nationally from April next year, with plans for its full chocolate bar portfolio to transition.

The packaging, made from sustainably sourced FSC-certi ed paper, was developed and trialed at Mars Wrigley’s manufacturing site in Ballarat, Australia. The Ballarat-based R&D team leading this project is pioneering paper-based sustainable packaging solutions for the Mars Wrigley

tained, seals and inks for labelling. While the packaging features a very thin plastic barrier, it remains able to be recycled via curbside recycling as validated by APCO’s PREP tool.”

Hutton con rmed Mars Wrigley is currently working on the second iteration of this packaging, which will remove the thin plastic barrier, and this will be available by the end of 2023.

“The transition to paper-based packaging for our locally made chocolate bars marks a signi cant milestone in our sustainability journey,” says Andrew Leakey, general manager of Mars Wrigley Australia. “Mars’ ongoing investment in local R&D has allowed us to be agile and create solutions that have a positive impact on our environment, meet our stringent quality and food safety standards but are also convenient for our consumers to recycle via curbside recycling.”

Leakey says ensuring consumers had easy access to recycle the new packaging was “crucially important” to the company.

“As one of the largest snacks and treats manufacturers in Australia, Mars has a responsibility to reduce our environmental footprint right across our business, including packaging. The launch of our new paper-based packaging is a signi cant step for us towards our local and global packaging targets.”

The step by Mars has been welcomed by Australian Packaging Covenant Organisation (APCO) CEO Chris Foley, who said Mars Wrigley’s new packaging was a prime example of innovation within the food industry to meet packaging targets.

“Mars Wrigley’s switch to paper-based packaging sets an “excellent example to all businesses in Australia of the critical role innovative packaging formats that are more readily recyclable play in meeting the 2025 National Packaging Targets,” Foley says.

The packaging will incorporate the Australasian Recycling Label (ARL) to provide clear instructions to consumers on how to recycle.

Once the Australian-made chocolate bar portfolio is fully transitioned to paper-based packaging, Mars Wrigley says it is set to eliminate more than 360 tonnes [397 tons] of plastic from its value chain. This, the company says, will contribute to its aim of creating a circular economy and achieving the 2025 National Packaging Targets.

business globally. The plan is for the technology, learnings, and insights developed and deployed locally in Australia to be shared and implemented in other Mars Wrigley markets across the globe.

The packaging material is manufactured locally by Amcor. Chris Hutton, R&D director, told PKN, “As this is a world- rst for Mars Wrigley, we didn’t have a playbook or a road map to follow, so our local R&D team worked really closely with Amcor Australia and New Zealand to come up with a solution that maintained the quality and freshness of our product, whilst working ef ciently with our machinery and technology in the factory.

“They have been an incredible partner to work with and they’ve played a pivotal role in getting to where we are today.”

PKN asked about the composition of the paper material, and how it was achieving the requisite barrier properties, to which Hutton responded, “Our paper-based packaging is made up of 86 percent paper, a thin plastic barrier to ensure the quality and freshness of the product is main-

Mars Wrigley’s transition to FSC-certi ed paper materials for its wrappers is a move applauded by CEO of FSC Australia and New Zealand, Melanie Robertson, who says it “sends an essential message about the importance of choosing forest-friendly alternatives to single-use plastics”.

“FSC ANZ is proud to partner with Mars Wrigley and congratulates them on this demonstration of support for the responsible management of the world’s forests.”

As part of the company’s commitment to its $1B Sustainable in a Generation plan, Mars Wrigley says it is “committed both in Australia and globally to supporting and creating a circular economy where packaging never becomes waste.”

Mars Wrigley’s new paper-based packaging will be available on 47and 64-g Mars Bars, 44- and 64-g Snickers, and 45-g Milky Way at all leading supermarkets and convenience stores in Australia beginning in April 2023. PW

16 PW JAN2023 NEWS

Packagers have long relied on A-B-C for hardworking machines that deliver top production with less wear and care. Today, our machines give you even more. Our advanced electronics give you total control at the operator station, for quick startup and rapid change-

over. All operating data is at your fingertips with full connectivity to your factory control station. Preventive maintenance notifications and remote service are designed to keep your line at top production...always. Today and tomorrow, we’re here to serve you.

Simple. Flexible. Reliable. Connected. End of line packaging solutions 800-237-5975 Since 1940, a tradition of innovation, quality & service 811 Live Oak Street, Tarpon Springs, FL 34689 - 727-937-5144

Depalletizers & Decasers Erectors & Sealers Robot Packers Palletizers

Hazelnut Growers of Oregon (HGO) is relaunching its Oregon Orchard CPG brand with what it says is striking new packaging for its baking, snacking, and chocolate-covered hazelnuts. The rebrand aims to elevate consumer awareness of hazelnuts as a delicious, healthy, and sustainable alternative to almonds and other popular nuts. The updated brand also introduces Hazel the Health Nut, an adventurous mascot that embodies the philosophy of the Lifestyles of Health and Sustainability (LOHAS) customer.

“This campaign is colorful and fun, but it serves a serious purpose: to expand people’s perception of hazelnuts beyond their role as a avor added to sweets or coffee. They’re a delicious, healthful snack on their own, and a versatile ingredient in baking and cooking,” says Dan Herdon, Vice President of Sales and Marketing.

The exographically printed pouches are produced and converted by Sierra Packaging & Converting in Reno, Nevada.

The new pouch uses the same PVDC and EVOH structure as the legacy pouch. The polyester (PVDC) uses an additive formula to increase the barrier. The EVOH is a polyethylene with an additive formula to further increase the barriers, with a higher barrier that PVDC, the company says. The duplex structure means the recyclability pro le is #7.

The pouch does have a new element, a window that’s designed “to give consumers a view of the hazelnuts and chocolate-covered hazelnuts so they can see the quality of our products,” a spokesperson told Packaging World. The company also worked with Blue Collar Agency of Hood River, Oregon, to update the design and branding.

“The redesign will bring attention to Oregon Orchard Hazlenuts and highlight the health bene ts and avor that each variety brings,” the spokesperson continued. “Hazel the Healthnut brings a new, fun and vibrant element to Oregon Orchard and its customers.”

Nut enthusiasts in the Twin Cities area of Minnesota will be among the rst to encounter the rebranded Oregon Orchard products at the prominent regional grocery chain, Lunds & Byerlys. Over 99% of U.S. hazelnuts are grown in Oregon thanks to the perfect blend of rain, sun, and wind, and Midwesterners will get the rst pick of this Paci c Northwest staple as part of the national relaunch of the Oregon Orchard brand.

To drive consumer awareness of Oregon Orchard products and availability, HGO is supporting retailers with a co-branded social media push that directly connects nut shoppers to a store near them. —Matt Reynolds

18 PW JAN2023 PRECISION CHECKWEIGHING DUAL CAMERA INSPECTION > Highly Precise Product Transport > Verifying Cover Films > Checking of Barcodes & Sell by date > Vision Inspection from Above & Below www.Wipotec.com/us NEWS

Rebrand Introduces ‘Hazel the Healthnut’

www.NitaLabeling.com | sales@nita.ca | 1.855.668.NITA (6482) GET TO KNOW YOUR NEW SUPER-EFFICIENT “EMPLOYEE” BY CONTACTING NITA TODAY. WE PREDICT LOVE AT FIRST SIGHT. This system WILL dramatically reduce operator touch-time, WILLspeed up changeovers beyond your wildest dreams, and WILLeliminate costly downtime on your labeler. Our simple fix to your complex problems. Nita is the original 100% Servo Labeler that WILL change your production universe forever. MEET . YOUR NEW “BEST LABELER OPERATOR EVER” YES, THAT IS CORRECT. WE BUILT YOU A SKILLED WORKER RIGHT INTO THE LABELER . Introducing the ALL-NEW Nita Sentient Labeling Machine with ULTRA-PRECISE FULLY AUTOMATIC CHANGEOVERS.

Popcorn Maker Deploys PFAS-Free Microwave Bag

Berkeley, Calif.-based Connect Snacks has an interesting backstory. The purveyor of whole grain popcorn was launched by eco-friendly fertilizer startup Pivot Bio to connect consumers with those farmers who are growing food with synthetic-free nitrogen fertilizers. Following the successful launch of its popcorn kernel product in October 2021, Connect Snacks turned its attention to developing a microwavable popcorn option. Given its better-for-the-planet mission, however, it knew it needed to nd a packaging solution that was more sustainable than the per-and poly uoroalkyl (PFAS)-lined popcorn bags currently on the market.

The drawback to PFAS compounds, which have a tendency to leach into the product, is that they are classi ed as “forever chemicals,” designated as such because they break down very slowly, accumulating both in the environment and in the human body. One report from the U.S. Centers for Disease Control and Prevention’s (CDC) National Health and Nutrition Examination Survey (NHANES) found PFAS in the blood of 97% of Americans. Interestingly, a 2019 study found that people who regularly eat microwavable popcorn have signi cantly higher blood PFAS levels; for those who consume it daily, their levels were up to 63% higher than average.

Bioaccumulation of these compounds can seriously impact an individual’s health. A recent CDC review outlined a host of negative health effects associated with PFAS exposure, including cancer, liver damage, decreased fertility, and increased risk of asthma and thyroid disease.

Removing the PFAS lining from popcorn packaging is not easy though, and alternative options also typically carry with them a higher price tag— up to three times higher, in fact, according to Temme. To address the challenge, Connect Snacks used several strategies. “We solved it by using the highest quality popcorn that’s also sustainably grown using no chemical nitrogen fertilizer,” he shares. “We also ask consumers to add their own oil to their popcorn rather than including it in the bag, and we invested in a lot of research and development to create delicious avors from natural ingredients that wouldn’t stick to the bag.”

While information on the exact material used for Connect Snacks’ microwavable popcorn bag as well as on the material supplier is proprietary, Temme does share that the bags are made from “FDA-approved, greaseresistant PFAS-free papers that were engineered for microwave popcorn packaging.”

PFAS is a man-made class of plastic chemical compounds commonly used in microwavable popcorn bags. It is also used in packaging such as cardboard takeout containers, pizza boxes, fast food packaging, and pet food bags. PFAS is added to microwavable bags to keep the oil that pops the corn from soaking out and to prevent the bag from burning.

Connect Snacks CEO Karsten Temme notes that the PFAS liner provides two other functions as well. “First, it seals in a metal susceptor, which improves heating to pop the kernels. And second, it helps seasoning not stick to the bag,” he explains.

Of the importance of developing such a bag, Temme cites how ubiquitous plastic-coated packaging is in the lives of consumers, adding that it’s also often hidden. “Coffee cups, sandwich wrappers, and paper takeout containers often have a plastic liner,” he says. “We want to do our part by removing the plastic coating in our microwave popcorn—and this means no more microwaving your popcorn in plastic, too.”

Connect Snacks’ Better for You Microwavable Popcorn was introduced in October 2022 and is available on the brand’s website as well as on Amazon in four avor varieties packaged in 3-ct cartons. —Anne Marie Mohan

Vibratory Feeders

With 100% more capacity (45 tph) and twice the available tray size/mass than our next largest feeder, Eriez high capacity 76 Series Electromagnetic Vibratory Feeders are designed for packaging applications with high head loads or needing exceptionally long overhang.

•Handles high head loads

•Exceptionally long overhang

•Up to 45 tph

•High speed and high deflection drives

Eriez.com | 814.835.6000 Vibratory Feeders, Conveyors & Screeners VibFeedersAd.qxp_Layout 1 2/12/21

20 PW JAN2023 NEWS

Long Overhang, High Capacity

12:37 PM Page 1

ON A JOURNEY TO MANUFACTURING 4.0

Cal Poly awarded 2022 Mark C. Garvey Scholarship

The PMMI Foundation, in cooperation with the Garvey Corporation, has selected Cal Poly as the recipient of this year’s $5,000 Mark C. Garvey Scholarship. PMMI, The Association for Packaging and Processing Technologies, provides nancial support for packaging and processing education at colleges, universities, and technical schools throughout the United States and Canada through the PMMI Foundation.

The student selected to receive the scholarship, Jayna Regehr, is a junior studying Industrial Technology and Packaging. Jayna has a GPA above 3.0 and is currently studying as part of a co-op education program with Annie’s Kitchen. She is actively involved in club activities, serves as a faculty research assistant, and recently attended the PACK EXPO International trade show in Chicago.

“The Garvey family is pleased to award the 2022 Mark C. Garvey Scholarship to Jayna Regehr at Cal Poly. Garvey Corporation has had the honor to hire Cal Poly graduates in the past and looks forward to supporting the program in the future. Cal Poly does an outstanding job preparing students for a future in the packaging industry. Congratulations Jayna,” says Jake Garvey, director of OEM sales, Garvey Corporation.

PMMI established the Mark C. Garvey scholarship to honor

the memory of Mark Garvey, former president and CEO of the Garvey Corporation, past chairman of PMMI, and longtime supporter of packaging education. Each fall, the Garvey family selects one PMMI Education Partner to receive this scholarship based on a commitment to excellence in the packaging industry. The school chooses a student to accept the award based on GPA, major, commitment to the packaging industry, extracurricular involvement, and nancial need.

The PMMI Foundation provides over $200,000 annually in scholarships to students attending PMMI Education Partner schools. These scholarships underscore PMMI’s commitment to the future of the packaging and processing industry.

For more information on the PMMI Foundation, visit pmmi. org/foundation. —Matt Reynolds

22 PW JAN2023 NEWS

BY THE NUMBERS

1.9B lb+

The amount of post-consumer PET collected in 2021 in the U.S. for recycling—the largest amount ever, according to NAPCOR—increasing PET recycling rates in the U.S. from 27.1% in 2020 to 28.6%

“As 2022 heads to its close, we’ve seen a return to normal that isn’t quite as normal as we had wished. There’s increased economic pressure on an already stretched global supply chain, increased focus on the foodservice packaging industry from a legislative and regulatory policy perspective, and movement and growth in both the foodservice segments drawing consumers and the ways in which they choose to have their foodservice delivered—or not.”

–Natha Dempsey, president of the Foodservice Packaging Industry (FPI), in a press release from the association, “Supply Chain Disruptions and In ation Continue to Impact Foodservice Packaging Industry”

“Between 2018 and 2020, the weight of our e-commerce in our sales nearly doubled from seven to 13%. Now, in 2022, in the post-COVID era, we see a certain slowdown of that growth, but we still continue to see that growth come in, and we are above 15% for the rst nine months of the year.”

29The number of Direct-to-Consumer companies Unilever has purchased since 2015, including Dollar Shave Club and Paula’s Choice

84%

The reduction in beverage container litter in states with bottle deposits; such laws have also been shown to increase recycling rates in states that have them versus those that don’t

–Bernard Meunier, executive vice president and head of strategic business units and marketing and sales at Nestlé, in an article from FoodNavigator-usa.com, “Nestlé aggressively pursues online sales, predicting a ‘rebound’ in e-commerce, rise of ‘channel-less commerce’”

“Digitalisation underpins automation, unlocking the potential of eCommerce and improves business operations based on data analysis. It is essential in the short term, with the looming recession, and it makes improving ef ciencies increasingly important. In the longterm, digitised packaging businesses will become more nancially and operationally attractive to customers as they will be able to produce material more cheaply and with eCommerce capabilities.”

–Rory Gopsill, associate analyst for Global Data, in an article from Inside Packaging magazine, “The trends shaping packaging in 2023”

6.3M MT

The amount of metric tonnes of global bioplastics production predicted by 2027, up from 2.23M MT in 2022, according to the European Bioplastics (EUBP) association

“Premium-priced products are at risk of being left on shelves, as consumers switch to private label/cheaper brand alternatives. This has clear implications for change on packaging design and costs. GlobalData forecasts that larger packs sizes, 3,001 to 5,000 g/mL, will grow in volume at a rate of 4.3% per year to 2025, outpacing that of smaller pack sizes. However, smaller pack sizes are still expected to continue to dominate the consumer packaging market overall. Longer term, rise of both shrink ation and larger pack sizes will lead to further polarization of packaging sizes in many product categories, with the standard medium-sized pack hit hardest.”

–Ramsey Baghdadi, consumer analyst at GlobalData, in a press release from the organization, “Medium-sized packaging hit hardest by in ation as customers turn to bulk buying or premiumization to get more bang for their buck, says GlobalData”

24 PW JAN2023 QUOTABLES

Inkjet

personalization

Package printing and

made easy

cartons,

print systems for high speed package personalization Print on corrugate,

mylar pouches, blister packs, clam shells, and other packaging materials Personalize with variable data such as barcodes, serial #'s, lot codes, expiry dates, graphics and other compliance information.

Minimize waste with print inspection and accurate job counts Minimize setup time with job storage and quick recall

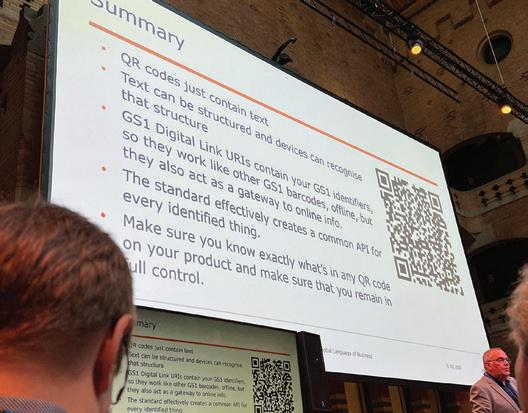

After Pandemic-Related Innovation Pauses, Active Packaging’s Back on Track

Packaging World sat down with Andrew Manly, managing director of AIPIA, at the AIPIA World Congress in Amsterdam, the Netherlands in November 2022. He helped to catch us up with all things active and intelligent packaging and gave us a valuable lens through which to view its recent growth.

Packaging World:

First, explain to our readers what AIPIA is and who you serve?

Andrew Manly:

AIPIA is the Active & Intelligent Packaging Industry Association. It was founded just over 10 years ago by a chap called Eef de Ferrante and myself. The aim is to make AIPIA a network hub, an information hub, and a meeting place for the smart packaging sector; those who are interested in it, and those who want to use it. A lot of companies entering the smart packaging space are not necessarily coming from a strong packaging background, so they need to know and understand the ways of the packaging industry, which is where I come in. We’ve created a website, which is really a place where people can gain information about those people who are active in this industry. Also, we run a regular newsletter which brings you up to date with some of the latest trends and activities from members, from brand owners, and from NGOs, anything and anyone that’s of interest.

From that, we extended our role into running live activities, which translates itself into the Congress you’re attending here in Amsterdam. It is a meeting place, a networking hub for the industry to talk to those companies, particularly brand owners who are interested in these technologies and who want to really start to adopt and implement the

smart packaging ideas into their daily packaging use. And that covers both active packaging—which is basically shelf extension and product safety—through to the sexier stuff, which is connected packaging. That can run from supply chain management, traceability, authentication, provenance, or anti-counterfeit, right through to the stuff that one of our regular exhibitors at the Congress showed you on the last session of the first day, which is how augmented reality can add a completely different dimension to your product, and entertain and engage consumers in completely new ways.

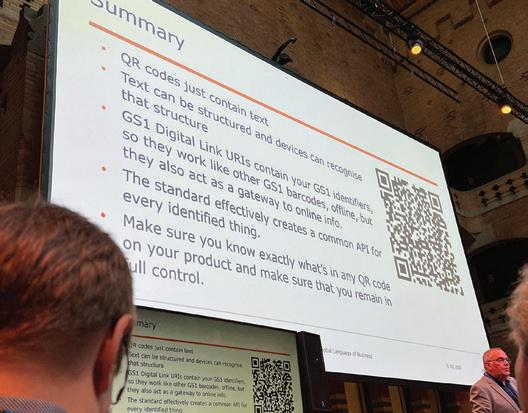

Read more details about the speci c technologies and systems debuted at the AIPIA World Congress on page 104.

Those are certainly top trends in packaging, but what specific technologies constitute active and intelligent packaging today? Obviously, technologies like RFID, NFC, QR codes, traceability, functionality, and all kinds of stuff around those, are where we’re at. And that’s a fast-moving and fast-developing sector. Particularly, we’re used to handle the digitization of packaging. And that includes not just the consumer-facing stuff, like the stuff [a consumer] can scan [on a smartphone], but also all of the background activity, the background software and search engines and data management and processing hubs that are so valuable, offering insights to the consumer in one way, and equally valuable to the product owners and the brand owners in the other.

A major takeaway from the brands I’m hearing from here at the AIPIA World Congress is that there are all sorts of interesting active and intelligent packaging capabilities available. But the challenge comes in knitting them together, often from several different suppliers and providers, with several different interfaces, into a practical, end-to-end product. Has this been your experience? There are lots of different technologies there, but one of the keys to opening and unlocking the usefulness of smart packaging is to combine technologies to provide a complete solution. And that’s one of the areas that AIPIA is working on, helping our members work together to offer the brands and the products a complete idea, rather than bits of ideas that need to be tted together.

We learned very quickly that a lot of [active and intelligent packaging suppliers] were going to brand owners and saying, “Well, look, hey, we got this wonderful capability.” To which the brands responded, “Yeah, it’s interesting, but how on earth do we use it in a real-life environment?”

26 PW JAN2023 FIRST PERSON

AUGER FILLERS | NET WEIGH FILLERS | CUP FILLERS | PISTON FILLERS | CHECKWEIGHERS VERTICAL FORM FILL & SEAL BAGGERS | LABELERS | UNSCRAMBLERS | CAPPERS PROUDLY MANUFACTURED & ASSEMBLED IN EXTON, PENNSYLVANIA & PHOENIX, ARIZONA. SINGLE SOURCE PACKAGING SOLUTIONS Bringing unsurpassed accuracy, efficiency, reliability & support to your packaging systems for more than 50 years. All-Fill packaging machines are engineered to excel with configurations built to outperform your production demands. ALLFILL.COM

One of the things that we had to really do is educate backwards, explaining that you can’t just take an RFID tag and tell a CPG that it does this, this, and this. You’ve got to have the complete background, the software programming, and the sustainability issues, which now are quite an important part. It’s a moving target, also, because elements like sustainability have come on the scene. Which probably 10 years ago, whilst it was important, it wasn’t really something we related to.

What did you expect to see at this World Congress?

We had a board meeting just before the event, and we picked out three pillars that seem to be key elements. One is recycling, one is food waste, and one is supply chain management. And we felt those are the three areas we need to be focusing on, as an industry. But one of the other elements that came out of that discussion—and was

from presenting at the Congress was from a company called Complete Inspection Systems, who is an American company and they’re doing really deep-dive QR codes. They can be quite dif cult [secure] in terms of anti-counterfeiting, so that your own U.S. Defense Department can use them. But also, they can have up to four functions in one code. You’re not just getting the normal barcode functions, you’re also getting consumer engagement, you’re getting deep security, and traceability just off a QR code. And the beauty of that is that you don’t always have to download an app to use a QR code.

But even with this increased amount of adoption, the fact is that a lot of [consumers] don’t really understand what’s on the pack when they see an RFID tag or a QR code, because nobody’s telling them what’s there to use, or how to use it.

I’ve seen loads of bottles of wine with RFID tags in my local supermarket, but nobody knows that they’re there because nobody’s telling people that they’re there. And they’re not exactly huge and easy to see, because you don’t want big RFID tags on small bottles of wine. Adoption is happening, but education is a big issue, and we are scratching our heads a little bit about that at the moment. And we will continue to work with other stakeholders, and it is something that we all are going to have to work on together to get the maximum benefit.

echoed in a lot of the presentations that we saw—is that we need to get the consumer a lot more on board with the technology. They need to understand it. And that is in-part our role, but we can only do so much. It needs the retailers and the brand owners to buy in to the technology, and not just in terms of using it, but in explaining to consumers the bene ts of it.

We’ve read that QR code adoption received a big boost among consumers since the outset of the pandemic, since touch-free ordering and menu access became prevalent. Was that evident at the event?

I think one of the things that was the great bene t to the industry, from a perverse point of view, in the COVID-19 pandemic was that people got used to remote shopping, scanning at restaurants, and non-contact access like the QR codes. And the QR code development has been quite exponential. There are a lot more people using more QR coding with more attributes to it. One of the guys who was out sick

Another effect of the pandemic was that there were fewer events over the past three years. Given this longer than usual time interval between major events (AIPIA World Congress is typically annual), have any trends become easier to spot, or maybe have accelerated since 2019? Did anything surprise you? We’re getting much more of a feel that there’s a lot more interest from the brand owners now. They’re much more focused on it. Digitalization is a key issue and I’ve just literally today read a report from one of the big research and analytics companies that’s saying in some respects, they can see digitalization in packaging becoming as important or even more important that sustainability in the current circumstances.

Visit pwgo.to/7826 to read about the digitalization report from GlobalData that Manly references above.

Whether they’re right or wrong, the fact that they’re even thinking about it that way shows how much the concept of digitization, smart packaging, and its use are getting further up the food chain.

Things like RFID are becoming a lot more ubiquitous, and not just in the apparel sector. We’re seeing a lot more uptake, and we are getting feedback from those companies who make them that there’s a lot more uptake, because obviously prices of the tags have come down and what they can do has improved. And you’ve got some big players, like Avery Dennison and others, who are really pushing the technology out so that you can now have, for example, RFID tags that

28 PW JAN2023 FIRST PERSON

can sit on metal and remain readable. Whereas, maybe five years ago, that was not a very distinct possibility. And they’re also much better in things like wet environments and other advances.

Does Moore’s Law apply here, where the technology improves and price goes down over time, as the hardware becomes more ubiquitous?

One of the inhibitors to using tagging or electronic antenna was that they had batteries, which contain some kind of conductive metal. We are now having companies like Wiliot, and they were here at the Congress, who have a battery-free tag which is much more feature driven. But it us also a lot easier to apply, is a lot more sustainable, and because it doesn’t contain [as much or any] metal, it is not as expensive to produce.

Looking back to 2019, one of the key differences [between then and now] is that is that [suppliers] have continued to develop the technology so that they’re more cost efficient and more cost effective. Because one of the walls that we have had to overcome—and there are still a few walls left—is a lot of brands like to use these technologies for campaigns or for particular product promotions, things like that. But using them in a general rollout was not as common as we would hope or expected to be. And that is partly due, we think, to the disruption caused by COVID-19. But we are now seeing the other side of it. In America for instance, Walmart is now mandating a lot of its suppliers to use RFID or codes on whole range of SKUs, which is encouraging. But we don’t see that rolling out yet to other big retailers in the way that we hope it will. But then, like all small industries, we all hope to go faster than we actually manage to do.

What did you see that’s new in traceability or track & trace?

You’ve got scanning technologies like the one that Systech uses, which is clever because it doesn’t require any amendments to the landscape of your packaging. [What the scanners are] picking up is differences—tiny, tiny differences—in the print register on each pack, and it can therefore use it as a unique identi er. Because they’ve developed in the software as well, they’ve also added in a lot more with product identi cation, and not just the traceability aspects. But even going into the [consumer] engagement side, you can say that as well. This is one of the things that I think Haleon and GSK liked about the Securikett [which they chose as a winner of a supplier challenge, more on page 106]. One of the reasons Securikett came out on top in the challenge was because they have both the hardware and the software elements in which they’re fairly well-developed, so only one provider of a solution instead of several. Another exhibitor, Kezzler, also has done a lot of work in traceability.

You already mentioned that sustainability, while important, wasn’t center of the bullseye for active and intelligent packaging as recently as five or six years ago. But that’s clearly changed. You mentioned recycling as a pillar, how and why is that?

It’s very important, and the Holy Grail 2.0 project [active and intelligent sorting of plastics at MRFs in Denmark, Germany, and France] has really developed very fast. They’re almost beyond the pilot stage with it now. They ran a pilot at the beginning of this year with Henkel, and now they’re going to be doing some more with it. At the Congress, there was another presentation from a company called FiliGrade Sustainable Watermarks, with the brand CurveCode, which embeds readable information about the plastic into the pack itself [so materials recovery facilities can scan and sort more easily]. But the nice thing about projects like Holy Grail is that they’re consortiums that span right across the value chain. They’re not just the smart and active packaging industry technologies who are trying to convince

people like Proctor and Gamble or Henkel to use these things. Also, we’re getting into reuse as well as recycle, and there are smart technologies like RFID in a company called 1Less. They’re doing an RFID-tagged set of cutlery, containers, cups, and saucers, that can be used in big venues [like sports or music, or in catering situations]. The consumer uses them, then puts them into a smart bin [trash can] and they’re automatically sent for washing and cleaning and reuse. But the good thing about them is that you can put any trash in the smart bin, and it will sort them out. The consumer doesn’t really have to think about separating.

30 PW JAN2023 FIRST PERSON

Another sustainability-related pillar of yours was food waste prevention. What do you see happening there?

Angela Morgan from Aptar was here, talking about active packaging and food waste prevention. And it’s such a big thing now—I’m sure there are more active packaging products out there than we are aware of because it’s one of those that I call an invisible technology.

You don’t know whether your plastic film on your snack wrapper has had a treatment on it unless you’re told. Provided again we can make the retailers understand both the consumer benefit and the cost benefit, I think that we’ll see a lot more active and monitoring devices on packs at item level, rather than at batch level. On your supermarket shelves, you might see some of these color changing labels getting going, stuff like that, because food prices are going through the roof. And people are becoming a lot more cost conscious and therefore, that should translate into better management of the food that you buy.

That’s where you get into nifty areas like dynamic pricing, correct?

There are a few dynamic pricing models out there. I’m not going so far as to say that everyone’s going to end up with an intelligent refrigerator. There are fridges like that already that will tell you when to use your products, but they’re probably quite expensive. And people don’t just change fridges every day because there’s a new feature. But in stores you’ll see active and compliance packaging. There was a lot of talk, if you recall, of GS1 rolling out coding and traceability standards,

and there’s better promotion of the bene ts of it now. That’s thanks to GS1 being a world network, and there’s a lot of people working with them now. A lot of drive comes from regulation, and I can only see regulation getting heavier rather than lighter in the next few years. I’m not talking about sustainable packaging. I’m talking about food regulation and food safety, and active and intelligent packaging can help there. So, those things are good for our industry.

Coming out of this latest AIPIA World Congress, where are you seeing active and intelligent packaging gaining the most traction?

In the early days, we thought that the things that would really excite the brands would be anti-counterfeiting and traceability, market diversion, avoidance, and all that. Actually, the thing that they really bit on was consumer engagement. It’s making a much closer relationship with their clients, with their consumers. And I don’t see that going away at all. Marks & Spencer had to cancel, but their contribution to the Congress was roughly going to be about consumer engagement aspects of active and intelligent packaging. And that was the thing that they as a retailer were interested in; in engaging their consumers more closely. We sort of went to the background elements of smart packaging a bit during COVID thing because other things, like safety, security, and traceability seemed to become more the focus. But now you’re getting a bit more relaxed again. We’re going to get more consumer engagement features, I think. —Matt Reynolds

32 PW JAN2023 FIRST PERSON

��������

��� ��

�� ������������ ��������� ���

��������� �������

����

�����

������

By Eric F. Greenberg, Attorney-at-law

Other Shoe Finally Drops on Cosmetics Regulation

In late December, the U.S. Congress passed, and President Biden signed, a big federal spending bill that included signi cant new changes to the laws applicable to cosmetics products. The new law places new requirements on cosmetics packagers, and gives FDA new powers over them. It’s a massive strengthening of FDA oversight over these products, and is the culmination of years of efforts by advocates for more FDA power, who asserted that FDA’s limited powers had resulted in safety issues.

Cosmetics companies will, starting December 29 of 2023, be required to register their facilities with FDA, and list with FDA the products they make (and update the list each year) including a list of their ingredients. They’ll also have to keep on hand records substantiating the safety of the ingredients they use in their cosmetic products, and report adverse reactions to its products. FDA gains new power to suspend a company’s facility registration if it thinks a product made there could be a danger to health, and can order a company to recall a product if it thinks there’s a “reasonable probability” that it’s adulterated and might be a danger to health and the manufacturer refuses to recall it. The new law calls on FDA to develop Good Manufacturing Practices regulations for cosmetics as well, and take steps to address asbestos in talc and PFAS in cosmetics.

Also, state and local governments are preempted by the new law from imposing other requisites relating to topics including those mentioned above, though they will maintain some powers over cosmetics, such as the ability to restrict some uses of specific ingredients.

The law’s definition of a “cosmetic” stays the same as it has been for decades:

The term “cosmetic” means (1) articles intended to be rubbed, poured, sprinkled, or sprayed on, introduced into, or otherwise applied to the human body or any part thereof for cleansing, beautifying, promoting attractiveness, or altering the appearance, and (2) articles intended for use as a component of any such articles; except that such term shall not include soap.

What you see here is a definition that incorporates one of the core concepts in FDA law, namely the packager’s or manufacturer’s intended use of a product.

What you also see here is that cosmetics’ intended use is all about making superficial changes to the body, not, for example, changing its structure. So, cosmetics include “skin moisturizers, perfumes, lipsticks, fingernail polishes, eye and facial makeup, cleansing shampoos, permanent waves, hair colors, and deodorants,” says FDA.

As noted, cosmetic products don’t need FDA approval before being marketed (except for the color additives in them), and the companies marketing the cosmetic can choose the ingredients they use, but have been responsible for assuring they are safe and must avoid the relatively small number of ingredients that are forbidden or restricted by FDA. It’s long been the rule that, as long as the ingredient and the cosmetic it’s in are “safe under labeled or customary conditions of use,” the product is “properly labeled,” and using the ingredient “does not otherwise cause the cosmetic to be adulterated or misbranded,” FDA says, the ingredient can be used.

Now, the packager will need to have proof of ingredients’ safety. What’s more, cosmetics labels had long needed to list the product’s ingredients on packages for retail customers, and also needed to include any material facts that would make use of the product safe, such as directions and relevant warning or caution statements, in addition to the common label elements for consumer products, which are a statement of identity, a statement of the net quantity of contents, and the name and place of business of the manufacturer, packer, or distributor. Now, companies will need to submit their ingredient lists to FDA each year.

Over my years practicing food and drug law, I have often found myself saying something to the effect that, of all the product types FDA regulates, it had the lightest touch on cosmetics packagers. It was a reflection primarily of FDA’s relatively limited legal powers over cosmetics, as opposed to drugs, foods, medical devices, biological products, animal foods and drugs, radiation-emitting articles, and tobacco.

And I sometimes wondered if saying that gave the false impression that cosmetics weren’t regulated at all, the same way too many people mistakenly think dietary supplements are not regulated simply because individual dietary supplement products aren’t specifically approved by FDA before they go to market. The reality is that supplement makers must, for example, follow Good Manufacturing Practices, comport with a range of labeling requirements and restrictions, and face important procedural steps when they decide to make “structure or function” label claims. That sure doesn’t seem ‘not regulated’ to me.

And in some ways, it was the same with cosmetics. For many years, cosmetics have been regulated in a variety of ways, even though individual products didn’t have to get FDA approval. The new law still doesn’t require premarket approval, but it sure does add lots of new requirements, such as those mentioned above. So, I think I will get out of the habit of using the expression “light touch” when describing FDA regulation of cosmetics. PW

Eric Greenberg can be reached at greenberg@efg-law.com. Or visit his rm’s website at www.ericfgreenbergpc.com.

34 PW JAN2023

THE LEGAL SIDE

ONLY, NOT

INFORMATIONAL

LEGAL ADVICE.

;FHZZR�UZRU UN(1&88.(r ;FHZZR�LWNUUNSL�X^XYJR 0JSTXr�08, 0JSTXr�0;, 0JSTXr�0;,1�8 MFSIQNSL 'JQQT\X HZUX 8ZHYNTS�HZUX 0JSTXr�08, 'FL�MFSIQNSL UN,7.5r ;FHZZR &ZYTRFYNTS ;FHZZR (TS[J^NSL 7TGTYNH ,WNUUNSL �NSKT�ZXF%UNFG�HTR ������������� *[TQ[NSL�FZYTRFYNTS

By Sterling Anthony, CPP, Contributing Editor

The Importance of Pallet Patterns

Palletization provides ef ciencies and economies by treating multiple boxes of product as a unit load rather than individually. Those bene ts are inherent and self-presenting. Optimizing palletization, however, requires knowledge-based decision making. Optimization must include considering how many boxes are put onto a pallet and how they are arranged on the pallet. Such is the essence of pallet patterns.

Optimization differs from maximization. The latter seeks to achieve the most from a given variable. The former seeks to achieve the best trade-offs among multiple variables. Optimized pallet patterns balance requirements for density, stability, and strength. Those requirements must be consistent with product characteristics, but also with the limitations imposed by material handling equipment, transportation conveyances, and storage conditions.

Citing transportation as an example, pallet patterns influence cube utilization, and therefore, impact the number of conveyances needed and their fuel and emissions. So as with everything related to packaging, pallet patterns have a sustainability component.

By its nature, a palletized load is of a size and weight that makes it a hazard to nearby personnel, if the load were structurally compromised. A load should remain intact until disassembled. Any prior event in which it comes apart can result in injury. Even in the absence of injury, there is the potential for damage to the goods. When damage renders goods unsellable, all the expended labor, time, and resources will have been squandered. But pallet patterns should not be the sole means for achieving load integrity. Auxiliary means, such as slip sheets, corner boards, straps, and stretch wrap play a role.

configurations. Typically, an interlocking pattern will result in fewer boxes per pallet.

Regardless of the chosen pallet pattern, there are fundamentals to be followed. One is to make sure that the pallet is of adequate design and construction. Another is to cover fully the surface area of the pallet, while avoiding overhang and its associated problems. Still another is to make sure that boxes are arranged such that bar codes and RFID tags are readable.

As packaging levels go, palletization is tertiary, distinguishable from primary which contains the product, and from secondary (the boxes). There are two approaches to integrating the levels.

The first and most common approach starts with the design of the primary package. Afterwards, a case-count is designated. Lastly, a pallet pattern is chosen. The approach is fraught with elements of default.

Optimizing palletization requires knowledge-based decision making. Optimization must include considering how many boxes are put onto a pallet and how they are arranged on the pallet. Such is the essence of pallet patterns.

With the second approach, the design of the primary package and of the secondary package are done to best utilize the dimensions of the pallet. Such does not mean that marketingrelated concerns have to be sacrificed, just that they be satisfied within certain constraints regarding size and shape. Case counts—often arbitrarily a dozen or multiple thereof—instead, are designated to accommodate case dimensions that complement pallet dimensions. This approach requires a series of mathematical calculations that can be tedious, if done longhand.