PERLITE TODAY PERLITE TODAY

It was so nice to finally get to interact in person with so many of you last year, and I am looking forward to our 2023 Annual Meeting in Athens, Greece in September. We are still in the process of planning the logistics of visiting Imerys on the beautiful Island of Milos while we are there. As soon as we work out those details, we will let you know the exact meeting dates. In the meantime, mark your calendars for September, either September 17 – 21 or 22. We will provide an update as soon as arrangements are finalized. Save the date! You won't want to miss this meeting!

I feel it is important to talk about another great membership resource, as well as the incredible members who have put in countless hours to update and improve Perlite Institute resources for the benefit of all members. Our resource library is a phenomenal member benefit provided by the Institute. Members can use the brochures for their own education, as well as share it with their customers. There are over 80 information-packed brochures to use on topics including: industrial applications, horticulture, filtration, environmental, sustainability, construction, and insulation. These brochures are educational in nature and range from general information about perlite to technical facts and applications.

If questions are more specific than what is covered in the brochures, members and the public can also reach out to our technical consultants… another great Perlite Institute benefit! Chuck Vogelsang and Panagiotis Angelopoulos can be contacted through the Technical Inquiries section on the Contact page of the Perlite Institute website.

Hess Perlite has benefitted many times over the years, as we have been able to provide customers with added information through these brochures. There have even been times when we have been able to reach even deeper into membership resources to access years of expertise, knowledge, and experience from the Perlite Institute’s consultants. I hope all our members are aware of these benefits, and I encourage you, if you aren’t taking advantage of these resources, to please give it a try. At Hess Perlite, we personally feel it is a tremendous benefit of our membership.

I wanted to give a huge shoutout to all the amazing work all the different committees are accomplishing together with the brochure committee to produce and update several brochures each year. I encourage you to get involved with these committees and share your thoughts and ideas with Brochure Committee Chair Alan Kiraly for future brochures. He can be reached at alan@supremeperlite.com

I look forward to becoming more engaged in all the committee work this year. Thank you to all the members currently serving on our respective committees. Your time, effort and knowledge are appreciated. The Perlite Institute is always in need of volunteers for our committees so please reach out to offer your services.

Best Regards, Jake

PERLITE INSTITUTE, INC. is a quarterly publication of the PERLITE INSTITUTE, INC.

2207 Forest Hills Drive Harrisburg, PA 17112 USA Phone: 717.238.9723

Fax: 717.238.9985

www.perlite.org

Jake Hess President Hess Perlite 100 Hess Drive Malad City, ID 83252 Phone: (208) 766 - 4777 jake@hesspumice.com

Alan Kiraly Vice President Supreme Perlite 4600 N. Suttle Road Portland, OR 97217 Phone: (503) 286 - 4333 alan@supremeperlite.com

Perlite Today is published electronically four times per year.

Reema Bolokbaeva Gulf Perlite, LLC Techno Park, PO 263275

Jebel Ali, Dubai, UAE Phone: +971 (0)56 6080223 admin@uaeperlite.com

Linda Chirico Carolina Perlite Company PO Box 158 Gold Hill, NC 28071 Phone: (704) 279-2325 lchirico@carolinaperlite.com

Michael Dunlavey P.V.P. Industries PO Box 129 North Bloomfield, OH 44450 Phone: (440) 685-4701 mike@pvpind.com

Israel Ferreres Treasurer Ausperl 177 Balmes Street Barcelona, Spain 08006 +34 633 066 006 israel@ausperl.com

Keith Hoople Past President Midwest Perlite, Inc. 4280 West Parkway Blvd. Appleton, WI 54913

Phone: (920) 731-2671 keith@midwestperlite.com

Jannick Knudsen

Nordisk Perlite

Hammersholt Erhvervspark 1-5 Hillerod, DK 3400

Phone: 0045 7878 9515 jannick@nordiskperlite.dk

Bridget Sheehy Tipton Whittemore Company 681 East 5th Street, Unit 1 Boston, MA 02127

Phone: (978) 815-6420 bsheehy@whittemoreco.com

Edgar Valmana Velazquez

Termolita

Callejon del Marmol 201 Zona Industrial Santa Catarina, NL 66364

The mission of the Perlite Institute is to further the success and growth of the perlite industry worldwide by providing its members networking opportunities, education and research; foster customer-driven marketing, promotion and product development; and increase the public’s awareness and knowledge of perlite and its current and potential uses.

Matt Goecker Dicalite Management Group 1 Belmont Avenue, Suite 500 Bala Cynwyd, PA 19004 Phone: (775) 287-9796 mgoecker@dicalite.com

Phone: +52 8181510480

evalmana@termolita.com

by Denise R. Calabrese, CAE

by Denise R. Calabrese, CAE

Just like other businesses, customer engagement is key to the success of the Perlite Institute. But, what does that mean? How can the Perlite Institute engage its customers on a regular basis to communicate the value of membership?

The Perlite Institute’s customers are its members and membership is at the business level. People make up those businesses and our customers include both the business owners and the individuals who work for those member companies. So, how do we reach out to everyone to communicate the value of membership? Let’s look at a couple of ways we try to do that:

1. Each member company can list three contacts who can receive information about the Perlite Institute. These individuals receive regular communications from the Institute via email, including this newsletter, invitations to educational events, and important news and information.

2. Member companies can send as many people as they want to the annual meeting. (We do understand there is a cost to do so; however, there is no limit to the number of people who are able to attend.) At that meeting, members can learn more about the Perlite Institute and its activities including committee work being conducted, research being funded, and leadership activity.

3. Committee involvement is open to all who work for member companies! In fact, committees will accept those with an interest in that committee’s activity and are looking for more people to volunteer. Serving on committees provides the opportunity to not only learn more about that particular area of the Perlite Institute, but also network with other members you may not know.

4. The Perlite Institute engages the services of two technical consultants who are available to answer questions received from members and from the general public. Have you received a question and are not sure how to answer? As a member of the Perlite Institute, you have access to those consultants! You can either direct inquiries to them through the website here or you can refer the individual making the inquiry to visit the website and ask their question directly. If YOU have a question for the consultants, you have direct access to them as well! Simply email them at techadvice@perlite.org or techconsult@perlite.org and both Chuck and Panos will receive your questions and help you with an answer.

These are just three examples of how your company – and the individuals who make up that company – can engage with the Perlite Institute. Have you considered getting involved? Do you read the newsletter when you receive it? Do you forward the newsletter on to colleagues so they have the benefit of reading news from the Perlite Institute? Have you used the services of our consultants?

The Perlite Institute can only share how you can make the most of your membership. It then is up to you to engage with the organization! We hope you will consider engaging with us and making the most of your membership. The time is NOW!

It is with deep regret that we announce the death of Perlite Institute member, Paul Dunlavey. Paul passed away on Monday, November 28, 2022. He was 80 years old. He was a valued member of our Perlite Institute community, and he will be greatly missed.

Paul was President and Founding Owner of P.V.P. Industries, North Bloomfield, Ohio. He was a fervent supporter of the Perlite Institute. Paul served on the Board of Directors for many years, most recently as Treasurer of the organization. Until recently, he attended meetings every year; and he always enjoyed seeing his friends and colleagues from around the world.

“I will always remember Paul’s laugh and smile,” said Perlite Institute Executive Director Denise Calabrese, CAE. “He lit up a room when he arrived and was always happy to see you! Paul also had a strong financial mind and served the Perlite Institute well as its Treasurer on the Board of Directors. Under Paul’s leadership, we created an investment policy for the organization that the board continues to use. Paul and his wife, Diann, attended meetings of the Perlite Institute each year and many times brought their family members with them. Paul was so willing to share information that he invited the Perlite Institute to hold a tour of his facility for the members attending the meeting in Ohio. Paul will be missed.”

We all extend our heartfelt sympathy to Paul’s family and all who loved him. Click here to read his obituary.

We are also sorry to announce the death of long-time Perlite Institute member, Niels Knudsen. Niels passed away on March 11, 2023 after a long illness.

Niels was founder of Nordisk Perlite ApS. He was an active member and great supporter of the Perlite Institute. Niels sat on the Board of Directors and attended annual meetings. In 2004, he was the distinguished recipient of the Perlite Institute's Lewis Lloyd Award.

Niels will be especially remembered by employees, customers, and colleagues in the industry for his enormous passion and knowledge of perlite and its production. Frank Petterson of Supreme Perlite shared his fond memories of Niels, “Because we were in the same business, we were friends; and because we appreciated each other’s perspectives, we were even better friends. Many times, Niels brought his family with him to the meetings, so we saw his boys grow to young adults; and he passed on his leadership position to one of them. Our daughters very infrequently joined in with the perlite meetings, but both have husbands who are in the thick of it (perlite) now. So, both our families represent relatively small business concerns, but represent the best of small business… something to be very proud of. We all will miss Niels and will cherish memories we created together.”

Niels is survived by his wife, Anne; three children, Pia, Victor and Jannick; as well as three grandchildren.

Timely, relevant, and accurate information makes it easier for businesses to grow and prosper. Perlite Institute members have access to vital industry information through complimentary technical guides in our online library. Members also have access to the Perlite Institute's studies and research in the members only section of the website. This material helps you grow your business and supports our collective knowledge about perlite and its uses.

“Perlite Institute members and technical consultants work collaboratively to develop these key resources,” explains Alan Kiraly, who chairs the Perlite Institute Brochure Committee. The work of the committee is presented in a "technical guide" format that is intended to serve as a resource and educational tool for both industry professionals and the general public.

The Perlite Institute is committed to serving as a resource on perlite and leading the industry forward in promoting its use.

Three new technical brochures were recently posted to the Perlite Institute website.

Perlite Filter Aid: Beer Filtration presents basic aspects of beer filtration using filter aids, and the advantages of using perlite as a filter aid. It is superior to other alternatives due to its purity and the elimination of risk from contamination by heavy metals, its low density and consequent reduction of filter aid mass, and its widespread availability and general reliability of supply. Click here to read more or download.

Among the many valuable applications of expanded perlite, mineral processing, speci cally for gold and silver extraction, is among the most important. In the most common extraction method, gold and silver are leached from the ore using cyanide solution then precipitated with zinc powder or adsorbed on activated carbon. In either process, solid-liquids separation via ltration provides an integral step to carbon recovery, precipitates collection, or pregnant solution clari cation.

Filter aids made with perlite o er a critical performance boost to any ltration process. Filter aids are used either as precoat to form a permeable layer on the lter septum before ltration initiation, or as body feeds (or body aids) during the ltration process. ey are vital additives to the process because their use enhances ltration performance in a variety of ways.

Filter aids improve the permeability of the lter cake, give the ltrate more clarity, and help prevent the septum from blinding. Perlite lter aid is widely used in such applications, applied either as precoat on the septum and/or as body feed in the liquid, providing enhanced performance due to its unique properties.

e Merrill-Crowe Process e Merrill-Crowe process, also called the zinc dust cementation process, is a widely used method for its simple and e cient operation for gold and silver recovery from cyanide leachate solution. e unit operations of the Merrill-Crowe process include: solid-liquid separation, clari cation, vacuum de-aeration, zinc addition and ltration of precipitated gold and silver. e entire process is depicted in Figure 1.

A er the ore is leached with cyanide, the pregnant solution is ltered to remove solids in suspension.

Solid-liquid separation is applicable only when heap leaching is applied and is carried out using thickeners. e clari ed solution is then de-oxygenated in a vacuum tower known as a Merril-Crowe Tower. Zinc dust is then added to the solution of gold cyanide using a belt conveyor or vibrating tables. A reaction ensues wherein gold is precipitated out from the cyanide solution and deposited on the surface of the zinc—the cementation process. e zinc-gold particles are then large enough to be mechanically separated using a lter press.[1]

a high-performance lter aid media.

e ltration process is an important step to ensuring the quality of beer because it helps stabilize beer, and gives it a polished, clear appearance, while removing elements that might make it unpalatable. Depth ltration is widely applied for this purpose, with lter aid media playing a decisive role in processing perfor- mance and the quality of the nal product. is document presents basic aspects of beer ltration using lter aids, and the advantages of using perlite as a lter aid (PFA). PFA is superior to other alternatives due to (i) its purity and the elimination of risk from contamination by heavy metals, (ii) its low density and consequent reduction of lter aid mass, and (iii) its widespread availability and general reliability of supply.

where sodium cyanide and oxygen have been added to dissolve gold into a solution. In the absorption stage, this solution ows through several agitating tanks containing activated carbon. Gold absorbs onto the activated carbon, which ows countercurrent to the pulp, while screens separate the barren pulp from the gold-loaded carbon.

As ltration processes go, beer-making is one of the more demanding processes because it must meet high standards for clarity, avor, and purity, while

and later when separating the precipitated metals. e pregnant solution is rst clari ed in lters such as horizontal leaf type clari ers. Precoating allows the production of an extremely clear solution. For e ciency, it is recommended to use two lters; one which is in use, and another which is being cleaned, precoated, and readied for service as soon as the rst is brought o ine. e solids removed by these lters are of no value and are back ushed to tails. Final ltration of the precious metals is accomplished by the precipitate lter feed pumps and lter presses. Most lters are either the plate and frame type or the recessed plate type. Filter cake is collected in the chambers between the plates and can be air blown to remove a substantial amount of water. In a continuous operation, a process will have several lter presses in parallel so that one lter can be cleaned while the others are kept in operation, typically on a ve- to seven-day cycle.

). It is resistant to chemical attack, odorless, pH neutral and can be produced to comply with ASTM C332 and ASTM C549. Construction grade expanded perlite replaces chemical insulators

and products such as expanded polystyrene (EPS), extruded polystyrene (XPS), and polyurethane foam. Such chemical products are highly combustible, contain Volatile Organic Compounds (VOCs), are organic and deteriorate with time. For example, the performance of cellular plastic foams as insulating materials is not stable over the long-term (see Figure 1). Both EPS and XPS deterio- rate with time in two main stages. In the primary stage (under 5 years), air from the outside penetrates the insulating material and replaces the insulating gas inside each enclosed cell. In the secondary stage (5 years and up), the gases that penetrated the internal air bubbles are slowly lost to the outside without being replaced, resulting in gradual shrinking of volume. e morphological change and the replacement of low conductivity gas with air causes an overall decrease in thermal resistance of the foam-based insulation.

Carbon-in Leach (CIL) di ers from CIP in that it is a simultaneous leach and absorption process. e CIL process was developed in response to gold ores that contain material that consumes too much of the pregnant solution, such as natural absorptive carbon. is type of carbon a ects yield by attracting gold meant instead for the activated carbon. e simultaneous leaching and absorption process of CIL helps to minimize this problem.

Perlite: e Safe and Fully Natural Material Both unexpanded and expanded forms of perlite are fully natural, inert, mineral-based materials. No long-term health e ects have been linked to perlite mining, processing, or application and installation activities, provided that the prescribed occupational exposure limits (OEL) and means of using Personal Protective Equipment are observed. For more infor- mation, see the relevant information published by the Perlite Institute.

maintaining uniform quality from bottle to bottle, and across the di erent brewing locations operated by the same brand. Key ingredients to maintaining that balance constitute the microbial load, the water quality, the control of yeast and bacteria content, clari cation, stabilization and nal ltration. e importance of ltration lies in the fact that contami- nants such as particles, crystals, treatment residue, organic aggregates, bacteria and yeast can all risk a ecting product quality and jeopardize the beverage’s nal taste.

As noted above, ltration takes place in several stages, both when clarifying the pregnant solution,

Carbon-in-Pulp(CIP)and Carbon-inLeach(CIL)Methods Gold also has a natural a nity for carbon, and because of this, another common industrial practice is gold recovery from cyanide solution by adsorption on activated carbon. Two main variants of the process are in use today: the Carbon-in-Pulp (CIP) method, and the Carbon-in-Leach (CIL) method [2] Carbon-in-Pulp (CIP) is the sequential leaching then absorption of gold from ore. During the CIP process, pulp ows through several agitating tanks

Filtration is the last major step in the beer-making process, and following fermentation and maturation. e aim is to remove solids—mostly yeast and other impurities—that are le in the beer following brew- ing. Filtration typically takes place just above 0°C in candle or plate lters until the desired clarity is achieved. More information on these and other types of ltration systems can be found in the Perlite Institute brochure Perlite Filter Aid for Vacuum & Pressure Filtration

Perlite lter aid is created through the expansion of perlite ore, the milling of that expanded perlite, and the classi cation of milled expanded perlite using cyclonic air separation. A range of perlite lter aid grades are produced, in terms of size, with varying technical properties to optimize ltration capacity for a wide variety of applications. e various grades utilize the jagged interlocking structures of the particles to create billions of microscopic channels between the lter aid particles (Figure 3). Perlite lter aids have gained acceptance in almost every industry concerned with the separation of liquids and solids, and even gasses and solids. In the mineral processing sector, perlite and diatomaceous earths are the most widely used lter aids.

PerliteFilterAidExplained

Perlitevs.DiatomaceousEarth(DE) Perlite lter aids are functionally like DE lter aids; in fact, both are used interchangeably when the collected solids are not wanted for subsequent treat ment. However, the di erent origin and physicochemical properties render perlite advantageous the following ways:

■ Perlite has 30-50% less bulk density, resulting 30-50% less mass needed for a given ltration application.[3],[4]

■ A wide network of perlite suppliers assures quick and uninterrupted local supply.

■ Perlite lter aid contains little to no crystalline silica, thus posing less of a health risk.

■ Perlite lter cake is not considered hazardous, not subject to strict disposal regulations.[5]

■ Perlite lter aid contains signi cantly lower iron, which can be detrimental to some processes.

Embodied Energy and Embodied Carbon Embodied energy (EE) and embodied carbon (EC) constitute two important metrics for examining the relative amount of energy involved in manufacturing a product. Embodied energy accounts for the energy used for extracting and processing of raw materials, manufacturing, transportation and distribution, and nal construction or assembly. Embodied

Perlite lter aid enhances the performance of the above processes in the following ways:

Perlite’s Role in Filtration

For the removal of carbon nes generated during the many adsorption process steps, thus keeping all of the internal screens and lters free from premature plugging with carbon nes.

■ For the concentration of carbon solids and removal of additional spent cyanide solution, aiming at the e cient recovery and dewatering of the carbon before the regeneration step. For the recovery of other metals (Pt, Cu, Mn, Co, Ni, etc.), which follow the precipitation step and subsequent solid-liquid separation through ltration.

Perlite lter aids have the following advantages:

■ Low lter cake density (< 270 kg/m3)

■ Grades can be tailored to custom applications

■ Wide permeability range

carbon is the sum of fuel-related carbon emissions (i.e. embodied energy that is combusted, but feedstock energy retained within the material) process-related carbon emissions (i.e. non-fuel emissions that may arise, for example, from chemical reactions). is document follows a cradle-to-gate approach, in which the impact of the product considered from the point of extraction of the materials up to distribution of the nished goods. Figure 2 and Figure 3 present embodied energy and embodied carbon, respectively, under the cradle-to-gate boundaries, for perlite and other insulating materials. Expanded Perlite has minimal embodied energy and embodied carbon compared to all other organic and inorganic alternatives. e values for perlite ore are 0.66 MJ/kg and 0.03 kg CO2 eq/kg, respectively.

■ More economical (as much as half as much mass is needed per unit of volume)

Less cake cracking and easy cake release

■ Sterile and inert

Perlite: The Most Sustainable Insulation Solution for Buildings points out that perlite is one of the most overlooked insulating materials, especially as it offers numerous advantages over other organic and inorganic insulation materials. Perlite is very much seen as a sustainable, natural and user-friendly alternative in the marketplace. Find out more here.

■ Safe to handle and easy to dispose

Global Warming Potential and Applications

Global Warming Potential (GWP) is the appraisal material’s relative contribution to greenhouse gas emissions, such as carbon dioxide (CO2), methane (CH4), and ozone (O3). GWP is calculated at the manufacture (Stage A), use (Stage B), and end-of-life

Perlite Filter Aid: Extractive Metallurgy explains that expanded perlite filter aid plays an essential role in the gold and silver mining process. Read more here

The number of inquiries received last year was 50% more than the year before (154 in 2022 vs. 104 in 2021). This year has started out with very few inquiries. There does not seem to be a pattern on when they come in as seen below.

Chuck Vogelsang, Perlite Institute Technical Consultant

Chuck Vogelsang, Perlite Institute Technical Consultant

Filtration:

• What perlite filteraid would be recommended for water treatment? This would be determined by the particles to be removed, the rate required, and the equipment being used.

• What PFA for pathogen and bacteria removal is recommended? The grade is dependent on the material to be removed, the equipment being used, and the targeted outcome. Recommended contacting filter manufacturers for their recommendations based on the conditions required.

The major areas of interest are reasonably consistent over time with construction, insulation, and filtration being the majority.

• Is there a concern about soluble chlorides in perlite coming into contact with stainless steel? There are no soluble chlorides in expanded perlite. Provided PI bulletin on typical perlite chemistry.

Insulation:

• What would be the expected R value for LWC? This would be dependent on the density and mix of the LWC as well as the thickness of the pour. Included PI bulletins on LWC and roof decks.

A few of the more interesting inquiries are summarized below:

Construction:

• Group wanted to know if light weight concrete roof could be used to span a 10 meter distance without supports. We recommended against this and referred our roof deck bulletins as to how such spans are bridged. Provided PI bulletins on LWC and roof decking.

• Inquirer wanted to know the differences between light weight concretes and foamed. Got fantastic input from Kostas at Gulf Perlite as to the differences.

• Person wanted to use loose fill for insulating a very old house. Informed them that one could expect a R factor of 3 for every 1 inch of thickness. Sent bulletins on Loose Fill as well as health effects. Instructed them to seal every opening since the perlite flows like water. Also that the PI recommends one wear a respirator when handling perlite.

Horticulture:

• Person wanted to know where to get bulk bags and expanded perlite. Gave him a list of PI members near him.

Nowadays, expanded perlite experiences increasing interest in a wide range of applications, with more and more scientific studies focused on its multidisciplinary applicability. The aim of the current article is to present 4 recent research studies that were published in prominent journals in 2023, and involve the use of expanded perlite in new applications that spread from the environmental sector, to energy saving applications in renewable energy sources and bio composites for construction purposes.

The first work is entitled “A pioneering study on the recovery of valuable functional compounds from olive pomace by using supercritical carbon dioxide extraction: Comparison of perlite addition and drying” presented in Separation and Purification Technology journal (Argun et al. 2023). Researchers applied supercritical carbon dioxide extraction to a mixture of two-phase olive pomace (olive pomace and olive oil) with perlite aiming to prevent the environmental risk that may arise from the leachate. Critical environmental parameters were chemical oxygen demand (COD), solid matter (SM), volatile solids matter (VSM), total nitrogen (TN), oil grease, pH, electrical conductivity (EC) and toxicity. Expanded perlite was mixed with two-phase olive pomace by a rate of 1:2 (w/w) to absorb water content and increase the interaction of CO2 with the pomace due to the high surface area.

It was found that indeed the diffusion of CO2 into the sample was enhanced by perlite thus being favourable to the process efficiency. The authors concluded that perlite usage was considered as an environmentally friendly and economically viable solution to absorb moisture of OP in recovering phenolics and fatty acids from it by supercritical carbon dioxide extraction. Main groups of the valuable compounds such as secoiridoids, flavonoids and phenolic alcohols were detected in the starting material (pomace) as 400, 290 and 100 mg/kg, respectively, while their concentrations increased up to 16430, 7370 and 3280 mg/ kg in the extracts. By this suggested application, while some valuable compounds were being recovered, the potentially toxic constituents such as oil-grease and TPC were withdrawn, then OP toxicity potentially reduced, therefore, the pomace residue can be used for soil reclamation.

The second paper is entitled “Evaluation of the impact of different composite phase change materials on reduction in temperature and enhancement of solar panel efficiency” and presented in Journal of Energy Storage (Govindasamy and Kumar 2023). The study deals with an important problem related to the efficiency of the solar panels; the amount of electricity produced by a solar panel is very sensitive to the temperature at which it is operating, on a way that the higher the temperature of a Photovoltaic system, the lower the efficiency of its conversion of sunlight into electricity. Therefore, the concept investigated is the use of phase change material (PCM) to reduce and manage the temperature of solar photovoltaic panels and through this increase the electrical energy efficiency. The considered system consists of monocrystalline solar panel joined individually with vermiculite and paraffin jelly composite PCM, as well as with expanded perlite and paraffin jelly composite PCM. PCMs were prepared in mass ratio of paraffin jelly: perlite of 50:50 (wt%). The mixture was heated and stirred in a beaker at 60 °C and subsequently vacuum was applied.

It was found that the PCM integrated panel that was used was successful in lowering the maximum temperature that could be reached by the photovoltaic, as shown in Figure 1, increasing the power output, and increasing the electrical efficiency. Without PCM the average efficiency was 15.78%, using perlite PCM the efficiency reached 17.98%.

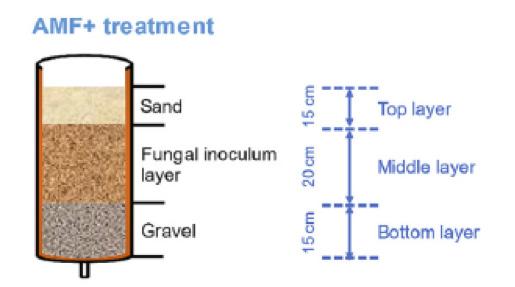

Constructed wetlands (CW) are treatment systems that use natural processes involving wetland vegetation, soils, and their associated microbial assemblages to improve water quality. An interesting paper was presented in Journal of Water Process Engineering by Hu et al. entitled “Do mycorrhizal symbiosis affect wastewater purification in constructed wetlands with different substrates?” (Hu et al. 2023). The researchers tested wastewater purification efficiency in wetlands filled with different substrates, including perlite, in the presence of arbuscular mycorrhizal fungi (AMF). Other substrates used were vermiculite, sand, biochar.

The authors concluded that adsorptive substrates (perlite, vermiculite, and biochar), AMF, and G. maxima significantly increased the pollutants (TOC, TN, PO43-P and NH4+-N) removal from wastewater in CWs. It was also shown that the application of adsorptive substrates in CWs showed a more critical role in pollutant removal than AMF inoculation, indicating that the presence of adsorptive substrate addition could improve the CWs performance in purifying wastewater.

Bio-composite materials consisting of agricultural wastes has gained importance because of the increasing urbanization that made lightweight construction materials with low thermal conductivity of interest. In a recently published study, Kolak and Oltulu investigated the use of camelina stalks which is considered an agricultural waste, in the production of bio-composite (Kolak and Oltulu 2023). The article is presented in Construction and Building Materials entitled “Investigation of mechanical and thermal properties of new type bio-composites containing camelina”

In the composite, unsaturated polyester was used as binder together with expanded perlite in various ratios.

The composite materials were investigated in terms of physical, thermal and mechanical characteristics, as well as microstructure. The most critical conclusions are the following:

• As the amount of camelina stalks and expanded perlite increased, the water absorption of the composite increased.

• As the filler amount increased, the unit weight decreased.

• The thermal conductivity coefficient is low due to the high void ratio of low unit weight composites.

• Camelina stalk and expanded perlite contain micropores that efficiently increase the thermal insulation of the building materials.

• The addition of expanded perlite reduced the thermal conductivity of composites from 15.29% to 39.27%.

• As a general comment, it is suggested that the composite material have a promising potential as lightweight insulation material.

Bibliography

1. Argun ME, Arslan FN, Ates H, et al (2023) A pioneering study on the recovery of valuable functional compounds from olive pomace by using supercritical carbon dioxide extraction: Comparison of perlite addition and drying. Sep Purif Technol 306:. https://doi.org/10.1016/j. seppur.2022.122593

2. Govindasamy D, Kumar A (2023) Evaluation of the impact of different composite phase change materials on reduction in temperature and enhancement of solar panel efficiency. J Energy Storage 60:106631. https://doi. org/10.1016/j.est.2023.106631

3. Hu B, Hu S, Vymazal J, Chen Z (2023) Do mycorrhizal symbiosis affect wastewater purification in constructed wetlands with different substrates? J Water Process Eng 52:. https://doi.org/10.1016/j.jwpe.2023.103498

4. Kolak MN, Oltulu M (2023) Investigation of mechanical and thermal properties of new type bio-composites containing camelina. Constr Build Mater 362:129779. https://doi. org/10.1016/j.conbuildmat.2022.129779

by Jeff Tippett

by Jeff Tippett

As I begin this three-part series on vision, I think it’s best to start by understanding the ‘why’ of vision. We know that vision helps bring your team onboard.

However, I think it’s even bigger than getting your team onboard. And I believe that with many segments— including younger team members—it’s more than just why.

I firmly believe that it’s essential that you know why what you do matters. Otherwise, what you do may be of little interest to those with whom you work. Vision gives purpose to the work.

Most successful visions include a grounding from the past and a plan for the future while acknowledging and embracing the challenges of today.

I like this quote from Bill Hybels: “Vision is a picture of the future that produces passion.”

It’s obviously important to plan for the future. But critical to realizing that future is believing in it passionately—and if you’re part of a team, conveying that passion.

You probably know where you want to take your team; in fact, you may even have a statement hanging on the wall. Vision is where you communicate to your team what matters most. A team leader must lay out the plan and follow it through, or there’ll be no cohesion.

John Graham outlined a few reasons why vision is critical. Consider these:

A vision inspires action.

A vision is a practical guide.

A vision helps keep organizations focused.

The value of these three can’t be overstated. Vision gives you a roadmap to achieve your goals, the inspiration to act on those goals and the framework to keep you focused on achieving them. That trifecta is key.

In considering vision, think also about the role that each player fills. It’s not enough to outline how things ought to be, with no consideration of how the members of your team interact under the vision’s framework.

Focus is essential when undertaking complex tasks. I’m sure there have been plenty of instances in which a longterm project was underway, consuming weeks or months of your time. How is it possible to achieve these tasks without a North Star, a clear pathway and focus on what it means? It isn’t.

Another topic to consider is the difference between your mission statement and your vision statement. That’s right, they’re distinct.

I’m sure your organization has a mission statement, something that describes what it is you’re doing and how you’re doing it. But that’s for the short-term.

When considering your vision statement, it must accommodate the desired trajectory of the organization— where you hope to be in a year, five years, 10 years. A clear and compelling vision requires that those around you and those from the outside know where you want to take the organization. It gives purpose to the team and prevents your work from stagnating.

Finally, in terms of focus, you need to be able to lend your hand where necessary, but delegate everything else. I advocate for the 80/20 method of leadership: Focus on the 20 percent of work that is essential and delegate the other 80 percent. You have a team around you for a reason, and they’ve earned your trust. Don’t be afraid to leverage them to make the company as a whole perform better.

Jeff Tippett is the international best-selling author of two books, Pixels Are the New Ink and Unleashing Your Superpower: Why Persuasive Communication is the Only Force You Will Ever Need. Speaking to international audiences through keynotes and seminars, Jeff helps attendees

increase their effectiveness, gives them powerful tools to reach their goals, and empowers attendees to positively impact and grow their organizations or businesses.

Social Media Icons

In 2014, Jeff founded Targeted Persuasion, an award-winning public affairs + communications firm. He has worked with renowned brands like Airbnb, The National Restaurant Association, The League of Women Voters, The League of Conservation Voters, plus others. Other industry experts have validated Jeff’s work with numerous awards including the prestigious The American Advertising Award.

Metro Style

Jeff is the host of Victory by Association with Jeff Tippett, a podcast that shares the victories of association executives with the world, highlighting the great work done across this country every day.

Social Media Icons

Social Media Icons

Metro Style

Metro Style

Jefftippett.com

VictoryByAssociation.com

The Horticultural Committee is working on a FAQ (frequently asked questions) document for the website. The committee is looking for questions you receive on a regular basis from customers or other individuals that could be answered in a FAQ document.

Do you have some questions that would be appropriate to include in a FAQ document related to use of perlite in horticulture? The questions can be simple or in-depth. The committee will review the questions received and develop answers to then post to the website.

If you have questions to share, please send them to info@perlite.org. The committee would like to post the FAQ document in the near future, so please send your questions by April 15. Thank you for your consideration of this request!