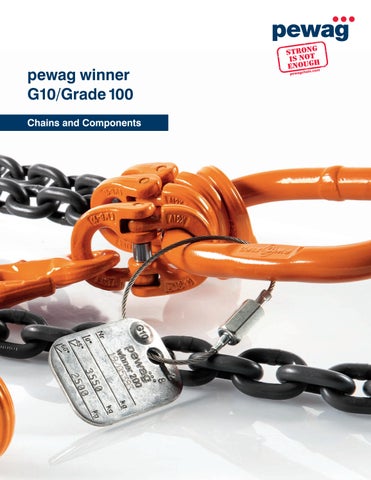

pewag ChainsG10/Gradewinner100andComponents

2 G10/Grade 100 winner History

First documented references of a forging plant in Brückl 1803 Founding of a chain forge in Graz 1923 Merger of plants in Graz and Kapfenberg Creation of the name“pewag” 1975 Established pewag Inc. the North American Distribution Company 2014 pewag opens first chain production plant outside Europe in Pueblo, CO pewag acquires Terrier Lifting Clamps 1787 Founding of a chain forge in Kapfenberg 1836 Establishment of an iron casting plant in Brückl 1912 Production of the first Snow Chain worldwide 1947 Production of the first Tire Protection Chain 2013 Creation of pewag Mexico 2015 pewag is the first producer of Friction Welded Chains Timetable of important events

At the core of chain innovation since 1479 pewag is one of the oldest chain manufacturers in the world and the company’s history goes back over 535 years when the first production facility was established in the town of Brückl, Austria in 1479. With over 535 years of engineering and manufacturing know-how, pewag has continued its research and development to provide the highest-quality innovative chain products to the market.

The pewag brand is well known for premium-quality chain products around the world and is well established as a global market leader. Today, pewag is the technological innovator in the high quality chain business. Stringent demands are placed on all employees to ensure high standards of quality.

pewag products The pewag group has a substantial and diverse spectrum of products and services. • Industrial Lifting Chains & Components • Traction Chains (cars, trucks, special purpose vehicles) • Tire Protection Chains (mining vehicles) • Conveyor and Hoist Chains & Components • Security Chains pewag,ContactInc 600 W. Crossroads Parkway Bolingbrook, IL 60440 P: 630.566.1394 F: pewagchain.comsales@pewagchain.com630.759.0788 1479

3 Features and Benefits ..............................................4 Lifting Chain WIN 200 / G10/Grade 100 Round Steel Chain 5 Master Links & Sub Assemblies AW / Master Link 6 MW / Enlarged Master Link 7 BW / Transition Link ..................................................... 8 VW / Quad Leg Master Link Assembly. 9 VMW / Enlarged Quad Leg Master Link Assembly 10 VAW / Special Quad Leg Master Link Assembly. 11 VLW 1 / Master Link Assembly 12 VLW 2/4 / Master Link Assembly 13 VSW 2/4 / Oversize Master Link Assembly 13 VSAW 1 / Master Link Assembly 14 VSAW 2 / Master Link Assembly/Double Leg 15 KMGW 1 / Enlarged Clevis Master Set 16 KMGW 2 / Enlarged Clevis Master Set/Double Leg 17 KMGW 4 / Enlarged Clevis Master Set/Quad Leg 18 VMXKW 1 / Clevis Master Set 19 VMXKW 2 / Clevis Master Set/Double Leg 20 VMXKW 4 / Clevis Master Set/Quad Leg 21 LXKW 1 / Clevis Master Set 22 LXKW 2 / Clevis Master Set/Double Leg 23 LXKW 4 / Clevis Master Set/Quad Leg 23 Lifting Accessories CW / Connex Connecting Link 24 CLW / Connex Connecting Link 25 CARW / Round Sling Connecting Link 25 AGWW / Load Distributor 26 HSW / Eye Sling Hook 27 LHW / Eye Safety Hook 28 WLHW / Swivel Safety Hook ...................................... 29 WLHBW / Swivel Safety Hook 29 WSBW / Swivel Hook 30 FW / Foundry Hook .................................................... 30 PW / Eye Grab Hook 31 PSW / Eye Grab Hook w/Safety Catch 32 XKW / Clevis Shortening Hook .................................. 32 BWW / Sheet Metal Plate Hook 33 GHW / Fork Hook 33 G10/Grade 100 winner ContentsLiftingAccessories (cont.) SCHW / Shackle 34 GSCHW / Bow Shackle 34 KNEW / Toggle 35 KRW / Coupling Ring 35 KOW / Clevis Reeving Link 36 AWHW / Weld-on Hook 36 KHSW / Clevis Sling Hook 37 BKHSW / Oversize Clevis Sling Hook 38 KFW / Clevis Foundry Hook 38 KLHW / Clevis Safety Hook 39 KPW / Clevis Grab Hook 40 KPSW / Clevis Grab Hook w/Safety Catch 41 KSCHW / Clevis Shackle 41 UEW / Transition Assembly 42-43 Lashing winner G10/Grade 100 Lashing 44 RSW / Loadbinder .............................................. 45 RSPSW / Loadbinder 45 KSSW / Loadbinder 45 Spare Parts KBSW / Clevis Load Pin 46 KBMSW / Bolt-Nut-Split Pin 46 SFGW / Safety Latch Set 47 SFGW-G / Safety Latch Set 47 SFGW-B / Safety Latch Set 47 SFGW-A / Safety Latch Set 47 CBHW / Connex Pin and Bushing Set 48 CLBHW / Connex Pin and Bushing Set 48 PSGW / Safety Catch 49 VLHW / Trigger Set 49 ID Sling Tags 49 G100 Slings Choosing a Sling 50 Sling Types ......................................................... 51 Chain Slings Working Load Limit 52-53 User Information ........................................ 54-58 Terms and Conditions 59

All dimensions given in this catalog are nominal dimensions. Depending on the production process they are subject to various manufacturing tolerances. Please contact our customer service if required.

• pewag is the first to offer parallel hooks with 100% load capacity – shortening of the sling chain does not require a reduction in load caused by shear effect of the hook!

• Pioneer: pewag was the first to sell G10/Grade100 lifting chains, therefore providing a wealth of experience in this field.

Three assembly systems of slings: welded, Connex and Clevis system.

• Quality grade stamp pewag winner 200 chain links are marked “pewag 10” at a spacing of approximately 12 inches on sizes up to 1/2”, and every 36 inches on chain 5/8” and larger. Additionally, “10” is marked on the back of each link.

•

4 G10/Grade 100 winner pewag is among the world’s best manufacturers of lifting chains for a good reason, as our products are the result of a responsible development process that focuses on user-friendliness and safety. These features are clearly measurable and form the basis of the pewag product development and manufacturing process, where only the best results count! pewag alloy chains are tested to a 25% higher standard! pewag G10/Grade 100 meets the EN-818 Standard that pull tests to 2.5 times the WLL, whereas the US standards only require pull testing to 2 times the WLL. • 25% higher load capacity compared to Grade 80. • Simplified handling thanks to a 30% weight reduction. G10/Grade 100 winner Features and Benefits In Safety Lies Strength. Lifting chains in G100 quality –benefits that outweigh the rest. CapacityLoad (lb) Grade 80 Grade 100 Max. % of ReductionWeightRequiredChainSize WeightChain (lb/ft) RequiredChainSize WeightChain (lb/ft) 5,000 3/8˝ 1.65 5/16˝ 1.06 36% 15,000 5/8˝ 4.22 1/2˝ 2.80 34% 20,000 3/4˝ 6.00 5/8˝ 4.22 30% 35,000 1˝ 10.21 3/4˝ 6.00 41% • Attractive price/performance ratio thanks to the small price differential compared to Grade 80. • One dimension smaller than Grade 80 slings, for many load ranges – thus providing excellent value. • Extended service life due to higher wear resistance. • Code on chain and component ensures traceability of all manufacturing data. • High-visibility orange powder-coating for simple visual identification of our G10/Grade 100. • Largest range of components in special G10/Grade 100 quality – for 11 chain dimensions. • Fastest and simplest assembly of slings thanks to VXKW set with unique shortening element. • Additional safety feature compared to shortening claws, thus reducing risks resulting from improperly attached chains of our shortening hooks. • Easier and faster annual inspection as fewer components are used. • Compatible with our G8/Grade 80 range – used slings are easy to repair. NOTE: Grade 100 components may be used to repair Grade 80, but not at an increased load capacity!

• Worldwide distribution network – smooth supply of spare and replacement parts.

• Quality-approved European production by an ISO 9001 certified company.

5 D P W1 W2 winner 200 / G10/Grade 100 Round Steel Chain Highest quality G10/Grade 100 chain. Operating temperature is -40°F to 400°F NOT for temperatures under -40°F or over 400°F Standard surface: shot blasted, clear coated winner 400 G10/Grade 100 lifting chain has an operating temperature of -40°F to 700°F but is available by special order only. Code ChainSize WLL (lb) BreakingLoad (lb) ThicknessNominalD PitchP (inch) WidthInsidemin.W1 (inch) WidthOutsidemax.W2 (inch) LengthDrum (feet) Weight (lbs/ft) WIN 6 200 (Formerly NI5.50) 7/32˝ 2,700 10,800 0.217˝ (5.5 mm) 0.67 0.31 0.83 400 0.47 WIN 7 200 (Formerly NI70) 9/32˝ 4,300 17,200 0.276˝ (7mm) 0.83 0.37 0.99 800 0.80 WIN 8 200 (Formerly NI80) 5/16˝ 5,700 22,800 0.315˝ (8mm) 0.94 0.43 1.13 500 1.06 WIN 10 200 (Formerly NI100) 3/8˝ 8,800 35,200 0.394˝ (10mm) 1.18 0.53 1.46 400 1.65 WIN 13 200 (Formerly NI130) 1/2˝ 15,000 60,000 0.512˝ (13mm) 1.54 0.69 1.84 200 2.80 WIN 16 200 (Formerly NI160) 5/8˝ 22,600 90,400 0.630˝ (16mm) 1.89 0.85 2.27 150 4.22 WIN 20 200 (Formerly NI190) 3/4˝ 35,300 141,200 0.787˝ (20mm) 2.36 1.05 2.73 100 6.00 WIN 22 200 (Formerly NI220) 7/8˝ 42,700 170,800 0.866˝ (22mm) 2.60 1.16 3.12 100 7.98 WIN 26 200 (Formerly NI260) 1˝ 59,700 238,800 1.024˝ (26mm) 3.07 1.38 3.70 100 10.88 WIN 32 200 (Formerly NI320) 1-1/4˝ 90,400 361,600 1.260˝ (32mm) 3.78 1.70 4.53 50 16.20

6 G10/Grade 100 winner AW / Master Link This is a standard master link, ideal for simple, speedy assembly of single and double leg chain slings using the CWP Connex Connecting Links. For Triple and Quad Leg slings it can only be used in conjunction with BW Transition Links in VW Quad Leg assemblies. May also be used as a master link in welded systems. Also suitable as an end link. t s dw Code legSinglesling legDoublesling (90SafetyWLL4°-45°) (lb) (90SafetyWLL5°-45°) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 d (inch) t (inch) w (inch) s (inch) Weight (lbs/pc) AW (Formerly10 A100) 7/32˝ 3,800 3,800 1.6 2.5 0.39 3.15 1.97 0.39 0.31 AW (Formerly13 A130) 9/32˝ 7/32˝ 5,800 5,800 2.5 4 0.51 4.33 2.36 0.39 0.75 AW (Formerly16 A160) 5/16˝ 9/32˝ 7,500 7,500 2.5 4 0.63 4.33 2.36 0.55 1.17 AW (Formerly18 A180) 3/8˝ 5/16˝ 10,000 10,000 5 6 0.77 5.31 2.95 0.55 2.03 AW (Formerly22 A220) 1/2˝ 3/8˝ 16,700 16,700 6 8 0.91 6.30 3.54 0.67 3.53 AW (Formerly26 A260) 5/8˝ 1/2˝ 26,000 26,000 8 10 1.06 7.09 3.93 0.79 5.42 AW (Formerly32 A320) 3/4˝ 5/8˝ 39,100 36,600 10 12 1.30 7.87 4.33 1.02 9.13 AW (Formerly36 A360) 7/8˝ 3/4˝ 61,100 55,500 16 20 1.42 10.24 5.51 1.14 13.71 AW (Formerly45 A450) 1˝ 7/8˝ 83,100 83,100 25 32 1.77 13.39 7.08 28.26 AW (Formerly50 A500) 1-1/4˝ 1˝ 111,000 111,000 32 40 1.97 13.78 7.48 1.69 36.49 AW (Formerly56 A560) 1-1/4˝ 156,600 147,300 32 40 2.20 15.75 7.87 59.55 AW (Formerly72 A720) 234,900 188,600 50 63 2.76 18.11 9.84 99.87

7 Code legSinglesling legDoublesling WLL (90° - 45°) (lb WLL (45° - 30°) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 d (inch) t (inch) w (inch) s (inch) Weight (lbs/pc) MW (Formerly10M100) 7/32˝ - 3,800 2,700 2.5 4 0.43 3.54 2.56 0.39 0.48 MW (Formerly13M130) 9/32˝ 7/32˝ 6,100 4,300 4 5 0.55 4.72 2.76 0.39 0.97 MW (Formerly16M160) 5/16˝ 9/32˝ 8,400 6,000 5 6 0.63 5.51 3.15 0.51 1.56 MW (Formerly18M180) 3/8˝ 5/16˝ 12,800 9,100 6 8 0.75 6.30 3.74 0.55 2.40 MW (Formerly22M220) 1/2˝ 3/8˝ 18,500 13,200 10 12 0.91 6.69 4.13 0.67 3.83 MW (Formerly26M260) 5/8˝ 1/2˝ 30,000 21,400 10 12 1.06 7.48 4.33 0.79 5.83 MW (Formerly32M320) 3/4˝ 5/8˝ 45,000 32,100 12 16 1.30 9.06 5.12 1.02 10.52 MW (Formerly36M360) 7/8˝ 3/4˝ 61,100 43,600 20 25 1.50 10.83 5.90 1.14 16.46 MW 56 1-1/4˝ 1˝ 111,000 79,200 50 63 2.20 13.78 9.84 1.81 48.36 MW / Enlarged Master Link MW Enlarged Master Link is ideal for the simple, speedy assembly of Single and Double Leg chains using Connex connecting elements, as a master link in welded systems and as an end link. Its inner dimensions are larger than those of the AW Master Link, making it suitable for larger crane hooks or special hooks. The MW Enlarged Master Link must not be used for Triple/Quad Leg chains, except when combined with BW Transition Links in VMW Quad Leg assemblies. t s dw

8 G10/Grade 100 winner BW / Transition Link These links are NOT sold separately. They are only available as part of a master link assembly. The information provided is for dimensional purposes only. t s dw Code WLL (90° - 45°) (lb) d (inch) t (inch) w (inch) s (inch) Weight (lbs/pc) BW 7 2,200 0.28 1.42 0.63 0.07 BW 8 3,080 0.31 1.42 0.63 0.11 BW 9 4,180 0.35 1.73 0.79 0.15 BW 10 5,500 0.39 1.73 0.79 0.20 BW 13 8,800 0.51 2.13 0.98 0.39 0.37 BW 16 14,740 0.67 2.76 1.34 0.55 0.86 BW 20 22,000 0.79 3.35 1.57 0.55 2.20 BW 22 27,500 0.91 4.53 1.97 0.67 2.55 BW 23 30,800 0.91 4.53 1.77 0.67 2.55 BW 26 35,640 1.06 5.51 2.56 0.79 4.22 BW 27 41,800 1.06 5.51 2.17 0.79 4.22 BW 32 58,300 1.30 5.90 2.76 1.02 6.95 BW 36 68,200 1.30 6.69 2.95 9.57 BW 40 88,880 1.57 6.69 3.15 9.06 BW 45 93,280 1.77 6.69 3.15 15.73 BW 50 140,800 1.97 7.87 3.94 23.28

9 Code Consisting of WLL (90° - 60°) (lb) WLL (60° - 45°) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) t (inch) w (inch) s (inch) Weight (lbs/pc) VW (Formerly6 V5.50) AW 18 + 2 BW 13 8,100 6,500 2.5 4 6.06 4.33 2.36 0.39 1.14 VW (Formerly7/8V70-80) AW 22 + 2 BW 16 14,800 12,100 6 8 9.06 6.30 3.54 0.67 5.10 VW (Formerly10 V100) AW 26 + 2 BW 20 22,900 18,700 8 10 10.43 7.09 3.94 0.79 8.40 VW (Formerly13 V130) AW 32 + 2 BW 22 39,000 31,800 10 12 12.40 7.87 4.33 1.02 14.21 VW (Formerly16 V160) AW 36 + 2 BW 26 58,700 47,900 16 20 15.74 10.24 5.51 1.14 22.13 VW (Formerly19/20V200) AW 50 + 2 BW 32 91,700 74,900 32 40 19.69 13.78 7.48 1.69 49.76 VW (Formerly22 V220) AW 50 + 2 BW 36 110,900 90,600 32 40 20.47 13.78 7.48 1.69 53.99 VW (Formerly26 V260) AW 56 + 2 BW 45 155,100 126,600 32 40 22.44 15.75 7.87 82.72 VW (Formerly32 V320) AW 72 + 2 BW 50 234,900 191,800 50 63 25.98 18.11 9.84 146.52 VW / Quad Leg Master Link Assembly This standard master link assembly is ideal for preparing Triple and Quad Leg chain slings in assembled or welded systems. Consists of an AW Master Link and two BW Transition Links. A flattened section on the transition links open up additional, universal connection possibilities (measurements can be obtained from the product “BW”). t s w e

10 G10/Grade 100 winner Code Consisting of WLL (90° - 45° ) (lb) WLL (45° - 30° ) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) t (inch) w (inch) s (inch) Weight (lbs/pc) VMW (Formerly6VM5.50) MW 18 + 2 BW 13 12,800 9,100 6 8 8.43 6.30 3.74 0.55 3.15 VMW (Formerly7/8VM70-80) MW 22 + 2 BW 16 18,500 13,200 10 12 9.45 6.69 4.13 0.67 5.42 VMW (Formerly10VM100) MW 26 + 2 BW 20 30.000 21,400 10 12 10.83 7.48 4.33 0.79 8.84 VMW (Formerly13VM130) MW 32 + 2 BW 22 45,000 32,100 12 16 13.58 9.06 5.12 1.02 15.65 VMW (Formerly16VM160) MW 36 + 2 BW 26 61,100 43,600 20 25 16.34 10.83 5.90 1.14 24.91 VMW 19/20 MW 56 + 2 BW 32 111,000 79,200 50 63 19.69 13.78 9.84 1.81 62.39 VMW 22 MW 56 + 2 BW 36 111,000 79,200 50 63 20.47 13.78 9.84 1.81 66.62 VMW / Enlarged Quad Leg Master Link Assembly This master link assembly for Triple and Quad Leg chain slings in assembled or welded systems. Consists of an MW Master Link and two BW Transition Links. A flattened section on the transition links opens up additional, universal connection possibilities (measurements can be obtained from the product “BW”). This master link assembly has larger inside dimensions than the VW Quad Leg Master Link Assembly and can thus also be used for the next size up crane hooks. t s w e

11 Code Consisting of WLL (90° - 45°) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) t (inch) w (inch) s (inch) Weight (lbs/pc) VAW 7 AW 18 + 2 AW 13 11,000 5 6 9.65 5.31 2.95 0.55 3.78 VAW 8 AW 22 + 2 AW 16 13,860 6 8 10.63 6.30 3.54 0.67 5.85 VAW 10 AW 26 + 2 AW 18 51,392 8 10 12.40 7.09 3.94 0.79 9.46 VAW 13 AW 32 + 2 AW 26 35,420 10 12 14.96 7.87 4.33 1.02 19.93 VAW 16 AW 36 + 2 AW 32 55,220 16 20 18.11 10.24 5.51 1.14 31.97 VAW 19/20 AW 50 + 2 AW 36 90,420 32 40 24.61 13.78 7.48 1.69 69.32 VAW 22 AW 50 + 2 AW 45 104,280 32 40 27.17 13.78 7.48 1.69 92.82 VAW 26 AW 50 + 2 AW 50 127,600 32 40 29.53 15.75 7.87 1.69 124.08 VAW 32 AW 50 + 2 AW 56 187,000 50 63 33.86 18.11 9.84 1.69 217.84 VAW / Special Quad Leg Master Link Assembly This Quad Leg master link assembly can be used for Triple/Quad Leg chain slings in the assembled or welded system and is even more versatile due to universal connection possibilities. Consists of an AW Master Link and two smaller AW Master Links as transition links. If safety is your strongest argument, you can’t do better than to choose this Quad Leg master link assembly with extra-large transition links for assembling your chain slings. For use in rope slings, please note that the load capacity utilizes a safety factor of 4. t w e

12 G10/Grade 100 winner Code Consisting of WLL (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) s (inch) Weight (lbs/pc) VLW 1-6/7/8 LW 22 + BW 13 5,500 25 32 15.51 0.91 13.39 7.09 0.67 7.41 VLW 1-10 LW 27 + BW 16 8,800 25 32 16.14 1.06 13.39 7.09 0.79 10.47 VLW 1-13 LW 27 14,740 25 32 13.39 1.06 13.39 7.09 0.79 9.68 VLW 1-16 LW 32 22,000 25 32 13.39 1.30 13.39 7.09 1.06 14.74 VLW 1-19/22 LW 40 41,800 25 32 13.39 1.57 13.39 7.09 1.14 22.00 VLW 1 / Oversize Master Link Assembly This master link assembly is for Single Leg chain slings in assembled or welded systems. Consists of an extra-large LW Master Link. The two smallest sizes use a BW Transition Link. Extra-large links make this master link assembly the perfect partner for crane hooks according to DIN 15401 up to no. 25 and according to DIN 15402 up to no. 32. A flattened section on the transition links open up additional, universal connection possibilities (measurements can be obtained from the product “BW”). t s w e d

This master link assembly is designed for the effortless creation of Consists of an oversize Transition The flattened section on the transition links opens

Double and Quad Leg chain slings in assembled or welded systems.

Links.

SW Master Link and two BW

up additional, universal connection possibilities. Extra-large links make this master link assembly the perfect partner for crane hooks according to DIN 15401 up to no. 40 and according to DIN 15402 up to no. 50. t s w e d

13 Code Consisting of WLL (90° - 45°) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) s (inch) Weight (lbs/pc) VLW 2-6/7/8/4-6 LW 22 + 2 BW 13 7,810 25 32 15.51 0.91 13.39 7.09 0.67 7.79 VLW 2-10/4-7/8 LW 27 + 2 BW 16 12,320 25 32 16.14 1.06 13.39 7.09 0.79 11.26 VLW 2-13/4-10 LW 27 + 2 BW 20 20,900 25 32 16.73 1.30 13.39 7.09 1.06 17.18 VLW 2-16/4-13 LW 32 + 2 BW 22 30,800 25 32 17.91 16.26 13.39 7.09 1.14 27.10 VLW 2-19/4-16 LW 40 + 2 BW 26 46,640 25 32 18.90 16.26 13.39 7.09 1.14 30.45 VLW 2/4 / Oversize Master Link Assembly This master link assembly is designed for the effortless creation of Double and Quad Leg chain slings in assembled or welded system. Consists of an extra-large LW Master Link and two BW Transition Links. The flattened section on the transition links opens up additional, universal connection possibilities (measurements can be obtained from the product “BW”). Extra-large rings make this master link assembly the perfect partner for crane hooks according to DIN 15401 up to no. 25 and according to DIN 15402 up to no. 32. t s w e d Code Consisting of WLL (90° - 45°) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) s (inch) Weight (lbs/pc) VSW 2-10 / 4/8 SW 30 + 2 BW 20 12,320 40 50 20.28 1.18 16.92 8.66 0.94 17.95 VSW 2-13 / 4/10 SW 33 + 2 BW 20 20,900 40 50 20.28 1.30 16.92 8.66 1.02 21.25 VSW 2-16 / 4/13 SW 36 + 2 BW 22 30,800 40 50 21.46 1.42 16.92 8.66 1.14 27.10 VSW 2-19/20 / 4/16 SW 45 + 2 BW 26 46,640 40 50 22.44 1.77 16.92 8.66 42.99 VSW 2/4 / Oversize Master Link Assembly

14 G10/Grade 100 winner Code Consisting of WLL (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) s (inch) Weight (lbs/pc) VSAW 1-10/13 SAW 32 + BW 20 22,000 50 63 23.03 1.30 19.69 9.84 1.02 22.00 VSAW 1-16 SAW 32 22,000 50 63 1.30 19.69 9.84 1.02 20.50 VSAW 1-19 SAW 40 35,200 50 63 1.57 18.11 9.84 1.26 28.86 VSAW 1-22 SAW 45 49,280 50 63 1.77 19.69 9.84 39.16 VSAW 1-26 SAW 50 73,920 50 63 1.97 18.11 9.84 1.69 46.16 VSAW 1-32 SAW 56 88,000 50 63 2.20 18.11 9.84 58.70 VSAW 1-32/320 SAW 60 88,000 100 125 2.36 31.50 12.60 2.13 105.60 VSAW 1 / Master Link Assembly Ideal for the quick and safe mounting of transition assemblies. These master links make it possible to create extremely short assemblies, facilitating the switch from a large to a small crane hook - useful in many lifting and transport processes! Consists of an extreme oversize SAW Master Link. The smallest size uses a BW Transition Link. This standard master link assembly is ideal for preparing Single Leg chain slings in assembled or welded systems and have a load capacity of up to 88,000 lbs. Extra-large internal link dimensions that are suitable for single hooks according to DIN 15401 no. 50/100 or for double hooks according to DIN 15402 no. 63/125 are yet another outstanding feature of these products. t w e d t s dw

15 Code Consisting of WLL (90° - 45°) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) Weight (lbs/pc) VSAW 2-10/13 / 4-10 SAW 32 + 2 BW 20 20,900 50 63 23.03 1.30 19.69 9.84 23.50 VSAW 2-16 / 4-13 SAW 40 + 2 BW 22 30,800 50 63 22.64 1.57 18.11 9.84 33.97 VSAW 2-19/20 / 4-16 SAW 45 + 2 BW 26 46,640 50 63 25.20 1.77 19.69 9.84 47.61 VSAW 2-22 / 4-19/20 SAW 50 + 2 BW 32 66,000 50 63 24.01 1.97 18.11 9.84 60.06 VSAW 2-26 / 4-22 SAW 56 + 2 BW 32 88,000 50 63 24.01 2.20 18.11 9.84 76.82 VSAW 2-26 / 4-22 / 320 SAW 60 + 2 BW 32 88,000 100 125 37.40 2.36 31.50 12.60 123.73 VSAW 2 / Master Link Assembly The VSAW 2 assembly comes with the same benefits as the VSAW 1 Assembly and can also be used to create transition assemblies. This system is ideal for simplifying lifting and transport processes as it enables the creation of very short transition assemblies. Consists of an extreme oversize SAW Master Link with two BW Transition Links. With a load capacity of up to 88,000 lbs, these master links may be used to create Double, Triple, and Quad Leg chain slings in the assembled or welded system. The flattened section on the links make them universally adaptable and the extra-large interior dimensions of the links make them easy to use with single hooks according to DIN 15401 no. 50/100 or double hooks according to DIN 15402 no. 63/125. t w e d

16 G10/Grade 100 winner Code Chain Size WLL (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) s (inch) Weight (lbs/pc) KMGW 1-6 7/32˝ 2,700 4 5 5.94 0.55 4.72 2.76 0.39 1.39 KMGW 1-7 9/32“ 4,300 4 5 6.42 0.55 4.72 2.76 0.39 1.43 KMGW 1-8 5/16˝ 5,700 5 6 7.20 0.63 5.51 3.15 0.51 2.01 KMGW 1-10 3/8˝ 8,800 6 8 8.35 0.75 6.30 3.74 0.55 3.37 KMGW 1-13 1/2˝ 15,000 10 12 9.21 0.91 6.70 4.13 0.67 5.69 KMGW 1-16 5/8˝ 22,600 10 12 10.43 1.06 7.48 4.33 0.79 9.13 KMGW 1-19/20 3/4˝ 35,300 12 16 12.76 1.30 9.06 5.12 1.02 15.67 KMGW 1-22 7/8˝ 42,700 20 25 14.84 1.50 10.83 5.91 1.14 25.00 KMGW 1 / Enlarged Clevis Master Set The MW Master Link and the welded-in KRW Captive Coupling are the perfect pair for creating Single Leg chain slings in the assembled system. The chain is mounted directly in the coupling, thereby eliminating the need for an additional connecting link. Disassembly is also simple and can be completed without special tools. However, make sure that it is performed by a qualified person. An added benefit from the enlarged internal dimensions of the master link make it suitable for the next size up crane hook. t w e d s

17 Code Chain Size WLL (90° - 45° ) (lb) WLL (45° - 30° ) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) s (inch) Weight (lbs/pc) KMGW 2-6 7/32˝ 3,800 2,700 4 5 5.94 0.55 4.72 2.76 0.39 1.52 KMGW 2-7 9/32˝ 6,100 4,300 5 6 7.20 0.63 5.51 3.15 0.51 2.49 KMGW 2-8 5/16˝ 8,100 5,700 6 8 7.99 0.75 6.30 3.74 0.55 3.48 KMGW 2-10 3/8˝ 12,400 8,800 10 12 8.74 0.91 6.69 4.13 0.67 5.60 KMGW 2-13 1/2˝ 21,200 15,000 10 12 10.00 1.06 7.48 4.33 0.79 9.52 KMGW 2-16 5/8˝ 32,000 22,600 12 16 12.00 1.30 9.06 5.12 1.02 18.67 KMGW 2- 19/20 3/4˝ 49,900 35,300 20 25 14.53 1.50 10.83 5.91 1.14 26.76 KAGW 2-22 7/8˝ 60,400 42,700 25 32 17.40 1.77 13.39 7.09 47.32 KMGW 2 / Enlarged Clevis Master Set This makes the master set with a MW Master Link and two welded-in KRW Captive Couplings even better suited for creating Double Leg chain slings in the assembled system. Product features include easy assembly and disassembly by a qualified person without the need for special tools – benefits that speak for themselves! Extra-large internal dimensions of the master link also make this system suitable for the next size up crane hook. The chain is mounted directly into the captive coupling, eliminating the need for an additional connecting link. t w e d s

18 G10/Grade 100 winner Code Chain Size WLL (90° - 45° ) (lb) WLL (45° - 30° ) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) s (inch) Weight (lbs/pc) KMGW 4-6 7/32˝ 5,700 4,000 6 8 9.65 0.75 6.30 3.74 0.55 4.28 KMGW 4-7 9/32˝ 9,100 6,400 10 12 11.14 0.91 6.70 4.13 0.67 7.28 KMGW 4-8 5/16˝ 12,100 8,500 10 12 11.14 0.91 6.69 4.13 0.67 7.41 KMGW 4-10 3/8˝ 18,700 13,200 10 12 12.87 1.06 7.48 4.33 0.79 12.24 KMGW 4-13 1/2˝ 31,800 22,500 12 16 16.10 1.30 9.06 5.12 1.02 24.58 KMGW 4-16 5/8˝ 47,900 33,900 20 25 19.29 1.50 10.83 5.91 1.14 38.96 KMGW 4-19/20 3/4˝ 74,900 53,000 50 63 23.39 2.20 13.78 9.84 1.81 82.94 KMGW 4-22 7/8˝ 90,600 64,000 50 63 24.49 2.20 13.78 9.84 1.81 101.46 KMGW 4 / Enlarged Clevis Master Set This clevis master set consists of the VMW Enlarged Quad Leg Master Link assembly and four welded-in KRW Captive Couplings. This master set is ideal for the creation of Quad Leg chain slings in the assembled system. The chain may simply be mounted directly into the captive coupling by a competent person, without the need for special tools. Disassembly is also easy and fast. Enlarged internal dimensions of the master link make this product suitable for the next size up crane hook – one of the outstanding pewag features! The coupling pin and the lock pin are available as KBSW spare parts sets. t w e d s

19 Code Chain Size WLL (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) Weight (lbs/pc) VMXKW 1-6 7/32˝ 2,700 4 5 8.03 0.55 4.72 2.76 1.63 VMXKW 1-7 9/32˝ 4,300 4 5 9.53 0.55 4.72 2.76 2.34 VMXKW 1-8 5/16˝ 5,700 5 6 10.31 0.63 5.51 3.15 2.86 VMXKW 1-10 3/8˝ 8,800 6 8 12.56 0.75 6.30 3.74 5.15 VMXKW 1-13 1/2˝ 15,000 10 12 14.69 0.91 6.69 4.13 9.68 VMXKW 1-16 5/8˝ 22,600 10 12 16.69 1.06 7.48 4.33 16.42 VMXKW 1 / Clevis Master Set With this assembly, there is no compromise when it comes to security. This master set consists of a MW Enlarged Master Link and a welded-in XKW Shortening Hook for the creation of Single Leg chain slings in the assembled system. The chain is mounted directly into the coupling unit of the shortening element, thereby eliminating the need for an additional connecting link. The hook functions both as a connecting link and a shortening element, making for simple assembly and disassembly by a qualified person, without the need for special tools. t w e d

20 G10/Grade 100 winner Code Chain Size WLL (90° - 45° ) (lb) WLL (45° - 30° ) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) Weight (lbs/pc) VMXKW 2-6 7/32˝ 3,800 2,700 4 5 8.03 0.55 4.72 2.76 2.29 VMXKW 2-7 9/32˝ 6,100 4,300 5 6 10.31 0.63 5.51 3.15 4.21 VMXKW 2-8 5/16˝ 8,100 5,700 5 8 11.10 0.75 6.30 3.74 5.18 VMXKW 2-10 3/8˝ 12,400 8,800 10 12 13.03 0.91 6.69 4.13 9.24 VMXKW 2-13 1/2˝ 21,200 15,000 10 12 15.47 1.06 7.48 4.33 17.75 VMXKW 2-16 5/8˝ 32,000 22,600 12 16 18.30 1.30 9.06 5.12 31.70 VMXKW 2 / Clevis Master Set The fact that the hook functions both as a connecting and a shortening element, there is no additional connecting element needed. The set consists of a MW Enlarged Master Link and two welded-in XKW Shortening Hooks, facilitating the speedy assembly and disassembly of Double Leg chain slings by a competent person, without the need for special tools. The chain may attached directly to the captive coupling of the shortening element. t w e d

21 Code Chain Size WLL (90° - 45° ) (lb) WLL (45° - 30° ) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) Weight (lbs/pc) VMXKW 4-6 7/32˝ 5,700 4,000 6 8 11.73 0.75 6.30 3.74 5.80 VMXKW 4-7 9/32˝ 9,100 6,400 10 12 14.25 0.91 6.69 4.13 10.67 VMXKW 4-8 5/16˝ 12,100 8,500 10 12 14.25 0.91 6.69 4.13 10.87 VMXKW 4-10 3/8˝ 18,700 13,200 10 12 17.17 1.06 7.48 4.33 19.86 VMXKW 4-13 1/2˝ 31,800 22,500 12 16 21.57 1.30 9.06 5.12 39.46 VMXKW 4-16 5/8˝ 47,900 33,900 20 25 25.59 1.50 10.83 5.91 67.28 VMXKW 4 / Clevis Master Set This enlarged clevis master set consists of a VMW Enlarged Master Assembly with four welded-in XKW Shortening Hooks for the creation of Quad Leg slings in an assembled system. The chain is directly attached to the captive coupling of the shortening element. This has the advantage, because there is no additional connecting element needed and the hook functions both as a connecting and a shortening element. The assembly and disassembly is done easily, quickly and without special tools by a qualified person. t w e d

22 G10/Grade 100 winner Code Chain Size WLL (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) Weight (lbs/pc) LXKW 1-6 7/32˝ 2,700 25 32 18.82 0.91 13.39 7.09 8.20 LXKW 1-8 5/16˝ 5,700 25 32 20.31 0.91 13.39 7.09 8.88 LXKW 1-10 3/8˝ 8,800 25 32 22.48 1.06 13.39 7.09 13.34 LXKW 1-13 1/2˝ 15,000 25 32 24.72 1.06 13.39 7.09 19.44 LXKW 1-16 5/8˝ 22,600 25 32 27.17 1.30 13.39 7.09 29.85 LXKW 1 / Clevis Master Set This oversize clevis master set is frequently used on mobile cranes. It consists of an V LW Oversize Master Link Assembly and a welded-in XKW Shortening Hook for the creation of Single Leg chain slings in the assembled system. The chain is mounted directly into the captive coupling of the shortening element, thereby eliminating the need for an additional connecting link. Assembly and disassembly of the system by a qualified person is easy and quick, without the need for special tools. The hook functions both as a connecting link and a shortening element and the master link is suitable for crane hooks up to no. 25 according to DIN 15401 and up to no. 32 according to DIN 15402. t w e d

23 Code Chain Size WLL (90° - 45° ) (lb) WLL (45° - 30° ) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) Weight (lbs/pc) LXKW 2-6 7/32˝ 3,800 2,700 25 32 18.82 0.91 13.39 7.09 8.75 LXKW 2-8 5/16˝ 8,100 5,700 25 32 20.31 0.91 13.39 7.09 10.67 LXKW 2-10 3/8˝ 12,400 8,800 25 32 22.48 1.06 13.39 7.09 16.95 LXKW 2-13 1/2˝ 21,200 15,000 25 32 24.72 1.30 13.39 7.09 31.48 LXKW 2-16 5/8˝ 32,000 22,600 25 32 27.17 1.57 13.39 7.09 51.08 LXKW 2 / Clevis Master Set Double Leg chain slings in the assembled system are created easily and quickly using this oversize clevis master set. Consists of a VLW Oversize Master Link Assembly with two welded-in XKW Shortening Hooks. The chain may be attached directly to the captive coupling of the shortening element, which eliminates the need for an additional connecting element. Assembly and disassembly of the system by a qualified person is easy and quick, without the need for special tools. The hook functions both as a connecting link and a shortening element and the master link is suitable for crane hooks up to no. 25 according to DIN 15401 and up to no. 32 according to DIN 15402. t w e d Code Chain Size WLL (90° - 45° ) (lb) WLL (45° - 30° ) (lb) Fits on single hook DIN 15401 Fits on double hook DIN 15402 e (inch) d (inch) t (inch) w (inch) Weight (lbs/pc) LXKW 4-6 7/32˝ 5,700 4,000 25 32 18.82 0.91 13.39 7.09 9.66 LXKW 4-8 5/16˝ 12,100 8,500 25 32 20.94 1.06 13.39 7.09 17.00 LXKW 4-10 3/8˝ 18,700 13,200 25 32 23.07 1.30 13.39 7.09 28.40 LXKW 4-13 1/2˝ 31,800 22,500 25 32 25.91 1.57 13.39 7.09 53.73 LXKW 4-16 5/8˝ 47,900 33,900 25 32 28.15 1.57 13.39 7.09 75.12 LXKW 4 / Clevis Master Set This high-grade clevis master set was designed for the creation of Quad Leg chain slings in the assembled system. Consists of a VLW Oversize Master Link Assembly with four welded-in XKW Shortening Hooks. The benefits of this system are obvious: the chain can simply be mounted directly in the captive coupling of the shortening element, thereby eliminating the need for an additional connecting link. The hook functions both as a connecting link and a shortening element and the master link is suitable for crane hooks up to no. 25 according to DIN 15401 and up to no. 32 according to DIN 15402. t w e d

24 G10/Grade 100 winner Code Chain Size WLL (lb) e (inch) c (inch) s (inch) t (inch) d (inch) b (inch) g (inch) Weight (lbs/pc) CW 5 3/16˝ 2,200 1.50 0.28 0.35 0.47 0.28 1.34 0.51 0.13 CW (Formerly6 C5.50) 7/32˝ 2,700 1.73 0.31 0.43 0.51 0.31 1.54 0.55 0.18 CW (Formerly7 C70) 9/32˝ 4,300 2.09 0.39 0.51 0.63 0.35 1.81 0.67 0.31 CW (Formerly8 C80) 5/16˝ 5,700 2.44 0.47 0.55 0.79 0.39 2.17 0.75 0.53 CW (Formerly10 C100) 3/8˝ 8,800 2.83 0.59 0.71 0.87 0.51 2.52 0.94 0.93 CW (Formerly13 C130) 1/2˝ 15,000 3.46 0.79 0.87 1.02 0.67 3.11 1.10 1.87 CW (Formerly16 C160) 5/8˝ 22,600 4.41 0.94 1.14 1.38 0.79 4.13 1.34 4.19 CW (Formerly19/20C200) 3/4˝ 35,300 4.96 1.26 1.38 1.77 0.98 4.96 1.73 6.83 CW (Formerly22 C220) 7/8˝ 42,700 6.18 1.42 1.54 1.81 1.02 5.83 2.05 10.14 CW (Formerly26 C260) 1˝ 59,700 7.05 1.57 1.81 2.24 1.18 6.89 2.44 14.99 CW (Formerly32 C320) 1-1/4˝ 90,400 8.11 1.85 2.20 2.48 1.38 8.50 3.15 25.04 CW / Connex Connecting Link This universal connecting link consists of two symmetrical, die-forged halves, one bolt and one safety sleeve. For the expert connection of master link/chain, chain/chain, chain/hook, master link/hook, and much Pleasemore!note that the product is suitable for straight pull only and must be assembled by a qualified person. Thanks to the sophisticated design, no special tool is required. e d g s c b t

25 Code Chain Size WLL (lb) e (inch) c (inch) s (inch) t (inch) d (inch) b (inch) g (inch) Weight (lbs/pc) CLW (Formerly7 CL70) 9/32˝ 4,300 2.09 0.39 0.51 0.63 0.35 1.81 0.67 0.31 CLW (Formerly10CL100) 3/8˝ 8,800 2.83 0.59 0.71 0.87 0.51 2.52 0.94 0.95 CLW (Formerly13CL130) 1/2˝ 15,000 3.46 0.79 0.87 1.02 0.67 3.11 1.10 1.87 CLW (Formerly16CL160) 5/8˝ 22,600 4.41 0.94 1.14 1.38 0.79 4.13 1.34 4.19 CLW / Connex Connecting Link Two symmetrical, die-forged halves and a special safety set ensure universal combination options of master link/chain, chain/chain, chain/hook, master link/hook and other elements. The CLW Connex Connecting Link is suitable for straight pull only and cannot be dismounted after assembly . The link is easily and quickly assembled by a qualified person, without the need for special tools. e d g s c b t Code Chain Size WLL (lb) e (inch) a (inch) c (inch) d (inch) b (inch) s (inch) g (inch) Weight (lbs/pc) CARW 8 (Formerly CAR80) 5/16˝ 5,700 2.60 1.14 0.47 0.39 2.68 0.71 0.75 0.73 CARW 10 (Formerly CAR100) 3/8˝ 8,800 3.19 1.57 0.59 0.51 3.23 0.83 0.94 1.57 CARW 13 (Formerly CAR130) 1/2˝ 15,000 4.09 1.73 0.79 0.67 3.98 1.10 1.10 2.95 CARW 16 (Formerly CAR160) 5/8˝ 22,600 4.45 1.85 0.94 0.79 4.33 1.57 1.34 4.03 CARW 22 (Formerly CAR220) 7/8˝ 42,700 7.48 4.33 1.42 0.98 8.46 2.28 2.05 17.59 CARW / Round Sling Connecting Link Extra-safe round sling connecting link with a wide, protecting half for round or webbing slings. It is easily assembled and disassembled by a qualified person. This product is for straight pull only e s g c ab d

26 G10/Grade 100 winner Code Chain Size e (inch) a (inch) d1 (inch) d2 (inch) h (inch) h1 (inch) s (inch) Weight (lbs/pc) AGWW 5/6 7/32˝ 1.38 5.83 0.63 0.87 0.43 0.35 0.39 1.19 AGWW 7/8 9/32˝- 5/16˝ 2.01 8.27 0.87 0.98 0.61 0.55 0.59 3.86 AGWW 10 3/8˝ 1.26 7.09 0.98 1.26 0.91 0.61 0.59 3.44 AGWW 13 1/2˝ 2.09 9.45 1.26 1.57 1.06 0.79 0.79 7.94 AGWW 16 5/8˝ 3.03 11.81 1.57 1.97 1.26 0.98 0.98 15.43 AGWW 19/20 3/4˝ 3.11 15.35 1.97 2.76 1.77 1.18 1.18 29.10 AGWW 22 7/8˝ 4.88 13.78 2.36 2.76 1.97 1.38 1.18 32.41 AGWW 26 1˝ 5.12 15.75 2.76 2.95 2.36 1.57 1.57 56.88 d1 e d2 a h1 h sAGWW / Load Distributor The AGWW Load Distributor is used for assembling Quad Leg chain slings with Connex Connecting Links. Load distributors are designed to equalize length tolerances of the chain legs in Quad Leg chain slings, as well as with non-optimal lifting point positions. If two Double Leg slings are used at the same time and one of them is provided with a load distributor, this system will be treated as a Quad Leg sling with four load-carrying legs providing increased safe load distribution as rated by ASME B30.9 and as part of a Special Master Coupling Link (MCL) The load distributor may be turned by 180° once the elimination criteria have been reached, thereby doubling its lifespan! Contact pewag for technical information. Code WLL - 2 Legs (in Quad Leg Sling) (90° - 45°) (lb) WLL - 2 Legs (in Quad Leg Sling) (45° - 30°) (lb) Master Link Assemblies to use Connecting Link L1Difference/L2 (chain links) AGWW 5/6 3,800 2,700 VW 6 / VMW 6 / VAW 6/7 CW 8 5 AGWW 7/8 6,100 / 8,100 4,100 / 5,700 VW 7/8 / VMW 10 / VAW 10 CW 10 6 / 5 AGWW 10 12,400 8,800 VW 13 / VMW 13 / VAW 13 CW 13 4 AGWW 13 21,200 15,000 VW 16 / VMW 16 / VAW 16 CW 16 4 AGWW 16 32,000 22,600 VW 19/20 / VMW 19/20 / VAW 19/20 CW 19/20 4 AGWW 19/20 49,900 35,300 VW 22 / VMW 22 / VAW 19/20 CW 32 5 AGWW 22 60,400 42,700 VW 26 / VAW 26 CW 32 5 AGWW 26 84,400 59,700 VAW 32 GSCHW VB G-1463 WLL 55t 5 L2 L1 L2 L1

27 Code Chain Size WLL (lb) e (inch) h (inch) a (inch) d1 (inch) d2 (inch) g1 (inch) b (inch) Weight (lbs/pc) HSW (Formerly5/6HS5.50) 3/16˝- 7/32˝ 2,700 3.35 0.83 0.67 0.79 0.39 0.75 2.68 0.75 HSW (Formerly7/8HS70/80) 9/32˝- 5/16˝ 5,700 4.17 1.06 0.75 0.98 0.43 1.02 3.46 1.25 HSW (Formerly10HS100) 3/8˝ 8,800 5.16 1.30 1.02 1.34 0.63 1.22 4.29 2.76 HSW (Formerly13HS130) 1/2˝ 15,000 6.47 1.73 1.30 1.69 0.75 1.54 5.28 4.10 HSW (Formerly16HS160) 5/8˝ 22,600 7.20 1.97 1.57 1.97 0.98 1.77 6.10 8.51 HSW (Formerly19/20HS200) 3/4˝ 35,300 8.07 2.17 1.89 2.17 1.06 2.09 7.01 13.25 HSW (Formerly22HS220) 7/8˝ 42,700 8.86 2.44 1.97 2.36 1.14 2.44 7.72 18.06 HSW (Formerly26HS260) 1˝ 59,700 10.20 2.96 2.76 2.76 1.46 2.87 9.25 28.13 HSW (Formerly32HS320) 1-1/4˝ 90,400 11.77 3.82 3.23 2.60 1.77 3.43 11.46 61.42 HSW / Eye Sling Hook This eye sling hook offers universal options for usage and is manufactured with a forged safety latch that locks into the tip of the hook, thereby offering increased protection against lateral shifts. The hook is suitable for Connex and welded systems. Please note that the product is suitable for straight pull only. Loads must not be placed on the tip of the hook or the safety latch! e g1 d1 b a h d2

28 G10/Grade 100 winner LHW / Eye Safety Hook Safe by name, safe by nature – this hook closes and locks automatically, which means that it cannot open when under load. It is perfect in combination with the Connex system and also offers additional, universal connection options thanks to the flattened section on the eye. As it comes with a wider jaw opening than HSW, it may be used with more flexibility. Please note that this hook is suitable for straight pull only The tip of the hook and the safety latch must not be placed under load and the hook should not be used in the welded system. e g d1 b a h d2 s max. Code Chain Size WLL (lb) e (inch) h (inch) a (inch) b (inch) d1 (inch) d2 (inch) g (inch) s max. (inch) Weight (lbs/pc) LHW (Formerly5/6LH5.50) 3/16˝- 7/32˝ 2,700 4.33 0.79 0.67 2.80 0.83 0.43 1.10 0.04 1.17 LHW (Formerly7/8LH70/80) 9/32˝- 5/16˝ 5,700 5.35 1.02 0.79 3.46 0.98 0.47 1.34 0.04 2.03 LHW (Formerly10LH100) 3/8˝ 8,800 6.65 1.18 1.14 4.21 1.38 0.59 1.77 0.04 3.46 LHW (Formerly13LH130) 1/2˝ 15,000 8.07 1.57 1.38 5.43 1.57 0.79 2.05 0.06 7.03 LHW (Formerly16LH160) 5/8˝ 22,600 9.88 1.97 1.61 6.61 1.97 1.06 2.36 0.08 13.76 LHW (Formerly19/20LH200) 3/4˝ 35,300 11.41 2.44 1.97 7.64 2.36 1.18 2.76 0.08 21.49 LHW (Formerly22LH220) 7/8˝ 42,700 12.68 2.56 2.05 8.31 2.76 1.26 3.19 0.08 27.45 LHW 26 1˝ 59,700 15.08 3.11 2.40 9.96 3.23 1.65 3.94 0.08 44.09 LHW 32 1-1/4˝ 90,400 16.73 4.01 3.15 12.24 3.23 1.77 4.72 0.12 71.43

29 Code Chain Size WLL (lb) e (inch) h (inch) a (inch) w (inch) w1 (inch) d2 (inch) g (inch) s max. (inch) Weight (lbs/pc) WLHW 5/6 3/16˝- 7/32˝ 2,700 6.34 0.79 0.67 1.38 1.42 0.47 1.10 0.04 2.65 WLHW 7/8 (Formerly WLH70/80) 9/32˝- 5/16˝ 5,700 7.17 1.02 0.79 1.38 1.42 0.47 1.34 0.04 3.40 WLHW 10 (Formerly WLH100) 3/8˝ 8,800 8.58 1.18 1.14 1.65 1.61 0.63 1.77 0.04 4.72 WLHW 13 (Formerly WLH130) 1/2˝ 15,000 10.59 1.57 1.38 1.93 1.85 0.79 2.05 0.06 9.74 WLHW 16 (Formerly WLH160) 5/8˝ 22,600 12.56 1.97 1.61 2.36 2.36 0.94 2.36 0.08 16.18 WLHW / Swivel Safety Hook This hook is at its best when used with the Connex system. It closes and locks automatically and cannot be opened and cannot be rotated while under load . The large swivel casing opens up a wide range of application options and compared to the HSW, the larger jaw opening allows for much more flexibility. The WLHW Swivel Safety Hook is suitable for straight pull only Also note that the tip of the hook and the safety latch must not be placed under load and the hook should not be used in the welded system. ge w1 w a h d2 s max. Code Chain Size WLL (lb) e (inch) h (inch) a (inch) w (inch) w1 (inch) d2 (inch) g (inch) s max. (inch) Weight (lbs/pc) WLHBW 5/6 3/16˝- 7/32˝ 2,700 6.34 0.79 0.67 1.38 1.42 0.47 1.10 0.04 2.65 WLHBW 7/8 (Formerly WLHB70/80) 9/32˝- 5/16˝ 5,700 7.17 1.02 0.79 1.38 1.42 0.47 1.34 0.04 3.42 WLHBW 10 (Formerly WLHB100) 3/8˝ 8,800 8.58 1.18 1.14 1.65 1.61 0.63 1.77 0.04 4.72 WLHBW 13 (Formerly WLHB130) 1/2˝ 15,000 10.59 1.57 1.38 1.93 1.85 0.79 2.05 0.06 9.77 WLHBW 16 (Formerly WLHB160) 5/8˝ 22,600 12.56 1.97 1.61 2.36 2.36 .094 2.36 0.08 16.20 WLHBW / Swivel Safety Hook Thi s showpiece can withstand operating temperatures of up to 248° F. The swivel safety hook closes and locks automatically and comes with an axial bearing, ensuring that it may be rotated when under load , but not opened. It is suitable for Connex systems and also offers additional connecting options thanks to its large swivel casing. Its jaw opening is larger than the HSW Eye Hook, making it more flexible in terms of potential use. Please note that the product is suitable for straight pull only . Also note that the tip of the hook and the safety latch must not be placed under load and the hook should not be used in the welded system. ge w1 w a h d2 s max.

.

This hook comes with an extra-wide jaw and is used in applications where other hooks simply aren’t up to the job. The model is frequently used in foundries and also does an excellent job when used with Connex and welded systems. This extra-wide hook has a lot to offer – but please avoid tip loading and ensure that it is used in straight pull only

hook,

This swivel hook may be used universally and comes with a die-forged safety catch that locks into the tip of the thereby providing excellent protection against lateral shifts. The WSBW Swivel Hook is suitable for the Connex systems, but also offers numerous other universal connection options thanks to its large swivel casing. Rotatability under load is ensured by an axial bearing design and comes as a special plus. The maximum operating temperature for this product is 248°F. This product is suitable for straight pull only Also note that the tip of the hook and the safety latch must not be placed under load. The swivel hook should not be used in the welded system. Eye

Foundry Hook

. e g d1 b a h d2 Code Chain Size WLL (lb) e (inch) h (inch) a (inch) d1 (inch) d2 (inch) g (inch) b (inch) Weight (lbs/pc) FW (Formerly7/8F70/80) 9/32˝- 5/16˝ 5,700 5.16 1.14 0.98 0.94 0.43 2.52 4.65 2.07 FW (Formerly10 F100) 3/8˝ 8,800 6.22 1.38 1.26 1.22 0.55 2.99 5.63 3.57 FW (Formerly13 F130) 1/2˝ 15,000 7.48 1.65 1.57 1.54 0.67 3.50 6.69 7.14 FW (Formerly16 F160) 5/8˝ 22,600 8.82 1.97 1.81 1.85 0.87 4.05 7.87 12.46 FW (Formerly19/20F200) 3/4˝ 35,300 10.24 2.40 2.13 2.20 1.10 4.49 9.09 20.94 FW 22 7/8˝ 42,700 11.30 2.95 2.48 1.85 1.22 5.51 11.18 29.54 FW 26 1˝ 59,700 14.09 3.31 2.87 3.23 1.50 5.98 12.28 47.18 FW 32 1-1/4˝ 90,400 14.57 3.98 3.54 2.60 1.73 6.69 14.13 77.16

30 G10/Grade 100 winner Code Chain Size WLL (lb) e (inch) h (inch) a (inch) d1 (inch) d2 (inch) g1 (inch) Weight (lbs/pc) WSBW 7/8 9/32˝- 5/16˝ 5,700 6.06 1.10 0.75 1.46 0.47 1.02 2.73 WSBW 10 3/8˝ 8,800 7.20 1.30 0.98 1.61 0.63 1.18 4.06 WSBW 13 1/2˝ 15,000 8.70 1.57 1.18 1.85 0.79 1.50 7.61 WSBW / Swivel Hook

g1e d1 a h d2 FW /

31 PW / Grab Hook Thanks to the special design of the chain contact area, this standard shortening hook ensures optimal interaction between chain and hook. Even when shortened, the load capacity is not reduced. The product comes with a full operating manual and is suitable for use with Connex and the welded system and can also be retrofitted. Code Chain Size WLL (lb) e (inch) b (inch) d1 (inch) d2 (inch) g (inch) Weight (lbs/pc) PW 5 3/16˝ 2,200 1.85 1.57 0.43 0.35 0.28 0.35 PW (Formerly6 P5.5) 7/32˝ 2,700 1.97 1.73 0.47 0.35 0.28 0.35 PW (Formerly7/8P70/80) 9/32˝- 5/16˝ 5,700 2.56 2.24 0.63 0.47 0.35 0.84 PW (Formerly10 P100) 3/8˝ 8,800 3.03 3.03 0.79 0.55 0.47 1.59 PW (Formerly13 P130) 1/2˝ 15,000 3.98 3.62 1.02 0.75 0.59 3.44 PW (Formerly16 P160) 5/8˝ 22,600 4.76 4.45 1.26 0.91 0.75 5.89 PW 19/20 1) (Formerly P200) 3/4˝ 35,300 5.94 5.91 1.42 1.06 0.98 13.58 PW 22 1) (Formerly P220) 7/8˝ 42,700 6.70 6.50 1.65 1.22 1.06 18.30 PW 26 1) (Formerly P260) 1˝ 59,700 7.91 7.68 1.97 1.46 1.26 30.09 PW 32 1) (Formerly P320) 1-1/4˝ 90,400 9.57 9.53 2.36 1.69 1.50 55.12 1) Shape without support surface e g d1 b d2 e g d1 b d2 Shape without support surfaceShape with support surface

32 G10/Grade 100 winner PSW / Grab Hook with Safety Catch This standard shortening hook ensures optimal interaction b etween chain and hook thanks to the special design of the chain contact area. Moreover, the integrated safety catch protects the chain from an accidental release. Even when shortened, the load capacity is not reduced. e g d1 b d2 Code Chain Size WLL (lb) e (inch) b (inch) d1 (inch) d2 (inch) g (inch) Weight (lbs/pc) PSW (Formerly7/8PS70/80) 9/32˝- 5/16˝ 5,700 2.56 2.24 0.63 0.47 0.35 0.88 PSW (Formerly10PS100) 3/8˝ 8,800 3.03 2.80 0.79 0.55 0.47 1.65 PSW (Formerly13PS130) 1/2˝ 15,000 3.98 3.62 1.02 0.75 0.59 3.55 PSW (Formerly16PS160) 5/8˝ 22,600 4.76 4.45 1.26 0.91 0.75 6.02 XKW / Clevis Shortening Hook This shortening hook is ideally suited for the Connex and welded system. Thanks to its clevis part, the shortening hook may be mounted directly into the chain. The eye of the hook makes it suitable for universal connections and applications as a hook in VXKW, VMXKW and LXKW chain slings. ge d1 b a d2 Code Chain Size WLL (lb) e (inch) b (inch) a (inch) d1 (inch) d2 (inch) g (inch) Weight (lbs/pc) XKW (Formerly5/6XK 5.50) 7/32˝ 2,700 3.31 1.46 1.14 0.71 0.35 0.32 0.49 XKW (Formerly7 XK 70) 9/32˝ 4,300 4.80 2.13 1.54 0.94 0.47 0.43 1.46 XKW (Formerly8 XK 80) 5/16˝ 5,700 4.80 2.13 1.54 0.94 0.47 0.43 1.48 XKW (Formerly10XK 100) 3/8˝ 8,800 6.30 2.76 1.97 1.22 0.55 0.51 2.89 XKW (Formerly13XK 130) 1/2˝ 15,000 7.99 3.62 2.52 1.46 0.71 0.59 6.24 XKW (Formerly16XK 160) 5/8˝ 22,600 9.21 4.02 3.15 1.89 0.94 0.79 11.16

33 BWW / Sheet Metal Plate Hook The lifting of sheet metal stacks, boards etc. requires perfect toolsand the BWW Sheet Metal Plate Hook is one of them. It can also be supplied in customised dimensions upon request. As a standard, it may be used with Connex and the welded system. The lifting process must be carried out by means of a Triple or Quad Leg chain sling. If a Triple Leg chain sling is used, the WLL is that of the corresponding Double Leg chain sling. The angle of inclination must be adjusted to between 75° and 60° e d1 h s g 87° b Code Chain Size WLL (lb) e (inch) s (inch) b (inch) h (inch) d1 (inch) g (inch) Weight (lbs/pc) BWW (Formerly7/8BW70/80) 9/32˝- 5/16˝ 5,700 5.16 3.15 1.97 0.59 1.10 2.17 3.30 BWW (Formerly10BW100) 3/8˝ 8,800 6.70 3.94 2.76 0.79 1.42 2.56 6.17 BWW (Formerly13BW130) 1/2˝ 15,000 8.23 5.12 3.15 0.98 1.57 3.54 11.68 BWW (Formerly16BW160) 5/8˝ 22,600 10.35 6.30 3.94 1.18 1.97 4.33 23.15 BWW (Formerly19/20BW200) 3/4˝ 35,300 12.05 7.28 4.72 1.57 2.36 5.12 38.58 BWW (Formerly22BW220) 7/8˝ 42,700 14.49 8.66 5.51 1.97 2.95 5.90 67.24 GHW / Fork Hook Safety is key when it comes to lifting sheet metal stacks, plates etc. The GHW Fork Hook makes a great partner for Connex and welded systems and is available in customised dimensions upon request. Tip loading must be avoided and care must be taken to ensure that the hooks are fully pushed onto the load. The hooks must always be used in pairs with a sling inclination angle of 60° to 45°. e s 87g ° b d Code Chain Size WLL (lb) e (inch) s (inch) b (inch) g (inch) d (inch) BW-link Weight (lbs/pc) GHW 5/6 3/16˝- 7/32˝ 2,700 7.99 3.94 7.48 2.56 0.91 BW 13 6.26 GHW 7/8 9/32˝- 5/16˝ 5,700 11.81 5.91 10.00 3.94 1.18 BW 16 15.98 GHW 10 3/8˝ 8,800 15.83 7.87 14.96 5.12 1.57 BW 22 35.27

operation. If

rest in the eyes and

observed, the shackle can cope with even the most demanding lifting operations. However, please note that the shackle cannot be mounted directly into the chain. e d1 a c ba d2 Code Chain Size WLL (lb) e (inch) b (inch) a (inch) d1 (inch) c (inch) d2 (inch) Weight (lbs/pc) SCHW 5 3/16˝ 2,200 0.94 0.43 0.28 0.31 0.63 0.31 0.24 SCHW 6 7/32˝ 2,700 1.18 0.55 0.31 0.39 0.79 0.39 0.44 SCHW 7/8 9/32˝- 5/16˝ 5,700 1.42 0.67 0.39 0.47 0.94 0.47 0.90 SCHW 10 3/8˝ 8,800 1.93 0.83 0.51 0.59 1.26 0.63 1.34 SCHW 13 1/2˝ 15,000 2.40 1.06 0.67 0.75 1.57 0.79 3.13 SCHW 16 5/8˝ 22,600 2.87 1.30 0.83 0.91 1.89 0.94 5.78 GSCHW / Bow Shackle This high-strength, bow shackle with a grade 10 special thread bolt and corresponding markings is ideally suited for all kinds of general lifting processes, without the risk of mix-ups. Both sides of the smooth bolt rest in the eyes and the thread does not protrude into the opening of the shackle. Please check that the bolt is sitting tightly prior to each lifting operation. The shackle cannot be mounted directly into the chain. e b1 a c ba d2 Code Chain Size WLL (lb) e (inch) b (inch) b1 (inch) a (inch) c (inch) d2 (inch) Weight (lbs/pc) GSCHW 7/8 9/32˝- 5/16˝ 5,700 2.01 0.87 1.26 0.51 1.34 0.63 1.01 GSCHW 10 3/8˝ 8,800 2.52 1.06 1.69 0.63 1.57 0.75 1.87 GSCHW 13 1/2˝ 15,000 2.99 1.22 2.01 0.75 1.81 0.87 2.80 GSCHW 16 5/8˝ 22,600 3.74 1.69 2.68 0.98 2.32 1.10 6.39

shackle. Please check

34 G10/Grade 100 winner SCHW / Shackle

high-strength shackle with a stud bolt in G10/Grade100 and marked accordingly prevents mix-ups and is suitable for general lifting purposes. Both sides

thread does

This of the smooth bolt the not protrude into the opening of the that the bolt is sitting tightly prior to lifting this is

each

precaution

35 c b a e d1 Code Chain Size WLL (lb) e (inch) a (inch) b (inch) c (inch) d1 (inch) d min. (inch) d max. (inch) ConnectingLink KNEW 8 5/16˝ 5,700 0.39 0.67 4.72 1.50 0.59 1.57 2.36 WIN 10 KNEW / Toggle Thanks to its special low design, this toggle is frequently used for general transportation purposes in the construction industry, for instance of sheet piles. As the toggle is welded into the sling with the next size up chain link, it takes up little space and is also suitable for small bores. Please refer to the table for the minimum and maximum bore diameter (d). Also available in other designs upon request. KRW / Coupling Ring This c oupling ring is also flexible when it comes to customized applications and is a component of the clevis master sets KAGW and KMGW. e s d b f a Code Chain Size WLL (lb) e (inch) s (inch) a (inch) b (inch) f (inch) d (inch) Weight (lbs/pc) KRW 5/6 3/16˝- 7/32˝ 2,700 1.22 0.28 0.71 1.50 0.31 0.29 0.26 KRW 7 9/32˝ 4,300 1.69 0.39 0.94 2.13 0.43 0.35 0.46 KRW 8 5/16˝ 5,700 1.69 0.39 0.94 2.13 0.43 0.39 0.46 KRW 10 3/8˝ 8,800 2.01 0.47 1.10 2.48 0.55 0.49 0.82 KRW 13 1/2˝ 15,000 2.48 0.59 1.30 2.99 0.67 0.63 1.70 KRW 16 5/8˝ 22,600 2.91 0.71 1.57 3.46 0.79 0.79 3.00 KRW 19/20 3/4˝ 35,300 3.70 0.91 1.97 4.49 0.94 0.94 5.14 KRW 22 7/8˝ 42,700 4.02 0.98 1.97 4.80 1.06 1.06 8.71

36 G10/Grade 100 winner KOW / Clevis Reeving Link This high-strength, die-forged coupling eye serves to establish a direct connection with the chain. The link may also be used as an end link. No connecting link is required. e w s d t Code Chain Size WLL (lb) e (inch) t (inch) w (inch) d (inch) s (inch) Weight (lbs/pc) KOW (Formerly7KO70) 9/32˝ 4,300 3.62 2.76 1.34 0.35 0.35 0.73 KOW (Formerly8KO80) 5/16˝ 5,700 3.58 2.76 1.34 0.39 0.35 0.73 KOW (Formerly10KO100) 3/8˝ 8,800 5.04 4.02 1.97 0.49 0.47 1.65 KOW (Formerly13KO130) 1/2˝ 15,000 6.65 5.35 2.60 0.63 0.59 2.38 KOW (Formerly16KO160) 5/8˝ 22,600 8.43 6.77 3.27 0.79 0.71 6.46 AWHW / Weld-on Hook This high-strength hook is particularly well suited for welding onto an excavator bucket, spreader beams, etc. Its outstanding features include a die-forged, tempered safety latch, making it extra sturdy. As the safety latch locks into the tip of the hook, it provides excellent protection against lateral shifting. G C L H B Code WLL (lb) L (inch) H (inch) G (inch) B (inch) C (inch) Weight (lbs/pc) AWHW 1.3 2,860 3.74 2.91 0.79 0.98 1.34 1.48 AWHW 3.8 8,370 5.20 4.17 1.02 1.38 1.57 3.09 AWHW 6.3 13,880 6.57 5.24 1.14 1.77 1.93 6.50 AWHW 10 22,000 6.89 5.35 1.14 1.97 1.93 8.86

37 KHSW / Clevis Sling Hook If you are looking for an easy, simple chain connection using a clevis system and without any connecting links, this universal sling hook with a forged safety latch is your best bet. The safety latch locks into the tip of the hook, thereby providing excellent protection against lateral shifts. For straight pulls only e g1 h b d a Code Chain Size WLL (lb) e (inch) h (inch) a (inch) d (inch) g1 (inch) b (inch) Weight (lbs/pc) KHSW 5/6 (Formerly KHS5.50) 7/32˝ 2,700 2.72 0.79 0.59 0.29 0.75 2.60 0.64 KHSW 7 (Formerly KHS70) 9/32˝ 4,300 3.74 1.10 0.75 0.35 1.02 3.54 1.34 KHSW 8 (Formerly KHS80) 5/16˝ 5,700 3.74 1.10 0.75 0.39 1.02 3.54 1.36 KHSW 10 (Formerly KHS100) 3/8˝ 8,800 4.29 1.38 0.98 0.49 1.22 4.25 2.62 KHSW 13 (Formerly KHS130) 1/2˝ 15,000 5.35 1.61 1.34 0.63 1.54 5.16 4.66 KHSW 16 (Formerly KHS160) 5/8˝ 22,600 6.10 1.93 1.46 0.79 1.77 6.02 7.68 KHSW 19/20 (Formerly KHS200) 3/4˝ 35,300 7.24 2.09 2.01 0.94 2.09 6.97 12.41 KHSW 22 (Formerly KHS220) 7/8˝ 42,700 8.43 2.44 2.05 1.06 2.44 7.72 19.91

38 G10/Grade 100 winner KFW / Clevis Foundry Hook The KFW Clevis Foundry Hook comes with an extra-wide jaw and is used in applications where other hooks simply aren’t up to the job. This model is frequently used in foundries and with the clevis system, linking to the chain is quick and easy. e h b d g a Code Chain Size WLL (lb) e (inch) h (inch) a (inch) g (inch) d (inch) b (inch) Weight (lbs/pc) KFW (Formerly7 KF70) 9/32˝ 4,300 4.76 1.14 0.98 2.52 0.35 4.65 2.25 KFW (Formerly8 KF80) 5/16˝ 5,700 4.72 1.14 0.98 2.52 0.39 4.65 2.29 KFW (Formerly10KF100) 3/8˝ 8,800 5.51 1.38 1.26 2.99 0.49 5.63 3.84 KFW (Formerly13KF130) 1/2˝ 15,000 6.69 1.65 1.57 3.50 0.63 6.69 7.45 BKHSW / Oversize Clevis Sling Hook The safety latch of the BKHSW Oversize Clevis Sling Hook locks into the tip of the hook, thereby providing excellent protection against lateral shifts. The jaw opening is significantly larger than that of the standard KHSW, making this product extra-flexible. This product is designed for straight pull only . e g1 h b d a Code Chain Size WLL (lb) e (inch) h (inch) a (inch) d (inch) g1 (inch) b (inch) Weight (lbs/pc) BKHSW 8 5/16˝ 5,700 3.66 1.06 0.98 0.39 1.26 3.86 2.23 BKHSW 10 3/8˝ 8,800 4.37 1.30 1.18 0.49 1.50 4.69 3.46

39 KLHW / Clevis Safety Hook This clevis safety hook closes and locks automatically and has a significantly larger jaw opening than the KHSW Clevis Sling Hook. For safety reasons, it cannot be opened under load. The hook is suitable for straight pull only and that load must not be placed on the tip of the hook or the safety latch. Assembly is quick and easy and does not require any special tools, but must be performed by a qualified person. e h b d g s max. a Code Chain Size WLL (lb) e (inch) h (inch) a (inch) b (inch) d (inch) g (inch) s max. (inch) Weight (lbs/pc) KLHW 5/6 (Formerly KL5.50) 3/16˝- 7/32˝ 2,700 3.70 0.79 0.67 2.80 0.29 1.10 0.04 1.23 KLHW 7 (Formerly KL70) 9/32˝ 4,300 4.84 1.02 0.79 3.46 0.35 1.34 0.04 1.92 KLHW 8 (Formerly KL80) 5/16˝ 5,700 4.84 1.02 0.79 3.46 0.39 1.34 0.04 2.20 KLHW 10 (Formerly KL100) 3/8˝ 8,800 5.67 1.18 1.14 4.21 0.49 1.77 0.04 3.55 KLHW 13 (Formerly KL130) 1/2˝ 15,000 7.09 1.57 1.38 5.43 0.63 2.05 0.06 7.16 KLHW 16 (Formerly KL160) 5/8˝ 22,600 8.58 1.97 1.61 6.61 0.79 2.36 0.08 13.12 KLHW 19/20 (Formerly KL200) 3/4˝ 35,300 10.20 2.44 1.97 7.64 0.94 2.76 0.08 28.42 KLHW 22 (Formerly KL220) 7/8˝ 42,700 11.26 2.56 2.05 8.31 1.06 3.19 0.08 35.08 KLHW 26 (Formerly KL260) 1˝ 59,700 13.31 3.11 2.40 9.96 1.30 3.94 0.08 47.02

40 G10/Grade 100 winner KPW / Clevis Grab Hook This standard shortening hook ensures optimal interaction between chain and hook thanks to the special design of the chain contact. Even when shortened, the load capacity is not reduced and the product is suitable for retrofitting. The clevis system makes it possible to link the chain to the hook quickly and easily, without the need for an additional connecting element. e g b d Code Chain Size WLL (lb) e (inch) b (inch) d (inch) g (inch) Weight (lbs/pc) KPW (Formerly6 KP5.50) 7/32˝ 2,700 1.85 1.73 0.29 0.28 0.42 KPW (Formerly7 KP70) 9/32˝ 4,300 2.48 2.24 0.35 0.35 1.01 KPW (Formerly8 KP80) 5/16˝ 5,700 2.48 2.24 0.39 0.35 1.01 KPW (Formerly10KP100) 3/8˝ 8,800 3.07 2.80 0.49 0.47 1.98 KPW (Formerly13KP130) 1/2˝ 15,000 3.66 3.62 0.63 0.59 4.08 KPW (Formerly16KP160) 5/8˝ 22,600 4.53 4.45 0.79 0.75 7.69 KPW 19/20 1) (Formerly KP200) 3/4˝ 35,300 5.55 5.91 0.94 0.98 15.17 KPW 22 1) (Formerly KP220) 7/8˝ 42,700 6.22 6.50 1.06 1.06 21.34 e g b d Shape without support surfaceShape with support surface 1) Shape without support surface

This high-performance

KSCHW / Clevis Shackle

41 KPSW / Clevis Grab Hook with Safety Catch This standard shortening hook ensures optimal interaction between chain and hook thanks to the special design of the chain contact, providing extra protection from accidental chain release. Even when shortened, the load capacity is not reduced and the product is suitable for retrofitting. The clevis system makes it possible to link the chain to the hook quickly and easily, without the need for an additional connecting element. The safety catch mechanism helps prevent the accidental unhooking of the chain during slack conditions. e g b d Code Chain Size WLL (lb) e (inch) b (inch) d (inch) g (inch) Weight (lbs/pc) KPSW 7 (Formerly KP70) 9/32˝ 4,300 2.48 2.24 0.35 0.35 1.05 KPSW 8 (Formerly KP80) 5/16˝ 5,700 2.48 2.24 0.39 0.35 1.05 KPSW 10 (Formerly KP100) 3/8˝ 8,800 3.07 2.80 0.49 0.47 2.05 KPSW 13 (Formerly KP130) 1/2˝ 15,000 3.66 3.62 0.63 0.59 4.19 KPSW 16 (Formerly KP160) 5/8˝ 22,600 4.53 4.45 0.79 0.75 7.83

shackle consists of a special screw, nut and split pin, which makes losing the screw practically impossible. The wide opening makes this shackle extremely versatile –for instance, it may be used on spreader beams. The clevis system makes linking the shackle to the chain quick and simple, without the need for an additional connecting element. For straight pull only . e d a c ba d1 e1 Code Chain Size WLL (lb) e (inch) e1 (inch) b min. (inch) a (inch) d (inch) c (inch) d1 (inch) Weight (lbs/pc) KSCHW 7 (Formerly KSCH70) 9/32˝ 4,300 2.99 2.13 1.02 0.47 0.35 1.22 0.63 1.41 KSCHW 8 (Formerly KSCH80) 5/16˝ 5,700 2.99 2.13 1.02 0.47 0.39 1.22 0.63 1.46 KSCHW 10 (Formerly KSCH100) 3/8˝ 8,800 4.13 2.99 1.26 0.63 0.49 1.54 0.79 2.69 KSCHW 13 (Formerly KSCH130) 1/2˝ 15,000 4.49 3.03 1.65 0.83 0.63 1.97 0.94 5.82

42 G10/Grade 100 winner UEW / Transition Assembly A smooth transition for simple hooks according to DIN 15401 Large master links, combined with CW Connex and HSW Eye Hooks, make it possible to use smaller hooks. Thanks to the modular assembly system, UEW opens up a wide range of possible combinations and load capacities! VSAW or AW CW HSW Code Consisting of WLL (lb) Fits on single hook DIN 15401 Weight (lbs/pc) UEW 32/16 I AW-HSW Connex AW 50 + CW 26 + HSW 19/20 35,300 32 63.62 UEW 32/19 I AW-HSW Connex AW 50 + CW 26 + HSW 22 42,700 32 67.33 UEW 32/26.5 I AW-HSW Connex AW 50 + CW 26 + HSW 26 59,700 32 81.33 UEW 50/4 I VSAW-HSW Connex VSAW 1-16 + CW 16 + HSW 10 8,800 50 27.65 UEW 50/6.7 I VSAW-HSW Connex VSAW 1-16 + CW 16 + HSW 13 15,000 50 30.27 UEW 50/10 I VSAW-HSW Conn VSAW 1-16 + CW 16 + HSW 16 22,600 50 33.18 UEW 50/16 I VSAW-HSW Connex VSAW 1-22 + CW 22 + HSW 19/20 35,300 50 62.21 UEW 50/19 I VSAW-HSW Connex VSAW 1-22 + CW 22 + HSW 22 42,700 50 65.92 UEW 50/19 I VSAW-HSW Connex VSAW 1-26 + CW 26 + HSW 26 59,700 50 92.35 UEW 50/40 I AW-HSW Connex AW 72 + CW 32 + HSW 32 90,400 50 178.04 UEW 100/26,5 I VSAW-HSW Connex VSAW 1-32/320 + CW 26 + HSW 26 59,700 100 151.87 UEW 100/40 I VSAW-HSW Connex VSAW 1-32/320 + CW 32 + HSW 32 90,400 100 192.37

43 UEW / Transition Assembly A smooth transition for simple hooks according to DIN 15402 Large master links, combined with CW Connex and HSW Eye Hooks, make it possible to use smaller hooks. Thanks to the modular assembly system, UEW opens up a wide range of possible combinations and load capacities! VSAW HSW CW AW Code Consisting of WLL (lb) Fits on single hook DIN 15402 Weight (lbs/pc) UEW 50/4 II VSAW-HSW Connex 2 x VSAW 1-16 + AW 36 + CW 16 + HSW 10 8,800 50 61.93 UEW 50/6.7 II VSAW-HSW Connex 2 x VSAW 1-16 + AW 36 + CW 16 + HSW 13 15,000 50 64.55 UEW 50/10 II VSAW- HSW Connex 2 x VSAW 1-16 + AW 36 + CW 16 + HSW 16 22,600 50 67.46 UEW 50/16 II VSAW-HSW Connex 2 x VSAW 1-16 + AW 36 + CW 19/20 + HSW 19/20 35,300 50 72.97 UEW 50/19 II VSAW-HSW Connex 2 x VSAW 1-22 + AW 50 + CW 26 + HSW 22 42,700 50 147.91 UEW 50/26.5 II VSAW-HSW Connex 2 x VSAW 1-22 + AW 50 + CW 26 + HSW 26 59,700 50 161.91 UEW 50/36 II VSAW-HSW Connex 2 x VSAW 1-22 + AW 50 + CW 32 + HSW 32 79,200 50 202.40 UEW 100/26.5 II VSAW-HSW Connex 2 x VSAW 1-32/320 + AW 50 + CW 26 + HSW 26 59,700 100 294.18 UEW 100/40 II VSAW-HSW Connex 2 x VSAW 1-32/320 + AW 50 + CW 32 + HSW 32 90,400 100 334.68

44 G10/Grade 100 winner G10/Grade 100 winner Lashing pewag winner key data - facts speak for themselves • Chain qualities: pewag winner 200 – pewag G10/Grade 100 meets the EN-818 Standard that pull tests to 2.5 times the WLL, whereas the US standards only require pull testing to 2 times the WLL. • This lashing chain has a 25% higher lashing capacity than standard G8 lashing chains. • Test stress: 625 N/mm². • Breaking stress: 1,000 N/mm². • Breaking elongation: min. 20%. • Admissible operating temperature: pewag winner 200: -40°F to 400°F. • Compatibility: Please note that the compatibility of pewag winner chains and components with those of other grades and from other manufacturers is limited and must be approved by pewag in advance. • This product must not be used for lifting or attaching loads. A full operating manual tells you all you need to know about how to use the chain to its best advantage. Build your own. Below you will find a detailed example of an order for a finished and commercially available pewag lashing chain. The lashing chain comes in a modular design with a standard length of 3,500 mm and is also suitable for frictional lashing, provided that the STF value is taken into account. Other end fittings and/or combinations and delivery lengths are available upon request and with short delivery times. ClevisKHSW Sling Hook ConnectingConnex Link Lashing Tag EyePSWGrab hook w/safety catch winner 200 chain LoadRSW binder ClevisKHSW Sling Hook L1 m Z (Denotes lashing) Load Binder / Chain size/specification / Component(s) / “L” Length / Connex Sample order: Z RSW / 7 200 / KHSW-KHSW-PSW / 8’ / Connex

45 I D L d RSW / Load Binder This load binder for one-part lashing chains in accordance with EN 12195 3 is also suitable for frictional lashing, depending on the selected lever length (always take the STF value into account!). It has a 25% higher lashing capacity than Grade 80 and is manufactured according to EN 12195 3. Code Stamping CapacityLashingLC (kN) TensionStandardSTFForce (daN) ClosedLengthL (inch) LengthOpenL (inch) TensionRange (inch) lengthLeverI (inch) D (inch) d (inch) Weight (lbs/pc) RSW (Formerly7/87G100RLB) Type A 50 1,900 13.98 19.69 5.71 9.33 0.79 0.63 7.05 RSW (Formerly1010G100RLB) Type B 80 3,000 14.37 20.08 5.71 13.98 1.02 0.71 8.37 RSW (Formerly1313G100RLB) Type C 134 2,500 22.68 34.09 11.42 14.13 1.22 0.87 21.83 RSPSW / Load Binder This load binder is the RSW with pre-loaded shortening hooks for easy positioning. L g Code Stamping CapacityLashingLC (kN) TensionStandardSTFForce (daN) ClosedLengthL (inch) LengthOpenL (inch) TensionRange (inch) lengthLeverI (inch) g (inch) Weight (lbs/pc) RSPSW 7/8 Type A 50 1,900 23.98 29.68 5.71 9.33 0.35 9.70 RSPSW 10 Type B 80 3,000 26.10 31.81 5.71 13.98 0.47 13.89 RSPSW 13 Type C 134 2,500 37.56 48.98 11.42 14.13 0.59 33.07 KSSW / Clevis Turnbuckle The G10/Grade 100 Clevis Turnbuckle is extremely robust. It can be assembled easily and quickly without the need for special tools thanks to its clevis structure. The turnbuckle is manufactured according to EN 12195 3. Its lashing capacity is 25% higher than that of Grade 80. Please note that the product is not suitable for frictional lashing! An optional safety chain w/hook available to prevent turnbuckle movement. d1 L Code Stamping CapacityLashingLC (kN) TensionStandardSTFForce (daN) L min. (inch) L max. (inch) TensionRange (inch) d1 (inch) Weight (lbs/pc) KSSW 16 Type A 200 20.87 30.71 9.84 0.79 22.05

46 G10/Grade 100 winner KBMSW / Bolt+Nut+Split Pin Replacement screw, nut, and split pin for KSCHW Clevis Shackles. Code For accessory part KBMSW 7/8 G10 KSCHW 7, KSCHW 8 KBMSW 10 G10 KSCHW 10 KBMSW 13 G10 KSCHW 13 KBSW / Clevis Load Pin Replacement clevis load pin. Code For accessory part KBSW 5/6 (Formerly PIN50/60) XKW 5/6, KRW 5/6, KHSW 5/6, KLHW 5/6, KPW 6, KVS 6 KBSW 7 (Formerly PIN70) XKW 7, KRW 7, KOW 7, KHSW 7, KCHW 7, KLHW 7, KFW 7, KPW 7, KPSW 7, KSCHW 7, KVS 7 KBSW 8 (Formerly PIN80) XKW 8, KRW 8, KOW 8, KHSW 8, BKHSW 8, KCHW 8, KLHW8, KFW 8, KPW 8, KPSW 8, KSCHW 8, KVS 8 KBSW 10 (Formerly PIN100) XKW 10, KRW 10, KOW 10, KHSW 10, BKHSW 10, KCHW 10, KLHW 10, KFW 10, KPW 10, KPSW 10, KSCHW 10, KVS 10 KBSW 13 (Formerly PIN130) XKW 13, KRW 13, KOW 13, KHSW 13, KCHW 13, KLHW 13, KFW 13, KPW 13, KPSW 13, KSCHW 13, KVS 13 KBSW 16 (Formerly PIN160) XKW 16, KRW 16, KOW 16, KHSW 16, KCHW 16, KLHW 16, KPW 16, KPSW 16, KSSW 16 KBSW 19/20 (Formerly PIN190) KRW 19/20, KHSW 19/20, KLHW 19/20, KPW 19/20 KBSW 22 (Formerly PIN220) KRW 22, KHSW 22, KLHW 22, KPW 22 KBSW 26 (Formerly PIN260) KLHW 26 G10/Grade 100 Spare Parts

47 SFGW / Safety Latch Sets These SFGW safety latch sets with die-forged and electrogalvanised safety latch and a spring from rust-proof spring steel are all about safety and security. Code For accessory part SFGW 5/6 (Formerly SFG5) HSW 5/6, KHSW 5/6 SFGW 7/8 (Formerly SFG7/8) HSW 7/8, KHSW 7, KHSW 8, WS 7/8, EHS 7/8, WSBW 7/8 SFGW 10 (Formerly SFG10) HSW 10, KHSW 10, WS 10, EHS 10, WSBW 10 SFGW 13 (Formerly SFG13) HSW 13, KHSW 13, WS 13, EHS 13, WSBW 13, SSM 5 SFGW 16 (Formerly SFG16) HSW 16, KHSW 16 SFGW 19/20 (Formerly SFG19/20) HSW 19/20, KHSW 19/20, SSM 7/8 SFGW 22 (Formerly SFG22) HSW 22, KHSW 22, SSM 10 SFGW 26 (Formerly SFG26/32) HSW 26, HSW 32, HS 32, SSM 13 Code For accessory part SFGW-G 8 GKHSW 8 SFGW-G 10 GKHSW 10 SFGW Safety Latch Set SFGW-G Safety Latch Set Code For accessory part SFGW-B 8 BKHSW 8 SFGW-B 10 BKHSW 10 SFGW-B Safety Latch Set Code For accessory part SFGW-A 1 AWHW 1.3 SFGW-A 3 AWHW 3.8 SFGW-A 6 AWHW 6.3, AWHW 10 SFGW-A Safety Latch Set

48 G10/Grade 100 winner CBHW / Bolt + Safety Bush Spare parts set for CW Connex Connecting Links and CARW Round Sling Connecting Links. We recommend replacing each safety set after it has been assembled/ disassembled three times. Code For accessory part CBHW 5 G10 (Formerly CBH 50 Grade 100) CW 5 CBHW 6 G10 (Formerly CBH 60 Grade 100) CW 6 CBHW 7 G10 (Formerly CBH 70 Grade 100) CW 7 CBHW 8 G10 (Formerly CBH 80 Grade 100) CW 8, CARW 8 CBHW 10 G10 (Formerly CBH 100 Grade 100) CW 10, CARW 10 CBHW 13 G10 (Formerly CBH 130 Grade 100) CW 13, CARW 13 CLBHW / Bolts + Safety Bush The CLBHW bolt and safety bush is the replacement part for CLW with non-removable bolts. Code For accessory part CLBHW 7 G10 (Formerly CLBH 70 Grade 100) CLW 7 CLBHW 10 G10 (Formerly CLBH 100 Grade 100) CLW 10 CLBHW 13 G10 (Formerly CLBH 130 Grade 100) CLW 13 CLBHW 16 G10 (Formerly CLBH 160 Grade 100) CLW 16 Code For accessory part CBHW 16 G10 (Formerly CBH 160 Grade 100) CW 16, CARW 16 CBHW 19/20 G10 (Formerly CBH 190/200 Grade 100) CW 19/20 CBHW 22 G10 (Formerly CBH 220 Grade 100) CW 22, CARW 22 CBHW 26 G10 (Formerly CBH 260 Grade 100) CW 26 CBHW 32 G10 (Formerly CBH 320 Grade 100) CW 32

49 VLHW / Trigger Set Trigger sets for LHW, KLHW and WLH(B)W Safety Hooks consist of a high-strength safety lever, a spring made of stainless steel and a retaining pin. Code For accessory part VLHW 5/6 G10 (Formerly VLH 50/60 Grade 100) LHW 5/6, KLHW 5/6, WLH(B)W 6 VLHW 7/8 G10 (Formerly VLH 70/80 Grade 100) LHW 7/8, KLHW 7, KLHW 8, WLH(B)W 7/8 VLHW 10 G10 (Formerly VLH 100 Grade 100) LHW 10, KLHW 10, WLH (B)W 10 VLHW 13 G10 (Formerly VLH 130 Grade 100) LHW 13, KLHW 13, WLH(B)W 13 VLHW 16 G10 (Formerly VLH 160 Grade 100) LHW 16, KLHW 16, WLH(B)W 16 VLHW 19/20/22/26 G10 (Formerly VLH 190/200/220/260 Grade 100) LHW 19/20, LHW 22, KLHW 19/20, KLHW 22, KLHW 26 ID Sling Tags ID tags for chain Electrogalvinized,slings.23/4” diameter. Code ID Tag 90 ID Tag For Single Leg Slings ID Tag 30/60 ID Tag For Multiple Leg Slings Code For accessory part Sling Warning-90 Plain (Formerly Sling warning single leg) ID Tag for Single Leg Chain Sling Sling Warning-30/60 Plain (Formerly Sling warning multiple legs) ID Tag for Multiple Leg Chain Sling PSGW / Safety Catch The ideal replacement parts for PSW and KPSW Grab Hooks with Safety Catches. The spring is particularly user-friendly and made of stainless steel. Code For accessory part PSGW 7/8 G10 (Formerly PSG70/80 Grade 100) PSW 7/8, KPSW 7, KPSW 8 PSGW 10 G10 (Formerly PSG100 Grade 100) PSW 10, KPSW 10 Code For accessory part PSGW 13 G10 (Formerly PSG130 Grade 100) PSW 13, KPSW 13 PSGW 16 G10 (Formerly PSG160 Grade 100) PSW 16, KPSW 16

50 G10/Grade 100 winner G10/Grade 100 winner Slings How to choose a chain sling • Determine the maximum load to be lifted. • Determine the type of sling needed (single, double, etc.) • Estimate the proper angle between the leg of the sling and the load during operation • Select the proper fittings (master links, hooks, etc.) • Determine the overall reach (measured from bearing point to bearing point) • Choose the chain size which meets your required work load, angle, and reduction factor • Choose a grade that meets your requirements Sling type explanation The type of chain sling is indicated by 3 letters (4th letter for adjustable) • First Letter indicates number of legs on the sling S = Single Leg D = Double Leg T = Triple Leg Q = Quad Leg • Second Letter indicates component on top of sling O = Oblong Link (AW, MW, VMW, VLW, VLW1, VLW2/4) S = Sling Hook (KHSW, HSW) G = Grab Hook (PW, PSW, KPW) P = Pear Link D = D-Link R = Ring • Third Letter indicates component on bottom of sling S = Sling Hook (KHSW, HSW) G = Grab Hook (PW, PSW, KPW) SL = Self Locking Hook (KLHW, LHW) O = Oblong Link (AW, MW) • Fourth Letter (if needed, indicates adjustable) A = Grab Hook with Connecting Link B = 3 Links of Chain and Grab Hook XK = In-line Shortener DOSA connectingcapacityMasterlinkLoadtagConnexlinkShorteninghook Chain End hook D (Double Leg) O (Oblong) S (Sling Hook) A (Adjustable) Sample order: 8 /G100/DOSA/4´ Chain Size(mm) / Grade / Sling Type / Length

51 Standard G100 Sling Types SOS SOSL SOG* SSS DOS DOSLSOO DOG* DOO DOSA TOS TOSL TOG* TOO QOS QOO SB DB * Must specify with or without safety catch SOSLXK DOSXK DOSLXK QOSXK QOSLXK

52 G10/Grade 100 winner Single Leg Double Leg Triple & Quad Leg Angle: 90° 60° 45° 30° 60° 45° 30° 90° - 45° 45° - 30° Load Factor: 1 1.7 1.4 1 2.6 2.1 1.5 2.1 1.5 Chain Diameter WLL (lb) WLL (lb) WLL (lb) WLL (lb) WLL (lb) WLL (lb) WLL (lb) WLL (lb) WLL (lb) WIN 6 200 7/32˝ 2,700 4,700 3,800 2,700 7,000 5,700 4,000 5,700 4,000 WIN 7 200 9/32˝ 4,300 7,400 6,100 4,300 11,200 9,100 6,400 9,100 6,400 WIN 8 200 5/16˝ 5,700 9,900 8,100 5,700 14,800 12,100 8,500 12,100 8,500 WIN 10 200 3/8˝ 8,800 15,200 12,400 8,800 22,900 18,700 13,200 18,700 13,200 WIN 13 200 1/2˝ 15,000 26,000 21,200 15,000 39,000 31,800 22,500 31,800 22,500 WIN 16 200 5/8˝ 22,600 39,100 32,000 22,600 58,700 47,900 33,900 47,900 33,900 WIN 19 200 3/4˝ 35,300 61,100 49,900 35,300 91,700 74,900 53,000 74,900 53,000 WIN 22 200 7/8˝ 42,700 74,000 60,400 42,700 110,900 90,600 64,000 90,600 64,000 WIN 26 200 1˝ 59,700 103,400 84,400 59,700 155,100 126,600 89,550 126,600 89,550 WIN 32 200 1 - 1/4˝ 90,400 156,600 127,800 90,400 234,900 191,800 135,600 G10/Grade 100 Chain Sling Working Load Limits Edge load - protection of load and chain The maximum load capacity of pewag chain slings was defined under the assumption that the individual chain legs are pulled straight under load, i.e. that they do not run over edges. In the case of edge loading, load protection (packing) should be used to avoid damage. For correct and incorrect use see the illustrations below. Quad Leg w/Load Distributor α

53 ChainEndlessSling Single Lifting Sling Double Lifting Sling Single Leg Double Leg DistributionAsymmetricalofLoad 90° - 45° 45° - 30° 90° - 45° 45° - 30° 90° 90° - 45° 45° - 30° Load Reducefactor:WLL by one (rated) leg. If in doubt, consider only one leg is carrying the load 1.6 1.4 1 2.1 1.5 0.8 1.12 0.8 WLL (lb) WLL (lb) WLL (lb) WLL (lb) WLL (lb) WLL (lb) WLL (lb) WLL (lb) 4,300 3,800 2,700 5,700 4,000 2,160 3,000 2,160 6,600 5,840 4,180 8,800 4,570 3,300 4,660 3,300 8,800 7,800 5,500 11,600 8,250 4,400 6,160 4,400 13,800 12,300 8,800 17,600 13,200 6,900 9,350 6,900 23,300 20,900 14,700 30,800 22,000 11,600 16,500 11,600 35,200 30,800 22,000 46,600 33,000 17,600 24,600 17,600 49,200 44,000 30,800 66,000 46,600 24,600 35,200 24,600 66,000 58,300 41,800 88,000 61,600 33,000 46,600 33,000 93,500 82,500 58,300 123,200 88,000 46,600 66,000 46,600 138,600 123,200 88,000 187,000 132,000 69,300 99,000 69,300 Edge loading If chains are guided over edges without proper protection, their load capacity is reduced. R > 2x chain dia. R > chain dia. R < chain dia. Load factor 1.0 0.7 0.5 Shock loading Light shocks Moderate shocks Strong shocks Load factor 1.0 0.7 Not permitted Temperature range Below 40° F 40° F to 400° F Above 400° F Load factor for G100 lifting chain Not permitted 100% of WLL Not permitted Even premium quality products will lose some of their load capacity when exposed to high temperatures, asymmetrical loading, edge loading, shocks or other severe operating conditions. Please refer to the operating manuals if you think that any of these conditions apply. pewag classifies the following factors as severe conditions:

Changes to the condition as delivered Modifying the original condition of the lifting accessories by bending, grinding, removal of parts, welding, drilling, stamping etc. means exposing yourself and others to unnecessary danger. In such a case, safety can no longer be guaranteed and usage becomes dangerous. Such potentially hazardous modifications include heating the G10/Grade 100 winner 200 lifting chain to a temperature of more than 400°F and/or removing safety parts such as safety pins, sleeves, catches etc. Do not apply any surface coatings to the pewag winner chain system, i.e. do not subject products to hot galvanizing or electrogalvanizing.

Dipping or removing a coating with chemicals are potentially dangerous processes that may give rise to hazards. We urgently recommend customers to check with the pewag technical team first.

pewag winner chains and accessories may only be assembled by competent persons using exclusively original parts contained in the scope of delivery, i.e. bolts, safety pins etc. As pewag winner chains and components have only limited compatibility with chains and components of other suppliers, each individual case where pewag winner chain system parts are combined with components from other suppliers and/or parts made from other grades must be assessed by a qualified person. Please note that pewag accepts no liability for damage resulting from such combinations. Please ensure that the load capacity is based on the weakest link in the assembly during every application. Labeling and/or color-coding help prevent situations where the load capacity is misjudged – for pewag, this is a key safety factor!

General information Like many other pewag quality products, the pewag winner chain system stands out for its versatility and flexible application modes when it comes to lifting loads. Prior to use, a competent person must determine whether the equipment is suitable for the intended application. If in doubt, please consult pewag directly.

54 G10/Grade 100 winner

The table on page 53 lists the load reduction values in case of extreme temperatures. These values apply until the chain and/or the components have returned to room temperature. pewag winner lifting equipment must not be used outside the indicated temperature range! If this has been the case, the chains must be removed from service.

Exposure to acids, caustic solutions or chemicals pewag winner lifting accessories must not be used in acids or caustic solutions or be exposed to their vapours. Please be aware of this requirement at all times as certain production processes release acids and/or vapours! If the use of pewag winner lifting accessories with highly concentrated chemicals in combination with high temperatures cannot be avoided, please make sure to obtain the express approval of such usage by a pewag expert.

There is also an alternative method in existence for rating the product load capacity, for which the specific application scenario of the chain and all operating conditions must be known. In such a case, please contact the pewag Technical Service team, as the information contained in the catalogues does not apply to such processes. pewag winner lifting chains may only be adjusted, inspected and serviced by competent personnel.

To ensure safe identification, pewag winner lashing chains must be labelled with a purpose-built load capacity tag. This tag may only be used if the load capacity of the chain corresponds to the tables on page 52/53. In situations where the load capacities are different due to combinations with products of other suppliers, this must be highlighted with a different tag (for instance round-shaped). Restrictions of use

G10/Grade 100 User Information

For hazardous or dangerous conditions, please refer to the table on page 52/53.