Nigel D’Souza, CAMA | President

Dear Members,

As we are witnessing snow falling and changing temperatures across the country, we are excited to bring you the Fall edition of PEMAC Now, the association's member magazine.

This issue highlights the incredible accomplishments and ongoing contributions of our dynamic membership and reflects the vibrancy of our asset and maintenance management community.

We celebrate our latest group of certification recipients, whose dedication to continuous improvement exemplifies a commitment to excellence asset management - congratulations to you all!

With our Members in Action section and a guest article from TRO Solutions (an organisation focused on proactive maintenance and team alignment strategies) we are inspired by their stories showcasing innovation and collaboration This issue also features updates on ISO 55000, and the application of the GFMAM Asset Management Landscape, offering practical insights for integrating these principles into everyday work.

This year’s MainTrain conference was a resounding success, and we are excited to share a recap of the event which not only celebrated knowledge sharing but also provided a platform to honor the outstanding work of our members. We are thrilled to spotlight the winners of our prestigious awards, whose achievements demonstrate excellence and inspire us all.

As we move forward, remember that your participation and engagement are what make PEMAC strong. Enjoy this edition of PEMAC Now and celebrate the stories that unite and uplift us. Thank you for your dedication and the passion you bring to our field

With excitement for the journey ahead,

Nigel D’Souza

President, PEMAC Asset Management Association of Canada

To these newly certified individuals!

Alexander Cloutier

Alireza Niavarani

Ankurbhai Patel

Arturo Bedoya

Ben Webster

Bennett Foster

Bernard Gagnon

Caleb Myram

Carl Gagnon

Catherine Fourcade

Chee Ming Kong

Cosmin Muresan

Daniel Lembcke

Darrell Stoby

Darryl Lapierre

Diljot Brar

Dominic Brule

Dylan Pinchin

Ebiere Birigeni

Ehsan Mousavian

Emeka Ekwukwo

Eric Smethurst

Eyitayo Fajinmi

Garth Hewitt

Heath Rouse

Jajar Singh

Jason Blanchard

Jason Legault

Jennifer C. Tween

Jesse Black

Jigarkumar Patel

Jimmy Dubuc

Jocelyn Audet

John Buck

Jordan Wright

Jory Maccan

Joseph Dale Breau

Justin Brideau

Kamorudeen Abass

Kevin Bradley

Louis-Martin Kojoian

Mark O'Neill

Michael Roy

Michel Geoffroy

Mohamed Ferawana

Muhammad Anas

Nambia Coulibaly Sirima

Olalekan Adeaga

Oluwole Aderibigbe

Ragulan Rajanayagam

Rajeshkumar Patel

Roger Lobe

Said Azanar

Shalend Sharan

Shawn Ryan

Shawne Simon

Simon Ntamack

Smit Vikeshkumar Chokshi

Stéphane Leduc

Stephanie Demkey-Loutit

Vikas Walia

Warren Vance

Yvonne Prusak

Certified Asset Management Professional (CAMP)

Andrew Fuentes-Morrill

Andrzej Wieczorek

April Tucker

Ashlee Mitchell

Brett Logan

Connor O'Brien

Curtis Hermans

Daniel Macdonald

Emeka Orji

Greg Malicki

Hongming Tong

Jonathan German

Karl Franco

Laura Archila Bustos

Matthew Kenel

Ned Lodge

Paul Ernsting

Praveen Cy

Ramandeep Kaur

Rick Dwyer

Sean Gerber

Spencer de Klerk

Steven Dobie

Stuart Gerber

Sudip Roy

Tyler Figgitt

William Joseph LeBoubon

Yuraima Redondo

The following professionals have receiving their PEMAC recognition between April 2 to November 30, 2024

Certified Technical Specialist in Asset Management (CTAM)

Amine Nouri

Wesley Payne

Certified Practitioner in Asset Management (CPAM)

Nicholas Bazin

Certified Senior Principal in Asset Management (CSAM)

Connor O'Brien

Alex Young

Ali Farhan Mohammed

Amarpal Singh Bhullar

Anthony Webster

Benjamin Allaway

Bennett Foster

Bonnie Morrone

Calvin Slemp

Chelsea Kowal

Cole Ristau

Cory Peters

Courtney Pelletier

Craig Thompson

Curt Failler

Daniel Everitt

Dayne Williams

Demetrio Flores

Dennis Ruddick

Dexter Montero

Digvijaysinh Rathod

Doug Anderson

Dusty Mcdonald

Earl Irwin

Elizabeth Juhlin

Gregory Taillon

Gurpinder Singh

Heath Rouse

Heather Taylor

James Dunaway

Jameson Fowler

Jason Dickson

Jason Grudzinski

Jigarkumar Patel

Jinay Patel

Joao Marques

Jody Gillis

Jon Pohl

Joseph Isodje

Joshua Martineau

Kelvinasen Subramaniam

Keswick Sam

Kevin Waldron

Kingsley Enwemiwe

Kong Fai Chow

Lea Esconde

Luis Trejos Zapata

Lukman Nahle

Lyndon Kotyk

Melinda Naziel

Michael Aforke Enakoko

Michelle Donald

Mitchell Adams

Myles Charlie

Owen Smith

Patrick Kent

Patrick McIvor

Paul Caraghin

Rebecca Lee

Reginald Keirstead

Robert Menzies

Ron Charles

Ryan Peterson

Ryan Smith

Sada Spaidal

Sandra Williams

Serdar Pirselimoglu

Shane Stephens

Steph Obrigewitsch

Stephanus Sunarko

Taya Ojo

Terminder Sumbal

Trevor Evans

Uzoma Adiuku

Ali Farhan Mohammed

Allanette Hayward

Andrew McMahon

Anthony Mwangi

Anwuli Ndia

Bennett Foster

Blake Elderkin

Bonnie Morrone

Brandon Chevalier

Brandon McKinley

Bryan Fowler

Calvin Slemp

Cosmin Muresan

Daniel Simard

Dexter Montero

Dusty Mcdonald

Dwayne Trynchuk

Elizabeth Juhlin

Gregory Taillon

Gurpinder Singh

Heath Rouse

Heather Taylor

Jason Grudzinski

Jason Roden

Joseph Isodje

Justin Matchett

Kamorudeen Abass

Keswick Sam

Kevin Cummins

The following professionals have receiving their PEMAC recognition between April 2 to November 30, 2024

Kingsley Enwemiwe

Kirby Fowler

Kyle Rathgeber

Matthew Mattucci

Mitchell Audit

Nolan Siemens

Norman Kerswell

Paul Caraghin

Rebecca Lee

Rocky DeCoste

Ron Charles

Ryan Sequeira

Ryan Smith

Serdar Pirselimoglu

Tayo Ojo

Trevor Lohman

Tristan Funk

William Sean Swiderski

Alberta

President Dennis Heinzlmeir alberta@pemac.org

Fort McMurray

President Nayef Mahgoub fortmcmurray@pemac.org

GTA

President Arun Gowtham gta@pemac.org

Metro Vancouver bc@pemac.org

Nova Scotia

President

Martha Myers nova-scotia@pemac.org

Ottawa ottawa@pemac.org

Quebec

President Charles Turgeon quebec@pemac.org

Saskatoon saskatoon@pemac.org

Winnipeg President

Neil Abercrombie winnipeg@pemac.org

Congratulations to all the distinguished recipients of the 2024 PEMAC Awards! Your exceptional contributions to maintenance and asset management have truly set you apart within our community For more details about the awards and to stay updated on future announcements, please visit the PEMAC website and follow us on our social media platforms.

Learn more about the PEMAC Awards

Welland Canal Tour

GTA Chapter members enjoyed an exclusive tour of the St. Lawrence Seaway Management Corporation’s (SLSMC) operations at the Welland Canal. Participants explored the advanced operations center and state-of-theart locks, where remote monitoring, automation, and skilled technicians manage eight canal locks for seamless ship navigation A highlight of the visit was watching a live laker navigate Lock 4, showcasing the canal’s impressive engineering The tour concluded with a presentation on SLSMC’s approach to risk management in maintaining the canal’s safety and efficiency.

The human factor in maintenance projects refers to the influence of behaviors, attitudes, skills, and interactions on project success. Companies often focus on their assets and processes but neglect the people who execute these projects. Effective communication, employee engagement, and psychological safety are essential for achieving project goals. Traditional methodologies such as ISO 55000 provide structured approaches to asset optimization, but there remains a need for strategies that address the complexities of the modern workplace, ensuring sustainable success through a people-centric approach

By Serah Sanni, Ph.D

This guest article was provided by Allied Member, TRO Solutions

Maintenance projects are pivotal for the longevity and efficiency of assets, yet many are marred by high failure rates. This article explores core reasons why maintenance projects fail and identifies popular pitfalls associated with these failures It proposes strategic recommendations for overcoming these challenges, emphasizing 'the human factor This analysis draws insights from asset management experts, case studies, and industry best practices. It highlights the significance of prioritizing workforce engagement and psychological safety, recognizing that motivated and well-supported employees are critical to successful project outcomes. The paper advocates for innovative approaches like the Flexible Thinker® Model, which combines traditional principles with modern innovation to improve project results.

1. Workforce Engagement: Employees need to feel valued and engaged to perform their best. Engaged employees have been shown to be more motivated, committed, and productive. Thus, more likely to take ownership of their tasks and contribute to the overall success of the project Ensuring they feel valued and involved in the project's processes can significantly enhance performance.

2. Psychological Safety: A work environment where employees feel safe to express their ideas and concerns without fear of retribution fosters innovation and continuous improvement.

3. Effective Communication: Maintaining clear and consistent communication among all stakeholders ensures alignment of goals, expectations, and progress, thereby reducing misunderstandings and conflicts.

4 Training and Re-training of Staff at all Level: Providing continuous training and skill development opportunities helps employees stay current with best practices and new technologies, boosting their competence and confidence. Also, specific training of those in the managerial positions on the need to pay more attention to the interest and presentations of employees helps foster a culture of continuous improvement.

5. Training and Re-training of Staff at all Level: Providing continuous training and skill development opportunities helps employees stay current with best practices and new technologies, boosting their competence and confidence. Also, specific training of those in the managerial positions on the need to pay more attention to the interest and presentations of employees helps foster a culture of continuous improvement

Project failures in asset management often stem from a combination of systemic and human factors, with lack of employee engagement and psychological safety being paramount.

Successful maintenance projects require robust senior management support, ensuring alignment of strategic priorities with operational execution. Engaging shop floor personnel is crucial, as their hands-on experience provides valuable insights Preparing for change and involving all stakeholders from the outset fosters ownership and reduces resistance Clear definitions of user requirements and roles, alongside comprehensive training, are essential for effective performance.

Taking a guide from the Flexible Thinker® Model, challenges involved in maintenance projects and recommended solutions are outlined as follow:

1. Lack of Senior Management Support: Without strong backing from senior leadership, projects struggle to secure the necessary support and authority, leading to delays and inefficiencies. Successful maintenance projects require robust support from senior management, ensuring that strategic priorities align with operational execution. Ensuring that senior management is actively involved and supportive of maintenance projects is critical. This can be achieved through regular updates, open door policy, clear communication of project goals, and demonstrating the value of the project to the organization

2. Insufficient Focus on the Human Element: Unengaged employees and an environment where people dread speaking out their concerns on a project for fear of retribution or negative consequences result in low motivation, missed opportunities, increased turnover, and reduced

accountability, all of which hinder project progress. Poor employee engagement, inadequate communication methods, ineffective leadership, and roadblocks in communication channels always lead to misunderstandings, resistance to change, conflicts, and ultimately undermining project success. Addressing these issues requires creating a culture of openness and trust, ensuring that employees feel valued and safe when sharing their insights and concerns This can be achieved through regular communication, inclusive decision-making processes, and strong support systems for employee feedback

3. Inadequate Shop Floor Involvement: Engaging shop floor personnel is crucial, as their hands-on experience provides valuable insights that can drive project success. Failing to engage those who perform the day-to-day tasks can result in practical issues being overlooked, causing disruptions and resistance to change Therefore, engaging shop floor personnel in the planning and execution of maintenance projects must take the fore front as it ensures that the insights and expertise of field workers are leveraged. This can lead to more practical and effective solutions.

4. Insufficient Preparation for Change: Projects must anticipate and manage change effectively Poor change management can lead to confusion and pushback from stakeholders Change management is a vital component of successful maintenance projects. Organizations should provide training, support, and resources to help employees adapt to new processes and technologies Preparing for change and involving all stakeholders from the outset is critical to ensure smooth project implementation.

5. Exclusion of Key Stakeholders: Not involving all relevant parties in a maintenance project can create gaps in communication and information deficiency This results to unmet needs and misaligned objectives. Thus, including all relevant stakeholders in the decision-making process ensures that their needs and concerns are adequately addressed. This collaborative approach fosters buy-in and reduces resistance to change especially from workers.

6. Undefined Business Processes: When business processes are ignored or poorly defined, projects lack a clear roadmap, causing misdirection and wasted efforts. Clearly defining and documenting business processes helps avoid confusion and ensures that everyone understands their roles and responsibilities. This can be supported by using standardized templates and checklists.

7. Outdated or Missing Data: Reliable data is crucial for informed decision-making Projects relying on old or non-existent data face significant risks of failure. Accurate and up-to-date data is essential for effective decision-making. Organizations should implement robust data management practices and regularly review and update their data.

8. Lack of Training: Without proper training, team members may not have the skills or knowledge required to execute the project successfully. Continuous training and development at all levels help management and employees stay current with best practices and new technologies. This can be achieved through workshops, online courses, and on-the-job training.

9. Undefined User Requirements: Clear and detailed user requirements are essential for delivering a product that meets stakeholders' needs Ambiguity in this area leads to unmet expectations and project rework. Clearly defining and documenting user requirements helps ensure that the final product meets the needs of the end-users. This can be supported by deploying Agile tools.

10.Undefined Roles and Responsibilities: Clear delineation of roles ensures accountability and efficient task management Ambiguity here can result in overlapping duties or neglected responsibilities Ensuring that all team members understand their roles and responsibilities helps prevent misunderstandings and conflicts. This can be achieved through clear communication and regular check-ins.

the Flexible Thinker Model

Agile practices involve a dynamic and flexible approach to managing projects, emphasizing iterative progress, collaboration, and responsiveness to change.

This approach allows teams to adapt quickly to changing requirements and stakeholder feedback. Agile promotes teamwork, continuous improvement, and direct communication, often utilizing frameworks such as Scrum and Kanban to facilitate efficient workflow and accountability. By prioritizing flexibility and customer satisfaction, Agile aims to deliver high-quality outcomes in a timely and cost-effective manner, iterative nature, and focus on collaboration. Agile methodologies can significantly enhance the management of maintenance projects by promoting adaptability and continuous improvement.

1. Individuals and Interactions over Processes and Tools: Emphasizes the importance of communication and collaboration among team members and stakeholders.

2 Working Solutions over Comprehensive Documentation: Values the delivery of functional and practical solutions over extensive documentation

3. Customer Collaboration over Contract Negotiation: Involves customers and stakeholders throughout the project lifecycle, ensuring their needs and feedback are continuously addressed.

4 Responding to Change over Following a Plan: Promotes flexibility and adaptability, allowing teams to pivot and adjust their approach as project requirements evolve.

The Flexible Thinker® Model: A Paradigm Shift:

The Flexible Thinker® Model represents a significant shift in project management strategies. It emphasizes flexibility, creativity, and leveraging human potential to create a comprehensive, agile framework This model encourages a people- centric approach, fostering ownership and a supportive project environment.

Core Principles of the Flexible Thinker® Model:

1. Flexibility and Adaptability: This approach encourages dynamic and flexible planning processes that can quickly adapt to changing circumstances and unexpected challenges. Notably, the ability to pivot and adapt to changing circumstances is crucial in today’s world

2. Creativity and Innovation: The Flexible Thinker fosters a culture of creativity, encouraging innovative solutions to asset management challenges. With this model, creative problem-solving and innovative thinking are more presented by the people and same results in a more effective solution.

3 Human-Centric Approach: This prioritizes the engagement and involvement of employees at all levels, and recognizing their critical role in successful maintenance projects creates an atmosphere of psychological safety. It also creates an environment where employees feel safe to share ideas, express concerns, and take calculated risks without fear of retribution. Attending to the needs and

4. Interdisciplinary Collaboration: The Flexible Thinker strongly encourages collaboration across different disciplines and departments to integrate diverse perspectives and expertise This entails adopting a system thinking approach to understand the interdependencies and interactions within any asset management ecosystem

Focusing on the human factor in maintenance projects involves recognizing the critical role people play in achieving project success. Addressing workforce engagement, psychological safety, communication, training, and leadership helps create an environment conducive to high performance and continuous improvement The Flexible Thinker® Model offers a comprehensive approach to addressing maintenance project failures, providing a framework for sustained operational efficiency and project success. Organizations adopting this approach can expect improvements in employee engagement, project outcomes, and overall performance.

Serah Sanni, Ph D , is the Marketing Manager at TRO Maintenance Solutions She blends a versatile expertise in project and asset management while exploring her unique skills in agility, mediation, and leadership. With a professional background as an educator, agile project manager, and lawyer, Sanni has made significant strides in team collaboration, stakeholder management, and project successes. Her diverse expertise has been instrumental in fostering robust partnerships and achieving key organizational milestones. potential of the people involved in the project enhances engagement and performance.

We are pleased to inform PEMAC members about the recent launch of updated standards in the ISO 55000 series by ISO/TC 251, the technical committee on asset management These updates, along with new standards, offer substantial advancements to support asset management practices worldwide

The ISO 55000 series now includes revised versions of ISO 55000, ISO 55001, and ISO 55010, as well as two new standards: ISO 55012, which provides guidance on people involvement and competence, and ISO 55013, which addresses asset management data needs. These new and revised standards offer a wealth of knowledge and guidance aimed at strengthening asset management practices within organizations.

ISO 55001, first published in 2014, serves as the foundational standard for establishing requirements for an asset management system. The 2024 update integrates over ten years of global insights from more than 50 countries, offering clearer guidelines on essential aspects of asset management, including:

• Strategic and operational risk management

• Enhanced planning processes for asset management

• Knowledge management and data practices

These improvements simplify the requirements and make ISO 55001 more actionable for organizations seeking to implement or refine their asset management systems.

As the introductory standard of the series, ISO 55000 outlines the essential principles and benefits of asset management. The 2024 edition reflects the evolution of the asset management field and places a stronger focus on the value generated through effective asset management activities Feedback from asset owners and managers around the globe has been pivotal in refining these concepts, making them more relevant and aligned with contemporary needs.

These standards build upon years of global insights and represent significant strides in asset management excellence. With the new focus on people and data, these standards cater to emerging needs within the field

The newly introduced ISO 55012 and ISO 55013 offer fresh perspectives on two critical aspects of asset management: people and data.

ISO 55012: Recognizing that effective asset management relies on skilled and engaged personnel, this standard provides guidance on building competencies and fostering involvement throughout the asset life cycle. It also emphasizes the importance of internal communication and collaboration to achieve asset management goals.

ISO 55013: In today’s data-driven world, this standard supports effective data management within asset management systems. ISO 55013 offers comprehensive guidance for managing asset data and making data-driven decisions, covering areas like data security, compliance, and feedback channels

ISO/TS 55010: Enhancing Financial and NonFinancial Alignment

The updated ISO/TS 55010 standard focuses on integrating financial and non-financial asset management functions, aiming to strengthen internal controls and improve organizational alignment. This is especially valuable for organizations seeking to harmonize various asset management activities as part of a unified management system.

ISO is also preparing to release ISO 55011, a new standard aimed at guiding public policy development to support asset management initiatives. PEMAC members can look forward to further updates as this standard is finalized and introduced.

We encourage PEMAC members to review these updates and consider how they can be integrated into their current asset management systems. For further details, members can access the updated standards through ISO or reach out to PEMAC for more resources

Visit committee.iso.org/home/tc251 or scan the QR

By Jennifer Ouyang, P.Eng., MMP

Recipient of PEMAC’s 2024 Maintenance Team of the Year (large organization) Award, City of Calgary Facilities Team shares insights into its journey towards maintenance management excellence.

The City of Calgary is a large organization with multiple service lines and holds stewardship over thousands of facilities. Before 2018, there were inconsistencies and many optimization opportunities across the city’s maintenance operations. With a decentralized maintenance program across the organization, the maintenance maturity varied and budget allocation for maintenance was difficult to manage. In response to these issues, the Executive Leadership Team of the City of Calgary started a transformational standardization initiative in 2018 to centralize all maintenance practices under the Facilities Business Unit. The initiative aims to:

• Streamlines operations

• Improve maintenance coordination

• Maximize the value of human and financial resources

This move was a significant shift towards a more cohesive and efficient maintenance framework, standardizing trade practices. During this initiative, Facilities’ Preventative Maintenance (PM) team was established with the task of managing preventative maintenance standards across all city buildings and equipment.

The journey to maintenance standardization started with team building When the new leader of the Preventative Maintenance team was hired, the manager suggested, “Build a strong team”. With these word, the team’s success was set in motion through the support and trust of the Manager and Leader. From there, a culture was cultivated at all levels within the team by showing trust from leadership and the importance of teamwork in the organization. With the culture in mind, a team was built around a key value: always perform above and beyond.

The preventative maintenance team was designed with two corresponding positions, a planner, and a coordinator. The planner supported the organizational need for expertise in maintenance management ensuring proper resource allocation to meet operational needs and the coordinator role further enhances the preventative maintenance program by ensuring an elevated level of engineering oversight. The team’s focus was set to be solution based, data driven, and value added. After hiring the right individuals with a mindset that aligns with the team’s focus, additional training followed for the team to be mutually supportive and cohesive Through this, a harmonious working environment was built around transparency and trust, which allowed its members to follow through with their commitment to exceed expectations.

The mindset and culture of the Preventative Maintenance team led to the success of the team, that now manages the preventative maintenance of over 700 buildings while maintaining a team size of under 10 people

Prior to the preventative maintenance team, facilities’ preventative maintenance program was led by facility operations based on the operators’ familiarities with the buildings. Under the maintenance centralization initiative, the preventative maintenance team operated with a risk assessment principle to manage the program. The priority matrix was used as a risk management tool to manage new preventative maintenance models based on regulatory compliance objectives, criticality of facility types, public impact, equipment type and condition This facilitated the intake of new buildings during maintenance centralization and ensured the priority of critical buildings or equipment.

Expanding on the concept of the priority matrix, a glossary cataloging all equipment requiring preventative maintenance was created Following the risk management principle, the dictionary was categorized into four distinct groups: life-safety, regulated, regular, and low risk. This categorization helped prioritize maintenance activities based on the criticality and risk associated with each type of equipment. Additionally, the team clearly defined the engineering discipline for each piece of equipment, such as mechanical, electrical, HVAC, plumbing, structural, and automation. This detailed classification allowed for precise and effective maintenance planning and execution.

In addition, the risk management approach to preventative maintenance management was crucial in the change process. A new management of change process was created with the name “preventive maintenance new or change request” to control the creation and modification of preventative maintenances.

The priority matrix was used as a risk management tool to manage new preventative maintenance models based on regulatory compliance objectives, criticality of facility types, public impact, equipment type, and condition.

The priority matrix and the dictionary served as the foundation for unifying all preventative maintenance activities under one standard. The standardization ensured that all preventative maintenance tasks were aligned with best practices and regulatory requirements and is continuously updated to reflect new insights, regulatory changes, and advancements in maintenance practices This ensures that the preventative maintenance program remains relevant and effective, greatly enhancing the reliability and safety of the city’s assets. At the same time, the new management of change process brought transparent communication to the management team, reducing risks of preventative maintenance adjustment while allowing immediate action and support on high-risk items such as life-safety and regulatory equipment. Overall, this standardization effort was crucial in streamlining maintenance processes and ensuring consistency across the board and set a solid groundwork for the preventative maintenance team to start the journey towards preventative maintenance optimization

Following the foundation set out by the standardization of preventative maintenance practices, the preventative maintenance team embarked on the journey towards preventative maintenance optimization. The primary objectives of preventative maintenance optimization include the development, implementation, and monitoring of a comprehensive preventative maintenance program that achieves 100% regulation compliance and targets industry benchmarks. The vision of the optimization was to explore present day technology and look for opportunities to maximize the efficiency and effectiveness of all maintenance activities and improve the lifespan and reliability of the city’s assets.

Commencing in 2022, the Predictive Maintenance (PdM) Pilot Project represents a significant step towards implementing predictive maintenance practices for critical equipment and facilities PdM techniques are applied, focusing on equipment such as boilers, chillers, cooling towers, air handling units, rooftop units, compressors, and pumps This multiphase project, expected to conclude in 2025, aims to leverage advanced monitoring and data analysis techniques to predict equipment failures before they occur. By doing so, a proactive approach can be taken to address potential issues, reducing downtime and maintenance costs while ensuring the reliability of critical infrastructure.

In the spring of 2023, the preventative maintenance team began experimenting with drone technology as part of their journey towards Reliability Centered Maintenance (RCM). The initial use of drones was to document the deflation of the Shouldice Seasonal Dome, demonstrating the potential to enhance operational efficiency and safety.

Building on this success, the team developed a business use case for a pilot project that expanded the use of small aerial drones to inspect facilities and document activities related to the operations of the facility portfolio Drones were particularly useful for assessing inaccessible roofs and spaces, confined spaces, safety-restricted areas, and emergency situations.

In December 2023, the team initiated aerial thermal and optical roof inspections on select buildings The pilot project proved successful, demonstrating the cost-effectiveness, efficiency, and quality of data collected through drone inspections. As a result, the preventative maintenance team plans to roll out the drone inspection program more broadly, enhancing their ability to maintain and monitor the city’s infrastructure.

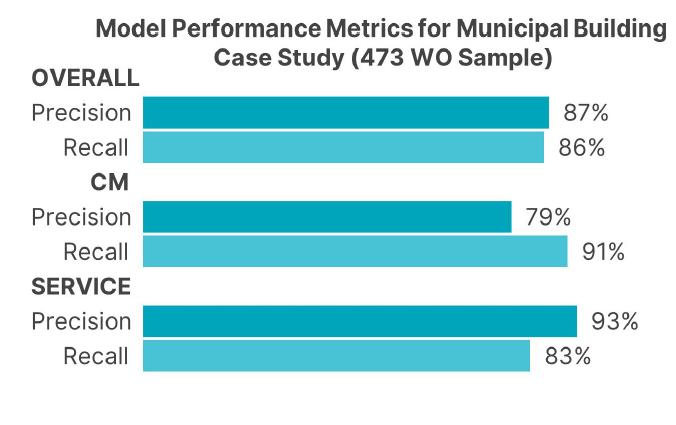

The Artificial Intelligence (AI) initiative represents another innovative approach to optimizing the preventative maintenance program. Manual classification of work orders is a time-consuming process, and the limited human resources available cannot manually categorize years of historical work orders for the city’s entire portfolio of buildings To address this challenge, the preventative maintenance team began exploring the potential of ai technology to drive data-based failure analysis and improve maintenance program effectiveness.

In November 2023, the team launched the first ai pilot project, “failure analysis of corrective maintenance data ” The goal was to determine if a machine learning solution could reduce the manual effort required to classify demand work orders (WOs) and and enhance the accuracy of preventive maintenance. The pilot successfully demonstrated the feasibility of using machine learning techniques to categorize demand WOs into corrective maintenance (CM) and service work orders. Additionally, the pilot showed the capability to categorize equipment for CM WOs.

The journey of preventative maintenance at the City of Calgary to standardization and optimization has been a transformative process In the process, a preventative maintenance team was built with the right engineering focus to be solution based and data driven, and with the belief to always strive above and beyond In the maintenance centralization initiative, the preventative maintenance program was standardized with a risk assessment approach, ensuring the preventative maintenance program for life safety and regulatory equipment were prioritized. This journey not only improved the efficiency and effectiveness of maintenance operations but also ensured the sustainability and reliability of city assets for the future. As the preventative maintenance team continues to explore new technologies for optimization opportunities, the City of Calgary is well-positioned to achieve its maintenance goals and deliver high-quality services to its residents.

This journey not only improved the efficiency and effectiveness of maintenance operations but also ensured the sustainability and reliability of city assets for the future.

Jennifer is a Professional Engineer, project management professional, MMP certified, and a certified energy manager. She is also an Engineering Responsible Member of Facilities authorized by APEGA. She has worked at the City of Calgary for over seventeen years in progressively responsible roles. Her main focus is on maintenance strategy planning, preventative maintenance program design and management, process mapping, RCM analysis, optimization and benchmarking.

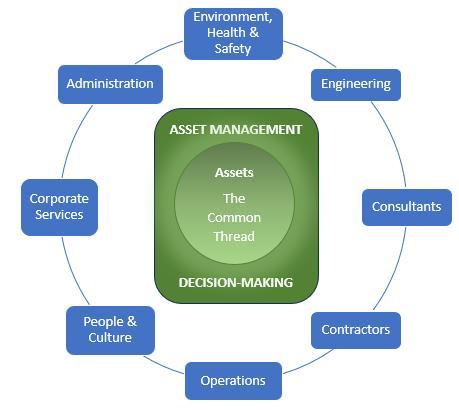

By Nigel D’Souza, CAMA

The Asset Management Landscape is a document published by the Global Forum on Asset Management (GFMAM) and which forms a collective perspective from multiple countries on the subjects of Asset Management. The purpose of the landscape document is to establish globally accepted practices that enable alignment, comparison, and contrast of knowledge bases, practices, maturity assessments, competency schemes and qualifications in this field. It also complements the ISO 55000x suite of standards, while providing readers with context of each of the subjects in Asset Management PEMAC, being a member of the GFMAM, had the opportunity to participate in the journey of this document and its most recent revision in 2024.

In February 2021 PEMAC formed their review team as part of the international effort to determine if a revision was required, and the decision to revise the document was made in 2022 Collaborative International teams who were focused on specific subjects, were assembled to complete the revision of the Asset Management Landscape to version 3 in 2024. The GFMAM ultimately published the revised document in the summer of 2024.

It was evident that Asset Management had matured since the previous versions of the Landscape document, and so this revision brings a harmonised and global view of the subjects comprising asset management with guidance and direction on where to find more information.

Particularly, all subjects were updated and new subjects were also introduced, but it is important to note that the principles of Asset Management are for the most part consistent with previous versions.

For those in the Asset Management practice, having this document as a reference is a great resource; whether you are starting your journey or are well seasoned. There are

40 Subjects which form the Asset Management Landscape and these are organised into Subject Areas:

● Context & Stakeholders

● Governance

● Asset Management Planning

● Leadership and People

● Data and Information

● Delivery

● Value Realisation

Visit gfmam.org/publications or scan the QR code to access a free copy

All of PEMAC’s content on the shared learning library is aligned to the 40 subjects of the Asset Management Landscape, while educational content is also updated to align with the revisions and subjects.

Although the document was also reorganised to better group content and allow for better reading flow, it is important to understand that the subjects have many relationships to each other, and so leveraging this content for use is not necessarily a linear reading of the document Depending on where you and your organisation are on your asset management journey you may want to focus on a subject, which may be in the middle, beginning, or near the end - you don’t have to start with the first subject and work through the document in the order it is written, but do know that the matrixed nature of the subjects means that there will be cross referencing across many of the sections.

Each subject is organised into standard headings including a definition and context to provide the reader with what the subject entails and considerations in its application. When reviewing the artefacts in each of the subjects you are provided with guidance on the information/knowledge which should be considered as well as relevant standards

Although this is purposely not comprehensive in order to keep the document relevant globally (and not specific to any locality or sector), it should prompt the reader to other similar content which may be relevant in their jurisdiction or sector

Organisational Purpose and Context is one of the subjects within Context & Stakeholders, and provides content to guide considerations for defining boundaries which inform the approach to Asset Management within an organisation, and that it should be aligned with the organisation’s purpose. From the context provided within the subject it guides the reader to alignment with aspects of the organisation such as its mission and vision, stakeholder requirements, and compliance among others

In application, Organisational Purpose & Context can be applied by first understanding how the organisation’s purpose its mission, vision, and strategic goals connects with its asset management practices. For example, a utility company focused on sustainability and operational efficiency must ensure that its asset management strategy aligns with these goals. This involves analysing both the external context, such as regulatory requirements and market trends, and internal factors like asset conditions and organisational objectives.

The company may then integrate its purpose into decision-making processes, ensuring that the asset management strategy supports not only operational needs but also long-term corporate goals. For instance, acquiring assets that contribute to reducing environmental impact or that enhance reliability would align with the company’s vision of sustainability and excellence. Regular reviews of the organisation’s purpose, alongside changes in the external context, help refine asset management practices to stay relevant and effective.

By linking organisational purpose with asset management, the company ensures that its resources are managed in a way that drives its strategic objectives, while adapting to both internal and external pressures. This connection between purpose and context creates a cohesive approach that strengthens the organisation's ability to meet its goals sustainably

For those in the Asset Management practice, having this document as a reference is a great resource; whether you are starting your journey or are well seasoned.

You don’t have to start with the first subject and work through the document in the order it is written, but do know that the matrixed nature of the subjects means that there will be cross referencing across many of the sections.

Similarly, we can take the subject Decision Making which can be applied by ensuring that an organisation’s asset management decisions are informed by both its strategic goals and operational context. For example, an energy company aiming to improve efficiency and sustainability must make informed decisions on asset investments, maintenance strategies, and risk management These decisions are guided by factors such as regulatory requirements, market trends, and internal performance data, ensuring alignment with the company’s long-term objectives.

Effective decision-making involves a structured process where risks, costs, and benefits are evaluated to choose the best course of action For instance, decisions about upgrading ageing infrastructure or investing in new technologies must weigh the impact on asset performance, regulatory compliance, and financial returns. By incorporating data and input from stakeholders, the company can ensure that asset management decisions are both evidence-based and strategically aligned.

This approach to decision-making ensures that all assetrelated choices contribute to the organisation’s broader goals, such as improving reliability, reducing costs, and enhancing sustainability. Regular review and adaptation of decisions ensure that they remain relevant as the business environment evolves, enabling the organisation to stay competitive and resilient in a dynamic industry Resourcing Strategy and Management

As a third example we’ll explore the application of the subject Resourcing Strategy and Management within asset management which starts by aligning resource planning with the organisation’s asset management goals. With alignment to the organisational goals and objectives and the asset management system/plan there should be consideration for key objectives, such as increasing efficiency or enhancing sustainability, and ensuring that the necessary resources— people, finances, and equipment—are allocated to meet these goals. For example, if your goal is to reduce environmental impact, focus resources on upgrading critical infrastructure or implementing renewable energy projects.

In reviewing the context of the Resourcing Strategy and Management subject you may then also prioritise critical resources by identifying which assets are most important to your operations and allocating the necessary skilled personnel, budget, and tools to manage them. This ensures that high-impact assets receive adequate support to maintain optimal performance. Additionally, develop a lifecycle management plan that accounts for the full cost of owning and maintaining assets, helping you avoid unforeseen expenses and manage resources more effectively over time

Regularly review and adjust your resource strategy to account for changes in business needs or external factors, such as new regulations or market trends. By doing so, you ensure that resources remain aligned with both current operations and future strategic goals

Collaboration between departments such as finance, operations, and maintenance is also key to ensuring that resources are managed holistically and efficiently across the organisation.

The goal is to ensure that your organisation has the necessary resources to manage its assets effectively and realising value while supporting both short-term operational needs and long-term growth objectives.

Where you can go for more information?

The Asset Management Landscape document is available as a free resource through the Global Forum on Maintenance and Asset Management.

To get a copy of the latest version you may visit: https://gfmam.org/publications/asset-management-landscapev30

This provided an opportunity for a review of the changes within the subjects comprising the subject area while allowing for an informal discussion on how participants apply the subject in their work, with a sharing of successes and challenges. The Fireside Chats were also recorded and are available to members on PEMAC’s Shared Learning Library.

There have also been a number of PEMAC events which have taken place online since the launch of the Asset Management Landscape version 3, and have provided context and discussion on the application of the document.

Following the launch of the Asset Management Landscape version 3, PEMAC held a webcast to review the changes which took place between version 2 and the revision, while articulating what this means to PEMAC and members. This provided a great overview of the revised document and was recorded for reference in PEMAC’s Shared Learning Library.

In September and October 2024, PEMAC also hosted a series of Fireside Chats with each focused on one of the seven subject areas of the Asset Management Landscape version 3.

Although there are resources which you can review independently, knowledge sharing and learning whether formal or informal, are great ways to build knowledge and competency. PEMAC events, content, and educational offerings are aligned with the globally harmonised subjects of the Asset Management Landscape, and there are many opportunities whether formal or informal to learn and share the application, successes, and challenges in the subjects of Asset Management

MainTrain 2024 brought together maintenance, reliability, and asset management professionals for three days of learning, collaboration, and networking. Packed with keynote presentations, workshops, tours, and an awards gala, the event offered invaluable insights for all attendees

Day 1: Monday, September 23, 2024

The conference opened with a warm welcome from the Hon. Brenda Murphy, Lieutenant Governor of New Brunswick, followed by an inspiring keynote from sustainability consultant Carl Duivenvoorden. Carl's session, “Your GREEN Filter:

Sustainability in Everyday Decisions,” set the stage for a day focused on sustainability and innovative approaches in asset management.

Workshops and Presentations:

The day was filled with educational workshops, including:

• PM Optimization led by Yoann Urruty of Spartakus Technologies, where attendees participated in hands-on exercises to optimize maintenance processes

• Henry Adarighofua and Philip Schachtner from ReVisionz provided insights into Using Reality Scans to update and restructure asset registers.

Two offsite tours offered attendees a closer look at major industrial projects:

• The Saint John Energy Burchill Wind Project tour, which showcased renewable energy initiatives in the region.

• A visit to Irving Pulp & Paper, where participants learned about advanced production methods and sustainable operations in one of New Brunswick’s leading industries

Delegates tour the Irving Pulp & Paper Mill in Saint John, New Brunswick

MMP Module 1 Workshop : An Integrated Strategy for Maintenance Management

Participants attended MMP Module 1: as a two-day workshop led by Alp Bora. This foundational module from PEMAC's MMP certification program explored the "Maintenance Excellence Pyramid" from Uptime 3, covering essential topics like RCM, RCFA, and performance management. Alp’s expertise helped attendees align maintenance strategies with business goals, building a foundation for maintenance excellence

The second day began with an engaging keynote from Rosalyn Hyslop, Co-CEO of Mrs. Dunster’s Bakery, who shared her company’s inspiring 10-year growth journey, including the challenges of building a 40,000-square-foot bakery during the pandemic.

The MRO Magazine Roundtable featured industry leaders discussing trends and challenges in maintenance and reliability It was a lively discussion that offered attendees an opportunity to exchange ideas and ask questions directly to the panelists. This columnated in a presentation that shared key insights discussed during each of the discussions the panelists facilitated.

Gala

The highlight of Day 2 was the Awards Gala held in the beautiful Atrium of Market Square, sponsored by Northern Lakes College The gala celebrated excellence in the maintenance and asset management professions, recognizing individuals and organizations for their contributions to the field. It was a night of celebration, networking, and honoring outstanding achievements.

Everything that is taught [at MainTrain] relates to the environment I work with and can directly be applied.

The final day began with a keynote from Jason Limongelli, Vice President at J D Irving, Limited, who provided insightful leadership lessons and shared innovations in asset management from his vast experience in the industry.

Panel Discussion and Closing Ceremony: The final panel, “Cultural Alignment: Bridging the Gap Between Strategy and Execution,” addressed the importance of aligning organizational strategy with practical execution. The panel offered advice on overcoming cultural barriers to successful implementation. The event concluded with a closing ceremony that acknowledged the contributions of speakers, attendees, and sponsors, setting the stage for the future of MainTrain

During the closing ceremony, it was announced that MainTrain 2025 will take place in Calgary, Alberta from October 27 -29. We can’t wait to see you there!

We extend our heartfelt gratitude to the attendees, delegates, speakers, and sponsors who made MainTrain

2024 a resounding success. Your engagement, insights, and contributions created an inspiring environment for learning, collaboration, and innovation. Special thanks to our sponsors for their generous support and to our speakers for sharing their expertise.

Together, we continue to elevate the maintenance, reliability, and asset management professions.

MainTrain Conference Highlights

• 6 Pre-Conference Online Sessions

• 1 Course (MMP Module 1)

• 8x ¼ Day Workshops

• 2x ½ Day Workshops

• 9 Sponsor Presentations

• 2 Off-Site Tour

• 3 Keynotes

• 2 Panels

• 64 Presentations

April Tucker, P.Eng., CAMP

Trying to define asset management (AM) with the following concise description is not easy and really doesn’t do it justice. My understanding of the benefits of AM has come from forming the connection to what we do at Halifax Water.

AM comprises the decision-making tools we use to realize the value from our assets in a way that meets our organizational objectives. It involves the balancing of costs, risks, and desired performance (aka “the triple bottom line”) to realize the most value from assets. AM focuses on the entire life cycle of an asset and on the decision-making approach.

One of the ways that AM is so impactful is that it creates a framework that can be established within any type of organization. The value of framework is not confined to the interests of one specific group and its power to build on what we have already accomplished, adapt with change, and continue to deliver results comes from a unified organizational effort.

Halifax Water’s Asset Management Framework is being designed to be asset-centric, focusing on the assets themselves. This approach ensures that every decision we make on a daily basis contributes to fulfilling our organization’s purpose as a utility and support the organizational objectives we have identified as priorities – The AM Policy.

Within Halifax Water we are grouped into departments and specialized teams Even though we see assets from different perspectives such as operational, regulatory or environmental, each of our different roles, locations and departments are focused on achieving success from the same group of assets. AM is founded on four fundamental principles of value, alignment, leadership and assurance (ISO 55000) Alignment and assurance have become the fundamentals that most resonate with me.

Alignment is sometimes referred to as “line of sight”. Using asset management to align decisions, action plans and activities with organizational objectives Alignment is required so that the AM framework gets embedded and supported from the executive level (our leaders) through the organizational business units and/or departments to the assets themselves.

The framework is developed so that we can consistently meet our organizational objectives by the way we do our jobs every day. Improving alignment has already affected the way our organization is structured with the 2023 . reorganization of the Engineering Department

into strategic teams, as well as recent changes in leadership and even changes in department names.

There is a progression towards cross functional teams such as workshops, Asset Management Implementation Teams (AMITs) and business units that work to improve the movement and interpretation of asset information.

Assurance refers to continuous improvement that allows the AM framework to accommodate changes Assurance is provided by delivering AM consistently and then monitoring the AM processes and the outcomes. Assets need to fulfill their purposes and potential. Organizational objectives must be met. As quality performance data becomes available, there is a continuous improvement component that refines the alignment from “the bottom up” by comparing anticipated results to the actual results. This is the confirmation step that our decision-making approach is yielding the right results.

Applying Asset Management at Halifax Water with a Reservoir Asset Management Plan

I recently completed PEMAC’s Asset Management Professional (AMP) Certification Program delivered by Northern Lakes College.

The final course, a capstone project, is intended to apply the expansive program content to produce an Asset Management Plan for a critical asset in your own organization.

Reservoirs were selected to show how an asset management framework can be built on past and ongoing work to improve alignment within Halifax Water. The Reservoir AMP demonstrates our internal capabilities and establishes alignment with the AM program. By comparing Halifax Water’s AM program against industry standards and best practices, additional content has been developed in areas such as life cycle analysis (see below), levels of service (LOS) and strategic asset management plan (SAMP).

Applying AM decision making will increase the value realized from our reservoirs There are future opportunities to apply the framework to other critical assets across water, wastewater and stormwater service types.

The Reservoir AMP was developed in parallel with our ongoing AM projects and programs, including the 2024 draft Critical Asset Inventory, Condition Assessment Program (2024/25), performance monitoring improvements (2024/25), and reservoir condition assessment project 2024/25).

On a personal note, this six-course program took me sixty weeks to complete, with a personal investment of 10 to 15 hours most weeks. I am especially pleased with my Capstone project because it is a culmination of what I learned about the field of AM and how to apply the fundamentals to improve what we each do every day at Halifax Water

The Reservoir AMP project was the recipient of PEMAC’s 2024 AMP Capstone Award, and I was invited to attend the MainTrain conference in Saint John, NB in September 2024 to present my capstone project

It received positive (and, frankly, very humbling) feedback from the course 6 instructor, Cliff Williams, who noted the AMP is applicable to our organization and practical to implement.

Having a chance to collaborate with professional peers across the country also reminded me that Halifax Water is a known and well-respected organization. We are all facing similar challenges of limited funding, aging infrastructure, population growth and adapting to climate change and we have an on-going opportunity to share the journey with others.

April Tucker is an experienced civil engineer with over two decades of expertise in water utility management and asset renewal. She joined Halifax Water, a prominent regulated utility in Atlantic Canada, in 2008 as a project engineer. After completing three of the six AMP courses and gaining new insights into asset management decision-making, April transitioned to the role of Asset Management Engineer. Her current work centers on condition-based and strategic asset renewal. April lives in Tatamagouche, Nova Scotia with her three children,

April is the recipient of PEMAC’s 2024 AMP Capstone Award, recognizing excellence in the Asset Management Professional (AMP) program final project, the Capstone.

By Caleb Myram, MMP

After starting out as a trucking and pipeline company, Plains Midstream Canada acquired several large fractionation and straddle plants for processing natural gas liquids. The addition of these larger facilities created a need for Plains to develop more robust work management processes to standardize the planning, scheduling, and execution of maintenance activities.

At the same time, the acquisitions required the development of more mature project management processes so that the projects team could execute larger scopes and support the engagement of more stakeholders. Over the past few years there has been significant development in these two areas of the organization, but that progress has happened in parallel with little integration between them.

While the work of process development has allowed the gaps to be more easily identified, it has also cemented the differences with how the two teams manage risks and allocate resources. Now that the maintenance teams and project teams have matured to a point where there is consistency internally, it is time to integrate their processes to increase the efficiency of both.

To address this gap, a project was initiated to integrate work management and project management processes focused on the Empress area of the organization located in Alberta The intent of the project is to produce a premise document and training material that clarifed how the Plains’ project and work management processes aligned. The project also addressed the need for integration of schedules, clarity on responsibilities of stakeholders, and ongoing communication between the teams to support continuous improvement.

In this article I will begin by summarizing the gaps that exist today with the Empress. I will then summarize the scope of the project that was kicked off to address those gaps. Finally, I will provide an update on how the project has progressed since it was initiated and summarize the planned next steps as the organization continues its journey to excellence in work management.

To date, the project and maintenance teams typically work in silos The project team, based out of Calgary, are not familiar with the processes used at the sites by the maintenance teams to manage resources and coordinate work activities. As a result, they find it difficult to engage the site resources required to define scope, plan, and execute their projects. This has left them with the perception that site stakeholders were unwilling to help ensure successful projects. In the end, the limited engagement of site resources and the tensions between the teams has resulted in inefficiency and increased risks.

At the same time, the maintenance teams are not well informed of project scopes and schedules. Since site personnel are not aware of project deliverables, conflicts often arouse due to the misalignment between project and maintenance priorities. In the worst examples of misalignment, project activities that require equipment shutdowns are planned and scheduled by the projects team without engaging the maintenance group at site.

In other cases, the fact that the project team has not engaged with the weekly maintenance schedule has meant that site resources required to support project execution are not available when required.

There were also technical gaps that create challenges for integration The most significant of these is the fact that the project team used project management software to task out and schedules work activities, while the sites uses a CMMS system and supporting scheduling software. Since the job plans and schedules are developed in different software, it is cumbersome to try and keep them aligned in both systems through planning, scheduling and execution. This leads to conflicting progress reports and confusion among stakeholders.

By Serah Sanni

To address these gaps, a project was kicked off to align the teams and eliminate technical barriers to coordination The project's scope was developed to allow the project team to deliver higher quality results with less risk and cost to the facilities while fostering a culture of collaboration and continuous improvement.

A key element of the project was the development of a premise planning document that detailed the requirements for integrating with the maintenance teams in the Empress area Once completed, the planning premise document helped to clarify how project stage gates, work order statuses, and how MOC stages aligned with one another. The document will also provide a reference for projects teams as they work to engage site resources for help in project development or execution. It is designed to provide guidance on everything from engaging the area advanced first aid team, to creating tasks in job plans that properly communicate scopes of work through the maintenance schedule.

The project will also deliver a solution that allows schedules to be developed by the projects team using project management software to be transferred into the scheduling tool used by the district for routine maintenance. This solution will include resource coding translation and will ensure that important scheduling information, like work area or risk mitigations, is transferred between software.

A key element of the project was the development of a premise planning document that details the requirements for integrating with the maintenance teams in the Empress area.

Once implemented, schedule updates completed in one scheduling software will automatically update the other and, in turn, provide all stakeholders with access to the latest information

To ensure that the integration efforts are supported, the project scope includes the creation and delivery of training material for project and maintenance team members. It also captures the development of a roles and responsibilities document for a dedicated Project Lead role that will be presented to senior leadership The Project Lead role is intended to support continuous improvement, provide training, support project development, and maintain plan and schedule quality for projects executed in the area This is combined with the formation of a project stakeholder group, made up of project and maintenance team members, which will meet quarterly to review learnings, update processes, and discuss upcoming projects to ensure readiness.

By Serah Sanni

The integration project was supported by a strong business case with significant financial and non-financial benefits. The financial benefits included reduced costs associated with poor equipment operation after project handover, reduced project execution costs, and reductions in production impacts resulting from delays in project execution. The non-financial benefits included fewer incidents and near misses, fewer MOC non-compliances related to project execution, and less stress among groups and individual stakeholders.

Since the project kicked off in the Spring of 2024, there has been substantial progress made in integrating the processes and teams. An important step has been getting construction coordinators engaged by the projects team trained in Maximo. These coordinators have begun to submit plans and schedules using the CMMS used by the maintenance team, which has resulted in significant improvements in communication between groups

A turnaround group, reporting to the projects team, has also been created and has begun work on the development of a technical solution for the integration of execution schedules. It is expected that this will be completed before a planned turnaround in the Spring of 2025. After the tool is developed and tested through the turnaround it will be available for use with all projects going forward

Since the project kicked off, there has also been a new gap highlighted that was not identified in the initial project scope. While working to align the processes, it became clear that there was not a common understanding among leadership about who is responsible for some of the tactical steps required to prepare and execute work plans. Misalignment on the responsibilities of leads, coordinators, and managers supporting work execution required us to add a new section to the planning premise document The new entry details items such as who is responsible to organize swipe cards for third-parties allowing them access to a site; who is obligated to attend site schedule lockdown meetings to ensure that project tasks are included in weekly maintenance schedules; and other similar responsibilities.

The integration project was supported by a strong business case with significant financial and non-financial benefits. The financial benefits included reduced costs associated with poor equipment operation after project handover, reduced project execution costs, and reductions in production impacts resulting from delays in project execution.

Going forward, our highest priority is the continued engagement of project team stakeholders to capture learnings and identify areas for improvement. There will always be new issues that arise, so the relationship between the teams and the use of the planning premise document to record resolutions will continue to be a focus.

Other stakeholder groups like pipeline integrity, environmental, and asset integrity have also seen the benefits of the clarity provided by this initiative. All these groups have expressed an interest in becoming more integrated with work management processes to better meet their own deliverables. Working with these groups to capture their requirements in the planning premise document will be another area of focus in the coming months.

By Serah Sanni

CalebMyram is currently the Planning and Scheduling Team Lead for the Empress area of Plains Midstream. He is a First Class Power Engineer, Journeyman Instrumentation Mechanic. He began his career in Fort Nelson BC as an operator at a natural gas processing facility where he was first exposed to maintenance management. Since then he has worked as an instrumentation mechanic, operations team leader, and chief power engineer before moving into planning and scheduling in 2021. He now lives in Medicine Hat AB with his wife and two children.

Caleb is the recipient of PEMAC’s 2024 MMP Capstone Business Process Focus Award. This award encourages and recognizes excellence in the Maintenance Management Professional (MMP) program’s final project, the Capstone Caleb completed the MMP program at Northern Lakes College and his project was nominated by his module 8 instructor He attended MainTrain 2024 in Saint John, NB to accept the award and present his MMP capstone project to his professional peers.

The issue of PEMAC Now has been stewarded by the PEMAC Editorial Board

This team has set an objective to increase the number of PEMAC members who contribute editorial content to PEMAC Now and other external publications

If you are interested in opportunities to contribute please submit your expression of interest to editor@pemac.org. The Editorial Team would like to thank our advertisers and everyone that contributed, making this issue of PEMAC Now possible See you next time

Scan the QR Code to contact the PEMAC Now Editorial Team