Paula Cano

M. Arch | B. Arch Selected Works 2024

USA

• Pavilion for Boggy Slough Conservation Area

• 2x4 Texas A-Frame Exhibition

• Let It Flow. Modular Structure of Logs

• Presentation to AIA Dallas: A Non-Conventional Spatial Intervention: Bamboo in a Modern Architecture Campus. 4th International Sustainable Buildings Symposium.

• Flexibode: Prefabricated Tiny Housing Solution

• Editor at ArchDaily

Building | Dwelling | Thinking

Projects and Collaborations

Canada. Calgary

• Feasibility of Multimodal Mid-Rise Timber Buildings.

Spain

• Editor at ArchDaily Arquitectura&Empresa.es Colaboration with ElConfidencial News

• School restoration and frame house construction.

Colombia

• Bus shelter of Bamboo

• Bamboo Dome

• Approaching lacustrine architecture: Extension of stilt school

Russia. Moscow

• Exhibition of The Russian Pavilion in Venice by Alexei Shchusev

China

• Certified researcher at INBAR, Virtual Anji Bamboo Study workshop.

Ecuador. Galapagos

• Master of Architecture Thesis: Recovering Landscape as a Building Practice

• Illustration for Book “As I from the south: Travel chroniques in Latin America

• Concert hall for Philharmonic Orchestra of Bogota

• Soft architecture. Hand weave textiles manufacturing

paula.naca3@gmail.com | +1 4692375826

Page 4 8 11 16 28 31 Page 16 18 22 31 Germany

31 20

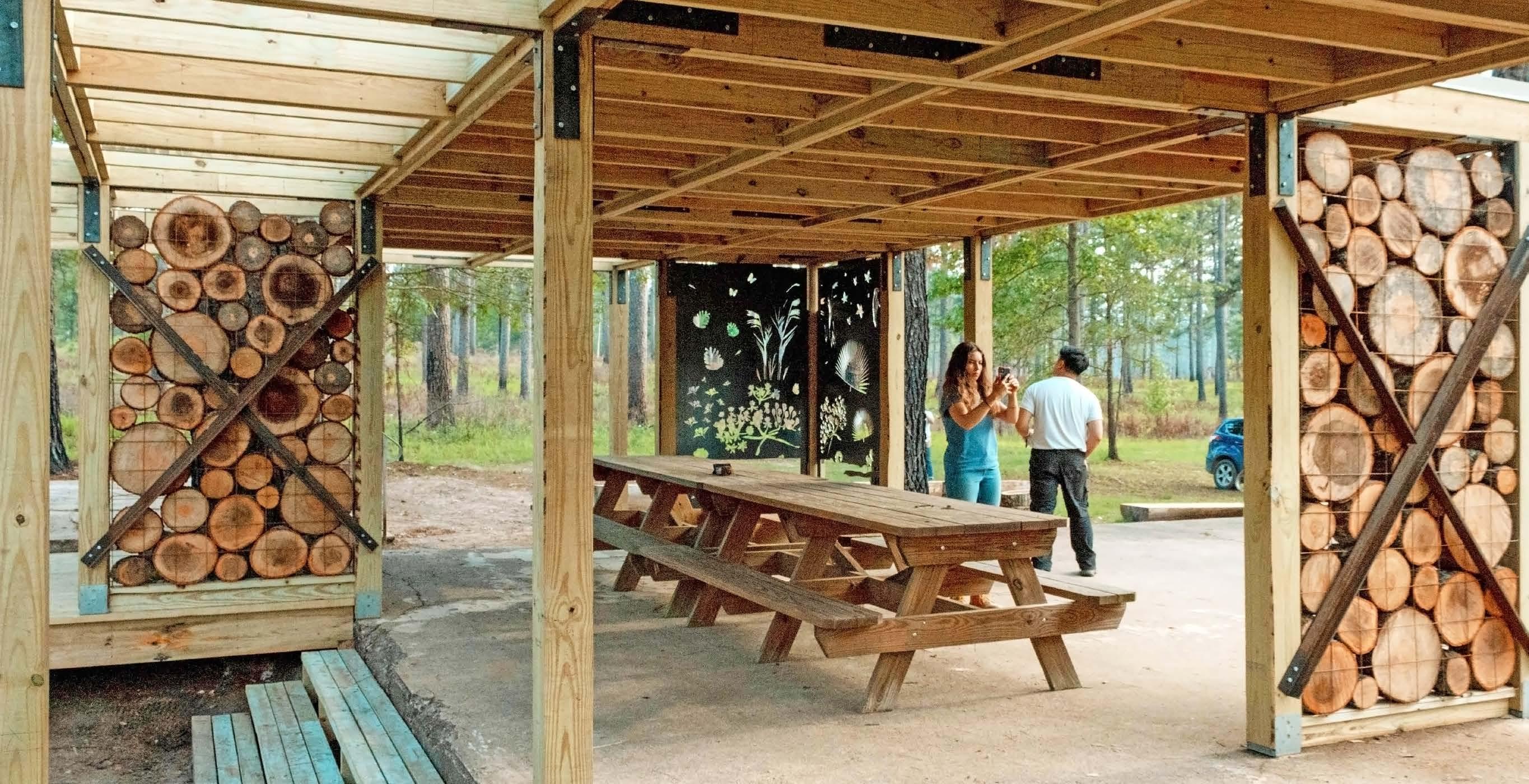

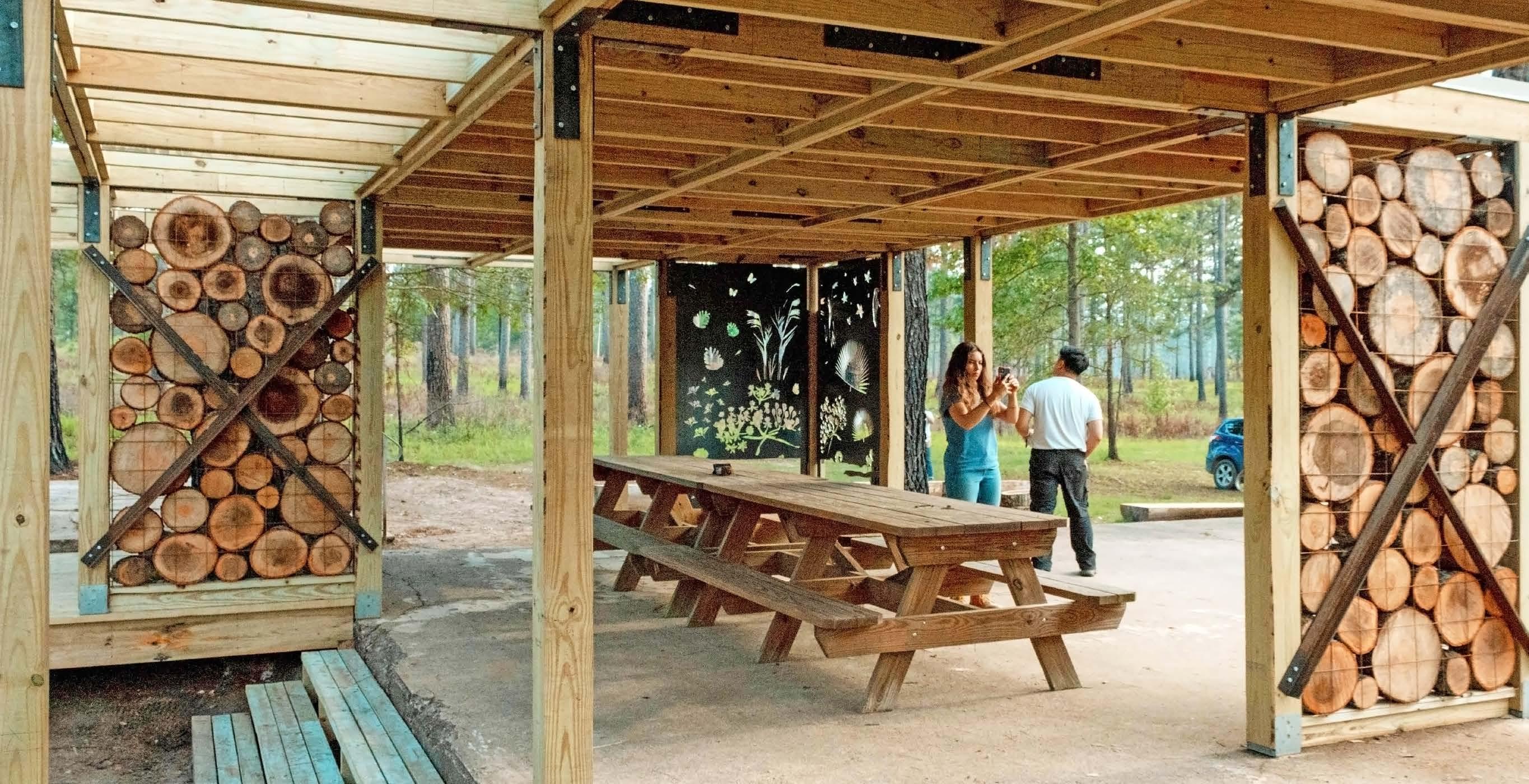

Pavilion and Master Plan for Boggy Slough Conservation Area

The Pavilion exalts the spirit of a Loblolly Forest to provide a site-specific place for education and appreciation of rural East Texas. As such, by acknowledging the history of the previous lodge on site, which burnt down 50 years ago, the project illustrates the remarkable potential of local materials by a single roofing to host 30 people.

The design footprint is based on the size of the largest loblolly pine ever recorded, measuring 54” in diameter. The module sets a pattern of fill and voids to provide shelter, respect existing vegetation, and frame views of Design and Construction Studio | 2023

University of Texas at Austin | Gulf Coast LabStudio In collaboration with bcWorkshop Lufkin. TX. USA. 48m² | 520 sq-ft²

Teamwork: Coleman Coker AIA, Sebastien Bartlett, Laura Bui, Paula Cano, Macarena de Salvidea, Yusuf Derya, Ciara Hackman, Madelaine Hamilton, Annie Hayes, Aya Kousa, Tessa Laplante, Miguel Magtaan, Keely Morgan, and Kate Shirley. | Client: The Temple Foundation

Texas Forestry Association (TFA) Wood Design Excellence Winner

Interior of the Pavilion from North Facade

Photo: Gulf Coast LabStudio

Teamwork: Coleman Coker AIA, Sebastien Bartlett, Laura Bui, Paula Cano, Macarena de Salvidea, Yusuf Derya, Ciara Hackman, Madelaine Hamilton, Annie Hayes, Aya Kousa, Tessa Laplante, Miguel Magtaan, Keely Morgan, and Kate Shirley. | Client: The Temple Foundation

Texas Forestry Association (TFA) Wood Design Excellence Winner

Interior of the Pavilion from North Facade

Photo: Gulf Coast LabStudio

6 5 4 3 2 1 B A C E F G H I J 7 A.1 K 8 9 10 11 12 13 14 15 1 6 4 2 9 10 11 12 0.00 TOS 0' 0" TOF -5' - 6" BOB 8' 0" ST.DCK 8' 7 1/4" A C E G H A.1 K 1/16" = 1'-0" Building Elevation - South 1/16" = 1'-0" Section 1 EXISTING STAIR TO BE REMOVED EXISTING STAIR TO BE REMOVED CHIMNEY LOG BENCH EXISTING SLAB EXISTING SLAB 1/16" = 1'-0" Site Plan 2

Site Plan and Building Elevation Modeling: Gulf Coast LabStudio

3 NS Connecting Deck Detail

3/4" = 1'-0"

5 Section - Roof Detail 03

3/4" = 1'-0"

LOCATION ARCHITECT

Apple Springs, TX 75926

3

3/4" = 1'-0"

4 NS Deck Detail

Coleman Coker

DESIGN TEAM

Jean Sebastien Bartlett

Laura Bui

Paula Cano

Ana Macarena de Salvidea

Yusuf Derya

Ciara Hackman

Madelaine Hamilton

Annie Hayes

Aya Kousa

Tessa Laplante

Miguel Magtaan

Keely Morgan

Kate Shirley

ISSUE DATE SHEET NAME

03/06/23

#4

SECTION DETAILS

SHEET NO.

EMBEDDED 6"X6" PRESSURE TREATED #4 REBAR J-ANCHOR

REBAR - 4 E.W. 2

FOUNDATION DETAIL

@

0.00 TOS 0'9 1/4" 0'1 1/2" 4' - 8 1/4" 4' - 9"

C - HALF-FOOTING

EXISTING SLAB

Yusuf Derya

JOIST HANGER 0' - 2 3/4" 0' - 8"

T.L.L. Temple Foundation

A5.50

3/4" = 1'-0" EW Connecting Deck

I 3' - 10 1/4" 6 7 ST.DCK 8' - 7 1/4" PRE-FORMED EAVE FLSHG. TRTD SYP ST.DCK 8' - 7 1/4"

= 1'-0"

Detail

3/4"

0'3 5/8" 0' 3 5/8" 1/4" / 1'-0" 0' 4" PRE-FORMED GUTTER SEE DET. X 2 x 8's TRTD SYP STEEL CONNECTION SEE DET. X 2 x 6 TRTD SYP WELDED WIRE MESH (SEE DET. X) 2X4'S @ 16" O.C. RIP MEMBER FOR SLOPE AS SHOWN ON ROOF PLAN 5/8" PLYWOOD DECKING Roof Edge Gutter Detail 5 1 Log Cookie Wall Wood Decking Laser Cut Steel Panel 2X10'S TRTD SYP 2X6'S TRTD SYP 2X8'S TRTD SYP REF. A1.03-2 REF. A1.03-2 6" CAST-IN PLACE CONCRETE TRENCH #4 REBAR - 4 E.W. 0'8" 0'6" 0'6" 1/4" / 1'-0" BOB 8' - 0" ST.DCK 8' - 7 1/4" 0'2 3/4"

Interior of the Pavilion from North Facade Photo: Gulf Coast LabStudio

North Facade

Photo: Gulf Coast LabStudio

North Facade

Photo: Gulf Coast LabStudio

Fabrication

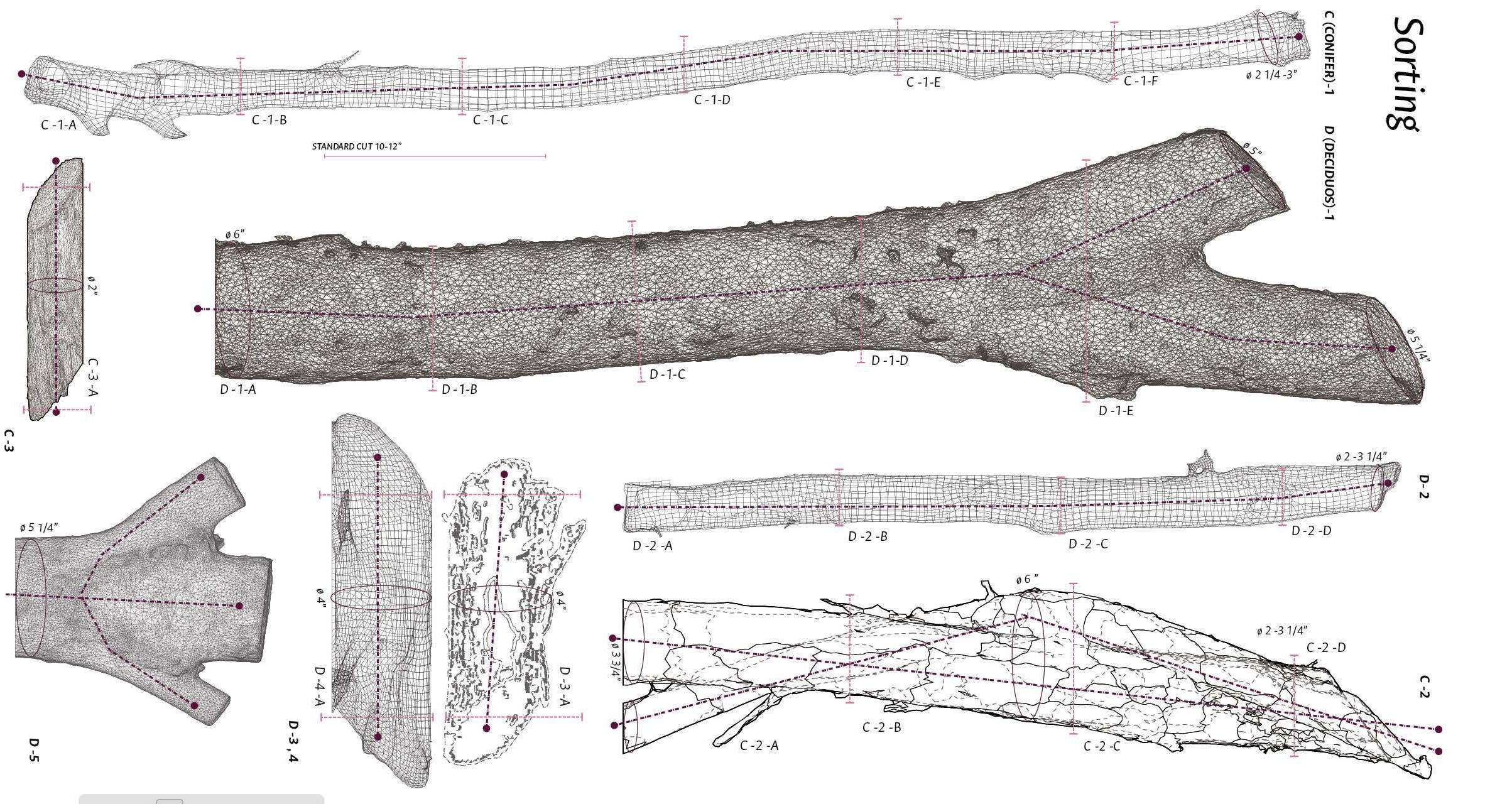

Let It Flow. Modular Structure of Logs

University of Texas at Austin Design Excellence Nominee 2022- 2023

Design and Manufacturing Studio | 2023

University of Texas at Austin Digital Fabrication and Material inFORMation Class. Advised by Danelle Briscoe AIA

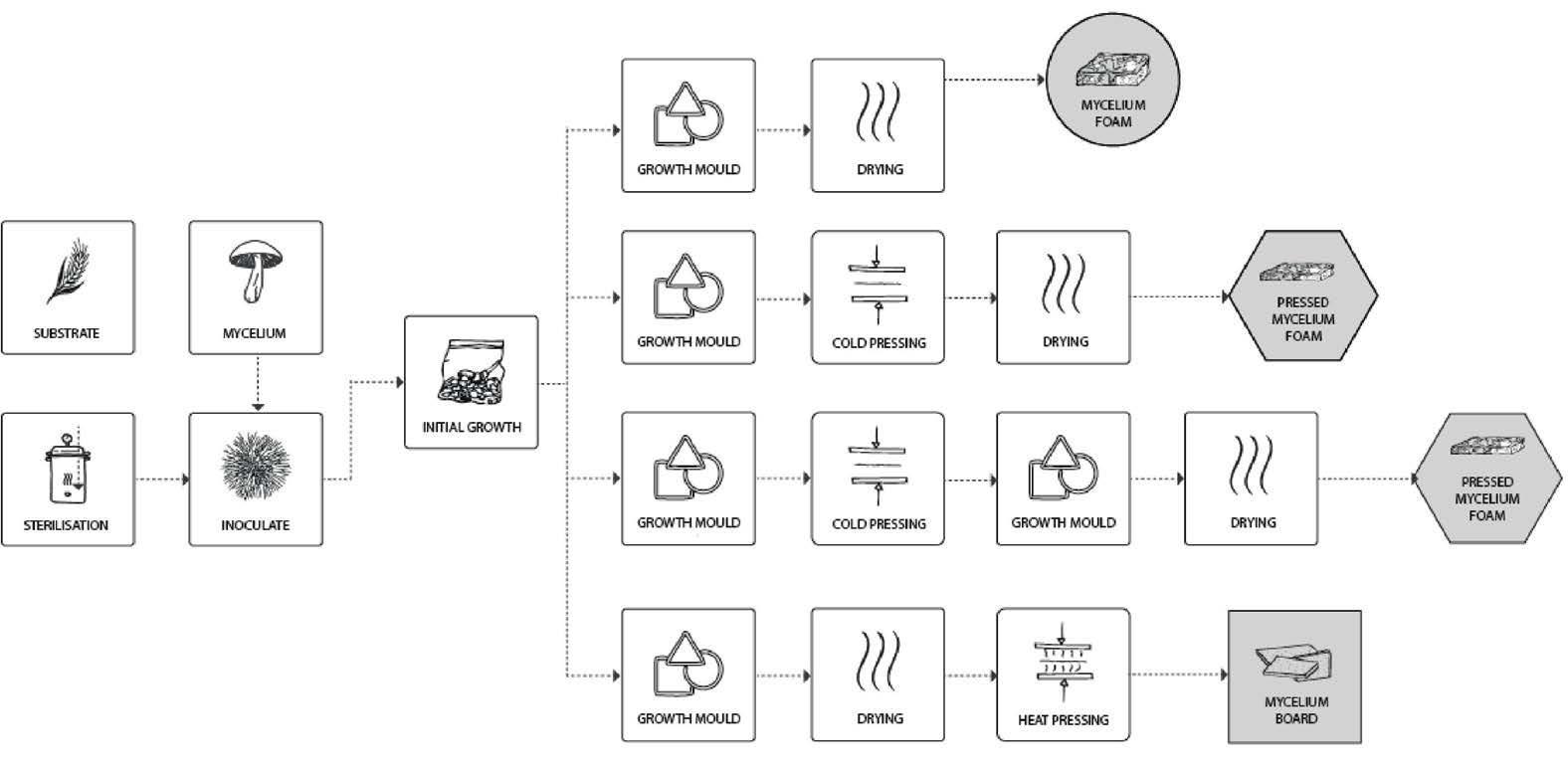

Let it Flow is a modular structure made of logs that seeks to up-cycle the massive wood “waste” after the freeze in Texas last February of 2023.

The project explores alternative approaches to using raw timber resources by demonstrating a possible use of unusual-form timbers not currently of value to the standard milling process. By 3D scanning the logs, a more accurate and precise analysis determines if the blocks are “filled” uniformly or following the branch patterns (non-uniform). The pieces comprise multiple configurations to adapt to interior design, enclosure, and architectural partition.

Keywords: Regenerative Materials, Assemblies and Processes, Material Composting

Block Prototype

by Paula Cano

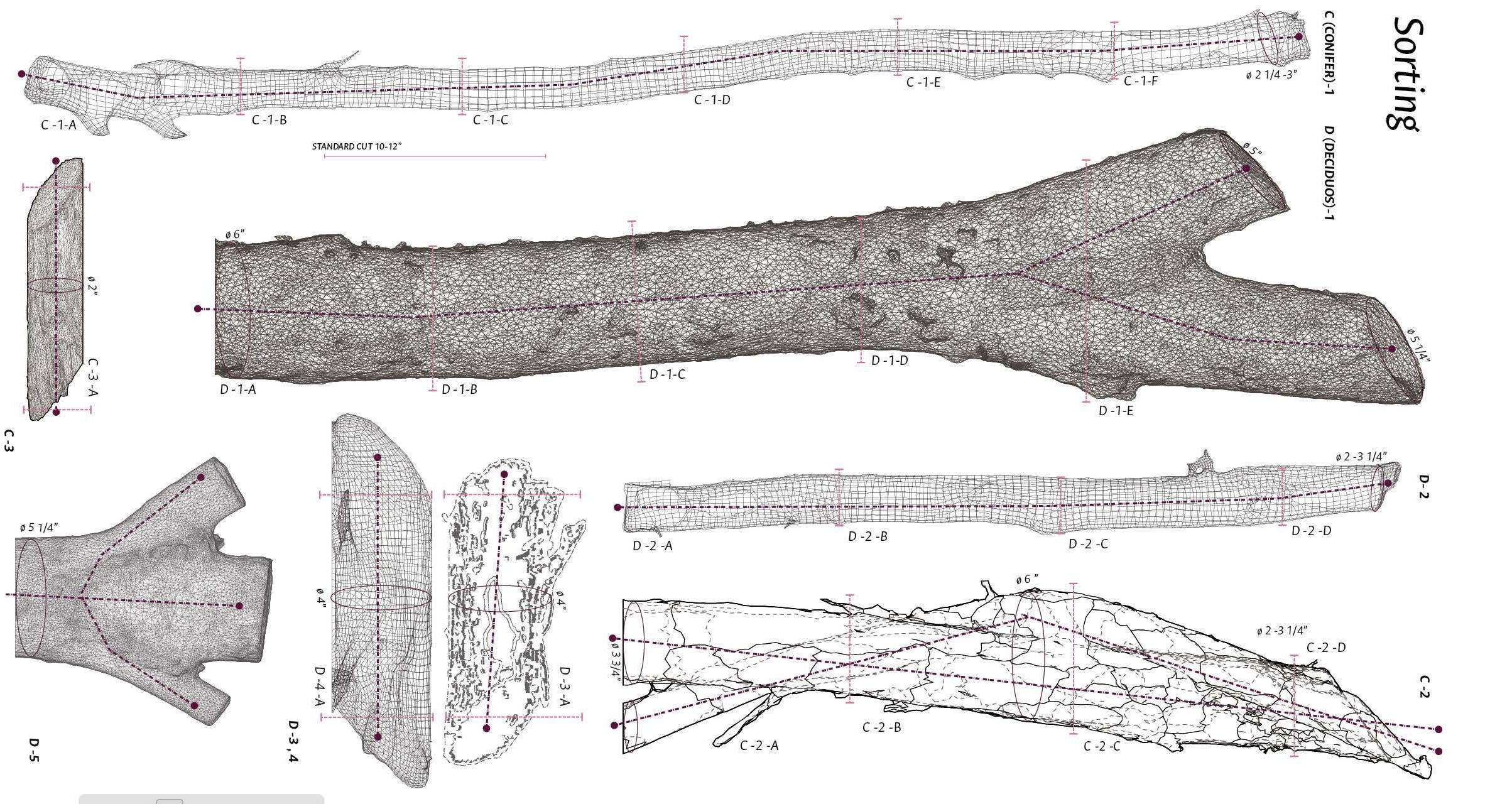

1. Sorting

Twenty-five (25) logs were 3D scanned to collect three-dimensional data and build vector models. Each piece was virtually “split” into 12” sections, labeled and analyzed in CAD to digitally assembled the blocks and approach a possible appearance and performance.

Uniform Space Filling Non-Uniform Space Filling

Even Region, Specified Space

Stacking and Joining

Stacking and Joining

Stacking and Joining Stacking and Joining

Set of Possible Combination of User-specified desired density distribution

2. Stacking and Joining

Focused on “letting the wood flow,” the stacking follows two strategies, Uniform and Non-Uniform, to take advantage of each log form by:

1) Doing a sort of puzzle and ensuring load-bearing joints in the block structure

2) Attaching the log with dowels to avoid complex wood joinery

3) Ensuring up-cycling by using virgin materials. Structural components are the most emissions-intensive parts of buildings due to their large volume of high-strength materials

3. Cutting

The nature of the project approach to two fabrication techniques which can work with the natural variation of timber and complex geometries for the modules stacking alternatives :

1) Robotic fabrication: A band saw on a six-axis robot arm trims the saw-log.

2) Traditional band saw: Pre-industrial homogenized fabrication.

Hackberry | Celtis Laevitaga Deciduous | Hard Wood Juniper | Juniperus Ashei Coniferous | Soft Wood

Hackberry | Hard Wood

To mock-up a block, the vectors CAD and a visual programming language are tested and determine the material efficiency, schedule, and spatial configurations. Lastly, a robotic arm or traditional sawing cut the modules.

Focused on design through fabrication, each block is an opportunity to use natural variations of timber with high eccentricity and increase mass - but homogenized - production. Let It Flow is not a block. It is a project to reconsider our notion of material sustainability and our current understanding of resiliency, adaptation, and clean construction.

Juniper | Soft Wood

Construction Process

Photo: Paula Cano

Mass Production and Application

Variation within each block comprises panels to adjust to different scenarios like panels, partitions, furnishing, or ephemeral structures.

- Advantage: Mass production of bespoke modules. The code produced for analysis guides the robot.

- Constraints: Customized pieces are required. Depending on the geometry, the robot needs manual control assistance for better blade performance.

- Advantage: Availability of tools and craft skills.

- Constraints: Limited shaping

L e t i r F low

structural elementservingecosystems and l and s c a p e s

Blockitisalsoasemi-natural

Wood Thrush Hylocichla Mustelina

1) Robotic fabrication

2) Traditional band saw

Block Prototype Fabrication by Paula Cano

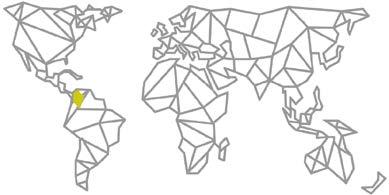

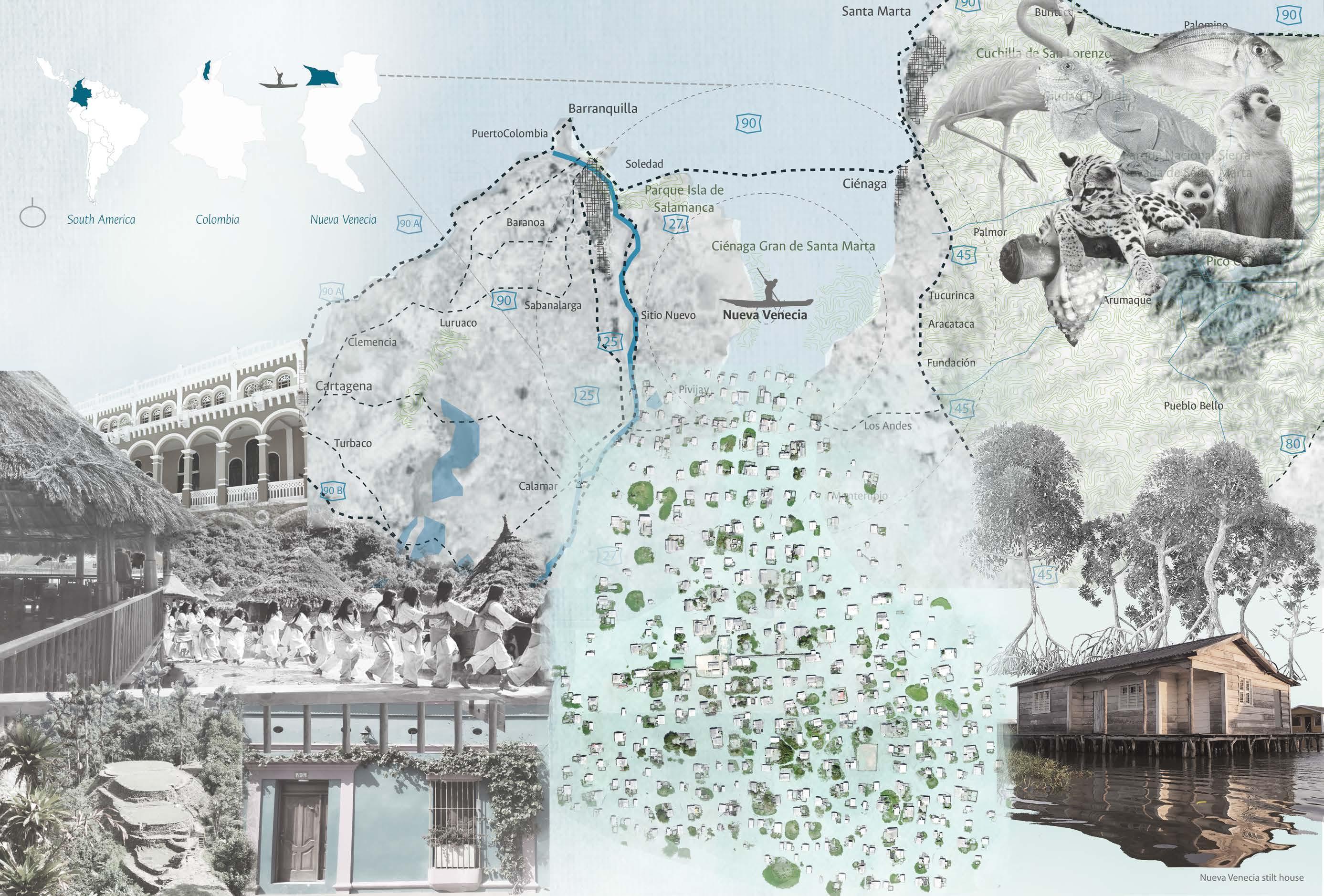

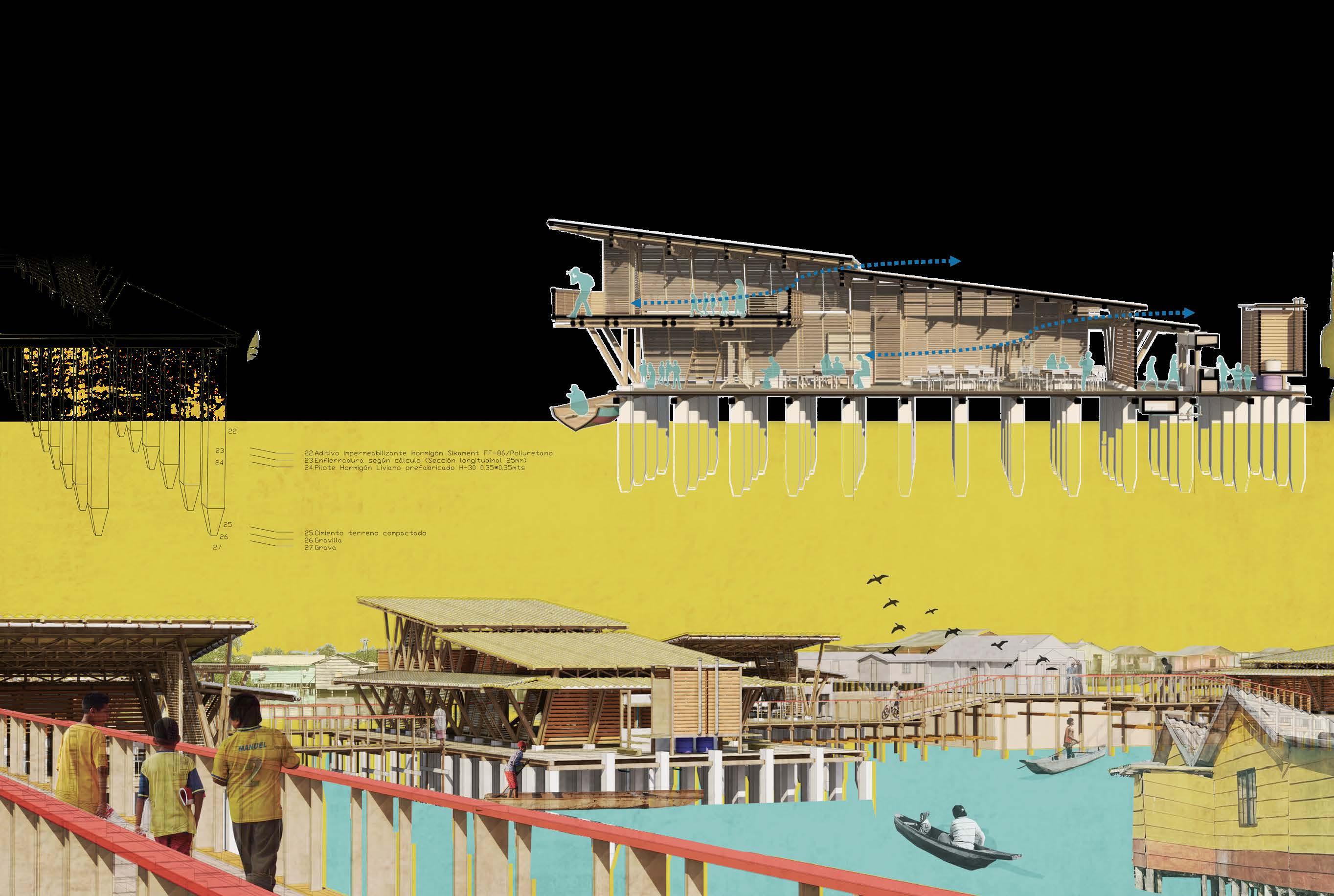

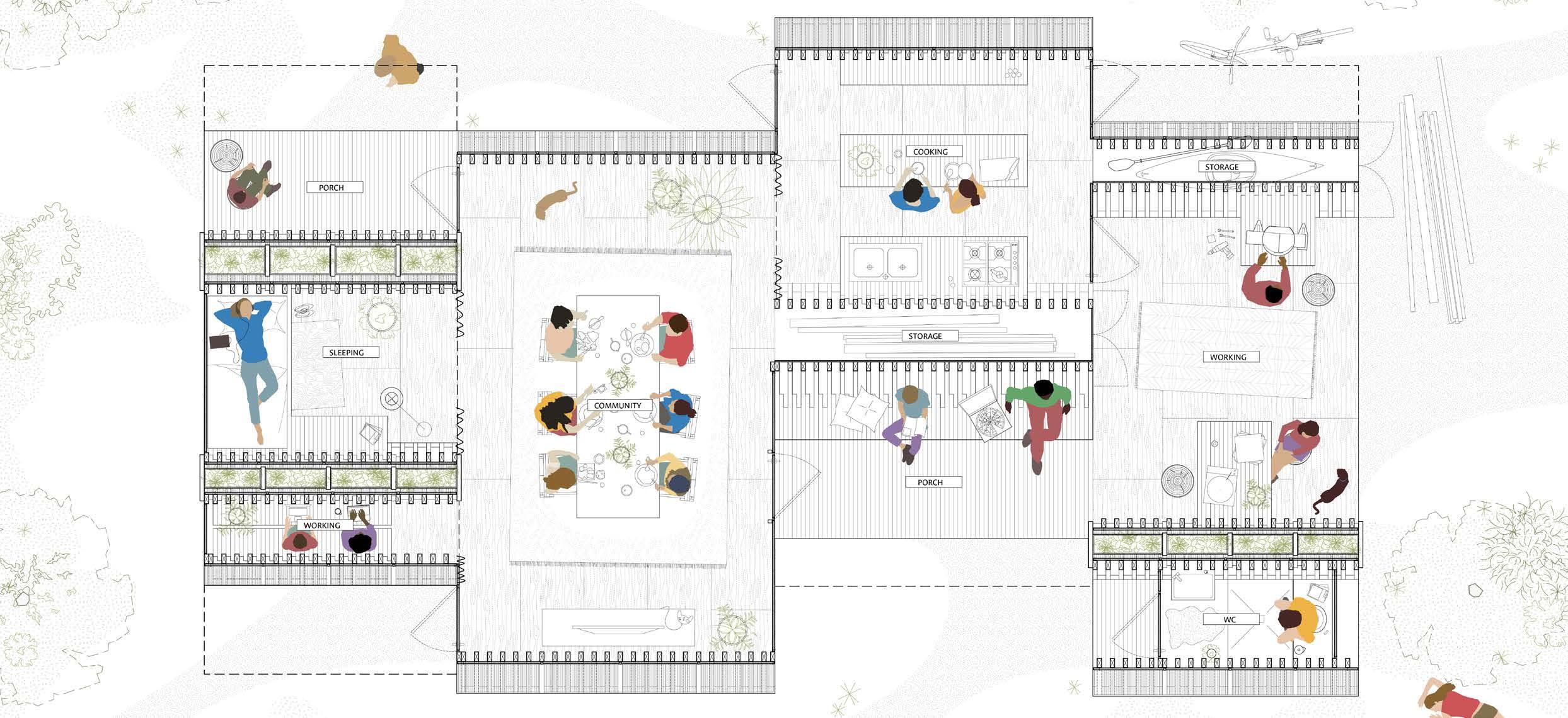

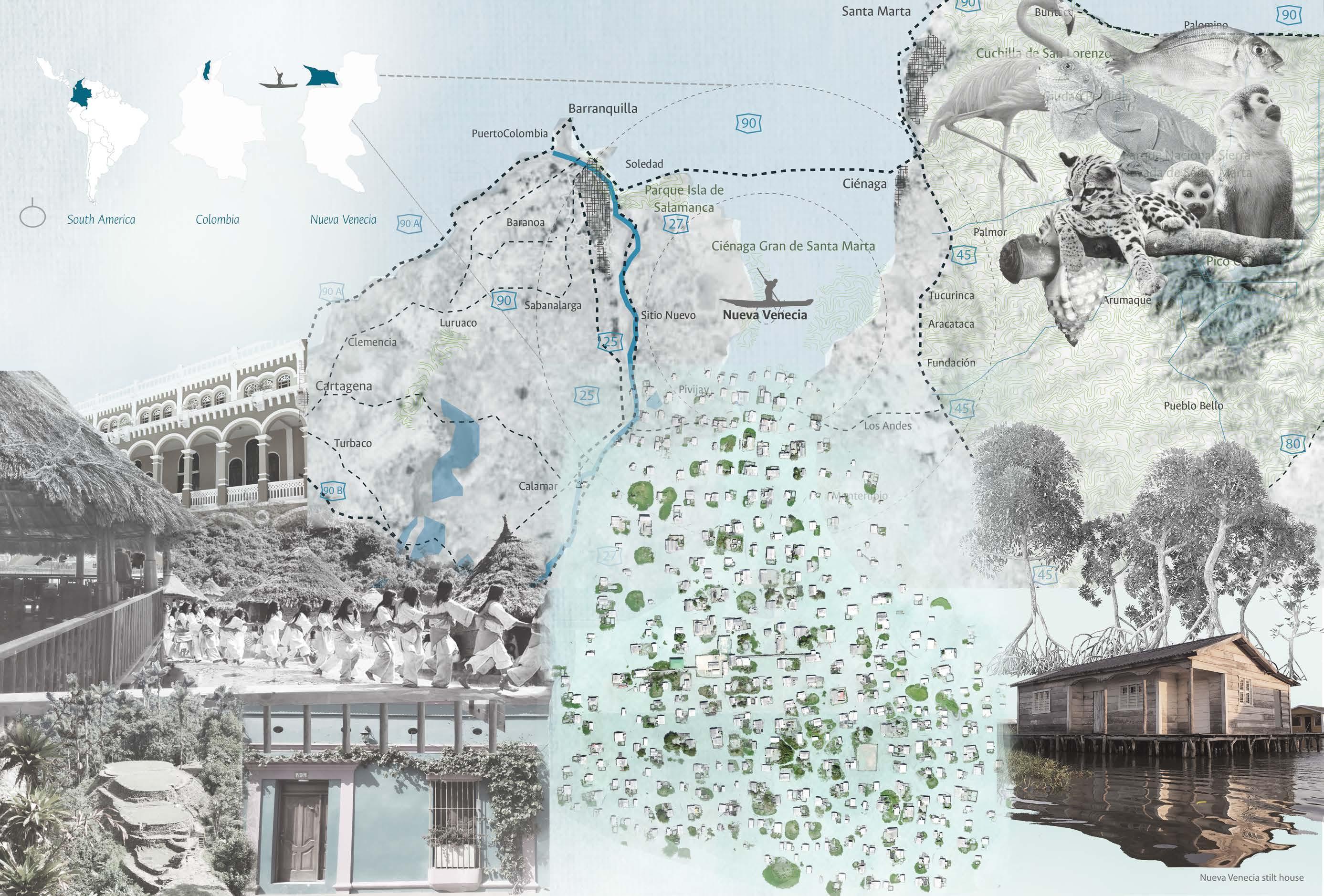

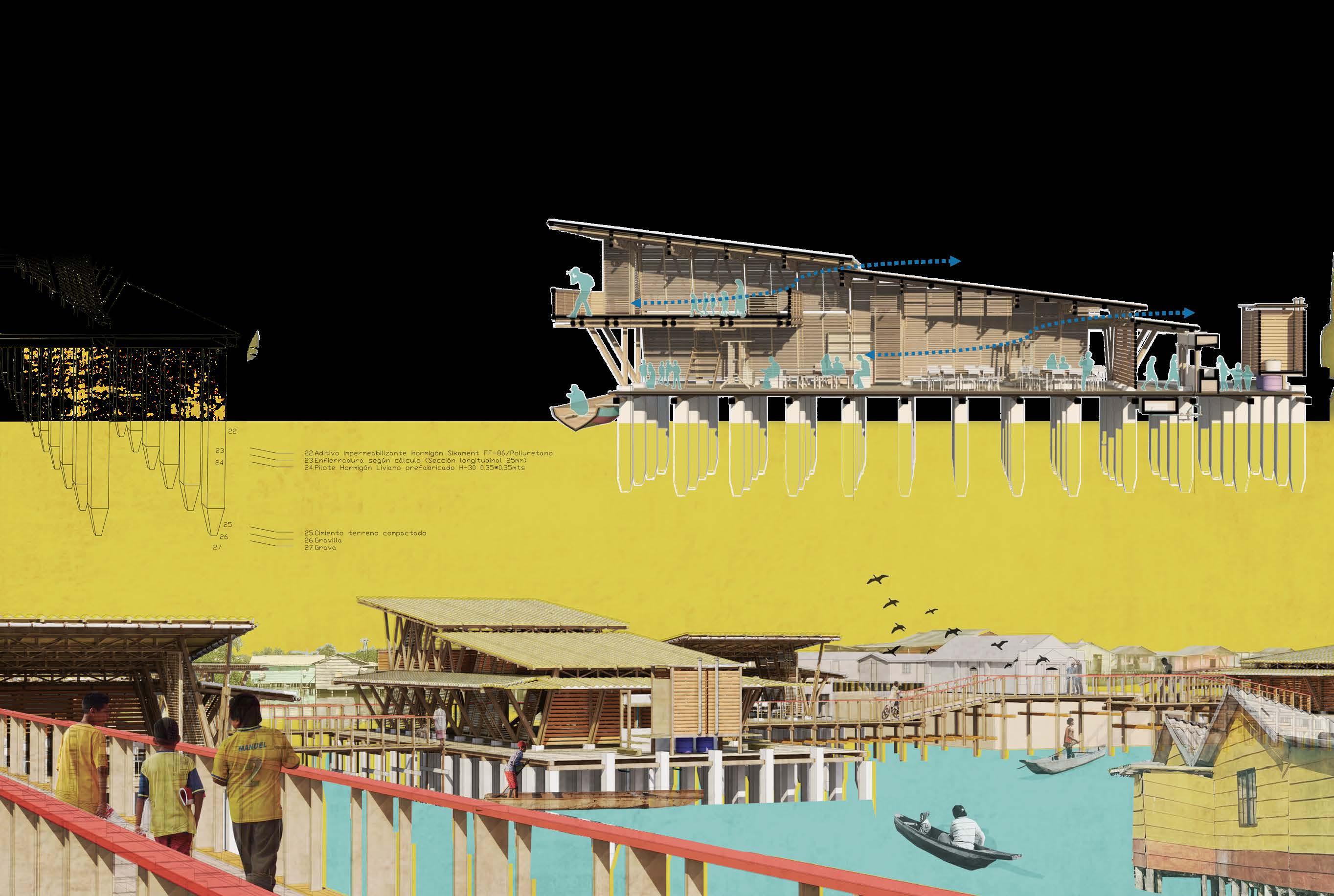

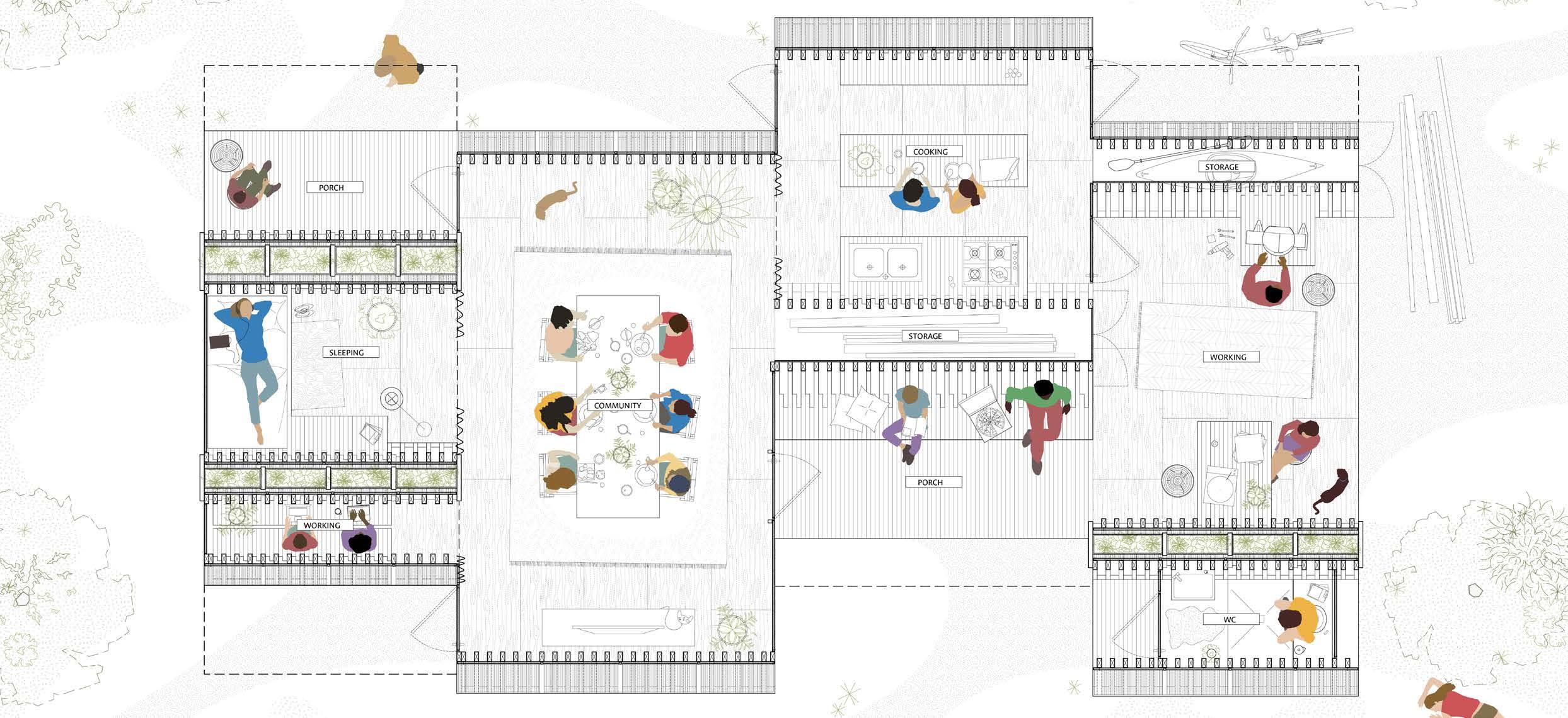

Approaching lacustrine architecture: Extension of stilt school

The undergrad thesis reinterprets the principles of stilt vernacular architecture by articulating porches, patios, and walkways in the extension of the existing school in Nueva Venecia in the Ciénaga Grande de Santa Marta. The research delves into the endogenous architecture of the swamp to solve a way of inhabiting and building in the territory based on local building techniques such as framing and wooden landing nets.

As one of the few active human settlements on the water on Earth, the architecture of Nueva Venecia is a landmark on the Colombian landscape and a sample of Caribbean culture. Through appreciation and documentation, potentially invigorates lost cultural heritage and reintroduces non-traditional education.

Keywords: Cultural Mapping, Educational architecture, Vernacular Structures.

B Arch, Undergrad Thesis | 2019 New Venice, Magdalena, Caribbean Sea. Colombia Universidad Nacional Bogota, Colombia 1674m² | 18018ft²

Classroom. Interior Render By Paula Cano

As the only educational institution in the town, the 1000 m2 school was insufficient to host 1000+ students, besides infrastructure problems such as no plumbing and waste management. The three main design strategies, Community engagement, public space, and landscape preservation, organized the project by flexible classrooms surrounding courtyards connected by bridges. Each classroom has rain and water filtration units and dry toilets to guarantee hygiene and teach water cycles.

The courtyards set a template for education-based periods of development rather than grades, providing physical independence. Lastly, piers and bridges connect the old school with the expansion, consolidating a network accessible to the community.

Urban Floor Plan

Colombian Caribbean Coast Cultural Mapping Collage by Paula Cano

Colombian Caribbean Coast Cultural Mapping Collage by Paula Cano

Porch Pier gaze

Classrooms

Library

Cadrizo Dry toilet Communal sinks

Classroom Section and Architectural Analysis

Urban Collage/Render

Structural section

Porch Pier gaze

Classrooms

Library

Cadrizo Dry toilet Communal sinks

Classroom Section and Architectural Analysis

Urban Collage/Render

Structural section

2x4 Texas American A-Frame Exhibition

Construction Collaboration | 2023

An exhibition and prototype developed by Barkow Liebinger

University of Texas at Austin at The Mebane Gallery 120m2 | 1300sq f

Using 2x4 wood studs, a common building material, this exhibition revisits the A-Frame as a versatile, sustainable architectural solution, and re-imagining it’s potential and evolution.

The Mebane Gallery prototype showcases adaptable configurations with triangulated trusses serving both structural and spatial functions. Its modular design can accommodate various programs and potentially adapt to different terrains. Clad with energy-efficient materials that can collect gray-water and support roof gardens the A-Frame is configurable.

The exhibition imagines a customizable, Eco-friendly house for under $100,000, transforming this underdeveloped typology into a contemporary, practical, and innovative housing solution that challenges traditional housing norms.

Exhibition at the Mebane Gallery

Photo: Paula Cano

AGGREGATE A-FRAME MODULE 3

KITCHEN + COVERED PORCH DOMICILE

PREFABRICATOR + INSTALLER MANUAL

66.1° 71.3° 55.5° 43.6° 45.1° 56.5° 79.4° 62.9° 129.1° 53.2° 53.2° 55.5° 50.9° 82.2° 113.9° 11'-0" 3'-6" 3'-6" 5'-0" 1'-6" 2'-6" 12'-0" 16'-0" 7'-6" 8'-6" LAYER Q O M K H E U W X D L P T 18 16 12 11 10 14 13 15 4" Spacers Structure Furniture 12' Uncut COLOR LEGEND structure spacers Prioritize your safety while constructing your wooden A-Frame with these precautions: - Protection Gear: Wear safety glasses, gloves and ear protection. - Tool Proficiency: Use tools you're familiar with and follow instructions. - Inspect Wood: Check for defects before assembly. - Stable Surface: Build on a level, stable surface. - Balance: Take care on the peak and elevated areas. - Safe Lifting: Use proper techniques or seek help for heavy parts. - Proper Fasteners: Use recommended screws 7 nails for stability. - Weather Watch: Avoid construction during bad weather. Stay safe by following these guidelines. Seek help unsure, prioritize stability, and prevent risks. WARNING: A-FRAME CONSTRUCTION SAFETY GUIDELINES NOTE TO INSTALLER / ASSEMBLER: Give this Operator's Manual to the Inhabitatants so that the Inhabitants may retain it for future reference.

FEATURES - Kitchen with built ins - Covered, integrated lounge bench - Pergola covered area - Integrated storage Fd 01 Sd 01 Sd Sd 03 Sd 04 Sd 05 Sd 06 Sd 07 Sd 09 Fd 02 Fd 04 furniture furniture x12 x12 x23 x24 x24 x23 x24 x23 x23 x12 LAYERA M CUTTING PATTERN LUMBER CUTTING PATTERN PATTERN PCS. STOCK x24 12' x24 x24 12' 12' 12' x23 x23 12' x24 16' x12' x12 Sd 04 REQUIRED TOOLS x24 x23 x24 x23 x23 x23 x24 x23 x24 x12 x12 x12 x12 x340 NAIL GUN RUBBER MALLET DRIVING RATCHET WRENCH HAND DRILL CHOP SAW

Graphics In collaboration with Barkow Liebinger

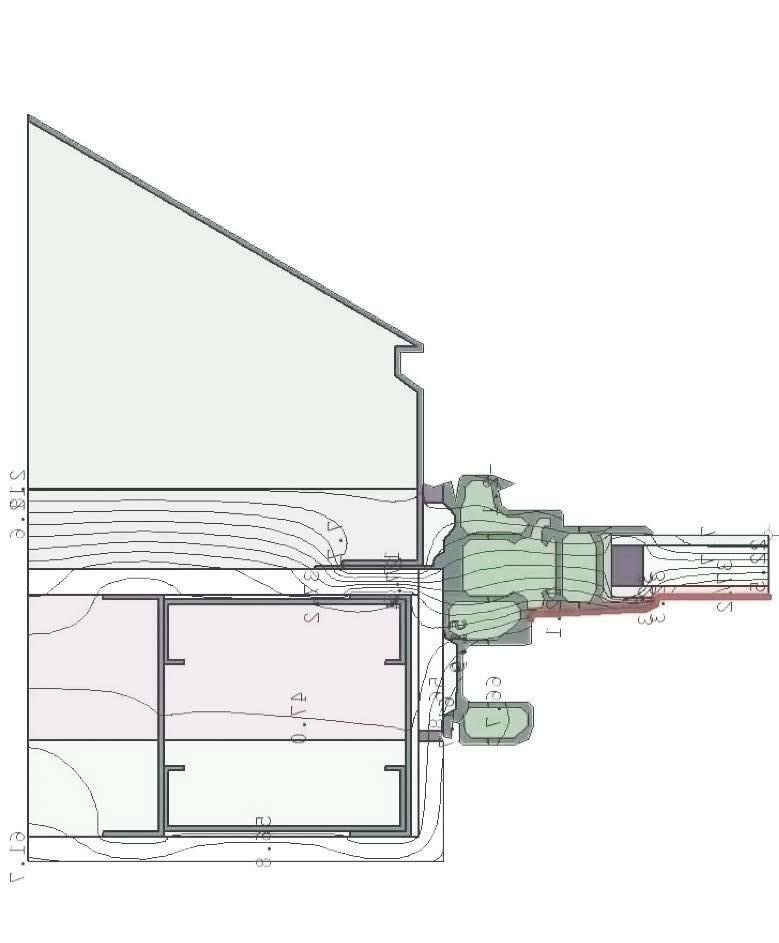

School Restoration and Frame House Construction

Timber Construction Collaboration | 2020

Michaelshof Sammatz. Lüneburg, Germany

1000m²| 10800ft²

Characterized by the design and management of the surrounding nature and international community engagement, Michaelshof Sammatz has boosted permaculture and circular economy for over 40 years in North Germany.

In 6 hectares of gardens and parks, constructions that hazard natural environments are now part of a master plan offering room and opportunities to international volunteers while expanding educational programs to Peronnik children with special needs.

The school envisioned a space proper for special education within sustainability goals like net zero emissions, waste management, and energy efficiency. By restoring old frame houses and incorporating highly insulated building envelopes, the school hosts 35+ children. The new homes, in six fully-equipped residential groups, are scattered throughout the village and are a natural part of the everyday Sammatzer life.

Permaculture Center

Photo: Michaelshof Sammatz

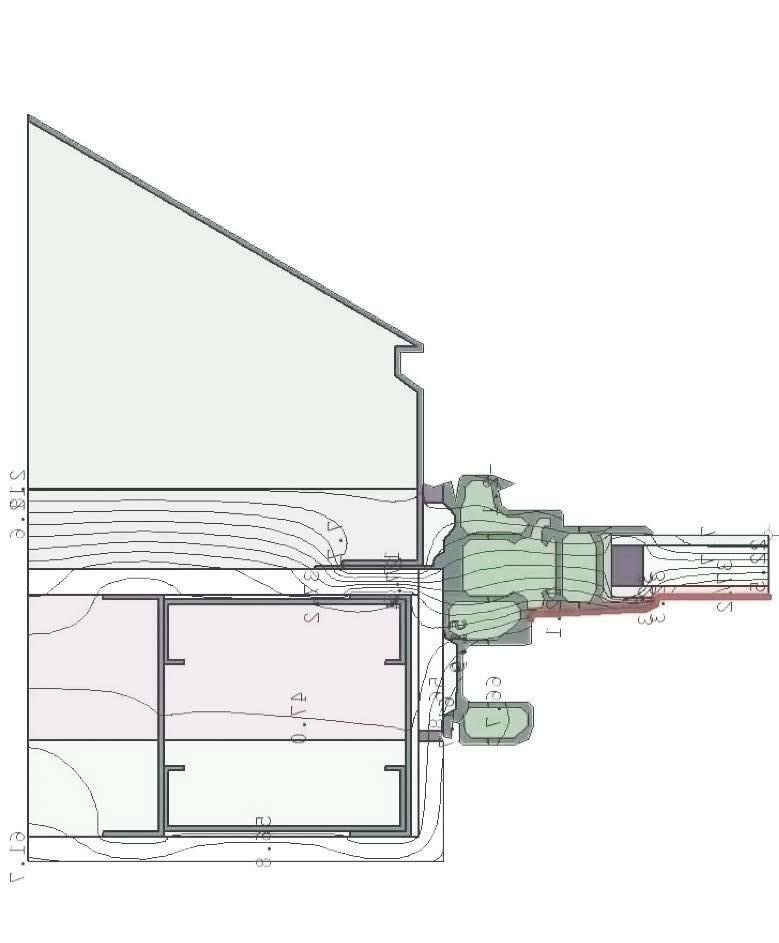

The designers noted that the space-conditioning of the area immediately surrounding the structural frames displayed moisture and air infiltrations, particularly at metal-panel cladding attachments and near window and door openings. Therefore, maintaining the continuity of the exterior insulation system to the greatest extent possible would reduce condensation risk from dew point temperatures at interior surfaces of glazing and frames of window units.

Without accurate window unit product data and drawings for THERM modeling, indications of condensation risk at the window units themselves needed to be considered preliminary, as the simulation models do not include some components regularly found in modern high-performance window assemblies (e.g., low-conduction IGU spacers, thermally broken frames, etc.).

The result is the installed significantly outperformed the simulation models in terms of lower condensation risk (for building durability) and higher radiant interior surface temperatures (for occupant thermal comfort). THERM simulations of the plinth did not indicate condensation at wall elements. Some condensation risks at the interior gypsum board were noted in simulations. Still, the reported dew point temperatures resulting from thermal bridging through the simplified window unit modeling were fixed during the restoration and construction.

After

Before

Frame House

Photo: Paula Cano

School Restoration

Photo: Paula Cano

Isoflux Diagram

Modeled by Paula Cano

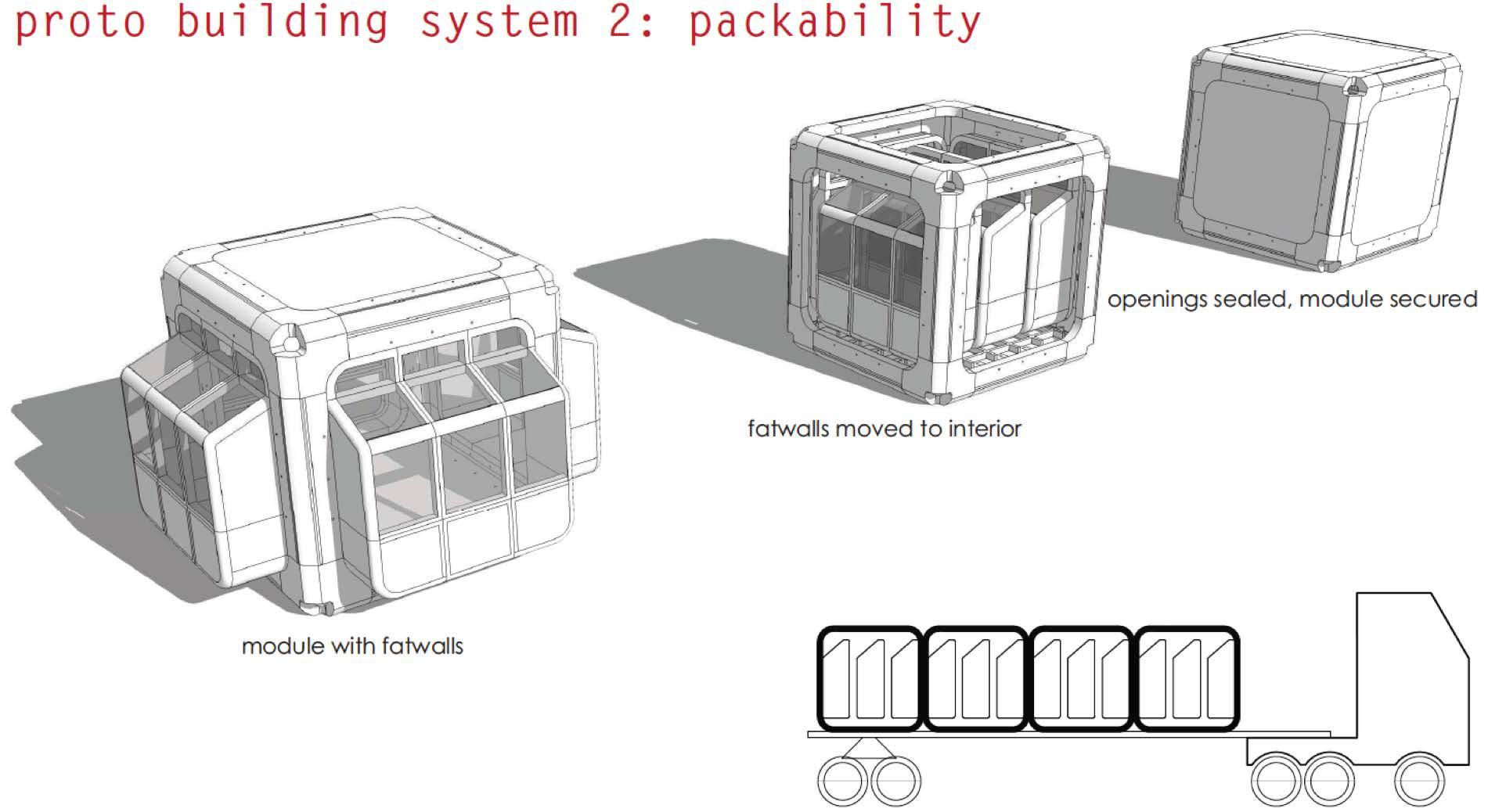

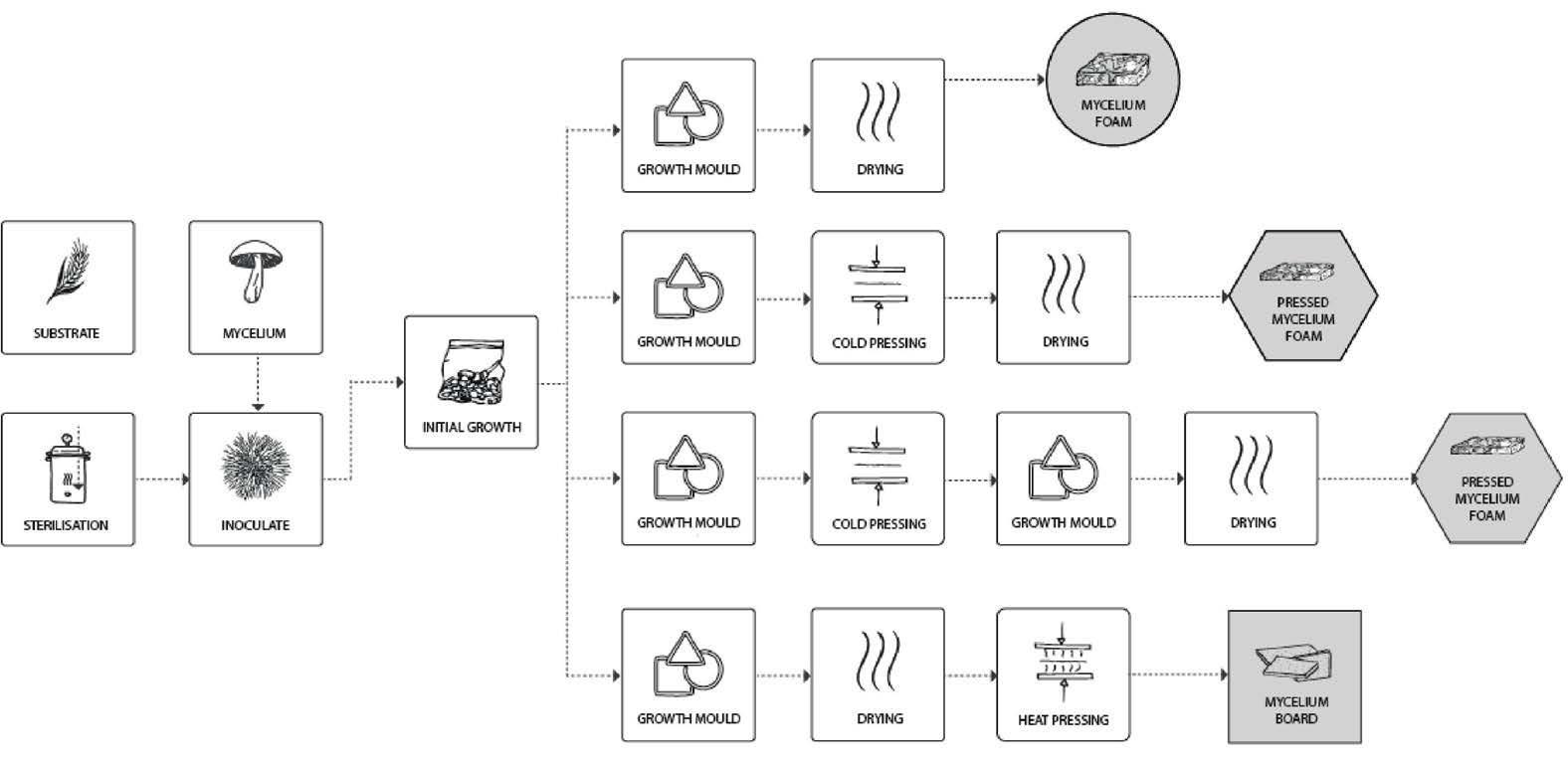

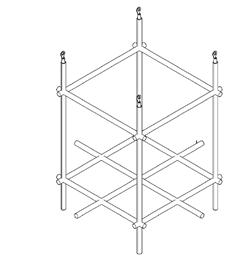

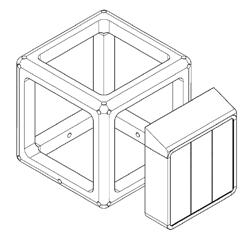

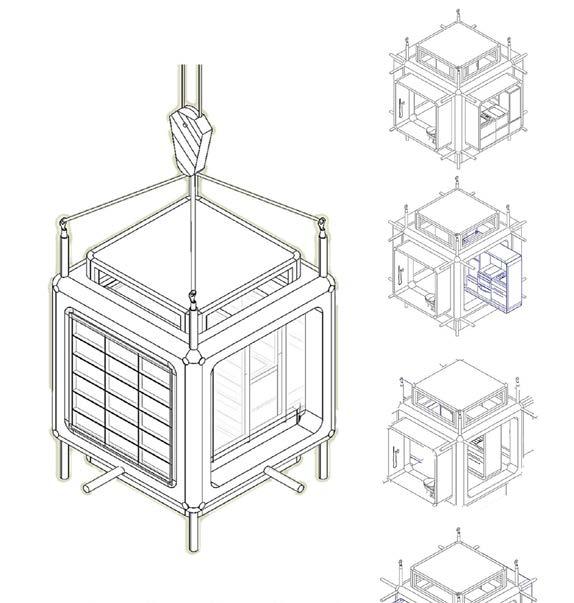

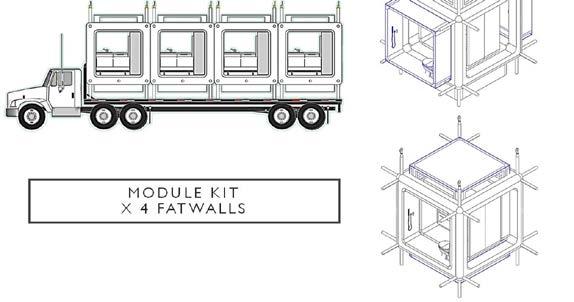

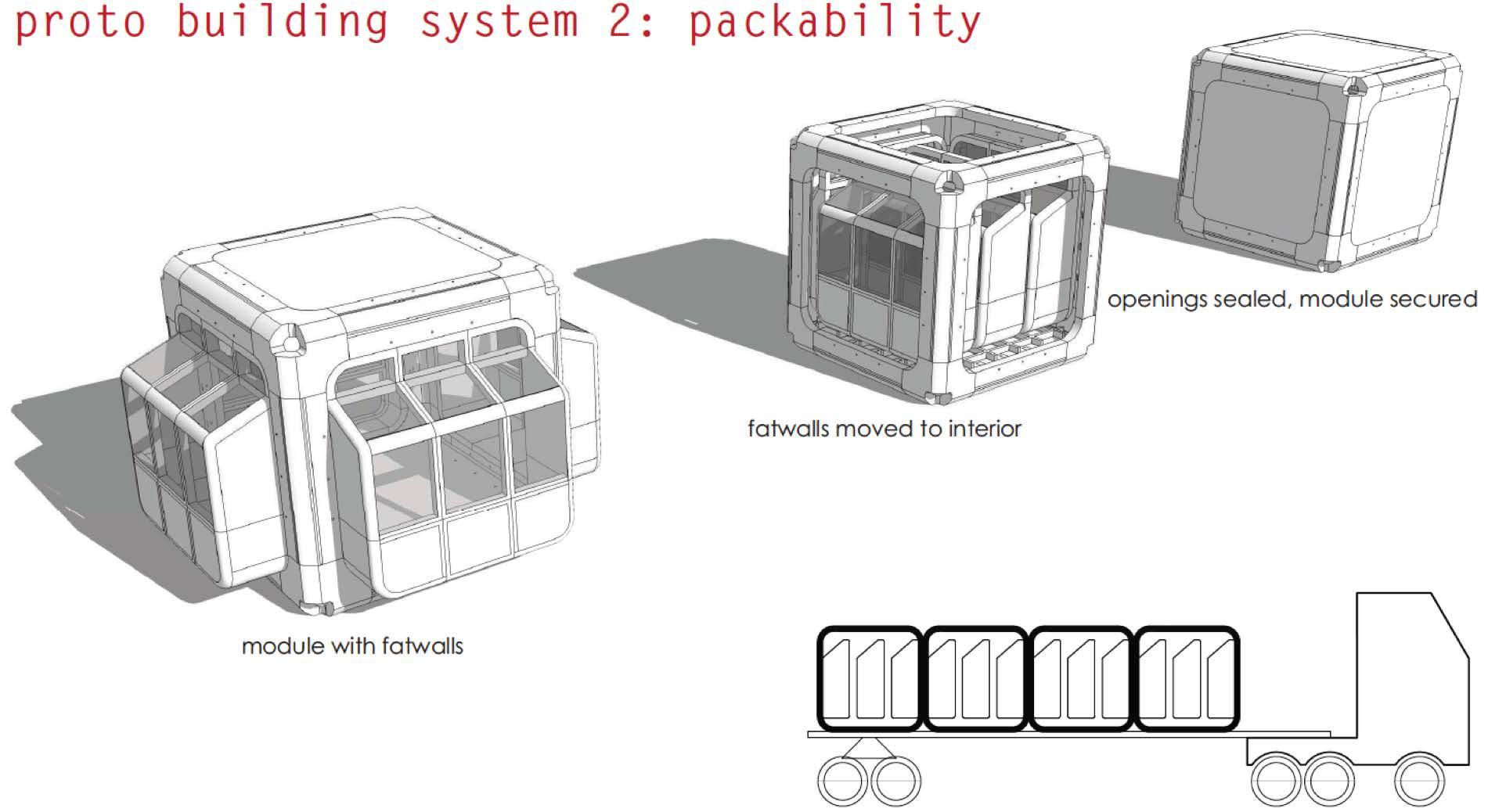

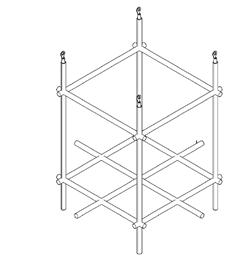

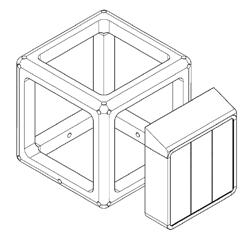

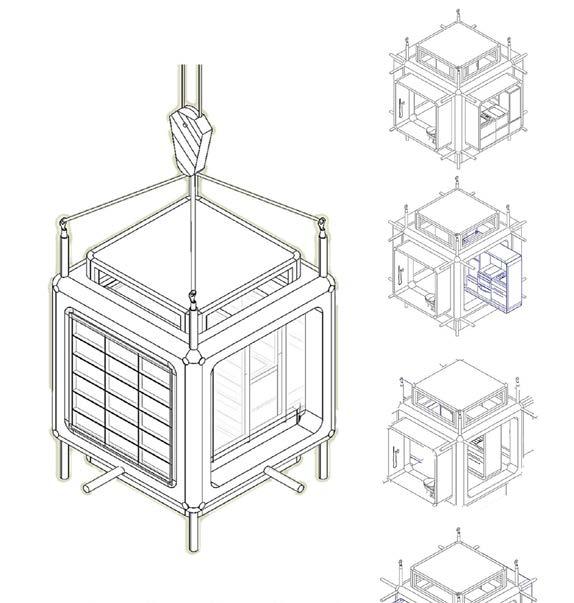

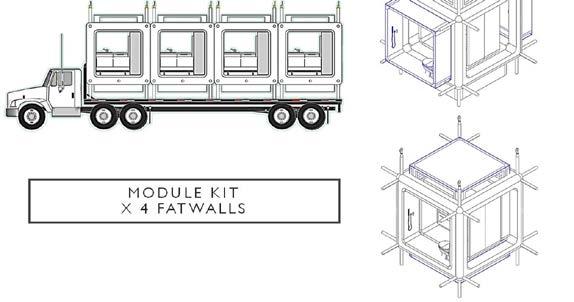

Flexibode: Prefabricated Housing Pod

Design and Prototyping Coordination | 2022

Austin, Texas. United States

Intern at The Center for Maximum Potential Building Systems . 21m² | 225 sq-ft² module

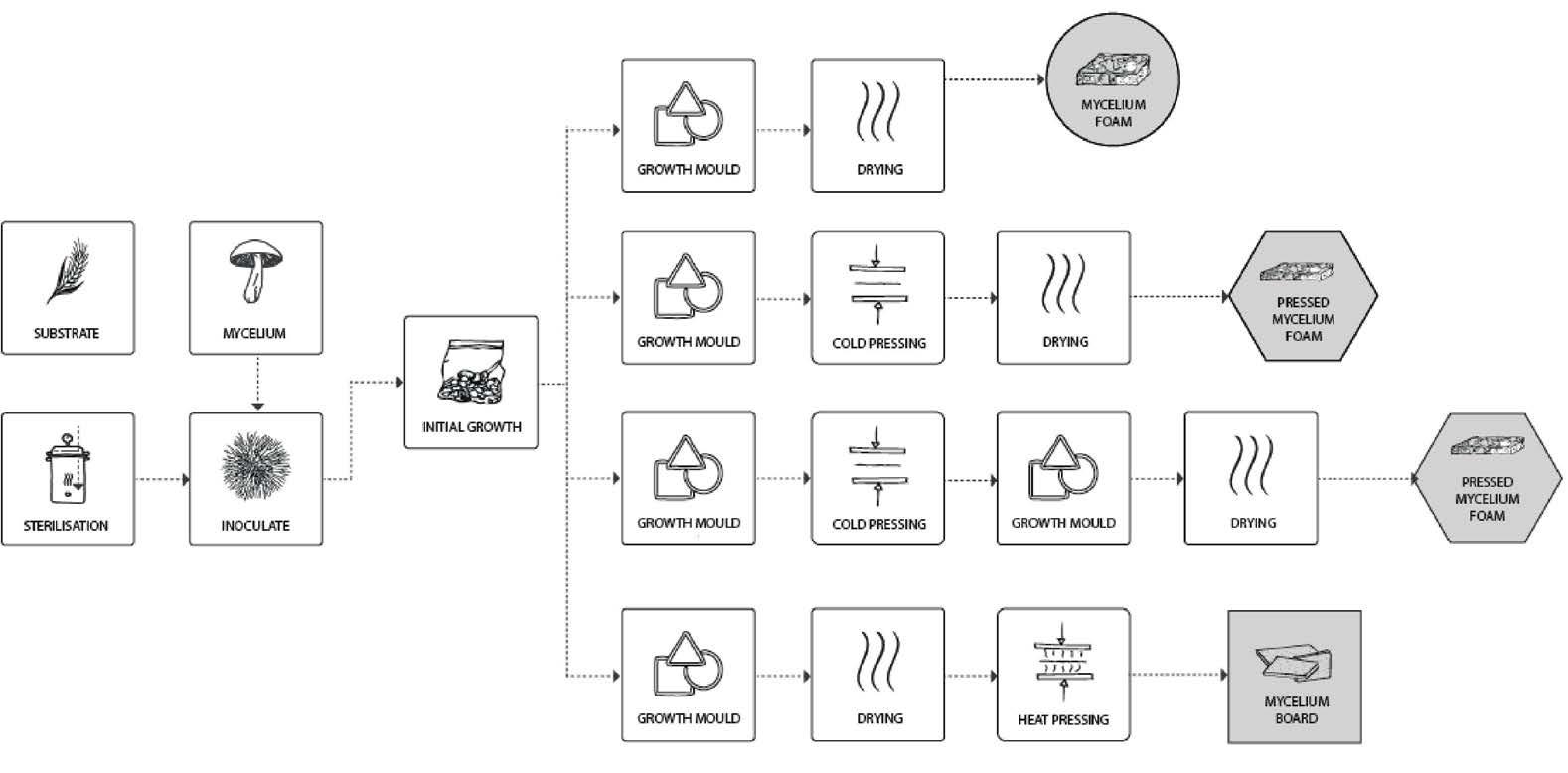

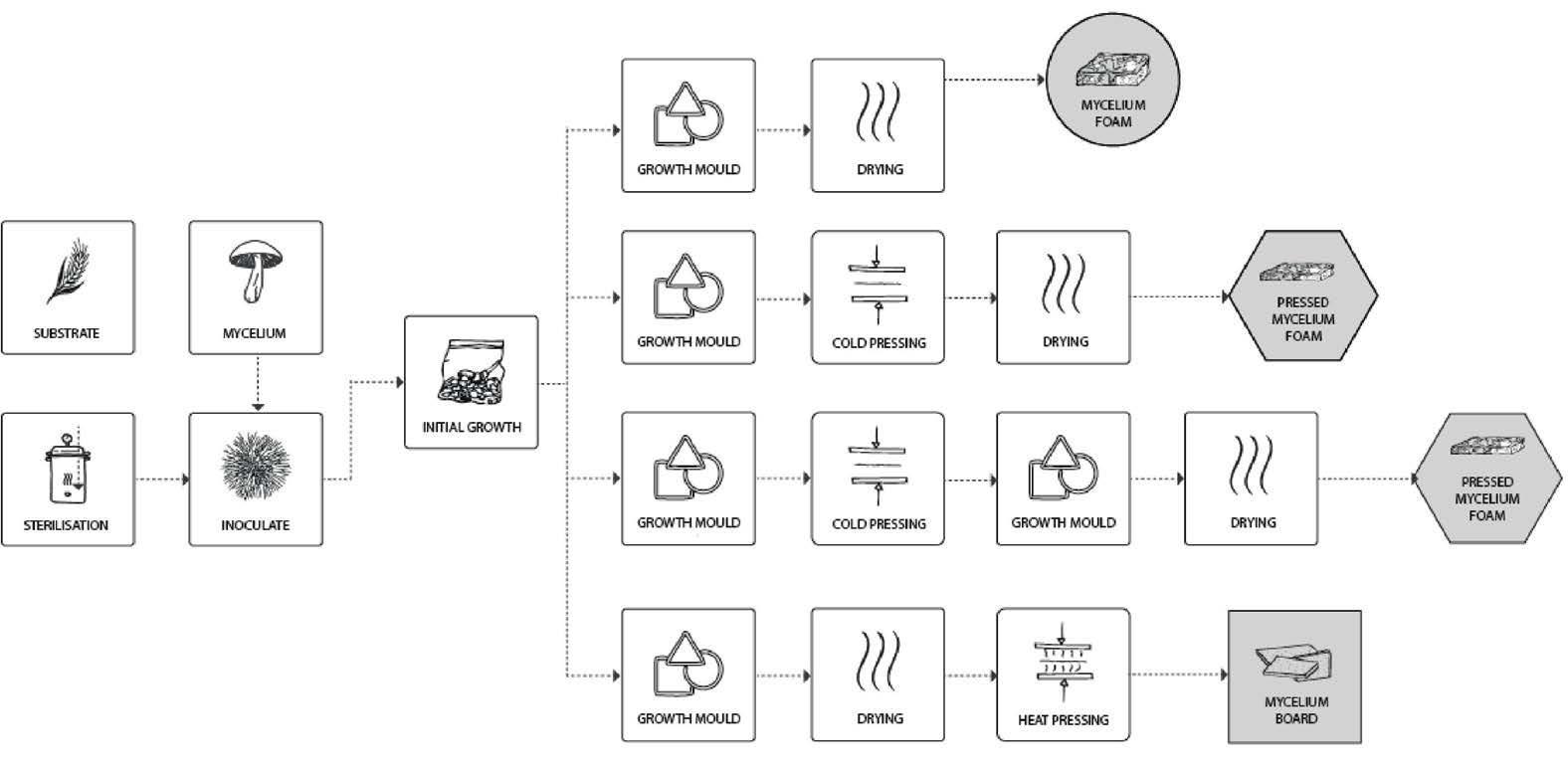

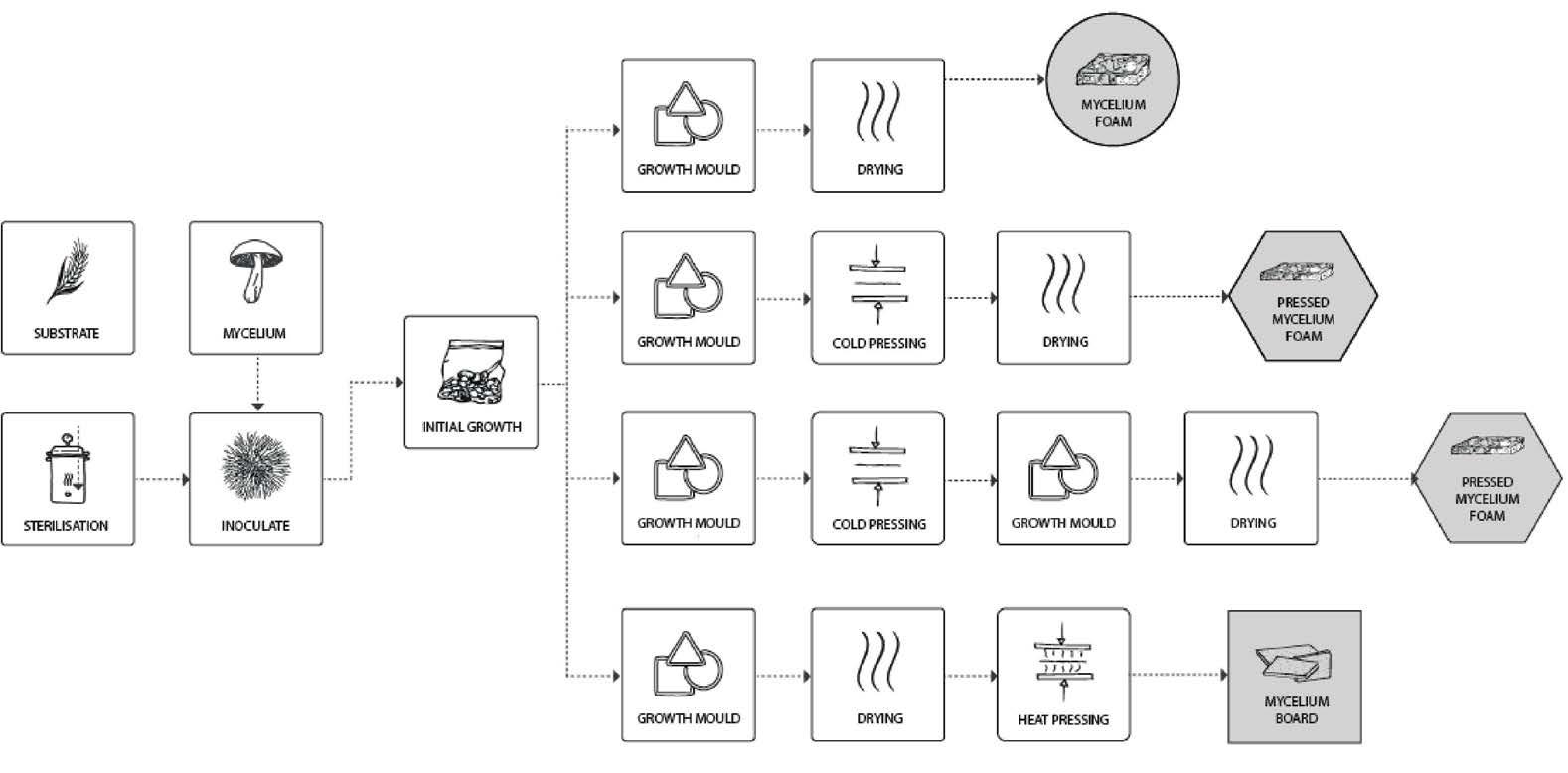

Facing housing and supplies crisis and, FlexiBode is a future-ready, modular solution made of aluminum and mycelium. This permanent housing, can be shipped, stacked horizontal and vertical to compound multistories blocks or single apartments.

Features:

- Temporary address (emergency housing potential)

- Customizing capabilities

- Pay as you evolve

- Solar ready | Water ready

- LEED certifiable

- Kit or complete

- Food fuel accessories

|

Urban Expansion

Vertical and Horizontal Configuration

Render by Paula Cano

Fat-walls

Fabrication and Shipping System

2. Prototyping and utilities fixture

3. Shipping

2. Prototyping and utilities fixture

3. Shipping

BODIFLEXTRANSPORT AND STORAGE MOVE OUT FRONT AND BACK FATWALLS ROTATE AND ADJUST TAKE OUT SIDES FATWALL FIX KALWALL

and accessories packed inside module

Tested for

Mycelium

Prototyping

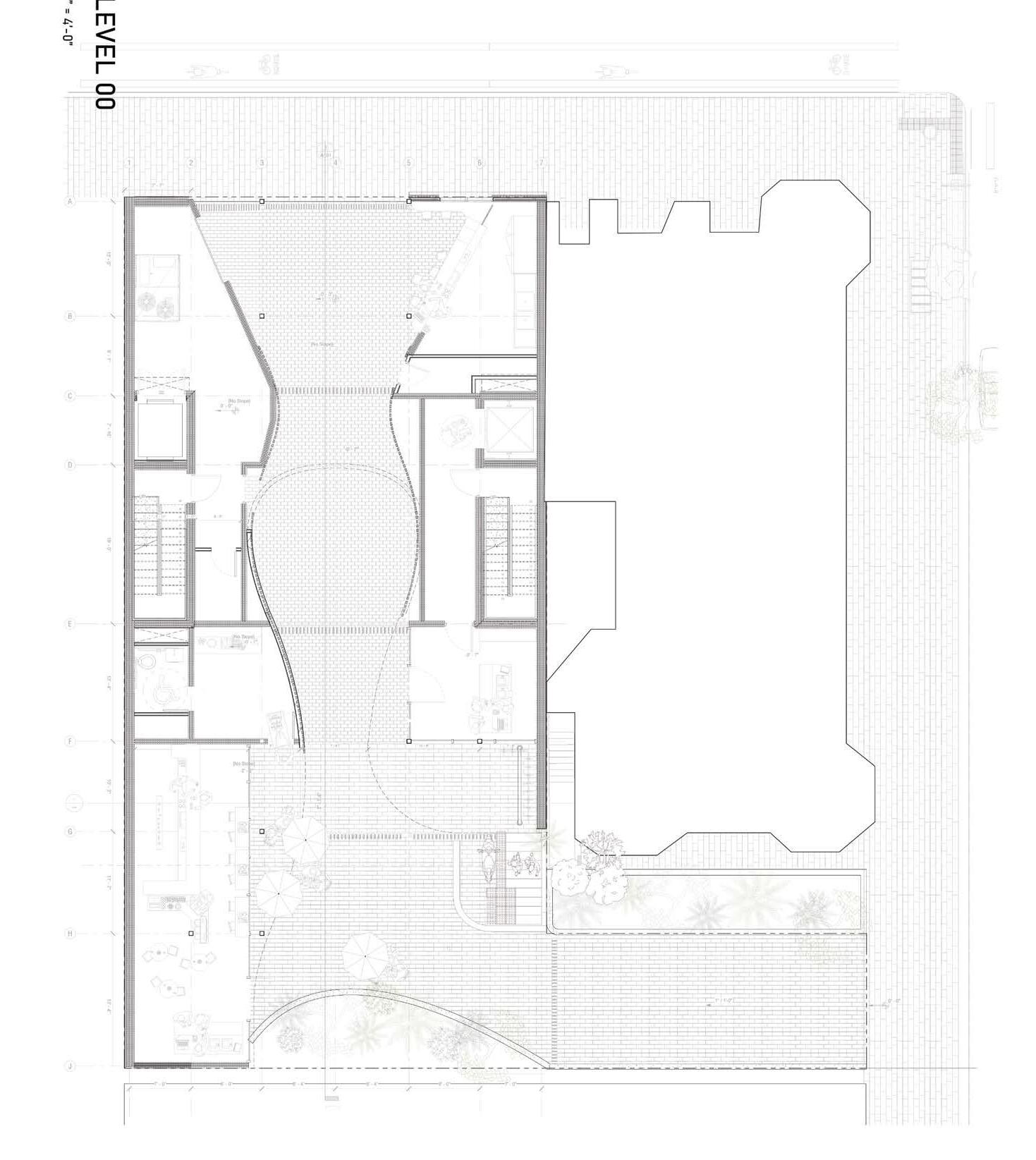

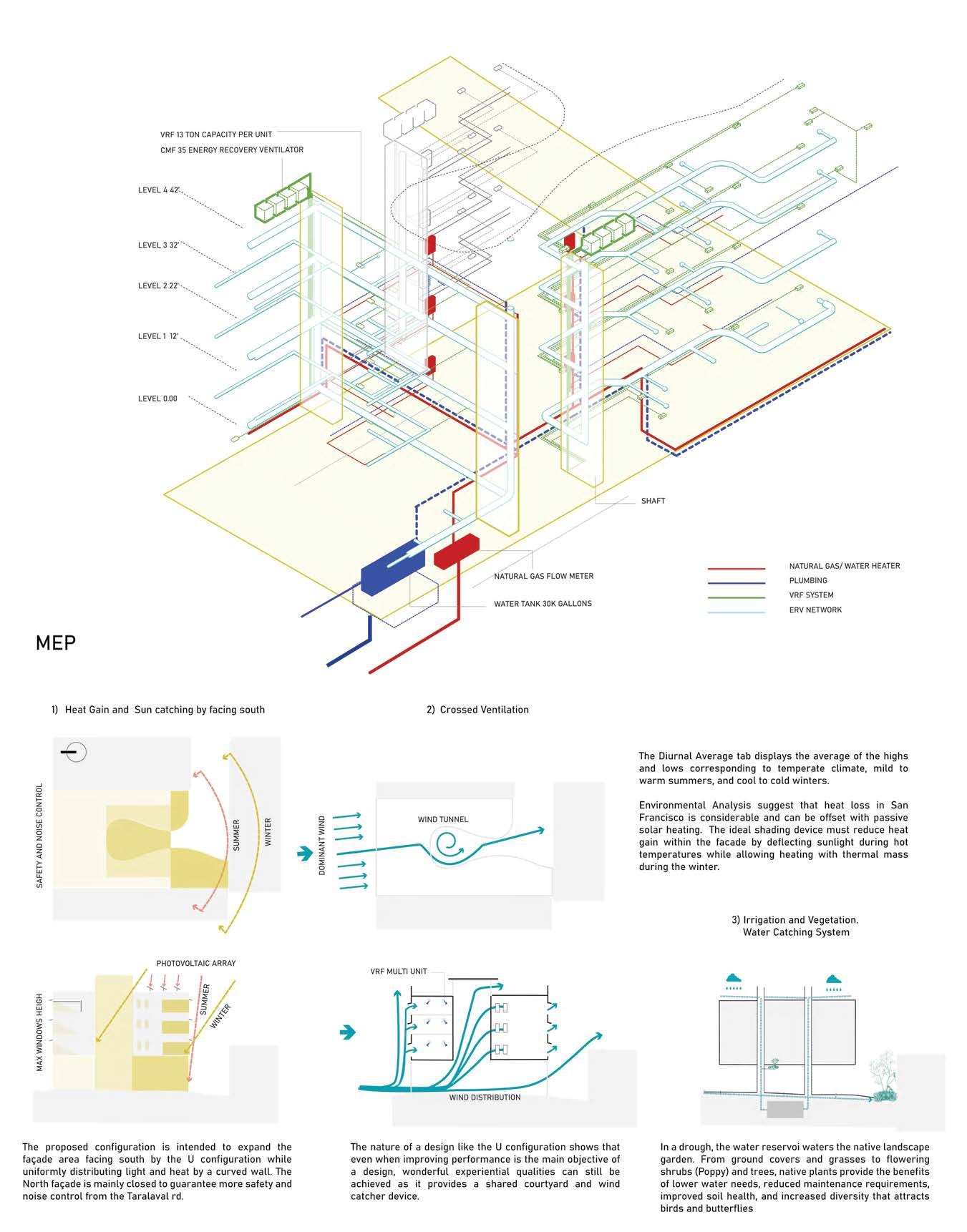

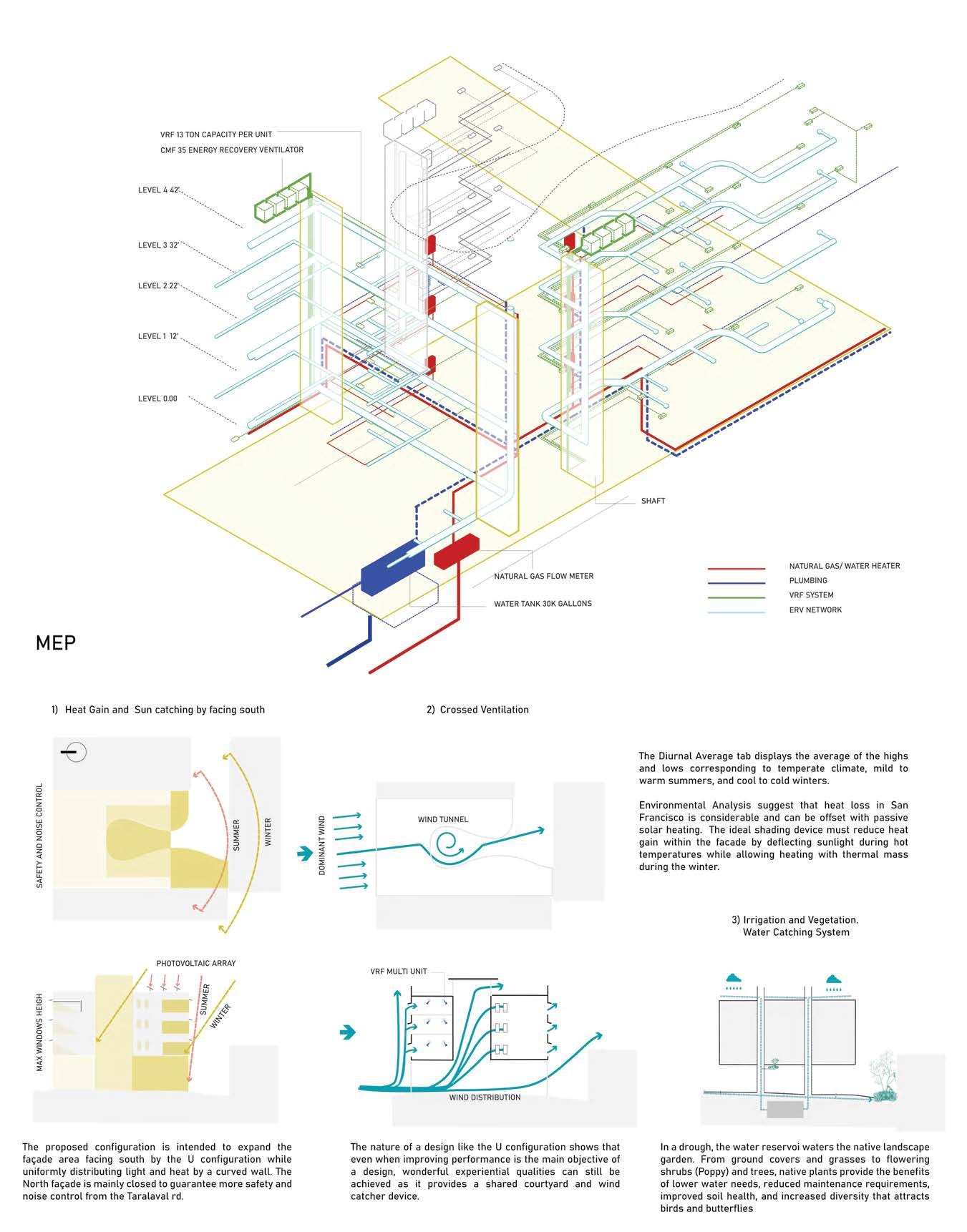

2209 TARAVAL IN SAN FRANCISCO, CA

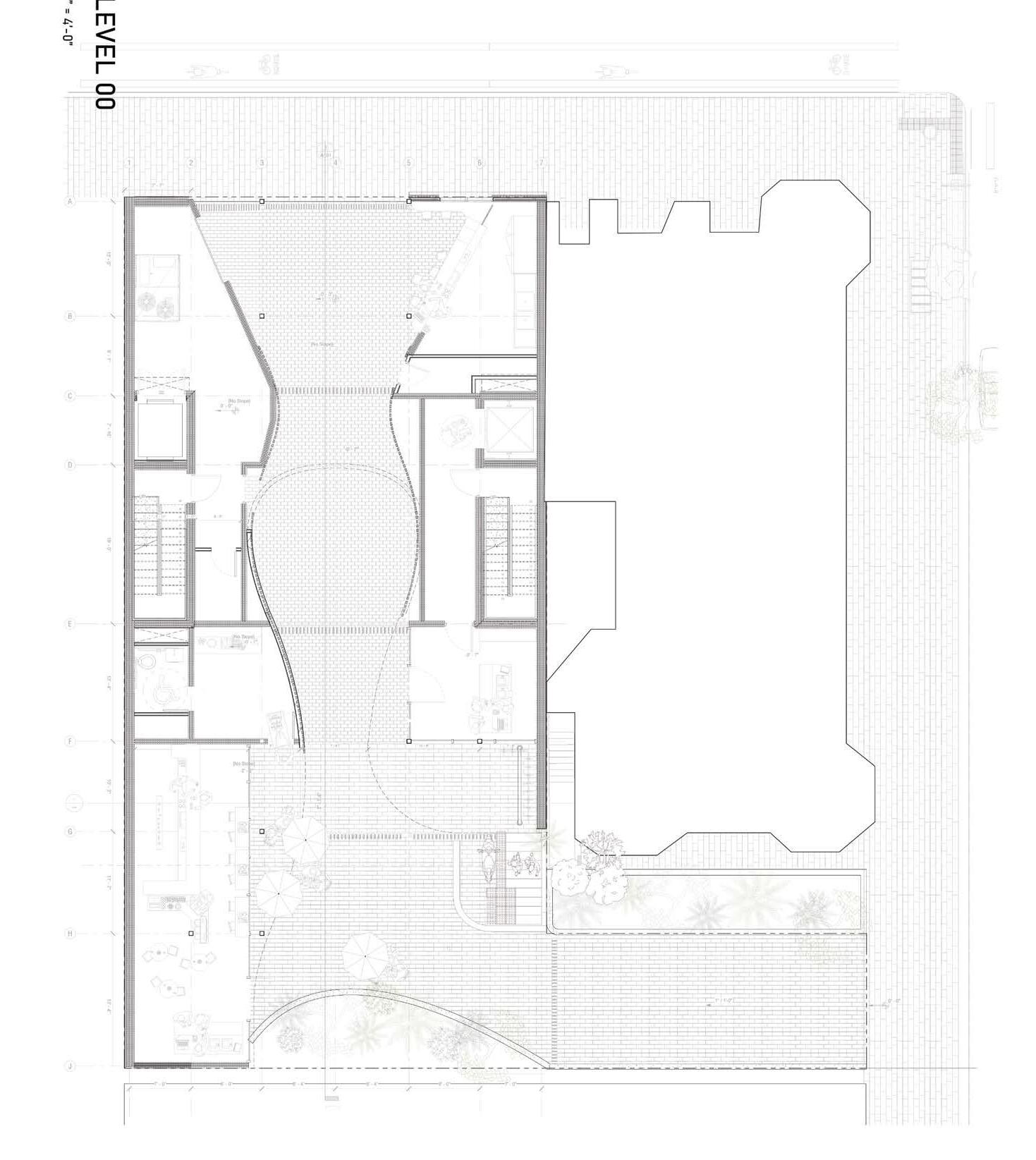

Design Studio | 2023

University of Texas at Austin Multi-family | 4800m² | 25000 sq-ft²

The Sunset District, located 6 miles from the Pacific Coast, is part of San Francisco’s history. The district is also part of San Francisco’s present housing crisis. This extends to a social crisis, represented in the lack of accessible public spaces.

While infill is the densification of housing, the project infills by opening a gap in the site and organizing public and private programs around the dominant architectural element; the wall. While usually a wall represents a barrier, the curved wall constitutes a courtyard, allowing people, city, and thermal comfort to combine.

2209 Taraval project is an urban amenity, dwellings, and a path of travel. It goes ownership back to the community to inhabit a third place where opportunities for diversity gather around the same space.

Interior Courtyard

Teamwork: Ciara Hackman

Perspective Section 1’: 1/16”

The ten units on site are a middle ground for the different demographics that aim to reconsolidate the Historical Sunset District Community. The project envisions a third place by incorporating shared services at non-cost prohibited activities for the surrounding to enjoy alongside the Sunset District.

A Third Place at the Commercial Corridor, Taraval Street

A Third Place at the Commercial Corridor, Taraval Street

Retail and Public Courtyard Internal Gathering Space/ Wide Circulation Shared Terrace/ Urban Gardening

Taraval Street Urban Landscape

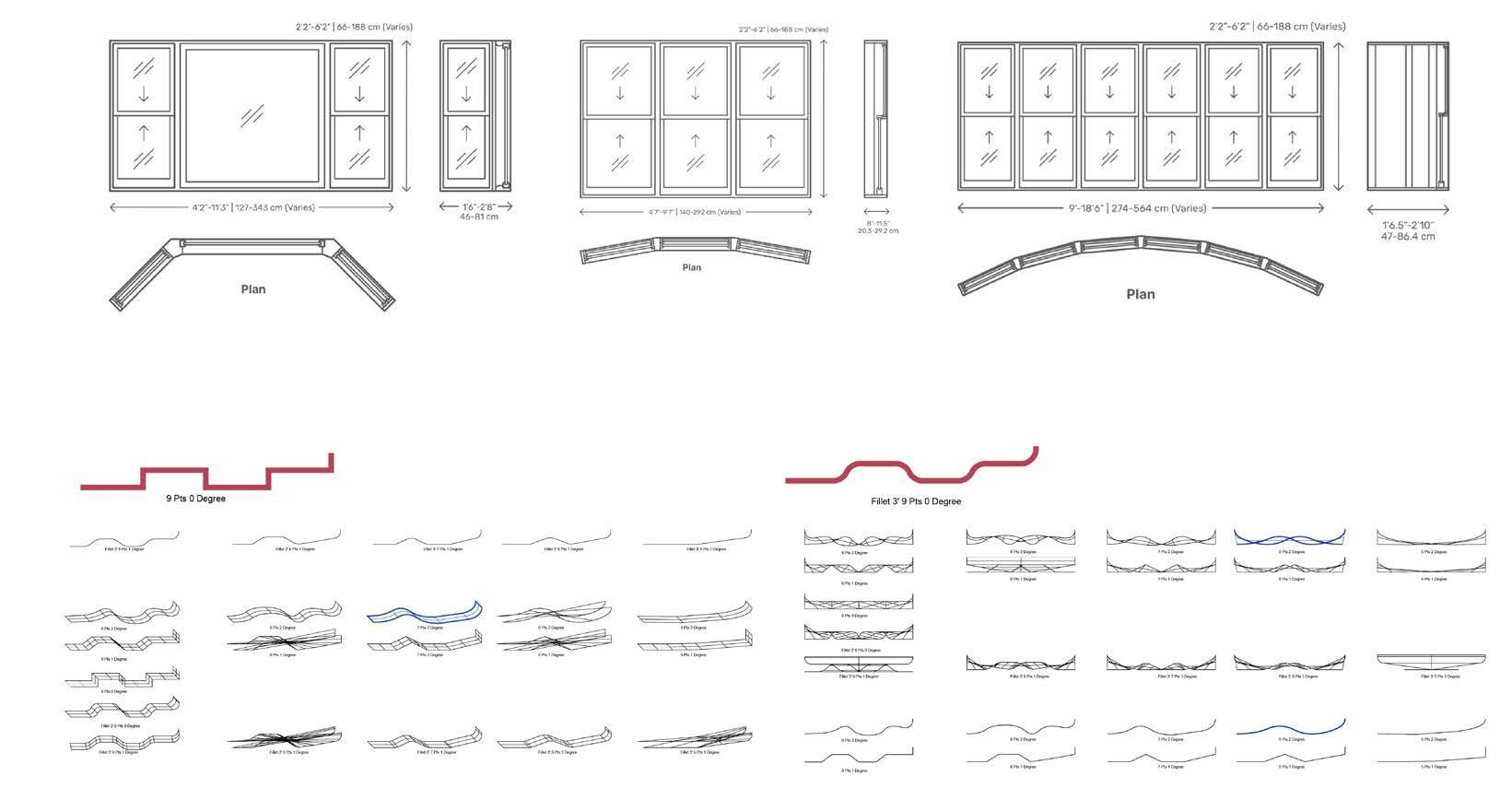

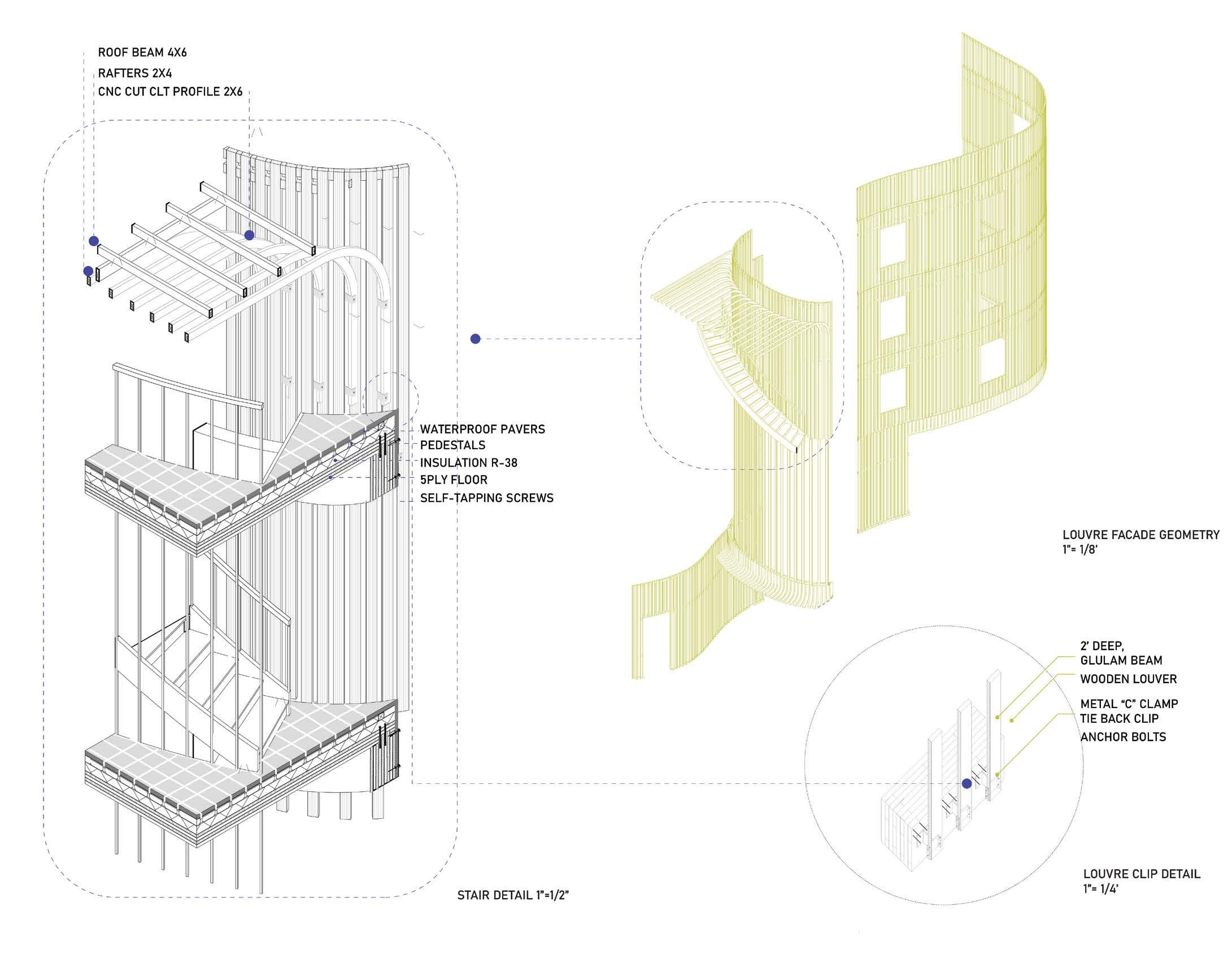

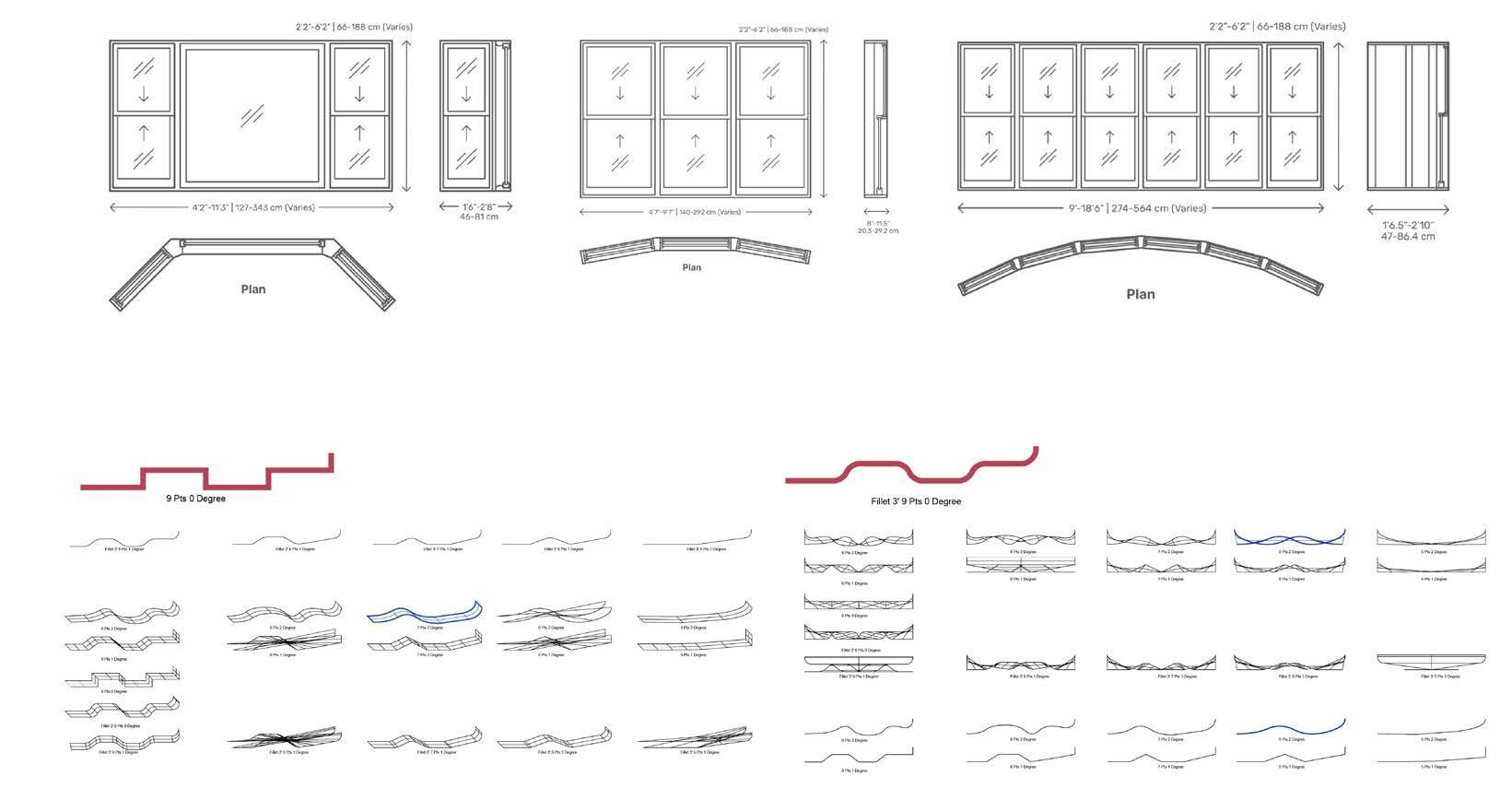

The series of diagrams is a reinterpretation of the iconic bay window of San Francisco.

The iterations go from a uniform line of two to five control points to rebuild the profile curve. The resulting geometry was tested in 3d printing and EQuest to achieve a smooth, continuous wall able to catch the sun along the profile and define the courtyard.

Curve Geometry build in Rhino and Grasshopper

Curve Geometry

“Painted Ladies” Houses. San Francisco, CA

Photo by Paula Cano

Curve Geometry build in Rhino and Grasshopper

Curve Geometry

“Painted Ladies” Houses. San Francisco, CA

Photo by Paula Cano

The facility offers 10 units ranging from studio occupancy to multi-family and three-bedroom duplex. Employing a diverse unit strategy on-site was essential to hosting multi-generational and diverse occupants, along ADA residents, contrary to the current neighborhood competition of single- and double-unit rentals.

Ground Floor 1’=1/16” Environmental

Strategies

MEP

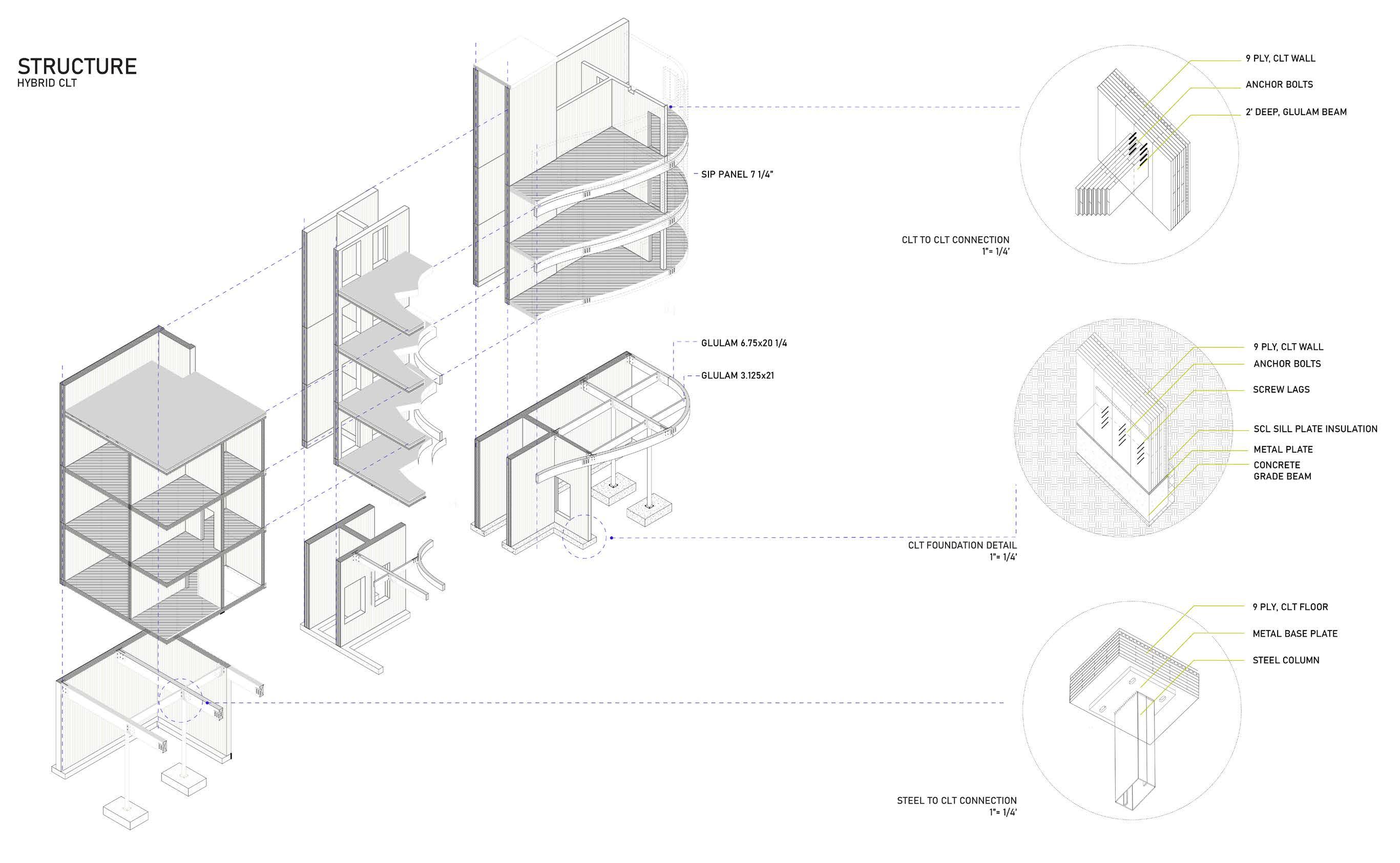

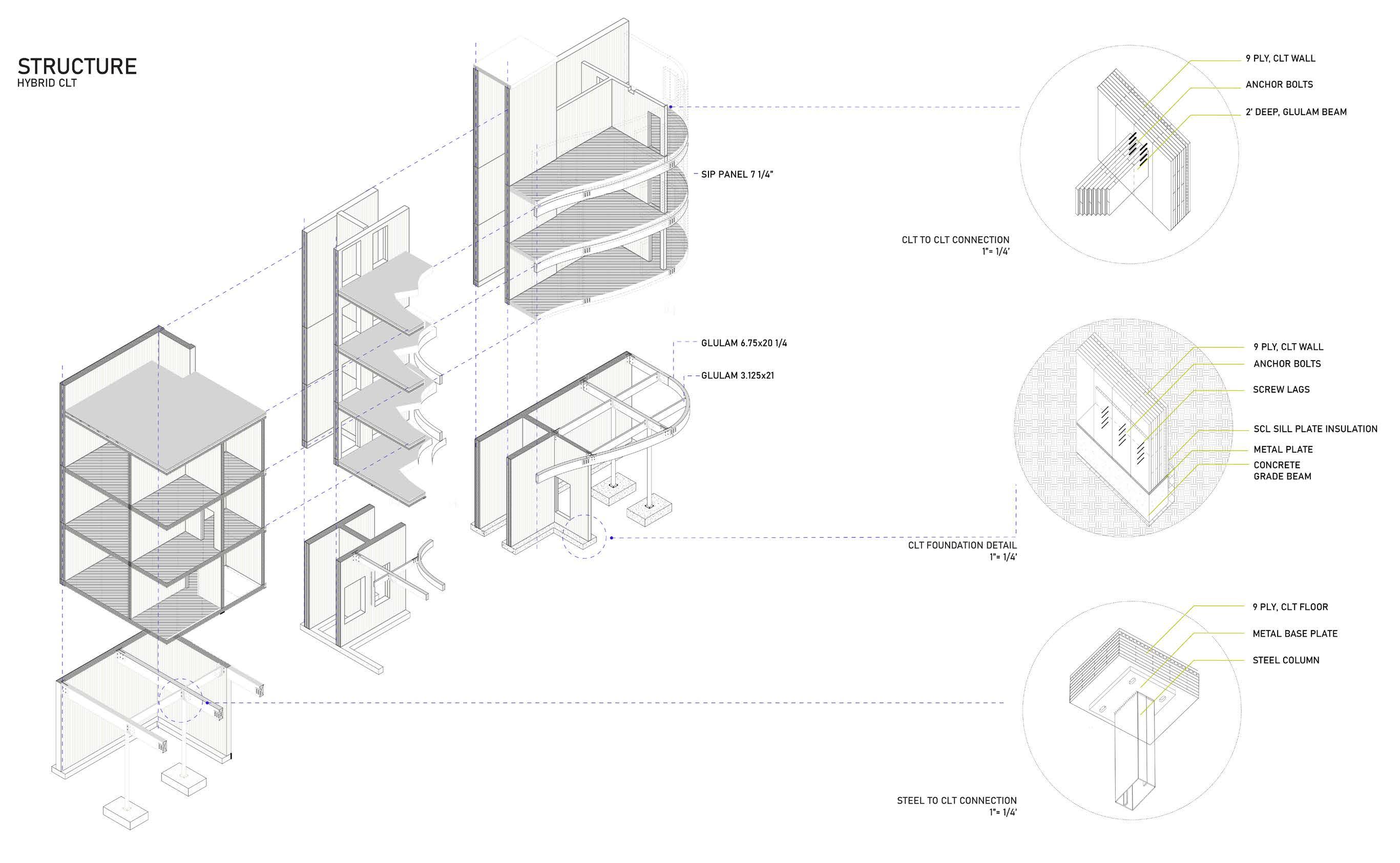

Hybrid CLT Structure

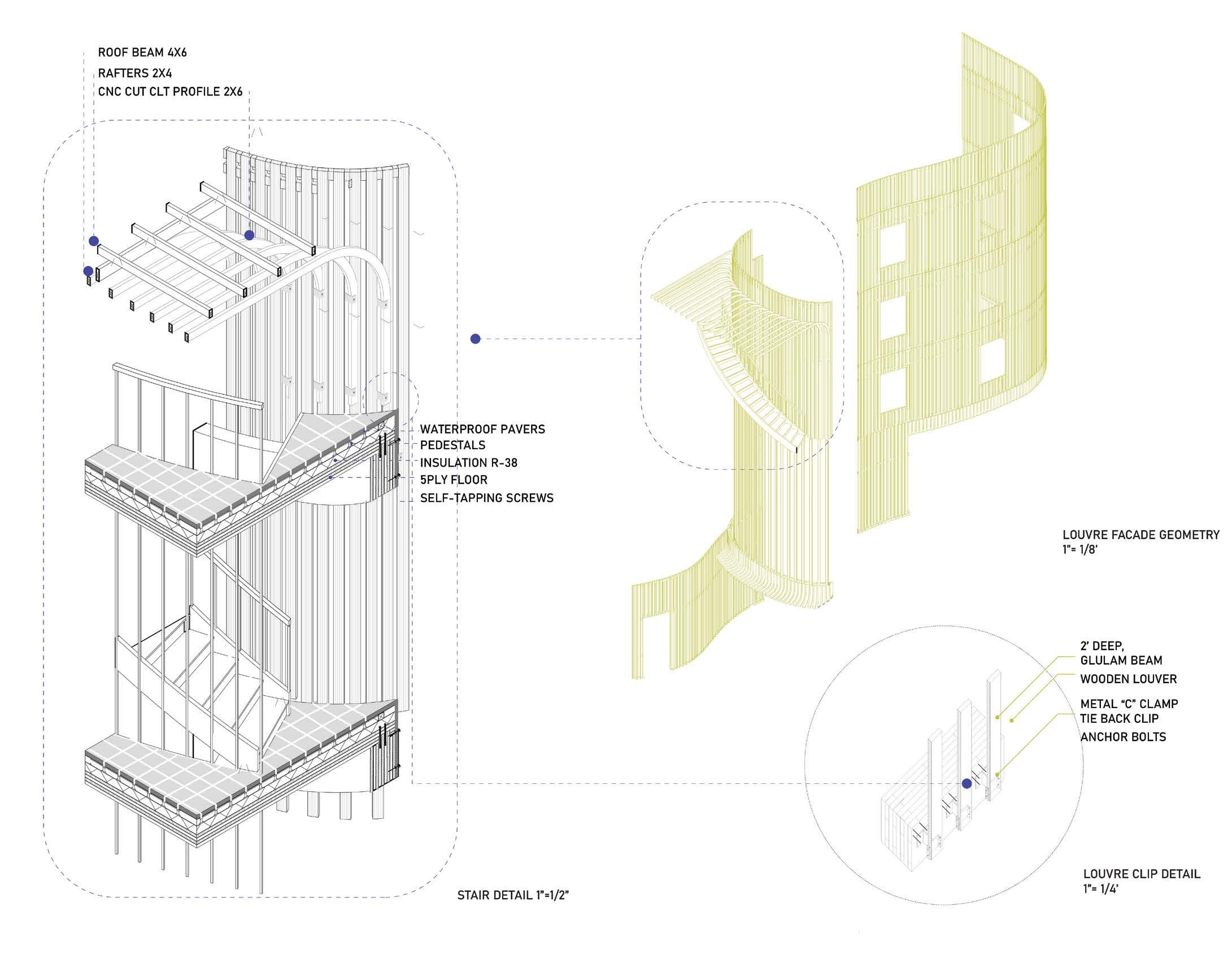

The use of wood is among the preferred approaches to reduce greenhouse gas emissions as it is a renewable material that lends itself well to zero-carbon and carbon-negative buildings. The hybrid system uses CLT floor panels and SIP walls in a platform-type construction to carry all gravity loads, transmitted to a conventional systems, of steel braced frames on ground level.

Exploted Structural Axon and Joints Details

Form-work for External SIP Panels

Community Service

2021 Assisted with Administrative Tasks and Funding Campaigns for | 800 Hours

Stars United Global Outreach Org. Dallas, USA

2020 Restored a Timber Structure for Frame Building School | 280 hours. AIESECMichaelshof Sammatz. Lüneburg, Germany

2020 Guided in an Educational Language Camp in English | 120 hours. Euroweek Foundation. Bystrzyca Kłodzka, Poland

Language Competencies

Native Spanish Speaker Teacher 100+ hours

English | TOELF C1 | Advanced

Russian | Certified B1

Technical Skills

Drafting: AutoCAD, Adobe

Energy Analysis: E-Quest, THERM, WUFI

Manufacturing: 3D scanning, 3D Printing, CNC, KUKA, Woodworking

Modeling: Architectural, Civil and MEP Revit, Grasshopper, Rhino

References

• David Heymann, FAIA

ACSA| University of Texas Distinguished Teaching Professor

Current Professor and M. Arch Thesis Advisor

heymann@austin.utexas.edu | 512.471.1922 | davidheymannarchitect.com

• Keith A. Simon, FAIA

Senior Architectural Consultant | Building Enclosures Practice Lead

Current Direct Manager at Terracon Austin Facilities

keith.simon@terracon.com | 512.800.4485 | Terracon.com

• Pliny Fisk III

Co-director of CMPBS. Professor Emeritus Texas A&M University

Former Direct Manager in 2020 and 2021, when I collaborated and as a researcher and architectural designer.

pfisk@cmpbs.org | 512.928.4786 | www.cmpbs .org

+1 4692375826 • paula.naca3@gmail.com • In/paulacanovergara • bit.ly/pcanoportfolio • archdaily.com/author/Paula-cano

Teamwork: Coleman Coker AIA, Sebastien Bartlett, Laura Bui, Paula Cano, Macarena de Salvidea, Yusuf Derya, Ciara Hackman, Madelaine Hamilton, Annie Hayes, Aya Kousa, Tessa Laplante, Miguel Magtaan, Keely Morgan, and Kate Shirley. | Client: The Temple Foundation

Texas Forestry Association (TFA) Wood Design Excellence Winner

Interior of the Pavilion from North Facade

Photo: Gulf Coast LabStudio

Teamwork: Coleman Coker AIA, Sebastien Bartlett, Laura Bui, Paula Cano, Macarena de Salvidea, Yusuf Derya, Ciara Hackman, Madelaine Hamilton, Annie Hayes, Aya Kousa, Tessa Laplante, Miguel Magtaan, Keely Morgan, and Kate Shirley. | Client: The Temple Foundation

Texas Forestry Association (TFA) Wood Design Excellence Winner

Interior of the Pavilion from North Facade

Photo: Gulf Coast LabStudio

North Facade

Photo: Gulf Coast LabStudio

North Facade

Photo: Gulf Coast LabStudio

Colombian Caribbean Coast Cultural Mapping Collage by Paula Cano

Colombian Caribbean Coast Cultural Mapping Collage by Paula Cano

Porch Pier gaze

Classrooms

Library

Cadrizo Dry toilet Communal sinks

Classroom Section and Architectural Analysis

Urban Collage/Render

Structural section

Porch Pier gaze

Classrooms

Library

Cadrizo Dry toilet Communal sinks

Classroom Section and Architectural Analysis

Urban Collage/Render

Structural section

2. Prototyping and utilities fixture

3. Shipping

2. Prototyping and utilities fixture

3. Shipping

A Third Place at the Commercial Corridor, Taraval Street

A Third Place at the Commercial Corridor, Taraval Street

Curve Geometry build in Rhino and Grasshopper

Curve Geometry

“Painted Ladies” Houses. San Francisco, CA

Photo by Paula Cano

Curve Geometry build in Rhino and Grasshopper

Curve Geometry

“Painted Ladies” Houses. San Francisco, CA

Photo by Paula Cano