Dense + passive + bikes + bio-based A manifesto for resilient living

Flat earth Tenement retrofit solution for Glasgow archetype

Material matters A palette for a vulnerable planet

Dense + passive + bikes + bio-based A manifesto for resilient living

Flat earth Tenement retrofit solution for Glasgow archetype

Material matters A palette for a vulnerable planet

Historic farm building gets low carbon deep retrofit

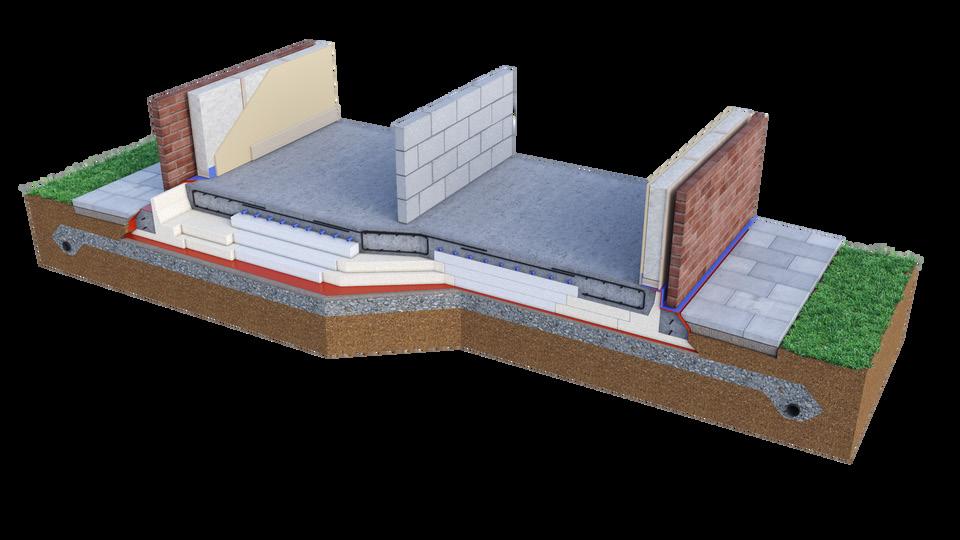

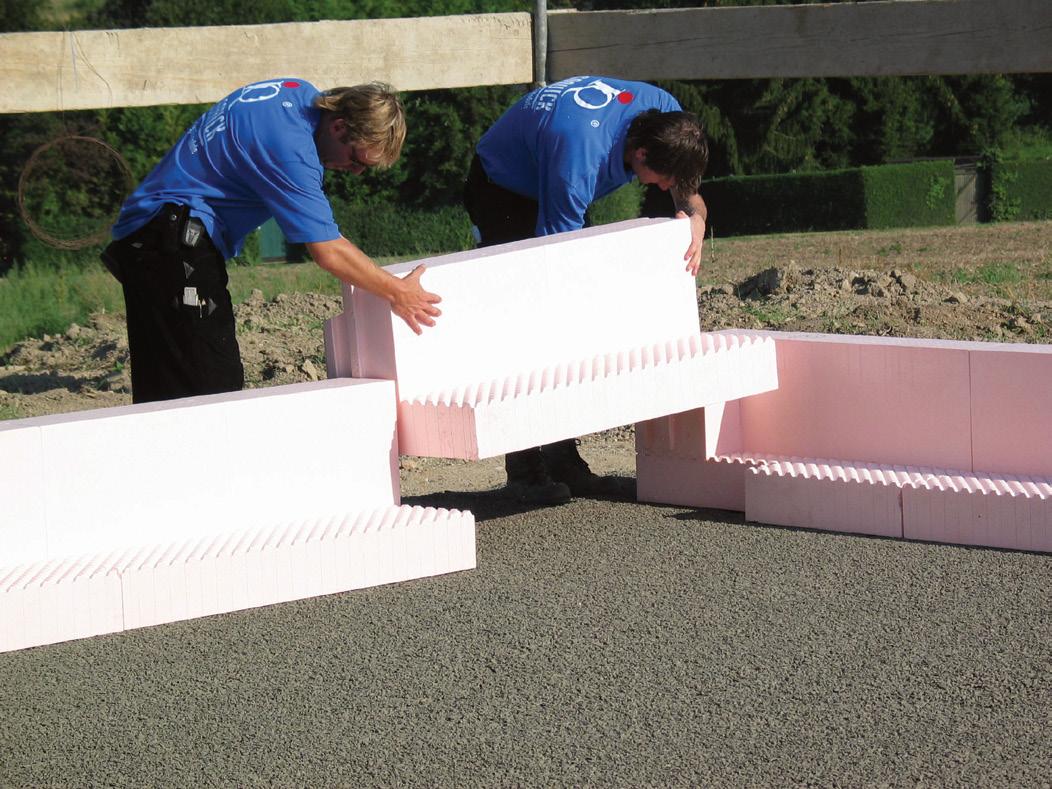

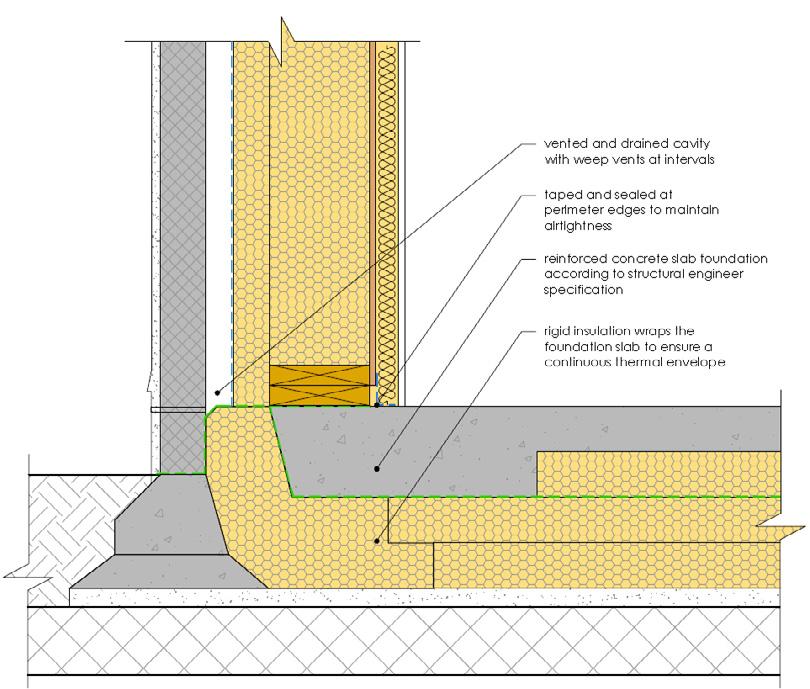

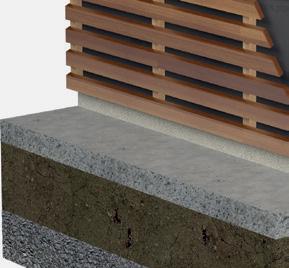

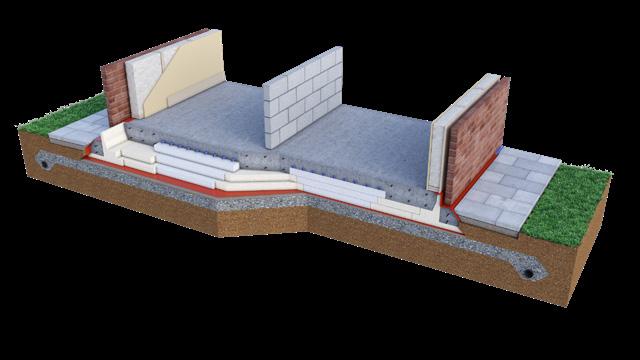

Design for performance, not just compliance and build with a foundation system that insulates from the ground up. KORE’s Insulated Foundation System wraps the entire foundation in a continuous layer of EPS, virtually eliminating thermal bridging while providing ground floor U-values as low as 0 10W/m2K Maximise efficiencies on-site, speed up foundation construction, reduce labour, waste, concrete and embodied carbon with one high-performance system If only other parts of the build could be this simple.

KORE’s Insulated Foundation System offers reduced embodied carbon by over 31% when compared to a traditional foundation system insulated with PIR - and we have the data to prove it Contact us today for more information.

Publishers

Temple Media Ltd

PO Box 9688, Blackrock, Co. Dublin, Ireland

t +353 (0)1 210 7513

e info@passivehouseplus.ie www.passivehouseplus.co.uk

Editor Jeff Colley jeff@passivehouseplus.ie

Reporter John Hearne john@passivehouseplus.ie

Reporter Kate de Selincourt kate@passivehouseplus.ie

Reporter John Cradden cradden@passivehouseplus.ie

Reader Response / IT Dudley Colley dudley@passivehouseplus.ie

Accounts Oisin Hart oisin@passivehouseplus.ie

Art Director

Lauren Colley lauren@passivehouseplus.ie

Design Aoife O’Hara aoife@evekudesign.com | evekudesign.com

Contributors

Lenny Antonelli journalist

Toby Cambray Greengauge Building

Energy Consultants

Mike Eliason Larch Lab

Ele George Elevate

Chris Morgan John Gilbert Architects

Marc Ó Riain doctor of architecture

Peter Rickaby energy & sustainability consultant

Andy Simmonds Simmonds Mills Architects

Jason Walsh journalist

GPS Colour Graphics www.gpscolour.co.uk | +44 (0) 28 9070 2020 Publisher’s

Cover

Tin Barn Enerphit

Photo by Ellen Christina Hancock

What makes a green home? And what aspects of green homes resonate with people? Or if we mash those questions into each other, how closely do the perceptions of homeowners and people in the industry align on what really matters? Do our views on green homes ignore the elephant that’s not so much in the room, but outside the front door – in the form of the lumps of metal, plastic and embodied carbon most of us have sitting in our driveways when we’re not whistling about our daily lives in them, using energy as we go?

As this issue of Passive House Plus goes to print, I’ve been processing the initial results from Green Homes Sentiments, a survey we’ve been running through our involvement in the Smarter Finance for EU project, a pan-European project aiming to unlock €100bn worth of certified green homes. Ostensibly the purpose of this was to produce some communications material for our partners to use when trying to convince everyone from lenders and investors to developers and municipalities to join the drive to commit to credible, roundly defined green home certifications. But to produce material that might actually connect with people, we thought it might be an idea to ask what makes a green home. One health warning here: most of the results yielded so far came from people who responded to emails and social media posts by Passive House Plus. Consequently the results are heavily weighted towards the UK and Ireland, and from people with an interest in sustainable building – and likely sympathetic to the passive house approach. We will be discussing the full results in depth on www.smarterfinance4.eu, and the survey is still live – so please go to the site to

have your say. But I can’t resist sharing some initial insights here.

We identified thirteen distinct aspects of a green home, including subjects as diverse as indoor air quality, embodied carbon, asset value, thermal comfort and energy efficiency, and reduced car dependency. And we asked people to rank which aspects they regarded as essential, important, or not important.

There was a clear winner. Over 92 per cent of respondents regarded thermal comfort and energy efficiency as essential, followed by 84 per cent who picked good indoor air quality. No other aspect clocked over 70 per cent. Conversely at the bottom of the list, under 22 per cent of respondents picked reduced car dependency as essential.

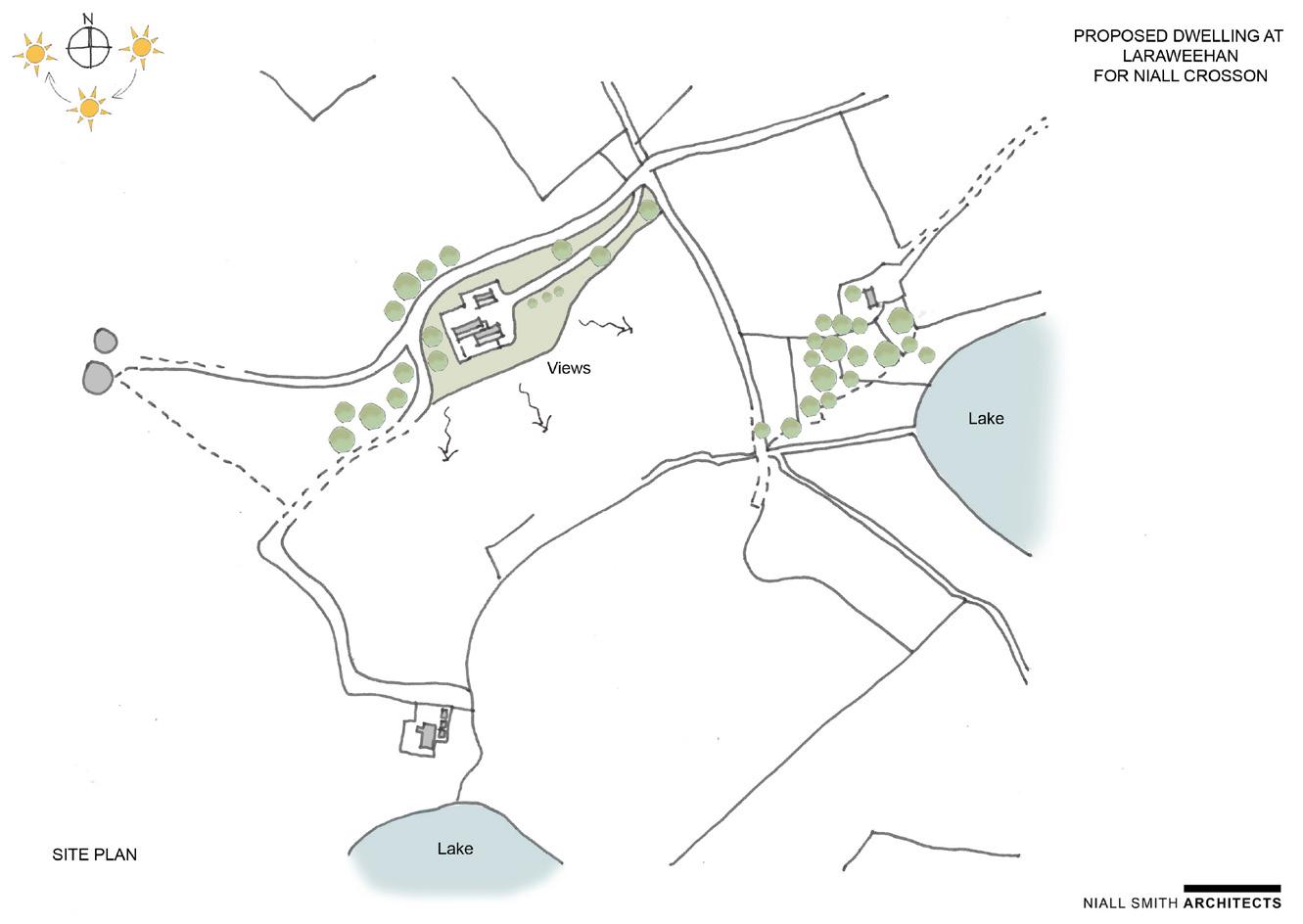

What does this tell us? Does this mean that, even among the kind of presumably green-minded people Passive House Plus is reaching, the prospect of giving up the car is a non-runner? And to be realistic, isn’t it really a matter of emphasis? No one is saying that isolated rural homes should be abandoned. But there’s something eminently sensible in encouraging settlement patterns which don’t require people to hop in the car to get about. In this issue, you will find a couple of examples which show both sides of the divide. Mike Eliason’s hijacking of our Big Picture feature makes a compelling case for high density, cyclable, walkable neighbourhoods. And if ever there was a case for a justified example of a one-off house, it’s green building stalwart Niall Crosson’s exemplary bio-based passive house – with his transport emissions mitigated by a largely PV-charged EV.

Regards, The editor

Points of access to resilient living

Mike Eliason, architect, founder of Larch Lab and author of the must read Building for People, reflects on how a series of personal and global crises – from pandemic lockdowns and climate disasters to urban housing challenges – shaped his mission to bring sustainable, community-focused, and climate-adaptive neighbourhoods to North America.

Scotland to accept passive house as regs compliant; Welsh social housing pattern book targets AECB & passive house standards; and new survey reveals UK public detached from net zero goals.

One of Europe’s key climate breakthroughs came in the form of the EU’s nearly zero energy building target, as Dr. Marc Ó Riain explains in the latest part of his series on the history of low energy building; and Ele George makes the case for industrialisation to level up the retrofit market.

Derelict to dream home

Historic barn reborn as bio-based Enerphit home

A couple breathes new life into a set of historic barns, creating an Enerphit dream home in the Gloucestershire countryside.

Tenement retrofit shows solution for Glasgow archetype What do you do when a building type is inefficient, common, hard to treat – and often used to house vulnerable people? Chris Morgan of leading passive house architects John Gilbert Architects tells the story of an extraordinary pilot project that may show the way to solve the stickiest of problems.

Cavan passive house proves powercut proof

Five years ago, a fabric first trailblazer took a dose of his own medicine – and delivered a family home that combines climate action, comfort, cost-effectiveness and resilience in the face of a record-breaking storm.

Material matters

A palette for a vulnerable planet

In recent years, the drive to reduce the embodied carbon of buildings has led to a resurgent interest in timber and other biobased building materials. But peering into the future, if we are to think not just about carbon but also land, water, and regenerating nature, how might we build to meet our essential needs, and what might we build with?

Three books and a taxi ride

Reflections on a career in energy efficiency and sustainability

Peter Rickaby looks back on an extraordinary career, the challenge of convincing people of the need for a new approach to buildings, and the people who helped him to do just that. 68

Keep up with the latest developments from some of the leading companies in sustainable building, including new product innovations, project updates and more.

AMOC running amok

Climate scientists are increasingly concerned that a key Atlantic Ocean circulation may be on the cusp of shutting down – with a range of catastrophic impacts including much colder winters in Ireland and the UK. What are the impacts for our buildings, asks Toby Cambray?

Points of access to resilient living

Mike Eliason, architect, founder of Larch Lab and author of the must read Building for People, reflects on how a series of personal and global crises – from pandemic lockdowns and climate disasters to urban housing challenges – shaped his mission to bring sustainable, community-focused, and climateadaptive neighbourhoods to North America.

On 13 March 2020, while I was in the process of moving back to the US from Bayern, where I had been working, I became stuck: with the Covid-19 pandemic worsening across the EU, Trump closed the US borders. He did this while I was sleeping, meaning I woke up to dozens of messages – emails, texts, social media DMs, missed phone calls – asking how I was getting home. Unaware, I laughed: “My flight home is in a few days – what are you talking about?”

This kicked off a strange year in which trauma became the norm. A few days later, repatriation flights were set up, and I flew back to the US, directly into pandemic lockdowns. Our kids were (barely) learning on computers in our new home – where we also would be working.

In June of 2020, the George Floyd protests kicked off across the US. In Seattle, police used tear gas against protesters in a dense neighbourhood, affecting residents who were in their homes.

September 2020 saw dense, toxic wildfire smoke blanket the Seattle area for nearly two weeks, as our state saw some of the worst wildfires in its history. We were lucky that our home had decent filtration in our ventilation system, but being trapped inside for nearly two weeks with kids who were already largely indoors due to the pandemic and online learning was difficult. To this date, I now notice even the faintest molecule of wildfire smoke. Clearly, there’s a bit of PTSD related to this trauma that overwhelms me.

And then, in June of 2021, a massive heat dome settled over the Pacific Northwest, leading directly and indirectly to the deaths of up to 1,400 people. While not a passive house, our home is relatively protected from direct

sunlight thanks to generous overhangs and trees. Our climate in Seattle is incredibly mild, such that we sometimes need sweaters on summer evenings, and night flushing has always been reliable.

The heat dome was different. Not only were the daytime highs more intense than anything we had experienced, but the nighttime lows, which normally range from 55-60F (13-16C) never really dropped below 20C. It was unbearable, and we were fortunate to be able to stay with a relative who had air conditioning, not to mention room for us. I have friends who were living in south and west-facing single aspect studios in new buildings that never saw their homes dip below the mid-80s at night – 29 degrees Celsius!

Just two weeks earlier, I had been on a local housing panel where a distinguished developer stated we didn’t need air conditioning due to the region’s cold evening temperatures. The

heat dome shattered that long held belief. We do not have an active solar protection industry in the US, external shades are rare for multifamily housing and most apartment buildings here don’t have air conditioning either –though that is slowly changing.

Throughout this period, I had a lot of time to reflect on the trauma and events from the last 16 months: time to look back on what I had been working on in Germany, why we had moved there in the first place (in part, to be closer to the global centre of mass timber and of passive house communities).

I also began to reflect on how those projects were so different to anything I was working on back in the US. I had already been researching how building codes affect housing design in different countries, and started to connect the dots on building codes, how they interface with land use codes, and what that means in terms of livability, quality of life, and climate adaptation.

Out of that research and reflection, came the desire to have a stronger voice in highlighting the deficiencies of the status quo. We have a growing housing affordability crisis in much of the US, and lack the ability to scale up the development of affordable and climate adaptive homes. When it comes to passive houses, it feels like we are still light years behind Europe. We aren’t very intentional in how we develop places and neighbourhoods – either over time, or from scratch and our development patterns ignore centuries of urban history, eschewing common sense approaches for buildings designed by excel spreadsheet to maximise yields at what seems like the greatest expense to comfort and quality of life.

I yearned to re-connect what I was working on and talking about in the US – with my roots and experiences working in Freiburg and Bayern. I had founded Larch Lab as an architecture and planning studio in 2021 to focus on decarbonised buildings and community-oriented housing, as well as to function as an urban think-tank working on advocacy, education, sustainable mobility, and climate adaptation.

In the lulls, I re-read my worn copy of Catherine Bauer’s Modern Housing (1934). Bauer was a leading member of the ‘houser’ group of planners who advocated affordable housing for low-income families. I was immediately struck by a single sentence: “Moreover, modern housing provides certain minimum amenities for every dwelling: cross-ventilation, for one thing; sunlight, quiet, and a pleasant outlook from every window”.

This was a profound, and succinct counterpoint to the aspects of housing built today. Due to our anomalous building codes, our multi-family housing generally uses a double-loaded corridor for unit access. This also results in narrow and incredibly deep units with windows only on one end, or if you are fortunate enough to live on a corner the possibility for daylight on two sides. These buildings cannot cross ventilate. Often, they are built just a few feet from property lines, with a similar building standing the same distance on their side of the property line. Consequently, there is little to no access to air, to sunlight, to pleasant views.

Building codes in the US and Canada are wildly anomalous from peer countries, resulting in buildings that are often much larger and deeper – and with homes that are much more compromised.

The workhorse for moderately dense urban housing is the single stair building, or as I call it the Point Access Block. These are found all over European cities, from small multifamily buildings on the outskirts, to dense perimeter blocks and high-rise towers. These buildings induce larger family-sized units and a more diverse unit mix, often in buildings with a far thinner building depth than we see in the US. This has the added benefit of allowing more courtyard or open space as well. Point Access Blocks allow for better daylight in homes, and often the ability to cross ventilate, as most units are dual or corner aspect.

However, Point Access Blocks are effectively illegal in the US above three storeys, with a handful of exceptions. The end result of this is that homes in US and Canadian multifamily buildings are far unlike anything being built in the rest of the world, and they are a poor substitute for other types of housing such as detached homes or rowhouses.

Increased development costs, overly permissive land use codes, and rising interest rates have also resulted in a preponderance of massive

buildings, often with over 150 units – and most of those units being small studios or one-bedroom homes. In Seattle, less than two per cent of new apartments have three or more bedrooms. Windowless bedrooms have become common in many cities where they are not specifically restricted. I have even seen projects under construction in Seattle with three-bedroom homes on a re-entrant corner where none of the bedrooms have windows, with the entire unit only having one small wall of windows looking onto a tiny courtyard.

Housing built today is a radical departure from the very types of projects Bauer was writing about in 1934, and not just in a quantitative sense. Much housing built today is being built in a manner that is car-centric, exacerbating climate change, and on top of which, the majority are not built to adapt to a changing climate.

In much of the US, we concentrate dense, affordable housing on arterial roads and highways, in order to preserve detached housing and sprawl off of them. Even Transit Oriented Developments – neighbourhoods around high capacity and frequent transit – are generally sited near highways or at the intersections of major roads. There is typically no comprehensive planning or mobility strategy, so instead of providing space for community and nature, these neighbourhoods are still largely autocentric and loud.

It doesn’t have to be this way We can chart a path to adequate affordable housing that prioritises a better quality of life, not to mention ecology, adapt to climate change, and better connect our communities to address the growing social isolation crisis that has only exploded in the aftermath of the pandemic.

The passive house community was one of the first to realise the benefits to reducing operational emissions, and then pivoted to reducing embodied carbon emissions. Many of my friends and colleagues in this world are doing incredible work with straw, wood, and other bio-based products. There is also an incredible effort around retrofits, rehabilitations, and so-called aufstockungen (vertical additions or top ups to existing buildings). These are all great, and I continue to believe that the passive house community is on the bleeding edge of all things related to efficiency and carbon.

The realisation that this issue didn’t just affect housing, but infrastructure and quality of life, and was strongly connected to public health outcomes really pushed me to start to connect the dots for solutions and frameworks to these problems.

The following strategies are ones that I believe we should be focusing on to create dense, walkable, low carbon neighbourhoods offering a high quality of life and positive public health outcomes in the face of a changing climate.

Compact, climate-adaptive, and nature-inclusive ecodistricts

Ecodistricts are ecologically oriented districts, such as the oft-cited Bo01 in Malmo, or Freiburg’s Vauban. They are typically brownfields redeveloped into socially mixed and ecologically focused neighbourhoods. They come in a variety of sizes and scales –from small settlements to massive projects like Vienna’s Seestadt, built over the former airport, with homes ultimately for 25,000 people and space for 20,000 jobs.

Switch to daily mode or activate a program

View indoor air quality and get feedback

Going on Holiday? Activate holiday mode

View indoor air quality by day, week and month

Be informed when it’s time to change lters and order them online

Set ventilation modes by hour to hour on a weekly basis

DESIGNED FOR EASY INVERSION OF AIRFLOWS ON SITE

CONFIGURATION A CONFIGURATION B

Elevate your indoor experience with InspirAIR Top MVHR system, a connected marvel of innovation designed to prioritise air quality, performance, comfort, and user interaction.

The unit is delivered in configuration A.

To switch to B, simply reverse the filters, confirm the change in the remote control and connect the condensate to the corresponding side.The change takes less than 5 minutes!

Exhaust air (outdoor) Fresh air (outdoor)

The integrally planned ecodistrict should be a district of blocks or neighbourhoods that facilitates sustainable and future-oriented mobility (think bikes and e-bikes) –over broad streets designed for cars. Traffic calming is carried out to ensure these places are safe for everyone, from children to elderly residents. These districts are usually oriented around transit and bicycle mobility to reduce car reliance. Schools, pre-school care, cafés, and grocery stores are also quite common, helping to facilitate walkability and low carbon living.

Priorities for climate adaptation should include flooding and rain inundation, incorporating sponge city principles and abundant trees and green space to mitigate overheating. The focus on climate adaptation in these neighbourhoods will lead not only to better public health outcomes but to better quality of life for residents as well, as they have access to nature and resources within reach without needing to hop in a car for everyday tasks. Cities that prioritise climate adaptive places offering a high quality of life, high quality public realms, open space, and car-light and even car-free neighbourhoods –will find they are lighthouses in the future of sustainable urban development.

‘Baugruppen’ and collaborative housing ‘Baugruppen’, German for building groups, are a form of collaborative housing where the people who will live in a multi-family building come together to co-participate in the planning and development process. Collaborative housing can include a variety of forms of housing (condominiums, co-operatives, apartment buildings, rowhouses, townhouses, and so on) developed by the residents that will be living in them, rather than by developers. The elimination of developer profit and marketing costs can result in significant savings – from ten to twenty per cent – over market-rate housing. Possibly more with better land disposition properties prioritising collaborative housing. Collaborative housing is a value-driven approach in which residents prioritise the levels of ecology and social spaces they want and need over the profit motive. Dr. Wolfgang Feist’s passive house in Kranichstein – the first multi-family passive house building – is itself a ‘baugruppe’. Mass timber was being incorporated in collaborative housing years before anyone in the US, other than a small handful of people, were even talking about it, including Kaden Klingbeil’s stunning seven-storey mass timber building in Berlin.

Passive house as a baseline to healthy, climate adaptive homes

Despite taking the passive house training course in 2010, I personally never really connected the dots to how passive house designs could provide the kind of dwelling that could expand the bounds of habitability in a changing climate. It took a series of conversations with my dear friend Monte Paulsen over the years, debating these very topics, the merits, the trade-offs, the benefits. It was Monte who pointed out the wildfire smoke protection benefits that come from an airtight building envelope, high performance

windows, and fresh, filtered ventilation. And he had the data to back it up.

Furthermore, passive houses are a buoy against energy poverty, as well as allowing for smaller mechanical systems and lower replacement costs down the line as efficiencies in HVAC improve over the decades. The designs radically reduce mould risk from condensation and vapor transfer. Residents in passive house-spec social housing in the UK have even noted a reduction in the severity of asthma and other illnesses over where they previously lived.

Indeed, the improved air quality benefits of passive houses are well noted, and it is fair to say that the pandemic brought healthy air to the forefront in a manner I hadn't really anticipated. While it has not resulted in an explosion of passive house buildings, there is at least a growing awareness that the way we have been designing buildings actively puts people at risk.

The Association for Environment Conscious Building (AECB) is an independent, not-for-profit organisation run for its members.

Our vision is to create a world in which everyone in the building industry contributes positively to human and planetary health. We work with our members to inspire, develop and share sustainable and environmentally responsible building practice.

Our Standards are a key pillar of the deployment of environmentally responsible building practices and the creation of sustainable low energy, low carbon buildings.

Owing to the power of PHPP (the Passive House Planning Package) – we can not only test to see how our buildings will perform in a warming world – but what efforts can be done to really design out the heat. Heat due to climate change is a growing concern, and better understanding how this will affect buildings – buildings designed for a cooler climate that no longer exists – is imperative. Crucially, passive house buildings are so efficient that they need minimal active cooling to remain habitable, and cooling loads can even be shifted to offpeak durations to reduce demand on electrical grids.

The heat dome was a perfect event that focused a lot of our office’s efforts on prioritising passive house as a new baseline for ensuring greater resilience and adaptability moving forward.

Proactive governments lead

We all saw the success in Brussels of ramping up the uptake of the passive house standard, with visionary leadership and collaboration. Cities and states build and manage many buildings, and can mandate that new and retrofitted public buildings meet the standard. Quasi-governmental agencies can also show effective leadership. Neue Heimat Tirol and ABG Frankfurt are standouts in the world of social housing and limited profit housing associations leading with climate and passive house. Companies like these were the impetus for Seattle’s own Social Housing Public Development Authority, whose board I serve on, that is tasked with building affordable community-oriented housing.

Cities can take an active role in planning and land disposition to prioritise non-market housing. The City of Amsterdam owns 80 per cent of its land, and holds parcels aside in large developments for self-builds and multi-family buildings similar to baugruppen called Collectief Particulier Opdrachtgeverschap (CPO). Natrufied Architecture’s Wooncoöperatie De Warren is a low-carbon, energy-positive co-operative in Amsterdam that was developed on land the city reserved for affordable, community-oriented housing. Cities like Vienna, Freiburg, and Tuebingen similarly reserve land for community-oriented housing, and use a creative tendering process to facilitate even more incredible projects – bike-friendly mass timber housing, multigenerational housing, LGBTQIA-oriented, and even family-friendly housing incorporating housing for refugees.

Under Mayor Ann Hidalgo, Paris has seen a mobility transformation that seemingly daily is changing streetscapes and saving lives. Cities that foster car-light neighbourhoods will realise the public health gains are incredible – reduced noise pollution, reduced air pollution, safer streets and less traffic violence. Residents will find they have quieter neighbourhoods where they can actually hear birds instead of cars, find better sleep, and be more socially connected.

The way we plan and build our cities and neighbourhoods is directly related to the quality of life in them. Our neighbourhoods will have a massive impact on our collective ability to rapidly adapt to climate change.

I used to think that we needed to imagine brilliant futures, but I have come to realise that these futures already exist within our collective knowledge and experience. They just have not been harnessed and synthesised anywhere near the levels needed to adapt to these tumultuous and changing times.

It is my fundamental belief that a better world really is possible and that with the right policies and leadership, we can ultimately unleash brilliant futures that foster more cohesive and socially connected communities; communities that prioritise ecology and create places in which we can thrive.

Mike Eliason’s book, Building for People, which delves deeper into these concepts, is available now from Island Press, and other book distributors.

Scotland’s devolved government has published amendments to building standards which are set to usher in a transition to the passive house standard – including the development of a local equivalent to the standard, and recognition of passive house certification as an alternative means of meeting compliance.

The amendment, laid by the Scottish parliament on 12 December, makes concrete a December 2022 commitment made by ministers to give effect to the ‘Domestic Building Environmental Standards (Scotland) Bill’, first proposed by Alex Rowley, a Labour member of the Scottish parliament, in May of that year.

The Building (Procedure) (Scotland) Amendment Regulations 2024 introduces a requirement for developers to provide an “energy and environmental design statement” with building warrant applications and an “energy and environmental construction statement” with each completion certificate.

A date of 31 March 2028 has been set for implementation.

The move to amend building regulations followed an initial consultation held in the summer of 2024, with a second round of consultations due in 2025 to set out proposals for the revision of performance targets, and for compliance re-vised standards are set to be published in early

2026 and become mandatory in early 2028.

One element being considered for the Scottish passive house equivalent definition is an energy use intensity (EUI) target, which may differ depending on building types. EUI refers to the amount of energy used annually per square metre of floor area and typically includes all energy use at the meter – including so called ‘plug loads’, or unregulated energy. Focusing on an EUI target would mean that the definition would include hard targets for the energy efficiency of the building itself, rather than relying on ‘primary energy’ targets – meaning the energy used at source, such as the power station. As less efficient electricity generation is phased out, the primary energy of the grid is improving. This means, in the case of electrically heated buildings, that primary energy-based targets may give the false impression of energy efficiency, lower running costs and higher thermal comfort, and risk undermining public confidence in attempts to decarbonise buildings.

A statement issued by Scottish Building Standards described the move as “an important milestone in the current review of building standards,” and said engagement with its working group and wider industry partners was now needed to agree the extent to which the ethos and components of the passive house standard can be embedded within performance targets are

defined and how compliance, and the real-world performance of new buildings, is assured.

The move has been given a guarded welcome by the UK’s Passivhaus Trust.

Sarah Lewis, the trust’s research and policy director said the Scottish government’s announcement was an “important first legislative step”.

However, the trust was nevertheless “still awaiting the fine details of what that policy will look like. We are hopeful that the recommendations we put forward in our consultation response will have been taken on board so that Scottish building standards have the accurate tools and absolute energy targets that would be essential for any standard aiming to be a passive house equivalent".

The trust stressed the importance of setting absolute energy targets in the new standard being set close to passive house levels, a modelling tool with accuracy equivalent to PHPP (Passive House Planning Package), and the need for training to up-skill the industry as needed.

“Everything is still up for grabs in terms of targets," said Passivhaus Trust CEO Jon Bootland. "We’re very supportive of the move towards absolute targets, and also of mechanisms to ensure greater certainty of actual performance for building occupants." •

Welsh social housing to be standardised using new typologies integrating passive house, CarbonLite and timber building.

Wales’s devolved government has moved forward with plans to standardise sustainable, timber-based affordable homes in the country with the publication of a new pattern book.

Unveiled at the University of Wales Trinity Saint David in Swansea on 15 January, the pattern book has been developed with support from the Welsh Government and twenty-three social housing providers who came together under the name Tai ar y Cyd.

The book sets out fifteen house typologies across two building performance standards, AECB CarbonLite and passive house classic.

The AECB CarbonLite new building standard is the baseline standard and draws on the passive house methodology, with a target space heating demand of 40 kWh/m2/year. The enhanced standard targets the passive house classic standard, with a space heating target of 15 kWh/m2/year (or peak heating load of 10 W/m2/year).

Steve Cranston, project lead on the Tai ar y Cyd project said the two performance targets were chosen to be “ambitious yet achievable”.

“They meet the needs of member landlords who wanted an ambitious ‘entry level’ place to start as well as an advanced position for landlords ready to push their ambition further. This approach has been found to suit the Welsh timber frame manufacturers and supply chain. Welsh government colleagues in the standards/technical scrutiny team were closely involved in this decision,” he said.

The pattern book is intended to make it easier for Welsh social housing providers to meet Welsh Development Quality Requirements (WDQR) 2021, criteria for a ‘fabric first’ alternative option to EPC A with a space heating target of 40 kWh/m2/year. Both the

baseline and enhanced standards will be accepted for Social Housing Grant technical scrutiny and grant application. The project is also aligned to the RIBA 2025 embodied carbon limit of <800 kgCo2e/m2 as a minimum and aiming for RIBA 2030 minimum carbon limit of <625 kCo2e/m2

Speaking ahead of the launch at a visit to Celtic Offsite in Caerphilly, a social enterprise within the United Welsh Group that manufactures timber homes from their factory, Welsh cabinet secretary for housing and local government, Jayne Bryant, said the Tai ar y Cyd patten book represented a “significant step forward” in the government’s commitment to building sustainable and affordable homes in Wales.

“We know that there is a real need for good quality and energy efficient homes across our communities, and this innovative pattern book give developers the tools they need to build homes more quickly and deliver against our target of building 20,000 affordable low carbon homes by the end of this Senedd term,” she said.

The pattern book also received a welcome from the Association for Environment Conscious Building (AECB), with a spokesperson saying it was an "exemplar" and that the industry body was “delighted to have our new build standard adopted in Wales and to be included in the pattern book. We wholly endorse the project and are poised to support further development in any way we can.”

(above) Welsh cabinet secretary for housing and local government, Jayne Bryant, praised the pattern book at a visit to Celtic Offsite in Caerphilly, a social enterprise within the United Welsh Group that manufactures timber homes.

A survey of 1,500 UK homeowners by the Social Market Foundation (SMF) – a cross-party think tank – has revealed government failure to make people feel confident in taking steps for the net zero transition, jeopardising its success. To turn general support for net zero into individuals taking the necessary actions (like switching over to heat pumps), the Labour government will have to engage in a comprehensive public engagement strategy, SMF said.

The SMF report comes at a time when many governments have been struggling to effectively engage with the public on aspects of the green transition. One stark example is in Germany last year, where new legislation aimed to enable the shift away from fossil fuel boilers was met with fierce criticism and protests. The German government’s popularity fell to record lows as a result. The lack of a proactive and trusted public engagement communications strategy was seen as having wrecked the heating transition, and severely damaged public opinion on the matter, the SMF noted.

In the SMF’s survey, two-thirds (63 per cent) of respondents believed that ‘reaching net zero by 2050 is a nice idea but it will be too difficult to achieve’. Many feel detached from the actions needed to make the transition a success. Nearly half (48 per cent) felt that the transition is happening to them, not with them. In focus groups with homeowners, participants further expressed that they “don't feel as if [they’ve] had any involvement whatsoever”. A similar proportion (45 per cent) think that government has not done a good enough job to engage the public on the topic of the net zero transition so far.

The sense of lack of involvement has kept trust in crucial technologies like heat pumps at low levels, leaving the UK reliant on its largely gas-powered heating approach. Despite heat pumps being long-established in different climates all over the world, only 4 per cent of homeowners already had a heat pump, or were in the process of installing one. A quarter said that they would not want a heat pump in their house. Despite some progress in installation rates in households and small businesses, the UK is well below the target of 600,000 heat pump installations a year

by 2028.

Building trust is also not made easy. Independent information, advice and guidance on low carbon heating is seen as absent by the public. SMF polling found that 50 per cent of people think there is too much conflicting information about heat pumps, clearly showing that misinformation is also taking root among the public. Among low-income groups in particular, there is a concern that being reliant on government funding for heat pumps will mean putting up with limited options, rather than having a true choice in the matter.

The SMF has recommended that the UK government engages in a comprehensive public engagement strategy, drawing on independent voices like Martin Lewis to provide reliable information about heat pumps, since heating engineers (54 per cent) and consumer websites (53 per cent) are the top go-to sources among homeowners, when the SMF asked them where they’d go if they wanted reliable information about heat pumps.

To show its commitment to the technology, the SMF argues the government should role model the installation and use of heat pumps by publicising their use in public buildings, like GP surgeries, schools and libraries, to build trust in the effectiveness of the technology. This is also crucial, as just over a third (34 per cent) think heat pumps will not be a long-term solution to home heating, either doubting the government’s commitment to it or seeing heat pumps as more of a fad.

Social Market Foundation researcher Niamh O Regan said: “The most critical barrier to UK’s net zero ambitions is no longer the belief in the mission, but rather whether people feel they can participate confidently in it. People want to feel that they are part of the transition – and the government has a lot to do to convince them of this.

“By directly engaging with the public, drawing on independent trusted voices, and showcasing its own actions that aid the green transition, the government can avoid the greenlash that [our] neighbours in Germany have faced. While financial support remains a necessity, the next stage has to be better communication.”

MCS Foundation head of research,

policy and campaigns Dr Richard Hauxwell-Baldwin said: “17 per cent of the UK’s carbon emissions come from heating our homes, meaning that replacing domestic boilers with heat pumps, on a mass scale, is critical for net zero.”

“While record numbers of heat pumps are being installed, the UK is still way behind where we need to be, and the vacuum of information on heat pumps is at least partly to blame.”

“The critical next few years in the transition to net zero must see clear, consistent and trusted public communication on the benefits of heat pumps and the process involved in installing them. Government must take a lead on that.” •

While record numbers of heat pumps are being installed, the UK is still way behind where we need to be, and the vacuum of information on heat pumps is at least partly to blame.

The Smarter Finance for EU consortium, which is aiming to unlock €100bn worth of green homes across Europe, announced the launch of a European centre of excellence to promote green home certification and investment across Europe at the Irish Green Building Council’s annual residential conference in Dublin.

The housing crisis, climate emergency and a raft of other crises including the postwar reconstruction of Ukraine can be tackled simultaneously – by a pan-European green homes investment driven, the consortium has said.

“The world is facing a number of environmental and social crises, including climate change, biodiversity collapse, and the need to provide safe, healthy, affordable homes for all. Green homes can help to tackle all of these problems and more – and deliver warm, healthy, affordable homes for families all around Europe,” consortium spokesperson Elena Rastei told delegates at the Smarter4EU Better Homes conference, held in Dublin in November 2024.

The EU-Life funded project is aiming to help standardise and align green home programmes across Europe with requirements affecting the finance world to support with the implementation of the European Green Deal.

The consortium includes partners with established green home programmes in Ireland, Romania and Spain, and new programmes in Portugal and Ukraine – all of which are being aligned with new rules for green investment, via the EU taxonomy for sustainable activities.

Rebuilding Ukraine

The day before the conference, the consortium brought a delegation of mayors and municipal leaders from Ukraine and Portugal to visit a Clúid affordable housing scheme in Cabra certified to the Home Performance Index, the Irish Green Building Council’s sustainable home rating system.

“Green homes should not be seen as a luxury – even in a post-war setting,” said Smarter4EU energy poverty lead Iva Merheim-Eyre.

“Green housing can be economically viable even in affordable housing sectors with a good blend of public and private investments”.

Julie Emmrich, sustainable finance lead for the World Green Building Council, emphasised the need to include green renovations of Europe’s existing housing stock.

“The EU taxonomy currently doesn’t sufficiently incentivise investments in green retrofits in residential homes,” she said. “The Smarter Finance for EU project aims to fill that gap.”

The Better Homes conference included a roundtable discussion on overcoming challenges to delivering green, healthy and affordable housing for all, including municipalities and financial agencies from Spain, Ireland, Portugal and Ukraine.

A panel session on ‘hybrid’ finance solutions discussed different types of hybrid funding, which include blends of private and public funding, to help deliver green homes for the social and affordable housing sectors across Europe. The panel, moderated by Passive House Plus editor Jeff Colley, discussed ways to strengthen cooperation between municipalities, financial agencies and private developers, and opportunities to access affordable housing.

According to Merheim-Eyre, hybrid finance will have a particularly key role to play in unlocking green home investment across Europe, including Ukraine.

“Given the scale of the reconstruction challenge in Ukraine, hybrid finance will be required, at a time when investors are under increasing pressure to green their investment portfolios,” she said.

As of November 2024, Smarter Finance for EU has unlocked finance and green home certification for over 37,000 new homes across Europe. •

One of Europe’s key climate breakthroughs came in the form of the EU’s nearly zero energy building target, as Dr. Marc Ó Riain explains in the latest part of his series on the history of low energy building.

In 1997, the Kyoto Protocol marked the first major international attempt to address climate change, but it was only in the early 2000s that energy efficiency in buildings began to gain serious traction, initially through basic U-value targets for retrofits and new builds. A key moment came in 2002 when the EU’s Energy Performance of Buildings Directive (EPBD) was transposed into national legislation, setting the stage for progressive improvements in building energy efficiency standards across Europe.

Despite these early steps, by 2005, the energy efficiency of many buildings remained subpar. In my experience with retrofitting a building from 2005, it became clear that early regulations had failed to address critical areas such as cavity wall insulation. At the time, only 50 mm of insulation on interior walls and floors was typical with perma-vents in windows – a stark reminder of how much work was left to achieve energy efficiency targets.

A significant milestone in the UK's and Ireland's energy efficiency journey occurred in 2007 with the introduction of energy performance certificates (EPCs). These certificates – named Building Energy Ratings (BERs) in Ireland – raised awareness about energy performance and gave consumers the knowledge needed to make informed decisions when purchasing or renting homes. EU studies, including those by the Fraunhofer Institute, called for a tripling of energy efficiency efforts to meet the EU’s climate and energy goals.

In 2010, the EU revised the EPBD, introducing the concept of nearly zero energy buildings (NZEBs). While NZEB standards were not directly linked to the passive house standard, they aligned with its principles. This revision required EU member states to calculate “cost-optimal” standards every five years, ensuring that building codes evolved beyond basic U-value targets. In Ireland, cost-optimal calculations for new builds were completed in 2013, and for retrofits in 2015.

Despite these policy advances, challenges persist, particularly in retrofitting the existing housing stock. In both the UK and Ireland, nearly 99 per cent of the buildings require retrofitting to meet the 2050 net-zero carbon targets. A

large proportion of the housing stock, especially older buildings, currently fall below the required energy performance standards, with many rated D or worse on the EPC scale.

The scale of the retrofit challenge is substantial. Government initiatives such as the UK’s Green Homes Grant (2021) and Ireland’s SEAI Better Energy Homes Scheme have provided vital financial incentives, driving the retrofit market forward. However, rising material and labour costs are threatening to derail progress. While technologies such as photovoltaic (PV) systems have seen price reductions, key retrofit measures like external insulation, heat pumps, and upgrades to elements such as sills, soffits, and fascia have become increasingly expensive. These rising costs pose a significant challenge for homeowners and landlords trying to meet NZEB targets, threatening the affordability and feasibility of deeper retrofits.

Compounding this issue is the escalating cost of construction, which has become a major barrier for property owners aiming to meet national decarbonisation goals. As retrofit costs increase, the gap between ambitious policy goals and practical implementation widens. Without effective measures to address these rising costs, both the UK and Ireland risk missing their 2030 zero-emission building targets.

The challenge of rising retrofit costs goes beyond affordability; it also raises concerns about equity and access. Increased costs may disproportionately affect lower-income homeowners, sidelining those who would benefit most from energy-efficient retrofits. If achieving NZEB standards becomes unmanageable, meeting broader climate objectives will be harder, and the disparity between high and low energy-performance buildings is likely to widen.

Looking ahead, addressing these cost challenges is essential to ensuring retrofitting remains accessible to a broad range of property owners, from homeowners to landlords. Policy frameworks must evolve to ensure that support structures for retrofitting remain effective and accessible, particularly in the face of economic pressures. The bureaucratic nature of grant application processes for NZEB retrofits also adds unnecessary costs and delays on-site.

The Irish National Retrofit Plan, while a cru-

cial step forward, is showing signs of strain. For example, the Better Energy Homes Scheme reported a 14 per cent drop in retrofit numbers, although solar PV installations continue to see strong growth. This indicates that while simpler retrofit measures with shorter payback periods are becoming more popular, more complex and costly measures are being sidelined due to financial pressures.

The path to zero-emission buildings is undeniably challenging, but it is not insurmountable. By building on the foundations laid by the EPBD, NZEB standards, and national policies, Ireland and the UK have the potential to transform their built environments into sustainable, energy-efficient, and zero-carbon assets for the future. However, achieving these ambitious goals will require addressing rising costs and improving bureaucratic efficiencies. The closure of the UK Green Homes Grant in 2021, following administrative issues and limited uptake, highlighted the need for better policy design and management.

As policymakers in both the UK and Ireland confront these challenges, they must recognise that 2030 targets will likely be missed without immediate action. Streamlining grant administration, increasing grant amounts to reflect market costs, reducing grant timelines (the 17-20 months for the Better Energy Warmer Homes Scheme is unacceptable), and removing VAT on essential retrofit materials such as triple glazed windows, insulation, ventilation, and heat pumps are critical steps.

In my next article, I will explore the current state of retrofit in more detail and assess the progress made toward achieving zero-emission buildings.

The retrofit market is messy, scuppered by knowledge and skills gaps, and inconsistent approaches.

Ele George makes the case for industrialisation to level up the retrofit market.

The UK’s housing stock is among the oldest and least efficient in Europe.

Poorly insulated homes result in high energy bills, uncomfortable living conditions, and significant carbon emissions. Retrofitting by upgrading buildings to improve energy efficiency (among other benefits) offers a vital solution. However, traditional methods of retrofit are slow, disruptive, and impractical at the scale required to address the problem.

Industrialised retrofit provides a better way forward. By adopting manufacturing principles in construction, we can transform homes faster, with less disruption, and at a scale that delivers tangible benefits for tenants, landlords, and the planet.

The scale of the challenge

We know that the need for retrofit is undeniable. An estimated 80 per cent of the buildings we will use in 2050 already exist, many of which were built to outdated standards, and unfortunately, we are still building some that will need upgrades in the near future –such as any property with a new gas connection. The consequences of inaction are severe. Poor housing conditions cost the NHS £2.5 billion annually due to health issues linked to mould, damp and cold. For residents, poorly performing homes bring the additional burden of high energy bills, forcing many to choose between heating and eating.

Social housing providers, who collectively manage millions of homes, face an even greater challenge. Many estates consist of poorly insulated properties with standardised designs that have been replicated across regions. However, the scale of these portfolios makes them ideal candidates for industrialised retrofit, enabling landlords to achieve economies of scale, improve tenants’ quality of life, and reduce operational costs.

Why industrialised retrofit?

Industrialised retrofit utilises both physical and digital manufacturing techniques such as prefabrication and standardisation for building upgrades. Instead of relying on slow, labour-intensive methods, some of the work is ‘manufactured’ offsite, while other innovations look to improve the efficiency of the ‘site work’ itself. Prefabricated panels, energy modules, and other components are

manufactured in factories and a ‘kit of parts’ is assembled on site, reducing construction timelines, costs, and disruption.

For social landlords managing large estates, industrialised retrofit offers significant advantages. Factories can produce retrofit components at scale, enabling faster deployment across hundreds or even thousands of homes. Offsite manufacturing ensures consistent quality, with a high level of precision that improves building performance and reduces defects. Additionally, prefabricated components can be installed rapidly, minimising disruption and allowing tenants to remain in their homes throughout the process.

The benefits for social housing

Industrialised retrofit provides solutions that address the unique challenges of social housing, where landlords must improve housing quality while managing tight budgets. By leveraging standardisation and bulk production at scale, industrialised approaches can lower the per-unit cost of retrofit components, allowing landlords to achieve more with their resources. Standardising components also reduces the variety of parts and controls, simplifying the adoption of new technologies for tenants.

Behavioural change can be a significant barrier, and overly complex systems often deter effective use. By ensuring simplicity, tenants are more likely to embrace the improvements, enhancing their well-being through better insulation and energy efficiency. Many social housing estates feature common archetypes such as terraced houses, flats, and semis. These repeated designs lend themselves to industrialised solutions, enabling landlords to retrofit entire blocks or estates efficiently.

A national priority

Industrialised retrofit aligns with broader economic and policy objectives. Retrofitting at scale has the potential to create jobs by developing a domestic supply chain for retrofit components, stimulating local economies and generating long-term employment opportunities. It also offers the chance to upskill the workforce, as retrofitting requires specialised skills in design, manufacturing, and installation. This presents significant opportunities for workforce development.

Furthermore, investment in manufacturing facilities and digital technologies will support the wider construction industry, improving both productivity and sustainability.

Government support is essential to realising these benefits, with policies that incentivise retrofit programmes, support research and development, and encourage public-private partnerships helping to accelerate progress and unlock the full potential of industrialised retrofit.

The time for industrialised retrofit is now. It provides a powerful solution to some of the UK’s most pressing challenges, from reducing carbon emissions to addressing fuel poverty and improving public health. For social housing providers, the opportunity is even more significant. By leveraging the scale of their estates and embracing industrialised approaches, landlords have the potential to lead the way in delivering warmer, healthier, and more energy-efficient homes. However, it’s crucial that we move beyond pilot projects, which are insufficient for testing at the scale needed. To truly address the housing crisis and meet our sustainability targets, we must be bold and commit to full-scale implementation.

Ele George is a sustainability engineer and founder of Elevate, a consultancy dedicated to transforming the built environment. With over two decades of experience, Ele has championed innovative approaches to design and construction that address the challenges of poor productivity, climate change, and technological stagnation.

Elevate collaborates with forward-thinking clients to deliver industrialised solutions that improve lives and drive positive change. By combining digital tools, offsite manufacturing, and sustainable practices, Ele and her team are helping shape a better future for the UK’s built environment.

HISTORIC BARN REBORN AS BIO-BASED ENERPHIT HOME

A couple breathes new life into a set of historic barns, creating an Enerphit dream home in the Gloucestershire countryside.

By Jason Walsh

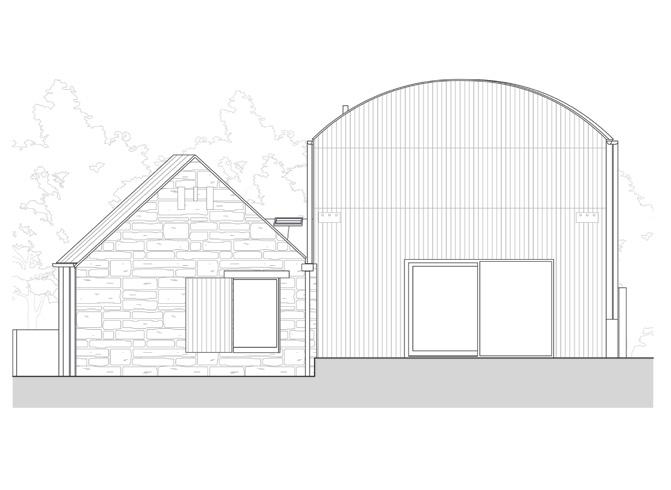

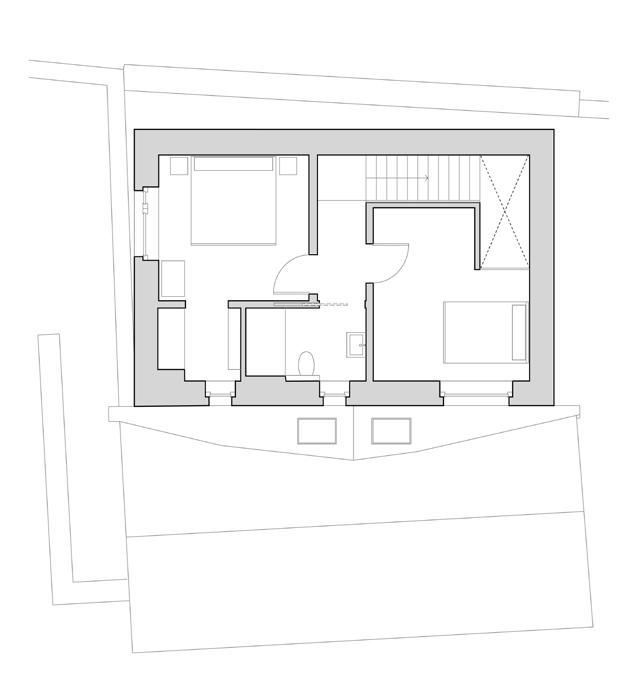

Development type: 132 m2 detached home plus outbuildings

Method: Derelict barns renovated into low energy home and office using cellulose-insulated timber frame, insulated foundations and heat pumps

Location: Bath

Standard: Enerphit

Space heating cost: £13 per month (estimate, for house only). See 'In detail' panel for more information

per month

Having friends around for dinner is pleasant enough but having them come to dine where once they laboured to remove plants can only be even more special.

This is what couple Richard and Chris have done having built their dream home, transforming a set of Grade II-curtilage listed derelict agricultural barns into a modern, energy efficient dwelling, while championing the use of timber and achieving certification to the Passive House Institute’s standard for retrofit, Enerphit.

Recalling the work that got them to where they are now, Chris smiles.

“All of our friends came and helped up.” she says. “We had them remove butterfly bushes and buddleia, and now they come round and have dinner, sitting where the buddleia was.”

Both having an interest in sustainability, the couple always intended to build green. Helping them along the way was the fact that the house they were living in at the time was deeply uncomfortable.

“It was 300-years old. Not listed, but it had all of the attractions of a listed building: damp, an Aga that used to burn five pound notes, and draughts. We sold that and lived in a flat while we set to work on this build,” says Richard.

Richard, an electrical engineer (“nothing remotely involved in building,” he says) and Chris, a former mechanical engineer who now works for the NHS, came to passive houses after hearing an item on BBC Radio Four.

However, their investigations went a little deeper than listening to the radio, Chris says.

“The Passivhaus Trust was really good. We did some remote courses with them,” she says.

The process that led up to the couple building what is now called the Tin Barn was not swift. Despite there being no shortage of land, no-one wanted to sell, and the first two prospective sites fell through.

“Round here, it is just impossible to find land. We’d write dozens of letters, but no-one wanted to sell,” says Richard.

Finally work could get started when the couple acquired a site on the edge of the village of Marshfield.

“We had a few false starts, but eventually found this plot for sale,” he says.

challenge. Architect Matt Hayes, a co-founder of Hereford-based, RIBA award-winning firm Arbor Architects, says that the challenge is that planning permission demands that the structures actually be used.

“It was a ruin,” he says. “The roof had fallen in [on the stone barn] 15 years previously and a lot of degradation had happened since that.”

The roof had fallen in 15 years previously and a lot of degradation had happened.

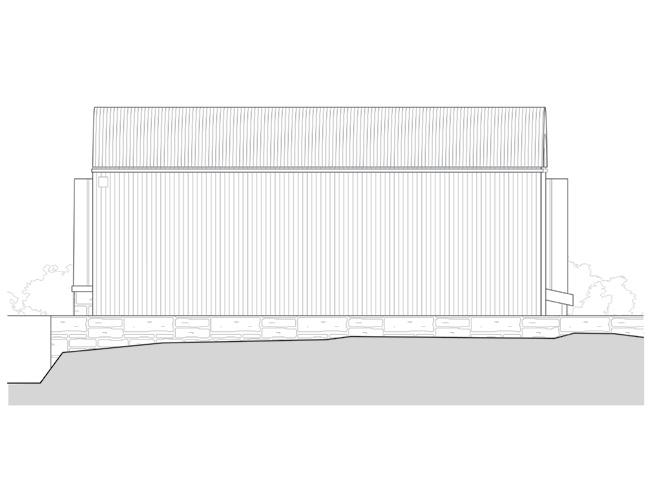

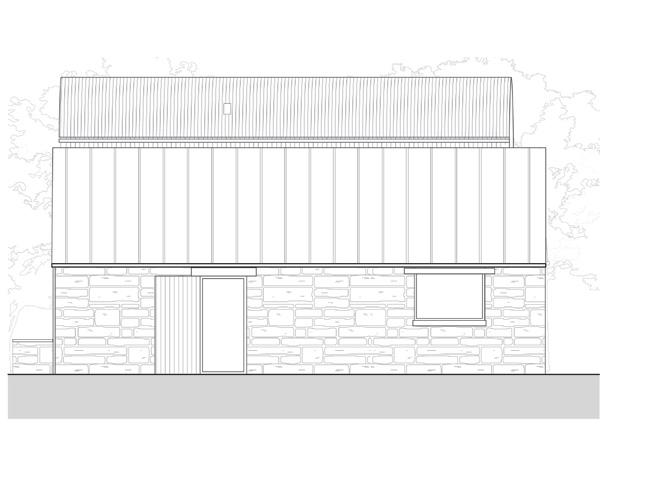

Comprised of three buildings – a traditional stone barn, a round-roofed Dutch barn, and an outlying building – the property is situated in the serene landscapes of Marshfield Conservation Area, and the house as such is a single dwelling constructed from the stone and Dutch barns.

Designing and building a retrofit is always a

The outlying building, which is used only as a home office, storage and guest accommodation, was not done to Enerphit standards. “It was in the best condition [of the three buildings],” says Hayes. “It pretty much just needed reroofing and a bit of stonework patching up.” This is something of an understatement: in addition to repointing, the walls were plastered internally with Diathonite insulated lime plaster and a cellulose-insulated engineered timber roof was added. But the majority of the budget was put into renovating the new home being fashioned out of the other two buildings –combining new structural elements with the retention of a significant amount of the existing buildings.

“You've got a structure there, you've got walls there [so] you can't just come in with a digger and put up a balloon frame,” Hayes says.

As a result, instead of simply building an engineered stud wall, Arbor worked out, onsite, how to, for example, build inside the steel frame of the Dutch barn.

“We spent a lot of time working out the details of how we were going to do this. That was an effort of structural engineer Beth [Williams], the QS, the builder, everyone,

just trying to work it out,” says Hayes.

The airtightness end result came in three times tighter than required for the Enerphit standard at 0.34 ACH. This is a testament to the fact that everyone on site managed to follow the details and work it out, he says.

The stone building also needed work.

Aside from the removal of the tree growing inside it, one wall was badly cracked and demanding repair. Additional matching stone was sourced from a local quarry, and a timber frame structure was built inside, using the original stone walls as a rain screen, with a ventilated cavity created behind the stone and an insulated timber frame that combined airtightness and breathability –insulated with moisture-buffering cellulose behind an intelligent airtight membrane.

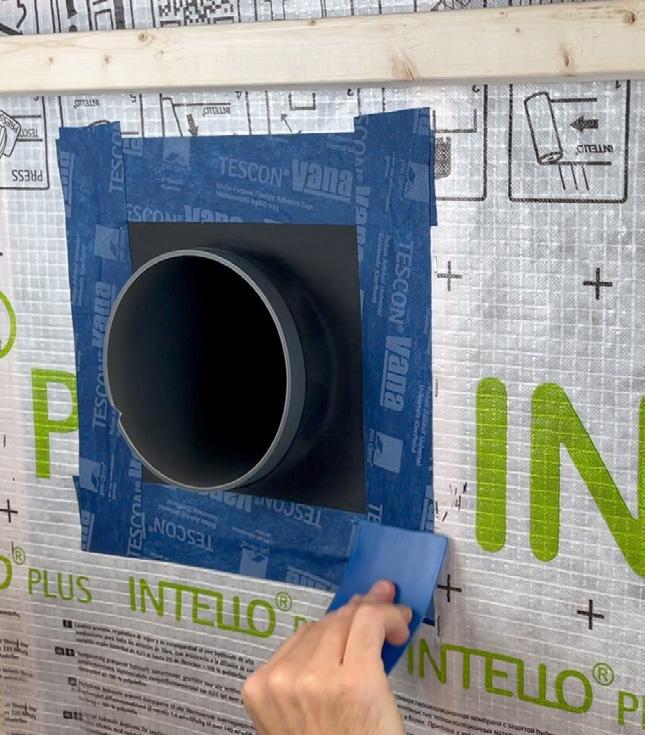

“On the inside face of the timber frame we used an Intello membrane so we could regulate the moisture – so it could breathe in both directions.”

Space heating for all three buildings, and hot water in the two that form the house, is provided by a Vaillant Arotherm heat pump.

An accurate analysis of energy use is not available because subsequent to construction some additional finishing touches were done with a heavy-duty chop saw in the living

room, not to mention an open door, but the couple have no complaints.

“We’re very satisfied. Unfortunately, we can’t see what’s using what as it's all on the same circuit [but] I suspect the office is disproportionate in terms of consumption,” Richard says.

Hayes said that while both embodied carbon and operational energy are a concern for his practice, operational energy came first in this case.

“In terms of our process, we actually did it the other way around. We did the energy model for the space heating demand so we could say, ‘yep, we know your space heat demand is going to be this’, which is the kind of passive house view on things.’”

To carry out that energy model, Arbor collaborated with Delta Q passive house consultants to push the barn conversion to the Enerphit standard. “Their input was invaluable in terms of their expertise around PHPP modelling and certification,” says Hayes. “We talked through some of the more complex details and agreed strategies to take the build forward.”

The blanker the canvas, the easier it is to achieve truly low energy buildings. One key aspect is the form factor – the ratio between

the surface area of the external envelope, and the volume of the building. The higher that ratio is, the more surface area in terms of walls, windows, floors and roofs through which heat can escape. It’s therefore simpler and cheaper to meet the passive house standard in buildings with a low form factor, meaning a cube-shaped building. But as Delta Q’s Dave Bryan explains, in this case the planning constraints on retaining the existing structure had a knock-on effect in terms of thermal performance aspirations.

“This effectively removed the ability to optimise the efficiency and form factor to assist with passive house compliance, resulting in a form factor of 3.86. This meant that achieving passive house classic was virtually impossible and in agreement with the certifier, Mead Consulting, the Enerphit standard was pursued.”

According to Bryan, careful consideration had to be given during the design phases to any material change on the envelope areas and treated floor area “as changes are amplified because of the high form factor.” Another key issue to address was the impact of retaining the existing structures. “This demonstrates not only the importance of a well thought out and conceived building at the earliest possible stage,” says Bryan, “but the even greater importance of effective collaboration when there are external influences that necessitate change".

As embodied carbon remains very much a new frontier in construction, the onus is on designers engaging with calculation at early design stage, so that the impacts of different design decisions can be considered before high carbon impacts get locked in. With no brief from the client to set embodied carbon targets, Arbor took a different approach.

“In terms of embodied carbon, we had a hunch that because we were working with natural materials, you know, it's all timber, the insulation is all recycled [paper].” said Hayes. “We knew there was some concrete in the ground and there's a bit of corrugated metal and steel on the roof, but we had a feeling that actually embodied carbon was going to be quite good on it.

“Towards the end of the project, we did the embodied carbon calculations so we could evidence the hunch and learn from the detailing when comparing to other projects in the office”.

The calculations, which were generated by Peter Morgan of Building Efficiency using PHribbon, are impressive – hitting a cradleto-grave total of 363 kg CO2e/m2 of gross internal area, although in some instances embodied carbon was provided from similar products. For context, the 2030 target for dwellings under the RIBA 2030 Climate Challenge is 625 kg CO2e/m2 GIA. While the house benefits from the retention of existing stone and steel structure and partial foundations, the benefit is arguably relatively

minimal in embodied carbon terms.

Essentially a new thermal envelope was built, complete with insulated foundation system, concrete slab, insulated timber frame superstructure, corrugated steel roof and cladding, larch cladding, and new building services and finishes.

Beyond embodied energy and energy, Arbor has additional concerns, Hayes says.

“In terms of our thinking, we're aiming at (reducing] both at the same time – the embodied carbon and the carbon in energy – but then also, there is a third one that we put into the mix: internal air quality and from an architectural perspective that's all around trying to specify materials which

have low VOC [volatile organic compounds] and low off-gassing. This is always in combination with an efficient MVHR bringing in a constant supply of tempered fresh air. In this scenario it helps that the external environment around the barn has good air quality,” he says.

If construction was stressful it was simply because it occurred during the Covid-19 pandemic, but activity on-site went as smoothly as could be hoped.

“There were lots of unforeseen events, but that's normal for building. We have a slightly weird dogleg in our living room, and that's because the old foundation stuck out that way,” says Chris.

Richard says that this resulted in some hasty recalculations.

“It’s really interesting how much analysis can be done during construction. They had to add extra installation,” he says.

Contractor CRD, which had never worked on a passive house project before, was keen to learn.

“We talked about them going to do the passive house contractor course, which they did. It was really good that they had an awareness on their side. They absolutely nailed that,” Hayes says. Delta Q director Piers Sadler agrees.

‘We were fortunate enough to have a main contractor in CRD Bath”, says Sadler, “who despite this being their first passive house project, embraced the site training provided by Delta Q and in particular rose to the challenge of constructing some of the more complex airtightness detailing.”

Internally, a modern open plan layout on the ground floor gives way to spectacular views, while bio-based materials were used to create soft and refined interiors, spilling light across varied and textured spaces.

Storm Darragh is raging as we speak, and you don’t notice it unless you go outside”.

“Elly [Deacon, also a director at Arbor Architects] and Matt listened, the thing we said was ‘chunky stuff’, materials that felt natural and they look lovely,” says Chris.

Now, a year after moving in, how has the build worked out for the couple? Very well, it seems.

“It’s all the things people who live in passive houses tell you and you never quite believe. There aren't any draughts anywhere,” says Richard.

“We’ve gone from somewhere where doors didn’t close to a place where you can have a storm – one is raging as we speak – and you don’t notice it unless you go outside”.

Indeed, Storm Darragh was battering the Cotswolds as the couple spoke to Passive House Plus magazine, but it was entirely inaudible during the video call, a testament to the standard achieved with the building.

For Chris, this says everything: “It’s a revolution. We can't quite believe it. It feels like, at some point the adults will come and take it back”.

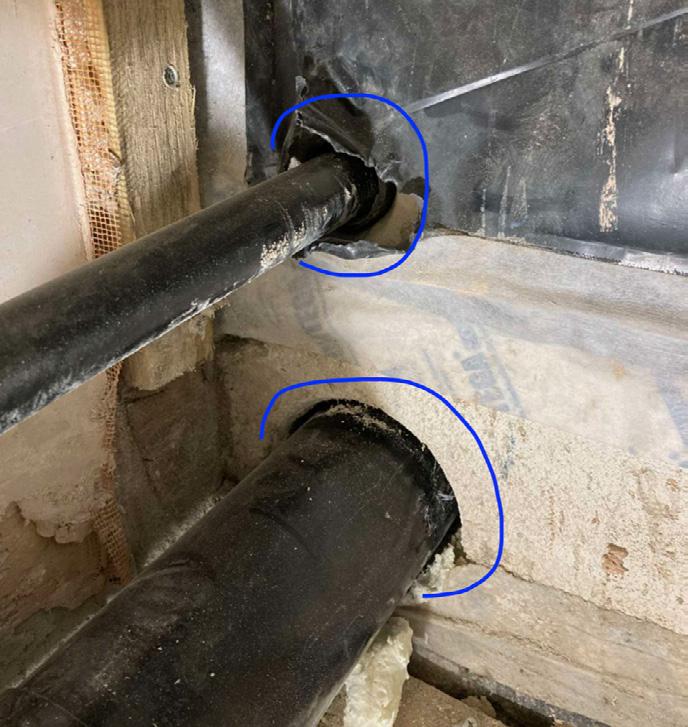

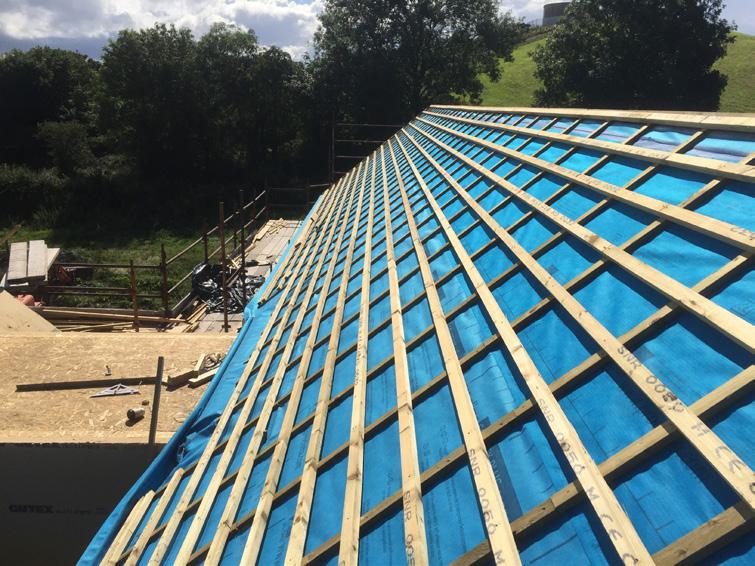

1 & 2 Care was taken to ensure airtightness where the roof timbers connected with the walls, such as an Intello airtight sock on the ridge beam; 3 the shape of the barrel-vaulted Dutch barn roof was reflected in the airtight layer, built with Smartply airtight boards; 4 which were taped together before the stud walls were added; 5 & 6 the same airtight strategy was used for the cathedral ceilings.

Pronunciation: Sty-Ko /ˈstaɪ.kəʊ/

Definition: The world’s largest manufacturer of wood fibre insulation, engineered by nature to provide high-performance, naturally better insulation.

Usage in Context:

1.

"Steico gave us more than insulation— comfort, sustainability, and savings we can feel."

"Steico is the natural choice for insulation—sustainable, engineered by nature, designed for performance." 2.

3.

"The architect recommended Steico, now we know why it’s called ‘naturally better insulation.’"

Origin: Derived from the original company name of "Gesellschaft für Bau-und Industriebedar Steinmann & Co GmbH". Steico, based in Germany, is a world leader in eco-friendly building materials recognised globally for its innovative approach to sustainable insulation solutions.

Related Words: Comfort, Breathable, Warm, Safe, Effective, Sustainable, Natural

Ÿ MVHR

Ÿ heating

Ÿ cooling

Ÿ hot water

Ÿ COP: 3-6

Ÿ for superinsulated & airtight homes

AS SEEN ON THE STREET

Building type: Conversion of curtilage listed barns dating to early 19th century. Build method was timber frame to Passivhaus Enerphit certified standard. TFA 118 m2

Site type & location: Rural site, outskirts of Bath. On edge of conservation area of a typical Cotswolds village

Budget: Private

Completion date: October 2022

Passive house certification: Enerphit certified

Space heating demand: 22.65 kWh/m2/yr (PHPP)

Heat load: 11.74 W/m2 (PHPP)

Primary energy non-renewable: 61.58 kWh/m2/yr (PHPP)

Primary energy renewable: 51 kWh/m2/yr (PHPP)

Heat loss form factor: 3.86 (PHPP)

Overheating: 2.08% (PHPP)

Number of occupants: 2 adults

Embodied carbon: 363 kg Co2e/m2 GIA for life cycle

stages A1-5, B1-5, C1-4 Calculated to RICS standard using PHribbon

Energy performance certificate (EPC): B88

Energy costs: Monitored usage is not yet available, and analysis is complicated by the fact the heat pump serves the main home and separate outbuilding too. Estimated space heating costs for the home are £155.34/year based on PHPP calculated space heating demand, and the tariff the home is on, the Octopus Flexible tariff, of 23.83p. To estimate the seasonal COP of the heat pump, the average SCOP for the heat pump model used (Vaillant Arotherm) was taken from www.heatpumpmonitor.org – showing an average of 4.1 for space heating and hot water. While the low space heating demand of a passive house may mean slightly lower efficiency, given the heat pump would

be required only to generate small amount of heat, rather than run for longer periods at low temperatures, in this case the heat pump also provide heating for the adjacent outbuilding with office and guest rooms, meaning longer running hours being required, and a better SCOP being attainable.

Airtightness (at 50 Pascals): 0.35 ACH

Thermal bridging: The thermal bridging strategy was to design out and if not possible minimise thermal bridging from the outset. The timber frame for all the walls and roofs utilises a timber I-joist which minimises thermal bridging. In terms of the main structure the timber roof beams were kept to the inside face of the insulating structure. The opposite is true of the existing steel structure positioned in the external cladding ventilation zone, which keeps the existing structure on the outside of a new insulated timber frame for the ’tin barn’ element. A ‘duvet’ layer of insulation starts below the raft slab and continues through the walls and roof, wrapping the building in insulation. The stone walls are thermally separate from the timber frame built within. The door thresholds sit on an insulating Compacfoam detail tying them back to the structure and allowing them to sit in the insulation zone.

Ground floor: Before: Earth floor. After: 150 mm hardcore, 50 mm blinding, 250 mm Isoquick Peripor, RIW Red DPM, 250 mm RC Slab and 250 mm Isoquick Peripor. U-value: 0.127 W/(m²K)

Stone walls: Before: 400 mm stone. After: 400 mm stone, ventilation zone, Proclima Fronta Humida Membrane, 12 mm panelvent board, 200 mm TJI fully filled with Cellulose insulation, Proclima Intello membrane, service zone,

Architect: Arbor Architects

Main contractor: CRD

M & E engineer: Hydrock

Civil / structural engineer: Build Collective

Cellulose insulation:

PYC Warmcel, via Smart Construction Floor insulation: Isoquick

Airtightness products:

Ecological Building Systems / Medite SmartPly

Windows and doors / MVHR:

21° (formerly Green Building Store)

Primary space heating system:

WDS Green Energy Ltd

Energy consultant: Delta Q

plasterboard & skim. U-value: 0.195 W/m²K

Corrugated tin walls: Before: Corrugated steel sheet on steel portal structure. After: 20 mm larch cladding, black vent membrane, 50 mm batten, 50 mm counter batten, Proclima Solitex Fronta WA, 12 mm Medite board, 360 mm TJI fully filled with cellulose insulation, 12 mm Smartply board, service zone, plasterboard & skim. U-value: 0.110W/m²K

Roof: Before: Corrugated steel sheet on steel portal structure. After: Pre-curved Galvanised corrugated sheet, 50 mm batten, 25 mm counter batten, Proclima Solitex Plus, 18 mm external ply board, 360 mm TJI fully filled with cellulose insulation,12 mm Smartply board service zone, plasterboard & skim. U-value: 0.110W/m²K

Windows & doors: Windows: GBS Ultra. U-value: 0.80 W/ m²K. Doors: GBS Ultra. U-value: 0.79 W/m²K

Roof windows: Fakro DMF U8 Rooflight. U-value: 0.80 W/m²K

Heating system: Mitsubishi PUHZ-W50VHA2(-BS) 4.5kw air-to-water heat pump heating the main home and outlying building

Ventilation: Ubbink NV - Ubiflux Vigor W325 MVHR (Passive House Institute certified). House designed to allow for natural night purge ventilation in addition to summer bypass on MVHR

Water: Low flow fixtures

Electricity: PV not permitted under planning permission Sustainable materials: Sandstone from local quarry within 5 miles of site (in addition to reclaimed stone from site), Warmcel cellulose insulation, timber Terrazzo Foresso internal finishes, Smartply airtight board, European spruce glulam structure, oak and larch cladding.

Passive house certifier: MEAD Consulting

Quantity surveyor: Adams Fletcher Consultants

Life cycle assessment consultant: Peter Morgan Building Efficiency

Cladding supplier: Russwood Timber Fit out: Parnosa

Furniture: Made In Ply

TENEMENT RETROFIT SHOWS SOLUTION FOR GLASGOW ARCHETYPE

What do you do when a building type is inefficient, common, hard to treat – and often used to house vulnerable people? Chris Morgan of leading passive house architects John Gilbert Architects tells the story of an extraordinary pilot project that may show the way to solve the stickiest of problems.

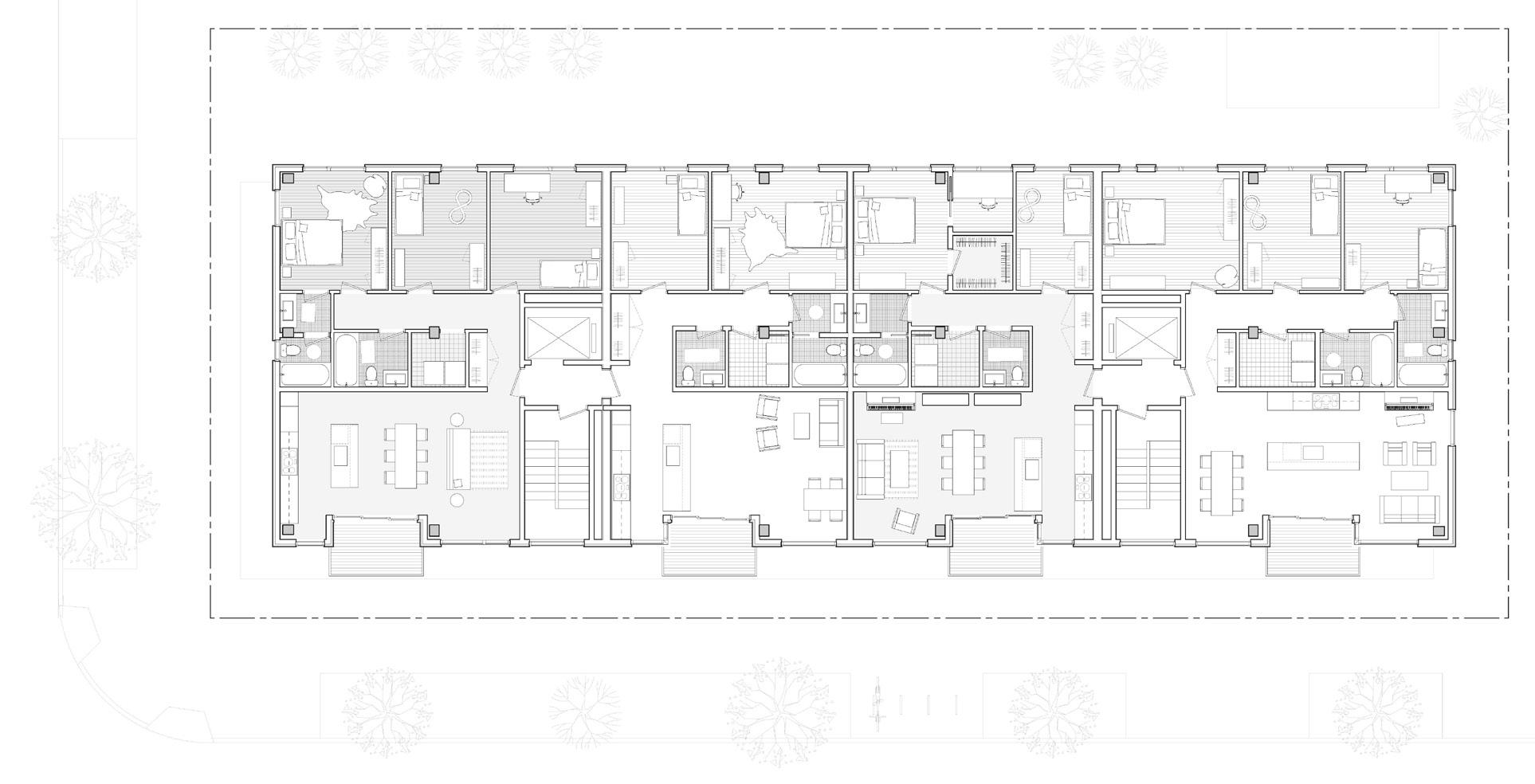

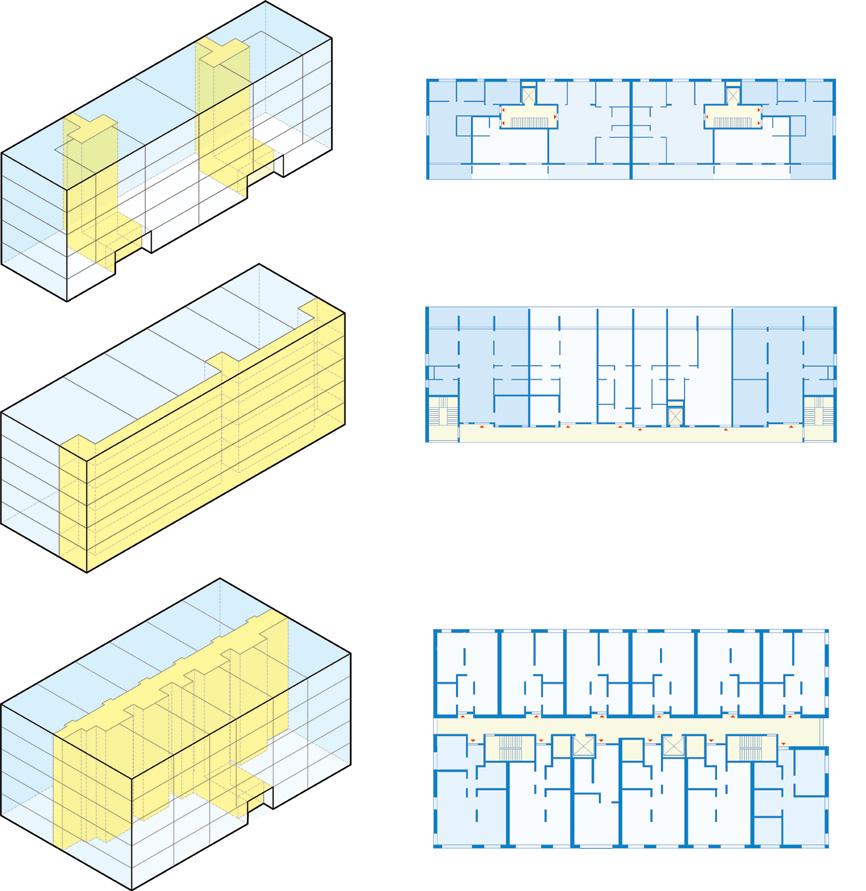

Building type: Victorian sandstone tenement with eight one-bed flats – each circa 49 m2

Method: Mix of internal and external insulation, hygrothermal simulation, thermal bridging calculations, heat recovery ventilation, mix of air-to-water heat pump and gas boilers

Location: Niddrie Road, Glasgow

Standard: Near Enerphit

Space heating cost: Too soon to say definitively – monitoring is ongoing

Built around 1900, the building at 107 Niddrie Road is a stone tenement consisting of eight one-bedroom flats over four storeys, located in the inner south side of the city. Southside Housing Association (SHA) approached John Gilbert Architects (JGA) to look at refurbishing the building. Unusually, SHA owned all the flats in the close and, even more unusually, all flats were empty.

This presented an almost unique opportunity to undertake a much more comprehensive refurbishment than is normally possible.

The project was conceived before the Passive House Institute developed its Enerphit unit pilot project, which enables certification of individual flats within a building. To achieve the standard, the whole block would need to be upgraded. For this reason, JGA proposed an Enerphit level retrofit, along with two

other, less rigorous options.