History repeating Incremental retrofit to Elizabethan home hits net zero energy

Embodied energy Is it more important than embodied carbon?

Passive Patagonia Glasgow architect designs Argentinian sanctuary

History repeating Incremental retrofit to Elizabethan home hits net zero energy

Embodied energy Is it more important than embodied carbon?

Passive Patagonia Glasgow architect designs Argentinian sanctuary

Publishers

Temple Media Ltd

PO Box 9688, Blackrock, Co. Dublin, Ireland

t +353 (0)1 210 7513

e info@passivehouseplus.ie www.passivehouseplus.co.uk

Editor Jeff Colley jeff@passivehouseplus.ie

Reporter John Hearne john@passivehouseplus.ie

Reporter Kate de Selincourt kate@passivehouseplus.ie

Reporter John Cradden cradden@passivehouseplus.ie

Reader Response / IT Dudley Colley dudley@passivehouseplus.ie

Accounts Oisin Hart oisin@passivehouseplus.ie

Art Director Lauren Colley lauren@passivehouseplus.ie

Design Aoife O’Hara aoife@evekudesign.com | evekudesign.com

Contributors

Toby Cambray Greengauge Building Energy Consultants

Dr Lois Hurst

Barbara Lantschner

architect and passive house designer

Marc Ó Riain doctor of architecture

Esmond Tresidder Highland Passive

Jason Walsh journalist

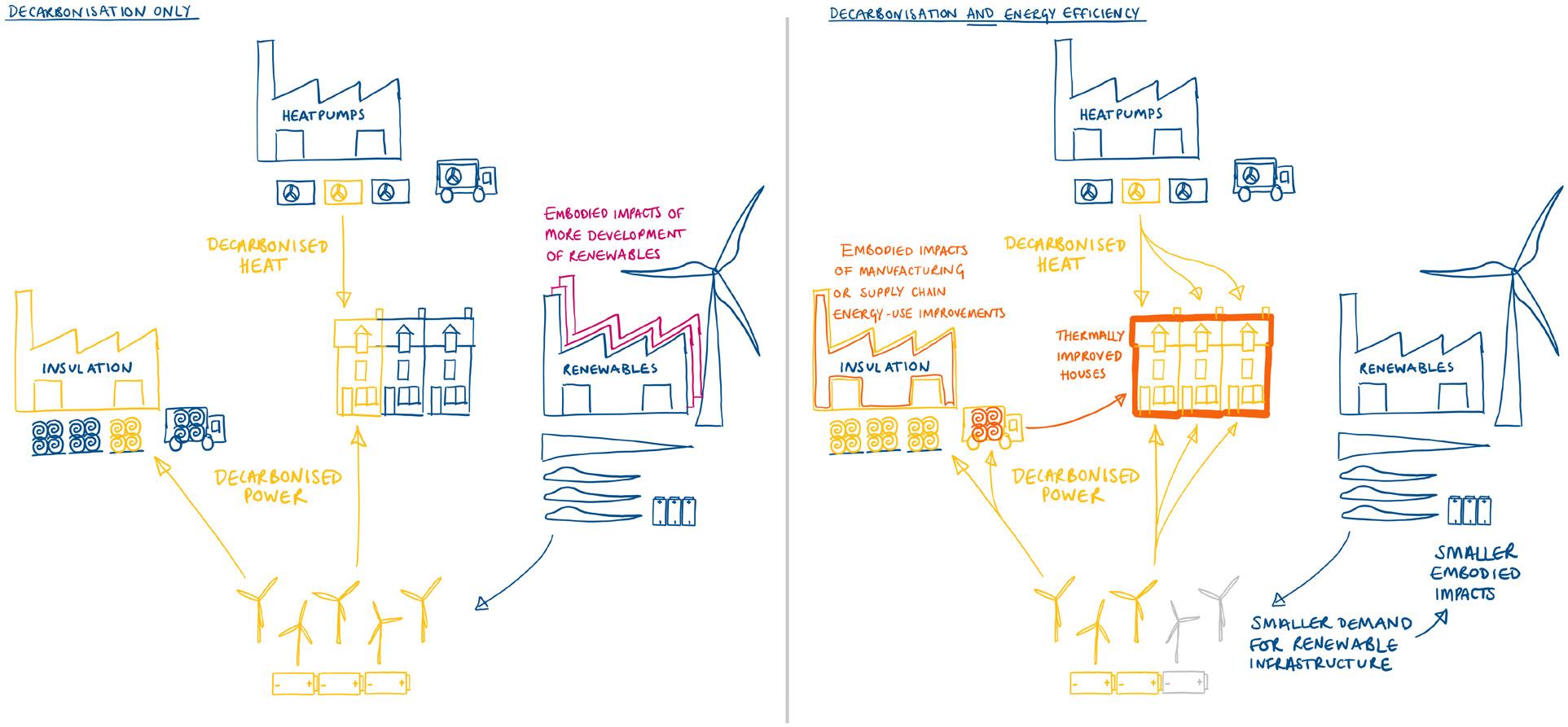

Decarbonisation may be the overriding challenge facing humanity this century, but that challenge must be approached with great care. A singular focus on carbon is bound to backfire in all kinds of ways.

What could be considered closer to a zero-carbon home than a cave inhabited by an early human? Presuming that human hadn’t mastered the art of lighting a fire, the home would have had zero operational energy use. The embodied carbon of the building was likely close to zero too, excluding any timber or animal bones and plant hides or plants used to cover the entrance.

But most people these days don’t wish to live in caves, without the amenities of light power, water, sanitation and comfort –though on the plus side, caves also tend to moderate temperature extremes.

The point, if we stop to think about it, is that when we are planning how to decarbonise, there will almost inevitably be other considerations which should come into our thinking. Kate de Selincourt’s article in this issue is a stark example. From a climate perspective, the electrification of heat is an absolute must, and should be rolled out at a rate of knots. But in countries like the UK where the spark gap – meaning the gap between the cost of gas and the cost of electricity – is high, this can have significant unintended consequences. In the UK, electricity is more than four times the cost of gas, meaning switching from a gas boiler to a heat pump may actually cause energy costs for British consumers to increase. Mercifully, even short of energy price reform, there are measures that can be used to tackle this problem – such as energy efficiency works that will reduce the need for heating of any kind, and enable a heat pump to operate at lower temperatures, or proactive utilities offering lower heat pump tariffs.

And the problem goes beyond affordabil-

ity. As Dr Lois Hurst explains in the first of a new series of articles on embodied energy, a focus on embodied carbon can risk masking profligate use of energy – which could have knock-on effects in terms of resource use, energy use, biodiversity and yes, even carbon emissions elsewhere. Perhaps the most obvious example in our increasingly AI-obsessed age is the phenomenon of data centres mopping up renewable electricity generation. Without the ability to plan and develop energy infrastructure to match the vast, rapidly increasing energy requirements of these emerging technologies, what are the knock-on effects in terms of providing the energy infrastructure to service the new homes needed in a housing emergency?

In reality, buildings face a convergence of demands. Small matters like building regulations and consumer expectations mean that the untouched cave stands little chance of gaining traction as a decarbonisation strategy. Nevertheless, when someone asks to pick my brains on a new build or retrofit project, the first question I ask is: what do you want to achieve? Even in sustainability terms alone, this question has many facets. Is it just carbon savings? Do low energy costs matter? Are you looking for comfort – in winter and summer? Do you want it to protect anyone who might have respiratory issues or allergies? Has the building been built to ensure it will keep working in 20, 40 or 100 years, in the face of an extreme climate?

Mercifully, the collective understanding within the sustainable building sector of these and many other sustainability issues has come on leaps and bounds over the years, as the buildings and themes explored in this issue demonstrate.

Regards, The editor

Cover

Es Tresidder Highland home

Photo by Ellen Christina Hancock Print GPS Colour Graphics www.gpscolour.co.uk | +44 (0) 28 9070 2020

Publisher’s circulation statement: Passive House Plus (UK edition) has a print run of 9,000 copies, posted to architects, clients, contractors & engineers. This includes the members of the Passivhaus Trust, the AECB & the Green Register of Construction Professionals, as well as thousands of key specifiers involved in current & forthcoming sustainable building projects.

Disclaimer: The opinions expressed in Passive House Plus are those of the authors and do not necessarily reflect the views of the publishers.

About Passive House Plus is an official partner magazine of The Association for Environment Conscious Building, The International Passive House Assocation and The Passivhaus Trust.

Casa Cuatro: a Patagonian sanctuary forged by passive house principles

Perched on a dramatic hillside overlooking the glacial expanse of Lake Nahuel Huapi in Argentina’s breathtaking Patagonia, Casa Cuatro stands as a testament to the enduring belief of two Glasgowbased passive house designers in thoughtful design and the rigorous application of passive house principles. Conceived and realised by Bárbara Lantschner and her partner Eoin Kavanagh, this two-storey dwelling is more than just a family home; it represents a profound commitment to energy efficiency, local craftsmanship, and a deep respect for the raw beauty of its surroundings.

Barratt launches record passive house scheme; sustainable building leaders crowned at Exemplar Awards; green homes and finance join forces for growth; and Irish and British associations unite for conference as passive house explodes.

The upgrade of Ireland’s retrofit target to A3 marks a critical step forward, bridging the gap between energy modelling and real-world performance, explains Dr. Marc Ó Riain; and Kate De Selincourt asks whether a drive to electrify heating could exacerbate energy poverty.

42 52

Peaky blinder

70s timber frame at Ben Nevis reaches deep retrofit summit

From frozen tea to thermal bliss: energy specialist Esmond Tresidder transformed his leaky 1970s Highland home into one of the highest performing retrofits ever featured in these pages, combining academic knowledge with hands-on retrofit innovation to create a comfortable, healthy family haven with breathtaking views of Ben Nevis, proving that even Scotland’s most challenging climates are no match for passive house principles.

The south Dublin scheme that has put passive house on the map

Ireland’s largest passive house development to date, Shanganagh Castle, is proof that with proper planning and collaboration, delivering high density housing doesn’t mean compromising on quality or climate action – without increasing costs or causing delays.

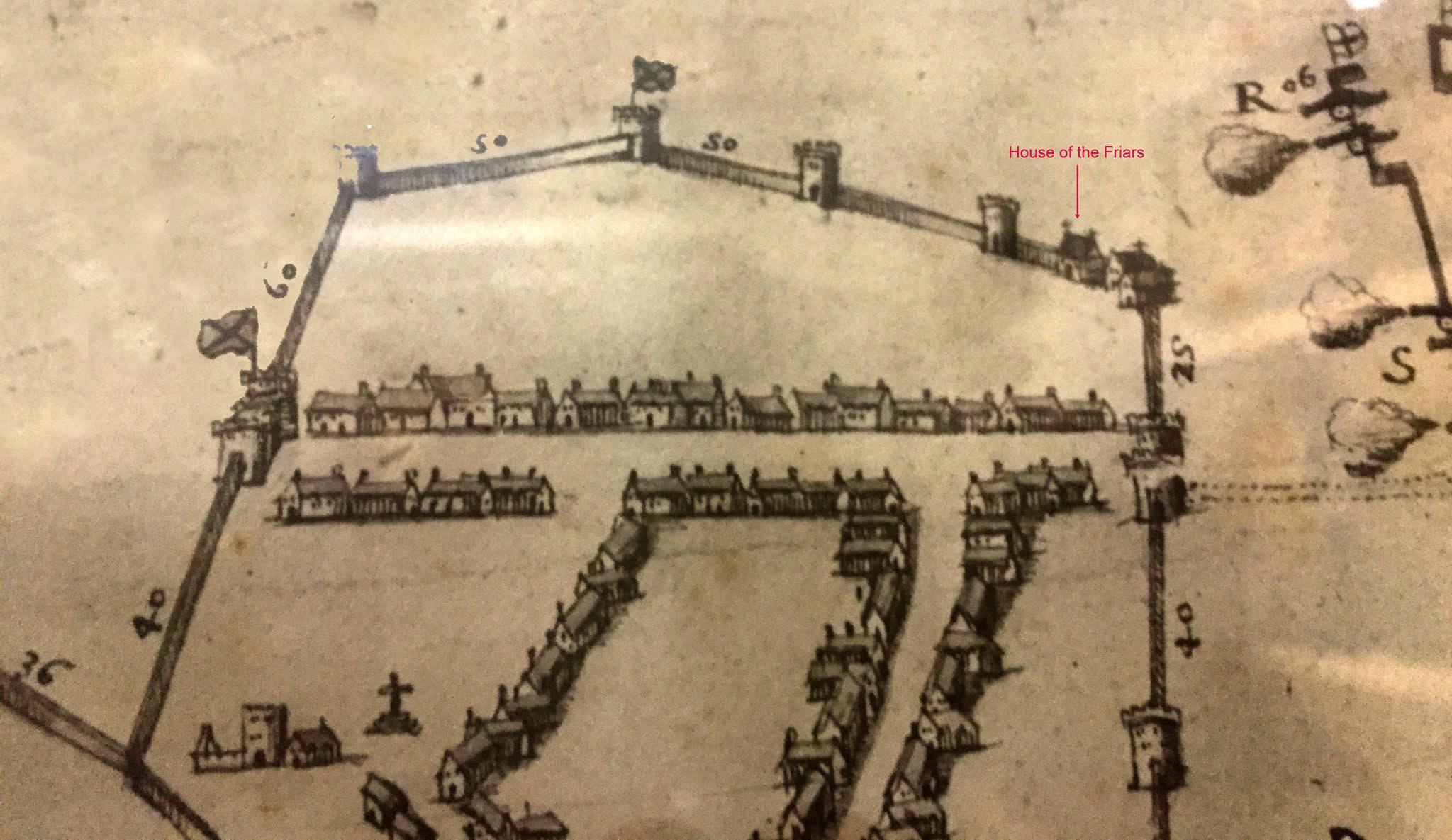

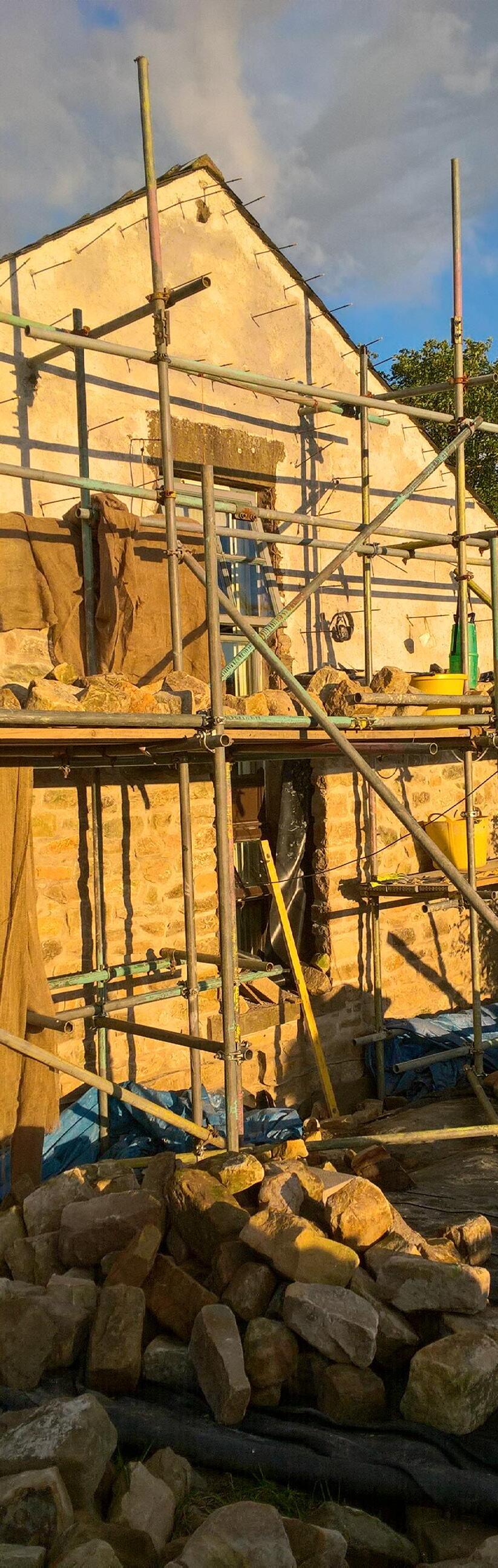

Incremental retrofit of 1560s Kinsale home hits net zero energy

Through passion, patience, and architectural expertise, a 16th century Carmel-ite friar’s cottage in Kinsale, owned by Passive House Plus columnist Dr Marc Ó Riain, has achieved what many thought impossible— an A1 energy rating for a Tudor-era building. But not without challenges.

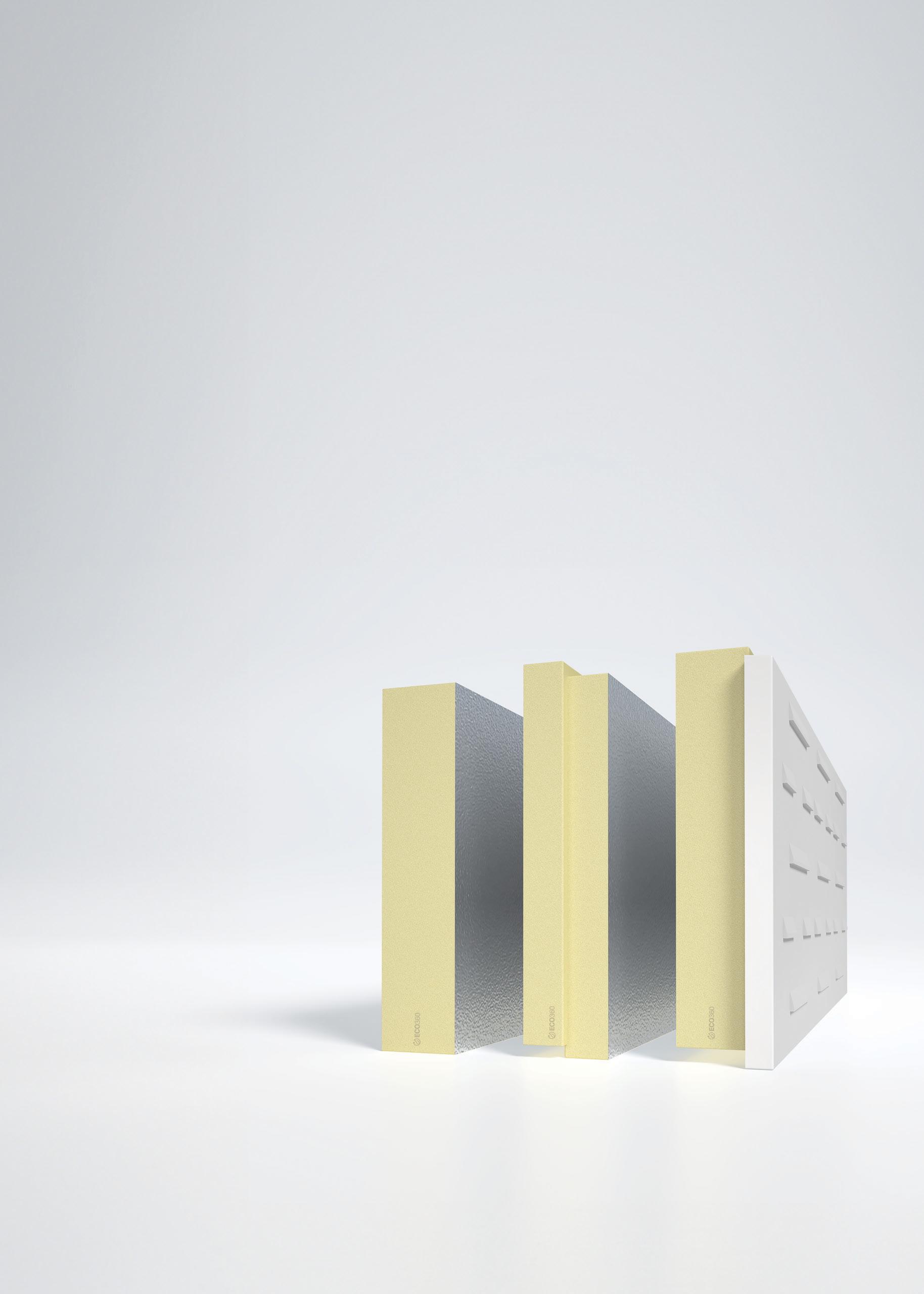

Embody language

Embodied carbon matters, but does embodied energy matter more?

With an increasing emphasis on the electrification of heat as the electricity grid decarbonises, interest in reducing the embodied carbon of buildings is growing.

But does a focus on embodied carbon alone risk giving needlessly energy intensive ways of making buildings a free pass? In the first of a new series of articles, Dr Lois Hurst journeys into understanding embodied and life cycle impacts in construction.

Smarter survey

The green home perception gap

There is a troubling disconnect in the green building world: while sustainability experts champion approaches which target numerous ways in which building homes impact on the environment, there are signs that the public remains fixated on a much narrower definition. This gap between expert knowledge and consumer priorities could be undermining efforts to tackle the climate crisis through better housing.

Marketplace

Keep up with the latest developments from some of the leading companies in sustainable building, including new product innovations, project updates and more.

The familiar North Atlantic drizzle may be giving way to more forceful, building-battering rain. A new study warns of shifting patterns that will test the resilience of structures, writes Toby Cambray.

Casa Cuatro: a Patagonian sanctuary forged by Passive House principles.

Perched on a dramatic hillside overlooking the glacial expanse of Lake Nahuel Huapi in Argentina’s breathtaking Patagonia, Casa Cuatro stands as a testament to the enduring belief of two Glasgowbased passive house designers in thoughtful design and the rigorous application of passive house principles. Conceived and realised by Bárbara Lantschner and her partner Eoin Kavanagh, this two-storey dwelling is more than just a family home; it represents a profound commitment to energy efficiency, local craftsmanship, and a deep respect for the raw beauty of its surroundings.

Words: Bárbara Lantschner

The genesis of Casa Cuatro lies in our shared architectural vision and my deeply personal connection to this land. This plot in San Carlos de Bariloche is where I was born and raised, a familial gift that spurred a larger ambition: a collaborative family project encompassing five individual homes, each embracing principles of high-performance construction. Casa Cuatro, the fourth in this evolving series, became our personal canvas to refine and innovate, drawing upon the accumulated knowledge of previous builds and the invaluable expertise of my father, a seasoned engineer with over five decades of regional construction experience. His insights bridged the gap between advanced design concepts and traditional building methods, facilitating the integration of high-performance solutions with locally available materials and techniques. This home, Casa Cuatro, is the fourth in a series of family residences located on the same plot, each designed using similar construction techniques and principles of energy efficiency. While the overall development was a collaborative effort, this specific house was designed by the two of us, for ourselves. We built this house to have a link to Patagonia, as an investment, to have a place to be able to work remotely for a few months a year.

Each previous build in the project provided an opportunity to refine and innovate high-efficiency construction methods, leading to ongoing improvements in both performance and cost. My father’s deep expertise enabled us to integrate high-performance design with traditional building methods, experiment with innovative

materials, and test various construction techniques with creative solutions. He also served as an invaluable on-site advisor, ensuring smooth execution in our absence.

For the first stage of the build, when the foundations and superstructure were built, we were not on site, so the work was led by my father. The house was built over two years, and we came for three months each year to work on the project. We came to oversee the work on the insulation and airtightness.

Located in the Andes at an altitude of 950 metres, the site presents unique climatic challenges, including strong winds, considerable temperature fluctuations, and heavy snowfall. Adopting passive house principles was essential – not only to ensure year-round comfort but also to reduce energy costs and protect our long-term investment. A key aspect of our approach was adapting the design to utilise locally available materials, skills, and technologies, ensuring both sustainability and resilience in the face of Patagonia’s harsh environment.

Harmonising with the landscape

The detached two-storey house is perched on a steep hillside overlooking Lake Nahuel Huapi, affording breathtaking views of the Andes and the Chilean border. Surrounded by a native cypress forest, the site’s sloping terrain presented a number of spatial challenges, necessitating careful consideration of the foundation, landslide risks, preservation of cypress trees, and circulation. However, this distinctive setting also allowed us to optimise the views by locating the main entrance and living areas on the upper level, allowing the house to frame the dramatic landscape while ensuring privacy for the bedrooms below.

To minimise the environmental impact and cost-effectively maximise energy efficiency, we maintained a compact form factor of 2.65 and an efficient footprint, integrating the house sensitively into its surroundings.

A significant advantage of the site was its north-facing orientation, which not only offered the finest views but also maximised passive solar gains during the colder months, aligning seamlessly with passive house principles. The topography was utilised to retain as much of the native vegetation as possible, with the ground floor partially embedded into the southern slope and terraced outdoor spaces designed to make the most of the garden area.

Core tenets of high-performance design

The design adhered to fundamental passive house principles to balance performance, cost, and aesthetics:

Fabric-first approach

Prioritising continuous insulation, airtightness, highquality windows, and minimising thermal bridges to enhance energy efficiency and reduce maintenance costs.

Patagonian aesthetic

Using corrugated metal, local cladding materials, and a pitched locally sourced timber roof to integrate the house into the landscape and climate. The cladding was chosen to create a lower visual impact from the lake and surrounding terrain. Fire risk is significant in the area, and materials were assessed to find a cost-efficient balance.

Simple design, compact form

A straightforward floor-plan design with the living room, dining room, open kitchen area, office space and porch placed on the top floor and bedrooms on the ground floor. This leads to an optimised form factor with a modular structural design, which optimises resources and costs. This approach allowed us to allocate the budget to advanced technologies and systems that are uncommon and therefore more costly in Patagonia.

Site-specific considerations

Factoring in solar radiation, wind direction, slope, native forest, and views to optimise comfort and efficiency while minimising environmental impact. Additionally, we chose a rain-screen system to reduce weathering issues throughout the year.

Passive house principles

While full passive house certification was challenging and not feasible for this stage of the project, core principles were applied, and a PHPP analysis was carried out to prove compliance. General quality assurance passive house recommendations were implemented from an early stage and during construction to minimise the performance gap.

Overheating mitigation strategy

Summer temperatures can exceed 30C from January to March. Mitigation measures include minimising west-facing windows, incorporating a highly efficient thermal envelope, generous roof overhangs on the north-facing façade, mechanical ventilation, and strategically placed roof lights to enable the stack effect and night cooling.

Heating system

The primary heating system consists of a condensing combi boiler feeding radiators on the first floor and providing underfloor heating on the ground floor optimised with smart heating controls. Heat pumps are difficult to access in this part of the world, and fossil fuels remain the dominant heating source, making the combi boiler the most carbon-effective solution.

Constructing a high-performance home on a budget demands meticulous planning and strategic decision-making. To balance cost-efficiency with quality, the construction timeline was deliberately extended, enabling a phased approach and hands-on involvement. One example of this was carrying out a part of the airtightness taping and painting ourselves, which, along with providing direct training to the local contractor, not only reduced costs but also helped develop local expertise in passive house principles.

The choice of glazing presented a particular challenge. In a cool-temperate climate, triple glazing would typically be the standard; however, due to constraints, double glazing had to suffice. The triple glazed options available in Argentina offered surprisingly poor performance – often inferior to their double glazed counterparts. The spacers and cavity between panes were of substandard specification, negating any potential thermal advantage. Importing high-quality alternatives from Europe was unfeasible due to costs and prohibitively long lead times.

Similarly, following a thorough assessment of the available options for a mechanical ventilation system, we opted for a continuous, on-demand system without heat recovery. Unfortunately, this increased approximately 20 kWh/ m² per year in space heating demand. However, due to the limited availability of advanced ventilation technology in this region, it was the most cost-effective and feasible choice. We do, however, intend to upgrade to a heat recovery system as soon as such technology becomes more readily accessible.

The final stage of the house was completed in 2024. Compared to standard local construction, it consumes at least 75 per cent less energy than similar properties in the area while maintaining exceptional indoor air quality yearround – underscoring the importance of high-performance building methods. Implementing passive house principles in a region with limited resources required innovative problem-solving, local expertise, and alternative material sourcing.

We have carried out, and continue to undertake, various building performance tests, such as smoke testing during construction, to identify leaks and refine airtightness strategies. Additionally, indoor air quality and energy consumption are currently being monitored in three of the six completed homes.

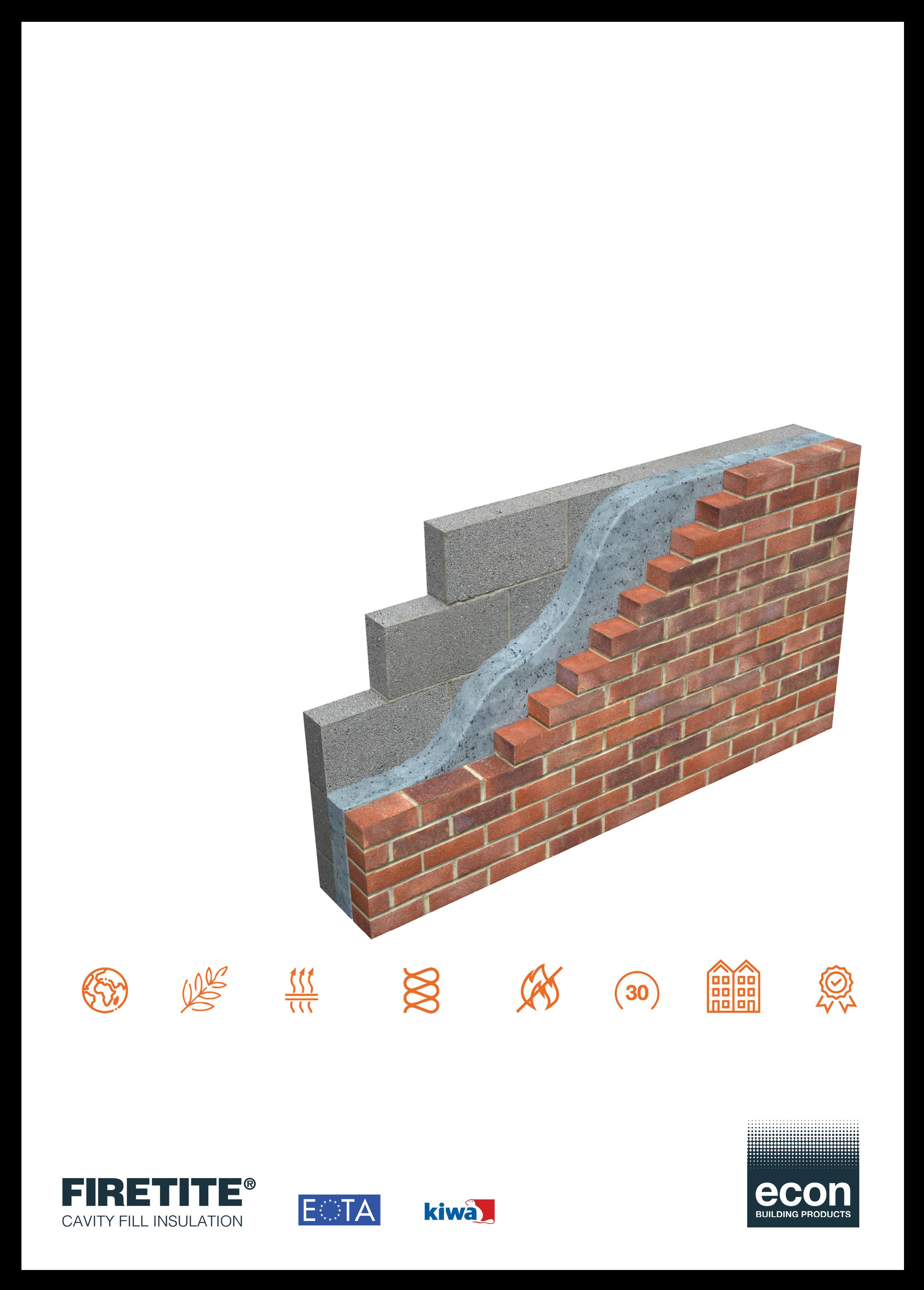

Predictable. Reliable. Unquestionably the right choice.

Mr Sameway doesn’t like change he, like many others, follows the crowd. “Insulation is insulation,” he said, confidently selecting the same synthetic insulation he’d always used. As far as he was concerned, thermal performance was the only thing that mattered. If it kept the heat in, that was what it was supposed to do and that was good enough for him.

But what Mr Sameway didn’t realise was that he was missing out—big time.

Meanwhile, Mr Wise took a different approach. He understood that insulation wasn’t just about keeping heat in; it was about creating a comfortable, healthy, and durable building. That’s why he chose Steico Wood Fibre Insulation.

With Steico, Mr Wise’s building breathed naturally, avoiding the trapped moisture and condensation problems that could plague synthetic insulation. His rooms were warmer in winter and cooler in summer, thanks to Steico’s high heat storage capacity, and his home was quieter too.

Setting a precedent for sustainable living in Patagonia

This project is not just a home – it is a testament to the potential of high-quality, holistic housing, spanning multiple generations in extreme climates and challenging landscapes. By showcasing high-performance design, local labour, and traditional construction skills, this project aims to inspire others to adopt these principles, fostering a more energy-efficient and resilient built environment, both in Argentina and beyond.

Building in Patagonia presented several challenges, from establishing a reliable professional network to educating teams on passive house principles and sourcing high-performance materials. These hurdles ultimately strengthened connections within South America’s emerging passive house community and reinforced the region’s commitment to sustainable construction.

The project seems to have had a lasting effect on the contractor. He is now working on another project with a local architect and has asked the architect to implement the airtightness principles he learnt on our house. There is a real need for airtightness in the harsh Patagonia climate, but while the need for insulation is fairly well understood in the region, the importance of airtightness remains relatively unknown.

The experience was both rewarding and inspiring, yet it raises important questions about adaptation. How can these practices be tailored to local contexts, particularly in remote areas with diverse socio-economic groups? In isolated regions, local skills are vital, but limited access to advanced technology can drive up costs or delay progress. Adaptation must be flexible, addressing regional constraints. Scotland offers an insightful example, where passive house principles are being integrated into social housing and building regulations. These initiatives show how sustainable construction can go beyond high-end projects, providing long-term carbon savings, healthy homes and affordability for communities.

Project name: Casa Cuatro

Location:

San Carlos de Bariloche, Patagonia, Argentina

Architectural design: Eoin Kavanagh (CEPH)

Bárbara Lantschner (CEPH)

Passive house consultancy and PHPP Modelling:

Bárbara Lantschner (CEPH)

Project area (GIFA): 188 m 2

Space heating demand (PHPP): 54 kWh/m 2/yr

L

eading developer Barratt London has announced plans for its ‘Lo-E’ Homes programme, which will deliver sustainable new homes at scale across the British capital and exceed passive house standards.

The developer will submit plans for an initial 728 homes at its upcoming High Barnet and Acton's Bollo Lane developments, delivered in partnership with Places for London, believed to be one of the biggest rollouts of passive houses in the country.

With summer temperatures in London reaching a record 40.2C in July 2022 and predicted to equal or exceed this regularly in the near future, Barratt London says its ‘Lo-E’ homes will be climate resilient, accounting for future heatwave conditions. Created by a team of experts, including passive house designers and building physicists Beyond Carbon, the ‘Lo-E’ homes seek to optimise high density, sustainable housing in the capital and exceed current building regulations.

"Our ‘Lo-E’ homes concept is an opportunity to think differently and deliver a new approach to high-density, sustainable housing in London," said Craig Carson, managing director at Barratt West London.

"This is a significant milestone for the business, as we look to the future and consider the unique challenges faced in the capital, such as more heatwave conditions every few years."

Key components in the design include carefully engineered facades that limit heat from solar gain, triple glazed passive house windows to offer a new level of thermal comfort, and climate resilient air tempering to fully filter air and improve air quality.

Crucially for consumers, Lo-E homes will offer significant savings in running costs and greatly improved winter health and comfort, alongside using less energy and producing lower carbon emissions. A typical resident is predicted to save around two-thirds on their heating bills compared to today's district heating system, representing a 75 per cent reduction in heating energy and as much as 90 per cent saving in carbon emissions.

High Barnet will be delivered through the West London Partnership, a £1.9bn collaboration between Barratt London and Places for London that will see more than 4,000 new homes built over the next 10 years. The site will deliver approximately three hundred new homes alongside small-scale commercial uses, with a target to deliver 40 per cent affordable homes.

The second phase of Bollo Lane will see 455 passive house certified homes delivered as part of the entire 900-home development near Acton Town Tube station. •

The 2025 UK and Ireland Passivhaus Conference, themed Climate Emergency: The Passivhaus Solution, is set to bring together hundreds of sustainable building professionals in Belfast this October.

The timing coincides with an explosion in activity in the passive house standard on both sides of the Irish Sea, reflected by the fact that the largest housebuilders are starting to build at scale to the passive house standard. Housebuilders such as Barratt and Cairn are increasingly turning to the standard as efforts to accelerate genuine building decarbonisation take hold, with new building regulations, investor pressure and net-zero targets driving demand for proven low-energy construction standards.

The conference, to be held on 7-8 October at the International Convention Centre Belfast, a joint initiative of the UK’s Passivhaus Trust and the Passive House Association of Ireland, is expected to play host to attract a wide mix of attendees including architects, engineers, contractors, local authority representatives, housing association professionals, and policy makers.

Themed around passive house solutions to the climate emergency, the conference represents the first major collaboration between the two organisations and marks a significant expansion of the event beyond British shores.

Sessions are set to include keynote presen-

tations on both residential and non-domestic passive house projects, alongside practical workshops on how to deliver passive houses, covering both new build construction and retrofit applications. The conference will open with a comprehensive session on the climate emergency, directly addressing the event's central theme of sustainable building solutions in response to environmental challenges.

Attendees can also expect final sessions focused on passive house futures, exploring emerging trends and innovations in the passive house sector. The programme will be complemented by sponsor exhibitions and dedicated networking opportunities, including coffee breaks and a drinks reception, providing delegates with the opportunity to connect with industry professionals, policymakers, and practitioners from across the UK, Ireland, and beyond. Speaking to Passive House Plus, Passivhaus Trust chief executive Jon Bootland emphasised the historic nature of the partnership.

“We’re delighted that we're working jointly with the Passive House Association of Ireland. It's the first time we've worked together, and it's the first time we've taken the conference outside Britain,” he said. Caroline Ashe Brady, chairperson of the Passive House Association of Ireland, described the collaboration as a landmark moment for the sector.

"We are thrilled to announce this landmark collaboration between the Passive

House Association of Ireland and the UK's Passivhaus Trust for our first-ever joint conference, taking place in Belfast in October. This event marks a significant moment for the passive house community across these islands – bringing together shared expertise, common goals, and a united commitment to delivering high-performance buildings in the face of climate and energy challenges. We look forward to welcoming professionals, policymakers, and practitioners from both sides of the Irish Sea, and beyond, to help shape the future of passive house development in these islands,” she said.

Bootland also noted that the conference would demonstrate that the passive house standard can be met at scale by mainstream developers, promising a major improvement in the housing stock of the two countries. Notably, the conference will showcase major developers embracing passive house construction, demonstrating the standard's viability for mainstream housing delivery

“We've also got two big developers setting out their story of moving to massive scale passive house: Cairn in Ireland and Barratt in London,” Bootland said. •

The winners of the inaugural Exemplar Sustainable Buildings Awards were announced in London on 25 June, celebrating the Sustainable Development Foundation's 20th anniversary.

The awards programme, delivered in partnership with the Passivhaus Trust and the Alliance for Sustainable Building Products, seeks to recognise the pinnacle of sustainable building achievement across the UK.

Entrants were required to provide monitoring data demonstrating that buildings perform as designed.

“The Exemplar Sustainable Buildings Awards have helped break down the often-perceived silos between operational and embodied carbon. The winners and shortlisted projects, products and initiatives have shown that sustainable building products are being successfully specified in buildings targeting low operational energy, helping with the transformation to a healthy low carbon-built environment,” said Simon Corbey, Alliance for Sustainable Building Products, in a statement.

Goldsmith Street by Mikhail Riches won the large project category. This Stirling Prize award-winning social housing development demonstrates that local authorities can deliver net zero-ready homes to a tight budget without sacrificing quality, with the 93-home

passive house project creating light-filled, community-focused homes with annual heating bills as low as £150.

In the small projects category, The Seed Cohousing by Kirsty Maguire Architects near Dundee was selected as winner. This co-living home for two households is almost entirely timber-based and meets both passive house classic standard and RIBA 2030 embodied carbon requirements, showing how passive house standards can be achieved in locations with difficult site constraints and restricted solar gain.

Notably, the vast majority of the projects shortlisted in this category achieved passive house or Enerphit certification, or use the passive house methodology in design and construction.

The retrofit project winner, Ward Grove by Progress in Practice, demonstrated the potential of deep retrofits. This whole-home transformation achieves exceptional energy performance, long-term comfort, and inclusive design within the constraints of an existing 1980s bungalow, with annual space heating costs of only £360 while being certified to the AECB CarbonLite Retrofit Standard.

Innovation initiatives

The product category was won by EcoCo-

con's Straw Panel System, described as a carbon-negative construction material. The straw wall system stores more carbon than it emits per square metre, with prefabricated panels from renewable timber and straw providing thermal performance, vapour permeability, and carbon sequestration.

Pacer by Preoptima took the initiative award. This digital platform empowers local planning authorities with tools to enforce whole life carbon policies in the planning process, automating the review of whole life carbon assessments and providing case officers with clear, data-driven insights into compliance.

The awards were sponsored by Ecological Building Systems and other industry partners including Lamilux UK. Projects were evaluated based on measured performance data rather than predicted outcomes, with judges requiring evidence of actual energy use and occupant satisfaction. The winning projects span different scales and budgets, from social housing to self-builds and commercial retrofits. •

(below) Large project winner Goldsmith Street by Mikhail Riches.

Photo by Rob Edwards

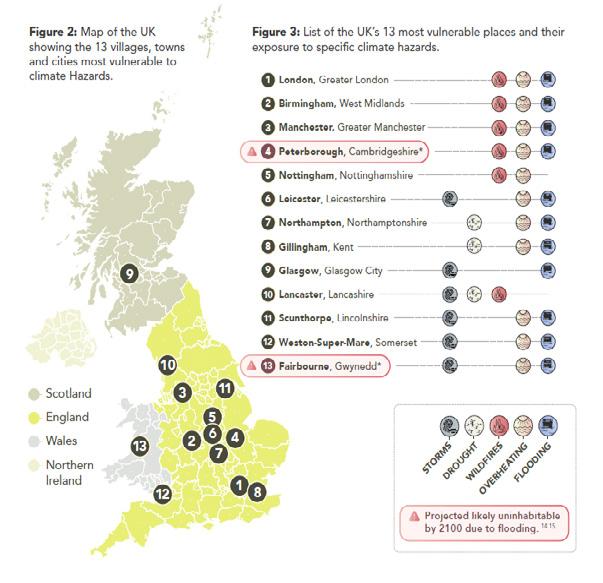

Anewly published landmark study has said thirteen UK areas face severe climate risks as schools brace for ten-week heatwaves.

The research, the UK Climate Resilience Roadmap, warns that climate change threatens to make parts of Britain uninhabitable within decades, with the cathedral city of Peterborough and Welsh village of Fairbourne facing potential abandonment due to flooding by 2100.

The roadmap, developed by the UK Green Building Council alongside major industry partners including Lloyds Banking Group, Mace, Arup and Zurich, identifies thirteen areas across Britain most vulnerable to extreme weather hazards. The comprehensive two-year study reveals that schools in London and the South East could face heatwave temperatures for 10 weeks annually under a relatively modest 2C warming scenario.

The report's stark findings were published as parts of the UK faced their second heatwave this summer, underlining the immediacy of climate risks. Six million homes in London and the South East will endure temperatures exceeding 28C for two weeks each year, whilst care homes in these regions face four weeks of such extreme heat annually. Beyond overheating, the roadmap details how Britain's homes, schools, hospitals, offices and infrastructure face mounting threats from five interconnected climate

hazards: overheating, flooding, drought, wildfires and storms.

The most vulnerable locations span England, Wales and Scotland, including major urban centres such as London, Birmingham, Manchester, Glasgow, and smaller communities like Scunthorpe and Weston-super-Mare. Hull, Portsmouth and parts of London could be underwater by 2100, with sea level rises of up to 1.12 metres projected under high-emissions scenarios.

Wildfire risks present another emerging threat, with extreme fire danger days potentially increasing five-fold from approximately twenty to over one hundred annually by 2080.

Simon McWhirter, chief executive of the UK Green Building Council, emphasised the urgency of action: "The UK Climate Resilience Roadmap starkly illustrates the threats of a changing climate, not in the future, but right here, right now. Our homes, schools, hospitals, parks and offices are on the front line, and they are in danger."

The report presents eight key policy recommendations, including establishing an office for resilience within the cabinet office, restoring the minister for resilience role, and ensuring all planning decisions deliver climate safety. It also calls for protecting communities with trees, parks and ponds whilst creating a new generation of green professionals.

Current global policies place the world on track for 2.7°C of warming by 2100, according to the Climate Action Tracker, significantly exceeding the Paris Agreement's targets. The roadmap argues that with such warming trajectories, immediate adaptation measures are essential alongside continued emissions reduction efforts.

The study involved extensive modelling using standard industry methods published by the Chartered Institution of Building Services Engineers, drawing on open-source government data to assess physical risks, access to green spaces, and social vulnerability across the UK. •

all you need, is the air that you breathe...

Ÿ heat recovery ventilation

Ÿ heating

Ÿ cooling

Ÿ hot water

Ÿ energy efcient COP: 6.8

Ÿ ideal for super-insulated & airtight ats or townhouses

Certified green homes are becoming mainstream across Europe – boosted by collaboration from experts in green building and finance. Smarter Finance for EU (Smarter4EU), a pan-European initiative dedicated to the creation of a mainstream European green housing market, announced a range of new initiatives at the “Banking on Green Homes" event in Madrid, on 28 May.

The consortium announced the launch of a European centre of excellence to help introduce green home certification throughout Europe, with support for certification bodies, banks, developers, municipalities and the full construction supply chain, as the industry grapples with requirements to decarbonise Europe’s housing stock. To help the finance industry avoid the risk of greenwash and to understand the business case for genuinely green homes, the consortium has also launched tailored green homes training for the finance industry.

Before the conference, Alliance HQE, which has certified over €348bn worth of green homes in France, signed a memorandum of understanding to collaborate with the EU LIFE-funded Smarter4EU consortium, which includes green building councils who have certified green homes at scale in countries including Romania, Ireland and Spain, while collaborating with Portuguese and Ukrainian partners to develop new green home certification systems. Meanwhile green building councils in Poland, Italy, and Bosnia have introduced green home certification in collaboration with the consortium, with other countries set to follow. Project co-ordinator Elena Rastei said the consortium’s work was focused on “Families seeking sustainable homes, businesses investing sustainably and communities building climate resilience,” and emphasized the importance of collaboration and sharing expertise to solve problems and unlock opportunities.

“The collaborative systems we have developed through Smarter Finance for EU aim to help transform the future,” said Rastei. “We have created lasting networks, shared knowledge and organic partnerships that will continue generating impact long after the formal project period ends. Leadership in this context means creating space for expertise to flourish, building bridges between different sectors and sometimes acknowledging that the best solutions emerge from collective intelligence rather than individual vision.”

Smarter4EU is aiming to unlock over €100bn worth of certified green homes across Europe, by aligning green home certification systems to new EU sustainability rules hitting the finance and property sectors.

The case for green homes has been transformed by European policy and investor pressure. While in the past the EU buildings policy landscape had tended to focus on the energy use and carbon emissions associated with heating, cooling and lighting buildings, a raft of policy including the EU taxonomy on sustainable economic activities and a 2024 recast of the EU Directive on the Energy Performance of Buildings (EPBD) are widening the net. Keynote speaker and European Greens co-chair Ciarán Cuffe, who was the European Parliament’s rapporteur on the new directive, stressed how the EPBD now requires EU member states to renovate existing buildings en masse – with the ultimate goal of a zero-emission European building stock by 2050.

Cuffe explained how Russia’s invasion of Ukraine added impetus to the argument for decoupling from gas and oil. European-Ukrainian Energy Agency CEO Anastasiia Vereshchynska told delegates that Ukraine was introducing a green home certification system in spite of the country being at war. “Green housing is not just an option,” said Vereshchynska. “It is a practical solution for safe, comfortable and sustainable living in Ukraine. Rotislav Rozsypal of the EU Directorate-General for Financial Stability, Financial Services, and Capital Markets Union (DG FISMA) said the work of Smarter Finance for EU was proving key in helping to ensure housing projects meet the requirements of the EU taxonomy on sustainable economic activities. Addressing the impact of plans announced by the EU in February under the Omnibus package to simplify sustainability reporting rules for businesses, Rozsypal explained that the commission was working to avoid moving backwards on sustainability while lessening the reporting burden on businesses.

“We would like to keep the ambition while simplifying the rules”, he says. The impact of the omnibus on the Corporate Sustainability Reporting Directive (CSRD) was discussed in a panel chaired by industry expert Peter Sweatman, including World Green Building Council sustainable finance lead Julie Emmrich; UCI ESG and corporate sustainability expert Pilar Campuzano López; Cairn Homes head of sustainable construction Stephen O’Shea and Enersave Capital managing partner Alex Hedesiu. In spite of the prospect of reduced reporting obligations under the CSRD, O’Shea spoke of Cairn’s commitment to delivering green homes. The leading Irish house builder is currently on site with over 1,750 homes that are set to be certified to the world-renowned Passive House low energy building standard and the Irish Green Building Council’s Home Performance Index green home certification system, while also meeting a biodiversity net gain target. Alex Hedesiu shared details on the Green Homes Accredited Finance Professional training courses developed by Smarter4EU to give the finance industry the tools to profit from the burgeoning green homes sector – and reduce the risk of greenwash. Smarter4EU chair Hanane El Hayek explained how Smarter’s European Centre of Excellence was helping to reduce confusion in a complex industry, while helping support new partners to introduce EU taxonomy-aligned green home certification schemes and tailored finance products across Europe.

For more information on Smarter4EU, including the Green Homes Accredited Finance Professional training courses, visit www.smarterfinance4.eu. •

The upgrade of Ireland's retrofit target to A3 marks a critical step forward, bridging the gap between energy modelling and real-world performance, explains Dr. Marc Ó Riain

In my 2015 research, I questioned whether Ireland’s retrofit strategy was fit for purpose. Cost-optimal calculations at the time recommended B2-level upgrades, often prioritising mechanical systems over the building envelope, and largely ignoring the actual condition or remaining lifespan of the buildings we were upgrading. Fabric-first strategies – proven to be effective for decades - were deemed “too expensive” in theoretical models, even though practice was already proving otherwise.

Fast-forward to 2025, and we’re finally catching up to what should have been common sense. Ireland is now moving its nZEB retrofit performance standard from B2 to A3, following a new cost-optimal review (DHLGH, 2025). This is not just a regulatory adjustment; it’s a much-needed recognition that the minimum bar was simply too low.

Over the past two years, the National Retrofit Programme has accelerated dramatically. A-rated retrofits are no longer niche – they are fast becoming the norm. In 2023 and 2024 alone, we saw a significant increase in homes achieving A-rated energy performance, supported by improved grant structures, a more capable contractor base, and a better-informed public. Notably, recent results from the National Retrofit Plan show that Community Energy and One Stop Shop retrofits are achieving an average BER of A2, far exceeding previous expectations (SEAI, 2024).

This is the result of a growing consensus around fabric-first approaches. Walls, roofs, floors, and windows form the energy backbone of any home. Upgraded properly, with adequate ventilation and airtightness, technologies like heat pumps and heat recovery ventilation systems can then perform efficiently and reliably. In poorly insulated homes, however, these systems can struggle to deliver the expected savings or comfort.

It’s not about technology being good or bad. It’s about sequencing: insulate first, ventilate well, then electrify with active renewables. That’s how the best retrofit outcomes have historically been achieved.

Ireland’s retrofit market has grown substantially in both value and capability. Re-

cent estimates place the sector at over €500 million annually, with government targets of more than 500,000 home energy upgrades by 2030, and at least 400,000 of those achieving a minimum of B2. However, under the latest cost-optimal review, the nZEB standard is now effectively defined as A3 (SEAI, 2024; Department of the Environment, Climate and Communications, 2023).

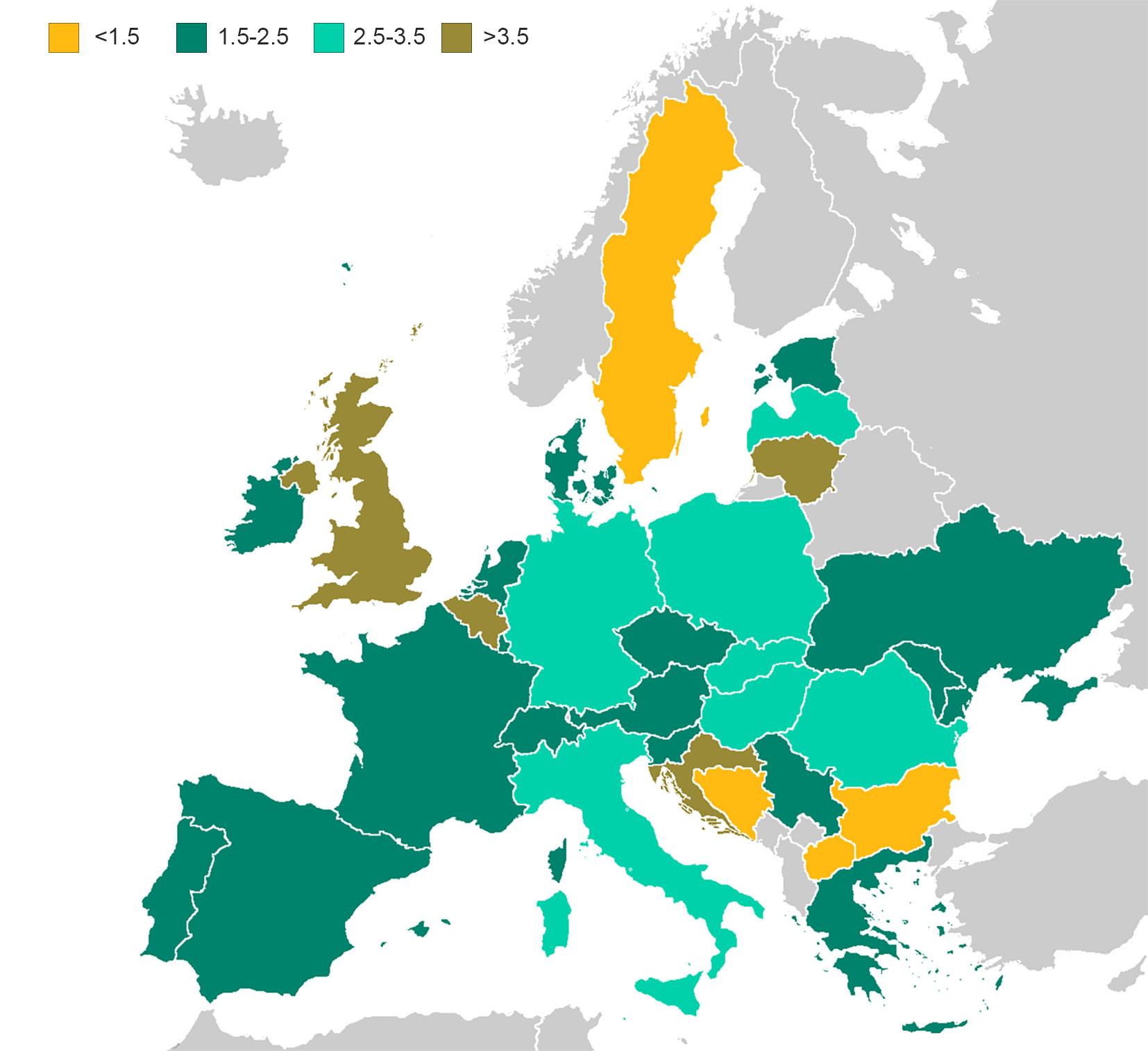

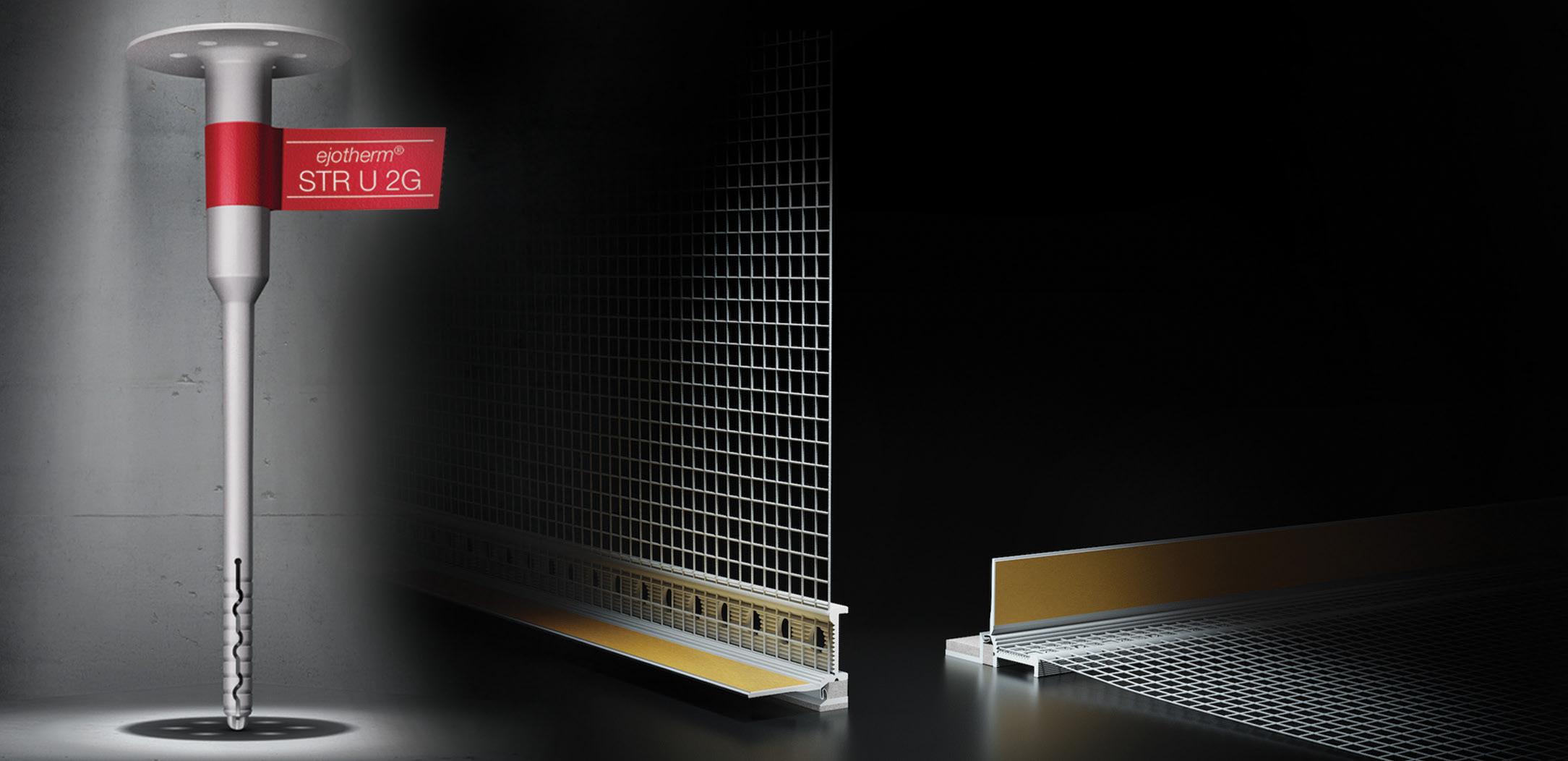

The scaling up of retrofit activity presents opportunities alongside significant risks, notably the doubling of insulation material costs in the last decade due to global disruptions and inflation, compounded by labour shortages. Ireland's high material costs – ranking as one of the most expensive locations in Europe for a range of core construction materials like insulation (Arigoni 2022) – could erode the affordability of deep retrofit for the very households who need it most and seriously impact the Irish government’s national retrofit targets.

To ensure we’re delivering on the promise of retrofit we need to shift from modelled to measured performance. Compliance tools like DEAP or PHPP are vital, but they can’t account for occupant behaviour or unregulated loads.

In low energy homes, plug loads can account for 40 to 50 percent of total electricity consumption, yet these are rarely factored into retrofit assessments (O’Driscoll, O’Sullivan and Harrison, 2013; Menezes et al., 2012). Without real-world monitoring, we risk overpromising and underdelivering.

To earn householders' trust, we need to record actual post-retrofit energy consumption across the whole building, improving design feedback loops and deepening public understanding.

As we scale, it’s critical we support householders with clearer, more tailored advice. Many don’t know where to start, what’s typical for their home type, or how to sequence upgrades within their budget. A simple roadmap, showing the most cost-effective way to reach A3 from, say, a 1970s or 1980s bungalow bliss, would empower more households to act with confidence.

Retrofit must be reframed not as an expense

but as an investment – in comfort, in health, in resilience. A well-retrofitted home is warmer in winter, cooler in summer, cheaper to run, and more resistant to global economic shocks, be it COVID, the war in Ukraine, or future trade instability like Trump’s tariffs. These are not just climate actions; they are acts of personal and national resilience.

For our colleagues across the water, there’s an important question: is the UK falling behind? While Ireland is aligning its retrofit targets with an A3 minimum, the UK’s retrofit landscape remains fragmented. Ambitious in rhetoric, but inconsistent in regulation and funding, with the Future Homes Standard still under debate and regional pilots patchy at best.

The UK once led on building energy performance but has lost momentum. The Irish shift to A3 could serve as both a benchmark and wake-up call, potentially reinvigorating confidence by defining minimum performance, supporting envelope upgrades, and connecting grant aid to measured outcomes could reinvigorate the sector, on both sides of the Irish Sea.

The move to A3 is not radical—it’s overdue. But it’s also an opportunity. One that must be seized with careful sequencing, informed decision-making, and robust support for households and industry alike.

In 2015, we underestimated the role of the building envelope and failed to account for the real condition of the homes we were trying to decarbonise. In 2025, we have the benefit of hindsight, real data, and a growing body of best practice. Let’s not waste it. •

Dr Marc Ó Riain is a lecturer in the Department of Architecture at Munster Technological University (MTU). He has a PhD in zero energy retrofit and has delivered both residential and commercial NZEB retrofits In Ireland. He is a director of RUA Architects and has a passion for the environment both built and natural. A fully referenced version of this article is published on www.passivehouseplus.ie

As electricity decarbonises, the case for switching from fossil fuel boilers to efficient use of electricity to heat buildings via heat pumps has become overwhelming. But in markets like the UK where electricity is far more expensive than the European average, and people on low incomes may be chronically underheating poorly insulated homes, could a drive to electrify heating exacerbate energy poverty?

Words by Kate De Selincourt

It is not, admittedly, that difficult to annoy me. But one sure way is to use the phrase “rebound effect”. This phrase implies disappointment that after energy retrofit, building occupants have exploited the improvements to bounce their temperatures up, so energy use falls less than the model predicted.

Are improvements in comfort and living conditions, for people who could previously never afford to keep properly warm, really a failure, to be regretted?

Perhaps one reason for this mis-categorisation of success as a kind of failure, is the long-standing conflation of “decarbonisation” – action to tackle emissions – with action to address fuel poverty and cold homes. They have never really been the same thing, but recent changes mean it is urgent that we recognise this explicitly.

For years, many home retrofit programmes have been run under the aegis of variously named agencies and departments with responsibility for energy and climate. Programmes established to reduce carbon emissions have also been used to address fuel poverty: in some, households with poor health or restricted income have been the only targeted beneficiaries.

When heating was pretty much all fossil fuel-based, this was a convenient elision, if not entirely an honest one. The demand reduction measures that used to form the bulk of decarbonisation programmes – insulation, draught-proofing, more efficient boilers – are also measures that would alleviate fuel poverty and improve living conditions. (There is a huge aside about ventilation provision here; air quality has been a serious casualty of the ‘two programmes one heading’ shorthand).

Yes, the comfort take meant that emissions did not always fall much, but nonetheless, people were being helped – so the work was worth doing.

But now there is a whole new, super-potent decarbonisation tool on the block. Thanks to the soaring levels of renewables on the grid, converting from fossil fuel to electric heating cuts emissions without a single roll of insulation being laid. With a heat

pump, emissions can be reduced again, two, three or even four-fold.

In fact, heat pumps have become so effective at reducing emissions that some are questioning the need for anything beyond the most basic fabric improvements — something Toby Cambray wrote very eloquently about a few issues ago (please read it!)

But while electrification is indeed great news for the climate, whether it benefits the end user or not is a different question.

Electricity remains far more expensive per kWh than gas in both the UK and Ireland. This means that decarbonisation of heating cannot in and of itself make living conditions easier for the most vulnerable.

We can, in other words, no longer pretend that decarbonisation and fuel poverty alleviation are one and the same thing.

When direct electric heating such as infrared panels or storage heaters are installed to replace fossil fuel heating, there is at least an understanding that fabric efficiency will have to improve, as everyone knows how expensive these systems are to run.

Heat pump installations are not always treated with the same caution, because the assumption is that they will, if anything, make bills lower.

Heat pumps are certainly more efficient than direct electric heat, and even in the UK with its huge spark gap, modelling indicates that running a reasonably well set up heat pump should probably cost about the same as running a boiler on mains gas – or even less. And this can indeed be the case (it has been for me, for instance).

But heat pumps have a perversity about them that can undermine all the modelled assumptions. By a particularly cruel irony, the less heat you can afford, the more expensive that heat is likely to be. All of a sudden, there is a danger that decarbonisation programmes might exacerbate fuel poverty, not alleviate it.

The problem here is that the understanding of “a well-run heat pump” means it is running for 21 or 24 hours a day, and possibly using

a smart tariff too. But this understanding excludes some of our most vulnerable households.

People on very constrained budgets may feel quite unable to run a heat pump continuously. They have never spent that much on heating and can’t begin to now. Because heat pump running costs are not being modelled with this reality in mind, we risk being blind to this.

Because of the non-linear physics involved in heat pump performance, running a heat pump for only a few hours per day can lead to extremely high costs per unit of heat, compared to gas. It can even lead to higher bills overall, even while there is less heat, overall, supplied into the home. This is a particular danger in the UK, with its very high electricity to gas price ratio.

Some low-income householders with newly installed heat pumps have run into real difficulties because of this. The situation can spiral as households cut back further, then see ever increasing costs of heat. At this point people may give up and resort to a single room heater instead.

So, what can we do? The most important thing is probably to recognise that while with fabric improvements, the modelled running cost savings can be more-or-less translated into increased affordability of warmth, this simply

We must make electricity costs constant and predictable, and to make constant heat – even at a low level – an automatic part of living with a heat pump, whatever your income and resources.

does not apply with a heat pump. The cost of heat actually depends on how much you are using. Hard to anticipate – for a householder, and for a policy maker too.

We have to start “stress testing” running cost modelling against different budgets, different heating patterns, and different heating needs, before we can say “bills will not rise”.

We should also understand the air source heat pump ‘double winter penalty’, where due to lower coefficients of performance (COPs) in colder weather unit costs of heat are highest, just when you need most of it –and consider how this impacts households using credit meters.

We urgently need to work out how to make running heat pumps affordable, and, equally critically, predictable, in terms of money in versus comfort out, so people with financial constraints can be in control of their spending.

The fact that people have been running

their heating for just an hour or two here and there was never acceptable. But if we continue to fool ourselves that “decarbonisation” will help them, the approach risks becoming catastrophic.

When we provide excellent fabric, the problem effectively disappears (heat pump running costs do not seem to be an issue in Energiesprong retrofits or passive houses).

If we can’t do that for everyone soon, then other ways must be found to protect the most vulnerable recipients of decarbonised heating. This might be a warm rent, a set price comfort guarantee, a heat-on-prescription model. But the important thing is to make costs constant and predictable, and to make constant heat – even at a low level – an automatic part of living with a heat pump, whatever your income and resources.

This is where heat pumps might really come into their own. A steady, modest supply

of heat from a well set up heat pump is one of the best ways to get a low unit cost of heat. Supporting this as part of decarbonisation would protect people’s health and wellbeing; it would protect buildings; it could even protect landlords’ rental incomes.

And it might even mean that fuel poverty alleviation and decarbonisation can work together again. Let’s just keep clear in our minds that they aren’t the same thing. •

Kate de Selincourt is a researcher and writer with an interest in the energy and health performance of buildings. A regular contributor to Passive House Plus since 2012, Kate is working with the Passivhaus Trust to help produce its report on the costs and benefits of passive house.

70S TIMBER FRAME AT BEN NEVIS REACHES DEEP RETROFIT SUMMIT

From frozen tea to thermal bliss: energy specialist Esmond Tresidder transformed his leaky 1970s Highland home into one of the highest performing retrofits ever featured in these pages, combining academic knowledge with hands-on retrofit innovation to create a comfortable, healthy family haven with breathtaking views of Ben Nevis, proving that even Scotland's most challenging climates are no match for passive house principles.

Development type: 84 m2 timber frame house built in 1975 extended to 102 m2

Method: House renovated with extensive use of woodfibre insulation, airtightness measures, mechanical ventilation with wastewater heat recovery, and an innovative air-to-air heat pump system.

Location: Rural Fort William, Inverness-shire Standard: Enerphit plus certification pending Space heating cost: £175 per annum, averaging at £14.58 per month.

£14.58 per month

With stiff fingers I bring the bike to a stop, swing my leg over the back wheel and push it up the drive to our house. I’m spent. For the last hour I’ve been slightly too cold, only able to maintain my temperature by cycling hard, but the harder I cycle the more the wind chills me. I’ve only been able to get comfortably warm when cycling uphill. Hunger, fatigue and cold have been gnawing at me. I drop the dirty bike at the top of the drive, a problem to be dealt with later, and hobble onto the porch, taking off my wet shoes and icy socks.

I open the door to our house. As I step through, I’m enveloped in calm warmth, my mind relaxes, knowing that I’m not warm yet, but I soon will be. As the hot water of the shower washes over me I reflect on how unlikely this all seems. A house that two years ago was cold, drafty, damp and expensive to keep that way is now a haven of comfort and has just achieved the lowest heating costs of any home in the UK monitored by heatpumpmonitor.org.

Before starting this project I had spent the previous fifteen years learning and thinking about low-energy buildings, first academically, then professionally. But my theoretical knowledge was not matched by anything practical – I had precious little hands-on experience. I didn’t even like DIY. Having a deep theoretical understanding of the problems with most houses and how much healthier and more comfortable they can be through good design created a cognitive dissonance because of my own living situation. I knew the projects I was working on – social housing, schools and leisure centres, all to the passive house standard – would be super comfortable and healthy buildings with radically lower running costs than conventional buildings, yet I was working on them from a freezing shed and living in a cold and damp house. Completing the AECB retrofit course in the first year we were here opened my eyes to the

potential for deep retrofit, and I started to wonder what could be done with our house.

We moved from Brussels to Lochaber, in the Western Highlands, in 2016. Finding the right house had been difficult and we settled for something that we knew would soon be too small – we were hoping for a third child – because of its fantastic location. The house looks onto Britain’s highest mountain, Ben Nevis, is within walking distance of schools, on a safe bike route into town and is five minutes’ walk from a train station. We were excited to swap the city for the mountains but didn’t want to become too dependent on cars, having enjoyed not owning one in Brussels, so the location suited us perfectly.

Our house, apart from its location and view, was unremarkable. Built in 1975, a timber frame provided the structure with white rendered blockwork keeping the worst of the weather off. Upstairs the rooms were ‘in the roof’ – the house was one and a half storeys high, with a couple of dormers to increase the usable space. This type of modern timber frame housing is ubiquitous in this part of the world.

With my curiosity piqued by the AECB course I started poking around our house. Under the carpet and floorboards, the suspended floor had no insulation at all. The loft and walls were not much better, with just a token 15 mm of glass wool insulation between the structural timbers. The windows were relatively recent UPVC double glazed but leaked badly around the frames. After a lot of deliberation we decided to go for a retrofit, and to target Enerphit certification as the outcome.

Before starting we had an airtightness test to establish the pre-retrofit airtightness. When the house was depressurised all the carpets lifted as air poured in between the floorboards. The tester had to admit defeat and couldn’t give a more accurate answer than more than 15 air changes per hour –our house was so leaky that the fan wasn’t big enough to maintain the 50 pascal pressure differential required for the test.

This fitted with our lived experience of the house. In cold weather it was uncomfortable – too hot close to the radiators and too cold everywhere else – and in hot, sunny weather the bedrooms upstairs remained unpleasantly hot well into the night. The oil cylinder feeding our old boiler needed refilling more often than either our finances or carbon conscience were comfortable with.

While I didn’t know of any examples of deep retrofit on modern timber frame houses, Chris Morgan’s excellent book ‘Sustainable Renovation’ had a couple of suggested details for how it might be done. These were my starting points. I started by thinking about insulating externally.

Doing this outside the existing blockwork looked risky in terms of thermal bypass,

thermal bridging and moisture, and removing the existing blockwork to insulate directly outside the timber frame came back with a whopping price tag from the contractor. I decided that insulating the walls from the inside was something I could largely do myself and I came up with a strategy –removing the plasterboard, removing the existing insulation then adding insulation between the studs, followed by tongue-andgroove woodfibre insulation board inside the studs, a vapour-control membrane and a service cavity to protect the membrane and allow easy running of electrical cables and hot water pipework around the house.

As I removed plasterboard from each room the extent to which moisture was a problem became clear; much of the insulation was covered in black mould. This was especially the case around electrical sockets where the air could more easily leak into and out of the walls, bringing with it moisture when going from the room and no doubt mould spores when coming into the room. This vindicated my decision to do a really good, moisturerobust job.

We used natural insulation throughout. This choice was partly to do with minimising moisture risk and partly because they are nicer to work with, but I also had half a mind on embodied carbon with every choice we made. I didn’t model the embodied carbon because in most cases our choices were simple and the lowest embodied carbon choice was relatively clear, but on a project with more

complicated decisions this would certainly be worthwhile.

Our floor joists were 180 mm deep. In order to meet the U-value requirements of the Enerphit component method I needed to add more insulation below the joists as well as between them.

I developed a detail where I extended the joists by 100 mm using pieces of ply, and then suspended a windtight, vapourpermeable membrane between these to create an enclosed space, protected from wind-washing, that I could add insulation to. The resulting space under and between the joists was quite a complex shape, so I used loose woodfibre insulation that could be packed into every nook. On top of the joists I fitted a vapour-barrier membrane to act as the airtightness line, and this was taped to the membrane in the walls. Continuing the airtightness line through internal walls was a challenge that required quite a lot of figuring things out on site, but generally I passed the membrane under the walls where I could and taped to the sole plate where I couldn’t.

Having the house at similar temperatures all summer, whether the weather is cool or warm was a luxury I hadn’t appreciated until living it.

We had brought in John Gilbert Architects to help with the architecture side of things, and by now I was also working full time for them as an energy specialist. Drew Carr was the project architect and brought an understanding of how to make the best of the building layout that I just didn’t have. He also brought a keen sense of aesthetics, and without him our house might have functioned very well – but looked terrible. He suggested rebuilding the first floor with

We knew that if we were going to stay in this house we needed more space – we only had three small bedrooms; our two boys were sharing a small room and our daughter had the small central room in the dormer. We considered various options for adding more space – extending out to the side into the driveway or out the back into the garden, but none of these seemed to work very well in terms of the layout of the house, and didn’t solve the problem that the existing rooms were small. Given that we were going to have to do radical things upstairs to improve the thermal performance we started to consider doing something really radical and completely rebuild the first floor as a full-height floor. The first floor in 1.5 storey houses loses a significant amount of space at the eaves, and by rebuilding to full height, or nearly full height, we could win extra space.

a shallower pitch on the roof to allow higher eaves without raising the height of the ridge beyond the height of neighbouring buildings. After some back-and-forth the result was a design with three reasonably sized bedrooms for the kids, a much bigger bedroom for us parents and a bigger bathroom. We even gained enough room for a new en-suite shower and a home office.

Drew also helped us improve the spaces on the ground floor; making the kitchen open plan with the dining room and making a separate utility room where we could hide hot water and ventilation plant as well as dry clothes and store an ever growing array of kit for biking, running, skiing and climbing.

Because the upstairs was new we were able to build really high performance walls and roof – deep I-joists filled with blown-in insulation and with airtight board on the inside – essentially how I would build a newbuild passive house, but built on top of our ground floor walls. The connection details needed a lot of thought to get them to work structurally while maintaining airtightness and insulation continuity.

Downstairs we were able to make some improvements to the window layout, the biggest of which was in the living room. Previously we’d had a large sliding door opening onto timber decking to the south, meaning the room quickly got too hot in sunny weather and the centre mullion of the sliding doors split the fantastic view of Ben Nevis right down the middle. We replaced this with a fixed window the same width but 400 mm less tall and with a window seat below.

This change reduced the overheating risk to this room (because the window is less tall) and significantly improved the view. Since this window is in a bay that projects out a small distance from the front of the house it gives a large and very popular window seat – effectively giving us an additional sofa in a part of the room that was little used before because it was either too hot in the sun or too cold at any other time. We also added an opening window to the east in this room to even out the light and to allow extra ventilation in summer or if we have a lot of guests.

The other opening on to the decking was a double door from the dining room. We replaced this with a single door and an opening window to the side. This reduced the total amount of glazing, reducing the overheating risk in sunny weather and giving us a window that can be left open overnight during hot weather. All other windows downstairs were kept the same size but replaced with beautiful triple glazed timber windows from specialist passive house supplier 21 Degrees.

Upstairs we had a clean slate in terms of windows, and were able to make the most of the previously neglected views to the south and north. Set in deep reveals these windows

insulation or

2

to reduce thermal bridging, with windtight membrane

to joists and loose fill

3 airtight membrane to floor; 4 existing blockwork rainscreen and timber frame extension; 5 existing timber frame ground floor wall fitted with 100 mm Thermojute insulation; 6 airtight layer on ground floor with service void; 7 airtightness detailing at first floor joists; 8 Finsa Vapourstop board serves as AVCL in the first floor. Note tapes over drill holes for cellulose insulation.

• Designed for the UK, with the highest levels of weather performance

• Triple glazed, with Swisspacer technology as standard

• Timber or aluminium clad timber options

• Dual compression seals that eliminate drafts

• Guaranteed for up to 10 years

• PHPP ready data, backed up with Flixo reports for certification

• Full fitting available from our expert in-house team

• Dedicated, specialist and experienced customer care

• Rated ‘Excellent’ on Trustpilot windows & doors | MVHR | heat pumps | solar batteries | passivhaus | low-energy design

perform brilliantly – harvesting the low winter sun and keeping the high summer sun out.

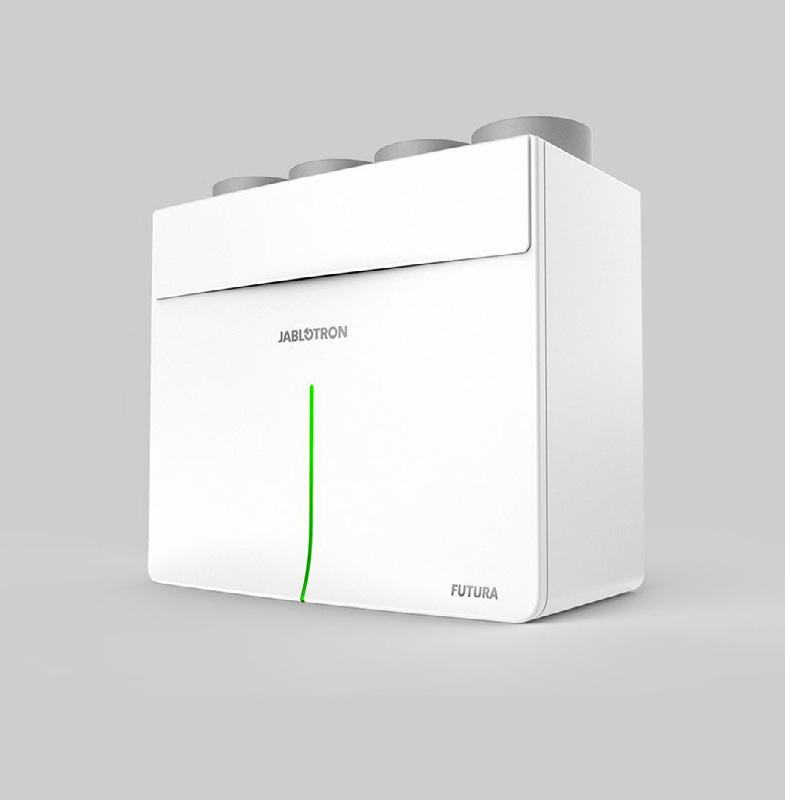

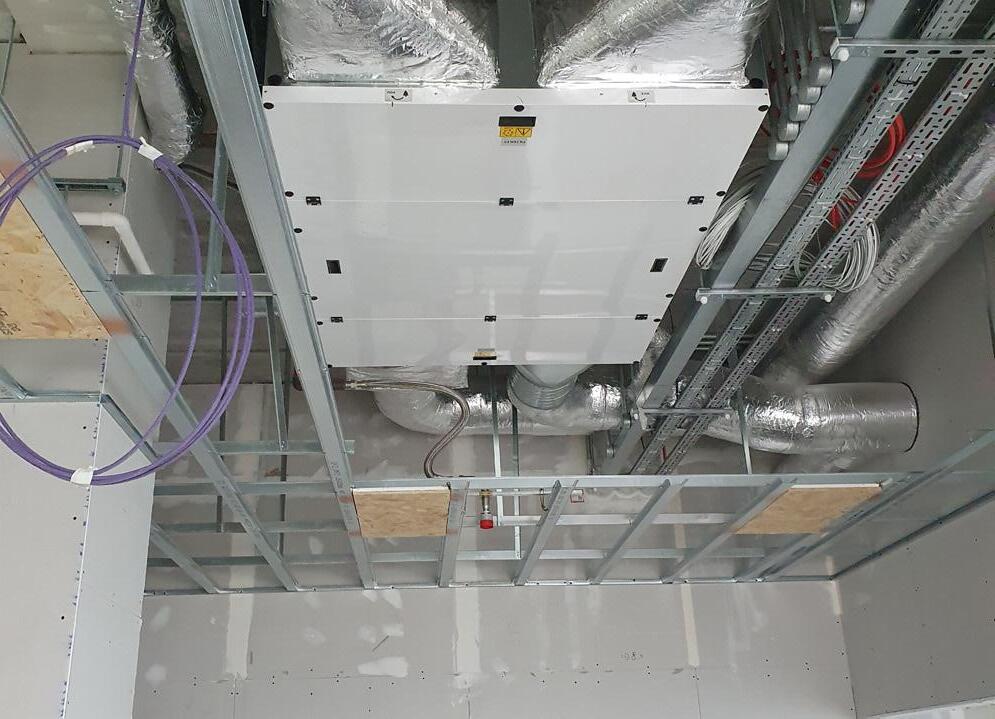

The MVHR was designed and commissioned by Paul Heat Recovery Scotland, who did an excellent job, but I did the install myself. We used semi-rigid radial ducting and were able to do a minimal amount of boxing out for ducts, manifold and silencers.

For the heating I took a novel approach, using a simple and very cheap air-to-air mini-split heat pump (aka an air conditioner) to supply heat to the dining room, with no heating in other rooms. The ground floor is relatively open plan, and a bit of modelling suggested that other rooms would get enough heat through internal doors most of the time. I planned for occasional back up heat from local plug in heaters if this was ever a problem.

This approach came about initially because when I spoke to a local heat pump installer I could not convince them that the heat load of the house would be below 5 kW (the size of the smallest air-to-water heat pumps), let alone the 1.5 kW the PHPP was suggesting. Mindful of how important sizing is to heat pump performance I started looking at alternatives. I also liked the idea that the radical things we had done to the fabric and ventilation of the house would allow us to save money on the capital cost of the heating system. The air-to-air minisplit ended up costing us £1,500 installed, a big saving on the typical cost of an air-to-water heat pump, even when factoring in that we had to make separate provision for hot water.

For hot water we went for a hot water heat pump – an insulated hot water cylinder with a small heat pump sitting on top. Typically, these are ducted to the outside and use outside air as their heat source, but we have ended up using the indoor air as our heat source. This decision also came about serendipitously – I had cored the holes for our MVHR supply and exhaust ducts in our concrete blockwork walls and my shoulders were keen that I didn’t do any more of this sort of work unless absolutely necessary. I decided there were potentially some other advantages to having the hot water heat pump stealing heat from the house and that we’d run the house for a trial period like this – I could always core some more holes if it didn’t work well. A centrally located hot water cylinder with radial 10 mm copper pipework minimizes

distribution heat loss and provides quick hot water delivery due to low pipe volume, though it requires good mains pressure.

Both showers are on the first floor, close to each other, meaning we could route the wastewater from these through a vertical wastewater heat recovery device. This reduces energy demand for showering by about 50 per cent and also meant we were able to go for a smaller (and cheaper) hot water cylinder.

We’d already lived in the house for a few months when we got the airtightness tester back in for the post-retrofit test. Usually, an interim test is a good idea to help identify and fix leaks before the airtightness line is covered up, but this wasn’t possible due to the sequencing of the project – the airtightness measures in some areas were covered up long before other areas were ready for

The Danes Have Always Had a Way of Changing Britain…

A timeline of surprising (and oddly life-improving) invasions.

865 AD – The Danelaw is established They came with axes and stayed for tea.

Result: 200 years of administrative reform, and the word “husband.”

1901 – Lurpak butter is born They came with butter. We never looked back.

Result: Millions of British Sunday breakfasts improved overnight.

1950s – Danish bacon arrives in UK supermarkets They came with rashers.

Result: A national obsession, a full English forever changed.

1958 – The LEGO brick is patented They came with plastic bricks and infinite imagination. Result: Every British child (and adult) learned to step carefully.

2025 – SkamoWall lands

They came with breathable, mould-resistant insulation boards.

Result: Healthier homes, happier families, and the end of damp walls.

Available in the UK from Ecomerchant Tel 01793 847 444 info@ecomerchant.co.uk www.ecomerchant.co.uk

testing. Having lived in the house we knew it performed, but I was still a little anxious that we would miss the Enerphit requirement. The final result came in at 0.46 air changes per hour, more than thirty times more airtight than the pre-retrofit house and comfortably under the Enerphit requirement of no more than 1 air change per hour.

Having lived back in the house for two years now it is everything we hoped it would be and more. Even as someone who spends their working life thinking about building performance I have been surprised by things. On the very first night I had a shower and hung the wet towel up, struck by a moment of doubt – how would the towel dry with no radiator and no direct heat in the room? In theory I knew that a high ventilation rate at 20C would dry it well, but my lived experience of houses here made it seem impossible; We live in one of the wettest places in the UK, almost every house here has a dehumidifier or a mould problem. Many have both. The next morning the towel was bone dry.

We expected the house would always be a nice temperature and it is, that drying out laundry and the endless wet kit from kids and adults sports would be much easier and it is, but things we hadn’t thought of surprised us often early on, and continue to occasionally; the window above the kitchen sink not steaming up when you drain pasta, the timber kitchen worktop still looking good, even around the sink where it’s constantly getting wet, because it doesn’t stay wet, my sense of smell becoming more sensitive because the air in the house is cleaner than outside, having to come back into the house to fetch a coat before the school run because you hadn’t realised how cold it was outside. Bedding feels much fresher than before, the house is beautifully quiet at night or when the neighbours are strimming the garden.

In summer the bypass on the MVHR automatically adjusts the amount of heat recovered to keep the house at the target temperature. This was something I hadn’t considered – normally I would turn the heating off in the spring and put up with whatever temperatures the house ended up at, often slightly chilly during cooler weather. Having the house at similar temperatures all summer, whether the weather is cool or warm was a luxury I hadn’t appreciated until living it. We’ve had two significant heat waves since moving back in. As predicted by modelling the house performs very well in these, but does need some temporary shading over the large living room window to avoid that room getting too warm. For now, I’ve a home-made shade from a friend’s old windsurf sail, and I’ll probably get a proper one made in due course. With this in place the house has stayed at 22 or 23C with outdoor temperatures of 28C and lots of sun. In these conditions walking into the house feels remarkable – like walking into an air-conditioned space.

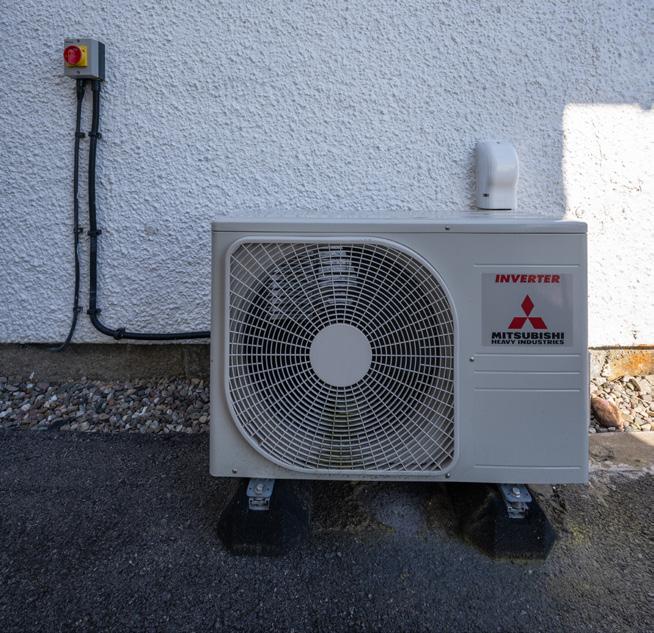

22 mm Gutex Multiplex Top sheathing board; 10 sealing the edge of the window cills to keep wind and water tight before cladding goes on; 11 taping and duct insulation for the supply and extract to the MVHR; 12 ducts labelled at manifold in case of future cleaning and maintenance needs; 13 outdoor unit of the Mitsubishi air-to-air heat pump; 14 the heat pump indoor unit with warm and cold refrigerant pipes running to it; 15 7 cm2 hole from the heat pump (£6 a year in heating costs) and a big impact on comfort if sat near this hole on a cold windy day; 16 a heat pump water heater draws heat from indoor air, its load reduced by waste water heat recovery and aerated shower heads.

Gramitherm is a groundbreaking, flexible insulation that’s the first of its kind in Ireland and the UK. This unique product delivers outstanding thermal and acoustic performance, while prioritising environmental sustainability.

Made from grass cuttings collected from public areas, combined with recycled jute fibres

Environmental Product Declaration, European Technical Approval, and Nature Plus certified

High thermal mass and low thermal conductivity enhance comfort in winter and summer

Natural hygroscopic properties help regulate humidity and enhances breathability

We’d previously run our house as cold as we could tolerate in the winter because of concern about climate change, and it took a while to get used to having a warm house. It felt so profligate to always have the house at a nice temperature, and we had a hard time trusting the modelling that even at comfortable temperatures the energy use would be very small. Once I had separate monitoring of the heat pump energy use we were able to relax a bit – the electricity use really was tiny. Our total cost for heating and hot water was just £175 for the first 12 months of monitoring. In the middle of an energy price crisis our heating and hot water was costing us less than half the cost of our internet connection.