3 minute read

W HY H vAC M AINTENANCE IS I MPORTANT Y EAR -R O u ND ?

HVAC maintenance is vital no matter the season, but your maintenance tasks will change depending on the time of year. Read our guide to spring, summer, fall and winter HVAC maintenance. Regular HVAC maintenance keeps your HVAC system performing efficiently and delivering conditioned air everywhere you need it. The nature of HVAC maintenance changes depending on the season, however. Here’s what you can expect throughout the year.

How to do HVAC Maintenance All Year?

Advertisement

Different parts of the system require different maintenance depending on the conditions they’re exposed to. Here are some of the maintenance tasks you’ll likely need to schedule on the different components of your HVAC system, though note that you should follow the manufacturer’s recommendations for how and how often to do maintenance on each part.

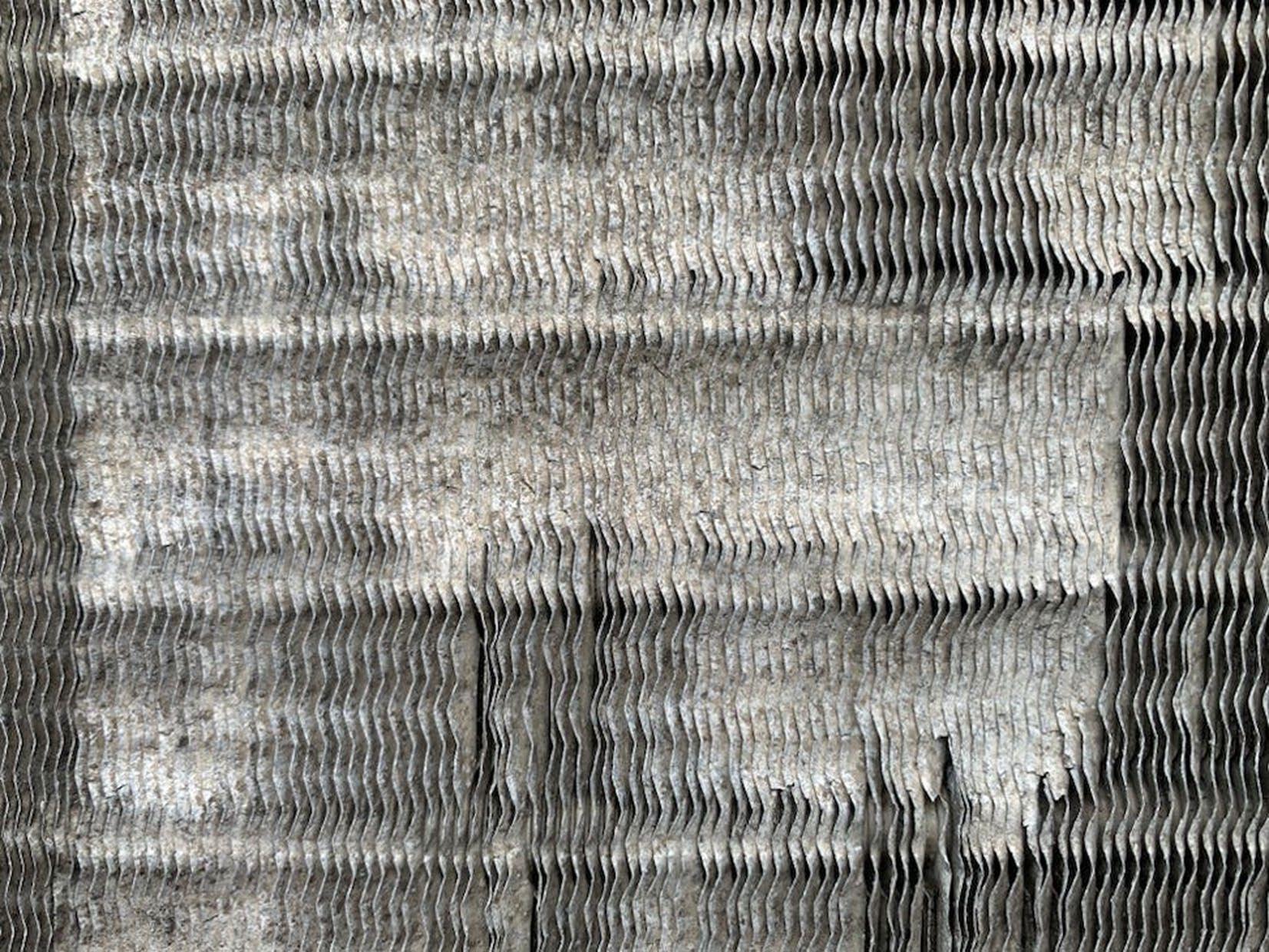

Coils

The coils and tubes in your HVAC equipment are responsible for heat transfer during both heating and cooling seasons. Heat is transferred out of your space during the summer and into your space during the winter via the fluid flowing through your coils. Dirty equipment won’t transfer heat and energy quite as well, so cleaning is the name of the game when it comes to annual coil maintenance.

Air-handling units should have their chilled water and hot water coils cleaned annually.

“Rooftop units and condensing units are a little different because these units are typically outdoors. “For rooftop units, you want to clean the evaporator coils. You’ll clean the condenser coils for both rooftop units and condensing units.”

For condensing units, this involves spraying the condenser coils (which are exposed to unfiltered outdoor air) with a microbial treatment that will prevent microorganisms from growing on the exposed coil.

You may need to clean more often than annually if your location demands it — for example, a building near a tree line that results in leaves getting trapped in the equipment.

Tubes

Tubes are very similar to coils in that they transfer heat. Pull out tubes annually to check for clogs and remove all of the debris — it can decrease your equipment’s capacity and efficiency. Plate and frame heat exchangers should also have their plates cleaned and the gasket replaced. Make sure nothing is clogging the space between the plates.

Cleaning tubes in the winter because chillers won’t be operating as much. Typically you might have one operating at partial load in the winter, so you can always service the other one while one is operating and vice versa.

Controls

Checking controls annually will ensure that your HVAC system is running properly.

Temperature sensor and thermostat calibration is one area you definitely want to focus on. Say the cooling setpoint of the space is 75 degrees F., but your thermostat is miscalibrated by 2 degrees. Therefore, in the summer, when your space is 77 degrees the thermostat is going to think you’re satisfied. You want to calibrate every year.

Control calibration tends to drift gradually, so periodic checkups are crucial to maintaining accurate operation. In addition to the main HVAC system checking the controls monitoring the temperature on heat tracing and other auxiliary equipment. The setpoints on heat tracing can drift just like the setpoints on any other controls.

Fans

Fans, as we all know, are chief components of many pieces of HVAC equipment. Many pieces of HVAC equipment incorporate fans, and they need to be maintained quarterly for maximum longevity. Concentrating maintenance in three key areas.

1. Wheels. The first item you want to look into for increasing the longevity of a fan is a dirty wheel. “That will put a lot of stress on the motor and reduce the airflow. It may also cause the fan to wobble, which puts a lot of stress on the bearings and causes noise issues.” He suggests vibration monitoring, which can reveal whether you have worn bearings that may be a symptom of something else.

2. Belts and belt tension. Belts that are too loose will slip, and belts that are too tight will stress the motor and bearings. Inspect the belts quarterly to make sure they’re not cracked or worn.

3. Bearings. Make sure your bearings are lubricated properly to reduce friction and corrosion.

Filters

Many pieces of your HVAC system also incorporate filters. Clogged filters increase the pressure drop in your HVAC system, making your fan work harder to maintain the same airflow (and ultimately reducing the airflow once your fan is working at maximum capacity). A quarterly cleaning for most filters, unless you’re in an area with higher-than-average particulates, such as high-pollen areas.

As we increase the total pressure as our filter gets clogged, our operating costs increase more and more. By adding an inch of static pressure, it’ll increase the operating costs of these units. If you have multiple units, that adds up.

Strainers

Strainers filter water in HVAC systems rather than air. Like air filters, a clogged strainer will increase the pressure drop in your HVAC system. For coil strainers, a blowdown process to flush debris out of the strainer so that you don’t have to isolate and drain that one piece of equipment.