5 minute read

Small plants, big gains

Sasha Strasser, Head Gas Solutions (Switzerland), and Toby Hahn, Global Technical Expert LNG (USA), Sulzer Chemtech, look at why small scale plants offer an ideal platform to enter the market for LNG fuel.

lobal demand for LNG is hitting record highs, offering producers the opportunity to grow at a blistering pace. To quickly boost throughput with only minimal investment, new and existing industry players can set up small scale LNG facilities. These support a rapid, capillary penetration in regional markets as well as future expansion.

The change to lower-carbon energy sources is driving the adoption of LNG, which is considered a transition fuel. This emits up to half the carbon dioxide (CO2) and offers a reduction of more than 90% in nitrogen oxides (NOx) and sulfur emissions when compared to conventional solutions. As a result, the LNG market is growing tremendously, with global demand for this resource expected to rise by 14% over the next four years and soar by 40 - 50% by 2031. Even more, 11 new potential import markets are predicted to be available by 2025.

In order to meet increasing global demand, LNG production needs to enhance its throughput accordingly to supply the required 485 million tpy. Therefore, this sector offers several highly appealing opportunities to new and existing businesses in this field.

Tapping into a new market often presents a number of technical challenges, but new players can rely on key chemical processing solutions to overcome them and provide a successful entry point. More precisely, to benefit from considerable profits, companies do not need to invest in large, expensive facilities that process millions of tonnes annually.

Small scale LNG facilities with a production capacity below 1 million tpy, or even under 500 000 tpy, offer a highly lucrative solution. In effect, a

global annual demand of up to 100 million t from small scale LNG is predicted by 2030. This means that the small scale LNG market, which currently accounts for approximately US$30 billion, is expected to almost double in a very short time, reaching an estimated value of US$50 billion by 2026.

When going small means going big

There are many reasons behind the growing role of small scale LNG. Firstly, its compact footprint, typically associated with modular designs, results in lower investment requirements as well as more immediate returns. Costeffectiveness can be further enhanced when LNG from small scale LNG plants can be delivered to users in its liquid form, as the need for regasification equipment that can increase CAPEX is eliminated.

The reduced cost of these facilities, which leads to more economical end-products, makes small scale LNG infrastructures highly attractive and strategic, even when the competition is fierce. Furthermore, these facilities can be expanded using a sustainable, modular approach to support the growth of the business, supply chain networks, and LNG market needs.

Perhaps the biggest benefit to users and the businesses serving them, is that small scale LNG plants can also be purpose-built to support localised demand. In particular, to maximise revenue, they can be strategically located to support customers that are currently underserved because other forms of energy are expensive, unavailable, or their supply is unreliable.

This is the case for three major end uses, namely fuel for heavy road transport, marine fuel (bunkering), and power generation in remote locations with no natural gas pipeline grid in the vicinity. More specifically, all these applications are expected to make up 42%, 32%, and 26% of the 2030 market, respectively. Similarly, small scale LNG facilities can be built close to the source, where the raw material is available.

By combining this availability with scalability and the possibility to maintain LNG in its liquid form, businesses can turn their plants into a network of fuelling stations for long haul trucks and marine vessels. This means they can benefit from reduced investment in regasification technologies, refrigerated pipelines, and fleets of vehicles to transport LNG. As a result, small scale LNG plants can maintain a low environmental footprint, making them profitable and competitive, even as carbon taxes become increasingly common worldwide.

Futureproofing the fuel industry

Ultimately, small scale LNG facilities support more flexible and agile operations, in line with just-in-time manufacturing, making these plants well-suited to meet growing customer demands and increasingly resilient to market fluctuations. Even more, they help producers to reduce their dependency on long-term offtake agreements with a single, large consumer in order to support the CAPEX of large scale infrastructures. Instead, companies leveraging small scale LNG can trade with numerous smaller end users on a spot or short-term basis, minimising investment risks.

The nature of small scale LNG plants, their business model, and strategies greatly differ from their larger scale counterparts. Therefore, to succeed in this market companies must implement processing technologies and solutions that are tailored to the needs of small scale LNG facilities. To this end, businesses should partner with a company that has extensive experience in designing small scale LNG facilities. In effect, a specialist, such as Sulzer Chemtech, can leverage its unique, thorough understanding of what these plants require as well as the design and delivery of micro, small, and medium scale LNG plants globally.

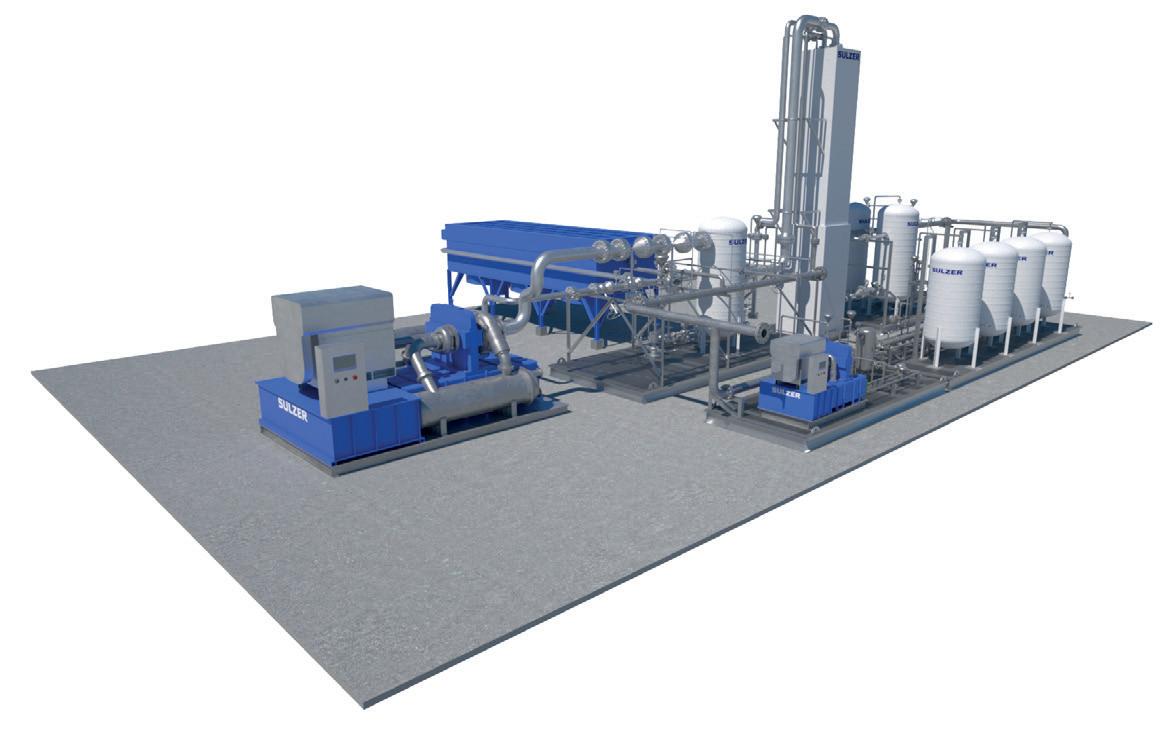

By simplicity of design the Sulzer small scale LNG process combines low CAPEX, low OPEX operations, and rapid returns for the customers. Sulzer Chemtech drives localisation of small scale LNG skid manufacturing as key to streamline project execution and minimise the required investment hurdles. As a gas technology licensor, Sulzer Chemtech provides a combined offering that includes feasibility studies; front-end engineering design (FEED); full basic engineering packages (BEP); proven, plug-and-play, skid-mounted process units with modular structures; as well as related commissioning and start up services. Sulzer Chemtech offers modular, skid-mounted, small scale LNG plants ranging from an average daily production capacity of 36 tpd up to 360 tpd of LNG. Almost any capacity in between can be economically realised.

Figure 1. Sulzer Chemtech provides processing technologies and fully integrated facilities that address the specific needs of small scale LNG production plants to drive competitiveness.

Enter the small scale LNG market now

There are considerable opportunities in the small scale LNG market, even for new industry players. As the sector continues to grow exponentially, it is crucial for companies to gain access to it quickly and ramp up their production of highquality, cost-effective fuel. By partnering with a full-service technology provider that has extensive experience in delivering competitive small scale LNG plants, such as Sulzer Chemtech, companies can rapidly achieve this. They can leverage stateof-the-art modular solutions with streamlined project execution timelines that maximise the potential benefits by slashing investment risks and providing near to immediate returns.