8 minute read

Tricks of the towing trade

Berit Vincentz Andersen, Svitzer, Denmark, outlines how the towing of LNG carriers in challenging conditions requires the best people, equipment, and a focus on safety.

Figure 1. Svitzer tugs servicing the LNG terminal in Bangladesh.

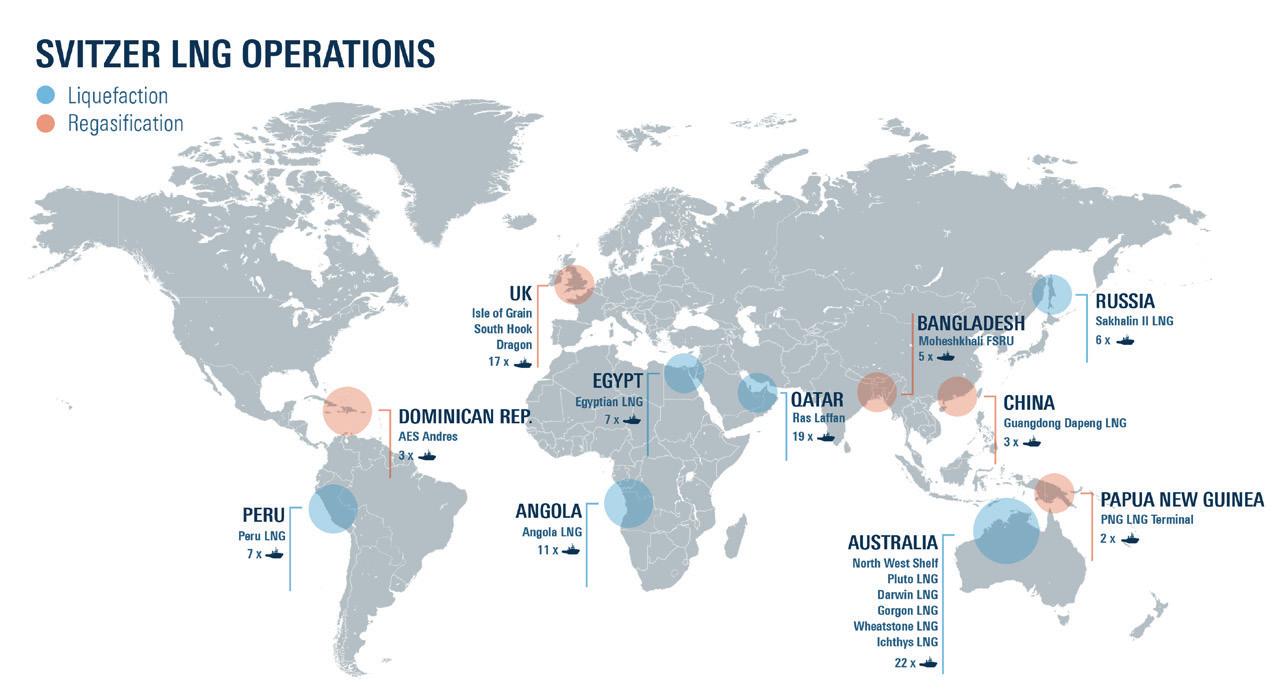

With roots stretching back nearly two centuries, global towage provider Svitzer is not only a company with a history, but a company with a strong heritage. Part of that heritage and part of the company’s DNA is doing difficult things in difficult places – be it port towage or oil and gas terminal towage, where Svitzer is involved in some of the most prestigious projects around the world and has long-term contracts with leading companies in the industry. LNG is an important fuel used worldwide and its use has surged exponentially over the last decade or so. In line with this, Svitzer’s experience with LNG projects has grown. Today, Svitzer’s LNG footprint has expanded to cover 18 operations in 11 countries, with a fleet of 102 vessels performing a multitude of services such as berthing and unberthing, pilotage, supporting ship-to-ship transfer, crew transfer, supply services, assistance with maintenance of an LNG terminal, channel buoy maintenance, safety and security standby, emergency response, and firefighting.

The services provided vary from operation to operation and are tailor made to meet the customer’s specific needs as well as the conditions of the location in question – for instance whether it is a land-based import or export LNG terminal, a floating LNG terminal, or an FSRU. However, a common denominator for operating LNG terminals is that reliability,

safety, and timely performance is a must. LNG carrier ships are in high demand and so is the need for quick turnaround times.

Operating under challenging conditions

Adding to the complexity of operating LNG terminals are the often-challenging and complex weather conditions in many locations where Svitzer operates – for instance severe ice conditions in Russia, currents of up to six knots in Angola, 2 m swell and fog in Peru, and a sensitive and delicate ecosystem in Australia, to name a few.

Each operation is very different from the next, hence each location must be carefully assessed as to which skills are required to ensure the operation is carried out safely and efficiently. Towing LNG carriers in icy waters compared to vessel manoeuvres in high winds and seas have their own individual challenges, and the masters and pilots must manoeuvre the ships in confined spaces as well as open seas. The tugs must therefore have state of the art equipment, including high-end complex winching systems, to ensure operations are completed with the utmost precision – in many cases with less than a few meters to spare.

The interaction and communication must be precise and clear with each team member working closely together from start to finish. The most technical part is the complex way the masters have to handle the azimuth stern drive tugs (ASD) specifically designed for such manoeuvres with LNG vessels. ASD methods have changed dramatically over the years – particularly with regards to high-speed ships, where direct towage methods are no longer practicable and/or effective in many situations and scenarios. Therefore, the tug masters must be able to control the tugs at a very high speed while simultaneously towing very powerful vessels, hence striking the balance between power and manoeuvrability is crucial.

No matter the location or type of terminal, extensive experience with operating under challenging conditions is needed, as Svitzer Global COO, Ingrid Uppelschoten Snelderwaard explains: “It requires a unique combination of skills, attitude, extensive training, and experience to complete operations in very challenging conditions. At Svitzer, we have vast experience as a result of working in the LNG sector for many years, but we have also invested time and resources – and will continue to do so – in extensive simulator trials with experienced masters and pilots who are familiar with each operation. This is to ensure that the correct tug configuration, tug type, and bollard pull are selected prior to and well in advance of the operation start up.”

Figure 2. Svitzer’s operations in Angola.

Every day a safe day

Figure 3. Svitzer’s LNG footprint. Operating under challenging conditions not only requires the best people, but it also requires the best equipment and a relentless focus on safety. Svitzer strives for operational efficiency, which includes ensuring the correct vessel is used for each operation. In most cases, LNG vessels are escorted by LNG vessel compatible tugs which have escort notation and full firefighting capabilities with specific enhancements to handle LNG cargo, including positive pressure systems enabling the tugs to engage in emergency response in the unlikely event of an incident. In addition, since reliability is an important factor for LNG terminals, all tug designs are tried and tested and have high spec engines and equipment. Additionally, sister tugs are often used to allow redundancy in terms of maintenance in most operations.

Svitzer works proactively together with its customers to ensure safe, reliable, and efficient services. The mantra is ‘safety first’ and Svitzer analyses each operation carefully and carries out extensive risk assessments together with the customer by bridging the standards of all parties involved in the operations, which then become the operational standard that ensures the safety of people, assets, and the environment.

Ingrid Uppelschoten Snelderwaard explains: “We take our safety responsibilities very seriously and always strive to prevent incidents from happening as well as ensure we learn from those that unfortunately do happen. We live by these principles every day and everywhere we operate. Our crews and frontline leaders are the experts on operational safety, and we promote collaboration and encourage dialogue to make sure that we learn from the occasional incident when things go wrong – as well as from all the times that things go right.”

Looking ahead

The future for LNG looks promising and as it is the cleanest fossil fuel, more and more consuming nations are looking towards

LNG to replace coal, especially in Asia which is still operating on coal for producing power. According to the Shell LNG Outlook, global demand for LNG increased to 360 million t in 2020 and is forecast to reach 700 million t by 2040 as demand for natural gas will continue to grow at high speed in Asia until alternate or green fuel has been developed and scaled up.

The past 10 years have seen an increase in countries with access to LNG, and with the development of FSRU technology, changes in local gas demand and supply can be met fairly easily as FSRUs are quicker and easier to establish compared to land-based terminals.

For Svitzer, this development represents promising growth opportunities and earlier this year, the company announced that it had signed a 10-year time charter party with FGEN LNG Corp. (FGEN LNG), a wholly-owned subsidiary of First Gen Corp. (First Gen) for the provision of towage and other vessel support services required by FGEN LNG’s Interim Offshore LNG Terminal (IOT) project, which will feature an FSRU located at the First Gen Clean Energy Complex in Batangas City in the Philippines.

Svitzer will provide four new 75 t bollard pull tugboats to assist the FSRU and LNG carriers that will deliver LNG to the complex, for berthing, unberthing, navigation assistance, and will provide other services including firefighting, pollution control, port and vessel security services, pilot and boarding party transfer, and fender management.

According to FGEN LNG, the IOT project as a whole will play a critical role in ensuring the energy security of the Philippines, particularly as the indigenous Malampaya gas resource is expected to be less reliable in producing and providing sufficient fuel supply for the country’s existing gas-fired power plants, and even less so for additional gas-fired power plants.

Figure 4. Svitzer operating in Angola.

Figure 5. Svitzer operating at the MLNG terminal in Bangladesh.

Figure 6. Svitzer operating at the LNG terminal in Idku, Egypt.

Becoming the preferred partner

The Maersk-owned company with headquarters in Copenhagen, Denmark, has firm growth ambitions and the goal is clear; to become the preferred LNG project partner – both when it comes to existing operational projects and greenfield projects such as FGEN LNG’s IOT project in the Philippines. Despite the positive growth perspectives for LNG projects, market conditions remain challenging for towage companies such as Svitzer.

As towage and marine solutions are very much a commoditised business, companies need to stand out from the crowd and offer solutions different from those of the competition. When bidding for FGEN LNG’s IOT project, Svitzer explored alternative ways to put together an attractive offer that went beyond just delivering steel and manpower, as Pankaj Kankan, Regional CCO in Svitzer’s Asia/Middle East/ Africa (AMEA) region explains: “At Svitzer, we very much believe in partnerships and building fit for purpose solutions together with customers to cater to their specific needs. That was also the thinking when we prepared the solution for FGEN LNG, where we focused on addressing the critical elements for our customer – especially since this is a greenfield project and by nature these projects have many pieces that must all come together and most importantly on time.”

“At the same time, we highlighted the Svitzer trademarks such as our solid experience with greenfield projects, our strong focus on safety, and our proven track record of delivering reliable and efficient services as well as showcasing how we would apply our global capabilities, know-how, network, and synergies locally to benefit the project.”

Operations in the Philippines are planned to commence in 3Q22, and Svitzer is now working on preparations to meet the start deadline, which include assessing the operational area together with the partners and commencing building the four new vessels that will service the complex.