IMPACT REPORT 2024

Green choices –rooted in reality

At Palcut, we take responsibility. For the environment. For people. And for running a business that makes sense – for us and the world around us.

Everyday decisions matter. That’s why we’re focused on reducing our footprint and developing solutions that make it easier for our customers to do the same.

Bold statements aren’t really our thing. We’d rather show than shout. Tangible actions. Real results.

It’s about data, improvements and real change. Sustainability isn’t something we talk about – it’s something we do.

We’re not at the finish line. But we’re on our way. Step by step – guided by data, experience and close collaboration. Because the green transition takes more than ambition. It takes action – and conviction.

Who we are – and why it matters?

For us, it’s not just about anti-slip paper and sheet dispensers. It’s about results. We help our customers achieve more stable pallets, faster production, smarter packaging – and fewer complaints.

For over 20 years, we’ve been one of Europe’s leading providers of intelligent palletising solutions. Today, we bring the same approach to partners across the world – with local warehouses, fast delivery and hands-on support.

We’ve got 900+ installations and over 70 global distributors. Add a team of experienced problem-solvers – and you’ll understand why we say quick support, reliable delivery and consistent quality aren’t just promises. They’re how we work.

At the core of it all is the Palcut Solution: The synergy between our anti-slip paper and fully automatic sheet dispensers. It’s this combination that boosts efficiency, reduces downtime and ensures stable deliveries – again and again.

Less waste. More uptime. Stronger deliveries.

We win with our customers. And we’re here to help them win every single day.

Built on what we believe in

At Palcut, our four core values aren’t something we hang on a wall. They’re embedded in how we work, collaborate and deliver – every day:

Responsible quality: FSC®certified paper. Stable pallets. Clear conscience.

Reliable delivery: Same high quality – every time. Delivered fast.

Quick support: No unnecessary waiting. No runaround.

Tailored to you: The solution fits your production. Not the other way round.

Fewer resources. Stronger results.

How are we doing on sustainability – in practice? Here are some of the numbers that show our direction – and progress.

Growth is clear. Production is up, while paper waste is down. That means better use of resources – and stronger results across the board.

In 2024, we bought 418 tonnes more raw paper – but sent 16 tonnes less to

and

Certified responsibility – from A to ISO

Our certifications aren’t just paperwork – they’re proof of our standards.

We work with third-party certified solutions that demonstrate our commitment to quality, the environment, and corporate responsibility. When we say our solutions are responsible, stable, and thoroughly tested – this is where we prove it:

FSC®-CERTIFIED ANTI-SLIP PAPER

We are FSC® certified under the FSC Recycled 100% label. All our paper is based on documented recycled content that protects forests and supports responsible consumption.

ISEGA-CERTIFIED

Our Antim and Liquim anti-slip paper is approved for use in food production as tertiary packaging.

QUALITY MANAGEMENT

Our quality is structured, monitored and continuously improved (certified by Bureau Veritas).

ENVIRONMENTAL MANAGEMENT

We monitor our environmental impact and work systematically to minimise it. (certified by Bureau Veritas).

Less talk. More CO2 reduction.

Sustainability isn’t a headline at Palcut. It’s a target – backed by documented reductions.

Our CO2 efforts are anchored in the UN Sustainable Development Goals (SDGs) – specifically goals 7, 12 and 15. That’s where we can make the most impact in practice.

We’re committed to the Science Based Targets initiative (SBTi) and have set concrete targets: We aim to reduce our Scope 1 and 2 emissions by 42% by 2030 campared to emissions measured in 2021.

In 2024, we also started tracking Scope 3 emissions – such as raw materials, transport and suppliers.

This is how far we've come – and we're not finished yet

Scope 1 Scope 2

• Scope 1 emissions increased from 51.3 to 58.4 tonnes CO2e in 2024. This rise is due to increased production activity and, consequently, higher energy demand.

• Scope 2 emissions dropped from 114 to 106 tonnes. This reflects a more energy-efficient production process and improved electricity utilisation.

BEYOND THE NUMBERS:

Curious how we do it? Turn the page.

Lower CO2 starts with small everyday adjustments

Less CO2 starts with better habits. At Palcut, we work with circular economy as an integrated part of our production – constantly fine-tuning to use fewer resources, reuse more, and cut waste where it really matters.

Our own production is our biggest climate contributor. That’s why we focus on how we can reuse, optimise and repeat processes – without compromising on quality.

It might sound low-tech. And it is. But it works.

Here’s what it looks like in practice

Below are some of the concrete adjustments we work with every day:

Reusing cardboard cores: Our core tubes (from the paper rolls) are reused 5 times before being replaced. That saves both waste and resources.

Closed-loop system: Excess friction material is reused in production – nothing goes to waste.

Water-based coating: We use an environmentally friendly coating without harmful solvents – which also makes recycling easier.

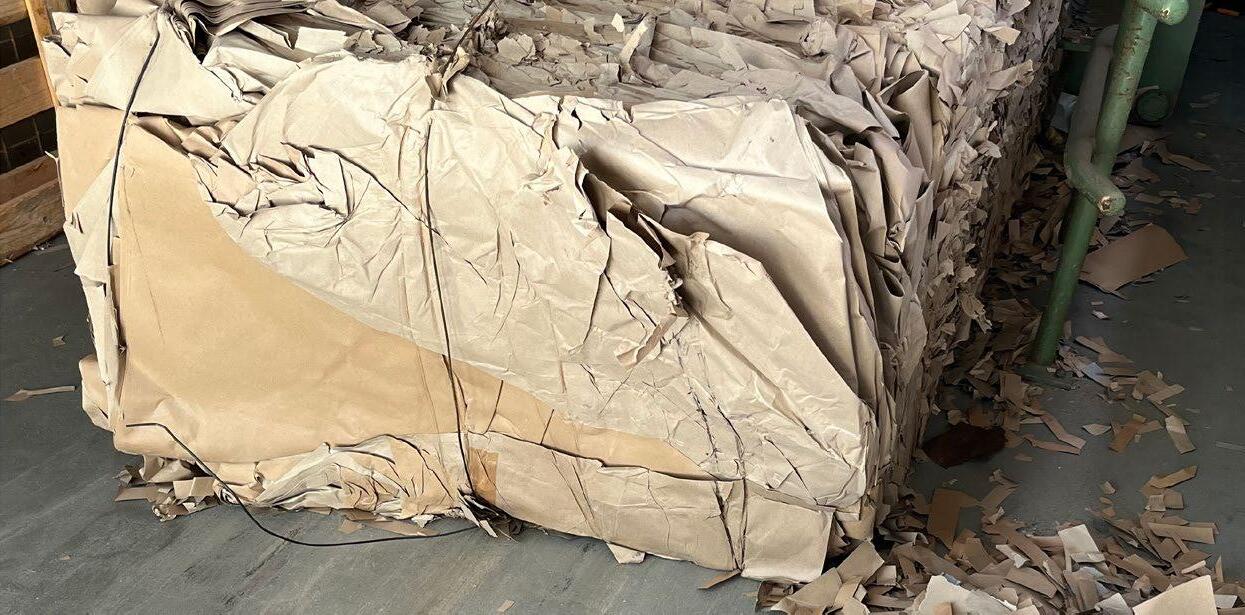

Paper waste for recycling: All excess paper is compressed and sent for recycling.

New wash station on the way (2025): From next year, we’ll clean rollers using recycled water and glue – cutting waste even more.

And it doesn’t stop at the factory gate. Our approach to CO2 and resources is all connected –all the way through the value chain. See how on the next page.

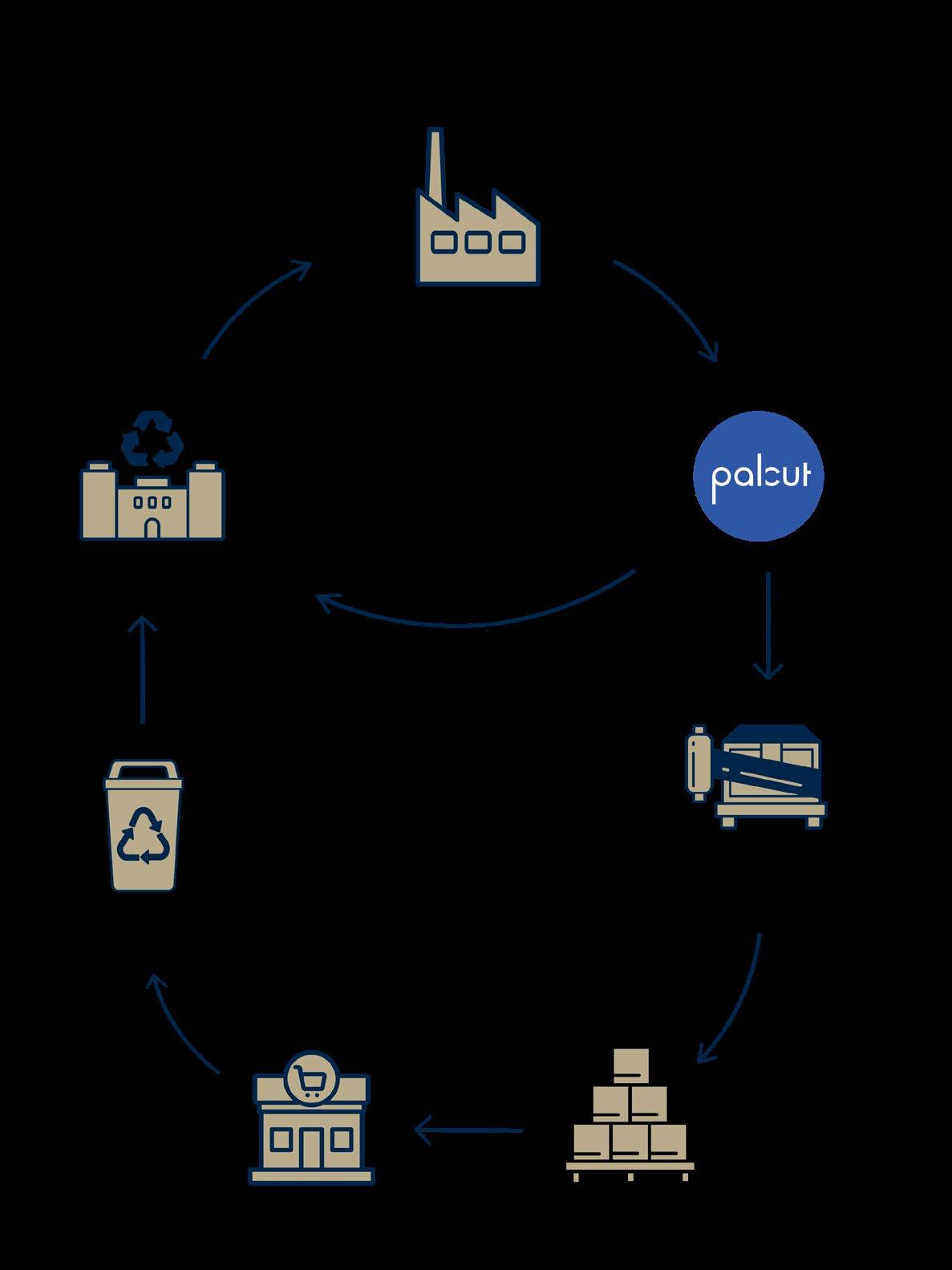

FSC®-certified paper mill

FROM PAPER TO PALLET – AND BACK AGAIN

From FSC®-certified paper to renewed use: Our solutions are designed to fit into a circular value chain – with responsibility at every stage.

Palcut distributor

Recycling facility

Energy and resources – less in, more out

We’ve significantly reduced both electricity and water use in 2024 – while increasing the share of renewable energy to 80%.

More electricity from green sources

We cut where it counts

Our improvements aren’t the result of major investments – but small, targeted adjustments in our daily operations:

• Drying zones were optimised so adhesive could dry at lower temperatures

• The coating machine was updated with new programmes to reduce energy use and waste

• Machines are fully switched off when not in use – not just left on standby.

Small adjustments. Lower consumption. Bigger impact – every day.

We take care of our most important resource

Skilled people are the key to everything we aim to achieve. That’s why we’re committed to being a workplace where both current and future employees can thrive – and grow.

Development drives well-being

When we listen and create space for professional and personal development, both job satisfaction and performance grow. It strengthens retention – and helps us attract the right people in a constantly changing industry.

We work in a sector where the gender balance is traditionally skewed – and that’s true for us too. Many roles still involve physical handling of large paper rolls and machines. While we use ergonomic tools, some tasks still require hands-on work.

We hire based on qualifications and potential – with a focus on equal opportunities for all. Even though we don’t set fixed gender targets, we track the numbers and act when it makes sense.

THIS IS WHAT IT LOOKED LIKE IN 2024:

We’re keeping a close eye on the development – and continuing to build a workplace with equal opportunities for all, regardless of gender or background.

When well-being is felt – and measured

Well-being is not just something we feel – it can be measured too. In 2024, our employee turnover was 6.06%, and sickness absence remained at an acceptable level.

We also work for fair and transparent pay. In 2024, the gender pay ratio was 1.05 – a small difference that largely reflects the distribution of roles in production and management.

We measure what matters – and the numbers show we’re on the right track:

Balance at home = energy at work

Good work starts with a good everyday life. That’s why we offer flexible working hours – so there’s space for both job tasks and family life.

When the balance is there, it shows – in our teamwork, energy and what we deliver.

Looking after our people – and the future

Safety is non-negotiable – especially in production. We use ergonomic tools and offer a health scheme with access to, for example, massage, to prevent injuries and keep people going.

We’ve had no workplace accidents since 2021. That’s something we’re proud of – and we’ll continue to meet every safety requirement and look out for each other.

The direction is set – and we’re moving

Effective management requires clear direction. Our professional board ensures exactly that –enabling strong governance and strategic progress.

The board consists of a chairperson and representatives for shareholders, ensuring broad representation of our key stakeholders. With 100% attendance at board meetings in 2024, we see high commitment and responsible leadership.

There are currently no women on the board – but we aim to change that. In 2025, we plan to appoint a female representative and strengthen diversity moving forward. At the same time, we aim to broaden perspectives in decision-making and further reinforce our strategic foundation.

Strong decisions start with openness

We believe in openness and honest dialogue – both internally and with our surroundings. With a flat structure and close collaboration, we prioritise employee input. That makes us more agile – and better equipped for change.

Quality that lasts – and keeps us running

Our ISO 9001:2015 certification helps us streamline processes and ensure high quality in our work. Our quality management system is embedded across the organisation and clearly defines what’s expected – and how we deliver it together. When we get it right internally, our customers feel it in the collaboration.

IT STARTS WITH GOVERNANCE

Turn the page – and see how leadership and quality pave the way for lower CO2 emissions.

SDG 7 – sustainable energy

At Palcut, we support Sustainable Development Goal 7 (SDG 7), which focuses on ensuring access to affordable and clean energy for all. For us, that means reducing CO2 emissions and using energy more efficiently.

We have chosen to focus on sub-goal 7.3, which targets improved energy efficiency. That’s where we can make the biggest difference – both in our production and in the solutions we deliver to customers.

Sub-goal 7.3 – improving energy efficiency

We work continuously to optimise energy use throughout our production. That includes finetuning our machinery, reducing waste and improving electricity usage.

CO2 calculations play a key role in our processes. They help us find solutions that make production more energy-efficient – without compromising on quality.

Our aim? To go even further by using fewer resources and reducing consumption of raw materials and auxiliary products by 2030.

ENERGY EFFICIENCY GOES BEYOND THE FACTORY

We also look beyond the factory – for example, how we transport our products and optimise our footprint all the way to the customer.

That’s why we continuously invest in new technologies and solutions that support our goal: a CO2-neutral future.

SDG 12 – responsible consumption and production

At Palcut, we support SDG 12 by focusing on reducing waste, improving resource efficiency and strengthening the circular economy in our production.

We focus especially on sub-goal 12.5, which is all about reducing waste – and using our paper smarter.

Sub-goal 12.5 – substantially reduce waste

One layer at a time. Our anti-slip paper is designed to reduce waste and get more out of each roll.

Through initiatives such as reusing cardboard cores, optimising production processes and improving sorting, we´re constantly working to reduce waste and use resources more efficiently.

The goal? To reduce the consumption of raw materials and auxiliary products by 2030 – and create stronger, more sustainable solutions for our customers.

SDG 15 – life on land

Our FSC®-certified paper supports sustainable forest management. That means our products help protect nature and ensure responsible use of forest resources.

We work particularly with sub-goal 15.2, which focuses on halting deforestation and supporting reforestation.

Sub-goal 15.2 – stop deforestation and restore degraded forests

95% of our paper is recycled – only 5% comes from virgin fibres. That reduces the need for logging and lowers our CO2 footprint.

When our paper is returned for recycling, we help close the loop and support a circular paper economy.

From responsible forestry to efficient production – FSC® is your guarantee for paper made with care. And that applies to every single sheet we deliver.

Sustainability in numbers

Key figures from 2023 and 2024 – based on internal data, used actively to track progress and drive improvement across climate, energy and people.

Behind the numbers

This report has not been reviewed by an external third party.

We’ve done our best to ensure up-to-date and reliable data, but we cannot guarantee 100% accuracy.

Palcut assumes no liability for any decisions made based on the contents of this report. This Impact Report is made with Valified