PRODUCT CATALOG

Is your palletizing as efficient as it could be?

As a manufacturing company, palletizing and transportation of your products are crucial to the flow, efficiency, and financials of your business. At Palcut, we are constantly striving for new standards within packaging to optimize your palletizing. We have summarized our recommendations and selected cases and aim to maximize your potential by optimizing your uptime, increasing your efficiency and reducing your costs.

WHY ANTI-SLIP PAPER?

Optimize your transportation with anti-slip paper

Say goodbye to the frustration of transportation damage and financial losses. With our anti-slip paper, unstable and insecure transport is a thing of the past. The friction coating ensures that your products remain on the pallet – all the way from production to the end customer. The paper is used between the product layers on the pallet and can be delivered as pre-cut sheets or in reels – depending on the type of paper and your specific requirements.

Palcut’s anti-slip paper is approved and certified by ISEGA in Germany for safe secondary or indirect contact with the food. We take social responsibility by exclusively using 100% recyclable FSC® certified paper (FSC®C147797), among other actions.

Antim®

The paper that keeps your products stable on the pallet

Antim is based on a testliner and ensures the ultimate stability of your products in the warehouse and all the way to the customer. The paper has a slip angle of more than 50° (TAPPI 548 standard), which means that your products will stay on the pallet, virtually regardless of terrain and speed.

WHERE CAN YOU USE ANTIM?

Antim is our bestseller, as the paper provides an efficient solution to most challenges. What’s more, Antim is especially suitable for heavy, slippery or bulky items.

Would you like to order a product sample?

Scan the QR code here or get in touch with your local supplier.

Antim® X

The paper that ensures secure transportation

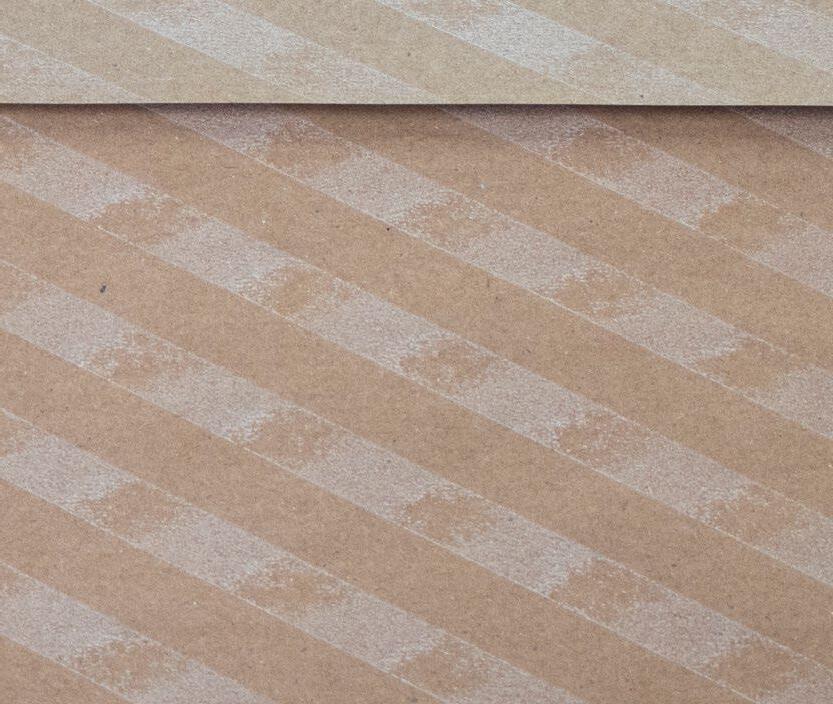

Antim X has a slip angle of over 45° and a coating applied in diagonal stripes. The paper ensures stable pallets in the warehouse, during transportation, as well as in the shops. Antim X is our most affordable paper. Therefore, it is a sensible choice if you do not require stabilization for heavy items and strong friction is not necessary.

WHERE CAN YOU USE ANTIM X?

The friction coating on Antim X is applied in diagonal stripes, which means that the paper can handle the same challenges as Antim but is recommended for lighter items.

Would you like to order a product sample?

Scan the QR code here or get in touch with your local supplier.

Tilt test

Antim makes a difference

We have tested our Antim interlayer sheets to illustrate the difference between transportation with and without the popular anti-slip paper. We placed eight boxes weighing 33 lbs. each in four layers on a pallet. Firstly, we conducted a test where we tilted the load without interlayer sheets between the layers. Then, we performed a test with two interlayer sheets and finally a test with four sheets. The results were as follows:

It may not sound like much, with a difference of 7.3° from not using interlayer sheets, to using interlayer sheets between all layers, but it can be the difference between a damage claim and a happy customer. If you think that a tilt of 19° is sufficient for your needs, and your goods are rarely damaged or shifted on the pallet during transport, then consider this additional benefit of interlayer sheets: By using interlayer sheets, you can achieve significant cost savings on stretch film. The Antim sheets improve load stability, reducing the number of wraps of stretch film you will require. Additionally, with the developments in recycled packaging, it will be cheaper and easier to recycle paper than plastic.

The load shifts at

The load tilts at

From lost boxes to a doubling of production speed

The challenge isn’t always external transportation via trailers or railcars – often, it’s short internal distances that present challenges for the stability of pallets with several product layers. This was the case for a food producer in the USA, where forklifts in the warehouse had to drive slowly from the palletizer to the stretch wrapper to prevent boxes of food from falling off the pallet. If they had used the self-driving robots, they would have had to run after them and pick up the boxes. Antim interlayer sheets between the top four layers of boxes was the solution that resulted in the manufacturer doubling the daily production rate from 1,000 to 2,000 pallets.

ADDITIONAL BENEFIT OF USING BASE SHEETS

When you use paper from Palcut as a base sheet, you reduce the pressure of the load and strengthen both the capacity and stability. When there is no base sheet, it does not take much before the stretch film loses its grip on the pallet. If you have a load that slips and the stretch film comes off the pallet, then there is no longer contact between the products and the pallet, which can result in it tipping over or collapsing. If an anti-slip base sheet is added, it creates friction that allows for better contact. You will also be able to prevent unevenness from boxes placed with one side in one of the pallet's grooves. You also benefit financially and environmentally when you use Antim or Antim X interlayer sheets to strengthen the load by saving up to 30% on stretch film.

Data sheet

Antim®

Antim is the paper that stabilizes your products, whatever the challenge.

Antim

Antim has a slip angle of more than 50° and is our bestseller. The anti-slip coating ensures ultimate stability on pallets in the warehouse and during transportation – all the way to the customer.

Antim is available with a single-sided coating, which is advantageous when products need to be moved and transported as well as for manual palletizing and de-palletizing. The downward-facing coating ensures stability while the upward-facing side allows for a full range of movement.

Available in reels and as sheets

Meets the transport safety standards

Especially suitable for heavy and unwieldy products

Reduces the use of stretch film

100% recyclable paper

Antim X

Antim X has a slip angle of more than 45° and is characterized by the diagonal stripes of coating. The paper ensures stable pallets at the warehouse, in shops, and during transportation and is a clear choice for lighter products.

Available in reels and in sheets

Less coating, lower price

Stabilizes pallets during transportation

Reduces the use of stretch film

100% recyclable paper

As we use recycled paper/cardboard, there may be color differences in the paper.

Coating: Water-based emulsion.

Recommended storage conditions: Temperature: 50-104°F, Humidity: 45-60%.

Approved as non-slip paper in the field of food packaging with no direct food contact – Certified by ISEGA Germany

Recommended maximum storage: 12 months.

* Length and width of sheets +/- 1.5%. Width of reel +/- 1.5%

For other weights or formats, please send us an enquiry.

Please note that this is a guide. If you have any questions or concerns, we recommend that you consult with an expert to find the right paper type for your specific requirements.

Liquim® GOLD

Avoid leakages and minimize losses

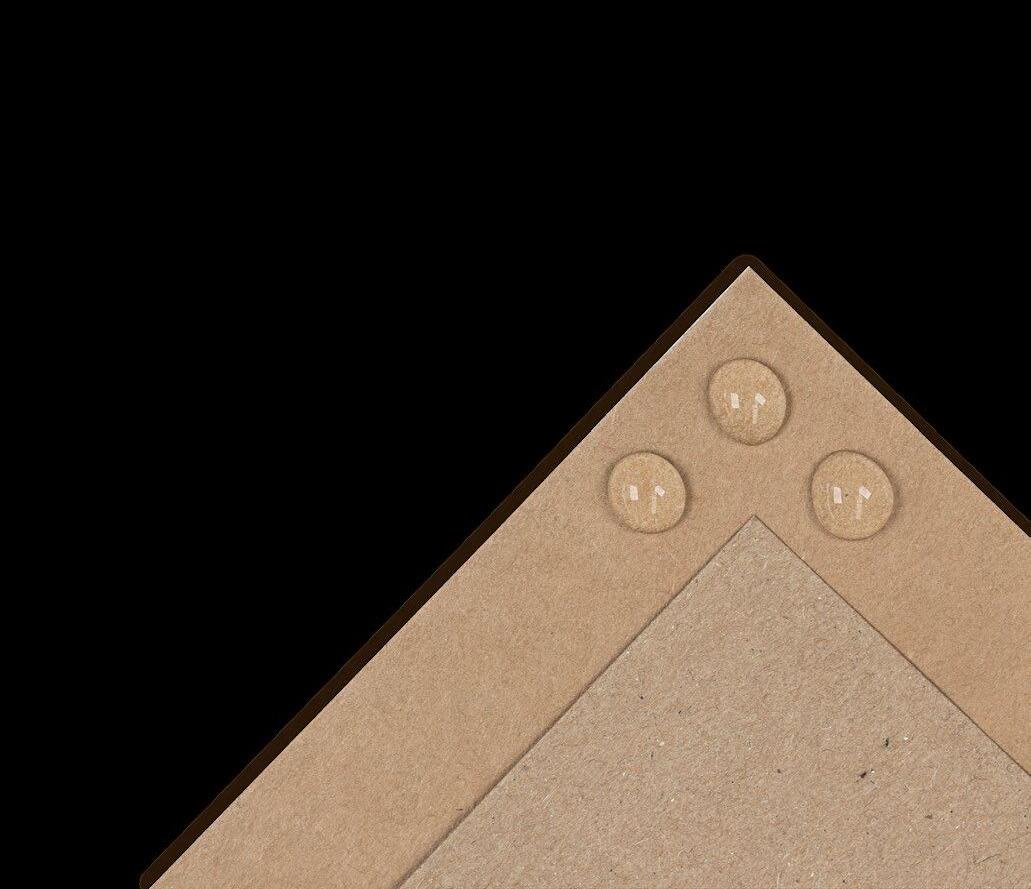

The paper’s liquid-resistant barrier and double-sided anti-slip coating ensures the ultimate stability of your products at the warehouse and all the way to the customer.

WHERE CAN YOU USE LIQUIM GOLD?

Liquim GOLD is ideal for products such as bulk bags, chemicals and pharmaceuticals. In the liquids industries there should not be any slippages, since leakage in one unit often results in the entire pallet being discarded, resulting in huge financial losses. If a leak were to occur, the liquid-resistant barrier would prevent the leak from spreading.

NOTE: Please be aware that the dark side of the paper repels water most effectively.

Would you like to order a product sample?

Scan the QR code here or get in touch with your local supplier.

Liquim® SILVER

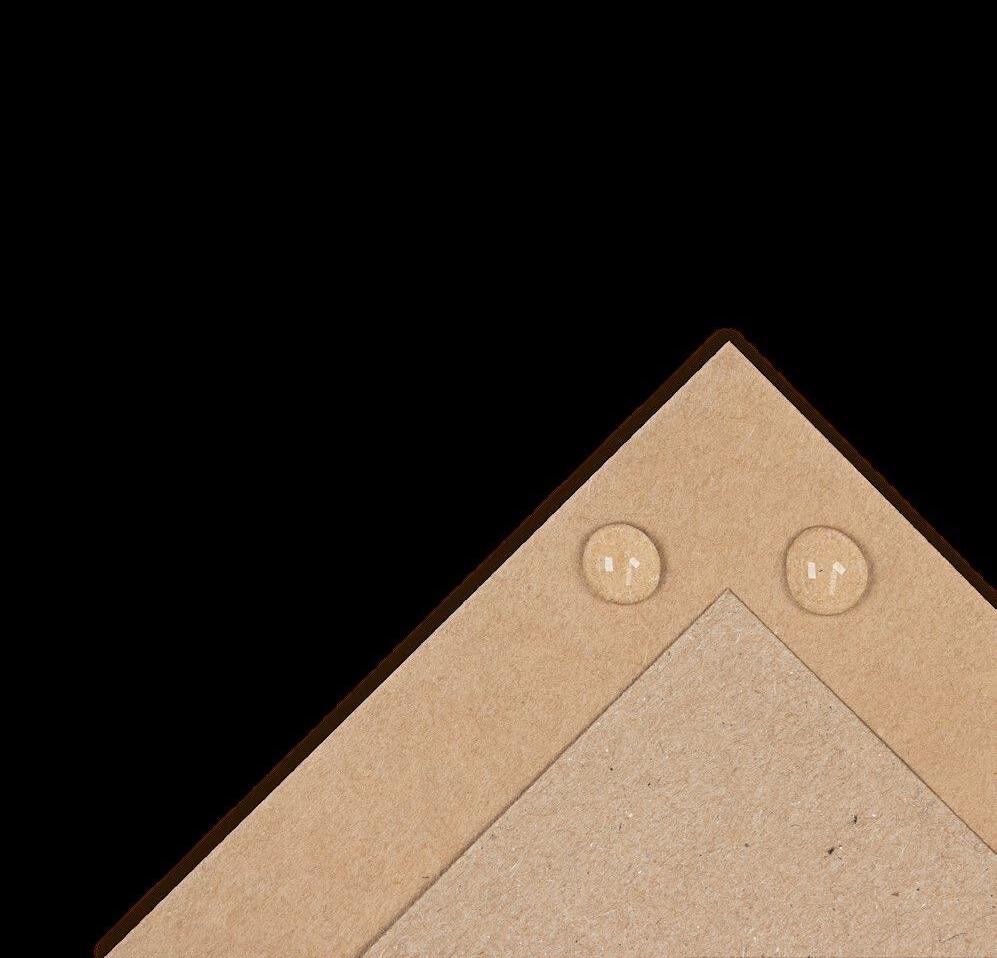

Prevent condensation from affecting the pallet’s stability

The paper’s liquid-resistant barrier and one-sided anti-slip coating makes the paper especially suitable for transport where condensation can occur.

WHERE CAN YOU USE LIQUIM SILVER?

Liquim SILVER is suitable for transportation in humid environments, or where fluctuating temperatures cause condensation. While condensation can destroy conventional interlayer sheets and significantly impair the stability of the pallet, Liquim SILVER ensures that the sheet retains its strength and keeps the pallet stable all the way to the customer. The one-sided coating can also help to facilitate palletizing when products need to be moved and repositioned, as well as with manual palletizing. The downward-facing coating ensures stability while the upward-facing side allows for a full range of movement.

NOTE: Please be aware that the dark side of the paper repels water most effectively.

Would you like to order a product sample?

Scan the QR code here or get in touch with your local supplier.

Condensation does not have to be a source of frustration

An example of the effect of

Liquim SILVER

In Southern Europe summers are very hot. However, the spring water, which is pumped from underground and poured into bottles, is no more than 45°F. When the water bottles are shipped to supermarkets, they are transported on trucks where temperatures easily reach 120°F.

Such temperature changes result in immediate condensation formation. The condensation runs down into the corrugated tier sheets, which are conventionally used for shipping water bottles, and dissolves them so that they are destroyed, compromising the stability of the entire pallet.

If you replace the corrugated sheets with Liquim SILVER, condensation will settle on the paper and soak in after some time, but the liquid will remain in the paper so that it can become dry again without being destroyed. Therefore, the stability is not affected.

Liquim® BRONZE

Prevent moisture from pallets from penetrating products

The paper’s liquid-resistant core makes it suitable for protecting your products against moisture from pallets, while being completely plastic-free.

WHERE CAN YOU USE LIQUIM BRONZE?

Liquim BRONZE is for the environmentally conscious company that requires interlayer sheets with a liquid-resistant function without any anti-slip feature/coating and would also like to reduce plastic consumption. Liquim BRONZE is ideal as a base sheet, as it reduces the moisture from wet pallets penetrating through the paper and into your products.

NOTE: Please be aware that the dark side of the paper repels water most effectively.

Would you like to order a product sample?

Scan the QR code here or get in touch with your local supplier.

Data sheet

Liquim®

Liquim is the paper that maintains pallet stability, even in the case of condensation and leakage.

Liquim GOLD

Liquim GOLD has a liquid-resistant barrier and double-sided anti-slip coating for ultimate stability during transportation, at the warehouse and in the shops.

Available in reels and in sheets

Liquid-resistant barrier and antislip coating in a single paper

Maintains pallet stability despite condensation 100% recyclable paper

Liquim SILVER

Liquim SILVER has a liquid-resistant barrier and anti-slip coating on one side that makes it suitable for transport in damp environments.

Available in reels

Liquid-resistant barrier and one-sided anti-slip coating

Prevents damage and collapse due to condensation 100% recyclable paper

Liquim BRONZE

Liquim BRONZE has a liquid-resistant and plastic-free core that keeps moisture from pallets away from your products.

Available in reels and as sheets

Liquid-resistant barrier with no anti-slip coating

Keeps products dry despite condensation

100% recyclable paper

The Liquim product is resistant to moisture penetration when the humidity level of a wooden pallet surface is maximum 14%. There may be color differences in the paper as it is made of a mix of recycled- and virgin paper fibers.

*The dark side of the paper is most resistant to liquids.

** Width and length of sheets +/- 1.5%. Width of reel +/- 1.5%

Coating: Water-based emulsion.

Recommended storage conditions: Temperature: 50-104°F, Humidity: 45-60%.

Recommended maximum storage: 12 months.

For other weights or formats, please send us an enquiry.

Please note that this is a guide. If you have any questions or concerns, we recommend that you consult with an expert to find the right paper type for your specific requirements.

Testliner

Versatile paper with good strength

Testliner is a double-layered paper produced from recycled fibres. One layer consists of strong recycled fibres that give the paper good strength properties.

WHERE CAN YOU USE LINERBOARD?

Testliner is good in situations where protection of products is beneficial, but further stabilization is not necessary. This could be in relation to stacking items that are subsequently packed in boxes.

Want to see more about the product?

Scan the QR code here or get in touch with your local supplier.

Data sheet

Testliner

Strong paper with many functions.

Testliner

Testliner is an interlayer sheet without antislip coating. The paper is made from strong recycled fibres that give the paper good strength properties.

As we use recycled paper/cardboard, there may be color differences in the paper.

Recommended storage conditions: Temperature: 50-104°F, Humidity: 45-60%. For other grammages or formats, please send us an enquiry.

Available in reels and in sheets

Good replacement for corrugated cardboard

Good paper strength 100% recyclable paper

Please note that this is a guide. If you have any questions or concerns, we recommend that you consult with an expert to find the right paper type for your specific requirements.

Sheet dispensers

Simplify your workflow and change reels in a split second

Unnecessary downtime in production is inefficient and expensive. With our fully automatic sheet dispenser you get a unique machine to dispense interlayer sheets for palletizing. Just relax. A Palcut sheet dispenser is not just another machine in your production. A sheet dispenser from Palcut ensures lightning-fast workflows and less downtime so you can reduce your costs from day one.

THE SHEET DISPENSER YOUR PRODUCTION WILL NEVER AGAIN WANT TO BE WITHOUT

Palcut 800 and Palcut 1200 are our fully automatic sheet dispensers, which quickly and precisely cut interlayer sheets directly from a paper reel with anti-slip paper. The sheet dispenser always ensures that only one sheet at a time is ready for collection, which eliminates spontaneous production stoppages resulting from incorrect lifting when the robot collects multiple sheets and/or drops excess sheets. Palcut 800 and Palcut 1200 indicate the maximum reel width of each respective sheet dispenser. A sheet dispenser is especially suitable for companies with a high sheet consumption or where automatic palletizing units must run continuously.

A Palcut sheet dispenser accommodates your production and pallet sizes – even if they vary from day to day or hour to hour. Downtime and production stoppages are a thing of the past, and your production speed can be kept at a steady pace. By fully automatic we mean fully automatic, and the advantages are many:

•

•

•

•

•

• you avoid picking up more than one sheet at a time you have automatic switching between 15 pre-programmed sheet sizes –changing sheet sizes is as easy as pressing a button or via an external signal from the palletizing control system you optimize the robot’s working speed, since the collection height is fixed you reduce the number of production stoppages by up to 90% you get extremely user-friendly operation you get easy integration with the palletizing control system

INTEGRATION OF THE SHEET DISPENSER

Both Palcut 800 and Palcut 1200 can be positioned for a custom fit in your production. The sheet dispenser can be integrated as either stand-alone, partially inside the robot's working area or completely inside the robot's work area/cell.

BASE DISPENSER – PRECISE PLACEMENT OF BASE SHEETS EVERY TIME

A Palcut base dispenser automatically applies base sheets to your pallets as they pass the line on the way to palletizing. The system increases capacity in the palletizing process, as the bottom sheet is already on the pallet. Therefore, there is no need for a pickand-place system – the paper is applied in-line without process stoppage. The system requires little space and has been developed to be compatible with all types of pallets.

CUSTOM SHEET DISPENSER SOLUTIONS

Every customer is unique, and it really shows when you look at companies' different needs for palletizing. All items have particular characteristics and must be handled accordingly. Our task is to make your palletizing run smoothly, regardless of whether you are a brewery or a toilet paper manufacturer. We have over 20 years of experience with custom solutions in existing palletizing lines and have tried a bit of everything over the years. 70% of Palcut’s sheet dispensers are tailored to the different needs of our customers, because unique needs require unique solutions.

Find out more about the sheet dispensers on our website or ask for our sheet dispenser brochure.

Put an end to costly production stoppages

Every time your palletizing robot drops an interlayer sheet and causes a production stoppage, it results in economic loss. Do you know what your downtime is costing you?

PALCUT SOLUTION COMPLETELY ELIMINATED LOST PRODUCTION TIME

The following case is an example of how even a few minutes of downtime in palletising can add up to significant economic losses.

Dropped sheets that caused a stoppage of the entire palletizing plant had gradually come to be an everyday occurrence with a customer. The challenge was a robot regularly took more than one sheet from the sheet magazine and then dropped it. Each dropped sheet had to be manually removed, resulting the entire plant shutting down for 2.5 minutes each time. It happened at least four times daily, which meant that the palletizing plant did not produce for 10 minutes every day. With 220 production days in a year, it equals 36 hours and 40 minutes of lost production time.

The customer reports that a lost production hour costs them $38,000, calculated on the value of the products coming through the production line in one hour of normal operation. With a Palcut solution ensuring delivery of a single sheet at a time, the customer has no more unwanted production stoppages. Since installation, they have managed to palletize products for a total value of $1,940,000 in additional sales.

Time is money – don’t waste it on changeovers and replenishment

Different items typically require different sheet sizes in palletizing, and the changeover between sheet sizes takes time. The following case is a good example of how a Palcut solution saved the customer an enormous amount of changeover time when products were not being palletized.

Different items and three different sheet sizes needed adjustment every three weeks. That might not sound like a problem – the challenge was that a single adjustment took an average of 30 minutes while the palletizing system was stopped. Therefore, the installation of a Palcut solution offered great improvement, as the customer could now change sheet sizes without switching off the entire plant. Annually, this solution has saved the customer eight hours of production downtime, which corresponds to 1/3 daily production of 33,333 units, that the customer can now produce additionally.

In the customer's previous setup, large quantities of corrugated tier sheets were also used. Production runs around the clock, and the sheet magazine had to be filled every three hours. A refill took 2 minutes, and during that time, the plant was idle. Therefore, every day there were 16 minutes of downtime in their palletizing every day. The Palcut solution has meant that the customer can now palletise 14 more minutes a day, which corresponds to approximately five extra pallets of production per day.

Save storage space and the environment

Many manufacturing companies lack storage space, and packaging materials are some of the items that take up the most space. By replacing traditional interlayer sheets with a Palcut solution, you will not only get more space in your warehouse, but you will also achieve large environmental savings.

PALCUT SOLUTION REDUCED 51 FULLY PACKED TRUCKLOADS TO 8

The following case is a good example of a customer who has experienced great improvements in terms of space and saved a significant amount of CO2 by installing a Palcut solution in their palletizing line. Annually, the customer used 1.2 million corrugated tier sheets in their manufacturing plant. These were delivered with 700 sheets on each pallet with a weight of 0.608 lbs per sheet. So, every year approximately 1,700 pallets were delivered, corresponding to 51 full truckloads of tier sheets.

With the installation of a Palcut solution and switching to a sheet weight of 0.304 lbs, the customer has reduced their packaging consumption from 366 tons to 183 tons per year. By replacing corrugated tier sheets with anti-slip sheets from a reel, the number of delivered pallets has reduced from 1,700 to 240. This reduction corresponds to 43 fewer fullload deliveries. According to the customer's request to always have 2 weeks of packaging materials in stock, the Palcut solution has also resulted in the materials only taking up 11 pallet spaces in the warehouse instead of the previous 76. This is because there are 7 times as many interlayer sheets on a reel compared to a pallet with corrugated. This reduction in packaging amounts to 183 tons of paper, equivalent to 66 metric tonnes of CO2

From 51 full-load deliveries to only 8 per year

From 366 tons to 183 tons per year

From 1,700 to 240 pallets per year

Savings of 66 metric tonnes of CO2 per year

A specially designed machine solution eliminated machine stoppages and frustration at McBride Denmark

Dropped sheets and machine jams several times a day – this scenario had become everyday life for McBride in Holstebro before they had a Palcut solution installed. They used a traditional sheet magazine solution with pre-cut non-slip pallet sheets on their palletizing line. The problem was that the robot far too often picked up too many sheets, and that the lower one was either placed askew on the pallet or fell all the way off. It triggered a machine stoppage every single time, much to the employees’ frustration, and it became expensive in the long run.

McBride decided to replace their problematic solution with a fully automatic sheet dispenser from Palcut, but space was tight, since it had to fit in the existing line configuration. A unique, specially designed machine solution is what now enables McBride to be free from both machine downtime and employee frustration. According to team leader Dennis Lago Hansen, the result is an increase in the company's productivity and a substantial financial gain.

Anti-slip paper makes it possible to comply with strict German transport requirements

Production stoppages due to lost sheets and lack of flexibility in the palletizing process was what made German Südzucker go to Palcut. With a fully automatic sheet dispenser, the switch between full and half-pallets is now seamless and has boosted efficiency. In addition, stability during transportation has significantly improved after Südzucker started using Antim anti-slip interlayer sheets. Sugar is a difficult product to transport because it easily moves during transportation, but with Antim transportation today is much more stable and secure.

“We have been able to do away with a large number of storage spaces for the different sheet sizes", says Markus Obermaier from Südzucker, which, in addition to increased efficiency and stability, can add more storage space to the list of benefits of switching to a Palcut sheet dispenser. Another important thing that has made life easier for Südzucker is that the pallets now meet the strict German requirements for load stability during transport.

The Palcut solution – get the full potential out of your palletizing

A Palcut solution is when you combine one of our sheet dispensers with a reel of our anti-slip paper. A Palcut solution can be 100% customized so that it easily fits into your production, no matter what your situation and challenges may look like.

Increase efficiency, reduce waste, and improve your pallets’ stability, without investment capital or significant changes in your existing equipment.

Would you like to maximise your palletizing performance? Then contact us today. We look forward to helping you.