ISSUE ONE SEPTEMBER 2023

Leading digital content hub for the international packaging industry

INSIDE: PPMA SHOW 2023

THE UK’S LARGEST PROCESSING AND PACKAGING MACHINERY EXHIBITION

OPRL: EPR - accountability counts, Responsible Packaging Expo, contributing writers & more! &

DIGITAL MAGAZINE

VISIT

THE UK’S NO.1 EVENT FOR THE VERY LATEST PROCESSING AND PACKAGING MACHINERY, ROBOTICS AND INDUSTRIAL VISION

SCAN THE QR CODE TO J0IN US

TECHNOLOGY

Showcasing the very latest and best technology in the processing and packaging industry – all under one roof.

KNOWLEDGE

Draw on the unique knowledge of hundreds of exhibitors to tailor the solutions right for your business.

EXPERIENCE

Invest with confidence; experience the latest machines on the market before you buy – only at the PPMA Show.

PPMA SHOW 2023 –

PPMA SHOW 2023 –

CONTENTS

Welcome to the September 2023 issue of Packaging Suppliers Global.

We are thrilled to present our inaugural digital magazine, setting the stage for an enriching and informative journey.

Within these pages, you will find a wealth of content designed to keep you at the forefront of the packaging industry. Explore a sneak peek into the upcoming PPMA Show and delve into our comprehensive suppliers directory. Immerse yourself in the ethos of the Responsible Packaging Expo, a dedicated platform shaping a sustainable future.

Guest features include OPRL and Ton Knipscheer. Stay updated on the latest developments in responsible packaging practices that are driving positive change across the industry.

We invite you to enjoy this inaugural issue, and we hope to serve as your trusted digital packaging hub.

4 7 21 26 30 32

PPMA SHOW 2023 The largest processing and packaging machinery exhibiton in the UK

Ask the expert Dean Willis on hygienic process equipment and machinery

Responsible Packaging Expo The UK’s leading sustainable packaging event

OPRL: EPR – accountability counts Why responsibility extends beyond packaging design

Pollution to solution Repurposing Ocean Waste for Sustainable Strapping Solutions

Meet Ton Knipscheer Unveiling the perspectives of our newest contributing writer 4

7 21

26 30 32

Packaging Suppliers Global | Issue One 2023 3

w: packagingsuppliersglobal.com e: info@packagingsuppliersglobal.com t: +44 (0)117

4321

318

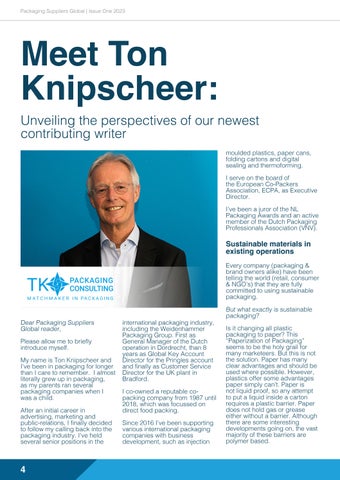

Meet Ton Knipscheer:

Unveiling the perspectives of our newest contributing writer

moulded plastics, paper cans, folding cartons and digital sealing and thermoforming.

I serve on the board of the European Co-Packers Association, ECPA, as Executive Director.

I’ve been a juror of the NL Packaging Awards and an active member of the Dutch Packaging Professionals Association (VNV).

Sustainable materials in existing operations

Every company (packaging & brand owners alike) have been telling the world (retail, consumer & NGO’s) that they are fully committed to using sustainable packaging.

But what exactly is sustainable packaging?

Dear Packaging Suppliers

Global reader,

Please allow me to briefly introduce myself.

My name is Ton Knipscheer and I’ve been in packaging for longer than I care to remember. I almost literally grew up in packaging, as my parents ran several packaging companies when I was a child.

After an initial career in advertising, marketing and public-relations, I finally decided to follow my calling back into the packaging industry. I’ve held several senior positions in the

international packaging industry, including the Weidenhammer Packaging Group. First as General Manager of the Dutch operation in Dordrecht, than 8 years as Global Key Account Director for the Pringles account and finally as Customer Service Director for the UK plant in Bradford.

I co-owned a reputable copacking company from 1987 until 2018, which was focussed on direct food packing.

Since 2016 I’ve been supporting various international packaging companies with business development, such as injection

Is it changing all plastic packaging to paper? This “Paperization of Packaging” seems to be the holy grail for many marketeers. But this is not the solution. Paper has many clear advantages and should be used where possible. However, plastics offer some advantages paper simply can’t. Paper is not liquid proof, so any attempt to put a liquid inside a carton requires a plastic barrier. Paper does not hold gas or grease either without a barrier. Although there are some interesting developments going on, the vast majority of these barriers are polymer based.

4 Packaging Suppliers Global | Issue One 2023

This would make a change from a plastic pack into a paper pack with a barrier non sustainable, as the plastic pack would be mono-material and the paper + laminate would be a composite material, making it virtually impossible to recycle. The claim that 80% less plastic has been used in this packaging is correct, but the previous pack was monomaterial, therefore recyclable, whilst this paper/plastic laminate will not be recycled.

If you do what you did, you’ll get what you got

There are some excellent fully recyclable plastics on the market, which perform very well. However, the biggest challenge converters and brand-owners are faced with is that they do not run so well on the existing machinery.

There is a clear trend that flexible packaging is replacing rigid packaging. Logistics, costs and performance are the key drivers for that. However, this transition from rigid to flexibles comes with some challenges. These focus mostly on material choice and processability. As all packaging, also flexible packaging needs to be closed after filling and this is done by sealing the flexible material. This seal needs to be tight (no leakages), robust and openable by the consumer.

Easy peesy, right? Not really. Here’s why.

There are 3 main criteria for sealing. First and most important is TEMPERATURE, after which comes TIME and thirdly PRESSURE. The current equipment, which was all developed in the 70’s, does not allow for much manipulation of the heating. This means that all that’s left to process the smaller seal windows are time and pressure. Time you do not have, as nobody wants to slow down the machine and pressure is only limited and could possibly even damage the seal.

This means that new solutions

are needed. One very logical solution has been developed by German high-tech scaleup company watttron (www. watttron.com). Their concept is that they minimise the thermal mass of the seal bar by splitting this into very small (5 x 5 mm) ceramic pixels, which can all be individually energized. This allows for an optimized control of the sealing window of the new materials. This is a clear example of revolutionary thinking and is so logical that it makes you wonder why it hasn’t been invented before.

Don’t believe me, trust science

This all is just your biased opinion, you could argue. So, let’s ask the scientists.

I spoke to Marieke Havermans, Senior Business Developer at TNO in the Netherlands.

TNO are an internationally renowned research institute, who are teaming up with the University of Twente to start an expertise center for sealing.

Here’s the interview I had with her.

Ton: “Marieke, you mention that machine learning can help sealing of sustainable

materials. Could you explain?”

Marieke: “With the EU ambition to make a transition for linear to circular packaging, the packaging industry has to move to more sustainable materials such as mono-material constructions or materials with recycled and/or renewable content. This will seriously affect the processability of packaging materials on high-speed filling lines as well as the sealing of packaging. It could mean slowing down production time, as sealing could require more time and lead to more microleakages, causing loss of product and quality.”

Ton: “Does this mean that there’s a mismatch between the

5 Packaging Suppliers Global | Issue One 2023

new materials and the existing machines?”

Marieke: “Yes, the current sealing process needs to be reviewed as many parameters will change; e.g. the molecular chain length of recycled materials differs from virgin plastics and renewable materials have different material characteristics. Furthermore, the sealing of mono-materials without a sealing agent, inducing direct contact with a sealing bar might result in melting of the outer layers due to their similar melting temperatures. To solve these issues out-ofthe-box thinking is required in addition to understanding the physics of plastics sealing.”

Ton: “OK, clear, but what can TNO do for this out-of-the-box thinking?”

Marieke: “TNO and the University of Twente are jointly creating an expertise center on sealing of “circular materials” with the aim to support the industry by minimizing sealing issues and optimizing the sealing process, for these new packaging materials.”

Ton: “What is the research scope of this expertise center exactly?”

Marieke: “One of the research areas of this expertise center, will be the development of a machine-learning based model to predict sealing performance for sustainable packaging and for different sealing techniques. A decision tool will be developed that can help manufacturers to find the most efficient sealing technique and parameters while taking into account the material characteristics and other sealing parameters.”

Ton: “How would this decision tool work?”

Marieke: “This tool will combine different sealing parameters and will apply machine learning to predict the seal quality based on a selected number of pre-determined material characteristics. The material characteristics of packaging

containing recyclates from different sorted streams will also be included in the model. In practice this could mean that for a specific filling line the machine settings, such as time and pressure, can be defined per material batch or specific material composition. Downtime, due to searching for the right settings or slowing down of the filling line due to extended sealing time, can be avoided.”

Ton: “And how does this help the converters making the right choices?”

Marieke: “The machine learning based sealing prediction model will support the industry in making the right choices and accelerate innovations in new sealing techniques and material constructions for packaging applications. This, in turn, is expected to significantly speed up the transition to more sustainable and circular packaging.”

Ton: “I would imagine this would involve large volumes of data, correct? How do you turn this into sustainable results?”

Marieke: “The development of a machine learning algorithm depends on large volumes of data, from which the learning process draws many entities, relationships, and clusters. To broaden and enrich the correlations made by the algorithm, machine learning, we contract data from both industry as from numerous sealing tests at our test facilities in Geleen.”

Ton: “Thank you very much for this really interesting perspective Marieke.”

6 Packaging Suppliers Global | Issue One 2023

Packaging and processing innovations on display at the 2023 PPMA Show

The UK’s largest processing and packaging machinery exhibition, the PPMA Show, returns to the NEC Birmingham in September. This is the ultimate event for anyone involved in the industry to see the latest processing and packaging machinery, robotics and industrial vision systems.

T he exciting three-day event on 26-28 September will be showcasing the latest innovations to visitors from numerous different sectors involved in processing and packaging. Some of these sectors include food and beverages, pharmaceuticals, household products and toiletries, building materials and supplies, pet care, and micro-brewery and distilleries as well as contract packers and more.

In less than two months, the show opens its doors to thousands of visitors, who will have the opportunity to hear from a range

of dynamic speakers. They are all eager to share with the visitors their extensive industry knowledge and some fascinating insights into future developments. These seminars are designed to inspire visitors to think about how they can improve their businesses.

The content rich seminar programme topics will include food packaging innovation, the importance of sustainability, successful selling and how manufacturing is evolving to meet the needs of the processing and packaging sector.

The show already has a line-up of exciting keynote speakers, including Cassandra Stavrou MBE, Proper Snacks Founder, who shares her entrepreneurial journey, including some takeaway “rules for business” and the importance of innovation in processing and packaging machinery.

Joining her will be Dimitrios Spiliopoulos, Industrial IoT Lead for Manufacturing at Amazon Web Services, and Philip Hooker, VP Strategic Programmes at Cumulocity IoT, who will share their vision

7 Packaging Suppliers Global | Issue One 2023

and expertise in empowering packaging and processing enterprises to tackle critical smart production and smart connected product challenges head-on.

This must-attend show will offer plenty of brilliant meeting opportunities with over 300 exhibitors, representing more than 2,600 brands. In addition, visitors can expect to see numerous exciting new product launches and live demonstrations at the show. This provides an ideal chance to get an up-close look at the latest technological innovations and products helping to shape the various markets.

“We are pleased to have once again such an array of exhibitors representing the full spectrum of the industry. These leading companies will be eager to demonstrate to visitors how they can improve their businesses with the latest cutting-edge technologies. This can help businesses stay ahead with the latest trends, improve efficiency, and make better use of resources.”

Scott McKenna, Group Exhibitions and Membership Manager at the PPMA Group

Here are just some of the hundreds of exhibitors taking part in the show:

Reiser

Reiser (D100) have been for over 60 years a leading supplier of processing and packaging equipment for the meat, food, pet food, bakery, and cheese industries. Their solutions can range from single machines to complete process-topackaging production lines. They provide solutions that combine specialised equipment, custom engineering and expertise to meet their customers’ challenges.

ULMA

ULMA (B32) offer a variety of packaging machinery and

applications that are available on the market, including Flow Pack, Thermoforming, Traysealing, Vertical, Shrink Wrapping and Stretch Film packaging technologies.

They also provide a range of automated solutions that can streamline your packaging process, including crate/case loading and product handling, pick and place, palletising, end of line and full turnkey project management.

Omori UK

Omori UK (G20) are suppliers of packaging and processing equipment, specialising in tempering, mixers, grinders, and coating equipment. In addition, they supply a variety

of packaging options such as flowrapping, stretchwrapping, stick packing and pouch (Doy Pack) filling and end of line checkweighing, metal detecting and X-ray inspection.

Ishida Europe

Ishida Europe (A104) are amongst leading companies in the design, manufacture, and installation of complete weighing, packing and inspection solutions for the food industry. They specialise in helping manufacturers increase automation, reduce cost and downtime, increase operational efficiencies, and maximise profits.

Visitors can take advantage of the comprehensive exhibitor listing on the PPMA Show website to help plan their visit.

The PPMA Show will offer a rare opportunity for visitors to see a complete production line in action from start to finish, from labelling, filling and packaging to processing, robotics, automation and industrial vision systems.

Those looking for new solutions will be impressed with a wide variety of cutting-edge innovations on display. By integrating new solutions into

8 Packaging Suppliers Global | Issue One 2023

The PPMA Show is the premier event of the processing and packaging industry, providing insights into the latest innovations designed to improve efficiency, minimise costs and increase sales. Here’s the video of last year’s PPMA Show to see why this year’s show is not to be missed!

their own businesses, they can streamline processes, improve efficiency, increase productivity, which when all put together benefits businesses by saving time and money.

Visitors can also connect with leading industry experts and gain access to an invaluable source of knowledge and insight. These experts can provide the latest information and trends, help identify opportunities and challenges, and offer guidance and advice. In addition, whether looking to make new business connections or network with industry peers, this is the perfect event for all.

To register for a free ticket to this year’s show, visit:https://ppmashow-2023-visitor.reg.buzz/ website

9 Packaging Suppliers Global | Issue One 2023

• High speed and weighing accuracy

• Minimal giveaway

• Automatic and fast changeover for different container sizes

• Easy access for effective cleaning

Packaging Suppliers Global | Issue One 2023

COST-EFFICIENT WEIGHING/PACKING LINE

newtec.com Ready meals: Visit us at PPMA Stand C42

Newtec shares buyer’s guide for investing in food weighing, sorting and packing machinery

The purchase of industrial weighing, sorting and packing machinery for food packhouses is a high capital investment that needs to be carefully researched and considered. Naturally, pricing and costs are top of the list of things businesses want to know when they begin searching the market for their required solution. Important questions include: how much is this machine going to cost me initially, how much will it cost to operate and maintain, and is the investment worthwhile?

Purchase price

While some machines may be sold off-the-shelf, finding the optimal solution for production requirements often involves

customisation. This makes it difficult for the manufacturers of the technology to give price estimates or quotes until they know the full details. The required degree of customisation can also vary each time. Generally, the more complex and bespoke the solution, the more you can expect its initial costs to be. In addition, customers requiring a complete turn-key solution rather than a single machine will be looking at the biggest investment, however, there are many other factors that dictate the equipment’s price.

Newtec is a leading manufacturer of weighing, sorting and packing machinery for the food industry, specialising in equipment for fruit and vegetable producers. The company offers a range of machines for different types and

sizes of products, all the way from small ready-to-eat fruit pots to 25kg bags of potatoes. With a variety of operating speeds, additional equipment and the option for customisation always available, price ranges vary.

There are some key details that a manufacturer like Newtec will need to define before they can offer a quote. These include what product you are weighing and its size, whether a new packing machine is required, the type of container you want to package into, and the desired capacity / speed in terms of portions per minute.

Once the manufacturer has that core information, they will be able to discuss options such as the number and placement

11 Packaging Suppliers Global | Issue One 2023

of outlets, conveyor belts and packing machines, all of which will further affect price, as well as pieces of extra equipment that may be needed such as portion collection systems and platforms.

Cost of ownership

Let’s imagine you’ve worked through the project details with the manufacturer and they’ve given you an idea of how much you’ll be paying. Figuring out how much the machine will cost doesn’t end there, as there is another very important component to be considered: total cost of ownership (TCO).

“Cost of ownership is the big one because no matter how much a machine costs, if it costs the same as the purchase price every year to run it, then it is false economy,” explains Newtec Odense (UK) general manager Dean Chilvers, who adds that Newtec machines have a very low TCO.

“If a customer is going to invest with us, as a company we need to pay back that investment with a good piece of equipment, great

back-up and support all the way through.”

Fruit and vegetable producers must be able to rely on the machinery in their packhouse for a constant output of saleable products. If their weighing, sorting or packing machinery breaks down frequently or cannot easily and quickly be fixed, not only will there be a sudden drop in output but they might also fail to meet orders, with fresh produce potentially going to waste. It is therefore crucial to choose a machine that is reliable and a manufacturer that will take care of it throughout its lifetime, with good servicing and speedy fixes when needed. For Newtec, values like this are close to the company.

“We see that what we’re dealing in isn’t bread and milk; we’re dealing in heavy, capital equipment, which is a major investment for any business. So for us, it’s about the respect and trust. If a customer is going to invest with us, as a company we need to pay back that investment with a good piece of equipment, great back-up and support all the way through,” Mr Chilvers says.

Of course, not all downtime is unplanned. Routine cleaning

and servicing is inevitable, but the less time it takes to do this the better. Newtec kept this in mind with the easy-access designs of its machines such as the Mini Weigher. In addition, the Mini Weigher’s low footprint, another consideration for TCO, makes it a cost-effective solution for a growing number of food producers.

Return on investment

By estimating the solution’s total cost of ownership, you have a more complete idea of how much you are investing into the into the weighing, sorting and packing equipment: If the price seems high, it is often largely due to the high-quality materials used. Newtec machines are made from stainless steel to ensure durability and longevity.

The next step is weighing up the costs of the equipment against how much money it can help you save, and this is where a good, cost-effective solution really shows its worth. Firstly, businesses converting their packhouses from manual labour to machine automation can expect a large reduction in labour costs. With Newtec machines, however, cost savings go much further than this.

Anyone investing in Newtec’s weighing machinery will benefit from the machines’ high accuracy levels. This precision keeps product giveaway at an absolute minimum, boosting profits. The

12

Newtec High Speed Container Filler for Various Convenience Food

company’s Multihead Weigher gives away less than 0.2% of the product, meaning that if you are packaging a 1kg bag of onions it will weigh exactly 1kg. It also operates at high speeds of up to 90 packs per minute, with the same being said for many Newtec solutions. This efficiency guarantees high output for busy packhouses looking to get fresh products weighed, packaged and out of the door quickly.

When it comes to Newtec’s optical sorting machines for potatoes and carrots, further cost savings can be achieved. The powerful Celox technology grades the vegetables according to their size, shape and quality standard, then directs the product into up to 16 different categories defined by the operator. With this, food producers can optimise the full value of their entire crop by splitting their products into the most profitable selections.

With cost savings being achieved in so many ways, Newtec machines ensure a quick return on investment and will continue to perform consistently and efficiently throughout their lifetime. Businesses investing today ensure an optimised production for years to come.

FIND OUT MORE

Dean Chilvers General Manager

Dean Chilvers General Manager

e: dean@newtecuk.com

t: +44 (0) 1406 426526

13 Packaging Suppliers Global | Issue One 2023 Visit us on Stand C42! We look forward to show you our: • Newtec Weighing Machine, model 2008PCM • Newtec High Care Step Conveyor, model HCSC Combined with four weighing machines, model 2008PCM and two double-sided Wash Down Trolleys, our High Care Step Conveyor is an important part of our weighing and packing line for mixed, fresh, cut fruits. We look forward to welcoming you at our stand and hearing about your future projects! Discover Newtec’s wide range of weighing machines!

Adpak to display cutting-edge packaging solutions at PPMA 2023

As we glance towards the calendar, it’s apparent that the muchanticipated premier UK event for processing and packaging machinery, robotics and automation exhibition (PPMA) is fast approaching. The countdown is now in earnest, and we’re thrilled to announce that Adpak Machinery Systems will be in attendance.

Packaging Suppliers Global | Issue One 2023 14

Adpak – a tradition of innovation in packaging solutions

Adpak, a leading provider of end of line packaging machinery, including shrinkwrapping and transit wrapping, has built an unparalleled reputation in the packaging industry. With a keen eye for quality and innovation, Adpak consistently delivers premium solutions that meet a wide array of packaging needs across different industry sectors. At Adpak, our dedication to customers goes beyond the initial purchase. We take great pride in delivering exceptional after-sales service and technical support, ensuring the sustained longevity and optimal performance of your investment.

Adpak at PPMA 2023 – what to expect?

Visitors to our stands can anticipate captivating live demonstrations of our

state-of-the-art machinery, accompanied by personalised one-on-one discussions with our experienced team members. Our comprehensive display will feature an array of packaging machinery, including L Sealers, Sleeve Sealer, Case Sealer, Flowrappers, and our Proven BVM Compacta 5022 Automatic Trim Sealing machine with Integrated Labeller for E-commerce.

Furthermore, we are set to dazzle with the latest in Carton Wrap Around Machinery and the much-anticipated unveiling of our new Compact Flowrapping Machine. Our confidence in the PPMA Exhibition’s suitability for this momentous launch is resolute. You can mark your calendars, as our new Compact Flowrapping Machine is set to hit the market in October 2023.

The anticipation surrounding an event like PPMA 2033, where the industry’s brightest minds converge, is exciting. We’re looking forward to the opportunity to meet with clients and industry peers, as we showcase our latest solutions and engage in enriching discussions about the future landscape of logistics and warehousing.

Save the date – September 26th to 28th – and make sure to drop by our stand at PPMA 2023 to experience firsthand the epitome of Adpak’s superior packaging solutions. We’re excitedly awaiting the opportunity to connect with you. See you there!

Find out more

w: adpak.co.uk

e: info@adpak.co.uk

t: +44 (0)1282 601444

Shaping a greener future: Our commitment to sustainable shrink film

With many years experience supplying films to our customers we have always been mindful of the need to supply packaging responsibly; following the mantra reduce, reuse, recycle.

Our shrink wrap films are fully recyclable and where possible contain a minimum of 30% post-consumer waste.

If food safe contact is required, we can offer fully recyclable virgin films or polyolefin films with recycled content, whilst still being fully recyclable.

For bagging only applications we can supply a variety of paper, degradable or home compostable films and for e-commerce we encourage the reuse of the bag for returns.

With a wealth of resource, we help our customers make the right decision for a more sustainable future.

15

COMPLETE END-OF-LINE PACKAGING SYSTEMS HIGH-SPEED PACKAGING LINES SHRINK WRAPPING SLEEVE WRAPPING TRIMSEALING CASEERECTING &CASETAPING PALLET WRAPPING E-COMMERCE AUTOBAGGING FLOW WRAPPING FEEDING& SEPARATION SYSTEM SPIRAL WRAPPING www.adpak.co.uk 3PENDLESIDE,LOMESHAYEINDESTATE,NELSON,LANCS,BB96RY Tel:01282601444 | Fax:01282612201 | info@adpak.co.uk ADPAK CAN DELIVER END OF LINE PACK AGING SOLUTIONS TH AT ARE RIGHT FOR YOU See us on stands C10 & E48

Acer Machinery Solutions Ltd

International packaging machine manufacturers, with their worldwide serving businesses, benefit from the services offered by agents dedicated to targeted markets.

Acer Machinery, an experienced agent in the field of flexible packaging machinery for the production of sachets, stick packs & pouches, cartoning and case packing requirements, represents to the UK & Ireland leading manufacturers Mespack, a Duravant company, and UET Bernd Siebler.

Sustainable packaging solutions and continuously investing into the latest technologies. Innovation centre facilities play a vital role in meeting the industry’s most challenging demands whilst constantly driving market growth.

Responsible packaging, being a comprehensive subject itself, has shared responsibilities of everyone, a development of habits and processes that bring flexible packaging into a circular economy.

Packaging Suppliers Global | Issue One 2023

17

Mespack being strongly committed to preserving our environment, with their specialised adapted technology, can across their range of horizontal and vertical form-fillseal machines handle recyclable, biodegradable and compostable materials while continuing to run at high output rates with minimal waste – achieving guaranteed efficiency levels of 98%.

With the largest portfolio of the industry, Mespack’s range includes:

• Form-fill-seal: Flat sachets with 3 or 4 seals

• Form-fill-seal: Stand-up pouches up to 16,000cc

• Pre-made stand-up pouches up to 3,000cc

• Vertical stick pack machines (2 - 20 lanes up to 1200ppm)

• Vertical multi lane machines (4 – 14 lanes up to 980ppm)

• Fill through Spout machines

All new machines are available to work with these new materials, designed to allow customers to reduce waste and lower energy consumption.

New smart technology further enhances their machines; the Industry 4.0 Mespack Athena platform gives customers a unique view to how their machine is performing, aids preventative maintenance and provides data analytics and troubleshooting measures.

New machine models recently launched include:

2 x Form-fill-seal models

• H180FE equipped with corner spout applicator.

• H640FEQ to produce stand up pouches to 160mm, 4up

One of the most current and challenging topics of the packaging industry is the production of monomaterial spouted pouches

on horizontal form, fill and seal machines (HFFS), this requires collaboration between machine, laminate and spout manufacturer to make it possible.

In collaboration with leading spout specialists Mespack have worked closely to improve technology to achieve the following goals:

• Avoid – low melting additive in the spout – bringing additional cost to end customer

• Avoid slowing down of the machine, when using a monomaterial laminate

• Increase the quality of sealing

Full details on this game changing achievement can be found in this article: https:// mespack.com/news/gamechanger-in-production-ofsustainable-mono-materialspouted-pouches/

18 Packaging Suppliers Global | Issue One 2023

Whether working from a simplex line or working from multilane machines for highspeed production, Mespack additionally manufacture end of line equipment for customers looking for case packing solutions with various product handling picking/collator modules available, providing complete turnkey solutions. With the entire line being manufactured within Mespack’s

infrastructure, full control is maintained of the tolerances according to the product and the link between the upstream HFFS/VFFS and the EOL tolerances and the arrival speed of the pouches.

“Acer Machinery has noticed manufacturers are more frequently asking and looking towards suppliers able to offer and support full turnkey solutions. Representing Mespack’s extensive profile of equipment, alongside their wide knowledge base further benefits customers looking for complete solutions, seeing advantages to be gained with full control maintained across the line by one manufacturer. On the stand at PPMA SHOW – D62 experts from Mespack will be available to discuss through any equipment / turnkey requirements in more detail.”

19 Packaging Suppliers Global | Issue One 2023

WATCH: The LoTUS spout from Menshen is perfectly adapted to mono-material pouches thanks to the Mespack’s HFFS technology

Acer Machinery Solutions Ltd receive many cartoning projects from customers looking to improve their manual operations, often with multiple operators sometimes as many as 8-10 per line packing products. Other scenarios include customers from a contract packing environment needing high levels of flexibility with frequent incoming business that could see small, medium or high batch volumes, each having different packing format requirements.

The high demands of the pharmaceutical sector are also met by manufacturer UET Bernd Siebler’s range of Compact cartoning machines, characterized by their low space requirements, which offer high versatility, based on a rotary system, patented, offering a large carton size format range, easy to use with short changeover times. These unique features make UET’s machines very suitable for businesses across a wide industry base sector.

added, including automatic leaflet insertion, pharma-code or multifunction track and trace cameras can be installed, a wide variety of coding systems are used in addition to available serialisation management systems.

Each machine being manufactured individually gives the customer the ability for their machine to be designed to run with a variety of carton formats: tuck-in, hotmelt, euro-hanger or cartons with a combination of these features. With customers looking for increasing flexibility, UET added to their portfolio, their Compact 5 machine with 10 stations enabling fixed positions with the ability to run multiple carton formats across up to 4 loading stations – suitable in circumstances where multiple components may require separate loading, or to meet output demands, etc.

The versatility of the compact range does not end here –machines are offered in either

product in question, there are several automatic dosing options available from overhead or upstream systems and in combination with collaborative robots. Recently launched, adding to UET’s profile, is their “retrofit solution” available as a separate module, which can be connected to existing systems, where products can be fed manually at various stations by one or more operators or automatically in combination with a robot

Packaging Suppliers Global | Issue One 2023

20

Ask the expert – hygienic process equipment and machinery

Adelphi Manufacturing’s Sales Director Dean Willis answers our

customers’ most relevant questions:

If you have a product with powerful corrosives or chlorides, 316L stainless steel is highly recommended as it will last longer than 304. If your product includes milder acids or does not run the risk of salt exposure, 304 grade is perfect. It can be very difficult to tell the difference between 304 and 316L grade with the naked eye, but with the use of our X-ray analyser, we can provide full traceability on our material accompanied with the relevant certification, for your peace of mind.”

Are there any process equipment or machinery elements specifically designed to improve hygiene, which I should be looking out for?

Which grade of stainless steel should I be looking for in the construction of process equipment and machinery, to provide the highest levels of hygiene for my product?

“PHP offer vessels and other process equipment in both 304 and 316L stainless steel. A simple description of the difference is that 304 grade contains 18% chromium and 8% nickel, while 316 grade contains 16% chromium, 10% nickel and 2% molybdenum. The molybdenum is added to help resist corrosion to chlorides. 316L grade stainless steel therefore has better corrosion resistance, especially against chlorides and chlorine solutions. This makes it more desirable in environments where salt exposure is likely.

Is this cost-effective for my production requirements?

“At PHP, we believe in investing in quality. Purchasing cheaper or plastic process vessels and equipment elsewhere often becomes false economy in the long run, as such alternatives are less hygienic and less durable. However, we also understand the need for economising where possible. We are part of the Adelphi Group of Companies, who also manufacture process machinery (including filling and capping); many of their machine components and parts are manufactured in 304 grade stainless steel, but all ‘wetted’ parts (coming into contact with your product) are made in 316L grade. They have found this to be the most cost-effective way of proceeding.”

“All PHP’s process equipment is made crevice and pit-free, to avoid bug traps. With respect to machinery, many of Adelphi’s filling machines features curved and sloping surfaces which meet GMP requirements; they offer no opportunity for product pooling. Non-drip nozzles mean that product flow is controlled. Quickstrip machines facilitate ease of cleaning, for the most hygienic finish possible.”

Are the hygienic equipment and machinery (described above) suitable for my industry?

“The high levels of hygiene facilitated by our process machinery and equipment are perfect for the pharmaceutical and laboratory, food and beverage, cosmetics and personal care, vaping and CBD oils industries. To speak to a specialist about your specific product/requirements, please don’t hesitate to contact us using the information below.”

Find out more

w: adelphi.uk.com

e: info@adelphi.uk.com

t: +44 1444 472300

Packaging Suppliers Global | Issue One 2023 21

Adelphi Manufacturing

– Come and talk to us at PPMA Show on stand D92

containers within an 8-hour shift.

Flexible Fill Volumes: Capable of accommodating fill volumes ranging from 3ml to 1L, catering to a diverse range of product requirements.

Swift Cleaning Process: Effortlessly strip down the filler for thorough cleaning in just 3 minutes, minimizing production downtime when switching between products and containers.

containers per minute and has a filling accuracy of up to +/-0.25%.

The Monobloc can incorporate the following elements to give a complete turnkey packaging line:

• In-feed table

• Bottle blower

• Filler

• Automatic cap placement

• Capper

• Labeller

• Collection table

Response Benchtop Filler

Industry-Leading Accuracy: Remarkable accuracy of +/0.25% (compared to the industry average of +/-1%) significantly reduces waste and enhances filling reliability.

Rapid Filling: Achieve a fast production rate of 20-40 bottles per minute, equating to an impressive average of 15,000

Versatile Capability: The Response Benchtop Filler is designed to cater to your complete product range, offering interchangeable nozzles to handle various viscosities such as essential oils, reed diffusers, candles, and more.

Configurations: Available in both single and twin-head configurations, providing versatility to cater to different production needs.

Response Monobloc

Adelphi’s Response Monobloc Filler is able to fill from 5ml up to 1000ml, fill and cap 15-25

Packaging Suppliers Global | Issue One 2023 22

Automatic Filling Machine with the new quick strip feature

Proven Excellence: A well-established and successful concept, with a track record of supplying over 1,000 units worldwide.

Rapid Changeovers: Quick-release nozzles enable seamless and tool-less transitions between different containers and products

Cylinder Options: A range of cylinder choices are available, allowing you to select the ideal capacity for your specific applications. Whether it’s 1L, 3L, 5L, or 6L, you have the flexibility to match your product’s volume accurately.

Variable Fill Speeds: Versatility with the ability to adjust fill speeds as needed during the filling cycle. This dynamic feature ensures optimal precision and efficiency, accommodating various product viscosities and container sizes seamlessly.

Automation Excellence: The system includes ‘no container, no fill’ sensing, minimizing wastage and streamlining your production process with effortless precision.

Easy Cleaning Option: For hassle-free maintenance, our system offers an optional flushing circuit. This feature allows for efficient in-place cleaning, optimizing downtime and ensuring a hygienic production environment.

Find out more

w: adelphi.uk.com

e: info@adelphi.uk.com

t: +44 1444 472300

IBC Mixer

Pharma Hygiene Products is pleased to present a new IBC mixer

Versatile Mixing Solution: Ideal for liquid-to-liquid, oilto-oil, and powder-to-liquid mixing, as well as maintaining consistent product blending during storage.

Quality Finish:

exceptional average finish of 0.5 micrometers Ra, ensuring a flawless surface without any pits or crevices.

Flexible Speed Range: Equipped with a variable

speed drive, the mixer offers 420rpm to 1400rpm, providing adaptability to various mixing

Designed for products with a viscosity of up to 700 CPS (mPas), ensuring suitability for a wide range of applications.

The mixer securely attaches to standard 1000L IBCs using ‘kill-switched’ toggle clamps,

Powered variable speed drive, ensuring

reliable and controlled mixing performance.

Tailored for IBCs: Specifically crafted for use on Intermediate Bulk Containers (IBCs) with a 150mm screw cap and sturdy metal outer frame.

Quality Construction: Constructed from durable 304-grade stainless steel, incorporating 316L pharmaceutical-grade wetted parts to prevent any risk of product contamination.

Find us on stand D29 at the PPMA Show to speak with one of our experienced machinery experts!

Packaging Suppliers Global | Issue One 2023 23

80+ palletizing machines in UK Cost effective palletizing solutions High speed stacking and proven technology Unique palletizing solution for crates Fully supported service in UK Official Representatives Innovative handling solutions for crates and cases! Scanmefor moreinfo www.phs-uk.com sales@phs-uk.com 0845 265 7570 Contact one of our specialists today! Phoenix handling SolutionS Unit 10, Mitton Business Park, Mitton Road, Whalley, Lancashire BB7 9YE Tel: 0845 265 7570 Email: sales@phs-uk.com Website: www.phs-uk.com Top of the range Fanuc CRX25iA Cobot offering a compact, versatile and fully automatic palletising system. Designed for multipick product handling and ideal for larger pallets up to 2 meters high. • Cost effective palletising solution • Quick and easy to install • 8 years maintenance free • Compact footprint • 25kg maximum payload • Up to 24 cpm • CE Certified • Low investment and fast payback Established Supplier of end of line ‘Cobot’ Robotic Palletising Systems

Stretch wrapping & strapping machines for the food, beverage, pharma and paperboard industries

PHS are the sole UK supplier of TOSA Italy wrapping and strapping machines, we have been the integrator of TOSA for more than 25 years, with more than 300 machines in operation within the UK alone.

The range extends to automatic turntable, rotating arm and high speed rotating ring machines catering for all budgets and technical requests. TOSA are renowned for producing well engineered and robust machines, typical life span being 25-30 years if well maintained.

As PHS have so many machines in the UK, we pride ourselves in providing first class service support to our vast database of clients.

Multi-visit service contracts can be provided, or simply a one off annual service visit to suit your business requirements.

To compliment the wrapping machines, TOSA also have a strapping machine division Namely ‘CMR’ who produce a large range of strapping machines for bundles or pallets, both horizontally or vertically. We can also place protective corner / edge protectors prestrapping if required, these can be plastic or cardboard as required.

The name TOSA is widely renowned for high quality and reliability and is a well trusted name with many ‘Blue Chip’ world-wide customers.

Should you be looking for a machine to strap or wrap your

products, then please contact PHS for more information.

t: 0845 265 7570

e: sales@phs-uk.com

w: www.phs-uk.com

Packaging Suppliers Global | Issue One 2023 25

EPR – accountability counts

Margaret Bates, Executive Director at UK labelling organisation OPRL, explains why responsibility extends beyond packaging design

meaning ‘good’ or ‘authoritative’, the real definition of responsible is being accountable. When it comes to packaging, producers need to be accountable to consumers, to the product and to the environment.

Anyone doubting the importance of sustainability in our industry has only to read the news pages of this magazine. Every major company is focusing efforts to reduce waste or replace materials with recyclable alternatives. Consumer demands and government legislation are aligning to drive change, but we still have a way to go before we can claim to produce truly responsible packaging.

The definition of responsible is often misunderstood. Instead of

As a starting point, packaging needs to protect the product – to deliver it in the condition consumers expect and, when it comes to food, to extend the life of the product inside; simple. But once we step away from the product and consider the resources used for manufacture and the waste created once packaging has served its purpose, wider accountability comes into play.

The UK has just announced a delay to the implementation of its legislation for Extended Producer Responsibility (EPR) for Packaging. The regulations are now planned for 2024, but with many businesses still unprepared, it is important to plan ahead. And it is not just in the UK that packaging is coming under scrutiny, similar legislation is coming in across the globe.

While most businesses are aware of EPR, many are uncertain of their obligations. Under the new system, the cost element has shifted to brands and importers, but other businesses are still required to report on the volume of packaging placed on the market, by nation. Those which are obligated will need to look at labelling requirements, along with new demands for data and submission timings. To find out whether your business is obligated, visit: https://www.gov. uk/guidance/packaging-wasteprepare-for-extended-producerresponsibility#check-if-youneed-to-take-action.

The legislation aims to encourage the design of products that are more recyclable, and which contain higher levels of recycled material. Many brands are already reducing the amount of packaging used, while others turn their attention to plastics. These actions can make a huge difference across multiple product lines, but they will only succeed if consumers place their waste packaging in the correct bins.

Packaging Suppliers Global | Issue One 2023 26

For this reason, labelling plays an important role in EPR.

OPRL’s most recent research into consumer insights showed that the majority of people look for recycling information on packaging, just before they place it in the bin. Over half of our 5,010 respondents (58 per cent) told us they look for recycling information when they are about to throw packaging away. A further 51 per cent said they source recycling information on packaging.

People also told us that they cannot always understand whether packaging can be recycled and that, when uncertain, they will make a guess. Others choose not to recycle. In both cases, potentially recyclable packaging is falling through the gap.

Under EPR, the current OPRL label will be used across all rigid

packaging, with film included in the scheme at a later date. The binary label, using the Recycle/ Do Not Recycle message and the recycling swoosh, is currently the only recycling label on the market that already complies with EPR rules.

As well as using the label to provide clear, standard messaging for consumers, businesses often turn to OPRL for a reliable assessment of recyclability. OPRL holds data on the number of local authorities across the UK that collect, sort and recycle individual packaging materials; we also collect information on end markets. When businesses sign up to the label, we apply our metrics to each new product and assess whether or not it is recyclable.

Labelling is one area where responsibility – or accountability – really counts. From 2026, when all packaging producers will be required to use the label, businesses will be permitted to use the label independently, as long as they are confident that claims around recyclability are correct. OPRL will still be on hand for any brands looking for independent assessment.

As EPR extends as far afield as Latin America, Korea and South Africa, demands on global businesses will increase. But with more standard designs and clear labelling, brands, consumers and our environment will all benefit from taking greater responsibility.

Packaging Suppliers Global | Issue One 2023 27

SPA Lasers by Macsa

SPA Lasers from Macsa ID offers the most complete range of CO2, Fibre, Green & UV lasers on the market, suitable for coding and marking across a wide range of packaging materials.

Macsa ID provides laser marking solutions which are compact for production line environments, but also modular options for flexible integrated applications.

Macsa’s revolutionary approach to laser technology ensures your ROI can be achieved within as little as 18 months. No contract required, no consumables used, no fuss.

Coming to the end of your current contract or looking to switch to laser technology? We’ve got you covered. Scan the QR code below with your smartphone or visit lasers.macsa.com/spa to find out more. Find

Sustainable

Consumable-free technology that uses less energy than inkjet alternatives.

Reliable

Ensure smooth running operations with minimal downtime, and reduced maintenance overhead.

Modular

Enjoy lower costs with products designed to work alongside your existing systems.

Lower TCO

Greater reliability, versatility and consumable-free ownership reducing total costs over the product lifetime.

13d Old Bridge Way, Shefford, Bedfordshire, SG175HQ 01462 816091 | Available 09:00 – 17:00 Mon-Fri

Choose laser technology from the global leaders to achieve high quality marking on any packaging material

out more by scanning me!

lasers.macsa.com/spa

Packaging Suppliers Global and Responsible Packaging Expo Join Forces

We are thrilled to announce that we have partnered with the Responsible Packaging Expo this year! Make sure to save the 10th & 11th of October and join us at the ExCeL London for the UK’s leading event bringing sustainable packaging to the forefront of the industry.

Packaging Suppliers Global

is proud to announce its partnership with the UK’s leading sustainable packaging event, Responsible Packaging Expo. This collaboration sets the stage for an exceptional and enlightening experience at one of the most eagerly awaited events in the industry calendar. As advocates for responsible and innovative packaging solutions, we are delighted to align our values with that of the Responsible Packaging Expo and invite you to mark your calendars for October 10th and 11th.

The ExCeL London, renowned for hosting world-class events, will serve as the backdrop for this remarkable occasion. As we gather under its roof, industry leaders, professionals, and enthusiasts will converge to explore the cutting-edge realm of sustainable packaging, igniting a conversation that will no doubt shape the future of the packaging landscape.

Elevating sustainability: Responsible Packaging Expo beckons

In an era where environmental

consciousness reigns supreme, the significance of responsible packaging has never been more pronounced. As the sustainable sector continues to burgeon, the Responsible Packaging Expo has emerged as a beacon of innovation and a catalyst for change. This year, the expo shines a spotlight on transformative packaging solutions that echo the call for environmental stewardship.

As attendees, you will find yourselves immersed in a captivating arena where the latest advancements in packaging will

Packaging Suppliers Global | Issue One 2023 30

be unveiled. Our collaboration with the Responsible Packaging Expo opens doors to a world of possibilities, offering a unique platform to discover groundbreaking products that resonate with the ethos of sustainability. Beyond the products themselves, the expo provides an invaluable opportunity to network with luminaries of the industry, exchange ideas, and glean insights that can empower your business.

A journey to success: unveiling the secrets of industry titans

The Responsible Packaging Expo is more than an event; it is a conduit for success. Drawing upon the collective wisdom of industry leaders, the expo promises to equip you with the tools, strategies, and knowledge to propel your business forward. The event’s rich tapestry of seminars and interactive sessions will expose you to the latest trends, emerging technologies, and best practices that are shaping the future of sustainable packaging.

Your participation in the expo unlocks more than just access to the Responsible Packaging Expo itself. A single ticket opens the door to an all-access

pass, allowing you to explore six additional industry-leading events. This collective synergy forms the esteemed Hospitality B2B Portfolio—a colossal assembly that underscores the growth and evolution of the hospitality industry.

The countdown begins: register now and secure your spot

Eager anticipation surrounds the Responsible Packaging Expo, and now is the time to secure your presence. The registration process is now open, and we invite you to act swiftly to guarantee your place at this transformative gathering. The ExCeL London awaits your arrival on October 10th and 11th, ready to host a convergence of minds, ideas, and innovations.

Packaging Suppliers Global is honoured to be part of this collaboration, united with the Responsible Packaging Expo in our commitment to delivering the latest in sustainable packaging. As we prepare to embark on this journey together, we extend a warm invitation to you to join us in shaping a more responsible and innovative future for the packaging industry.

CLAIM YOUR FREE TICKET HERE

31

“Elevate your packaging prowess, connect with industry luminaries, and unlock the doors to a world of sustainable innovation. Register now and be a part of the Responsible Packaging Expo — a testament to the power of collaboration and the pursuit of a greener, more responsible tomorrow.”

POLLUTION TO SOLUTION

SeaStrap – Repurposing

Ocean Waste for Sustainable Strapping Solutions

Amidst mounting concerns over plastic pollution plaguing our oceans, SeaStrap emerges as a transformative force, addressing this global crisis with innovative solutions. By harnessing recycled ocean plastic waste, SeaStrap pioneers a path towards sustainable strapping while championing environmental stewardship.

Packaging Suppliers Global | Issue One 2023 32

A tangible response to plastic pollution

Recovered Seaside Plastic® is a certified recycled raw material made from plastic waste collected from at-risk Mediterranean coastal areas within 10 km from a coastline, and saved from ending up in the sea.

• By using Recovered Seaside Plastic®, companies help keep plastic away from the sea and into the packaging loop.

• By replacing virgin plastic with Recovered Seaside Plastic®, they also help save natural resources and energy and lower their environmental footprint.

Harmonising sustainability and practicality

Our SeaStrap ocean waste PET extruded polyester strapping boasts the same

qualities and characteristics as conventional green extruded strap.

Full traceability including location, date, and time can be provided to buyers of SeaStrap and those wanting to contribute towards cleaner oceans.

Inspiring a paradigm shift

SeaStrap’s utilisation of recycled ocean plastics extends beyond business innovation – it represents a paradigm shift. This solution attests to the power of innovative thinking and responsible action in tackling pressing global challenges. It stands as an inspiration for industries to reconsider their material usage, waste management, and broader environmental impact.

Improve your sustainability by actively contributing to cleaner oceans and a sustainable future.

KB Packaging are specialist suppliers of innovative and quality packaging products, equipment and bespoke packaging solutions to businesses across the UK.

33

Packaging

KB

Find Out More kbpackaging.com sales@kbpackaging.com 0115 944

1600

Improve Safety

Improved ergonomics help reduce the risk of injuries caused by incorrect handling. Operatives can wrap to the base of the pallet with ease. No more bending down or backwards walking!

Convenient Magnets High Performance Nano Film Free Standing Base

Technology TM

Superior Stretch & Strength o Engineered for high speed wrapping! o Eliminate downtime with enhanced tear resistance o Improve holding force o Thin yet tough, reducing plastics in your process o Achieve a carbon footprint reduction per pallet wrapped Easy Adjust Torque Control Ergonomic Handle 0115 944 1600 | sales@kbpackaging.com | wwwkbpackaging.com

Nano Stretch Film

67 Layer

System

Anti Fatigue Stretch Wrap

Maxwell Birch WhatsApp Business Account Find Out More! Scan to start a WhatsApp chat

Secure Transit Protection

PaintGuard™ is the new and secure way to send your tins and tubs of liquids through the post.

PaintGuard™ is suitable for a wide variety of goods within the decorating sector, including paint, varnishes and oils. PaintGuard™ is available to secure a range of container sizes and is available in single or double-pack carton options.

Manufactured using fully recycled materials and being fully recyclable, our pulp fitment range fits into specially designed cartons that can securely fit multiple sizes of metal tins/plastic tubs, providing functional, affordable transit packaging protection.

Scan me

to visit the full PaintGuard™ range

www.allpack.uk.com sales@allpack.uk.com 01543 396 700

Protects against in-transit spills. UK Courier approved 100% Recyclable

by

Supplied

Allpack receives Award of Excellence for Provider of Paint Transit Packaging Solutions 2023

Allpack is a renowned packaging company that has been at the forefront of providing innovative packaging solutions for businesses across various industries.

Serving UK & European clients, they have multiple UK Distribution Centres and manufacturing sites across UK & Europe all providing substantial manufacturing and purchasing power. They have a strong commitment to quality, efficiency and sustainability, Allpack has emerged as a trusted partner for companies seeking reliable packaging solutions. Allpack offers a comprehensive

range of packaging tailored to meet the specific requirements of its clients. They specialise in creating customised packaging solutions that not only protect products during transit but also optimise supply chain efficiency. The company understands that packaging plays a crucial role in safeguarding products, enhancing brand reputation, and reducing environmental impact.

The reputation they have is fully justified and is now beginning to earn them more tangible forms of recognition, that being said we at the South East Star are delighted to announce that Allpack is the latest recipient of one of our

Awards of Excellence for Provider of Paint Transit Packaging Solutions 2023. With our awards, we think it’s important to recognise organisations that are bringing something new and innovative to their marketplace. They don’t necessarily have to be the biggest, but they have to be an organisation that is trying to offer something different to what is already out there and above all they must offer a great product or service. We feel Allpack ticks all the boxes and are worthy winners of our award.

The award is quite clearly no accident with there being several factors that contributed to being

Packaging Suppliers Global | Issue One 2023 36

selected as the winner. First and foremost, they are good at what they do with the entire team sharing the same steadfast determination to deliver an outstanding service for their clients. The high regard they are held by their clients tells you all you need to know not only about the service that they deliver but also the honest and ethical way they operate.

Allpack recognises the unique requirements of the paint industry, which demands specialised packaging solutions to transport paint products securely. Their paint transit packaging solutions are tailored to accommodate different sizes and types of paint containers such as cans, pails and bottles. These packaging solutions offer robust protection against leaks, breakages and product damage, ensuring that the paint arrives in perfect condition. Their packaging provides tamper-evident closures for paint containers to maintain product integrity. These closures are designed to withstand the rigours of transportation and ensure that paint remains securely sealed until it reaches its destination. The packaging also incorporates shock-absorbing materials that protect against impact and vibrations during transit. This minimises the risk of damage to the containers and helps maintain the quality of the

paint and is backed by thirdparty accreditations and testing.

Being sustainability-driven is a key mission of Allpack, as they work towards being a carbonneutral business by the end of this year and are proud to be an FSC-accredited partner, that sources its packaging solutions from an array of sustainable suppliers.

The challenge in the future as their burgeoning reputation grows and the demand for their award-winning services increases will be to continue to maintain the high standards that have given them so much success. For more information on Allpack’s PaintGuard™ product range, please visit www.allpack.uk.com/ paintguard

“Obtaining the Award of Excellence for Provider of Paint Transit Packaging Solutions 2023 only goes to highlight our determination and commitment to developing new and sustainable packaging products for the industry sectors we serve. We are committed to protecting the environment, promoting sustainable resources and engineering the highest quality recycled packaging materials, which assists in reducing our client’s carbon footprint.”

37

Marcus Clarke, Allpack’s Sales

SPARK is the result of 35 years of Macsa’s continuing pursuit of excellence. Combining an easy-to-use touchscreen system with intuitive software, the full potential of SPARK can be unleashed even to the newest of operators.

Designed with cost-saving in mind and offering unparalleled reliability in a compact form that integrates seamlessly with your existing setup, SPARK delivers optimum performance day-in, dayout, without the costly overheads associated with inkjet alternatives.

Capable of producing high-quality coding and marking on almost any packaging material, SPARK aims to make switching to laser technology as easy and affordable as possible.

With SPARK, Changing to laser has never been easier. Whether you’re exploring inkjet alternatives, or coming to the end of your current contract, Macsa can provide you with advice and equipment you need. Find out more by scanning the QR code below with your smartphone or by visiting lasers.macsa.com/spark Find out more by scanning me!

Easy to install

Intuitive software to reduce setup time, eliminating trial and error approaches.

Easy to own

Greater reliability and versatility ensures maintenance budgets are kept to a minimum, for smooth running operations.

Easy on the environment

Consumable free technology that’s better for the environment and for the workplace.

Easy to afford

SPARK is a high quality laser at a very competitive price, with lower TCO compared to inkjet alternatives.

13d Old Bridge Way, Shefford, Bedfordshire, SG175HQ 01462 816091 | Available 09:00 – 17:00 Mon-Fri

A state of the art small character coding and marking system that’s easy to use and reduces carbon footprint

lasers.macsa.com/spark

SPARK by Macsa

YOUR PARTNER IN PERSONAL CARE PACKAGING SOLUTIONS DISCOVER BERLIN PACKAGING UK info.uk@berlinpackaging.com +44 (0)1953 605700 www.berlinpackaging.co.uk Berlin Packaging UK is your One-Stop Packaging Shop, bringing together the best elements of Design & Innovation, Manufacturing Services, and Customer Solutions for the packaging industry.

Aluminium cans – Strong, flexible,

A luminium cans are widely used for packaging beverages and foods due to their durability, lightweight, and ability to protect the products from contamination and spoilage.

The decoration process is an important step in the manufacturing of aluminium cans, as it enhances the visual appeal and brand recognition of the product.

Known as green metal, aluminium is one of the most environmentally friendly metals. As the most recyclable industrial material, aluminium can be recycled infinitely to produce the same product.

Recycling aluminium also saves 95% of the energy used in its production from raw materials

Today more than 70% of the material used in aluminium cans is recycled into new products – almost double that of glass (34%) and plastic (40%).

A recycled aluminium beverage can, car door or window frame is often recycled directly back into itself. And this process can happen virtually infinitely.

The benefits of aluminium

1. Recyclable: Aluminium cans are 100% recyclable and can be reprocessed indefinitely, reducing the amount of waste going to landfills and helping conserve natural resources.

2 . Lightweight: Aluminium cans are lightweight, making them easy to transport, handle, and store. This reduces transportation costs and energy consumption during shipping.

Packaging Suppliers

| Issue

Global

One 2023

3 . Durable: Aluminium cans are durable and resistant to corrosion, ensuring that the product packed inside remains fresh for longer periods.

4. Cost-efficient: The use of aluminium cans in packaging can reduce costs in production, transport, and storage as compared to other packaging materials.

5. Energy-efficient: The recycling of aluminium cans requires only about 5% of the energy needed to produce new ones, reducing greenhouse gas emissions.

6. Safe: Aluminium cans are safe for the environment and for human health, as they do not release chemicals or harmful substances when in use or during recycling.

7. Convenient: Aluminium cans are easy to open and reseal,

making them an ideal packaging solution for customers on the go.

8. Versatile: Aluminium cans are available in a variety of sizes and shapes, making them ideal for a wide range of products, from soft drinks to food items.

We’re a one-stop shop for decoration and accessories

No container is complete without the right closure and the right dressing.

At Berlin Packaging UK we present ourselves as a one-stop shop, we offer a wide range of expertise in terms of caps & closures and different decoration techniques.

Screen printing: up to 7 colours

Screen printing is a well-known

decoration method and it has never lost its classical elegance effect. It is possible to use ceramic inks or organic UV-activated inks to replicate any colour reference. Screen printing can be combined with a coating to achieve complex, full-body designs.

Labelling and Sleeving

We specialise in cutting-edge label solutions with a focus on superior quality, innovation, and brand recognition.

Applying a sleeve allows to play with designs wrapping the whole packaging body, creating colourful products.

Berlin Packaging UK

w: berlinpackaging.co.uk

t: +44 (0)1473 823011

e: info.uk@berlinpackaging.com

Packaging Suppliers Global | Issue One 2023 41

3 Pendleside, Lomeshaye Ind Estate, Nelson, Lancs, BB9 6RY Tel: 01282 601444 Fax: 01282 612201 sales@adpak.co.uk www.adpak.co.uk Let Adpak Provide your Perfect Automatic Packaging Solution We can offer a vast range of products & technical solutions across many market sectors, we provide our customers with access to new technology and the highest technical standards. DEPALLETISERS CARTON ERECTORS PICK & PLACE CARTONING CARTON CLOSERS TRADITIONAL & ROBOTIC PALLETISERS WRAP-AROUND & DISPLAY BOX AUTOMATED GUIDED

INTEGRATED LOGISTICS See us on stands C10 & E48

VEHICLES (AGV)

JENTON GET THE JOB DONE Jenton Packaging Automation Air and Surface Disinfection Bag and Pouch Sealing Banding DESIGNED & MANUFACTURED TO YOUR NEEDS WEBSITEVISITOUR www.jentonpackaging.co.uk +44 (0)1256 892194 sales@jenton.co.uk BANDING AUTOMATION DISINFECTION SEALING

Jenton Packaging

Excellence in banding and sealing

Packaging machines have been at the heart of Jenton since 1968. Originally a distributor of overwrapping and bag making machines, The Jenton Group now designs and manufactures over 50% of the machines it sells from sites in Whitchurch (Hampshire) and Bedford.

The company has extensive experience in heat sealing technologies for a wide range of applications and industries and, since 2005 has developed ranges of equipment for the food packaging industry specialising in automation, disinfection and verification. Jenton were founder members of the Processing and Packaging Machinery Association in 1987 and have a position on the board.

Banding Machines

www.jentonbanding.co.uk »

Jenton’s banding machines are found in industries as diverse as cash handling, printing, food packaging and industrial goods. The principle of banding with 20 to 60mm wide paper and film bands is widely accepted as a minimal packaging technique - which can also maintain a secure pack, create a secure stack, be used as a label, provide tamper evidence, provide easy shelf ready packaging, easy shelf loading packaging and be used to create multipacks for all manner of reasons. Banding machines from Jenton can be smaller, bench top systems or fully automatic in line systems. Heat or ultrasonic seals are possible and the bands can be printed or plain – and now even plastic free. www.pouchandbagsealers.co.uk

Pouch & Bag Sealers

Our company offers a fantastic wide range of band sealers used for sealing bags from plain LDPE to specialist materials and laminated pouches. The new plastic free pouches seal well on our machines. Applications range from plastic parts, to pet food and coffee, to fresh food and secure packaging of medical liquids. Machines can be bench or floor mounted, fed manually or automatically fed and loaded. Vacuum systems are available as are gas flush options. Other options include trimming and printing. Jenton are experts in helping customer incorporate our systems into lines and we can build support conveyors and other accessories.

Tray & Sandwich Pack Sealers

www.sokenengineering.com

Jenton were delighted to acquire Soken Engineering Limited in 2022, and production of the Soken range of heat sealers for trays and for sandwich, wrap and salad packs has now been moved to a new facility in Whitchurch, where all machines are made in-house. Soken offer a wide range of heat sealers both for film lids and pre-coated board. Phase one machines are simple single pack bench-top systems – ideal for restaurants and small local operations. As production increases, Soken shuttle type sealers can seal multiple packs at once and then faster production can be achieved with the automatic in line systems.

»

»

Ariana became part of the Jenton Group in 2005. Pioneers in the automation of thermoformed lines in the 1980s, Ariana designs for pad placing machines, convergers, seal testers and automatic portioning of ground meat were the first to market for all of those applications. The current product range include the fast and efficient (and short!) BCS convergers, high speed product stackers, multi head seal testers and pad placers for food trays. All JentonAriana equipment is in wash down food grade stainless steel with excellent easy-to-use software – all written in-house. JentonAriana equipment is installed all around the world and we welcome OEM opportunities and interest from distributors.

JenAct UV Disinfection

Jenton, via its JenAct brand design and manufacture UV disinfection systems for air and surfaces. JenAct GRU-V Jet™ systems are in use in food production halls and JenAct UV disinfection conveyors are used for transfer of packaging and actual packs from low care into high care in food packaging environments. JenAct have 12 granted patents in the generation of UV for multiple applications including disinfection of packaging prior to filling – or refilling, such as systems installed in The Body Shop stores as long ago as the 1990s. Systems have also been installed in medical applications as well as many Covid-19 related installations in schools, surgeries, clinics, gyms etc.

Label Verification

Dimaco Limited became part of the Jenton Group in 2015. JentonDimaco are the market leaders in data driven label verification for food packaging in the UK. As automation of food packaging lines becomes faster and more widespread, it becomes more and more important to check that everything printed on the label(s) is not only printed legibly but is also correct – from weights to cooking times etc. JentonDimaco’s class leading OCR software (all bespoke and written in-house) combines with exceptional data management to allow customers to not only be sure that printed data is the correct data but to have full visibility and reporting on the production lines that our equipment is installed on.

During the last 50 years The Jenton Group has become the go-to place for customers who want innovative and bespoke equipment that improves their production efficiency and process.

Automation www.jentonariana.co.uk »

» www.dimaco.co.uk »

Packaging

www.jenact.co.uk

Contact us to find out more or discuss your requirements +44 (0) 1256 892194 sales@jenton.co.uk

the Grip® Taper

The Grip® Taper is an automatic, water activated, hand held, tape dispenser, enabling biodegradable reinforced paper tape to be used by operators anywhere on the go.

The taper has a multitude of settings, enabling the user to adjust the tape length and speed as required. The machine is compact and mobile meaning it can be used both on the go and takes up less space on the packing bench.

Grip® Taper benefits:

• Hand held & battery operated

• Compact in size

• Run time of approximately 8 hours*

* Dependant on usage

Supplied by

www.allpack.uk.com sales@allpack.uk.com 01543 396 700 Logo wording colour Introducing

to visit the Grip® Taper Scan me 800M of tape application per battery 2.19KG loaded unit weight 10 second roll change time

SPA 2 D by Macsa

Sustainable and compliant coding and marking solutions for FMCG packaging

As more major FMCG retailers switch to eco-friendly packaging alternatives, manufacturers are seeking coding and marking solutions that are not only kinder to the environment, but which offer versatility across a new era of packaging materials.

New packaging materials such as PET and OPP films present a challenge for inkjet based systems, where high-quality coding and marking with minimal thermal impact is a must.

With the SPA2 D laser from Macsa, manufacturers can now leverage state of the art technology that’s fully compliant and able to meet the demands of the industry. Using UV & green wavelength technology, SPA 2 D is suitable for marking delicate substrates and for laser coating ablation.

If you’re struggling to meet the demands of new packaging requirements, or you’ve considered the move to laser technology, Macsa ID’s team of experts can advise you on the next best step. Find out more today by scanning the QR code below with your smartphone or by visiting lasers.macsa.com/fmcg Find

Versatile

Designed to work across a broad range of packaging materials, even on the most delicate.

Reliable

Ensures smooth running operations with minimal downtime, and reduced maintenance overhead.

Easy to setup and use

Intuitive software included to deliver best in class user experience, combined with online learning resources for hassle-free use.

Sustainable

Consumable-free technology that consumes less energy than inkjet alternatives.

5

13d Old Bridge Way, Shefford, Bedfordshire, SG175HQ 01462 816091 | Available 09:00 – 17:00 Mon-Fri

out more by scanning me!

lasers.macsa.com/fmcg Logo icon

PPMA SHOW 2023 –

PPMA SHOW 2023 –