INGLETT & STUBBS LLC

Providing electrical services for commercial, industrial, and institutional buildings for seven decades

BELTRAIDE

The investment agency making Belize a Central American hub for trade and economic potential

AIR TRANSAT A.T. INC

Advancing North American air travel

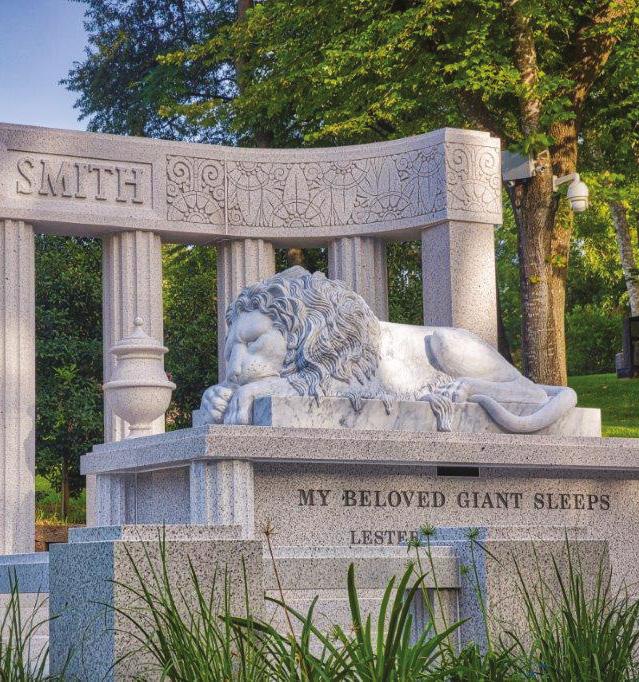

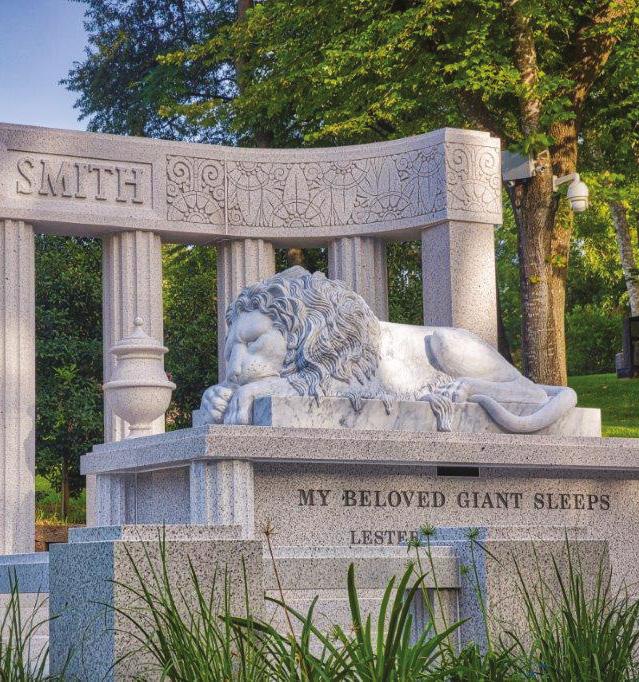

As deathcare undergoes a technological transformation, Mel Payne, CEO and co-Founder of Carriage Services, provides insight into an industry where compassion is key

SOUTHWEST ELECTRIC CO. / TRULY NOLEN

Issue 17

“Proud to be Digital”

For over a decade, our portfolio of in-house magazines has been lovingly produced, printed, and distributed to our esteemed subscribers across the globe from our headquarters in the UK.

But now we are moving with the times, adopting a digital-first approach by producing online-only publications. A major factor in this decision is to minimize our environmental footprint, reducing the carbon emissions involved in the logistics of print magazine distribution and the resources required therein.

Going forward, we will provide print orders of any magazine in-line with the requests of our featured companies, subscribers, and conference & expo partners.

Please get in touch for a print-on-demand quote or visit our website to find out more.

www.outlookpublishing.com/subscribe

diagnostics for Africa RESOURCES SABCO CERBA LANCET AFRICA WOOLWORTHS VICTORY FARMS World-class medical CERBA LANCET AFRICA Innoquest Diagnostics moving forward as one in pursuit of Ginny Foo CEO, gives us the details ZERELLA FRESH BATCHFIRE RESOURCES the low-fugitive emission energy coal producer Innoquest Diagnostics moving forward as one in pursuit of transformative healthcare. Ginny Foo CEO, gives us the details SCHLAM CR3 GROUP BATCHFIRE RESOURCES pursuing plans for Net Zero VAN MOER LOGISTICS European manufacturing VAN MOER LOGISTICS INHA WORKS Expert Eye, Amanda Li, MOELLER AEROSPACE AGRA INDUSTRIES, INC Expert Eye, Amanda Li, discusses the unsustainable nature modern infrastructure investment MOELLER AEROSPACE Ascending to new heights of YACHTING’S PUERTO VALLARTA We Behind the Lens with culinary storyteller, Karolina Wiercigroch CYPRUS PUERTO VALLARTA ROW K I NGMOR E SUSTAI N YLBA ROW K I NGMOR

N YLBA

E SUSTAI

“We always planned that when our digital subscribers consistently accounted for 85% of our total magazine subscribers, we would cease printing our publications in-line with our environmental and sustainability goals.”

– Ben Weaver, CEO, Outlook Publishing Ltd

EDITORIAL

Editorial Director: Phoebe Harper phoebe.harper@outlookpublishing.com

Senior Editor: Marcus Kääpä marcus.kaapa@outlookpublishing.com

Editor: Jack Salter jack.salter@outlookpublishing.com

Editor: Lucy Pilgrim lucy.pilgrim@outlookpublishing.com

Junior Editor: Ed Budds ed.budds@outlookpublishing.com

Junior Editor: Rachel Carr rachel.carr@outlookpublishing.com

PRODUCTION

Production Director: Stephen Giles steve.giles@outlookpublishing.com

Senior Designer: Devon Collins devon.collins@outlookpublishing.com

Designer: Sophs Forte sophs.forte@outlookpublishing.com

Junior Designer: Louisa Martin louisa.martin@outlookpublishing.com

Production Assistant: Megan Cooke megan.cooke@outlookpublishing.com

Digital Marketing Manager: Fox Tucker fox.tucker@outlookpublishing.com

Social Media Executive: Bria Clarke bria.clarke@outlookpublishing.com

Web Editor: Oliver Shrouder oliver.shrouder@outlookpublishing.com

BUSINESS

CEO: Ben Weaver ben.weaver@outlookpublishing.com

Managing Director: James Mitchell james.mitchell@outlookpublishing.com

Sales Director: Nick Norris nick.norris@outlookpublishing.com

Commercial Director: Joshua Mann joshua.mann@outlookpublishing.com

REGIONAL DIRECTOR

Tom Cullum tom.cullum@outlookpublishing.com

PROJECT MANAGERS

Felix Revell felix.revell@outlookpublishing.com

Lauren Robinson lauren.robinson@outlookpublishing.com

Louis Locke louis.locke@outlookpublishing.com

Michael Sommerfield michael.sommerfield@outlookpublishing.com

Scarlett Burke scarlett.burke@outlookpublishing.com

Yamin Khan yamin.khan@outlookpublishing.com

HEADS OF PROJECTS

Callam Waller callam.waller@outlookpublishing.com

David Knott david.knott@outlookpublishing.com

Deane Anderton deane.anderton@outlookpublishing.com

Eddie Clinton eddie.clinton@outlookpublishing.com

Ryan Gray ryan.gray@outlookpublishing.com

Thomas Arnold thomas.arnold@outlookpublishing.com

TRAINING & DEVELOPMENT MANAGER

Marvin Iseghehi marvin.Iseghehi@outlookpublishing.com

SALES & PARTNERSHIPS MANAGER

Donovan Smith donovan.smith@outlookpublishing.com

SALES MANAGERS

Alfie Wilson alfie.wilson@outlookpublishing.com

Krisha Canlas krisha.canlas@outlookpublishing.com

ADMINISTRATION

Finance Director: Suzanne Welsh suzanne.welsh@outlookpublishing.com

Finance Assistant: Suzie Kittle suzie.kittle@outlookpublishing.com

Finance Assistant: Victoria McAllister victoria.mcallister@outlookpublishing.com

CONTACT

North America Outlook Norvic House, 29-33 Chapelfield Road

Norwich, NR2 1RP, United Kingdom

Sales: +44 (0) 1603 363 631

Editorial: +44 (0) 1603 363 655

SUBSCRIPTIONS

Tel: +44 (0) 1603 363 655

phoebe.harper@outlookpublishing.com www.northamericaoutlookmag.com

Like us on Facebook: @northamericaoutlook

Follow us on Twitter: @NA_Outlook

The Bare Necessities

Welcome to our 17th issue of North America Outlook. In this edition, we speak to some fascinating companies delivering the fundamental cornerstones of modern life in an innovative and future-facing way.

A recognized leader in electrical construction, Inglett & Stubbs LLC has been keeping the lights on across Atlanta since 1954. Providing electrical services for commercial, industrial, and institutional buildings, we shine a light on how the company has established itself as a permanent fixture of the North American construction industry.

“Our goal is to provide speed to market while ensuring the highest quality service for our customers,” shares Inglett & Stubbs LLC’s President, Miller Chalk, in our exclusive interview.

Elsewhere, in the food and beverage space, we spotlight some of the sector’s most exciting innovations delivering fuel for life fit for the modern age. One such example is Atlantic Sapphire, the South Florida-based company reinventing the historic tradition of salmon fishing in the Atlantic Ocean with environmentally friendly farming methods.

For a futuristic food mission, read our feature covering the joint efforts of NASA and the Canadian Space Agency, as they seek to provide sustainable food systems for long-duration space flights that will also be used here on Earth. Meanwhile, we delve into a burgeoning frontier of food production that represents the dynamic combination of sustainability and biotechnology as MycoTechnology harnesses ground-breaking research into mushroom fermentation.

Finally, turning from the vital sustenance of life to its one inevitable certainty, we speak with Carriage Services – a leading provider of professional funeral and cemetery services – as it embraces the latest digital deathcare innovations. Co-Founder, CEO, and Chairman of the Board, Mel Payne, shares his thoughtful insight into an industry founded on compassion.

“The customer-centric approach is at the heart of Carriage Services, and we are building all our processes around it. We leverage digital transformation principles and apply them to the customer journey, and it consciously revolves around wowing our clients.”

We hope that you enjoy your read.

Phoebe Harper Editorial Director, Outlook Publishing

WELCOME FROM THE EDITOR North America Outlook Issue 17 | 3

6 NEWS Around North America in seven stories 8 EXPERT EYE Upcycling cacaofruit to protect the planet BUSINESS INSIGHTS 10 Healthcare Fresh From the Lab Redefining the beauty industry 14 Food & Beverage Harnessing the Fifth Kingdom Delving into the magnificent world of mushroom fermentation and its transformative effects TOPICAL FOCUS 18 Food & Beverage Gastronauts – the Final Food Frontier Preparing to lunch with NASA CONTENTS 18 8 00 INDUSTRY SPOTLIGHTS 22 BELTRAIDE Becoming an economic hub for investment and trade in Central America 212 40 REGULARS 10 4 | North America Outlook Issue 17

168 Air Transat A.T. Inc

Evolving Canadian Aviation Advancing North American air travel

180 United Ground Express

A New Destination

The vital connection to the success of over 55 airports

180

FOOD & BEVERAGE

190 Chicken N Pickle

Food and Fun on the Court Serving up the thrill of pickleball

198 Atlantic Sapphire Spearheading Salmon Sustainability Promoting environmentally friendly salmon farming across the world, from South Florida

204 Southwest Electric Co. Modern

FEATURES 38 SHOWCASING LEADING COMPANIES Tell us your story and we’ll tell the world CONSTRUCTION 40 Inglett & Stubbs LLC Illuminating the Industry Prefabrication, projects, and productivity 62 Hill Fire Protection The Summit of Construction Full-service fire protection contracting in the US 68 Truly Nolen Truly the Future The best of pest control in North America and overseas HEALTHCARE 76 Carriage Services Directing Change in the Funeral Profession Digital deathcare industry innovations 96 Center for Breakthrough Medicines Leading with Science, Driven by Passion Achieving pivotal medical breakthroughs 110 NOVO Health Services Leaders in Healthcare Linen Healthcare laundry that puts patients first 120 Roper St. Francis Healthcare Looking after the Lowcountry Breaking new ground in South Carolina 128 Xanitos The Aid to Saving Lives On the frontline of hospital services MANUFACTURING 134 SAFE Boats International You’re Going to Need a Safer Boat Securing safety at sea 110 134 68 96

SUPPLY CHAIN

UTILITIES

ENERGY &

in power 204 146 Aerosonic Precision Flying At the forefront of air data systems 154 Winbro Group Technologies Vision Engineered The fresh face of sustainable manufacturing 160 Seeley International Innovative and Evaporative Air conditioning solutions that redefine cooling

Life, Uninterrupted An unparalleled partner

North America Outlook Issue 17 | 5 NORTH AMERICA OUTLOOK ISSUE 17

Around North America in seven stories…

THE LUNAR THE BETTER FOR SPACEX

ELON MUSK STILL envisions success for SpaceX and its Starship rocket later this year, despite the mega-rocket spectacularly exploding seconds after departing its launch pad last month.

During a subscribers-only interview on Twitter, the bold tech billionaire spoke candidly about the shortcomings and highlights of the launch. In the face of this setback, Musk expects SpaceX to spend around $2 billion on the Starship rocket in 2023.

Claiming that the outcome was roughly as expected, Musk expressed his belief of an 80 percent probability that Starship will reach orbit in 2023, and that the chances are even higher for next year.

Since the launch, he has remained optimistic about trying again in six to eight weeks, as SpaceX continues to work on multiple Starship prototypes.

COMPENSATION DEBATE STILL UP IN THE AIR

PRESIDENT JOE BIDEN is aiming to implement new compensation rules for airline passengers who have been severely impacted by flight delays or cancelations.

This proposed initiative would require airlines to compensate travelers beyond a ticket refund if the carrier is deemed directly responsible for the disruption to their journey and could also stretch to covering food and hotels in the case of people becoming stranded.

Unveiled alongside the slogan “holding airlines accountable”, this rule would, for the first time in US

history, demand that all airlines reimburse both initial travel costs and bonus expenses.

This ambitious announcement is part of a broader strategy from the Biden administration to intervene on behalf of consumers around a multitude of current issues including resort fees and airline seating policies.

FORD FLEXES ITS MUSCLES WITH NEW TRUCK

IN DETROIT, FORD Motors has unveiled the latest addition to its growing muscle truck franchise, the Ranger Raptor. A midsize pickup with a 405-horsepower engine and suspension designed for racing across the desert, the Ranger Raptor, and the rest of the new generation of Ford Ranger pickups, will launch fully in North America later this year.

This new vehicle illustrates how established automakers are starting to refocus their combustion vehicle lines towards more powerful, higherprofit models as regulators continue to clamp down on carbon emissions.

For Ford, the Ranger Raptor is part of a broader strategy to develop performance variants of its most popular vehicles. These variants share 80 percent of the parts of the basic truck or SUV, but can guarantee a 30 percent higher profit margin on average over the cost of assembly.

At present, Ford uses profit from combustion vehicles to subsidize losses on its electric models.

AUTOMOTIVE

AEROSPACE TRANSPORT

NEWS 6 | North America Outlook Issue 17

NO CONSOLE-ATION FOR NINTENDO

NINTENDO HAS REPORTED a drastic fall in profitability and revenue across the last 12 months in the US, impacted heavily by a drop-off in sales of its flagship Switch console.

Suffering a 5.5 percent year-on-year dip at present, Nintendo is experiencing the decline of an aging console with the Switch, which has been on the market for six years, culminating in fears that the product has peaked.

The company has now twice slashed its American-based sales forecast after further setbacks, despite attempts to refresh the

DRASTICALLY UNENTHUSIASTIC FOR PLASTIC

DISPOSABLE E-CIGARETTES

ARE becoming a growing problem in Canada, as they have been identified as a major environmental liability.

The nation is attempting to meet the ambitious goal of zero plastic waste by 2030 and plans to introduce a ban on single-use plastics such as grocery bags and straws. However, plastic disposable e-cigarettes are thwarting these efforts as the vaping industry, which produces millions of such devices a year, is yet to identify a method of recycling them effectively.

As well as plastic, disposable vapes contain rechargeable lithium-ion batteries and toxic metals that can seep harmfully into the environment when littered and are currently nonrecyclable, contributing to the more

console with a handheld upgrade and screen improvements.

In contrast, rival Sony reported an all-time high profit for the last tax year. The company sold a record breaking 19.1 million PlayStation 5

EDUCATION

REBOOTING THE FUTURE OF

EDUCATION

ARTIFICIAL INTELLIGENCE

(AI) is primed to heavily impact the entire American education system as experts predict that ground-breaking technology in the field could usher in a new model to produce more efficient and relevant students within the workforce.

While many critics have argued that embracing AI will exacerbate cheating or hinder critical thinking, many more believe it’s necessary to train students to set them up for future success.

According to David Espindola, a digital technology entrepreneur and author, the landscape is ready to be disrupted and he considers the current educational system to be broken and outdated.

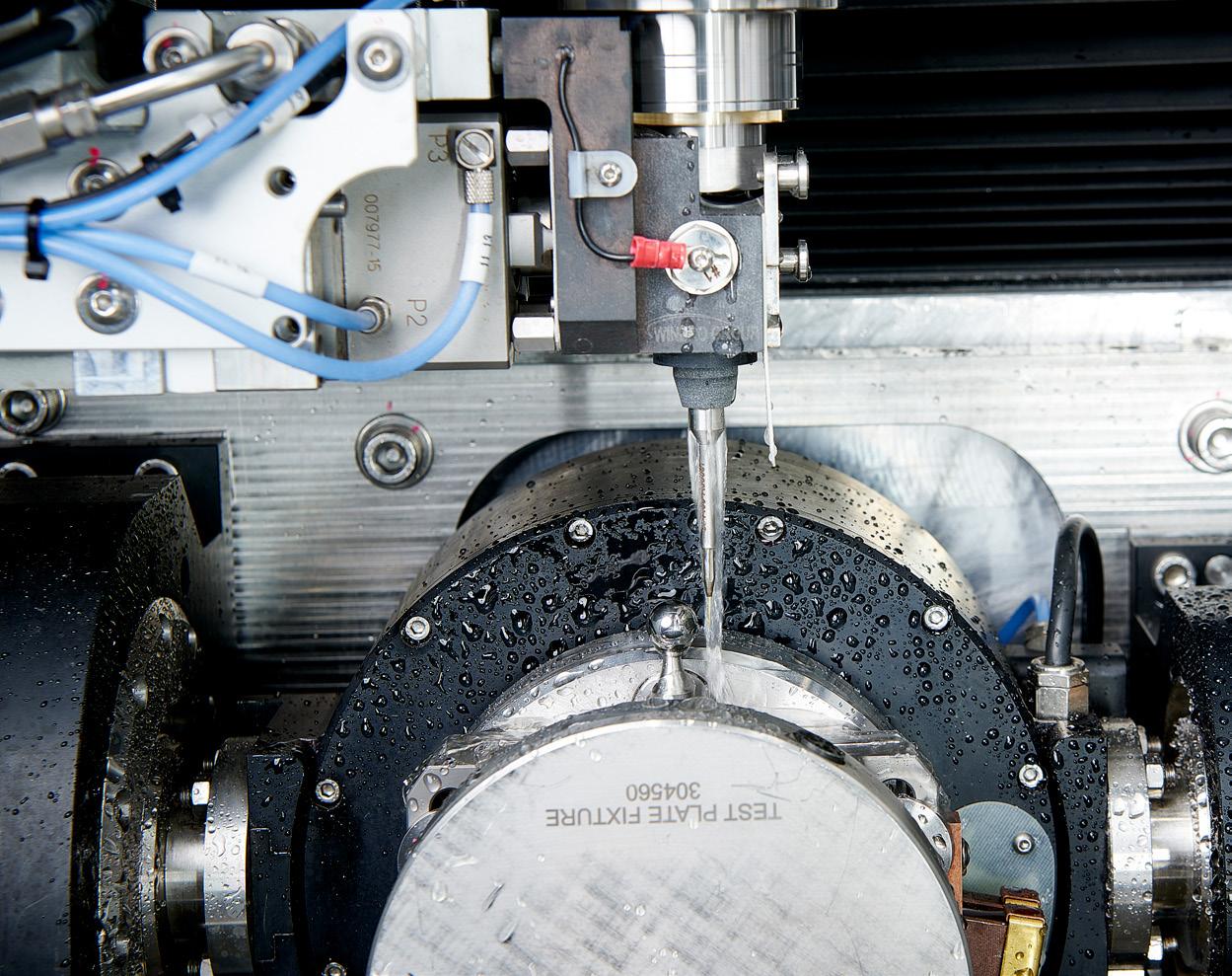

With everyone from major tech companies to small start-ups announcing new technological implementations on a near-daily basis, Espindola believes these swift advances will quickly lead to some knowledge currently being taught in schools to become obsolete.

FOOD & BEVERAGE

BUN VOYAGE FOR NEW SUPERHERO WHOPPER

BURGER KING IS launching a Spider-Man themed Whopper to its menu this week.

Despite the chain announcing it would close more than 400 US stores last week, Whopper sales are up and its share price has risen to an all-time high.

than 50 million tons of electronic waste generated globally each year, according to the UN.

The Canadian vaping industry works with waste management company, TerraCycle to recycle used e-cigarettes, empty vapes and nicotine cartridges, but currently requires consumers to return the devices to specialized vape stores or send them in the mail.

The superhero themed burger will coincide with the release of the upcoming ‘Spider-Man Across the Spider-Verse’ movie, out next month.

The new Whopper is very similar to the original, classic incarnation, except it’s sandwiched between a red bun spotted with black sesame seeds. It will be available at participating restaurants across the US from 15th May through to 21st June.

TECHNOLOGY SUSTAINABILITY North America Outlook Issue 17 | 7

The US is one of the top 10 chocolate-consuming countries in the world, with the average American consuming approximately 4.5 kilograms (kg) of chocolate annually1.

Despite this, many Americans do not realize that our favorite confectionery comes from the cacaofruit.

Traditionally, the cacaofruit has been harvested for its seeds to use in the manufacture of chocolate. However, the seeds represent only about 30 percent of the fruit, with the remaining pulp and peel discarded once the beans have been harvested, amounting to as much as 10 million tons of waste a year.

Figures show that the average American family wastes nearly $2,000 worth of food a year2. Food waste is central to some of the key

Preventing food waste is the single most effective solution to reduce global warming.

Sylvie Woltering-Valet, Head of Marketing at Cabosse Naturals, highlights cacaofruit as one of the most impactful fruits to fully upcycle

Written by: Sylvie Woltering-Valat, Head of Marketing, Cabosse Naturals

challenges facing the world today, including hunger and poverty, climate change, health and well-being, and the sustainability of agriculture and oceans.

It is also a waste of the energy needed to grow, harvest, process and cook food, and waste in landfill can additionally cause methane emissions, a potent greenhouse gas3

Reducing food waste is therefore

the single greatest way of fighting climate change, and a key contributor to the rise in food upcycling. Around the world, about 30 percent of all food, 50 percent of all fruit and vegetables and 70 percent of all cacaofruit goes to waste yearly.

If harvested cacaofruit was used to its fullest, including its pulp and peel, it would reduce the same amount of CO2 as planting 3.5 billion trees per year –that’s an area bigger than Texas and Kansas combined.

UPCYCLING CACAOFRUIT

Cabosse Naturals – the global expert in cacaofruit – has started to upcycle this largely undiscovered fruit, creating a range of high quality, 100 percent natural pure cacaofruit ingredients to be used in food manufacture from its waste.

8 | North America Outlook Issue 17

The range unleashes the full power of the cacaofruit by making use of its beans, its dense peel and its fresh and fruity pulp and juice.

Cabosse Naturals is a brand by Barry Callebaut, the world’s leading chocolate manufacturer, responsible for one in five of all chocolate and cocoa creations consumed worldwide. We have unlocked a new food and drink category with cacaofruit juice, pulp, concentrate and powder, which can be used in a variety of ways in food and drink manufacture.

We are playing our part in igniting change, helping brands and artisans to create new products which contain upcycled cacaofruit ingredients and empower consumers to make a positive impact with their everyday purchases.

Some pioneering US retailers and brands have already seized the trend, including BevCacao, which is made with Cabosse Naturals’ upcycled certified cacaofruit and sold online at Walmart. BevCacao is a functional

Cabosse Naturals predicts more new products containing ingredients from upcycled cacaofruit will soon launch in the US.

NATURAL RICHNESS

Just like an apple or orange, the cacaofruit has its own uniquely fruity taste, but few people know anything about it, let alone have tasted it.

The cacaofruit’s zesty signature flavor is deliciously refreshing and brings complex notes and natural sweetness to ingredients that are very versatile and can be found in a number of consumables, including drinks, ice cream, dairy products, confectionery and snacks.

We have worked on an innovative and unprecedented upcycling supply chain for years to harness the natural richness of this delicious but largely unknown fruit, of which about 14 million tons is harvested around the world.

The journey of the cacaofruit starts in farms in the tropical regions around the Equator. Once ripe, the cacaofruit is harvested by hand, cleaned and opened to remove the seeds from the fresh pulp.

As soon as the cacaofruit is opened, its pulp is immediately pressed into juice to preserve its fresh aromas, then filtered, gently pasteurized and concentrated to obtain the cacaofruit juice concentrate. The juice makes a refreshingly fruity base for a large range of functional beverages, ready to drink teas, coffees and even beers and kombuchas. It has a light-yellow color with a fruity scent, naturally contains magnesium and potassium, and is a good source of antioxidants, bringing a deliciously exotic flavor to drinks.

Characterized by its golden-brown color and a fruity honey scent, the concentrate is 100 percent pure and free from sweeteners, additives and preservatives, and caters to growing consumer demand for products and ingredients which are kinder to the environment.

ABOUT THE EXPERT

Sylvie WolteringValat is Head of Marketing of the global cacaofruit expert Cabosse Naturals, a brand by Barry Callebaut. In her current role, she is passionate about driving the evolution towards tasty and nutritious food and drinks that also do good for the planet and its people.

Sylvie has over 20 years of experience in marketing at various food and beverage and cosmetics companies such as Cadbury, Schweppes, L’Oréal and General Mills, before joining the world’s leading manufacturer of high-quality chocolate and cocoa products in 2016.

During this period, her responsibilities extended from strategy, innovation and communication, through to brand activation and commercialization.

Sylvie received her master’s degree in management at the Grenoble Graduate School of Business and did a specialization in marketing and sales.

https://www.barry-callebaut.com/en/ manufacturers/cabosse-naturals

1. World Population Review

2. U.S. Department of Agriculture’s National Household Food Acquisition and Purchase Survey

3. World Food Programme

North America Outlook Issue 17 | 9 EXPERT EYE FOOD & BEVERAGE

COSMETICA LABORATORIES

FRESH FROM THE LAB

Trend trailblazers in custom cosmetic development and manufacturing, Cosmetica Laboratories creates awardwinning products from the ground up for the world’s most renowned beauty brands

Writer: Ed Budds

Writer: Ed Budds

10 | North America Outlook Issue 17

Driven by mindful innovation and guided by its strategic imperatives to remain the beauty industry’s partner of choice, Cosmetica Laboratories (Cosmetica) is globally recognized for unparalleled quality, operational excellence and sustainability.

With a highly personalized approach to cosmetic development and manufacturing, Cosmetica posesses a passion for unconventional beauty, which is channelled into the company’s iconic products that disrupt the industry status quo.

We find out more with Alessandro Mendes, Cosmetica’s Vice President of Research and Innovation.

North America Outlook (NA): Could you introduce us to Cosmetica?

Alessandro Mendes, Vice President of Research and Innovation (AM): Cosmetica is a 30-year-old innovation house and cosmetic manufacturing company, developing breakthrough beauty products for the world’s most iconic brands. We have two laboratory formulation facilities in Toronto and Los Angeles, with all manufacturing housed within two plants in Toronto, now with over 600 employees.

As a company, we specialize in research, development, and manufacturing of color cosmetics, skin, hair and personal care products. Our goal is to create innovative, high-quality products through proficient execution and superior service, driving positive change and improvements to the social, economic and environmental well-being of our business, employees, clients, and community.

NA: What is the role of technology and automation in helping to ensure reliability and consistent data analysis in cosmetic trends?

AM: With the vast amount of data available in the cosmetics industry,

technology helps streamline the collection and analysis process, providing insights into consumer preferences and behavior that would otherwise be difficult to obtain. This is highly valuable to our clients as they plan and forecast product innovations for their customers. In addition, the use of artificial intelligence (AI) and machine learning (ML) continues to grow in our industry. These new tools can analyze vast amounts of data to identify trends and patterns, helping companies make data-driven decisions when it comes to product development and marketing. For instance, research and innovation (R&I) laboratories in our industry have been adopting predictive models for stability, compatibility and other tests leveraging historical data and AI.

NA: Can you tell us about the company’s internal innovation showcase?

AM: Cosmetica works with the most innovative ingredient and component suppliers to develop cutting-edge products. The company’s teams are constantly exploring new and emerging ingredients and technologies to create innovative textures and high-performance color cosmetics and skincare products. By partnering with top suppliers, Cosmetica can leverage the latest

advancements in ingredient technology to create products that meet the needs and expectations of clients. This includes using natural and sustainable ingredients, as well as incorporating new technologies that improve the performance of the products.

In addition to using innovative ingredients, Cosmetica also prides itself on developing innovative textures. This includes lightweight and breathable formulations for skincare, and long-lasting and highly pigmented formulas for color cosmetics.

NA: What is your take on the industry in North America at the moment?

AM: Overall, the cosmetics industry in North America is experiencing significant growth and is expected to continue to do so in the coming years. The industry is becoming increasingly competitive, with companies seeking to differentiate themselves through innovation, sustainability, and technology-driven marketing.

It is an exciting space to be working in as the current competitive business landscape provokes industry professionals to challenge the status quo.

One of the key trends in the industry is a growing demand for natural and sustainable products. Consumers are becoming increasingly aware of the impact that their purchasing decisions have on the environment and are seeking out products that are eco-friendly and free from harmful ingredients. This has led to a rise in the number of natural and organic cosmetics brands in the market.

Another trend concerns the use of technology and data-driven marketing. Companies are leveraging social media platforms and influencer marketing to reach consumers and build brand awareness. They are also using data and analytics to understand consumer preferences

North America Outlook Issue 17 | 11 FEATURE HEALTHCARE

Alessandro Mendes

and purchasing behavior, which is helping them to develop more targeted marketing campaigns and product offerings. In general, the North American cosmetics industry is seeing a rise in the popularity of skincare products, driven by the increasing cultural shift to focus on health and wellness. Consumers are prioritizing self-care and are seeking out products that provide not just cosmetic benefits, but also health and wellness benefits.

In the color cosmetics sector, we are continuing to see the rise of inclusivity and diversity reflected in brands’ product offerings. Consumers are demanding a wider range of shades and products that cater to a variety of skin tones and types and as a result, many brands are responding to this by expanding their shade ranges and creating products that are specifically formulated for different skin types.

NA: How did the COVID-19 pandemic affect the industry?

AM: As we all know, the COVID-19 pandemic initially led to widespread lockdowns and restrictions on social gatherings, which resulted in a decrease in demand for makeup and other cosmetics products as consumers spent more time at home.

The color cosmetics sector was particularly hard hit, as consumers were no longer attending events or going out as much, which resulted in a

decrease in demand for products such as lipstick and foundation. In addition to the shift in consumer habits, many makeup brands also experienced disruptions in their supply chains, which led to delays in product launches and reduced levels of production.

On the other hand, the skincare sector experienced a boost in demand as consumers shifted their focus to self-care and home-based beauty routines. With more people working from home and spending more time indoors, consumers were more interested in maintaining their skin health, leading to increased sales of skincare products such as cleansers, moisturizers, and serums. Overall, the cosmetics industry has seen a gradual

recovery from the fallout of the COVID-19 pandemic. With the easing of restrictions in many countries, there has been an increase in demand for cosmetics products across all sectors.

NA: What would you say is the ‘defining difference’ with Cosmetica as a contract developer?

AM: The defining difference with Cosmetica as a contract developer of formulas, components, and solutions lies in our focus as a company on innovation, quality, and customization. The company is committed to staying ahead of trends and constantly pushing the boundaries of what is possible in cosmetics and skincare formulation.

This commitment to innovation allows us to create unique and high-performing products that not only meet, but exceed the needs of our clients and their customers. Secondly, Cosmetica has a strong focus on quality. The company uses only the highest quality ingredients and components in its formulations and adheres to strict quality control processes to ensure that its products meet the highest standards of safety and efficacy.

Finally, we work closely with our clients to understand their unique needs and create customized formulations and solutions. Whether it’s creating a new product from scratch or reformulating an existing

“BY CONTINUING TO PRIORITIZE INNOVATION, CUSTOMIZATION, AND SUSTAINABILITY, COSMETICA CAN POSITION ITSELF AS A LEADING PROVIDER OF HIGHPERFORMANCE COSMETICS AND SKINCARE PRODUCTS IN NORTH AMERICA AND BEYOND”

– ALESSANDRO MENDES, VICE PRESIDENT OF RESEARCH AND INNOVATION, COSMETICA LABORATORIES

12 | North America Outlook Issue 17 FEATURE HEALTHCARE

This commitment to innovation allows Cosmetica to create unique and high-performing products

product, Cosmetica has the expertise and flexibility to deliver customized solutions that meet the needs of our clients.

NA: How does your relationship with vendors play into your sustainability initiatives?

AM: Vendors play a crucial role in our business, providing the raw materials, components, and packaging that go into the products we develop. By working closely with our vendors, Cosmetica can ensure that we are sourcing sustainable materials and reducing our environmental footprint. As a company, Cosmetica prioritizes vendors that have sustainable practices and certifications. For example, 100 percent of our palm derived raw materials are Roundtable on Sustainable Palm Oil (RSPO) certified. In addition, our Ecovadis certification is another way to promote sustainability in our

processes, as a platform that provides sustainability ratings and assessments for companies across different industries. By obtaining an Ecovadis certification, a company can demonstrate its commitment to sustainability and responsible business practices to its customers, investors, and other stakeholders.

NA: What do the next 12 months look like for the company?

AM: Cosmetica will continue to grow, leveraging the relationships with existing clients to identify new opportunities, as well as actively seeking out new clients in the cosmetics industry. Our growth strategy will be driven by our two innovation sites, in Los Angeles and Toronto. These sites are equipped with state of the art facilities and staffed by a team of experienced scientists and industry experts who specialize in developing innovative cosmetic and skincare products.

By continuing to prioritize innovation, customization, and sustainability, Cosmetica can position itself as a leading provider of highperformance cosmetics and skincare products in North America and beyond.

In terms of product development, Cosmetica will continue to focus on developing innovative, highperformance color cosmetics and skincare products that meet the evolving needs of consumers. Over the next 12 months, this could involve identifying new trends and opportunities in the market, as well as working closely with clients to create customized solutions that meet their specific requirements.

And finally, from a sustainability perspective, Cosmetica will continue to prioritize initiatives that reduce its environmental impact and promote more sustainable practices throughout its supply chain. This is a core value of our company and will continue to be a primary focus.

North America Outlook Issue 17 | 13

HARNESSING THE FIFTH KINGDOM

Through the process of mushroom mycelial fermentation, MycoTechnology is at the cutting edge of the food and beverage industry with the advanced combination of food sustainability and biotechnology

Writer: Lucy Pilgrim

Writer: Lucy Pilgrim

14 | North America Outlook Issue 17

As titans of the food fermentation and protein alternatives sector, MycoTechnology is tackling the predominant issues of the food and beverage industry: taste, nutrition, sustainability, and food security.

FUTURISTIC FUNGI

MycoTechnology is world renowned for its work in creating unqiue ingredients, tastes, and textures. FermentIQ™, derived from mycelial fermentation, is used to manipulate plant proteins to improve the taste, texture, and nutritional value of plant-based ingredients to be more competitive with animal counterparts. Additionally, ClearIQ™, also obtained from mycelial fermentation, helps reduce off-notes, enhance desirable notes, and optimize flavor profiles. MycoTechnology use a specific proprietary fermentation proccess that is targeted to create ideal characteristics of flavor and texture.

As humble members of the fungi kingdom, mushrooms obtain energy externally, unlike the internal energy consumption of humans. Fungi secrete a variety of powerful enzymes into the external environment and then absorb these predigested foodstuffs back into their cells. It is then the job of the enzymes to break down organic matter into simpler nutrients, such as sugars, nitrates and phosphates, which is all controlled by the mycelia.

In non-scientific terms, the mycelia are the engine of the mushroom. In more natural environments, the mycelia’s role is to cleanse the forest floor of toxins and indigestible matter. Additionally, the mycelia also provide nutrients for the surrounding plants to maintain the forest’s ecosystem.

As the lifeblood of the mushroom, the mycelia can easily adapt to its surrounding environment. As a result, certain mushrooms have 500 times more digestive enzymes than humans, allowing mycelium to consume a wide variety of substances and thrive on the forest floor.

North America Outlook Issue 17 | 15 FEATURE FOOD & BEVERAGE

MOBILIZING THE MUSHROOM

Founded in 2013, BioTech giant MycoTechnology has been harnessing the powerful properties of the mycelia, and its place in nature, to elevate the food and beverage industry to a new level.

Due to its adaptability and growth speed, the mycelia is an incredibly versatile organism to work with, as it requires limited human intervention, and its natural properties allow the fermentation process to be conducted on a large scale.

Consequently, MycoTechnology has utilized the natural fermentation process of the mycelia to create specialized proteins and ingredients. This process has opened the door to new tastes, textures and nutrition levels, expanding biodiversity.

To complete the fermentation procedure, MycoTechnology has constructed a platform in which the mushrooms are trained to digest a liquid substrate, rather than ferment solid materials as they would do in the natural ecosystem. Thus, the mycelia are encouraged to survive on a liquid diet, as the resulting by-product is collected as the special ingredient.

MAXIMIZING FLAVOR

The work of MycoTechnology has been instrumental in combating the unhealthy and unsustainable habits of the world’s appetite. Evidently, one of the biggest issues facing North America, alongside the rest of the

LIQUID FERMENTATION PROCESS

• THE CULTURE OF A SPECIFIC MUSHROOM MYCELIAL VARIETY IS INOCULATED IN A STERILE ENVIRONMENT. THE INITIAL FERMENTATION TAKES PLACE AND IS DESIGNED TO INITIATE GROWTH, INDUCE THE MYCELIA’S DIGESTIVE PROCESS AND ENCOURAGE SPECIFIC ENZYMES.

• THE FERMENTATION TRAVELS THROUGH INCREASINGLY LARGER TANKS. IN EACH TANK, THE MYCELIA ADJUST TO THEIR NEW ENVIRONMENT AND CONTINUE TO SECRETE DIFFERENTIAL ENZYMES.

• ONCE THE MYCELIUM HAS REACHED MATURITY, DIFFERENT INGREDIENTS CAN BE EXTRACTED FOR THEIR SPECIFIC COMPOUNDS, WITH EACH INGREDIENT BEING UTILIZED AS A FOOD SOLUTION.

FEATURE FOOD & BEVERAGE

world, is a sugar epidemic. The over consumption of sugar is causing a serious health crisis, with only 15 percent of the global population considered healthy. Consequently, the world has relied on the power of sugar and its addictive flavor.

To tackle such a wide-reaching problem, MycoTechnology has introduced ClearIQ™, which is a flavor modifier that enhances and subsequently reduce the need for excess sugar and other masking agents. Along with the battle against the realm of sugar, ClearIQ™ is also

making waves in the taste and texture of meat and dairy alternatives, as well as snacks, protein shakes, and even baked goods.

Furthermore, the introduction of FermentIQ™ uses plant protein to improve taste, texture and the nutritional quality of meat and dairy alternatives. Both these innovative ingredient lines provide solutions that can create healthier, better tasting food and beverages by naturally enhancing the taste of nutritious ingredients.

Looking at the case of meat

alternatives in more detail, the use of FermentIQ™ has transformed the texture to more accurately mimic ground beef. The FermentIQ™ ingredient is made by fermenting pea and rice protein with shiitake mycelia, in a texturized format, to create superior meat alternatives. The process improves flavor, aroma, digestibility, and functionality, providing a juicy, meat-like texture and experience.

FEEDING THE FUTURE

One of the greatest issues facing future generations is exponential population growth. A pressing issue to result from this is food security; in less than two decades, global food resources will no longer be able to support the population.

Through the advanced research of MycoTechnology, the company is discovering new ways to harness the power of mushroom mycelia to upcycle waste streams and create healthier, more stable and sustainable food systems that can address food security and environmental concerns.

Therefore, through the advanced BioTech force that is MycoTechnology, ground-breaking research in mycelial fermentation will transform the food and beverage industry to create revitalized and delicious food for the future.

North America Outlook Issue 17 | 17

GASTRONAUTS –THE FINAL FOOD FRONTIER

18 | North America Outlook Issue 17

NASA and the Canadian Space Agency are on a mission to launch sustainable food systems for longduration space flights which can also be utilized on Earth

Writer: Rachel Carr

In a competition that is out of this world, NASA’s Deep Space Food Challenge is being launched in a coordinated effort with the Canadian Space Agency (CSA).

As technological advances could allow manned missions to Mars in the future, with a nine-month travel time to the Red Planet, nutritious food production is an essential component. The innovations will also benefit Martian agriculture in facilitating a possible colonization, while having a broader impact on terrestrial food sources.

Innovation and sustainability are key, but there are other criteria to consider - the food must be palatable, nutritious, and safe. There must also be minimal processing time for crew members, and the participants are required to harness the power of space to solve food production challenges.

A nutritious food source is critical for all space exploration missions, especially for those with a longer duration. Moreover, the goal of spacebased food systems with maximum and non-wasteful output and minimal input is critical for a sustainable human lunar presence and for future missions to Mars.

North America Outlook Issue 17 | 19 TOPICAL FOCUS FOOD & BEVERAGE

The Deep Space Food Challenge has entered Phase 2 for the finalists, which leaves eight selected qualifying teams from the US, with an additional three international teams chosen by NASA and the CSA.

The CSA has chosen four Canadian finalists, in a parallel competition with a separate application and judging process. The Canadian grand prize winner is due to be announced in spring 2024 with a separate prize of CAD$380,000.

Experts at the Johnson Space Center in Houston and the Kennedy Space Center in Florida support the competition in partnership with the Methuselah Foundation – a biomedical charity backing projects on longevity.

As NASA plans to send astronauts further into the cosmos than ever before, the space agency aims to upgrade the production of food

Therefore, a $1 million investment for the US winner is in the pipeline to feed the explorers of tomorrow.

BACK DOWN TO EARTH

The planet is orbiting a crop crisis. Moreover, areas of the globe are already experiencing food scarcity with as many as 828 million of the population unsure of where their next meal is coming from.

In order to create sustainable food sources here on Earth, NASA has extended its Deep Space Challenge to address the terrestrial food insecurity problem.

Global food resources have been exacerbated by a combination of issues which include climate extremes such as flooding and drought, economic shocks such as hyperinflation and rising commodity prices, and conflict.

This is happening to varying

NASA’S COSMIC COMPANIES

As the competition rockets, we look at the different kind of food innovations designed for lift off. The eight participating US companies through to Phase 2 are:

• AIR COMPANY, New York, manufactured foods. Carbon dioxide exhaled by astronauts is captured from the air, combined with hydrogen, and produces alcohol via water electrolysis, which is then fed to a type of edible yeast.

• FAR OUT FOODS, Minnesota, growth systems. The Exo-Garden is a nearly closed-loop self-contained food production system, which can produce a variety of fresh mushrooms and hydroponic vegetables.

• INFYNITY, Illinois, bioculture/hybrid. A microbial biomass is grown in a novel bioreactor.

• INTERSTELLAR LAB, California, growth systems. NUCLEUS is a modular biogenerative system that produces fresh microgreens, vegetables, mushrooms, and insects. It combines autonomous phytotrons to create a self-sustaining food production system that minimizes water, air, and nutrient inputs.

• MU MYCOLOGY, Oregon, bioculture/hybrid. A closed-loop, modular, liquid media mushroom cultivation system.

• KERNAL DELTECH, Florida, growth systems. An autonomous device produces an inactivated fungal biomass from well-defined starting materials. The continuous cultivation technique is adaptable to low-gravitational conditions where the culture variables are tightly controlled to maximize biomass yield and product safety.

• NOLUX, California, bioculture/hybrid. An artificial photosynthetic system, capable of producing plant and fugal-based foods.

• SATED, Colorado, manufactured food. Derived from long-shelf-life and in-situ grown ingredients, is a device designed to operate in zero and low gravity environments.

20 | North America Outlook Issue 17

degrees around the world. In more extreme environments, there is abject poverty and hunger, and in other more economically and political stable countries there are food shortages on supermarket shelves.

The advanced food systems that the competition finalists are set to develop will have benefits on Earth too. Sustainable solutions to the challenge could enable new avenues for food production around the world, especially in regions where natural disasters disrupt critical infrastructure.

NASA has already begun developing options for the current and future global food insecurity with a series of plant experiments on the International Space Station (ISS). Interestingly, the development cycle of plants is not dependent on spaceflight conditions, as previously evidenced on the ISS. Plants obtained from seeds formed in microgravity did

CSA’S COSMIC COMPANIES

The four finalists announced by the CSA to go through to Phase 3, which requires a full system demonstration, are:

not differ from ordinary earth plants. Whichever sustainable food system succeeds in nourishing astronauts, one thing is certain – it will be one giant leap for mankind.

ASTROYEAST MICROFARM, Concordia University, spaceadapted nutrient and flavor factory, centered around a yeast strain that is adapted to the environment. The production of nutrients and flavor molecules is performed in an automated and optimized bioreactor system.

CANADA GOOSE, University of Guelph, Growth Options for Outer Space (GOOSE) is a controlled environment plant chamber, innovating ways to achieve homogenous conditions.

CRICKET REARING, COLLECTION, AND TRANSFORMATION SYSTEM (CRCTS), McGill University, supporting the growth of tens of thousands of crickets every month, using advanced filters, UVC lamps, and vacuum systems.

ECOATION, Vancouver, CANGrow

Modular Indoor Food Production uses technologies to grow diverse foods from strawberries to a mycelial meat substitute - “space bacon”.

North America Outlook Issue 17 | 21 TOPICAL FOCUS FOOD & BEVERAGE

is a key industry for economic activity and an invaluable source of foreign exchange for Belize BELTRAIDE INDUSTRY SPOTLIGHT 22 | North America Outlook Issue 17

Tourism

SPOTLIGHT ON INVESTMENT IN BELIZE

Exploring diversified opportunities in untraditional avenues, we shine a light on Belize as a beacon for domestic and foreign investment

Writer: Phoebe Harper | Project Manager: Krisha Canlas

Located on the northeast coast of Central America, Belize is a country that is fully alert to the potential of investment as a crucial tool for sustainable economic development, income growth, and employment – both for local and foreign direct investment (FDI).

The exploration of non-traditional agricultural products and manufacturing activities has been a consistent focus of the Belizean government since the end of the 20th century to open the national economy, following a decrease in the commercial logging and timber export activities that had previously been a mainstay of its investment landscape.

Tourism is a key industry for economic activity and an invaluable source of foreign exchange for Belize. This runs parallel to the extensive export of seafood, particularly to the US, with a continued foray into different avenues of aquaculture such as shrimp farming.

Whether domestic or FDI, a healthy enabling environment for business is the cornerstone on which successful investment rests. In Belize, this entails a sound macroeconomic environment, a robust domestic financial system, effective rules of law, good governance, and a suitably skilled workforce to meet capacity demands. In addition, the country fully leverages a host of incentive schemes devised through the government and designed to function as a catalyst for investment.

Complementing these internal initiatives, which specifically target the growth and development of the country’s micro-, small- and medium-sized enterprises (MSMEs), is Belize’s active involvement in various agreements that maintain an openness to international trade. The country’s myriad investment opportunities are supported by the National Investment Policy and Strategy (NIPS), which enables greater cohesiveness in the investment value chain and a new Fiscal Incentive Act, which provides broad-based incentives to MSMEs as engines for macroeconomic growth; a legislative tool that is geared towards improving the local business climate and streamlining the facilitation of short-, medium-, and long-term opportunities. Through NIPS, Belize confronts investment challenges with an eye to mitigate the existing trade imbalances, the result of a weak manufacturing sector and an export specialization that traditionally relies on products that are vulnerable to the risks posed by climate change, including sugar cane, citrus, and bananas.

As the country pioneers its economic recovery from the impacts of the COVID-19 pandemic, Belize stands by its stringent environmental commitments, including a target of reaching net zero, and navigates the exploitation of investment opportunities that do not compromise or threaten the protection of its pristine habitats.

North America Outlook Issue 17 | 23

CALL-CENTER SOLUTIONS WITH

RCCBPO –

PROUD TO BE FULLY PCI CERTIFIED AND A MEMBER OF THE BELIZE CHAMBER OF COMMERCE AND INDUSTRY.

As a pioneer of the call center industry in Belize, RCCbpo specializes in business process outsourcing (BPO) providing a range of customer relationship management services to companies in the US and Canada.

RCCbpo’s values are honesty, commitment, and common purpose. We are committed to going beyond expectations, being honest in all interactions, and sharing the same goals to achieve the best outcome. With a mission to deliver exceptional customer service on behalf of its global clients, RCCbpo is an industry leader with six locations, whose plethora of specialities include:

· Customer service

· Live chat

· Technical support

· Lead generation

· Sales and telemarketing

· Booking and reservation

· Appointment setting

· Back office

· Financial

· Debt collections

· Data entry

Whatever your call center requirements are, RCCbpo provides the simplest and most cost-effective solutions. Offering top quality, 24/7 service from a skilled workforce, its performance driven culture and analytics ensure your demands are met.

Established in 2005, RCCbpo has grown to over 800+ occupied seats, and as the biggest employer in Belize, its team consists of more than 2,000 co-workers. RCC serves a wide variety of industries in North America:

· Logistics

· Field services

· Public utilities

· Telecommuncations

· Marketing and media

· Warranty and insurance

· E-commerce and retail

· Healthcare

· Financial and debt collections

· Hospitality

BENEFITS OF BELIZE

Belize is conveniently 1,000 miles from Florida, which presents an opportunity for clients to come and meet the RCCbpo team, while enjoying the paradise that the country has to offer.

Eliminating the difficulty of navigating time zones, RCCbpo is not only based in a tourist location, but it is a prime position for US territory availability. The mountain time zone sits in the middle of the Pacific and Central Time Zones.

As businesses continue to expand, there is a growing need to reduce their environmental impact. For the BPO industry it is a crucial time to reflect on it practices and move towards an eco-friendlier and more sustainable operation.

At RCCbpo, digital documentation is the way forward, as the company believes it has a responsibility to mitigate climate change and reduce its carbon footprint.

Digital documentation is a practice that benefits businesses - it reduces paper waste, playing a

RCCBPO IN NUMBERS

· 1.7 MILLION CALLS PER MONTH

· 720,000 MONTHLY MESSAGES

· 288,000 MONTHLY EMAILS

vital role in decreasing deforestation. Additionally, going digital is efficient as files can easily be stored, organized, and accessed.

It also removes the need for physical storage, and saves energy, reducing electricity, water, and fuel. RCCbpo recognizes the importance of a sustainable future, and by implementing eco-friendly practices, businesses and the planet can benefit.

THE RCCBPO EXPERIENCE

Customer service with RCCbpo improves your organization by ensuring valued clients receive the best experience.

Live chat and email support will communicate with customers in real time, leaving a written record of resolved issues.

Technical support provides troubleshooting, product activations, onsite repair appointment scheduling or field technicians.

Data processing and database clean-up will keep information accurate with data imaging, data correction, medical records uploading, mail receipt, document scanning, and address correction/ verification services.

Booking reservations and appointments has never been easier and more reliable. Never miss a booking or appointment again with RCCbpo’s help to qualify, gather, organize, record and execute books within predefined parameters.

Sales and telemarketing with RCCbpo mean assistance with acquisition sales, order taking and fulfillment, lead generation, up sell products, and business-to-business (B2B) sales resolution.

Quality assurance with in-house professionals will verify that procedures and policies are consistently followed, and customer satisfaction is always achieved. Dedicated analysts will ensure processes are standardized and efficient.

Financial and debt collection will ensure that you will receive what you are owed. RCCbpo’s experience in receivables management and loss mitigation means collections are called in efficiently.

As a company committed to the local community and an industry leader, RCCbpo is guaranteed to provide a service to suit your needs with highly skilled and qualified labor.

Providing an ideal combination of low cost, nearshore proximity and native English and Spanish speakers, RCCbpo ensures that it adapts accordingly to the high demands of your customers and business models.

INTERVIEW:

BELTRAIDE

Making business happen in Belize, we speak with Dr Leroy Almendarez, Executive Director of BELTRAIDE, as the national statutory body pursues diversification and increased domestic capacity

North America Outlook (NA): Could you talk us through BELTRAIDE’s inception and your current mission?

Dr Leroy Almendarez, Executive Director (LA): BELTRAIDE originally began in 1998 as a trade and investment promotion agency, looking specifically at that landscape as a vehicle to try and enhance those areas. Shortly after, in 2000, it transitioned into what is now formally known as BELTRAIDE, which branched into functional areas such as training and employment, small business development, and exports. We remain focused on investment as the country’s interface, but there is a whole ecosystem that exists under BELTRAIDE. Now

that we are focused on economic recovery, our role has become even more significant. MSMEs are seen as an engine for growth, especially with the current mandates from government, so that has given us greater relevance.

NA: What would you identify as the key industries that are currently transforming the economy in Belize?

LA: There are increasing investment opportunities within offshore and outsourcing, agriculture, fishing, manufacturing, and tourism, and these remain our priority areas. Due to the impact of the COVID-19 pandemic, there was a very quick decline in gross domestic product

28 | North America Outlook Issue 17 BELTRAIDE INDUSTRY SPOTLIGHT

(GDP). But now, it’s rebounding, and agriculture has acted as a substitute in terms of economic activity and income generation for the country.

Business process outsourcing (BPO) is a big focus for us, especially with increased diversity. In fact, there are 28 BPOs operating, employing around 8,000 people with the intention of expanding to 12,000. As a result, there are many avenues available for the expansion of the BPO industry.

The government has enacted various policies, strategies, and put a legal framework in place. Certain legislations have been amended, repealed, and entirely replaced, and we have a national investment policy and strategy

(NIPS) that was passed by the Cabinet last year. This takes a very broad look at some of the major challenges that we face when it comes to doing business in Belize. Skills development is so important when it comes to investment, and we now have a new Fiscal Incentive Act in place since the old version was repealed. This has several incentives for MSMEs that allow for increased productive capacity as we intend to bridge the trade imbalance that exists between exports and imports into the country.

We have also developed an MSME policy and strategy that is all-encompassing with the private and public sectors working very closely together. Ultimately, it’s the government that creates the enabling environment, but it’s

North America Outlook Issue 17 | 29

the private sector that puts it into business. It’s important to build confidence so that they can invest to expand and find new avenues for business growth. At first, we were mainly focusing on traditional products, but now we’re exploring non-traditional sources of output and that has been working well. This includes resources such as coconuts and seaweed, which previously, we would not have included as part of our industrial basket.

NA: A stable political and business environment is an essential consideration for investment. Is this something that Belize benefits from and how does that advantage translate to potential investors?

LA: We have a level of political tranquility that lends itself to economic activities which are stimulated by the various incentives that we have in place. These don’t cater solely to FDI, but also to local investors since we want to

encourage a landscape of joint ventures (JVs) and possible mergers. These are just some of the avenues available to us to expand. Tourism is one such area where there have been several investments, and it’s the same with the blue economy. We have now segregated our economy into blue, green, and orange, because the creative industry is an area where previously, we hadn’t put enough effort into tracking its wealth contribution to the country. There is now a direct focus on how MSMEs can benefit from incentives and programs that will allow them to generate greater economic activity.

NA: How is Belize navigating the global labor shortage across many industries? Would you say the country benefits from a skilled workforce?

LA: Although this is certainly something that we benefit from, there is still a great need to focus on this area. It has never been more important for academia to become aligned with industry, since at the end of the day, this is where skill development should come from. Our academic institutions need to understand the demands that have been created, and the skills required to meet them. This could be anything from a bachelor’s degree to an initiative that simply facilitates upskilling. We want the labor force to have the opportunity for upward mobility across all industries, so that they can progress through to the upper echelons of the value chain.

“WE REMAIN FOCUSED ON INVESTMENT AS THE COUNTRY’S INTERFACE, BUT THERE IS A WHOLE ECOSYSTEM THAT EXISTS UNDER BELTRAIDE”

– DR LEROY ALMENDAREZ, EXECUTIVE DIRECTOR, BELTRAIDE

30 | North America Outlook Issue 17 BELTRAIDE INDUSTRY SPOTLIGHT

BELTRAIDE believes in the green economy and the need to create jobs in areas such as aquiculture and renewable energy

https://bts.gov.bz

MOVING TOWARDS A DIGITAL TAX ADMINISTRATION: YOUR CONTRIBUTION, OUR DEVELOPMENT

A Paperless Department

Meeting your technological needs

Increase of Online Presence

Use of Modern Systems

The Belize Tax Service Department (BTSD) is moving forward to establish a modern tax administration that that will redesign its business model process and procedures to achieve alignment with current good practices and standards of other tax administrations within the region.

With the launch of the Revenue Management System (RMS) and the Integrated Revenue Information System (IRIS), BTSD is one step closer to becoming a paperless department.

The Modernization of the Belize Tax Service Department aims at supporting an atmosphere of ease of doing business in Belize that will build economic growth and sustainability, increase compliance and, provide a fair and transparent tax environment.

Advancing the country’s tourism experience, we speak with the Belize Tourism Board.

Can you tell us about the origins and history of the tourism board?

The Belize Tourism Board (BTB) was established in 1990, as a direct result of the growing needs of the industry and its documented and projected impact on Belize’s economy at the time. Prior to that, Belize gained Independence from Britain in 1981 and around that time tourism had already begun to profit the local and commercial sectors of the country. As Belize became known for its pristine attractions and kaleidoscopic cultures and cuisine, the industry grew. Today, Belize has gone from being mother nature’s best kept secret to a top recreational and adventure destination within the Caribbean region, and our unique offerings continue to be recognized on the international stage. Tourism continues to play a fundamental role in Belize’s GDP growth; this realization is a confirmation of the tourism industry’s significance and potential for further sustainable growth and investment.

What kind of traveler does Belize mostly cater to?

Belize caters to a wide array of travelers but our most notable visitors range from the beach seekers (those wishing to dive and explore the marine ecosystem or just relax on the beach side) to those who wish to explore inland adventurous opportunities. Belize has also been recipient to numerous group trips including religious affiliated groups, university students on field trips and families. More and more, the destination is also being recognized by those seeking to immerse themselves in local cultures, music and food.

Looking ahead, what are the board’s key priorities and targets for the next 12 months?

We are committed to the overall upgrade of the sector, positioning Belize as a premium eco-sustainable destination and investing in the development of our people. The BTB recently rolled out its Elevate Training Program, aimed at improving service delivery and security standards across the industry.

In terms of strategic policy development, Belize’s tourism sector is experiencing dynamic growth. As such, the completion of the National Sustainable Tourism Master Plan in 2023 will ensure that adequate policies and legislation are in place to provide guidance to the industry and preserve our product and environment.

An enhanced tourism product centered on conservation initiatives is leading the change for transformation in Belize. We look to focus on the development of our orange economy, partnerships with local NGOs to develop tourism trails and attractions, as well as increased sustainable practices employed by hotels and resorts.

We are also looking to gain continued

sector support for increased industry resilience regarding natural disasters and economic shocks. Significant insight has been gained throughout the last three years to ensure that mechanisms are in place for the recovery of the industry post shock, as well as strategic alliances with local financial institutions to make emergency finances available in the form of grants and low interest loans. What trends have you identified recently within the travel and tourism industry?

Belize continues to be a pioneer in sustainable tourism, with over 40 percent of our land and marine environment in protected status. This is evidenced by our recent Blue Bond initiative, which resulted in a debt swap for nature conservation, as well as our commitment to the Bonn Challenge which will increase our current acreage of littoral and riparian forests.

We continue to see growth in experiential tourism, with adventurebased eco-tourism topping the list. We are renowned for diving, our archaeological sites, and an expansive underground cave network. Essentially, we are a melting pot of cultures, and our communities have given birth to engaging experiences where individuals

are able to explore unique hiking trails, discover hidden waterfalls and immerse in all aspects of our culture and gastronomy.

Festival tourism has also begun to gain a foothold, with products such as the Chocolate Festival of Belize, our Annual Lobster Festival, and the recent addition of the Belize International Music and Food Festival, creating diverse experiences for visitors.

Could you identify some recent challenges faced within the industry and how the board has overcome and dealt with these?

One challenge faced is the lack of direct flights from Europe. Currently, the European market can connect through the US, Cancun and Panama. Additional connections are available from major cities such as Roatan, San Salvador, San Pedro Sula and Guatemala City, which alleviate connectivity challenges. A fixed charter service or dedicated airline will greatly assist in bridging the gap for European connectivity.

Another challenge is the need to expand and upgrade facilities at our international airport. Our load capacity exceeds 90 percent and requires infrastructural upgrade and expansion. To meet the increased demand, the airport concession group will be investing BZD200 million in a three-phase renovation and expansion process. The project includes the addition of six new aprons, a multi-level terminal expansion, enhanced safety and security requirements, and the addition of an FBO facility.

What is the most underrated spot or best-kept secret location for tourists and visitors that the board would recommend?

Toledo is a hidden gem in Southern Belize. The region is brimming with tradition, culture, serenity, and

relaxation and is rich in experiences such as tucked-away caves, ancient archaeological sites, cultural experiences, and paradisiacal islands off the coast. Toledo offers an adventure for every type of traveler. But beyond our most popular visited locations such as San Pedro Town in Ambergris Caye, Caye Caulker, Hopkins, and Placencia, emerging destinations such as the Sarteneja (the Corozal Bay) and the Gales Point Manatee regions are poised for growth due to new highways now being built to connect these destinations for easy access.

www.belizetourismboard.org

In terms of the green economy, we need the creation of green jobs in areas such as aquaculture, and renewable energy. Belize is a country that is committed to net zero, and we are dedicated to reducing our carbon footprint in the era of climate change. We are focusing on renewable energy sources, since this is what we primarily use in Belize. We still import fossil fuels from Mexico, but we are hoping to bridge that gap with renewable sources and ultimately become a net exporter of renewable energy. Furthermore, there are employment opportunities in the blue economy, where we are focused on our fisheries, aquaculture, and mariculture both onshore and offshore. Under the orange economy, we are placing a greater emphasis on business methodologies and for those businesses to understand that the more activities that are generated, everyone can find a niche. This is how we have segregated our economy to be able to identify the skills being demanded by the different industries.

NA: How does Belize maintain an openness to trade?

LA: The Caribbean Forum (CARIFORUM) is a big advantage for us as an expansion of The Caribbean Community and Common Market (CARICOM), since it includes the Dominican Republic as well. CARICOM is key, and we engage through that scheme as a signatory to the CARICOM single market and economy (CSME).

Belize holds the position of Deputy Chair of Caribbean Export Development Agency (CEDA), and I currently occupy the post of Deputy Chair for Belize. When we sit and plan, we look at the region in terms of trade, investment, and how we can develop best practices when we analyze our projects and try to understand how we can make our space more competitive. These forums provide us with a greater opportunity to sell these projects by interacting with international trade bodies. We have been involved with Saudi Arabia and two conferences held in Dubai. This allowed us to convene meetings with potential investors, looking at our rate of return and the entire investment banking process.

CARIFORUM is very beneficial to us, since not all countries are on the same level. Belize has also been a

34 | North America Outlook Issue 17 BELTRAIDE INDUSTRY SPOTLIGHT

Flags of the Caribbean Community and Common Market (CARICOM)

member of the Caribbean Basin Initiative (CBI) for quite some time, and that continues to provide us with benefits, alongside the Caribbean Basin Trade Partnership Act (CBTPA).

Outside of the Caribbean, we engage in partial scope agreements (PSAs). As an example, we have an existing agreement with Guatemala, and have been negotiating to try and expand that arrangement. We are also currently in discussions with Mexico, and we have an economic cooperation agreement in place with Taiwan. The latter is extremely beneficial as Taiwan looks to import more seafood.

Central America is a huge market for us, since Belize is known as the bridge between Central America and the Caribbean. We seek to bridge CARICOM and Central

America. Being both English and Spanish speaking, we can take advantage of different possible opportunities in terms of trade and investment. Under CSME, you can enjoy the free movement of trade, goods, and people. Furthermore, we have political integration with Central America, with an eye towards economic integration. We are also looking to our private sector to ensure that, with any negotiation or agreement that is formalized, we have the availability to provide the necessary product or commodity, since these arrangements are typically quota driven.

There are a lot of markets for us to explore, but it means that domestically, we need to increase our export productive capacity. The environment for that is being created, and so we need to continue building confidence with the private sector by reducing the cost of doing business as much as possible. By allowing them to increase capacity, we can then explore other markets available with the suite of products to allow us to play in those areas.

NA: How does BELTRAIDE support the development of local women in business?

LA: Belize benefits from a seat at SICA in Central America. In fact, the country currently occupies the presidency pro-tempore. There are several bodies under SICA, one of which I preside over, CENPROMYPE, that oversees

rc brokerage & consultancy co. ltd our ser VI ces

and export custom clearance -

I on ser VI ces

I ng ser VI ces

I ng agent

I on and quotat I on

ser VI ces - cargo I nsurance - comprehens IV e, fr I endly and knowledgeable staff rcbrokerage . b Z coro Zalbrokers@yahoo.com 501-423-8575 501-610-5157 14 YEARS OF EXPERTISE YOU CAN RELY ON

- I mport

transportat

- complete handl

- fre I ght forward

- free consultat

of our

“WHATEVER WE DO, WE CREATE AN EQUILIBRIUM BETWEEN INVESTMENT AND MAKING SURE THAT OUR ENVIRONMENT IS PROTECTED”

North America Outlook Issue 17 | 35 BELTRAIDE INDUSTRY SPOTLIGHT

– DR LEROY ALMENDAREZ, EXECUTIVE DIRECTOR, BELTRAIDE

Central American countries. Here, we have been discussing methodologies and opportunities to create greater economic activity through diversification in Central America as well.

Through this, we adopted an initiative called the Female Entrepreneurship Program (FEP), where we provide training in leadership and business methodology. This guides them through how to access the market with a product or service and how to brand it. So far, we have had four cohorts of graduates, and it is a methodology that has been catching on. We have also partnered with Taiwan and through this, we have been able to provide even greater opportunities. We recently concluded the ‘MSME Roadshow’, where we went to 10 different locations to launch pop-up shops that local women could get involved in to bring greater awareness for those in the area on what is being produced.

Recently, we also launched an incubator, guiding women in business on how to develop a start-up, understand how a business works, and how that business can interact with others. We have also launched a solar-powered ICUBE which has been converted into a mobile office and travels across the country to reduce the cost for MSMEs that cannot afford to come to us, and that way we can interact with them. We are also setting up digital connect centers in rural areas of the country, where there are many single mothers who work from home, so they can go to that location and access the information they require. We are bridging the digital divide, since the COVID-19 pandemic showed us the importance of being connected digitally.

NA: Finally, how do you forecast the investment landscape developing across Belize over the next five years?

LA: Firstly, thanks to the expansion of the fiscal incentive, those who were operating under the old model have now transitioned. As a result, they now benefit from additional incentives, customs duty, excise duty, replacement duty and in some cases, business tax. The process has now been shortened, so it is simpler for foreign direct investors. We also have a designated processing area and are becoming far more technologically minded. We have broadened the landscape of incentives that potential investors will be able to benefit from over the next five years and I forecast exponential growth in certain areas. This particularly applies to renewable energy, agriculture, agro-processing, tourism, and BPO. In addition, there are the non-traditional areas that have risen to the fore, including seaweed farming, where we are seeing traditional fish farmers transition to that model.

We are exploring and taking full advantage of the natural endowments that we have, but in a way that has no potential for costly damage to the environment. Whatever we do, we create an equilibrium between investment and making sure that our environment is protected.

BELTRAIDE Tel: (501) 880 – 3737 / 0137 beltraide@belizeinvest.org.bz www.beltraide.bz

36 | North America Outlook Issue 17

Business Consulting

Belize companies; LLCs; trusts; foundations; bank accounts; international insurance licenses; FSC licenses; and ancillary services

Real Estate full-service brokerage; relocations; property management; new developments

Title and Escrow appraisals; title searches; escrow agent; attorney title closings

CONTACT US support@ame.bz

+501-223-4501 123 Barrack Road, P.O. Box 322, Belize City, Belize

www.ame.bz

www.amerealty.bz

North America Outlook Issue 17 | 37 BELTRAIDE INDUSTRY SPOTLIGHT

Tell us your story and we’ll tell the world

NORTH AMERICA OUTLOOK is a digital product aimed at boardroom and hands-on decision-makers across a wide range of industries on the continent.

With content compiled by our experienced editorial team complemented by an in-house design team, the resultant Outlook Creative Services department ensures delivery to the highest standards in promoting the latest in engaging news, industry trends and success stories across the length and breadth of the US & Canada.

As a bi-monthly publication, North America Outlook constantly has its finger on the pulse of the latest trends, biggest developments and business successes from each corner of the region, epitomized by the diversity displayed across each magazine. It incorporates an annual calendar-tailored front-of-book section, a showcasing segment dedicated to the most fascinating success stories in North America, and an event focus assortment sure to fill executives’ diaries throughout the year. The aligning North America Outlook website is also honed and ready to serve as a host for these facets and much more.

To get involved, please contact Outlook Publishing’s Managing Director, James Mitchell, who can provide further details on how to feature your company, for FREE, in one of our upcoming editions.

Providing electrical services for commercial, industrial, and institutional buildings for seven decades SOUTHWEST ELECTRIC CO. / TRULY NOLEN INGLETT & STUBBS LLC As deathcare undergoes a technological transformation, Mel Payne, CEO and co-Founder of Carriage Services, provides insight into an industry where compassion is key BELTRAIDE The investment agency making Belize Central American hub for trade and economic potential AIR TRANSAT A.T. INC Advancing North American air travel FREE Marketing Opportunity www.northamericaoutlookmag.com/work-with-us

ILLUMINATING THE INDUSTRY

Inglett & Stubbs LLC has been providing electrical services for commercial, industrial, and institutional buildings for seven decades. President, Miller Chalk, sheds light on the company’s projects