TREAD ON THE RUNWAY

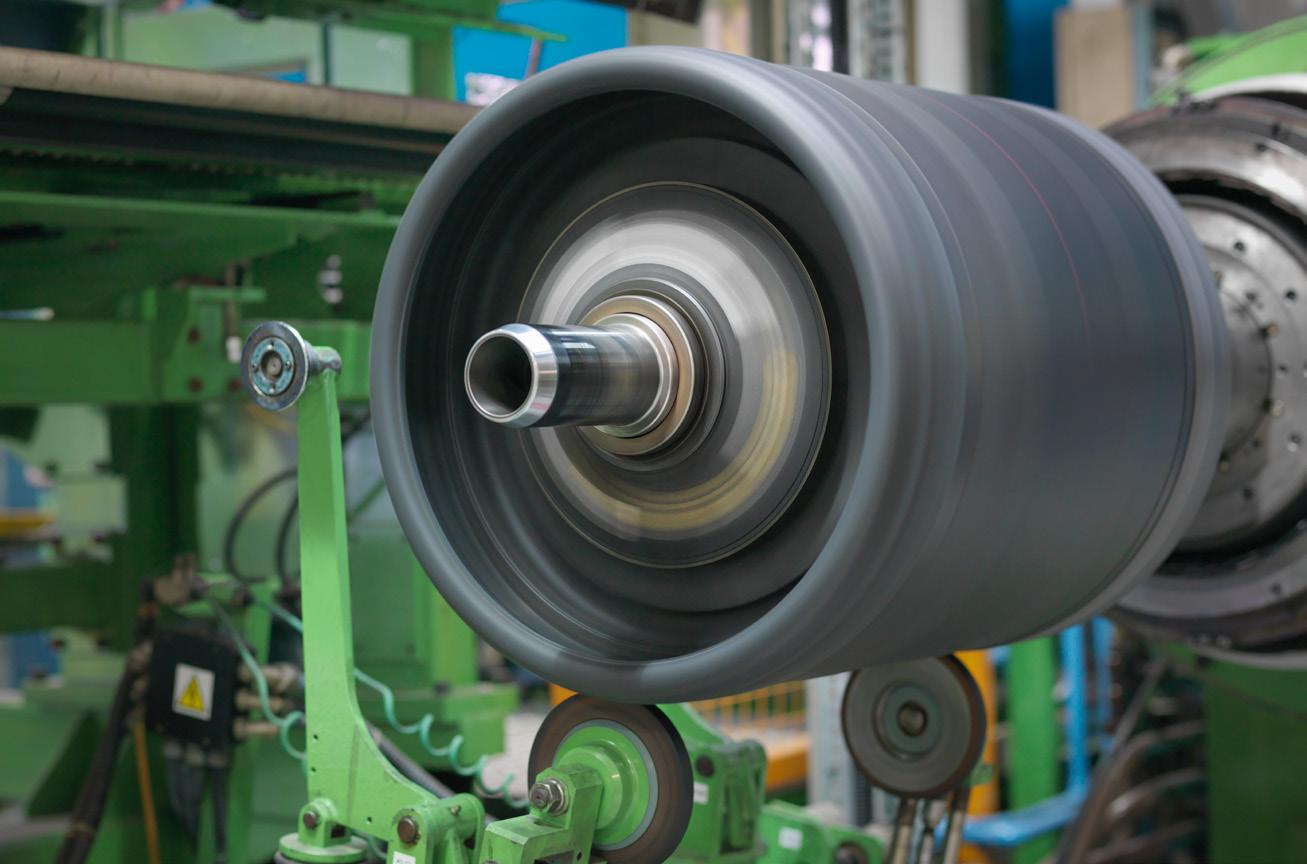

Most importantly, Dunlop is 100 percent focused on designing, manufacturing, and retreading worldclass aircraft tyres.

ÖZKA TYRESA VALUED PARTNER

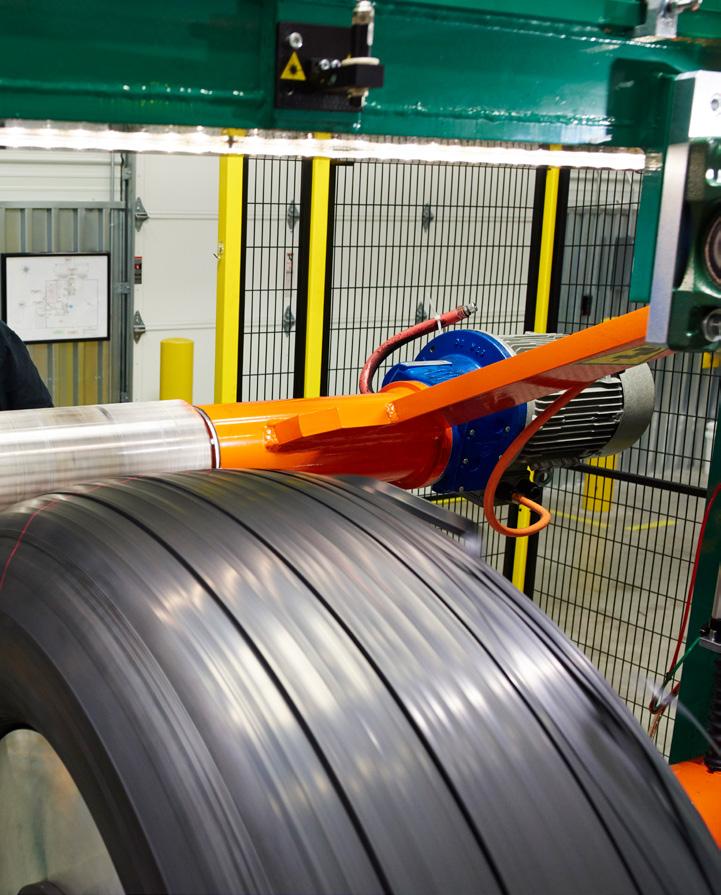

Özka Tyres (Özka) has been a valued partner in broadening Dunlop’s manufacturing base and helping to meet demand surges. The collaboration has allowed Dunlop to test new supply chain models whilst maintaining high standards.

Recognised for its excellence in manufacturing and innovation, Özka continues to expand its presence across global markets, with particularly strong and growing sales figures in Europe.

Operating with an extensive international footprint and delivering products to over 90 countries, the company stands out for its commitment to high performance, durability, and continuous development.

Özka’s production facility supports a daily capacity of 260 tonnes, establishing it as one of the leading players in the global tyre industry. Its integrated R&D centre drives innovation in tyre engineering, creating solutions tailored to agricultural and industrial needs.

The company offers one of the industry’s most comprehensive product portfolios, including VF (Very High Flexion) and radial tractor tyres, flotation and implement tyres, as well as products for harvesters, irrigation equipment, forestry, industrial and off-the-road (OTR) vehicles, forklifts, compactors, light trucks, and minibuses. Özka embraces sustainability as a core strategic pillar, investing in environmentally responsible materials, energy-efficient production, and advanced waste management systems, actively shaping a future where highperformance tyres and environmental responsibility coexist.

A BROAD PORTFOLIO

What sets Dunlop apart is that it is currently the only tyre company in the world solely dedicated to aircraft tyres.

“Our core focus is on designing, manufacturing, and retreading tyres for both fixed-wing and rotary aircraft. Headquartered in Birmingham, UK, with service facilities in the US and China, our global presence spans over 80 countries,” explains Susan.

“We supply tyres to a diverse range of customers, including commercial passenger airlines, military forces, recovery services, and freight operators.”

With over 300 product approvals, Dunlop’s tyres support a wide array of aircraft, from AgustaWestland helicopters to the massive Antonov AN-124 transporter.

“Our tyres are fitted on everything from regional aircraft like the Bombardier Q400 to narrow-body jets such as the Boeing 737 and freight carriers including the Airbus

A300, Boeing 757, Boeing 747, and McDonnell Douglas MD-11.”

In the military sector, Dunlop provides tyres for advanced platforms such as the Lockheed Martin F-35B fighter jet and BAE Systems Hawk trainer aircraft, as well as large transport aircraft like the Boeing C-17 and Airbus A400M.

As air transport continues to evolve rapidly, the company is now also actively engaged in the emerging unmanned aerial vehicle (UAV) and air taxi sector.

RELIABLE SERVICE

For Dunlop, nothing is more important than the customer.

“The operator is always at the heart of everything we do because each tyre we make or retread earns its right to be called a Dunlop,” states Susan.

“This means our drive for everimproving product performance and tyre safety is as determined as it is relentless,” she affirms.

“WE ARE SMALL, BUT THAT’S OUR STRENGTH – WE’RE FOCUSED, HUNGRY, AND HAVE THE COURAGE TO DO THINGS DIFFERENTLY”

– SUSAN MCKENNA, CEO, DUNLOP AIRCRAFT TYRES

As a true aviation specialist, Dunlop understands better than any the crucial contribution of both performance and service to dispatch reliability.

“With the operator at the heart of everything we do, dispatch reliability is our focus.”

Now standing as a globally recognised brand and symbol of quality, working in partnership with airframers and industry stakeholders, it’s no surprise Dunlop also meets the world’s most exacting aviation standards, approvals, and certifications.

CONTINUOUS GROWTH

Dunlop has recently completed several successful expansions of its retreading capabilities, supporting circular economy objectives by extending tyre life without compromising safety.

“Parallel to this, we’ve invested in digital inspection tools and

data analytics to enhance lifecycle forecasting for operators. In 2023, we also introduced policy deployment to align our long-term vision with actionable goals,” Susan prides.

This approach enables the setting of annual targets that support Dunlop’s medium and long-term

strategies, with goals cascaded across departments to ensure alignment and accountability.

“In addition to our ongoing attention on new products, improvements, and infrastructure, I’d say our most significant investment today is in our people.

DUNLOP’S KEY PRIORITIES FOR THE COMING YEAR

The company is laser-focused on:

• Delivering growth despite a tough cost environment.

• Continuing its leadership development programme.

• Enhancing digital capability in operations.

• Expanding its reach in strategic markets, including defence and in Asia.

• Becoming more investment-ready by driving performance and clarity in everything it does.

“We’re currently implementing a multi-year transformation strategy that prioritises leadership development, technical training, and rethinking how we embed innovation at every level of the company,” she tells us.

Undoubtedly, Dunlop recognises the future lies in empowering its team to drive progress, which is why it remains focused on nurturing talent and fostering a culture of continuous growth.

“We believe leadership is visible in the agency of others; that’s why we give our people space to grow. We’ve implemented weekly, monthly,

and quarterly check-ins focused on behaviours, not just tasks.”

For Dunlop, it’s about unlocking the best version of someone each day and celebrating progress, not just outcomes.

“Alongside this, we’re investing in developing new compounds to further enhance performance and sustainability, ensuring we stay at the forefront of technological advancement and environmental responsibility,” Susan acclaims.

RESILIENT TO THE CORE

At Dunlop, company culture is built on quiet resilience.

“There is a deep sense of pride in the craftsmanship of what we produce. We are still operating on the tyre factory site built in 1916, and many of our employees have been with us for years, contributing to our strong sense of continuity,” Susan posits.

“We’re able to give tailored, responsive service, something that makes a real difference to operators who can’t afford downtime. We’re also proud of our UK-based manufacturing legacy and close relationships with our customers.”

Resilience is a core value for the company; Dunlop always stays the course. It also values collaboration

and open-mindedness and, above all else, remains entirely responsible, never sacrificing the quality or safety of its people, products, or customers.

Alongside this, the company operates a tightly-controlled, highlycompliant global supply chain. Strong relationships with partners are critical – Dunlop can’t deliver safety-critical products without total trust and performance transparency.

Moving forwards, Dunlop is working to nearshore some aspects of its supply chain to mitigate risk and improve responsiveness.

“I believe this is a pivotal moment for the company. We are small, but

that’s our strength – we’re focused, hungry, and have the courage to do things differently.”

“We’re not trying to be our competitors – we’re trying to be the best version of Dunlop,” Susan concludes proudly.