w w w.e u r o p e o u t l o o k m a g.c om

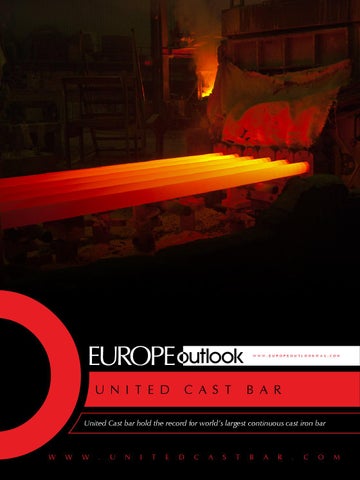

UNITED

CAST

BAR

United Cast bar hold the record for world’s largest continuous cast iron bar

w

w

w

.

u

n

i

t

e

d

c

a

s

t

b

a

r

.

c

o

m

w w w.e u r o p e o u t l o o k m a g.c om

UNITED

CAST

BAR

United Cast bar hold the record for world’s largest continuous cast iron bar

w

w

w

.

u

n

i

t

e

d

c

a

s

t

b

a

r

.

c

o

m