A MASTERCLASS IN SUSTAINABLE ENERGY

Positioned as key enablers of the increasingly prevalent energy transition, Nooter/Eriksen Milan has become an industry leader in sustainable energy management, specialising in world-class heat recovery steam generators amongst other state-of-the-art products. We delve into the company’s innovative solutions

Writer: Lucy Pilgrim | Project Manager: Cameron Lawrence

The sustainable energy management sector continues to evolve at pace, expected to be worth over USD$111 billion by 2030.

Such rapid development is primarily driven by growing digital technologies and an industry-wide push towards electrification, which are steadily increasing demand and calling for more forward-looking energy solutions.

At the helm of this evolution is Nooter/Eriksen Milan (Nooter/ Eriksen), a leading specialist in sustainable energy management,

responsible for designing and constructing cutting-edge equipment for more efficient power plants worldwide.

Established in 1987, the company was formed from an amalgamation of two local businesses, whose combined expertise created the perfect formula for continuous growth into a vast range of energy markets.

Today, Nooter/Eriksen is proud to be part of CIC Group, a US-based industrial holding company renowned for advancing global energy infrastructure.

Nooter/Eriksen is a fundamental component in this mission as it brings value to sustainable power through long-standing process and thermal design expertise across gas-fired power plants, ensuring its customers’ facilities are as economical and environmentally friendly as possible.

More specifically, it delivers unmatched knowledge and support services to unlock efficiencies and minimise unnecessary power and heat wastage, allowing plant owners to enjoy tangible profit margins whilst also reducing their greenhouse gas (GHG) emissions.

Leveraging the financial muscle of CIC Group, Nooter/Eriksen strives to continue its vision of reducing the negative environmental impacts associated with the energy industry in collaboration with its customers, delivering cutting-edge solutions across the world to eliminate power and energy wastage.

Delivering mission-critical infrastructure to gas plants across the world, Nooter/Eriksen is a world leader in heat recovery system generators (HRSGs) which are key to improving plant efficiency and cutting GHG emissions.

With more than 1,000 HRSGs in operation globally, the company’s leading heat recovery technology has evolved to meet the growing needs of combustion turbines and achieve key targets in thermal performance and sound and emissions reduction.

Nooter/Eriksen’s primary offering comprises a natural circulation system with a horizontal exhaust flow and vertical tube design, both with internally insulated casing and structure. The company is also on-hand to offer alternative vertical solutions when needed.

Once-through steam generators (OTSGs), also available to clients, use two single-pass stages to evaporate and partially superheat steam flows

once through the initial stages.

Nooter/Eriksen’s leading HRSG technology is specially designed to alleviate concerns around constructability, shipping, reliability, and maintainability, whilst still meeting project requirements.

Regarding the former, the company guarantees low installation costs through tailored field construction solutions that overcome local building challenges and in-land transportation restrictions.

Indeed, design details are purposefully curated to minimise field construction hours whilst maximising the size and scope of components, which can be designed to accommodate jobsite space and crane limitations.

Elsewhere, Nooter/Eriksen designs and supplies a vast portfolio of comprehensive products which help it to meet increasing industry demand and advance customers’ plants across the world.

Nooter/Eriksen is distinguished in the sustainable energy management sector by its unmatched experience and adaptability, with a diversified project portfolio at each customer’s disposal.

Indeed, sustainability principles are considered from the earliest stages of engineering and product development, compounded by the company’s cutting-edge planning and implementation strategies upheld by

a project management-centric ethos.

As a result, clients can trust that each contract is executed in a timely manner and to a world-class standard, no matter its complexity.

On top of this, Nooter/Eriksen specialises in international procurement and sourcing, drawing from an extensive global supplier network that ensures the sound delivery of products.

For instance, the company depends on the expertise of steel and manufacturing suppliers across many parts of Asia, including Thailand, China, South Korea, and Vietnam, whilst acquiring many of its emission control devices and systems from vendors in the US and Europe.

Nooter/Eriksen’s international partnerships are forged in the same way it nurtures client relationships – establishing collaborations built on mutually understood goals and objectives.

• HRSGs

• Selective catalytic reduction and carbon monoxide catalyst systems

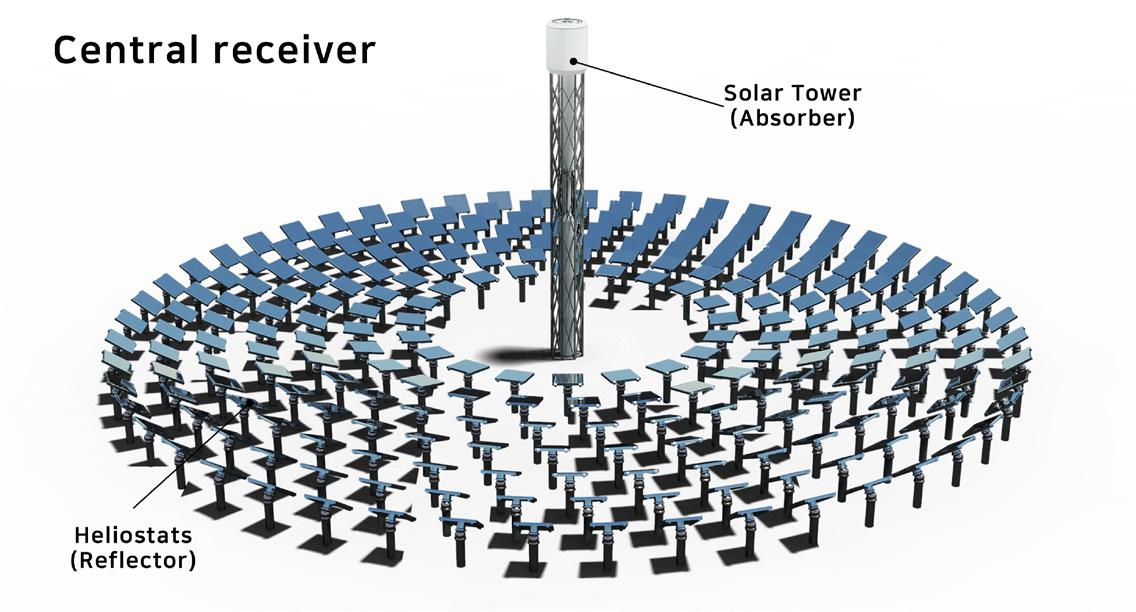

• Molten salt receivers to be integrated into concentrated solar power towers

• Fired boiler packages

• Grate combustion boiler packages for WtE and biomass plants

• Enhanced oil recovery steam generators

• Low-low temperature economisers

To ensure a clear set of standards are consistently met, the company puts both its suppliers and products through rigorous testing, inspection, and quality controls to guarantee sourced products meet customer expectations.

Nooter/Eriksen also works with notable engineering, procurement, and construction (EPC) companies such as Bechtel Corporation, GE Vernova, Siemens Energy, and many more.

Nooter/Eriksen has achieved an enviable global footprint, with its Italian headquarters (HQ) supported

by offices in the US, UK, South Korea, Thailand, the United Arab Emirates, and China.

This allows the company to be in close proximity to its international customer base thanks to a further 19 remote sales representatives, enabling it to provide localised support.

In particular, Nooter/Eriksen’s Italian HQ specialises in world-class aftermarket services, having recently launched its new Waste-to-Energy (WtE) and Aftermarket Department, collating WtE and biomass expertise under one roof.

This means that clients now have an end-to-end point of contact

throughout their project lifecycle, from initial ideation through to design, engineering, manufacturing, and construction, making the company a trusted supplier of energy management services.

In addition to project execution, Nooter/Eriksen is also on hand to provide post-competition support services, including maintenance, spare parts, performance optimisation, and equipment upgrades.

Going beyond mere organisational restructuring, the creation of the WtE and Aftermarket Department signifies a step change in client support and underpins the company’s ongoing commitment to project delivery.

SINCOO METAL LIMITED

is one of the most reliable and globally active sales and marketing organisations in the steel pipe and tube industry. With over 15 years of experience, we have built a solid worldwide network and provided comprehensive steel piping and tubing solutions for a broad range of industries — including Power Generation, Oil and Gas, Chemical and Petrochemical, Automotive, Rail Transportation, Offshore, and Construction.

2023: Continued cooperation with a supply volume of 5,440 tonnes.

Our product portfolio covers stainless steel and alloy steel seamless pipes and tubes, welded pipes and tubes, fittings and flanges. Thanks to our long-term partnerships with first-class manufacturers in China, we are able to guarantee premium quality, stable supply, and cost-effective solutions for both bulk project orders and customised requirements.

In the Power Generation sector, SINCOO has built a strong reputation in the Heat Recovery Steam Generator (HRSG) field — a core component of Combined Cycle Power Plant (CCPP) projects. We specialise in supplying super-long tubes for modules and large-diameter pipes and fittings for headers, nozzles, and piping spools. With years of experience supporting global CCPP projects and profound technical experience, we provide reliable and complete solutions that meet the high technical specifications of leading project owners and EPCs.

Since 2021, SINCOO has established a strong partnership with Nooter/Eriksen (NE), a world-leading specialist in sustainable energy management. By successfully delivering complete packages in different projects with NE, SINCOO has made steady progress in the CCPP field:

2021: Partnered with NE for the Syrdarya Combined Cycle Gas Turbine (CCGT) Power Plant Project in Uzbekistan, supplying module tubes and header and nozzle pipes totalling 3,882 tonnes, officially entering NE’s supplier list.

2022: Cooperation deepened with a supply of 5,800 tonnes of tubes, pipes, and fittings for the Tuxpan CCPP, González Ortega Power Station, and San Luis Rio Colorado CCGT Power Plant Project.

2024: Supplied 7,900 tonnes of tubes and piping products for Saudi Arabia’s Taiba-2 and Qassim-2 decarbonised CCGT Projects (2 × 1,800 MW).

2025: Undertook Saudi Arabia’s Ghazlan and Hajr Projects, totalling 8,256 tonnes of supplied materials.

SINCOO believes that material quality defines project success. We maintain direct cooperation with top-tier steel mills and global manufacturers to ensure all products meet international standards and strict project specifications. For example, as the sole export agent of Jiangsu Yinhuan, a world-leading seamless stainless steel pipe and tube manufacturer, we fulfill this commitment by delivering not only high-quality products but also technical consultation, material selection advice, and project-based support.

These services extend across all our partnerships, allowing SINCOO to provide complete end-to-end solutions — from production and quality control to logistics and after-sales service — simplifying complex global procurement processes whilst helping clients reduce costs and improving competitiveness.

At SINCOO, we focus on one mission — to make our valued clients more valuable.

Nooter/Eriksen is also proud to have been recently awarded a new project in Southeast Asia, which involves three two-pressure-level HRSGs. Significantly, these are fitted with next-generation technology to ensure maximum efficiency and reliability for the project, enabling the power plant to effectively meet the needs of the oil and gas sector.

This project represents a major progression in the company’s longstanding collaboration with the client, further solidifying the partnership.

Through its operations, Nooter/ Eriksen recognises that effective energy management – and the way power is produced and transformed

– are key obstacles facing sustainable development and combatting climate change.

On a mission to bring value to sustainable energy management, environmentally friendly operations are at the heart of the business, as is Nooter/Eriksen’s dedication to collaborating with local communities in its supply chain.

The company’s principles and commitments are defined in its Code of Sustainability, which is drawn from the UN’s Sustainable Development Goals (SDGs).

Elsewhere, at the core of the company’s spirit is an ownership mentality which has carried it from strength to strength, as each staff member has a vested interest in the success of the business, leading to

• 1987 – Founded from the amalgamation of Eriksen Engineering in Tulsa, Oklahoma and Nooter Cogan Group located in St. Louis, Missouri, where the company opened its inaugural facility.

• 1992 – Awarded its first HRSG contract for a project in Medway, UK. This also marked Nooter/Eriksen’s first design with reheat systems for improved plant efficiency.

• 1993 – Became the first HRSG supplier in the US to be ISO 9001-certified and obtained an Occupational Health and Safety Assessment Series (OHSAS) 18001 certification.

• 1998 – Awarded the first HRSG used in the Westinghouse W501G gas turbine as part of the Millennium Power Plant Project in Massachusetts.

• 2006 – Worked on a project with Toshiba that meant Nooter/Eriksen was the first supplier to import a large HRSG into Japan.

• 2010 – Awarded the first H-Class HRSG for the US market.

• 2011 – Awarded the first J-Class HRSG from Mitsubishi Motors for the Yulchon Power Project in South Korea. The company was also awarded the Crescent Dunes Solar Energy Project – the first concentrated solar power plant with a central receiver tower and advanced molten salt energy storage technology.

• 2017 – Developed supercritical HRSG technology.

• 2019 – Acquired Pensotti Technology – an Italian boiler manufacturer –greatly expanding Nooter/Eriksen’s product range.

• 2020 – Signed an exclusive licensing agreement with HydroFLOW USA to combine electronic water conditioning technology with power generation, refining, and other industrial facilities.

• 2023 – Launched NEXT – a new business unit that designs and supplies cooling towers and air-cooled condensers for different industries and applications.

consistently outstanding results and steadfast project execution.

With this in mind, Nooter/Eriksen proactively creates a workplace environment where each employee feels valued and empowered to do their best work, enabling them to contribute ideas to better the business.

This is underpinned by Nooter/ Eriksen’s dedication to the provision of equal treatment, applicable to all in-house staffing decisions including recruitment, hiring, placement, development, promotion, training, scheduling, benefits, and compensation, amongst other areas.

To further value its team members, the company continually facilitates staff development opportunities to allow them to reach their full potential, including on-the-job training, in-house education initiatives, and a tuition reimbursement programme to support growth across the organisation.

Such comprehensive employment strategies correlate with Nooter/ Eriksen’s unmatched capabilities in designing and constructing stateof-the-art equipment, cementing the company’s position as the world’s leading specialist in energy management.