PEVCA MALTA AVOIRA Direct access to unmatched technology services EPC GROUPE Mining success and innovation in the Euro-Mediterranean area Safe, clean, and efficient offshore and onshore well decommissioning WELL-SAFE SOLUTIONS LTD Adel Mir, CEO, speaks about his passion for trailer manufacturing and NAZ Industries LLC’s proud journey to becoming an international name www.emeoutlookmag.com Issue 59

Africa Outlook, APAC Outlook, EME Outlook, North America Outlook, Mining Outlook, Healthcare Outlook, Manufacturing Outlook, and Supply Chain Outlook are digital publications aimed at boardroom and hands-on decisionmakers, reaching an audience of more than 800,000 people around the world. With original and exclusive content compiled by our experienced editorial team, we look to promote the latest in engaging news, industry trends and success stories from across the globe. Your company can join the leading industry heavyweights enjoying the free exposure we provide across our platforms with a free marketing brochure, extensive social media saturation, enhanced B2B networking opportunities, and a readymade forum to attract new investment and to help you grow your business. Visit www.outlookpublishing.com/work-with-us for details on how your company can feature for free in one of our upcoming editions.

Tell us your story, and we’ll tell the world www.outlookpublishing.com/get-involved DEICORP Experts in residential, commercial, and retail property development RGGOLD Kazakh innovation, exploration, and excavation The envy of industry around the world, Australia’s high-productivity heavy vehicles are ready to undertake any and every task imaginable HEAVY VEHICLE INDUSTRY AUSTRALIA Darren Webb CEO of Evolution Data Centres, tells us about the company’s success in building, owning, and operating hyperscale infrastructure PHILIPPINE AIRLINES PEVCA MALTA AVOIRA Direct access to unmatched technology services EPCGROUPE Mining success and innovation in the Safe, clean, and efficient offshore and onshore well decommissioning WELL-SAFE SOLUTIONS LTD Adel Mir CEO, speaks about his passion for trailer manufacturing and NAZ Industries LLC’s proud journey to becoming an international name www.emeoutlookmag.com Issue 59 THE DREW COMPANY LOCKHEED MARTIN At the forefront of Founded in 1982, The Drew Company has curated a diverse portfolio of visionary real estate projects and public-private partnerships Leon de Bruyn President and CEO, discusses Lummus Technology’s fully integrated, end-to-end solutions solidified by global expertise and an extensive history RESONAC GRAPHITE BUSINESS in-class graphite www.northamericaoutlookmag.com DECATHLON CANADA ECONET TELECOM LESOTHO PATTERN MATCHED TECHNOLOGIES Committed to reaching one billion people across Africa on reverse billed data Taelo Mojapelo CEO of bp Southern Africa, ushers in a new era of sustainable socioeconomic development for the region KFCAFRICA Finger Lickin’ Good food across subwww.africaoutlookmag.com Ngaire Tranter, General Manager at BUMA Australia, takes us through her vision to build a modern mining and rehabilitation company driving growth, sustainability, and prosperity BCI MINERALS Delivering multigenerational KMCMINING Growth and an evolving industry The latest updates from De Beers on the underground expansion of South Africa’s leading diamond mine VENETIA UNDERGROUND PROJECT PIMSGROUP resource potential www.mining-outlook.com ARIS MINING VILLAGE NATIONAL GROUP Dr Ahmed Hersi MD, MBA CEO of King Saud University Medical City, speaks about the hospital’s aim to advance its medical practices Advanced Dermatology and Cosmetic Surgery Utilising a relationshipbased care model between patient and clinician to deliver premier healthcare MATILDA INTERNATIONAL HOSPITAL APOLLOMD ST. ANTONIUS HOSPITAL Providing innovative and person-centred care for the Netherlands NOVACINA Facilitating Australian manufacturing REVOLUTIONARY INNOVATION THE ROAD TO FORMEX INDUSTRIES World-class manufacturing capability THE DRAKE GROUP has emerged as a significant force within Australia’s transport, logistics, and heavy haulage industry, providing high-quality and wide-ranging products and services KONGSBERG DEFENCE AUSTRALIA The premier supplier of defence products and systems César Habib Regional Director for Rolls-Royce Motor Cars Middle East and Africa, discusses the growth of its bespoke projects and private office network www.mfg-outlook.com KROMBERG & SCHUBERT / BAMBURI CEMENT PLC PHILIPPINE AIRLINES With a proud heritage, Philippine Airlines continues to forge a path of innovation and customer-centric service with Captain Stanley Ng at the helm; the President and COO discusses plans, pilots, and progress WEERTS GROUP Optimising efficiency with logistical flow DELTA CARGO global cargo network DHL EXPRESS express shipping Trendsetters in end-to-end package delivery solutions, we unwrap what makes UPS Canada stand out with President, Stephanie Dexter DIGISTICS / HEAVY VEHICLE INDUSTRY AUSTRALIA www.supplychain-outlook.com ISSUE 1

EDITORIAL

Head of Editorial: Jack Salter jack.salter@outlookpublishing.com

Senior Editor: Lucy Pilgrim lucy.pilgrim@outlookpublishing.com

Editor: Ed Budds ed.budds@outlookpublishing.com

Editor: Lily Sawyer lily.sawyer@outlookpublishing.com

Junior Editor: Lauren Kania lauren.kania@outlookpublishing.com

Junior Editor: Rachel Carr rachel.carr@outlookpublishing.com

PRODUCTION

Art Director: Stephen Giles steve.giles@outlookpublishing.com

Senior Designer: Devon Collins devon.collins@outlookpublishing.com

Designer: Louisa Martin louisa.martin@outlookpublishing.com

Production Manager: Alex James alex.james@outlookpublishing.com

Digital Marketing Director: Fox Tucker fox.tucker@outlookpublishing.com

Web Editor: Oliver Shrouder oliver.shrouder@outlookpublishing.com

Social Media Executive: Jake Crickmore jake.crickmore@outlookpublishing.com

BUSINESS

Chief Executive Officer: Ben Weaver ben.weaver@outlookpublishing.com

Managing Director: James Mitchell james.mitchell@outlookpublishing.com

Chief Commercial Officer: Nick Norris nick.norris@outlookpublishing.com

HEADS OF PROJECTS

Josh Rayfield josh.hyland@outlookpublishing.com

Deane Anderton deane.anderton@outlookpublishing.com

Eddie Clinton eddie.clinton@outlookpublishing.com

Ryan Gray ryan.gray@outlookpublishing.com

BUSINESS DEVELOPMENT DIRECTOR

Thomas Arnold thomas.arnold@outlookpublishing.com

TRAINING & DEVELOPMENT DIRECTOR

Joshua Mann joshua.mann@outlookpublishing.com

SALES & PARTNERSHIPS MANAGER Donovan Smith donovan.smith@outlookpublishing.com

PROJECT MANAGERS Alfie Wilson alfie.wilson@outlookpublishing.com

Cameron Lawrence cameron.lawrence@outlookpublishing.com

Kierron Rose kierron.rose@outlookpublishing.com

Kyle Livingstone kyle.livingstone@outlookpublishing.com Liam Pye liam.pye@outlookpublishing.com

Nicholas Kernan nicholas.kernan@outlookpublishing.com

ADMINISTRATION

Finance Director: Suzanne Welsh suzanne.welsh@outlookpublishing.com

Finance Assistant: Suzie Kittle suzie.kittle@outlookpublishing.com

Finance Assistant: Victoria McAllister victoria.mcallister@outlookpublishing.com

EME OUTLOOK

Norvic House, 29-33 Chapelfield Road

Norwich, NR2 1RP, United Kingdom

Sales: +45 (0) 1603 363 631

Editorial: +45 (0) 1603 363 655

SUBSCRIPTIONS

Tel: +45 (0) 1603 363 655

jack.salter@outlookpublishing.com

www.emeoutlookmag.com

Like us on Facebook: facebook.com/emeoutlook

Follow us on Twitter: @eme_outlook

WHERE THERE’S A WELL, THERE’S A WAY

Welcome to our 59th edition of EME Outlook magazine.

The economic and sociopolitical importance of decommissioning continues to grow in the UK.

Though around nine percent of UK Continental Shelf platforms have been decommissioned to date, there remains plenty of work to do to manage the country’s petroleum legacy.

Indeed, several more assets in one of the world’s most tightly regulated and safety-conscious mature basins are set to move into the decommissioning phase in the coming years.

However, this requires different methodologies to those needed for drilling and therefore necessitates a dedicated well decommissioning specialist – enter this issue’s cover star, Well-Safe Solutions Ltd.

Phil Milton, CEO, discusses the company’s groundbreaking approach to this fast-growing segment of the global energy sector.

“We’re still in the early stages of well decommissioning, and it’s exciting to address some of the challenges that are out there,” Milton states.

By comparison, the Euro-Mediterranean quarry industry historically served by EPC Groupe is a mature and well-established market in France, where the worldleading explosives company built its first ever plant in Saint-Martin-de-Crau over 130 years ago.

Luis Calvo, Area Manager for Europe and the Mediterranean, tells us how EPC Groupe works with stakeholders in the region to provide the best technical and operational solutions.

“We play a key role in the mining chain, and we enact this responsibility with passion in order to continue contributing positively to our industry,” Calvo affirms.

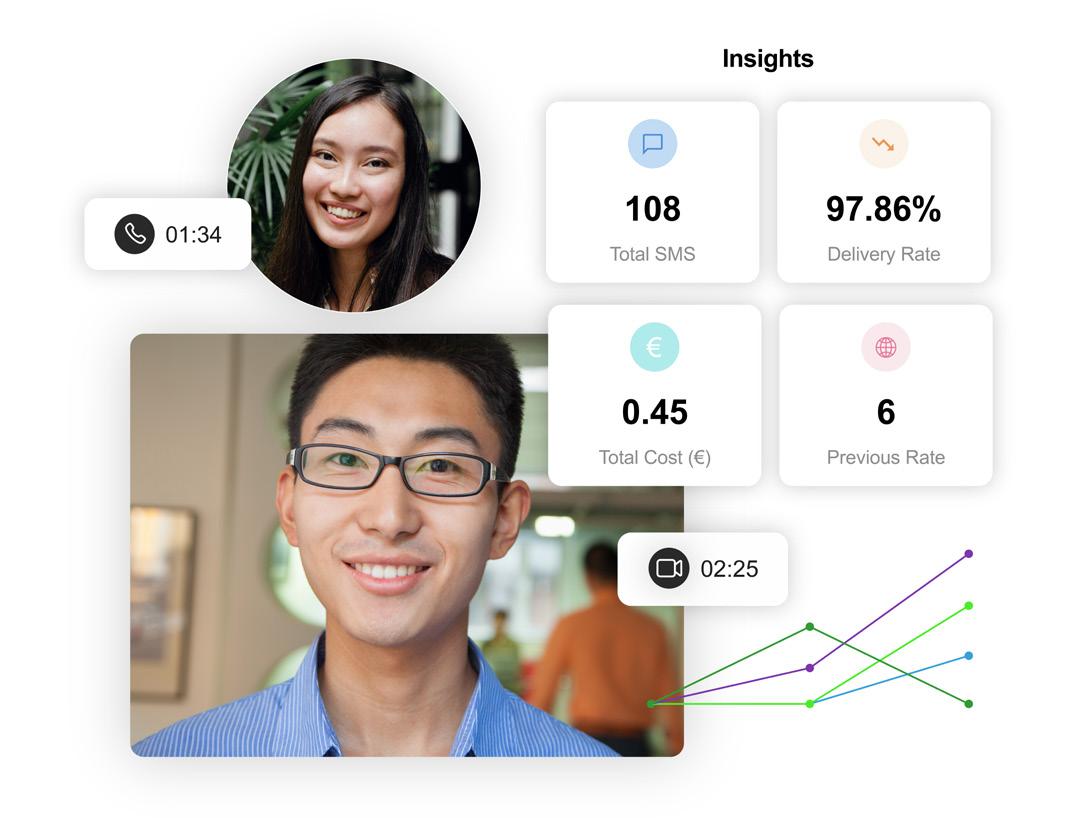

The key business areas that Avoira offers leading expertise in, meanwhile, include radio, IT, communications, devices, audio-visual, and more.

Serving a plethora of customers across many public and private industry verticals, we learn about the numerous projects in the communications powerhouse’s burgeoning portfolio.

“We have so many exciting customer projects, from working with hospitals and schools to transform their telephone solutions, through to equipping hundreds of meeting rooms with video conferencing equipment,” enthuses Head of Marketing, Scott Mordue.

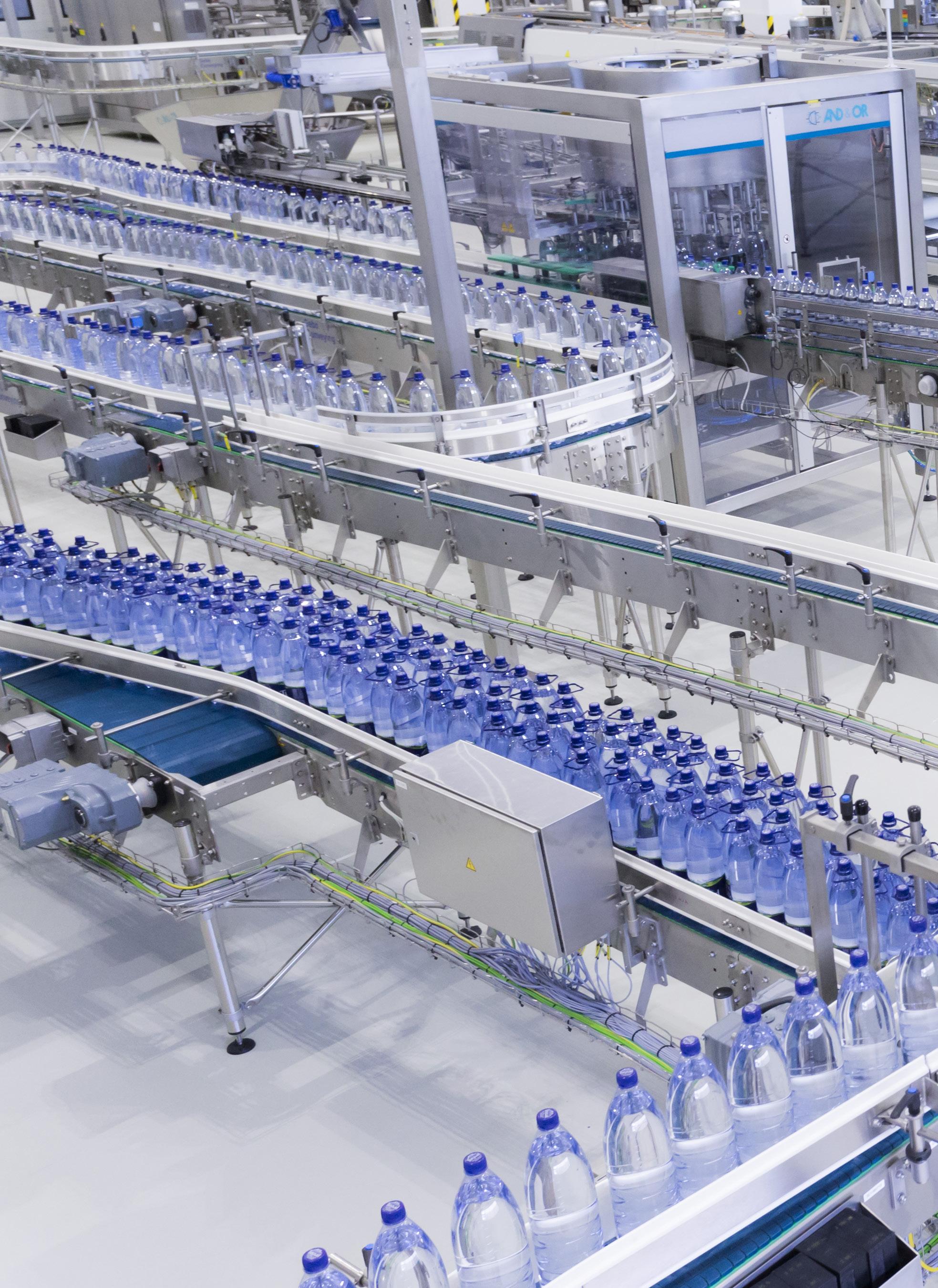

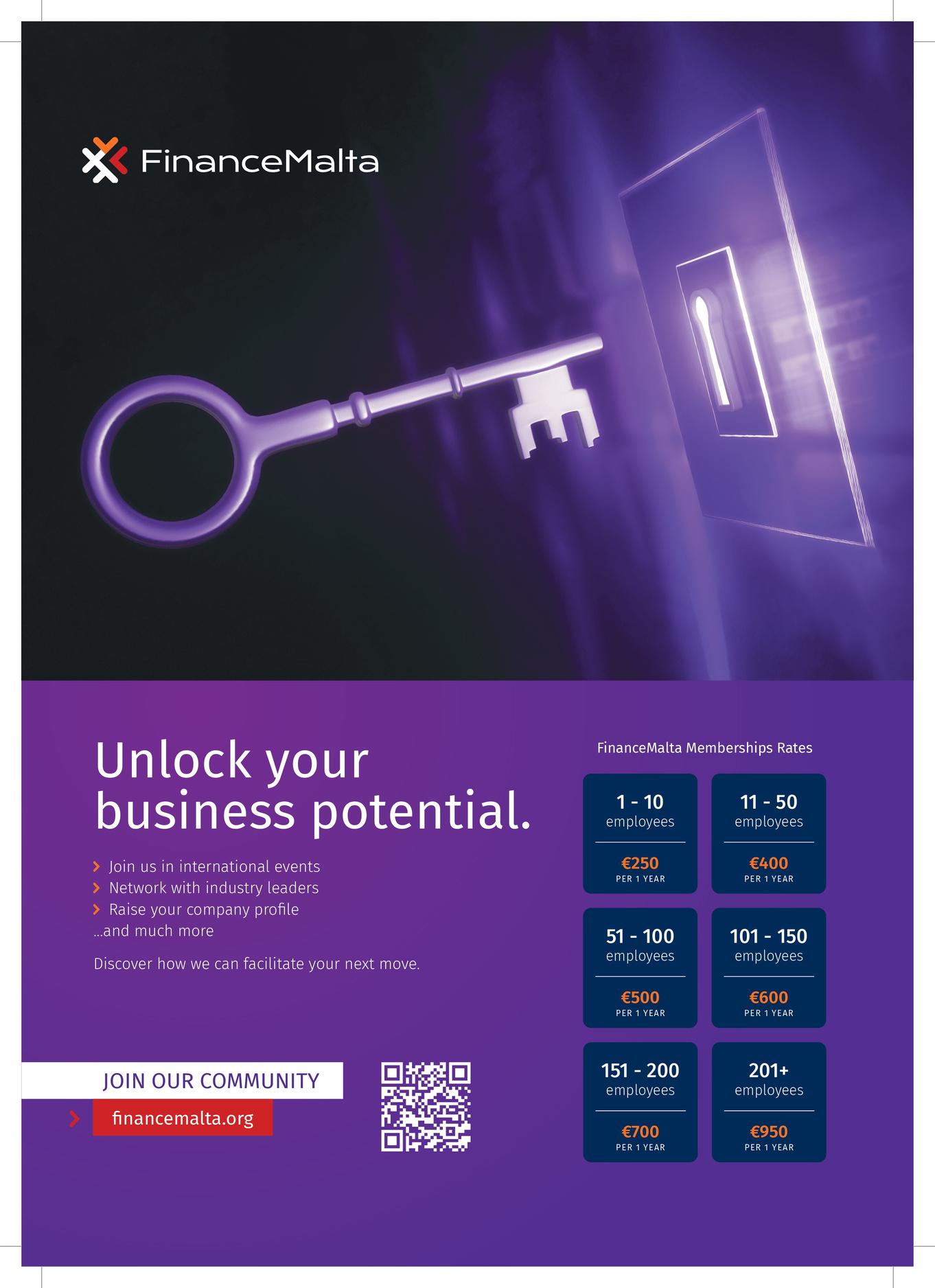

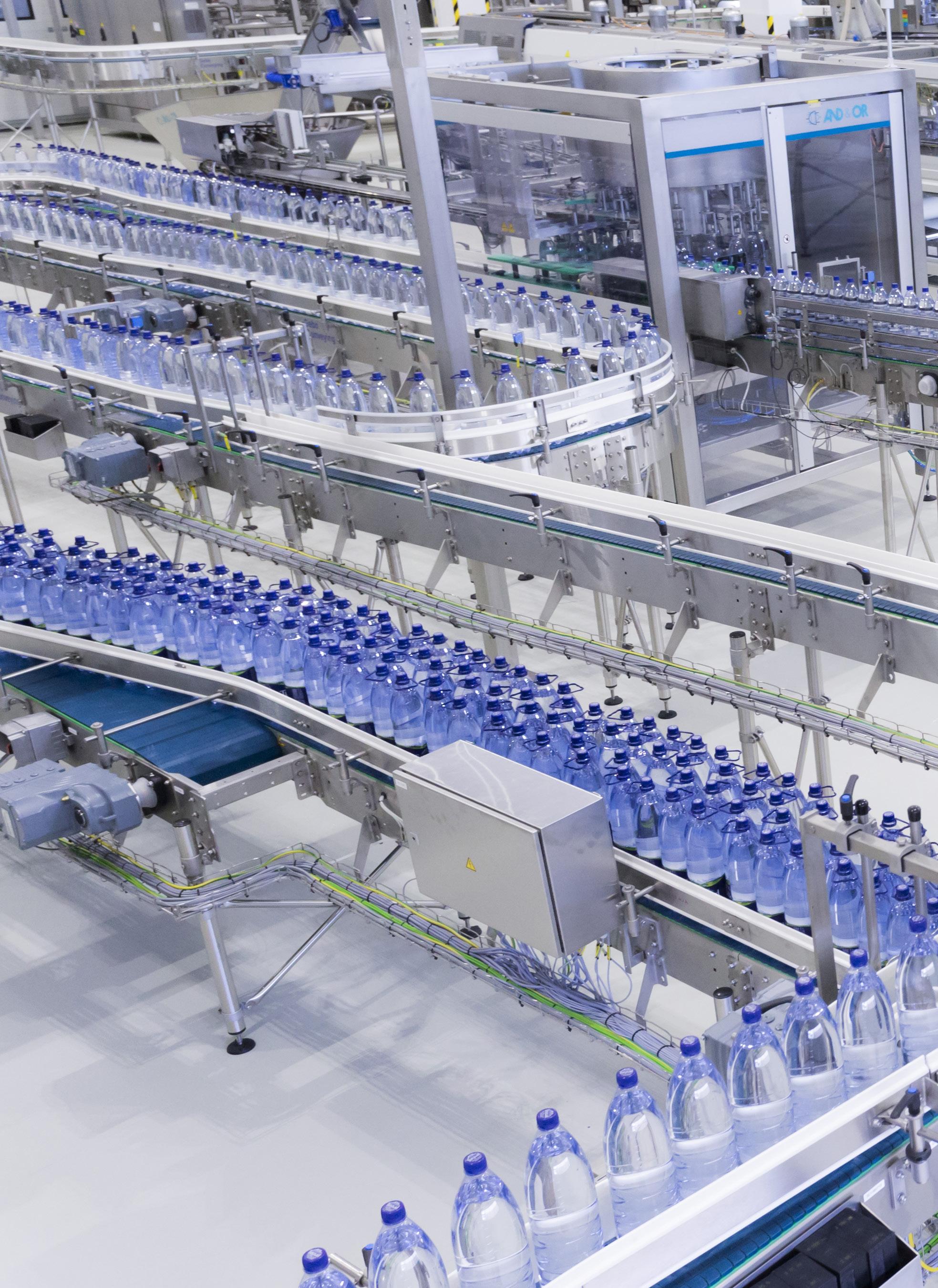

This issue also spotlights NAZ Industries LLC as a beacon of success in trailer manufacturing, PEVCA Malta as a hub for collaboration, innovation, and growth in the financial services sector, Perla Harghitei and Apemin Tușnad as Romania’s most modern and dynamic natural mineral water companies, and more.

We hope that you enjoy your read.

Jack Salter Head of Editorial, Outlook Publishing

EME Outlook Issue 59 | 3 WELCOME FROM THE EDITOR

REGULARS 6 NEWS Around Europe and the Middle East in seven stories 8 EXPERT EYE A new management model to cultivate a healthier workplace BUSINESS INSIGHTS 10 Manufacturing Bike to the Future Partnering to craft bespoke, highperformance cruisers 16 Technology Optical Networks that Bridge Gaps Cutting-edge optical networking solutions 10 20 16 TOPICAL FOCUS 20 Sport Samba Showdown England face Brazil in preparation for EURO 2024 118 THE FINAL WORD Who or what do you look up to for inspiration? CONTENTS 26 4 | EME Outlook Issue 59

SHOWCASING LEADING COMPANIES

Tell

your story and we’ll tell the world

Dedicated to Decommissioning

48 EPC Groupe

Pushing the Boundaries of Excellence

Mining success and innovation in the Euro-Mediterranean

MANUFACTURING

68 NAZ Industries LLC

Delivering Energy, Driving Progress

A beacon of success in trailer manufacturing

76 Agrostroj Pelhřimov

A Leader in Industrial Production

Comprehensive production solutions for global players

82 Resonac Graphite

Business Unit

The Power of Chemistry

Supplying best-in-class graphite electrodes

Powering Prosperity Promoting the Maltese economic environment

FEATURES 24

OIL

us

& GAS 26 Well-Safe Solutions Ltd

Safe, clean,

offshore

well decommissioning 36

Navigating Efficiency, Economics, and Environment Leading the world in process technology and solutions 68 76 48 36 102 112 FINANCE 102

and efficient

and onshore

Lummus Technology Successfully

PEVCA Malta

TECHNOLOGY 94

Avoira

Today Direct access to unmatched technology services

Towards Greatness Leading the way in explosives technology MINING

Unlocking Tomorrow’s Solutions

58 EPC Asia Pacific Blasting

area FOOD & BEVERAGE 112 Perla Harghitei

Apemin

and

Tușnad

Sustainably Quenching Romania’s Thirst

natural mineral water

EME Outlook Issue 59 | 5 EME OUTLOOK CONTENTS

The country’s most modern and dynamic

companies

VIVA LA ATOS

STRUGGLING IT COMPANY, Atos, has received an offer from the French government to acquire its advanced computing, mission-critical systems, and cybersecurity product divisions.

The deal is based on an indicative enterprise valuation of between €700 million and €1 billion. In addition, Atos’ sovereign activities must remain under the control of France. The company is facing mounting debt, which is causing financial difficulties.

Shares in Atos jumped by as much as 19 percent when the news broke of the French government’s offer. However, over the past seven years, supply chain issues, accounting errors, and broader industry challenges have set the company back.

DIAMONDS ARE NOT FOREVER

UK-BASED MULTINATIONAL

MINING giant, Anglo American, has announced plans to sell or demerge major parts of the company, including its De Beers diamond operation, Anglo American Platinum, and its steelmaking coal business.

TRANSPORT

FLY TO DUBAI SUPERSIZED

DUBAI’S LEADERSHIP HAS approved a USD$35 billion plan to build a new passenger terminal at Al Maktoum International Airport, which will be the largest in the world.

When completed, the airport, also known as Dubai World Central (DWC), will cover 27 square miles and is projected to have the capacity to service 260 million passengers and handle 12 million tonnes of cargo annually. The increased activity means a new city will be built around the airport, creating housing for one million people.

Dubai’s Ruler, Sheikh Mohammed bin Rashid Al Maktoum, says new technologies will be employed for the first time in the aviation sector.

The news follows the rejection of a £34 billion bid from Australiabased BHP, which has pressured the 107-year-old company to deliver value to investors.

BHP wants to buy Anglo American for its copper operations, however, the company declined an increased takeover offer. The deal would have brought two of the biggest mining firms in the world together.

TECHNOLOGY

MINING 6 | EME Outlook Issue 59

Europe

the Middle

in seven stories… NEWS

Around

and

East

THE PUBS OTHER BEERS CANNOT REACH

BREWING BEHEMOTH, HEINEKEN, has recently reopened 62 closed pubs and invested £39 million in refurbishing hundreds of sites across the UK.

Moreover, a cash injection into its Star Pubs & Bars chain will create more than 1,000 new jobs. The industry has been hit hard

PLANS TO WALK THE PLANK

A POWER COMPANY in the UK has drawn up plans for the world’s first wood-powered cargo ship as Drax claims it can help reduce greenhouse gas emissions (GHG) from sea freight.

The UK government supports using wood as a fuel and has allowed the company’s subsidiaries to produce green energy.

However, using natural materials as an energy source can cause air pollution issues, and critics point out that trees grow slower than the time

by closures due to the COVID-19 pandemic, whilst cost-of-living pressures have taken a toll on consumer spending. Many of the pubs that Heineken is reopening have been shut for more than four years.

The move was bolstered by the UK government’s Spring Budget, which announced that a freeze on alcohol duty would continue until February 2025 and that a 75 percent discount to business rates for retail, hospitality, and leisure companies had been extended.

it takes to use them for fuel, raising questions as to how sustainable they are.

Furthermore, Drax has signed a deal with three Japanese shipping companies to develop a bioship fuelled by wood chips instead of marine diesel.

FOOD & BEVERAGE

LIQUID GOLD

A SHORTAGE OF olive oil has driven prices to record highs and pushed the industry into crisis mode, causing a surge in crime.

The superfood staple of the Mediterranean diet has been severely affected by extreme weather, which has impacted production in Southern Europe, particularly in Spain, Greece, and Italy.

Spain, the world’s largest exporter of olive oil, has halved its production due to drought and heat, increasing prices by 112 percent in the last couple of years. Supermarkets in the country have reported it as the most stolen item, with criminal gangs as the main culprits for resale on the black market.

TECHNOLOGY

BOT WARS – A FALCON FOR THE MILLENNIUM

ABU DHABI’S TECHNOLOGY

Innovation Institute (TII) has released a new open-source generative artificial intelligence (AI) model to rival efforts from large technology companies.

TII has released two groundbreaking versions of Falcon 2, the institute’s best-performing model yet. Falcon 2 11B is a more efficient and accessible large language model (LLM), whilst Falcon 2 11B VLM is distinguished by its vision-tolanguage model capabilities.

The Falcon 2 series has arrived just as companies are racing to develop their LLMs following the release of ChatGPT in 2022 by OpenAI.

In the near future, there are plans to broaden Falcon 2 by introducing a range of sizes. Advanced machine learning (ML) capabilities will further enhance these models.

RETAIL

REOPENING

ENERGY & UTILITIES EME Outlook Issue 59 | 7

A NEW APPROACH: HELPING LEADERS NAVIGATE TODAY’S BUSINESS CHALLENGES

Dominic Ashley-Timms, CEO of performance consultancy

Notion, assesses the growing disconnect between today’s business leaders and their employees and explores the feasibility of implementing a new management model to cultivate a healthier workplace

Writer:

Dominic Ashley-Timms, CEO, Notion

It is difficult to ignore the growing disconnect between businesses and their employees that most industries are witnessing today. Despite organisational attempts to introduce more agile ways of working, leaders are still failing to respond to the fact that the world has progressed. People’s values have changed; they’re more selective now and they want more for themselves, their work-life balance, and their sense of purpose and development at work. If these elements are found wanting, people vote with their feet, placing a strain on recruitment, engagement, and the retention of remaining staff.

Organisations across the board are similarly affected. For instance, the construction industry faces exceptionally high staff shortages, needing nearly a million new recruits over the next decade. A similar story can be seen in the mining industry, with 86 percent of mining executives finding it harder to recruit and retain the talent they need. The challenges faced by the retail, health and social care, travel, tourism, and hospitality sectors are further compounded by being counted among the top 10 industries with the least job satisfaction.

The quality of management plays a

crucial role in helping to address these business challenges. Shockingly, 28 percent of workers have left a job just to escape from a negative relationship with their manager; research reveals this has a disproportionately larger impact on mental health than other close relationships. The message is clear – time is up and we must transform management capability with a new approach now to have a measurable impact on employee satisfaction, engagement, recruitment, and retention.

WHY MANAGEMENT NEEDS A REVOLUTION

For too long, managers have been regarded as super workers, relied upon to keep the show on the road by resolving day-to-day issues and managing performance. This prevailing command-and-control style has remained essentially

8 | EME Outlook Issue 59

unchanged for the past century; leadership determines the strategy and issues directives, which are cascaded to managers who direct the workforce to carry them out. This approach is now outmoded in the modern work environment.

Why? Consider for a minute the impact that this can have if the mindset is: I’m the manager, I’m in control, and the buck stops with me. I’ve got to direct my team; there’s work to be done. I should be there for my team, and when they come to me with problems, I’ll need to have the answers. It’s my job to solve their problems and fix the issues. I need to firefight to keep everything on track. What actually happens is, as a result of this mindset, managers take on too much work, which leads to increased stress. Their team perceives ‘problem solving’ as a managerial task, and therefore don’t try to resolve issues themselves; they wait to be told what

to do and lean on management for direction.

In this situation, the manager is not only taking on more, but they’re also inadvertently robbing employees of valuable learning opportunities to devise solutions to challenges themselves, which is crucial for their own learning and career advancement. The consequence is that staff become discouraged by a lack of development and their confidence, growth, and competence is impacted. Ultimately, this diminishes employee engagement and productivity levels.

ADOPTING AN ENQUIRY-LED APPROACH

True leadership is less about directing and more about enabling others and helping them flourish. What can leaders do if the traditional command-and-control approach to management isn’t working? The answer, it turns out, is for managers to adopt more of an enquiry-led approach, which means learning to ask more powerful questions.

By helping managers learn when and how to ask more insightful questions in situations that offer the potential for a better outcome, instead of directing staff, a culture of value and appreciation emerges, leading to higher levels of employee productivity, performance, and retention.

When a team member comes to their manager with a problem, for example, a well-intentioned question designed to stimulate the other person’s own thinking might well lead to a better idea or action. For example, “what could have been the impact of that?” or, “is there a way we could achieve a different result?”. This also means that the ownership of any ideas generated by this dialogue remain with the employee; they’re their ideas, not the manager’s.

By learning to tune in to the different situations they encounter

daily, managers can learn when and how to ask more powerful questions that provoke deeper reflection from team members. By utilising this Operational Coaching® style of management, leaders develop a coaching mindset that helps them to tap into the talents of their team members, whilst preventing themselves from stepping in to solve every problem. In this way, team members retain accountability for solving more of the day-to-day problems, increasing confidence and resourcefulness.

CONCLUDING THOUGHTS

Mastering the skill of asking more powerful questions requires training – it’s not something managers have been taught how to do, but it is a crucial skill for leaders in every industry to develop. A wellintentioned, purposeful question builds collaborative and trusting manager-employee relationships, with staff more satisfied in their roles and better equipped to tackle future challenges. This enhances a sense of ownership and fulfilment amongst team members, improves productivity, and cultivates a healthier workplace.

Who wouldn’t want to work in an environment like that?

ABOUT THE EXPERT

Dominic Ashley-Timms is the CEO of performance consultancy Notion, creators of the multi-award-winning and globally-certified STAR® Manager programme being adopted in over 40 countries. Ashley-Timms is also the co-author of management bestseller The Answer is a Question.

EME Outlook Issue 59 | 9

EXPERT EYE BUSINESS

We showcase Hexagon’s partnership with ARCH Motorcycle to craft bespoke, highperformance cruisers, supporting the quality control demands of engineering and producing unique riding experiences

Writer: Jack Salter

ARCH Motorcycle (ARCH) owners seek more than just a machine.

Rather, these passionate individuals are in search of a completely immersive riding experience.

As such, each ARCH motorcycle is built from an obsession with innovative design, engineering excellence, and dedication to the rider.

Founded by Keanu Reeves and Gard Hollinger in 2011 to challenge the perception of what an American motorcycle could be, ARCH has partnered with Hexagon, a global leader in digital reality solutions headquartered in Stockholm, Sweden.

Hexagon is a major player in the industrial technology space, focusing on harnessing highprecision data to boost efficiency, productivity, quality, and safety across a wide range of industries including aerospace, automotive, construction, and mining.

The company’s cutting-edge technologies utilise data from design and engineering, production, and metrology to make manufacturing

10 | EME Outlook Issue 59

BIKE TO

EME Outlook Issue 59 | 11 HEXAGON MANUFACTURING

smarter, contributing to the production of 90 percent of aircraft, 75 percent of smartphones, and 95 percent of every automobile worldwide.

Whilst a lot of its business is centred around mass production, Hexagon’s measurement technologies are also trusted by precision manufacturers, including prominent names such as Hendrick Motorsports, Oracle Red Bull Racing, and the regulatory bodies of F1 and WorldSBK.

By taking advantage of the technologies behind industry giants,

smaller manufacturers can enhance their accuracy, quality, speed, and cost-effectiveness without compromising on creativity, allowing them to push the boundaries of what is possible in bespoke motorcycle manufacturing.

HARNESSING DIGITALISATION

The Hexagon partnership is all about harnessing the power of digitalisation to elevate quality and efficiency. Indeed, it is geared to help ARCH expand its commitment to producing bespoke motorcycles by fully digitising quality processes

throughout engineering and manufacturing with advanced measurement technologies.

Hexagon technologies to be implemented by the ARCH manufacturing team include an easy-to-use portable measurement arm and a state-of-the-art 3D laser scanner.

The latter provides a guided workflow that helps users visualise 3D models and, paired with tightly integrated measurement software, simplifies the scanning of large components and reverse engineering of parts.

12 | EME Outlook Issue 59 HEXAGON MANUFACTURING

Hexagon’s 3D laser scanning technology therefore helps companies such as ARCH to capitalise on time invested in previous projects by providing the ability to retain, reuse, and apply elements of successful designs for products in development.

As a result, there is no need to return to the drawing board for time-consuming development when existing design data can easily inform and enhance in-progress designs.

3D laser scanning also makes it possible to easily capture accurate measurement data to ensure

HEXAGON MANUFACTURING EME Outlook Issue 59 | 13

that high-quality parts are being accurately produced and can be seamlessly assembled.

Hexagon’s laser scanning solutions help ARCH to create tailored, ergonomic motorcycle designs that incorporate individual customer specifications. By digitising these customisations, they can be seamlessly integrated into the manufacturing process.

This blend of craftsmanship and digital efficiency strengthens ARCH’s ability to produce meticulously finished bikes while maintaining repeatability and precision.

DIGITAL BLUEPRINT

Highly custom manufacturing entails keeping track of a much larger number of details and differences that may appear minor but could significantly affect the success of a project.

However, the partnership with Hexagon allows ARCH to keep an accurate digital 3D record of each customer’s motorcycle, supporting future customer service and potential customisations.

Keeping a paper trail of job details and changes is a comparatively error-prone and time-consuming

endeavour that diminishes throughput and makes it difficult to communicate project details across departments and teams.

Fully digitised processes, on the other hand, provide a blueprint that everyone can easily follow, from engineers through to production and inspection personnel.

This ensures that staff have access to identical, up-to-date, accurate, and easy-to-access information, streamlining communication and

14 | EME Outlook Issue 59 HEXAGON MANUFACTURING

reducing errors.

Hexagon has therefore found a natural partner in ARCH and understands the unique passion and appeal of its bikes.

This collaboration is a starting point that extends beyond digitising parts; it’s about enhancing future product development workflows.

Now that ARCH has the ability to quickly digitise parts, it is also streamlining its 3D digital workflows for computer-aided design

(CAD), making 3D scanning an invaluable part of its future product development.

The partnership is a great example of the benefits of combining precision engineering with cutting-edge technology that has been tested and proven at production scale.

Together, Hexagon’s metrology expertise and ARCH’s artistry demonstrate a shared commitment to excellence in craftsmanship and innovation.

www.hexagon.com

EME Outlook Issue 59 | 15 HEXAGON MANUFACTURING

THAT BRIDGE GAPS OPTICAL NETWORKS

Emerging with a simple yet determined dream to take India to the forefront of technological advancements, the inception of Sterlite Technologies Limited (STL) was marked by humble beginnings and bold ambition.

Initially established by Anil Agarwal in 1988 as a telecommunications (telecoms) cable company in Aurangabad, India, STL began its journey to international recognition by producing jelly-filled telephone cables.

The business quickly found success and grew its operations over the years, expanding its customer base into international markets. Eventually reaching

With the purpose of transforming billions of lives by connecting the world, Sterlite Technologies Limited is proud to be a leading optical and digital solutions company. Rahul Puri, ONB Sales Head for EMEA, APAC, and India, tells us more

Writer: Lauren Kania

10 global production facilities, offices in 16 different countries, and over 2,628 employees worldwide, STL has proudly made a name for itself as a vital marketplace for cutting-edge optical networking solutions.

“We have a long and accomplished history, and today, we have become a leading global optical and digital solutions company providing advanced offerings to build 5G, rural,

Fibre to the X (FTTX), enterprise, and data centre networks,” introduces Rahul Puri, ONB Sales Head for EMEA, APAC, and India.

“Telecoms operators, cloud companies, citizen networks, and large enterprises alike all rely on STL for advanced capabilities in optical connectivity, global services, and digital and technological solutions to build ubiquitous and future-ready digital networks.”

16 | EME Outlook Issue 59

Puri has over 20 years of experience in the technology and telecoms industry, having worked for companies such as Apple, Samsung, LG, and Airtel.

In his current role, he aims to further increase the company’s global footprint of optical solutions.

36 YEARS OF UNIQUE CAPABILITIES

STL prides itself on providing solutions that are co-developed with its customers to cater to the most pressing needs of today and tomorrow.

As proven by its vast and diverse history, innovation runs through the company’s veins.

This can be directly observed through a variety of STL’s accomplishments, including its ability to continue to find success throughout the COVID-19 pandemic.

“During the lockdowns in 2021, we inaugurated a new optical fibre cable unit in Aurangabad in order to serve overseas clients better,” shares Puri.

“Additionally, in 2022, we launched our first optical interconnect design and assembly unit in India to address global markets.”

Alongside the company’s admirable ability to continue expanding during such an internationally debilitating event, it has also been able to open further locations across Italy, the UK, and the US over the course of the past six years.

“In 2018 and 2020, we acquired both Metallurgica Bresciana, an Italian

optical fibre cable business, and Optotec, an optical connectivity solutions company in Italy. This addition to our optical networking portfolio has allowed us to offer end-to-end optical solutions for national long-distance (NLD), metro, FTTX, and enterprise applications,” details Puri.

The following year, STL acquired Clearcomm, a network integration services company based in Manchester, in an attempt to begin its network planning and deployment services in the UK as well as strengthen its design offerings for hyperscale data centres.

The most recent development occurred in September 2023 when the company inaugurated its fibre optic cable plant and North American headquarters in Lugoff, South Carolina.

These various strategic initiatives, alongside many others, were made in order to accomplish STL’s overarching ambition of making India the fibre capital of the world.

MADE IN INDIA FOR THE WORLD

STL is steadfast in its belief that researching and building accessible network technologies is the way of the future.

Specifically, the company’s optical connectivity solutions are paving the way for digital connectivity in Europe.

“Optical connectivity products such as terminals, connectors, and enclosures are pivotal in taking fibre connectivity to the next level, providing scalable solutions to de-skill field installations and speed up the fibre deployment process,” expands Puri.

STL is able to purpose-engineer solutions that solve specific customer challenges and has found tremendous success with the top service providers across Europe.

Some of these solutions include opto-CRS terminals, compact optical ribbon closures, and opto-bolt

connectors with drop cables.

“Opto-CRS terminals were co-designed and deployed for one of the largest service providers in the region,” explains Puri.

“It is an IP68 enclosure used for underground and aerial networks. The IP68 rating ensures these boxes are shielded against all above-ground and underground elements and are highly compatible across different network architectures.”

This ultimately leads to a longer network life and reduced costs due to a double-layered sealing mechanism that excludes all human error factors.

In addition to these innovative and industry-leading solutions, STL is working in a multitude of ways to achieve its commitment to creating a world with next-generation technologies that transform everyday lives.

“We are working with leading national operators in Italy and top-tier companies in the US to support their rural connectivity plans,” explains Puri.

As part of this effort, the company has brought fibre connectivity to far-flung and underserved villages in Ireland, where it has established an 8,000-kilometre (km) network, and connected thousands of remote islands in Indonesia, where it has built a 5G-ready network.

STL IN NUMBERS:

10 global production facilities

650+ patents in glass science, precision manufacturing, and more TWO innovation centres

Revenues of USD$863 MILLION in 2023

2,628 employees

Customers served in 100+ countries

Offices in 16 countries

EME Outlook Issue 59 | 17 STERLITE TECHNOLOGIES LIMITED TECHNOLOGY

In India, STL is associated with BharatNet, the world’s largest digital inclusion programme, where it is connecting more than 7.5 million citizens in 250,000 villages. In the UK, the company is playing an important role in supporting “Project Gigabit” and working with UK-based service providers. Similarly, it is working with leading national operators in Italy and top-tier companies in the US to support their rural and national connectivity plans for Fibercop and ROF.

EME OUTLOOK: HOW IS YOUR GLASS TO GIGABIT CAPABILITY POWERING EUROPE’S GIGABIT AMBITION?

Rahul Puri, ONB Sales Head for EMEA, APAC, and India: “STL is amongst six players globally (excluding China) to manufacture its own glass preform.

“We are uniquely placed to provide end-to-end gigabit connectivity solutions. With in-house expertise in glass science, material science, precision manufacturing, a bigpicture understanding of network architectures, and deep knowledge of networking deployment and operations, STL brings complete control and predictability across the digital connectivity value chain.

“With extensive experience in the region and advanced manufacturing set-ups in Italy, we have served as a key partner to regional service providers, delivering purposeengineered solutions, meeting the demand for fibre, and reducing lead times across Europe. Our optic fibre cable and connectivity solutions have found tremendous success with top service providers across the region.”

These efforts, alongside many others, showcase STL’s position as one of the top optical players in the world and its determination to continue to pave the way for the future of optical living.

BUILDING A FUTURE-READY STL

STL is steadfast in its determination and commitment to build a better world beyond tomorrow.

The company believes it is essential for future generations to design and implement programmes that create meaningful and lasting change across its value chain and in communities.

It aims to create holistic programmes and undertake sustainability initiatives in a way that benefits society and the environment in a multi-dimensional manner while creating change that is both sustainable and replicable.

“We are committed to minimising our footprint by focusing on developing eco-friendly products and driving community transformation,” prides Puri.

“Our goal is to achieve net zero by 2030, and we are actively working towards 100 percent sustainable manufacturing. Morgan Stanley Capital International (MSCI) has already recognised our environmental, social, and governance (EGS) efforts as A-rated.”

All of the company’s manufacturing units in India and two in Italy are certified for zero waste to landfill and liquid discharge, ensuring responsible water management.

Additionally, STL conducts life cycle assessments (LCAs) for its optical fibre cables to identify the environmental impact throughout a product’s life cycle.

“We also emphasise local procurement, with approximately 61 percent of our cable manufacturing supplies sourced locally in 2022,” further expands Puri.

Innovation, technology, and collective action have always been at the core of STL’s ESG programmes. The company takes pride in levering these competencies to transform lives through sustainable digital networks across its value chain and partnerships that drive equitable growth.

Led by the firm belief that every interaction should be guided by strong moral and ethical standards, STL ensures responsible and sustainable operations, creating shared value for its stakeholders and local communities.

“Behind all the technology-driven capabilities and processes lies our purpose of transforming billions of lives by connecting the world,” concludes Puri.

18 | EME Outlook Issue 59 STERLITE TECHNOLOGIES LIMITED TECHNOLOGY

Transforming lives through sustainable digital networks

The global resource for supply chain professionals and organisations

Building on the global success of our regional titles – EME Outlook, Africa Outlook, APAC Outlook, and North America Outlook – Outlook Publishing is proud to introduce a digital magazine and web platform, dedicated to the supply chain sector.

As supply chain organisations worldwide confront unprecedented change, embracing technological innovations and incorporating critical environmental sustainability agendas, now more than ever is the time to showcase the strides being taken in this dynamic sector.

A multi-channel brand, Supply Chain Outlook brings you the positive developments driven by organisations across the global supply chain industry through its various platforms. Discover exclusive content distributed through its website, online magazine, social media channels, and dispatches delivered straight to your inbox with a bi-weekly newsletter.

Through this compelling new venture, we foreground the movers and shakers of the industry. To participate as a featured company and join us in this exciting endeavour, contact one of our Project Managers today.

www.supplychain-outlook.com

SUBSCRIBE FOR FREE TO THE DIGITAL MAGAZINE

SAMBA SHOWDOWN

Despite

defeat to Brazil denting preparations for EURO 2024, England remain one of the favourites to win the showpiece football tournament

Writer: Jack Salter

This summer, England will once again be looking to win the UEFA European Football Championship for the very first time.

The Three Lions fell just one short on home soil at the previous tournament when they were consigned to an agonising defeat in the final on penalties by Italy under the iconic Wembley arch, where England infamously won their only ever trophy in the 1966 FIFA World Cup more than half a century ago. Wembley also staged England’s recent high-profile friendly against Brazil on 23rd March 2024, which ended in a 1-0 victory for the Seleção and a first defeat in 11 for the hosts.

MATCH REVIEW

In-form England started the game brightly, however, pressing high and pinning the visitors in their own half for much of the first 10 minutes, with Phil Foden narrowly bending a free

kick past the far post.

Sporting an unfamiliar blue away kit rather than the famous canary yellow shirts synonymous with superstars such as Pelé and Ronaldo, Brazil survived the early onslaught and quickly warmed to the task.

Rodrygo fired the first warning shot, testing the palms of Jordan Pickford with a low effort to the goalkeeper’s left after a strong surge towards the England 18-yard box.

Lucas Paquetá, who plies his trade at club level in the capital with West Ham, then played Vinícius Júnior through on goal. However, the rapid Real Madrid forward was denied by Manchester City’s Kyle Walker, who scampered back to clear off the line.

After a nervy spell of Brazilian pressure, the home side settled down and should have taken the lead when Ollie Watkins blazed over the bar from six yards after he was teed up inside the box by debutant Anthony Gordon.

TOPICAL FOCUS SPORT 20 | EME Outlook Issue 59

ENGLAND V BRAZIL –MATCH STATS

Possession: 53 percent – 47 percent

Shots: 14 – 14

Shots on target: 3 – 5

Corners won: 7 – 2

Fouls conceded: 11 – 19

A frantic first half full of chances, including an effort from Raphinha that flew narrowly wide just before the break, ended goalless, giving players and fans alike a much-needed breather.

England started the second half in a similar fashion to the first, on the front foot and forcing Bento into a diving save.

A lack of attacking thrust after the interval meant both defences were on top, with England manager Gareth Southgate bringing on the likes of Jarrod Bowen, Marcus Rashford, and Kobbie Mainoo to inject some fresh legs into midfield and try to break

down the bulletproof Brazilian back line.

However, it was the visitors who finally broke the deadlock through 17-year-old Endrick in the 80th minute, handing England a first home defeat in two years.

TOURNAMENT PREVIEW

The defeat to Brazil was not the ideal start to England’s preparations for EURO 2024, which is being hosted in Germany, the joint-record three-time winners along with Spain.

A 2-2 draw against Belgium soon followed, salvaged only by a stoppage time Jude Bellingham strike to spare

England from successive Wembley defeats.

England have two remaining friendlies ahead of the tournament, against Bosnia and Herzegovina and Iceland on 3rd and 7th June 2024, respectively, to ready themselves for the tournament.

Despite the result, the Brazil friendly was an ideal litmus test for England ahead of EURO 2024, with the South Americans sitting fifth in the FIFA World Rankings, just one place below their opponents.

England have been drawn in Group C along with Denmark, Serbia, and Slovenia, from which the

22 | EME Outlook Issue 59

team will be fancied to qualify as winners.

Doing so should, in theory, ensure a more favourable draw in the Last 16 against one of the third-placed teams in Group D, E, or F, before likely crossing paths with big hitters such as France, Italy, Spain, and Germany en route to the final.

Should England reach their second successive UEFA European Championship final, football’s perennial underachievers will be hoping to exorcise the demons of EURO 2020 and claim the trophy for the first time.

EURO 2024 GROUPS

Group A: Germany, Scotland, Hungary, Switzerland

Group B: Spain, Croatia, Italy, Albania

Group C: Slovenia, Denmark, Serbia, England

Group D: Poland, Netherlands, Austria, France

Group E: Belgium, Slovakia, Romania, Ukraine

Group F: Turkey, Georgia, Portugal, Czechia

EME Outlook Issue 59 | 23 TOPICAL FOCUS SPORT

EME OUTLOOK is a digital product aimed at boardroom and hands-on decision-makers across a wide range of industries in Europe and the Middle East regions.

With content compiled by our experienced editorial team, complemented by an in-house design and production team ensuring delivery to the highest standards, we look to promote the latest in engaging news, industry trends and success stories from the length and breadth of Europe and the Middle East.

Reaching a combined audience of more than 395,000 people, EME Outlook covers a full range of industrial sectors: agriculture, construction, energy & utilities, finance, food & drink, healthcare, manufacturing, mining & resources, oil & gas, retail, shipping & logistics, technology and travel & tourism.

In joining the leading industry heavyweights already enjoying the exposure we can provide, you can benefit from FREE coverage across our digital platforms, a FREE marketing brochure, extensive social media saturation, enhanced B2B networking opportunities, and a readymade forum to attract new investment and to grow your business.

To get involved, please contact Outlook Publishing’s Managing Director, James Mitchell, who can provide further details on how to feature your company, for FREE, in one of our upcoming editions.

Tell us your story and we’ll tell the world PEVCA MALTA AVOIRA Direct access to unmatched technology services EPCGROUPE Mining success and innovation in the Euro-Mediterranean Safe, clean, and efficient offshore and onshore well decommissioning WELL-SAFE SOLUTIONS LTD Adel Mir CEO, speaks about his passion for trailer manufacturing and NAZ Industries LLC’s proud journey to becoming an international name www.emeoutlookmag.com FREE Marketing Opportunity www.emeoutlookmag.com/work-with-us

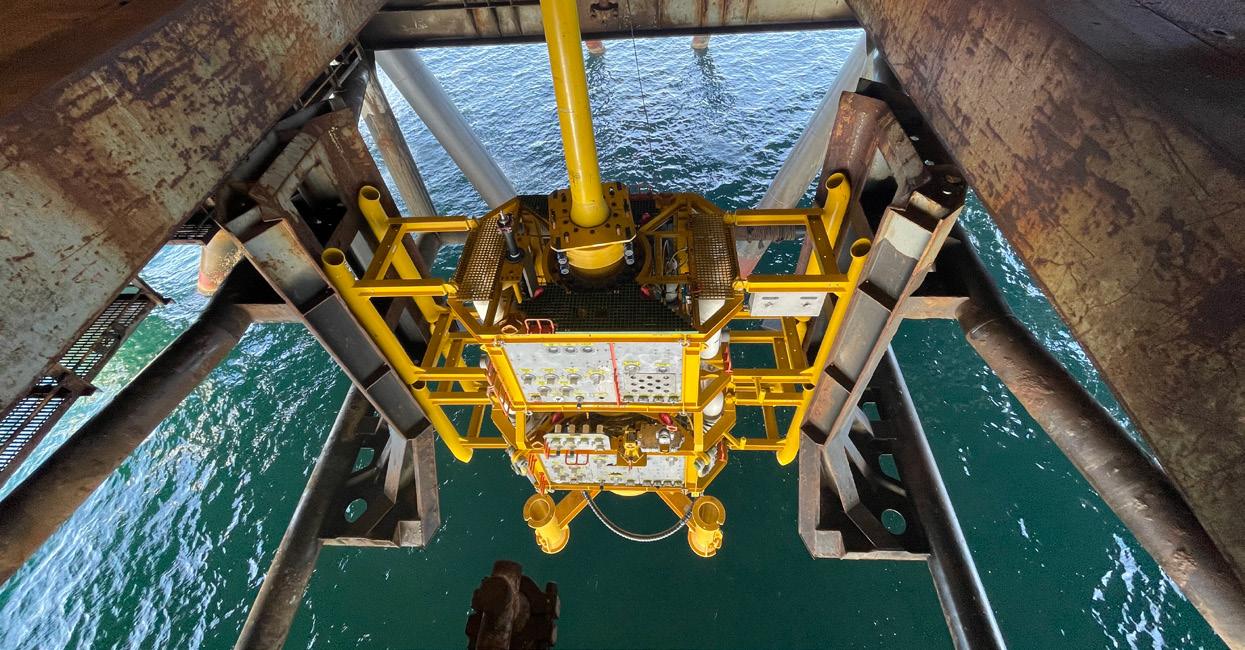

DEDICATED DECOMMISSIONING

26 | EME Outlook Issue 59 WELL-SAFE SOLUTIONS LTD OIL & GAS

DEDICATED TO DECOMMISSIONING

Well-Safe Solutions Ltd is the industry’s first Tier 1 capable contractor and energy transition specialist focused on well decommissioning and carbon capture, utilisation, and storage. Phil Milton, CEO, discusses a groundbreaking approach to this fast-growing part of the global energy sector

Writer: Jack Salter | Project Manager: Joshua Mann

While decommissioning in the UK continues to grow in economic and sociopolitical importance, there’s still a lot of work to be done to manage the country’s petroleum legacy.

Approximately nine percent of platforms in the UK Continental Shelf (UKCS), one of the most tightly regulated and safety-conscious mature basins in the world, have been decommissioned to date.

In the coming years, several more UKCS assets are set to move into the decommissioning phase, which requires different methodologies to those needed for drilling.

EME Outlook Issue 59 | 27

The industry therefore requires a dedicated well decommissioning specialist – this is where Well Safe Solutions Ltd (Well-Safe Solutions) comes in.

“We’re the only contractor that purely focuses on well decommissioning,” acclaims Phil Milton, CEO.

As onshore and offshore oil and gas wells reach the end of their lifecycle, it is a legal requirement that they are decommissioned.

Well-Safe Solutions works with the energy industry to safely, efficiently, and permanently close wells, ensuring no harm to the environment.

Since being founded in 2017, the company’s experience to date has shown that decommissioning requirements are far from one size fits all.

However, Well-Safe Solutions’ ‘building block approach’ enables clients to piece together a bespoke decommissioning package that

WELL-SAFE SOLUTIONS VISION AND MISSION

VISION – To be the trusted well decommissioning service partner of choice.

MISSION – To deliver safe, efficient well P&A operations in collaboration with clients, resulting in cost reductions through open and transparent communication.

is scalable and tailor-made to suit distinct project needs.

“We can scale the number of services that we provide to our customers according to their requirements,” Milton tells us.

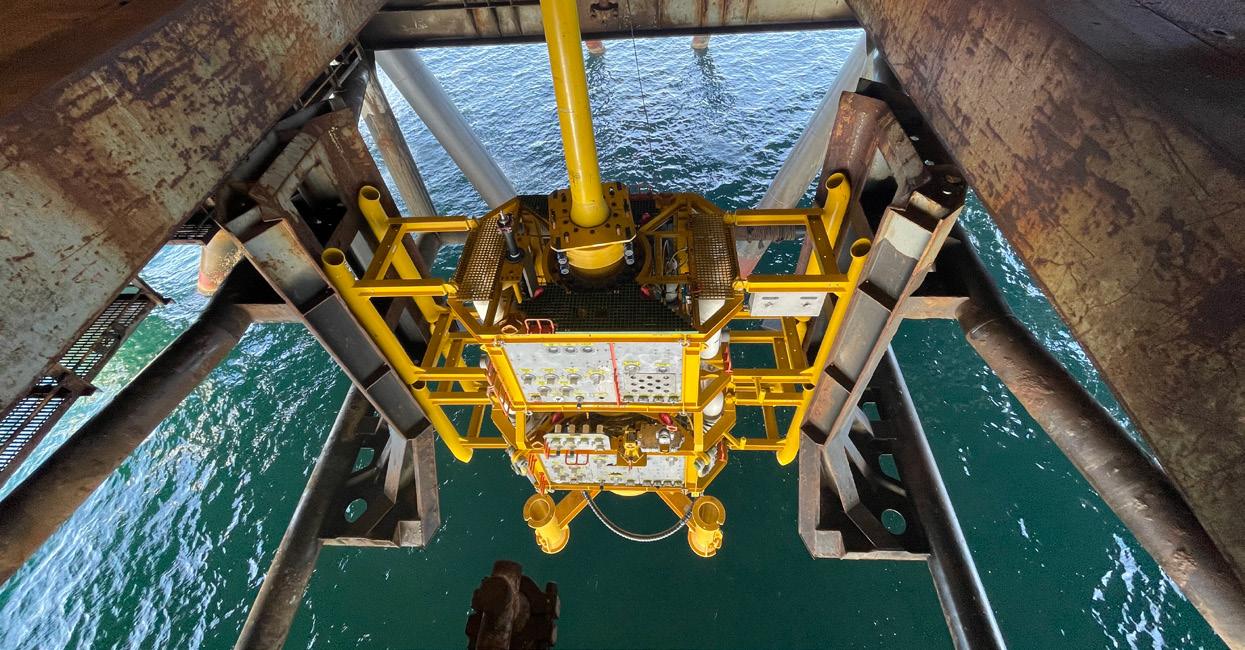

VERSATILE FLEET

Well-Safe Solutions offers complete, fully integrated well plug and abandonment (P&A) services, from front-end engineering and design through to project management and execution, using its own bespoke assets.

The company’s three decommissioning rigs – Well-Safe Guardian, Well-Safe Defender, and Well-Safe Protector – comprise its robust, high-performing fleet.

“We’ve got two semi-submersible drilling rigs and a jack-up drilling rig

28 | EME Outlook Issue 59

that have all been repurposed for well decommissioning and carbon capture and storage (CCS) drilling,” outlines Milton.

The Well-Safe Guardian, a highly efficient and experienced Earl & Wright 700 series midwater semisubmersible unit, has a strong track record in multi-well, multi-operator campaigns and is complemented by the Well-Safe Defender, an enhanced pacesetter semi-submersible asset.

A saturation diving system has been manufactured and installed on

the Well-Safe Guardian, enabling safe access to legacy subsea wellheads and Christmas tree systems that were originally designed for diver intervention. This makes the Well-Safe Guardian the sole North Sea asset of its type to feature a saturation diving system.

“It gives us the ability to deploy divers directly from the rig while we’re working on old wells that were put in place using divers prior to the existence of remote-operated vehicles,” Milton explains.

“WE’RE STILL IN THE EARLY STAGES OF WELL DECOMMISSIONING, AND IT’S EXCITING TO ADDRESS SOME OF THE CHALLENGES THAT ARE OUT THERE”

– PHIL MILTON, CEO, WELL-SAFE SOLUTIONS LTD

The system is a cost-effective, flexible alternative to the industry standard, which typically involves a light well intervention vessel used to plug and lubricate the well before completing decommissioning operations with a standard semi-submersible mobile offshore drilling unit.

This single-asset solution offers an alternative to the conventional approach and does not require multiple vessel mobilisations and demobilisations, which lowers operating costs, minimises the risk of weather-related disruption, and boosts overall project efficiency.

“Instead of mobilising multiple assets, we can do it from a single asset using the Well-Safe Guardian. Not only does this offer significant cost savings for our customers, but it also reduces fuel consumption and emissions, so it’s a very unique offering,” prides Milton.

WELL-SAFE SOLUTIONS LTD OIL & GAS

The Well-Safe Protector, meanwhile, is a heavy-duty jack-up rig with an extensive, enviable history in the North Sea.

It boasts a rig-owned platform interface system with power, water, and air tie-ins, as well as a large amount of deck space for tubing, casing, and conductor recovery.

“This is a really unique asset in terms of some of the modifications that were done both prior and subsequent to us buying it, which have made it an optimal solution for wells that need to be re-entered with a jack-up,” Milton notes.

ATTRACTING TALENT

Coupled with the company’s 430+ highly-trained personnel, the technical attributes of these three assets ensure increased operational safety and efficiency for decommissioning campaigns.

“We’ve got well engineering, project management, and subsurface capabilities. Our team determines how we decommission and safely cap these wells,” Milton informs us.

30 | EME Outlook Issue 59 WELL-SAFE SOLUTIONS LTD OIL & GAS

First Marine Solutions, First Integrated House, Broadfold Road, Bridge of Don, Aberdeen, AB23 8EE

www.firstmarinesolutions.com

we are first marine solutions global service provider of mooring solutions to the offshore energy sector

■ Mooring Solutions

■ Survey & Positioning

■ Equipment Rental & Sales

■ Marine Project Management & Consultancy

building

■ Design & Draughting

■ Engineering Design & Consultancy

■ Marine Assurance & Consultancy

■ Shore-based support

Established in 2017, Well-Safe Solutions has been working closely with FMS’ Marine Services team since Day One. Well-Safe Solutions recognised that a partnership with FMS would provide a wealth of Marine Assurance and Consultancy services which would not only guide the company through the purchase of its first rig, but all subsequent asset purchases. By creating operational efficiencies, and applying smart strategic planning, the synergies developed allow FMS to support Well-Safe Solutions as it continues to innovate within the well P&A field, ensuring it maintains it’s market-leading position.

Offering a complete moorings solutions package inhouse, including a strong track record in Engineering and Project Managing surface asset decommissioning scopes, FMS offer a fully integrated mooring solutions on a global scale.

scan the qr code to visit our website

relationships, building success

EME OUTLOOK: WHAT ARE CURRENTLY THE PREVAILING CHALLENGES IN THE UK?

Phil Milton, CEO: “There’s no doubting the impact of the Energy Profits Levy (EPL) on retaining the supply chain and talent needed to deliver the energy transition.

“There are some headwinds in terms of the political and fiscal instabilities that we’ve had in the UK, which is hampering our ability to deliver on some targets, and it certainly means that the focus has to be more on overseas markets.”

Ultimately, well decommissioning and CCS are global requirements, and there are many decades of work ahead to be done by the likes of WellSafe Solutions.

Indeed, the international cost of decommissioning is expected to reach USD$200 billion over the next 20 years, approximately half of which is forecast to be spent on well abandonment alone.

In recognition of this critical need, the company continues to attract the necessary new talent both in the business and the industry as a whole.

The newly launched Well-Safe Excelerator programme, for example, aims to build lasting careers and deliver the decommissioning expertise required to support the global energy transition, combining bespoke training with practical experience.

“Well-Safe Excelerator looks to bring in apprentices, graduates, and ex-armed forces personnel to try and attract new talent into the industry and demonstrate that there’s actually a career in well decommissioning for people who want to help deliver the energy transition,” highlights Milton.

By decommissioning legacy oil and gas wells and repurposing reservoirs for CCS, Well-Safe Solutions is trying to address the net zero energy transition.

“The company was launched specifically for that purpose; for us, it’s about effectively helping to deliver it,” states Milton.

“Clearly, the net zero transition has to consist of the removal of the old wells and infrastructure that were part of the oil and gas phase.”

The capabilities and skillsets that Well-Safe Solutions has mean it is perfectly placed to work with customers to determine the most efficient way to remove old well infrastructure and either drill or, when possible, repurpose wells for CCS.

“It’s a key element, and I think the more that you bring those

32 | EME Outlook Issue 59 WELL-SAFE SOLUTIONS LTD OIL & GAS

MARINE DIESEL ENGINE AND PROPULSION PACKAGE SPECIALIST

+44 (01)141 445 2455

sales@britishpolarengines.co.uk

kelvindiesels.co.uk

“Kelvin Diesels is totally committed to providing a level of individual customer service which is equal to the high-quality products we manufacture and maintain.”

Established in 1904, Kelvin Diesels was one of the pioneers of marine engines for commercial and leisure use, manufacturing and supplying mechanical marine equipment. Kelvin Diesels is part of a modern progressive group of companies with a worldwide reputation for the manufacture and supply of diesel engines, marine diesel generator sets, spare parts, and the maintenance of engines and ancillary equipment.

Providing protective coatings

Jotun Paints has been in a partnership with Well-Safe Solutions since the company’s inception.

From the re-fit of the Well-Safe Guardian through to three rigs now in operation, Jotun has supplied protective coatings for the entire fleet and provided technical support throughout this period.

Well-Safe Solutions has utilised Jotun’s innovative Jotamastic Smart Pack system which reduces waste, VOC’s and complexity with 1:1 mix ratios or single component product, suitable for the harsh offshore environment.

We look forward to continuing our partnership with Well-Safe solutions in the years to come.

+44 1724 400 000 | info@jotun.co.uk | jotun.com

EME Outlook Issue 59 | 33 WELL-SAFE SOLUTIONS LTD OIL & GAS

elements together, the more you can optimise cost efficiencies and the environmental impact of carrying out those different scopes,” Milton says.

GROWTH JOURNEY

Well-Safe Solutions is focused on its environmental, social, and governance (ESG) credentials, and recently achieved ISO 50001 accreditation as part of the ESG pathway it started around 18 months ago.

As well as looking after the environment, the company prioritises the safety of its employees.

“Looking after our staff is fundamental to the success of the business. The same applies to

“CLEARLY, THE NET ZERO TRANSITION HAS TO CONSIST OF THE REMOVAL OF THE OLD WELLS AND INFRASTRUCTURE THAT WERE PART OF THE OIL AND GAS PHASE”

– PHIL MILTON, CEO, WELL-SAFE SOLUTIONS LTD

partners, suppliers, and customers; we’ve never lost sight of the fact that everyone plays an important role in Well-Safe Solutions’ success,” emphasises Milton.

Equally, another of the company’s focus areas is international expansion.

The idea for Well-Safe Solutions was always to build its foundations in the UK, which is a highly regulated environment, demonstrate that the model could be deployed safely and efficiently, and then look to export it internationally.

34 | EME Outlook Issue 59 WELL-SAFE SOLUTIONS LTD OIL & GAS

Operating from its Scottish headquarters in Aberdeen, the company recently opened an office in Perth, Western Australia as it targets adding further assets to the business.

“Moving into the Australian market last year was the beginning of our international growth journey, and now we’re very focused on continuing and accelerating into the global market,” Milton specifies.

“Australia and Southeast Asia are key areas, so there are several opportunities and future investments that we’re looking to pursue.”

As well as delivering the ongoing growth that has already been seen in these two regions, Well-Safe Solutions

is likewise considering the possibility of an additional European office.

It is also seeking to grow and exploit opportunities in the European land market through onshore wells that need to be decommissioned and geothermal wells that may need to be drilled in the future.

“There are some ongoing discussions that I expect to progress through the course of this year and early into 2025,” outlines Milton. These growth and investment opportunities reiterate that the WellSafe Solutions model can be deployed and provide results for customers across the world, having an impact on their projects.

Tel: +44 (0)1224 584 400 info@wellsafesolutions.com www.wellsafesolutions.com

EME Outlook Issue 59 | 35

SUCCESSFULLY NAVIGATING

EFFICIENCY, ECONOMICS, AND ENVIRONMENT

More than just a technology company, Lummus Technology proudly offers customers fully integrated, end-to-end solutions solidified by global expertise and an extensive history. We speak to Leon de Bruyn, President and CEO, to learn more

Writer: Lauren Kania | Project Manager: Lauren Robinson

LUMMUS TECHNOLOGY OIL & GAS 36 | EME Outlook Issue 59

EME Outlook Issue 59 | 37

Due to the foresight, planning, and entrepreneurial spirit of Walter E. Lummus over 115 years ago, Lummus Technology (Lummus) first came to fruition in Massachusetts with the mission of developing and producing specialised equipment for the process industries.

Since this initial desire to provide technology solutions and evolve the downstream energy industry, the company has established an extensive history of cutting-edge innovation and unparalleled leadership.

“We provide technology solutions that empower customers to produce products sustainably and profitably to enhance everyday life,” opens

Leon de Bruyn, President and CEO of Lummus.

More specifically, Lummus licenses process technologies in clean fuels, renewables, petrochemicals, polymers, and gas processing, and supplies lifecycle services and products such as catalysts, proprietary equipment, and digital solutions.

From those early years, and through many generations of employees and evolutions, there has been one constant – Lummus has always been one of the world’s most innovative technology licensing companies.

This enduring dedication towards progress and innovation is what

inspired de Bruyn to delve into the downstream energy industry after graduating as a chemical engineer from the Eindhoven University of Technology in the Netherlands.

“It has been an amazing journey, and I am incredibly grateful to have grown alongside the company,” says de Bruyn, whose interest in the industry stems from his upbringing.

“My parents, both educators, instilled a love for learning and solving complex problems early on. In this industry, that is exactly what we do – develop innovative technology solutions that make a real difference in the world, contributing to modern life in various ways.”

38 | EME Outlook Issue 59 LUMMUS TECHNOLOGY OIL & GAS

Lummus and NET Power sign strategic agreement for heat transfer equipment

“OUR TECHNOLOGIES MEET CRITICAL ENERGY, INDUSTRIAL, AND SOCIETAL DEMANDS, DRIVING ECONOMIC GROWTH AND IMPROVING QUALITY OF LIFE AROUND THE WORLD”

– LEON DE BRUYN, PRESIDENT AND CEO, LUMMUS TECHNOLOGY

EME OUTLOOK: HOW IMPORTANT ARE PARTNER RELATIONSHIPS TO THE SUCCESS OF THE BUSINESS?

Leon de Bruyn, President and CEO: “Partnerships are critical to our success, and many of our technology innovations are the result of bringing scientists and engineers from multiple backgrounds together.

“Combining our expertise with that of our partners builds a collaborative environment that fuels innovation, accelerates the development and time-tomarket of new solutions, and increases scale, which, in turn, drives meaningful change.

“We have formed partnerships with various organisations, from established global players like Zeolyst International, BASF, and Chevron to many smaller companies. We also recently added several new partners, such as NET Power, Toshiba, RWDS, and Resynergi, to name a few. For Lummus, these partnerships leverage their strengths and create synergies that benefit all involved.”

Lummus and established it as a standalone company. Previously part of a larger engineering, procurement, and construction company, Lummus is now freed from its prior constraints and better positioned to grow and align with its customers.

“We first stabilised the business and built the infrastructure and organisation capabilities we needed to forge our path forward,” notes de Bruyn.

partnership to license high-density polyethylene (HDPE) technology with Texplore, a subsidiary of one of Asia’s largest operators, SCG Chemicals, and acquiring the rights to license and market Air Liquide’s estergrade acrylic acid technology, using propylene as the main feedstock.

Having lived in various countries, worked with a variety of colleagues and customers on fascinating projects, and worn many different hats, de Bruyn can proudly attest that Lummus stands apart from the rest in developing and implementing process technologies that make everyday life possible.

THE INDUSTRY’S MOST COMPLETE PROVIDER

In 2020, Lummus embarked on a bold new chapter. The Chatterjee Group and Rhône Capital purchased

Following this, the company rapidly evolved its business strategies and culture, alongside aggressively expanding its portfolio to better position itself to provide customers with the best solutions and outcompete traditional players.

The results speak for themselves, as Lummus is in a strong position today and poised for continuous growth well into the future.

Since 2020, Lummus has added many new technologies to its portfolio, with nearly 20 additions in 2023 alone. With its expansion focused on traditional technologies as well as sustainability technology offerings, the company anticipates continuing its rapid growth into 2024 and beyond.

A portion of the company’s recent growth includes forming a

“These acquisitions and partnerships give Lummus a more complete offering in the specialty high-value polymer market. As a result, we are able to provide customers with tailored, comprehensive, and integrated solutions,” details de Bruyn.

Additionally, Lummus demonstrated its endless determination and strength throughout the COVID-19 pandemic when the downstream energy sector, like many other industries at the time, faced significant challenges such as a decline in product demand, disrupted supply chains, and volatile market conditions.

“We were able to adapt rapidly and show our resilience,” states de Bruyn.

For example, the company accelerated its efforts to decarbonise and invest in cleaner, more sustainable operations and also embraced digital transformation, an area where the industry previously lagged.

EME Outlook Issue 59 | 39 LUMMUS TECHNOLOGY OIL & GAS

ILLUMINATING THE WAY

Lummus has established an unparalleled track record of developing and commercialising new technologies, alongside having the industry’s most diverse and comprehensive technology portfolio. Its technologies are recognised as best-in-class for their superior performance and the company proudly holds market-leading positions in many areas, such as ethylene, polypropylene, and hydrocracking for clean fuels.

Additionally, Lummus continues to ensure its customers’ success and longevity by going beyond

“LUMMUS HAS RAPIDLY DEVELOPED SOLUTIONS AND TECHNOLOGIES FOR THE CIRCULAR ECONOMY, THE ENERGY TRANSITION, AND DECARBONISATION”

– LEON DE BRUYN, PRESIDENT AND CEO, LUMMUS TECHNOLOGY

technology licensing and offering lifecycle services. This allows the company to integrate its offerings and ensures it remains by the customer throughout the project and during the investment and operating cycles.

“Our customers trust us to be their partner, guiding them through every phase of their investment’s lifecycle,” emphasises de Bruyn.

While maintaining an enduring presence in traditional technologies and solutions, Lummus also places a strong focus on its sustainability offering. This is done by providing innovative, cutting-edge technologies that reduce emissions and improve

Left: Lummus and RWDC announce agreement to accelerate and scale PHA production

Below: Lummus and NET Power sign strategic supplier agreement for heat transfer equipment

Bottom left: Lummus and Toshiba announce partnership for advanced carbon capture solutions

40 | EME Outlook Issue 59 LUMMUS TECHNOLOGY OIL & GAS

Bottom right: Lummus and Citroniq announce licensing and engineering agreements for green polypropylene plants

PART OF YOUR PROCESS

Exceptional Energy Recovery & Process Solutions by SCHMIDTSCHE SCHACK

We, SCHMIDTSCHE SCHACK | ARVOS, are best known since 1910 as a leading designer, fabricator, and service provider for our outstanding and customized heat transfer solutions for highest pressures and temperatures.

Among our most successful products is the Transfer Line Exchanger we created for the production of ethylene. For more than 60 years, our design has been setting new standards in durability, performance and enabling highest ethylene yields.

Yet we are not resting on our success but are continuously refining our product portfolio to support new pioneering processes such as methane pyrolysis, the production of e-fuels, the generation of hydrogen or the production of green steel with our process solutions.

For more Information: www.schmidtsche-schack.com

efficiency by optimising resource usage and minimising waste, ultimately helping companies reach their sustainability targets.

Recently, Lummus has implemented a variety of new initiatives and programmes to continue its sustainable practices even further.

“We have launched ethanol-based sustainable aviation fuel (SAF) technology to meet the aviation industry’s growing demand for SAF,” enlightens de Bruyn.

Lummus also formed a partnership with RWDC Industries to accelerate and scale polyhydroxyalkanoates (PHA) production, which will increase

ZEOLYST INTERNATIONAL PARTNERSHIP

Established since 1988, Zeolyst International quickly emerged as a global leader in the disciplines of zeolite powders, catalysts, and adsorbents. Zeolyst International has a long-standing partnership for Lummus, successfully developing and deploying specialised zeolitic solutions for current and emerging technologies throughout the ongoing relationship.

Zeolyst International combines strengths in product development and manufacturing expertise in zeolites and catalysts from parent companies Ecovyst and Shell Catalysts and Technologies, into a single entity. As a result, Zeolyst International is fully capable in the entire development and commercialisation of zeolite applications.

Zeolyst International has worked diligently to become the partner of choice when it comes to customising zeolites for specific applications and providing flexibility to optimise businesses’ processes for maximum success.

global availability and adoption of natural alternatives to petroleumbased plastics.

In addition, Lummus is working diligently towards driving sustainable practices, including partnering with NET Power for near-zero emission

power plants, and Toshiba for advanced carbon capture solutions, developing VerdeneTM, a biopolypropylene derived from ethanol, and acquiring Zimpro® water and wastewater treatment technologies from Siemens Energy.

42 | EME Outlook Issue 59 LUMMUS TECHNOLOGY OIL & GAS

Our expertise lies in customizing zeolites for various applications, offering our customers unparalleled flexibility and the ability to optimize processes for maximum success. From catalysts in refining and petrochemical processes to sustainable applications like renewable fuels and plastic circularity, our versatile zeolite products cater to diverse industries.

An exceptional line of zeolite products curated to drive progress in the renewable fuels industry and revolutionize catalytic technologies, leaving a considerable mark on Renewable Fuels production.

A portfolio of zeolites for advanced plastic recycling applications, delivering substantial value by enabling precise control of the end products and lowering energy requirements of pyrolysis processes.

At the forefront of developing customized zeolite products across various industries. Our expertise extends to tailoring zeolite materials and catalysts to meet the specific requirements of customer processes.

Zeolyst International offers a large selection of zeolites and Catalysts tailored to Refining and Aromatics processing, Emission Control, Clean Water and Adsorption, and many more applications.

Contact us and learn more on www.zeolyst.com

These examples highlight how Lummus is growing its traditional business while successfully expanding its sustainability offerings, or as de Bruyn often says, “balancing energy efficiency, economic viability, and environmental stewardship.”

CREATING THE FUTURE

Innovation has always been in Lummus’ DNA, and R&D is part of its innovation ecosystem.

As a technology company, R&D is very important to Lummus, enabling the company to create new, extended platforms and improve its technologies.

With four strategically located facilities across the US and Europe that offer advanced R&D, analytical labs, proprietary equipment and catalyst manufacturing, pilot plants, testing and modelling, and other services, the company is able to readily develop, commercialise, and improve its technologies.

“R&D helps us push boundaries and turn big ideas into real commercial solutions that address the evolving needs of our customers and industry,” details de Bruyn.

As Lummus continues to look towards the future, not only is further progress in R&D a key priority, but equally as prominent is the company’s growth in key markets and regions.

One such region is the Middle East, which holds tremendous opportunities for growth and collaboration. As a result, Lummus is strengthening its presence in the Middle East by deepening relationships with customers and building in-country platforms to support the investments of its clients.

This is directly reflected by the recent relocation of Lummus’ Chief Technology Officer, Ujjal Mukherjee, to Saudi Arabia, where he is expanding his team. His presence, along with the dedicated regional team, signifies Lummus’ commitment to fostering

greater knowledge transfer and technological collaboration in a highly active market.

“We are confident that this strategic focus on the Middle East, combined with our continued dedication to innovation and customer success, will position us for growth in the years to come,” concludes de Bruyn.

www.lummustechnology.com

44 | EME Outlook Issue 59

Navigate Your Career with CTS: Expert Placement for Energy Professionals YOUR CAREER PARTNER FOR SUCCESS Unlock your potential with CTS. We specialize in placement services for the refining, petrochemical, LNG, and offshore industries. Whether you are looking for the security of a permanent position, or seeking a long or short-term contract assignment, CTS can find the perfect fit for you! Serving the major engineering, construction and operating companies nationwide since 2000. Contact CTS today! bcopeland@ctstechnical.com | www.ctstechnical.com Meet environmental regulations without compromising on efficiency or reliability. Our expertise, coupled with market-leading combustion technology, combine to provide ultra-low NOx and low-carbon solutions. Experience the benefits of reduced fuel consumption, cost savings, and the flexibility of solutions tailored to your needs. Partner with us today. johnzink.com | +1 918 234 1800 burnerparts@johnzink.com SUSTAINABILITY WITHOUT COMPROMISE © 2024 Koch Engineered Solutions. All rights reserved. EME Outlook Issue 59 | 45 LUMMUS TECHNOLOGY OIL & GAS

Discover our exclusive content, delivered straight to your inbox

As mining organisations worldwide confront unprecedented change, embracing technological innovations and incorporating critical environmental sustainability agendas, now more than ever is the time to showcase the strides being taken in this dynamic sector.

A multi-channel brand, Mining Outlook brings you the positive developments driven by organisations across the global mining industry through its various platforms.

Discover exclusive content distributed through its website, online magazine, social media campaigns and digital dispatches, delivered straight to your inbox with a bi-weekly newsletter.

Through these compelling media channels, Mining Outlook continues to foreground the movers and shakers of the industry.

To participate as a featured company and join us in this exciting endeavour, contact one of our Project Managers today.

PUSHING THE BOUNDARIES OF EXCELLENCE

EPC Groupe, a world leader in explosives, has primarily served the global mining sector for over 130 years. Luis Calvo, Area Manager for Europe and the Mediterranean, shares his insights into the company’s burgeoning success in the region

Writer: Lily Sawyer | Project Manager: Eddie Clinton

With locations across Asia Pacific, the Americas, Africa, and Europe, supported by a 2,600-strong global employee base, EPC Groupe has established itself at the forefront of explosives manufacturing, storage, and distribution over the years, with a specialism in drilling and blasting.

In 2023, EPC Groupe’s collective turnover totalled €548 million, including joint ventures (JVs). Boasting 800 employees, five factories, and 35 storage magazines, EPC Groupe’s activity in the EuroMediterranean area is responsible for around a third of this total.

EME Outlook Issue 59 | 49 EPC GROUPE MINING

“Counting all our EuroMediterranean plants, EPC Groupe produces a wide range of bulk and cartridge explosives, boosters, and detonators. Regarding on-site production, mobile explosives mixing units (MEMUs) deliver bulk products directly into the boreholes of blasts,” opens Luis Calvo, Area Manager for Europe and the Mediterranean.