LEVERAGING CUTTING-EDGE TECHNOLOGY TO ENHANCE EVERYDAY LIVING

LEVERAGING CUTTING-EDGE TECHNOLOGY TO ENHANCE EVERYDAY LIVING

As the home appliances sector in South Africa evolves to meet modern demands, Defy Appliances stands at the forefront of innovation and sustainability. Hugo Coetzer, Regional Director of Manufacturing and Technology, discusses how the company spearheads efforts to enhance everyday living

Writer: Rachel Carr | Project Manager: Josh Whiteside

The history of domestic appliance manufacturing in South Africa (SA) reflects both the technological advancements of the time and the evolving needs of households.

In the early 20th century, the local manufacturing sector was relatively nascent, with few companies engaged in the production of household appliances.

However, as electrification spread across the country, the demand for electric appliances increased significantly and manufacturers began to emerge, focusing on essential items such as refrigerators, stoves, and washing machines.

Towards the end of the 1900s, SA’s appliance manufacturing industry featured a combination of established local brands and international companies. The sector evolved as manufacturers embraced advanced technology and energy-efficient designs to meet the needs of ecoconscious consumers.

Recently, there has been a focus on the rise of sustainability and smart technology, with products that integrate into modern smart home systems. The arrival of multinational corporations has also increased competition, driving local companies to innovate and improve production standards.

Standing out as a key player in the industry is Defy Appliances (Defy), a prominent manufacturer of domestic equipment in SA. Established in 1905 as a producer of hollow building blocks and cast iron parts, the company has a long history and is well-known for producing a range of products, including refrigerators, washing machines, stoves, and other kitchen appliances, focusing on innovation and quality.

Aiming to provide reliable and efficient solutions for everyday household needs, Defy has become a trusted brand amongst consumers in the region since it was acquired

Hugo Coetzer, Regional Director of Manufacturing and Technology:

“We’ve built strong partnerships with several tertiary institutes across SA to create a pipeline of future-ready talent through tailored training and graduate programmes.

“These collaborations aren’t just about recruitment – they’re co-designed initiatives that bridge academic theory with real-world application. Together, we shape curricula, offer hands-on industrial exposure, and host joint research or innovation projects that align with our future skills roadmap.

“For example, we host annual career fairs, offer student vacation programmes such as Fresh Start and WE-inTech, and engage in conversations with tertiary institutes about Industry 4.0 skills – whether that’s manufacturing, sustainability, or automation. These efforts not only help graduates transition smoothly into the workforce but also ensure our teams remain agile and innovative.

“Ultimately, this investment strengthens our talent pipeline, enriches our teams with fresh perspectives, and contributes to a more resilient, future-ready workforce.”

by Arçelik, now rebranded as Beko Global, in 2011.

“Thanks to this investment, which has gone into three factories and products, we have launched new pioneering innovations such as the Solar Off-Grid refrigerator, allowing us to solidify our leadership in the domestic appliances industry,” opens Hugo Coetzer, Regional Director of Manufacturing and Technology.

“We operate factories located in Jacobs, Durban and Ezakheni, Ladysmith, and employ more than 2,600 permanent staff members with a presence in 13 countries, where we export and sell our products.”

As the continent with the greatest potential for exponential growth, the manufacturing sector in Africa is currently experiencing significant transformation and substantial progress as various countries have invested in the industry in recent years.

“Our holding company has also opened a manufacturing plant in Egypt, which shows that Africa is currently a market where people can invest, and existing businesses will continue to invest further to see more growth,” Coetzer confidently states.

Many countries across the continent are currently witnessing economic developments which will boost demand for goods, especially household appliances. Furthermore, like elsewhere in the world, there is a need to adapt to new technologies such as automation and robotics.

“Remember that no one has closed borders anymore, and we all compete with other African nations that had a head start in automation,” affirms Coetzer.

The continent also has a large

and youthful population, which presents significant opportunities for a dynamic workforce. As this demographic offers a wealth of fresh ideas and energy, particularly in conjunction with the rapidly evolving manufacturing industry, Coetzer is optimistic about the future.

“Given the constant change in consumer trends and needs, the appliances industry is always an exciting space to work in.

“Having an accredited lab on site

allows us to develop new products that are not only improving people’s lives but also ensure we lead in energy efficiency and conform to our group’s sustainability targets,” he continues.

Coetzer opines that artificial intelligence (AI) is the future and, when implemented correctly, will not only reduce man-hours but also ensure quality improvements, especially when paired with robotics.

“Given our products and processes, there are many

opportunities to automate and use AI, so we are actively adapting it into manufacturing. Companies that don’t follow suit will not survive the next five to seven years.

“The challenge of a poor exchange rate means the local currency has less purchasing power when the technology you are after comes from countries with stronger currencies. So, it makes the financial calculations on payback much more difficult to justify.”

Maintaining these systems, obtaining spare parts, and receiving technical support can be difficult, whilst the continuous emigration of skilled professionals to developed countries results in a significant brain drain in Africa.

“However, this situation compels us to invest more in our own people and address these challenges.

1905 – Defy was founded in Durban by John Skinner and Sir Benjamin Greenacre and originally named Hollow Block Syndicate.

1922 – Coal stove manufacturing commenced.

1955 – SA’s first gas stove was manufactured and branded as Defy.

1988 – Produced the first microwave oven at the Jacobs site, becoming the only company to do so in SA.

2007 – The company was acquired by Franke Holding AG.

2011 – Turkish company Arçelik, part of the Koç Group, acquired Defy.

2015 – The company celebrates 110 years in existence.

2019 – Defy opens the top loader plant in Jacobs.

PRESENT DAY – After pioneering the SA landscape with the firstever electric stove, winning the company awards for innovation and technology, Defy has evolved into the leading appliance brand with 80 percent of its product range sold in Africa and at least one dealer in each of the 34 subSaharan countries.

Unfortunately, developing these technicians is not a quick process; it takes time to equip them to support the business effectively,” Coetzer elaborates.

As Defy’s parent company, Beko Global has manufacturing facilities in Africa, Turkey, Romania, Russia, Thailand, India, Pakistan, Egypt, and Bangladesh, creating a collaborative environment where innovation is fostered and shared amongst all.

“Our various internal R&D facilities help us to foster continuous learning and have a pool of mentors that shape the future of this company across the globe. These various departments working together also fosters a diverse perspective and innovative solutions,” Coetzer impassions.

Indeed, Defy offers a dynamic

space that cultivates and encourages creativity using brainstorming, hackathons, and innovation labs, with collaboration being the key.

“The recent launch of our solar fridge shows our dynamic approach leads to a tangible result.”

Despite the company’s positive outlook, several challenges remain across Africa, including inadequate infrastructure, limited access to financing, and a shortage of foreign exchange in many countries. Additionally, there is often a lack of political will to support local manufacturing and recognise its benefits to reduce unemployment in the country.

“Addressing all relevant issues is critical for our sustainability and growth. Overall, however, I would say that manufacturing in Africa is a dynamic space full of opportunities for innovation,” Coetzer acknowledges.

Wurth Industry, Action Bolt’s Holding company, presents itself to industry customers as a world class partner in C-Parts Management with a complete range of over 420,000 items. We offer customized supply concepts for handling your requirements in manufacturing, maintenance and servicing primarily in the fields of:

• All Categories of Fastener and assembly techniques

DIN/ISO and standard parts

• Manufactured according to technical drawing specifications

• Automotive engineering supply and component supplies

• All forms of Mechanical fitting components

• Rivet Technology

Action Bolts C-Parts-Management System is a process management concept for:

• Procuring and Stock Control of the complete range of C-Category Parts.

• Creating customer-individual supply and service concepts.

Bringing significant and quantifiable savings to our customers

Objectives

• Cost Optimization Supplier Reduction

• Standardization Stock Reduction

• Allowing more time to focus on A-Category procurement activities

• Lean processes Benefits

Lower Capital commitment by inventory reduction

• Maximise process security and protection of supply chain management

• No tracing of goods or deadline monitoring

• Our inventory management system tracks stock levels, automates orders, and integrates with systems to maintain real-time accuracy.

Process simplification

Action Bolt is now trading as “Würth Industry South Africa (Pty) Ltd”, as part of our continued integration with the Würth Group.

We’re proud to be aligning fully with the global Würth Industry network.

• Same team

• Same service

• Stronger brand

• Stronger global alignment

We’re embracing innovation and global best practices to serve you better.

Expect smarter solutions, seamless service, and world-class excellence— with the same trusted team.

New name. Bold future. Same commitment to excellence.

Since the acquisition of Defy in 2011, nearly ZAR2 billion has been invested in the company, with an additional commitment of ZAR500 million over the next five years. A significant portion of these investments has gone into manufacturing facilities and new product development.

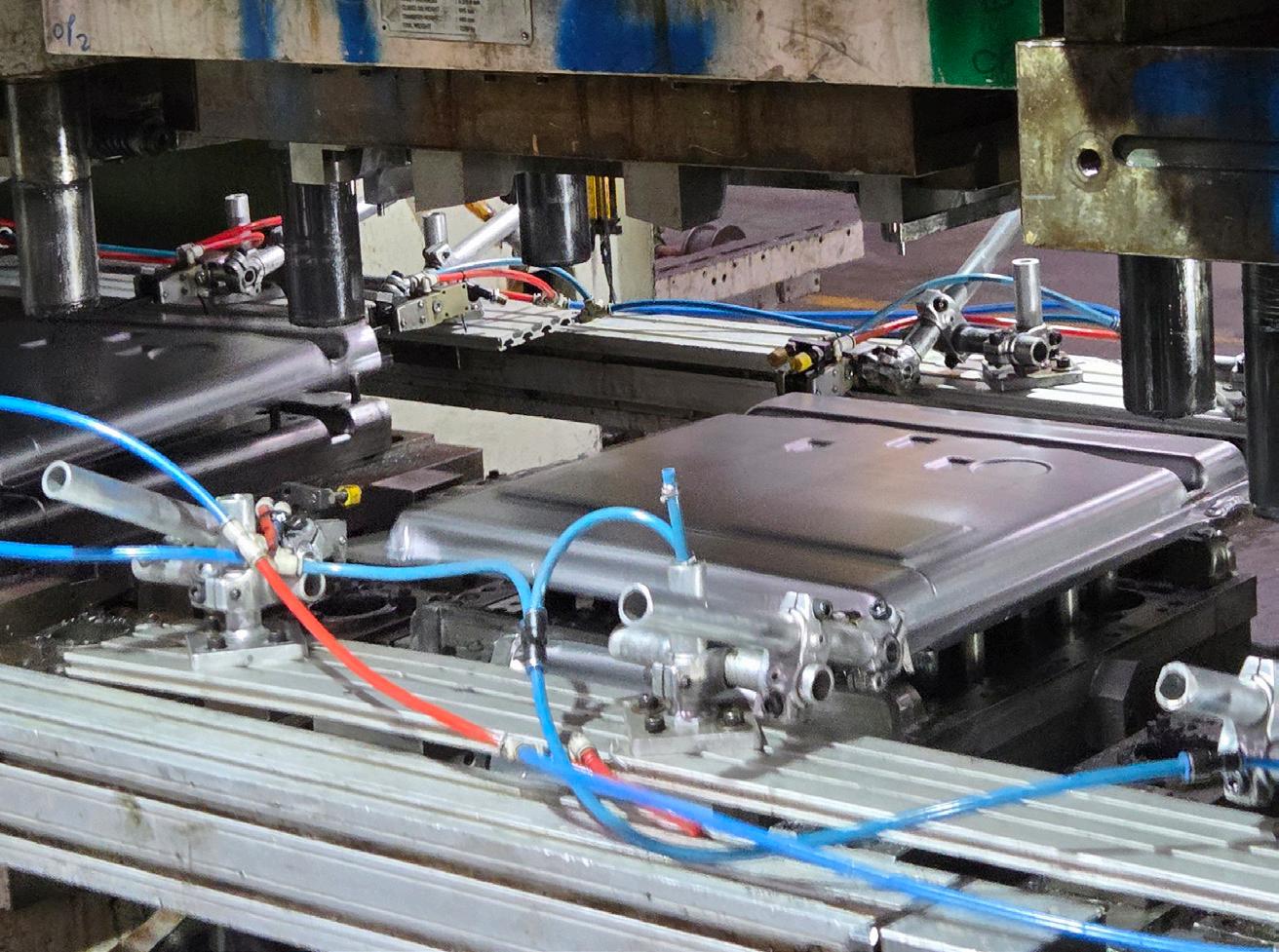

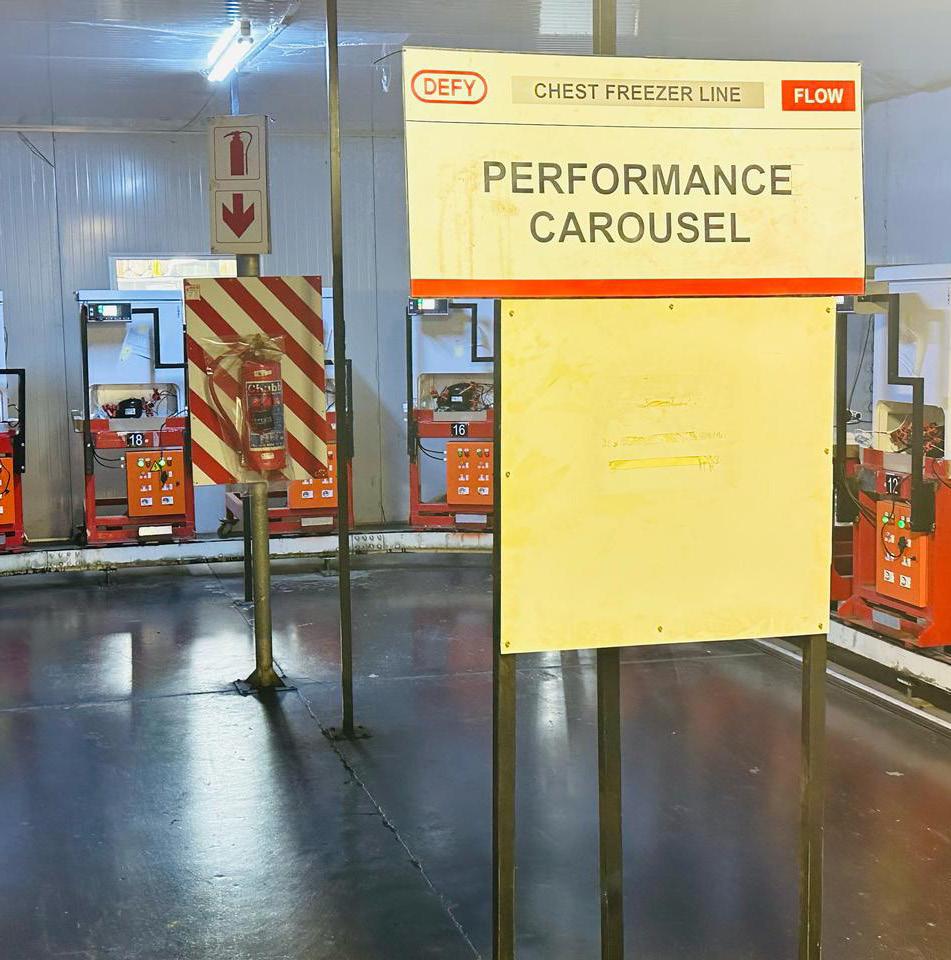

“Our refrigeration factory has production lines equipped with the latest technology, matching that of our other global factories. Additionally, our cooking and laundry factory has received upgrades, bringing our equipment and technology in line with European standards,” he notes.

“These investments serve not only to modernise our factories but also reduce our environmental impact, addressing both our processes and the energy efficiency of our appliances.”

Investing is crucial for Defy’s future, and these enhancements will enable the company to withstand

“OUR VARIOUS INTERNAL R&D FACILITIES HELP US TO FOSTER CONTINUOUS LEARNING AND HAVE A POOL OF MENTORS THAT SHAPE THE FUTURE OF THIS COMPANY ACROSS THE GLOBE”

– HUGO COETZER, REGIONAL DIRECTOR OF MANUFACTURING AND TECHNOLOGY, DEFY APPLIANCES

the competition faced from imports and help mitigate the environmental effects of its products.

“Our strategic investments not only position us favourably in the market but also reinforce our commitment to sustainability, ensuring long-term success in a highly competitive landscape,” summarises Coetzer.

The new Defy Solar Off-Grid refrigerator marks the beginning of an important phase for the

company, reinforcing its position as an innovative market leader dedicated to sustainable development and social impact.

By harnessing solar energy, this cutting-edge appliance addresses the critical energy challenges faced in SA and across the continent, where limited or unreliable electricity access hinders food preservation and the safe storage of essential supplies.

“The Smart Control Box, which serves as the product’s brain, features USB ports that allow for phone charging or powering lights, providing

NES Electrical was born from the demand for quality electrical supplies at unbeatable prices in 1992. From humble beginnings we pride ourselves on striving to be the best.

Our team services each and every client with the highest priority, starting with exceeding expectations of communication lines, competitive pricing and all round delivery.

We are currently operating nationally to promote client satisfaction to as many industries as we can reach.

Services:

• Hazardous Area Installations

• Temporary Installations

• New Installations

Maintenance of Existing Installations

• Transformer and Switchgear Installations

• Compliance Testing and Certification

• Energy Efficiency Consulting

• High Mast Lighting

• Solar Installations

• Solar Maintenance

T +27 (0) 31 902 8237 | info@nesgroup.co.za | www.nesgroup.cp.za

“HAVING AN ACCREDITED LAB ON SITE ALLOWS US TO DEVELOP NEW PRODUCTS THAT ARE NOT ONLY IMPROVING PEOPLE’S LIVES BUT ALSO ENSURE WE LEAD IN ENERGY EFFICIENCY AND CONFORM TO OUR GROUP’S SUSTAINABILITY TARGETS”

– HUGO COETZER, REGIONAL DIRECTOR OF MANUFACTURING AND TECHNOLOGY, DEFY APPLIANCES

added flexibility for users. When fully charged, the product can operate for up to three days during periods of low sunlight or no sun,” explains Coetzer.

“Additionally, the refrigerator is equipped with phase change material, an advanced technology which helps maintain its temperature for extended periods. As climate change poses challenges to traditional energy systems and infrastructure, solutions like our Solar Off-Grid refrigerator offer a resilient and eco-friendly

alternative that supports both environmental goals and human development.”

Defy is also developing an off-grid cooker aimed at providing a transformative solution for communities lacking stable access to electricity or clean cooking energy. Designed to function independently from electricity, it seeks to provide a safe, affordable, and sustainable option.

“Amongst its key benefits, the offgrid cooker will significantly reduce

household air pollution, lower the risk of fires, and eliminate fuel costs over time. It also promotes sustainable living by decreasing deforestation and carbon emissions associated with traditional cooking fuels.

“Once completed, this innovative appliance will empower households with a cleaner, safer, and more efficient cooking method, enhancing everyday life whilst contributing to long-term environmental and economic sustainability,” he urges.

Industries we specialise in are:

• Small Appliances

• Houseware

• Engineering

• Medical

• Hardware

• Forestry

• Mining

• Farming

Specialists in plastic injection moulding, we have a team of experts focused on creating and manufacturing end-to-end solutions that help businesses to innovate and create maximum addition for its customers.

To keep our business competitive and marketable, we created value-added services to be able to offer a complete manufacturing solution of products:

• Research, Development and Design

• Toolmaking

• Assembling of components/ parts

• 4 Colour Pad printing

• Screen printing

• Complete supply chain of product

Telephone: +2731 7006900

Email: kevingov@gpsplastics.co.za | sales@gpsplastics.co.za

Website: www.gpsplastics.co.za

What truly differentiates Defy from its competitors is its commitment to local manufacturing, innovation, and quality.

“As a company, we invest heavily in R&D to ensure our products are competitive, have the latest innovations and quality with the lowest possible consumption of natural resources, and are safe for our consumers,” Coetzer prides.

“We are also focused on environmentally-friendly practices. For example, we use solar energy to help power our factories and limit our water consumption through rainwater harvesting and water recycling plants that form part of our infrastructure.”

Additionally, Defy provides comprehensive after-sales service and support, offering peace of mind to customers with locally-sourced parts and service capabilities across

SA, as well as agents in the African countries it exports to.

As such, the company’s commitment to embracing modern technology and sustainable practices positions it well to meet the demands of an evolving market.

With a focus on fostering collaboration across its global manufacturing network, Defy is poised to continue leading the way in enhancing everyday living, ensuring its products meet consumer expectations and contribute positively to the environment.

This year is remarkable for Defy as it proudly celebrates its 120th anniversary – a significant milestone that highlights its enduring legacy.

“We are excited to celebrate this momentous occasion through a PR campaign, which will launch in June or July,” Coetzer emphatically concludes.

The future remains bright for Defy

as the industry navigates the rapid changes in consumer behaviour and technological advancements. The company’s adaptability and forwardthinking approach will undoubtedly sustain its legacy of excellence.

www.defy.co.za