SALMON EVOLUTION

Quality, texture, colour, taste – a new standard of salmon

ATOS

Smart manufacturing with global IT leader

Atos

Quality, texture, colour, taste – a new standard of salmon

Smart manufacturing with global IT leader

Atos

Gulf Craft’s Deputy MD, Abeer AlShaali dives into the waters of a business born from passion that has grown to become a leviathan on the global stage of elite boatbuilding

For over a decade, our portfolio of in-house magazines has been lovingly produced, printed, and distributed to our esteemed subscribers across the globe from our headquarters in the UK.

But now we are moving with the times, adopting a digital-first approach by producing online-only publications. A major factor in this decision is to minimise our environmental footprint, reducing the carbon emissions involved in the logistics of print magazine distribution and the resources required therein.

Going forward, we will provide print orders of any magazine in-line with the requests of our featured companies, subscribers, and conference & expo partners.

Please get in touch for a print-on-demand quote or visit our website to find out more.

“We always planned that when our digital subscribers consistently accounted for 85% of our total magazine subscribers, we would cease printing our publications in-line with our environmental and sustainability goals.”

– Ben Weaver, CEO, Outlook Publishing Ltd

EDITORIAL

Editorial Director: Phoebe Harper phoebe.harper@outlookpublishing.com

Senior Editor: Marcus Kääpä marcus.kaapa@outlookpublishing.com

Editor: Jack Salter jack.salter@outlookpublishing.com

Junior Editor: Ed Budds ed.budds@outlookpublishing.com

Junior Editor: Rachel Carr rachel.carr@outlookpublishing.com

PRODUCTION

Production Director: Stephen Giles steve.giles@outlookpublishing.com

Senior Designer: Devon Collins devon.collins@outlookpublishing.com

Designer: Sophs Forte sophs.forte@outlookpublishing.com

Junior Designer: Louisa Martin louisa.martin@outlookpublishing.com

Production Assistant: Megan Cooke megan.cooke@outlookpublishing.com

Digital Marketing Manager: Fox Tucker fox.tucker@outlookpublishing.com

Social Media Executive: Bria Clarke bria.clarke@outlookpublishing.com

Web Editor: Oliver Shrouder oliver.shrouder@outlookpublishing.com

BUSINESS

Chief Executive Officer: Ben Weaver ben.weaver@outlookpublishing.com

Managing Director: James Mitchell james.mitchell@outlookpublishing.com

Sales Director: Nick Norris nick.norris@outlookpublishing.com

Commercial Director: Joshua Mann joshua.mann@outlookpublishing.com

HEADS OF PROJECTS

Callam Waller callam.waller@outlookpublishing.com

Josh Hyland josh.hyland@outlookpublishing.com

Deane Anderton deane.anderton@outlookpublishing.com

Eddie Clinton eddie.clinton@outlookpublishing.com

Ryan Gray ryan.gray@outlookpublishing.com

BUSINESS DEVELOPMENT DIRECTOR

Thomas Arnold thomas.arnold@outlookpublishing.com

TRAINING & DEVELOPMENT MANAGER

Marvin Iseghehi marvin.iseghehi@outlookpublishing.com

SALES & PARTNERSHIPS MANAGER

Donovan Smith donovan.smith@outlookpublishing.com

PROJECT MANAGERS

Alfie Wilson alfie.wilson@outlookpublishing.com

Kierron Rose kierron.rose@outlookpublishing.com

Krisha Canlas krisha.canlas@outlookpublishing.com

Nicholas Kernan nicholas.kernan@outlookpublishing.com

Liam Pye liam.pye@outlookpublishing.com

ADMINISTRATION

Finance Director: Suzanne Welsh suzanne.welsh@outlookpublishing.com

Finance Assistant: Suzie Kittle suzie.kittle@outlookpublishing.com

Finance Assistant: Victoria McAllister victoria.mcallister@outlookpublishing.com

EME OUTLOOK

Norvic House, 29-33 Chapelfield Road

Norwich, NR2 1RP, United Kingdom

Sales: +45 (0) 1603 363 631

Editorial: +45 (0) 1603 363 655

SUBSCRIPTIONS

Tel: +45 (0) 1603 363 655

phoebe.harper@outlookpublishing.com www.emeoutlookmag.com

Like us on Facebook: facebook.com/emeoutlook

Follow us on Twitter: @eme_outlook

Across myriad industries, female leadership and the status of women in business is on the rise.

Highlighting this central topic in our latest issue is a trinity of businesses. Born and bred gamer Anne Lise Waal, CTO and COO of Attensi, and leading female tech figurehead, discusses turning passion into a business in a male-dominated industry. Meanwhile, Maddy Russell and Rose Radtke, co-founders of Each to Their Own, tell us about helping businesses build community trust through the power of brand identity, and its impact on growth success.

Standing at the prow of female-led business is Gulf Craft, one of the world’s leading shipyards producing a range of vessels from fishing boats to megayachts - a leviathan business based in the UAE. Bearing a passion for seafaring in style, Deputy Managing Director Abeer AlShaali dives into how the company has navigated the choppy waters of the industry and is now making waves at the forefront of the market.

“We are made in the UAE, and we are very proud of that, but we don’t think of ourselves as an Asian builder or as a Middle East and North Africa (MENA) region builder. We are a boat builder for boat enthusiasts, and that’s international,” she shares.

Staying on course with the ocean theme we take a look at Salmon Evolution, the Norwegian salmon farming company by the coast, producing sustainable fresh fish utilising its advanced hybrid flow-through technology.

“Salmon Evolution represents a step change in salmon farming. Raising our salmon on land gives us a unique opportunity to optimise the environment so the salmon thrive and live a happy life. This results in quality the world has never seen before,” details CEO Trond Håkon Schaug-Pettersen.

Elsewhere, quench your thirst with Coca-Cola HBC Hungary, delve into the digital world with Atos, build your knowledge on VSL Middle East, and dive into many companies showcased in this fresh issue of EME Outlook.

Enjoy!

Marcus Kääpä Senior Editor, Outlook PublishingFacilitating the connections and building the bridges that join the vast payments ecosystem 42

Representing Finland’s defence, aerospace and security industries

What trends do you forecast impacting your industry in 2023?

78 Salmon Evolution

Extending Ocean Potential

86 Coca-Cola HBC

Quenching the Thirst for Success

106 Oman Tower Company

Towering New Heights

Fresh future for the Omani telecoms sector

112 Belinus

The New Aesthetic of Energy Efficiency Meeting domestic solar demand with Belinus CONSTRUCTION

116 VSL Middle East

Building the Middle East

Innovative structural development from the UAE

96

Around Europe and the Middle East in seven stories…

SEAWEED IN THE Baltic Sea is becoming an environmental concern with increased amounts causing oxygen deficiency, therefore impacting marine life.

The rapidly multiplying blue-green algae is being harvested to create ingredients for food products and cosmetics. Finnish biochemist Mari Granström’s passion for scuba diving helped to alert her to the problem the

TECHNOLOGY

SWEDISH AUDIO STREAMING

app Spotify is planning to announce job cuts. It is the latest technology giant to reassess its staffing numbers in the last year.

Spotify, which recently saw its share price drop by 66 percent, has around 10,000 employees, and began the redundancies in October with 38 staff laid off from its podcast studios. It joins Meta, Twitter, Microsoft, and Amazon in the cutting of workforces.

toxic plant was causing the marine ecosystem.

Origin by Ocean (ObO), founded by Granström, sources and separates unwanted seaweed into useable materials at ObO’s pilot processing facility in northern Finland using patented biorefinery technology. The extracts are utilised for a host of products, including a replacement for plastic.

NEOM, A PLANNED smart city in Saudi Arabia, has revealed plans to open London-based hotel company, Yotel, in Oxagon - an octagonal floating business hub.

The fear of recession and a fall in advertising revenue have affected companies across the technology industry which saw the staff intake increase during the COVID-19 pandemic.

The futuristic hotel brand is scheduled to open in 2025 with a robot concierge, motorised SmartBedsTM, and fully integrated technologies which Yotel is known for. The surrounding areas and communities will be connected through advanced and autonomous mobility solutions.

The city’s name is derived from the first three letters from the Ancient Greek prefix for “new” and the fourth letter is from an abbreviation of an Arabic word meaning “future”.

THE GOVERNMENT PLANS

to give two of the UK’s biggest steelmakers £300 million each to go green. The funding will help Tata decarbonise its Port Talbot steelworks. The plant is the biggest industrial contributor to carbon emissions in Wales at around 5.8 million tonnes per year.

The process would involve investing in arc furnaces that use recycled steel and electricity will power the furnaces harnessed from renewable sources.

A similar financial package is

POPULAR UNITED ARAB

Emirates (UAE) diamond company

Evermore is looking to expand into the Indian market. It is currently scouting for a big name in Bollywood to recruit as its brand ambassador.

Evermore has initially earmarked

USD$500,000 for an entry plan onto the sub-continent, although that amount will increase as the enterprise expands.

The diamonds were first launched in Dubai, Bahrain and London, and are from Siroya ALTR, a joint venture between UAE-based Siroya and New York-based ALTR jewellery companies, which creates its gems in a state of the art laboratory.

THE ITALIAN AIRLINE Italia

Trasporto Aereo S.p.A. (ITA), formerly known as Alitalia, has received an offer from German airline Lufthansa for a minority stake with options to purchase the remaining shares at a later date.

Italy, along with the US, is the most important market for Lufthansa outside of its home market. Its importance for travel lies in its status as one of Europe’s top vacation destinations.

However, the German airline was not Italy’s first choice when it came to selling shares in ITA. Air France-KLM Group was its preferred option, but negotiations dried up.

ECONOMY GERMAN FINANCE MINISTER, Christian Lindner, has revealed that the country faces a mild recession this year, despite feeling positive about 2023 and 2024 overall.

Although there is a small amount of uncertainty, Lindner says the economic outlook is improving. The country’s inflation reading for December came back lower than expected as it declined to 9.6 percent.

Lindner said the government is now focused on “strengthening the competitiveness” of its economy. He believes the German economy is resilient and expects to see opportunities for a faster recovery.

expected to be offered to British Steel’s primary plant in Scunthorpe to support decarbonisation.

As we move towards a cashless world, accessibility and inclusion have come to the fore. Biometricenabled payment cards are among the innovations being recognised as key to ensuring security and transaction experience amid increasing contactless limits.

Earlier this year, challenger bank Rocker launched Sweden’s first biometric payment card – a huge commercial milestone and a step forward for the inclusive and diverse payment ecosystem. Supported by IDEMIA and powered by IDEX Biometrics’ (IDEX) cutting-edge fingerprint sensor technology, the card is easy to use, helping customers

improve their financial lives without PINs or passwords.

Diversity and inclusivity have been instrumental in bringing the industry to this point, as well as being a key focus for the future to cultivate an inclusive ethos and drive growth and innovation in payment technology.

Women are one of the most excluded demographics in payments. This is a worldwide issue, but particularly so in developing countries. One reason for this is that women are less likely to own a mobile phone or use mobile internet.

Despite this, women still make up the majority of today’s retail consumers – indicating a missed opportunity for growing economies. IDEX research shows that most women are comfortable embracing biometric technology to overcome the digital divide. As one example, 91 percent of women in Brazil are ready to switch from PIN to fingerprint authentication for in-store payments.

Payment diversity, however, doesn’t stop at women – it includes making payments accessible to all demographics, including the elderly, vulnerable and unbanked populations. Those suffering from dementia, literacy challenges or impaired vision

Catharina Eklof, Chief Commercial Officer of IDEX Biometrics, discusses diversity and inclusivity as instrumental factors in unlocking growth in biometrics, payments and more

Catharina

Eklof is Chief Commercial Officer of IDEX Biometrics (NASDAQ: IDBA) where she brings seamless payment experiences to consumers around the world through world-leading biometric sensor solutions. She is also a non-executive board director of Avanza Bank (NASDAQ Stockholm: AZA), Sweden’s largest digital bank.

Catharina has 20 years of global executive management across financial services, retail, travel, and security. She has led the commercialisation of new customer-centric solutions across Fortune 500 companies including more than 12 years spent in leadership roles at Mastercard in Brussels, London, and New York. Catharina established Mastercard’s global strategic merchant programme, bringing digital payment solutions and new, data-driven business models to organisations around the world.

Catharina Eklof holds an MBA in International Business and a Master of Science in Economics from the University of Uppsala, Sweden. She is based in Brussels, Belgium.

can find current payment methods extremely challenging and introducing fingerprint biometrics into payment cards offers a simple and easy way to authenticate payments with the simple touch of a finger.

Today, despite increasing numbers of people gaining access to banking services, over one billion adults remain unbanked around the globe. While the majority of the unbanked live in the developing world, around 42 percent of Europeans currently lack basic digital skills that prevent them from

accessing online or mobile banking.

This needs to be tackled head-on to ensure people have access to paid services, especially in countries that are moving away from the use of cash. For example, in 2020, just nine percent of all transactions in Sweden used cash.

Advances in biometric fingerprint authentication can be particularly effective to support these consumers as the person is linked directly to their card by fingerprint alone, without a smartphone or the need to remember PINs. Remote enrolment capabilities

also mean that users don’t need to visit a bank branch to start using this technology.

Currently, women make up only 28 percent of the workforce in STEM roles. In order to grow these industries, this urgently needs to change. Biometrics is just one field where a diverse workforce is beneficial.

As a field underpinned by a wide span of technologies including system engineering, custom application-

specific integrated circuits (ASIC), sensor development and cryptology, the biometric industry requires the creativity and collaborative power of every possible diverse mind and personality. Everyone has a unique background experience and a unique perspective. Problems are solved faster and more elegantly when everyone approaches a problem a different way. Attracting a diverse talent pool to the industry, therefore, will not only help strengthen it but also deliver future growth.

I have always supported women in the industry, starting with my involvement in the women’s talent programme while at Mastercard, which included mentorship, training and networking on a global scale. At IDEX, I continue to mentor new talent and share my own experiences within tech. In addition to supporting women in my industry, together with the IDEX team I am formalising our engagement around diversity and inclusion. We are establishing our environmental, social and governance (ESG) agenda, ensuring that sustainability and diversity is integral to who we are as a business and how we operate.

As a woman in an executive role in a heavily male-dominated industry, I am in a privileged position to act as a bridge for women who are interested in biometrics but may feel that the industry is too specialised. Here, IDEX is focused on connecting a very powerful technology with use-cases that have real meaning and can make a difference for millions of people – and that’s something that many people can become a part of.

IDEX is a firm believer in the importance of promoting inclusion. This means offering financial education and developing solutions that foster an inclusive environment for those from diverse backgrounds or for those who would otherwise be financially excluded. Biometric payment cards and offline wallets (a digital wallet that is stored on a platform not

financial inclusion around the globe by providing simple and secure authentication to all.

IDEX Biometrics is leading the way in biometric technological development. We believe diversity and inclusion is part of our DNA, which brings with it immeasurable innovation and developmental potential. Our diverse team of engineers has pioneered the industry. Our 120 team members operate across 13 different locations around the world and speak over 12 languages. Whilst there is always more to be done, we are pleased by the growing number of women in leadership roles.

We are committed to building solutions that will drive payment inclusion around the world, actively working alongside card manufacturers and financial institutions to bring biometric payment cards to the mass market and tackle the challenges around financial inclusion and diversity. Both are essential to the future of tech and payments, paving the way for a more equal payment ecosystem and untapped innovation and growth.

linked to the cloud or internet) are concrete solutions to supporting

Each to Their Own is creating brands for communities to gather around. We speak to the co-founders, Maddy Russell and Rose Radtke, about designing strategies and identities for community-driven businesses and membership organisations, and all the benefits that follow

Writer: Marcus Kääpä

Writer: Marcus Kääpä

Community-driven business differs from the traditional model by its concentrated success. On top of the many benefits, including a high level of trust between business and consumer, the impact of community association can be felt in lower business costs and a higher level of scalability, answering the demands of said community and building alongside it.

This community trust not only helps secure customer retention (and consequently spending) but allows a business to build a belonging for people while also contributing their own energy to the business, combining knowledge, skills and expertise to help grow the entity that has helped its community.

The advantages of communitydriven business stem from the base of community engagement, not

Maddy Russell, Co-Founder

Maddy has worked with a whole range of organisations from large global brands to small independent businesses. She believes that strategically sound, creatively brilliant design paves the way for long-term success. Maddy is ETTO’s Chief Art Director, but also loves to get stuck into the details. She’s passionate about turning a big vision into a beautiful reality.

Rose Radtke, Co-Founder

With more than a decade’s experience in the strategic branding of purpose-driven organisations, Rose researches, devises and shapes story-led narratives and communications that set progressive brands apart in today’s hectic marketing landscape. Over the years, Rose has worked in agency, freelance and consultancy roles across private, public and third-sector organisations. She’s passionate about marrying thinking with creativity to help to shape the world that she wants her children to grow up in.

only building familiarity but also allowing specific businesses to drive sales through qualifying leads; when people engage with a company, such as by attending an event, the business has access to a greater level of data that can be used to better understand its customer base and develop with people in mind. This in turn helps a business retain a loyal and frequent customer base, and ultimately own a niche in the market where it can grow and thrive alongside the community. At the root of this success lies design, branding and identity. For companies across the globe –traditional and community-driven - these elements are key, reinforcing

products and services through the establishment of a narrative that sets a precedent for what businesses are to provide. While design and branding can be considered the face of a company, the visual elements that customers and clients meet first, identity is the heart – the mission, values and purpose that lay at the core of a business, and what it aims to achieve within its market and community.

Based in the UK, Each to Their Own (ETTO) is an agency created to build brands for the community to gather around, helping deliver a strategy to community-driven businesses.

In 2020, ETTO founders Maddy Russell and Rose Radtke met through a community of like-minded women in business. While their passion and drive were similar, their skills were completely and delightfully different. Rose was all about strategy and words, and Maddy was immersed in the world of design. A creative alliance made perfect sense.

By 2022, ETTO had grown into a collective of talented strategists and

creatives. Today, ETTO’s mission is to collaborate with good people, helping them to connect deeply with their customers and build better communities within complex cultural landscapes. We speak to the founders to learn more.

EME Outlook (EO): What was the initial drive and vision behind starting Each to Their Own (ETTO)?

Maddy Russell, Co-Founder (MR): ETTO started when Rose and I realised that our skills were complementary, and our impact was far greater together. We had a shared belief in the power of people to change the world, particularly when they pull together. It made sense to use our talents to help businesses bring people together to enact change.

EO: Could you talk us through your agency model and the client journey and experience?

Rose Radtke, Co-Founder (RR): We design strategies and identities for communities and membership organisations. All our projects begin with a period of discovery, which involves lots of research and talking to people that are closest to the organisation. We’ll also do surveys, focus groups and workshops to get to the heart of the organisation. All

this leads to a strong identity: the organisation’s vision and mission or purpose; its values, personality and its visual and verbal identity. We then apply the identity to the spaces that the community or members gather in, both on and offline, and work with the core team to define the community culture and member experience. We often go on to enjoy long-term relationships with our clients, applying the brand to templates and collateral and creating campaigns and content to help the organisation grow.

EO: Could you tell us about your work with communities and member organisations?

MR: We’re entering an age where people want connection over material things, and businesses that offer an opportunity to belong are the most successful. Creating a community or a membership organisation isn’t easy though - it’s an art, founded on understanding and engagement, and brought to life around a flexible set of principles. We lead our clients

through a process to understand the truth that lies at the heart of their own community or organisation and help bring it to life through branding, engagement strategy and heartfelt communications with the people that matter to them. Our goal is always to create a truly unique and inspiring strategy and identity that serves an organisation well for years to come.

EO: How do design, branding and identity impact client growth, and why does this matter?

RR: Branding is a capital expenditure (CapEx) cost. That means it’s an investment into a long-term fixed asset that will benefit a business far into the future. A study by brand valuation consultancy Brand

Finance found that a strong brand can increase the valuation of a company by as much as 20 percent. Investment in strategy and identity is worthwhile in the short term, too. A strong identity helps communities and member organisations attract and keep members. It can also increase the value of a membership as people are willing to pay a premium for the perceived value of a brand they identify with and trust. Having a strong identity, a solid culture and a member experience strategy helps engage and retain members, who in turn become the best kind of brand ambassadors. Ultimately, this reduces your paid advertising spend.

EO: How has your vision of the future changed since you started ETTO?

MR: We started with an ambition to bring people together. Since then, we’ve been on a long journey of discovery and gained insight and expertise in the wonderful world of community building. Our passion for community has developed as we’ve seen people’s need for connection grow. We’re living through difficult times, and we wholeheartedly believe that organised groups of passionate people with common interests, skills and the will to do something different are the key to solving the biggest challenges of our generation.

“WE BELIEVE THAT GREAT BRANDS HAVE THE POWER TO BRING PEOPLE TOGETHER, SPREAD JOY AND SHAPE THE FUTURE” – ETTO

Wintech Façade Engineering supports the construction industry with the provision of independent, impartial, technical and façade engineering consultancy services. We speak to Paul Savidge, Managing Director of the company, to learn more

Writer: Ed Budds

Writer: Ed Budds

Rapidly approaching a prestigious 40th anniversary later in 2023, Wintech Façade Engineering (Wintech) leads the way in expertise for new build and refurbishment projects. Its expert engineers look at building physics, thermal modelling, and the energy performance of façades, as well as providing specifications and

detailed designs for contractors to follow and meet the necessary performance criteria supplemented with site monitoring to check on the installation quality.

Wintech is also deeply embedded in the sustainable transformation of the construction industry, being part of numerous technical industry committees such as the Centre for

Window and Cladding Technology (CWCT) sustainability work streams and UK NZC task groups.

2022 was a busy period for Wintech, having recently opened an office in Edinburgh, a move which is just one of the latest developments in the company’s current expansion programme, building on the advancement of a new larger flagship office in London and the expansion of its Wolverhampton headquarters. This underpins the continued growth of the business and underlines the group’s commitment to building a market-leading façade engineering consultancy business across the UK. We find out more with Managing Director, Paul Savidge.

EME Outlook (EO): Firstly, could you briefly introduce us to Wintech?

Paul Savidge, Managing Director (PS): Building on four decades of success, the Wolverhampton group has grown into a strong company employing more than 100 industry experts in a range of specialist sciences and disciplines, focused on the aesthetic, environmental and structural challenges crucial to the successful completion of the building envelope. Wintech is now a recognised international centre of excellence for the science of façade engineering in what is fast becoming an integral part of the building process.

Wintech’s specialism in providing consultancy services to commercial and high-rise buildings includes:

• Façade engineering and design

• Sustainability

• Façade access and maintenance

• Fire engineering

• MEP

Anticipated services for sample buildings include:

• Site survey and information gathering on existing construction and systems

• Net zero carbon assessment

• Energy modelling

• Overheating calculations

• Ventilation assessments

• Daylighting assessments

• Options report for fabric and MEP improvements

• Options for the introduction of renewable energy sources

• Complete carbon appraisal for the refurbishment and remedial measures proposed

• Breakdown of carbon scopes into construction, operational energy, and whole life

• Remedial concept design detailing

• Tender assistance and review of contractors’ proposals

• Design audit of contractors’ design details

• Site monitoring of installation works

• Thermal analysis involving U-value calculations

It’s a really exciting time to be a part of the business as it enters a new phase of growth.

We are building upon our current core strength of façade engineering, but also looking to prepare the business to assist with the nation’s net zero building transformation requirements. This includes sustainability and building energy advice for the mechanical and electrical systems, in addition to the envelope which is of course the building’s primary energy modifier. The government has already committed to all new builds achieving net zero by 2030 and all existing buildings achieving net zero by 2050.

EO: How does the company seek to improve cladding and façade standards across the UK?

PS: Across the UK there are 30 million homes that need to be upgraded to assist in achieving the UK’s lawful obligation of becoming net zero by 2050. It is anticipated that to achieve

this, all new builds should aim to be achieving net zero carbon by 2030. The built environment is responsible for 50 percent of the UK’s carbon emissions in both construction and operation.

The challenge is unprecedented and requires a radical change not only for local authorities, but for the country as a whole.

Wintech’s future strategy is to provide a dedicated business unit to assist in the decarbonisation of the existing building stock, in addition to our core consultancy work assisting in the façade construction of new build projects.

EO: How does Wintech encourage talent attraction and retention, particularly in the context of ongoing labour shortages?

PS: Wintech approaches its 40th year in 2023, and one of the main core building blocks of the company has been investing in and developing our

people. This includes providing vital support to our new starters as they begin their careers, and upskilling our existing talent has always been our priority. By sponsoring education for our employees, we send a clear message that we value our staff, and in doing so have increased our staff retention, created a talented team, and boosted productivity through the years.

Wintech has always understood the importance of contributing

to a thriving industry, and with integrity at the heart of what we do, we understand that training and upskilling are necessary for Wintech to thrive and in turn support the industry and built environment.

EO: Why is Wintech particularly keen to drive recruitment amongst younger generations?

PS: Building upon Wintech’s solid reputation of investing in education

and upskilling has led to the creation of Wintech’s MSc Façade Engineering Scholarship. Launched last year, the scholarship provides additional funding for those students who need it most, assisting aspiring façade engineers in accessing the education, skills and knowledge required to enter the field. As a company, we understand the importance of attracting the younger generation to the industry and removing the barriers to entry.

Wintech has a history of working alongside academia and has over the years collaborated with several universities, with some of our engineers stepping into the lecture theatres to share and raise awareness of the science of façade engineering.

Our workforce is diverse and one of the main roles of the company has been, and continues to be, supporting talent from all backgrounds to join the façade engineering profession.

The diversity within Wintech’s workforce is further reflected in the more than 15 different nationalities represented across the company. Moreover, our commitment to representation has meant that 33 percent of our technical team is made up of women, and this has been increasing year after year.

Wintech Group is a dedicated engineering specialist in the science of façade engineering and design. The discipline also includes façade access, fire engineering and sustainability consultancy services from the early phases of building delivery strategic development to the building completion.

Taking the helm of one of the largest privately owned business houses in the Gulf region, we spotlight Mohsin Hani Al-Bahrani, CEO of the ACERE cluster at Mohsin Haider Darwish LLC, as an inspiring business magnate on a mission

Writer: Phoebe Harper

Writer: Phoebe Harper

As one of the leading conglomerates in Oman, Mohsin Haider Darwish LLC (MHD) has a prestigious legacy. Since its inception in 1974, and its subsequent establishment as a corporate entity in 1987, MHD has followed an impressive trajectory of growth and progress.

Equally impressive however, is the

rise of Mohsin Hani Al-Bahrani, who at just 25 years old takes the helm as CEO of MHD’s ACERE (Automotive, Construction Equipment and Renewable Energy) cluster.

A family-run business, Al-Bahrani was not deterred by the potentially daunting prospect of following in his grandfather’s footsteps in joining and scaling the company.

“It was imperative, and in many ways, my responsibility, to one day receive the baton and take on the task of driving the organisation to new heights,” he shares.

Through both tenacity and ambition, Al-Bahrani’s efforts within the business are noteworthy. Within just one year of joining MHD as Director of Automotive, he had been promoted to CEO. This came at a critical time, as all companies were forced to weather a storm of economic turbulence during the COVID-19 pandemic. Not long after, in 2022, Al-Bahrani was ranked as a key figure in the prestigious Forbes 30 Under 30 Middle East.

“It is extremely gratifying to be acknowledged for your work and to know that you are on a good path – a path that leads to the greater good of all,” he says.

“I am honoured to be a part of this illustrious group of achievers. But more than that, it’s a reaffirmation of the work I have done and the impact it has had not just on our employees, but also on people at large and the nation in general.”

As Al-Bahrani suggests, the welfare of the nation is a key concern for MHD as an enterprise founded on far-sighted entrepreneurial values of responsible corporate citizenship whereby both country and company benefit. Indeed, from the company’s very beginning, its development and successes have been intrinsically linked to the progress of Oman as a whole.

“The growth of the company has kept pace with the tremendous progress the Sultanate of Oman has achieved under the wise and able leadership of the Late His Majesty Sultan Qaboos bin Said and continues to align with the new renaissance under the able leadership of His Majesty Sultan Haitham Bin Tariq Al Said,” he comments.

“MHD has been a great partner in the nation’s progress over the past few decades and it was only logical for me to align with and join in this path to greatness that Oman has embarked upon.”

Several initiatives pioneered by Al-Bahrani have been instrumental in this regard, including the introduction of iconic brands within the automotive

segment that have led to the creation of much needed employment opportunities while also contributing to Oman’s overall socio-economic development.

“Drawing on my business acumen and resilience, I was able to bring in niche brands such as McLaren Automotive, ABB EV Chargers, Varta Batteries, XCMG, and Weir Trio,” he says.

Other developments within this branch have included merging the Tyres and Batteries division, to facilitate the growth and expansion of major names including Michelin, BF

Goodrich, Riken, and Eneos.

“I have also been active in promoting MG Motors in the Sultanate. In 2019, the brand ranked 15th in terms of local sales volume, according to the MEAC Report. Now, it occupies second position behind Toyota,” Al-Bahrani shares proudly.

This increasing prominence for MG Motors is largely thanks to MHD ACERE’s launch of e-commerce operations for the brand, whereby consumers can purchase a car in just three clicks.

“This launch was intended to help MG reach a wider customer base and

maintain a continuous relationship with current customers and partners. In addition, to provide a premium, personalised experience to our niche customers, I enhanced the e-commerce platform of Jaguar Land Rover,” he continues.

With regards to the MHD ACERE entity as a whole, Al-Bahrani has overseen significant expansion across the sales and aftersales network in the wake of the COVID-19 pandemic, establishing seven new sales facilities across Oman and increasing its aftersales facilities from three to 12 in the space of two years.

“These moves have enabled MHD ACERE to achieve its goals of delivering utmost customer satisfaction and improving overall brand awareness,” he affirms.

A key part of Al-Bahrani’s strategy as CEO is centred on diversifying MHD ACERE’s operations, setting up new verticals to enhance its reach and product offering. To date, this has included the launch of MHD Leasing LLC, which caters to Oman’s tourism industry, and its newly formed healthcare division which fulfils a critical role in supporting the nation’s well-being in a practical and physical way.

“Under my remit we have partnered with some of the leading global brands in the medical sector such as Spark Meditech, Comen, Schrack Seconet AG, FUJIFILM, and Sonosite, to bring some of the best medical equipment and practices to the

Sultanate,” Al-Bahrani elaborates.

“This HospiCare division of MHD ACERE also supplies intra-aortic balloon catheters, hernia repair meshes, and other vital equipment to top medical organisations and hospitals in the country.”

As with all socially responsible corporate citizens, MHD ACERE demonstrates an awareness of environmental concerns, and seeks to tackle the immediate threat of global warming and climate change.

“I have introduced sustainable business practices to MHD ACERE and established the Renewable Energy and Electric Vehicle (EV) Chargers division” he shares.

The aim of this division is to drive technological innovation, powered by clean energy. In addition, Al-Bahrani recently signed a

contract with ABB, a pioneering technology leader focused on digital industries, for the supply of high-power EV chargers that will be installed throughout the country.

“There is no doubt that e-mobility is growing across the globe and my aim is to be among the pioneers providing the best green and sustainable solutions in Oman.”

Through this powerful combination of passion and ambition, Al-Bahrani will continue to build on the legacy of MHD while developing the nation with a focus on sustainability, and innovation.

“Our ambitions are not just limited to the organisation but transcend to a national level. We are one of the key partners in Oman’s Vision 2040 plans and as such, seek to be the biggest contributor to the achievement of the charter and the eventual progress of this nation,” affirms Al-Bahrani, hinting at the pursuit of greater expansion across both sectors and geographies.

“For us, the sky is not a limit.”

“ FOR US, THE SKY IS NOT A LIMIT”

– MOHSIN HANI AL-BAHRANI, CEO, ACERE CLUSTER, MOHSIN HAIDER DARWISH LLC

Building on the global success of our regional titles – EME Outlook, Africa Outlook, APAC Outlook, and North America Outlook – Outlook Publishing is proud to be launching a dedicated platform for the Mining & Resources sector.

As mining organisations worldwide confront unprecedented change, embracing technological innovations and incorporating critical environmental sustainability agendas, now more than ever is the time to showcase the strides being taken in this dynamic sector. A multi-channel brand, Mining Outlook will bring you the positive developments driven by organisations across the global mining industry through our various platforms. Discover exclusive content distributed through our website, online magazine, social media channels, and dispatches delivered straight to your inbox with a bi-weekly newsletter.

Through this compelling new venture, we intend to foreground the movers and shakers of the industry. To participate as a featured company and join us in this exciting endeavour, contact one of our Project Managers today.

www.mining-outlook.com

a male-dominated industry

Lise WaalAnne Lise Waal has been described as one of the leading women in tech across Europe. For the past decade, she has worked as CTO and COO at Attensi – a provider of bespoke gamified training for a host of companies, with clients including Microsoft, NHS, Equinor, Bosch Siemens, Hiscox, Volvo, ASDA and the NSPCC.

Within her role, Waal has supported the company’s impressive growth and international expansion through her extensive knowledge and experience within the technology industry and by continuously scaling Attensi’s technology platform and simulationbased learning products.

As a passionate advocate for women working in the tech industry, we find out more about her take on the field today.

EME Outlook (EO): Firstly, could you provide us with a brief overview of your career background and current role?

Anne Lise Waal (ALW): I am currently the CTO of Attensi - the world’s leading provider of high impact gamified training. I first began my

career as a consultant in Enterprise Architecture and IT Governance with a Masters in Computer Engineering. After that, I was initially planning to do a PhD but dropped out in favour of going into business. From there I quickly moved into the gaming industry after seeing a job opening with leading Norwegian game developer, Funcom. I spent seven years there as senior producer overlooking the development of AAA massively multiplayer online (MMO) games.

I thought I would never be able to go into gaming because I was not working as a programmer. That was until I came across an opening in project management, which I saw as my chance to get into the gaming industry. I started at Funcom in 2006 and worked closely with Trond Aas (co-Founder and CEO of Attensi) throughout my years there. We both left in 2012 and Trond started Attensi the following year. I then joined in 2013 when there was just five people on the team.

A born and bred gamer, we discuss making a business of your passion in

with CTO and COO of Attensi, Anne

Writer: Phoebe Harper

EO: Women in tech is still an area of great gender inequality. What was your motivation to pursue a career in this field?

ALW: I am a born and raised gamer and it has always been a huge part of my life. After receiving my first games console at four years old, then my first computer (a C64) at seven, I was hooked from that point on. My dad is a tech geek, so it was always my dream to work in the creative tech business. I thought that to go into the gaming industry you had to be a brilliant programmer and my passion was not in programming, even though my education was. Instead, I transitioned into the business interface of tech, which began my journey in gaming.

EO: How has your career journey been so far? What would you consider to be your greatest accomplishment?

ALW: It has been an extremely exciting journey so far! Building a company takes blood, sweat and tears, but it is so worth it when you succeed.

My earliest accomplishment was to get that first break into the industry at Funcom. It was the first and only job interview I have ever done, so I was extremely proud of getting into the

industry and working with talented people.

My greatest accomplishment has been being able to build a kickass team from scratch developing software as a service (SaaS) technology and simulation-based training products that have enabled us to rapidly grow into a market leader and most recently raise money for global expansion. It is difficult to find motivated people who share the business’ key values that make up the company culture.

EO: What has been the most challenging thing so far?

ALW: The biggest challenge has been keeping up the stamina. When you are building a new business, times can be tough. You might not see the long-term bigger picture when working on the day to day, but when you remember to look at the longterm vision it helps you to keep your energy high.

In those first three to five years, it was challenging trying to grow both revenue and the business fast. Essentially, it’s about working to go beyond your limits when you think you don’t have any more to give. I think about it like a marathon. When you know the finish line is waiting for you, you can hardly

imagine how you’re going to get there, but the secret is stamina and motivation.

EO: What plans do you have for the next few years?

ALW: At the moment I am focused on further continuing the business’ international expansion as the goal is to take a market-leading position in both Europe and US. I also plan for us to scale our business with great people, while keeping our culture and values at the core of what we do.

As a business we are always scaling the technology platform and simulation-based learning products. Attensi takes untraditional gaming technology into new market sectors that have never used it before and it has been highly successful, but our biggest enemy is the status quo. I like to challenge the ways things have been done in the past and be truly innovative. I would love for us to be completely radical on the product side, perhaps even expanding from B2B into the B2C segment.

EO: Finally, what advice would you give for women considering getting into tech?

ALW: I would say just to take the leap, and make sure that your work is fun!

Europe is a region currently witnessing phenomenal change throughout the vast and complex payments industry, driven by a combination of technological advancements and immense consumer demand

Writer: Ed Budds | Project Manager: Deane Anderton

Writer: Ed Budds | Project Manager: Deane Anderton

Trading in Europe within the expansive payments industry is not cheap. In order to stay afloat, many financial institutions must now rely on the backbone of large and complex organisations.

For both domestic and international businesses, Europe remains much more complex than other continents, mixing languages, payment methods and even regulations.

The European region has also seen an explosion of FinTech businesses in recent years, offering many similar products to traditional banks.

As the world still struggles to return to pre-COVID-19 levels, several such industries have turned adversity into a fresh advantage. With digitalisation processes already well underway, the payments sector has received a key boost, with European citizens increasingly demanding better customer experiences through digital payments.

With the EU’s payments sector as varied as the cultures of each member state, the European point-of-sale (POS) market recently announced a post-pandemic increase of 14 percent yearly growth, with Norway, Belgium and Spain as the most dominant forces in this impressive rebound.

The European Banking Authority (EBA) claims the utilisation of digital platforms to bring customers and financial institutions closer together is rapidly expanding and this growth is projected to continue surging as financial institutions look to satisfy customer demands for both convenience and decreased costs.

The Payments Association exists today as the largest community in the field of payments. Now curating communities in the UK, Europe, and Asia, helping almost 300 companies enhance their commercial interests, The Payments Association endeavours to solve societal problems such as financial exclusion and evaluate new opportunities for innovation in payments.

CONNECT - Save time and money by connecting with the industry’s key stakeholders each month at inperson and virtual meetups, as well as identifying new opportunities and initiating new partnerships.

SHAPE - Join a working group project alongside a group of subject-matter experts in order to drive meaningful change and gain a position as a thought leader on a certain topic.

LEARN - Gain actionable, bite-sized insights on today’s business-critical industry issues in the membersonly resource hub.

MARKET – Gain brand exposure by profiling your company on The Payments Association’s website by positioning it as a part of the most influential community in payments.

The Payments Association’s purpose is to empower the most influential community in payments, where connections, collaboration and learning shape an industry that works for all. We dig deeper with Director General, Tony Craddock

EME Outlook (EO): Could you talk us through The Payments Association – when was it founded and what was its initial vision?

Tony Craddock, Director General (TC): The association was founded in 2008 by myself and a small board of

directors who identified that the payments industry was undertaking a period of rapid evolution and change. Back then, there wasn’t a network that could act as the catalyst for that growth, so we saw an opportunity to set up such a community that could support and serve the interests of companies across the entire breadth and depth of the payments industry.

We’ve since deployed a commercial community model that has a range of services to cater for the various needs of the community and as a result, we have built a very loyal and growing membership base.

We have also achieved a high level of engagement from our members and were recently recognised as the UK Association of the Year by the Association Excellence Awards 2022, which we’re really proud of.

EO: Do you think you’ve succeeded in delivering that initial vision?

TC: I think we’re just starting out really. We started off in a tiny room with a small group of people. We didn’t have a big pot of money to invest in this, and it’s been built organically using our own investment, hard work and creativity.

I believe there’s now a need to play an even greater role on several fronts to serve the interests of the

payments industry. It’s an unusual sector because, unlike many markets, where you find yourself competing with other companies, for those in the payments industry, collaboration is a prerequisite for success. Today’s partner or competitor may be tomorrow’s supplier or customer. So everybody must get on with everyone else. We enable this collaboration by providing a range of different events, research projects, and industry engagement working groups, which make collaboration easy and efficient.

In payments, collaboration is not a project. It’s a lifestyle. With the economic downturn and the hangover from the pandemic ringing in our ears, we have to further improve how we influence industry institutions such as the regulators, the Treasury and central banks, to make sure that the foundations of our industry are rock solid.

We must also look to deepen the breadth of services we provide, particularly around training and development, and broaden them, by growing across the EU and in different regions of the world.

TC: One of the issues that keep our members up at night is that fraudsters and scammers are getting smarter, so we as an industry must get better at preventing them from scamming and exploiting consumers.

Secondly, we’ve got to incorporate new technologies into our blueprint for the future. For example, the Bank of England is running a proof of concept for a Central Bank Digital Currency (CBDC) wallet, which is really progressive and exactly the sort of new technology that we must encourage the industry to embrace.

Thirdly, our community must try to encourage the adoption of new innovations without unsettling the underlying financial system, while promoting the UK as a market-leading provider of the different components that make our industry work. And we need access to an informed and progressive government that is prepared to provide support for our sector, so we are in the process of encouraging and inspiring the current government ministries to promote and embrace the adoption of new technologies and proportionate, agile regulation.

Elsewhere, there is going to be greater pressure to consolidate because of the changing nature of funding in the industry. After a decade of major investments into FinTech and payments, there’s less money around right now, and the money that there is will be more carefully focused on short-term profit rather than longer-term growth. This means that some people’s cash runways will be shorter than they had expected, and they will therefore be looking to consolidate with others. Personally, I welcome this, as it means those companies that focused on revenue rather than profit, with all the risks attached to this approach, will be absorbed into others built on more robust foundations.

“Chargebacks911 has worked to mitigate chargeback risk and eliminate fraud for more than a decade. In fact, we were the very first global company dedicated to tackling the problem of chargebacks, which represents more than $200 billion in annual liability to the market. With a laser focus on this goal, we have developed the most effective strategies for minimising the impact of chargebacks, helping businesses streamline processes and optimise data insights to reduce loss.”

The opening words of Monica Eaton, founder of Chargebacks911, encapsulate not only the size of the chargebacks issue for companies but the dedication and focus that has led Chargebacks911 to become the first global company fully dedicated to helping merchants combat post-transactional fraud.

The origin of Chargebacks911 was not rooted in banking or payments. In fact, Monica wasn’t in the financial sector at all. She was a merchant that had poured years into building up an online business only to see its success and revenue eaten away by customer disputes.

She needed a fast and reliable solution, one that prevented chargebacks, recovered lost revenue, and equipped her business for sustainable growth. After trying just about every available provider, she reached a frustrating conclusion: there simply wasn’t an effective, merchant-centric solution available — so she created one.

Over a decade later, Chargebacks911’s exclusive datadriven platform provides true end-to-end chargeback

prevention and remediation technology that safeguards more than 2.4 billion online transactions every year, representing clients in 87 different countries.

With more people buying online than ever before, there will be a greater number of mistakes, especially from new and inexperienced online users. Additionally, with more money being spent through ecommerce, there is more incentive for fraud. Both of these factors are going to increase the number of chargebacks initiated by consumers, and that’s bad news for any business selling online.

Chargebacks aren’t just another way to get a refund –they cost merchants significantly more when factoring in admin fees and the potential for card schemes to raise fees or assess penalties. It becomes a particular problem when you look at how many chargebacks aren’t legitimate but are in fact examples of “friendly fraud”.

At one end, friendly fraud can be the result of simple mistakes – not recognising a transaction on a bank statement or not checking if a package is running late. We are increasingly finding that chargeback claims are more likely to be fraudulent than not, perhaps as high as 86 percent.

Most merchants don’t know how to distinguish friendly fraud from genuine chargebacks, or how to effectively respond. To combat the issue, retailers must implement a multi-layered fraud solution composed of both pre- and post-transaction elements to identify the root cause of chargebacks. Enter Chargebacks911.

Having built success, trust, and results with its merchant customers via its Chargebacks911 brand, the leadership team launched its revolutionary new brand, Fi911, to provide financial institutions with a suite of next-generation chargeback and merchant lifecycle management technology.

Developed by Chargebacks911’s experts in collaboration with some of the world’s largest institutions and payments processors, Fi911 empowers financial institutions with APIs and innovative quick launch components to help deliver speed-to-market capabilities for managing chargebacks and related activities. Its tools are built for the challenges that financial institutions face today in the midst of the global growth in card payments and double-digit, yearover-year growth in chargeback volumes – such as its proprietary DisputeLab™. This solution helps make resolving chargeback disputes faster and more efficient by optimising each step in the dispute cycle. In addition, as part of its AI-driven platform, Fi911 offers merchant onboarding, post-transaction monitoring, lifecycle management and reconciliation services.

The company is proud of the unique and comprehensive suite of solutions it has developed to help safeguard transactions for industry stakeholders. Its products are developed to serve financial

institutions and merchants, with varied implementation options to fit virtually any budget and size. Its clients are either merchants, served by the Chargebacks911 brand and product suite, or banks, supplied by the Fi911 brand catered to acquirers and related financial service institutions.

It also works with many third-party vendors and suppliers, such as CRMs, gateways, fraud filters, processors, etc. The platform aggregates connections and data, driving efficiencies and reducing requirements for manual reviews.

Monica and her company have the capacity to bring on any business, large or small, that receives chargebacks and disputes. The company’s goal is to minimise the loss from post-transaction fraud and utilise data analytics to help prevent it from happening in the future – offering a one-stop shop for everything dispute related.

Disputing high volumes of chargeback claims would be extremely difficult with the limited information that card schemes give merchants about chargebacks, which is usually not much more than a generic reason code. Merchants need a way to get the information that they need to challenge disputes and win, and Chargebacks911’s solutions solve this problem.

Its unique solutions system was built from the ground up by industry experts, taking into account the breadth of experience gathered at Chargebacks911

and its wide-reaching network. When paired witrealtime management solutions for the acquirer and their merchants so they can reduce chargebacks and prevent related issues going forward.

Through DisputeLab, acquirers and their partners can face the growing levels of first-party fraud and chargebacks knowing they have the tools that will protect them against any fast-paced or dynamic events that give rise to chargebacks and potentially devastate bottom lines. Overall, the system mends an archaic chargeback management process that was not meant for today’s digital world. It allows acquirers to scale their business and operate more efficiently. It can also protect their merchants if paired with Chargebacks911’s merchant portal.

DisputeLab’s effectiveness when protecting financial institutions and merchants against damages associated with chargebacks hasn’t been seen anywhere else in the acquiring chargeback management space. As such, a number of global acquirers have chosen this solution for its key features and benefit from:

1. Reducing human error: Automating the chargeback management process and equipping acquirers with an intuitive user interface significantly reduces staff training time for ‘chargeback competence.’ DisputeLab also enables acquirers to deploy full-time equivalent (FTE) on value-adding tasks rather than relying on manual processing.

2. Operating with an in-built rules engine: This ensures that an acquirer’s now-automated chargeback management system is kept entirely up to date with the latest card scheme rules. These can be configured to business’ bespoke rules at any time. Keeping in line with scheme rules is complex and time-consuming when done manually. Through DisputeLab, acquirers are protected against costly penalties from not meeting rules or deadlines.

3. Handling dynamic or fast-moving business events: It can reorganise or ring-fence chargebacks in real time, so acquirers can immediately locate, isolate, and treat associated transactions differently to suit the business’s requirements when managing a crisis event.

4. Flexibility: The cloud-based system can be easily integrated with almost any end point, file type or system without the need for anyone to visit a business’s premises, making onboarding swift and simple.

5. Competitive advantage: Merchants are more likely to opt for an acquirer who can protect them from the huge profit loss to chargebacks, making DisputeLab a competitive differentiator for acquirers.

Chargebacks911’s operations have grown significantly over the last year. It now services more than 45,000 merchants across 87 countries and 27 verticals, working closely with some of the largest merchants and financial institutions in the world. Through its chargeback remediation platform, which has the broadest coverage and supports virtually all payment methods that have chargebacks, it has protected over 10 billion transactions and recovered more than £1 billion in falsely disputed and stolen revenue to date. Fi911 is the technology platform provider for 40 financial institutions, supporting many of the world’s largest Tier 1 acquirers. It has provided a reduction in churn and attrition by over five percent for acquirers, and merchants have reported an increase in processing sustainability and growth by over 12 percent.

Through consistent rules adherence, chargeback monitoring, merchant communication, and responsible deadlines, Chargebacks911’s technology promotes significant industry-wide savings and helps acquirers, and their merchants, tackle the ever-growing issue of chargebacks head-on. Chargebacks are a problem that isn’t going away anytime soon. Shopping habits have been forever changed. So, going forward, Chargebacks911 and its sister brand Fi911 will be investing further to help all entities fight unnecessary chargebacks, enabling them to efficiently and effectively mitigate friendly fraud and lost profit.

Chargebacks911® drives profitability for online merchants by decreasing payment disputes and recovering revenue lost to chargeback fraud. Through a proprietary suite of software and service offerings, the company delivers transparent, end-to-end chargeback management solutions backed by the industry’s only performance-based ROI guarantee.

Phone: 877.634.9808

Email: info@chargebacks911.com

Website: chargebacks911.com

Address: 18167 US Highway 19 N. Clearwater, FL 33764

systems. There is for example room to make some cross-border payments more seamless as the world of lower value transactions grows. Swift is working hard to address all the elements that are within our control and to upgrade the industry’s infrastructure to enable instant cross-border transactions 24/7 between over four billion accounts on our network worldwide, regardless of size or value.

In today’s rapidly moving world, people everywhere expect to be able to send and receive payments instantly with a touch of a button or a tap on a screen. All payments therefore need to be fast, transparent, efficient and frictionless regardless of size or value, both domestically and across borders.

We can see firsthand the increasing benefit of values smoothly flowing across borders in our fast-paced, globally enabled society. Cross-border payments are essential to the world’s economic growth and international trade – not only for the world’s largest banks, but also for small businesses and individuals across continents.

While the majority of today’s cross-border payments are made quickly– settling within minutes or even seconds on routes where well-established direct links exist between countries – they are by nature more complicated than domestic payments. Our data shows that delays often occur at the receiving end of an international payment, likely because of capital controls and associated compliance checks, local operating hours, fragmented or incorrect data, and the use of batch processing

Together with our global community of financial institutions, Swift has made huge strides to enable instant and frictionless cross-border transactions for wholesale payments. Today, thousands of financial institutions use Swift to send and receive payments quickly and securely across the world, with full transparency over where the payment is at any point in the transaction. We give institutions confidence to send payments abroad knowing where their money is every step of the way, that all proper controls have been passed and that it will arrive on time. Not only that, but we have also delivered easy-to-implement solutions to address other friction points in the payments chain – including fixing avoidable errors upfront to avoid delays down the line, streamlining operational investigations when necessary, and ensuring compliance processes can keep up with faster payments.

While wholesale payments have traditionally dominated the cross-border payments space, we have more recently witnessed consumer behavior trends shift from a largely domestic payments model to one that regularly includes sending money abroad. The need for a frictionless experience for low value payments is clearer than ever.

Swift is committed to helping financial

Nasir Ahmed, Head of UK & Ireland, Swift

Nasir Ahmed, Head of UK & Ireland, Swift

institutions improve the experience for consumer and lower-value business payments to help these businesses thrive. The foundations we laid in the high value corporate payments space have given us the opportunity to deliver the same experience in the highly competitive retail and consumer space, allowing banks to re-use infrastructure investments they have already made.

For instance, our Swift Go service allows financial institutions to enable their customers to send predictable, fast, highly secure and competitively priced payments anywhere in the world with ease – directly from their bank accounts. With a fastgrowing community of more than 630+ banks in 130 countries, Swift Go is not just rivalling the offers of card players and Fintechs, but it is doing so on a global scale as it rapidly grows to become the new standard in lowvalue international payments.

The increasing demand for instant cross-border payments has also fueled a global curiosity around central bank digital currencies (CBDCs). The Bank for International Settlements recently reported that nine out of 10 central banks are currently exploring digital currencies, covering economies that account for more than 90 percent of global GDP. However, the risk of these CBDCs becoming fragmented is high, since central banks are using different technologies, standards and protocols.

While we don’t yet know the exact role that CBDCs will play, we do know that interoperability and linking between different CBDCs on a cross-border level will be critical to fully realising their potential and to ensuring protection against market fragmentation. We have launched a number of experiments which show that Swift can enable interoperability between different CBDC networks and between CBDCs

and existing payment systems. We are committed to working with our community and partners to support this major shift in the financial ecosystem and ensure that value in all its forms – whether digital tokenbased or traditional account based – can move around the world quickly, seamlessly and securely for as many people as possible.

This is a pivotal moment as the global payments industry stands ready for an instant, secure and frictionless future, with Swift at the forefront of this digital revolution. Our work today to innovate the industry’s global financial infrastructure will set it up for decades of success, creating a digital foundation for banks, corporations and small businesses to keep raising the bar on the services they provide to their customers.

Swift is further automating the end-to-end execution of payments on our platform, ensuring data issues are a thing of the past, and that service levels are sustained –making processing transactions faster, more efficient and cheaper without compromising on security. Underlying all of this is the rich data of ISO 20022, a standard for communicating financial information that is being adopted for cross-border payments across the Swift community from March of this year. Not only has Swift played a leading role in defining the standard, but it has been entrusted by the financial community to facilitate industry-wide adoption for crossborder payments.

We can see clearly that the future of payments is powered by better data, artificial intelligence, APIs and cloud-based solutions – and that future has already started.

www.swift.com/future

EO: Is it challenging to keep up with the rapidly changing technology landscape within the payments sector?

TC: Yes, and our role is to continue to champion those new developments and to encourage people to take on and adopt new approaches, new solutions, and new technologies. Equally, we must be mindful of the fact that although our industry is dramatically different to how it was even 10 or 20 years ago, in the grand scheme of things. The debit card was invented 30 years ago, and the credit card was only invented 60 years ago, so these are long term innovation cycles.

Looking at an example such as the addition of digital currencies into the technology landscape, while we’re all excited about what it might mean, we also recognise that the adoption of something like this will take several decades, so we must possess short-term enthusiasm, but keep our eyes on the long-term horizon.

EO: How do you see the association developing over the next five years?

TC: As a membership platform business grows in scale, the value for both the buyer and the seller also grows. In such a virtuous circle, the more members you have, the more value they get and the more productive our community becomes to run. This allows us to invest more in delivering value to our members, and the virtuous circle continues.

Secondly, we’ll become increasingly focused on our policy and government relations agenda because the government needs to be completely aware of and excited about the potential for this industry sector to generate new jobs, new businesses, and successful shareholders and to do that in a way that competes with other countries. Now that we’re outside the EU we need to remain focused on building the UK as a centre of leadership in payments.

And finally, we believe that bringing people together

“THE KEY TO THE FACILITATION OF PROFITABLE BUSINESS PARTNERSHIPS IS COLLABORATION, WHICH IS ENABLED THROUGH ENGAGEMENT”

– TONY CRADDOCK, DIRECTOR GENERAL, THE PAYMENTS ASSOCIATION

post-pandemic is increasingly important, so we’re going to invest in delivering larger events to make sure that our members and sponsors get access to greater opportunities, not just here but around Europe.

EO: What is the key to facilitating profitable business partnerships?

TC: The key to the facilitation of profitable business partnerships is collaboration, which is enabled through engagement.

For example, we facilitate an Advisory Board of 18 senior executives who have been elected by their peers to represent the industry. They help to set our content agenda, ensure our governance is world class and serve as our voice in the community. In return they create profitable partnerships with each other and our members.

We also get senior executives involved with our seven

ASSOCIATIONcommunity projects. These focus on the things that matter to our members, including financial crime, financial inclusion, regulation, cross-border payments, open banking and digital currencies. This year, we have launched a new initiative, Project ESG, which will help our industry to achieve a set of responsible, sustainable goals. It is proving to be extremely popular because our members really care about these things. And through these projects, relationships and partnerships are formed.

What makes this such a lovely business to work in is that we enable people to have a greater impact on the world around them in a way that makes them happier and more fulfilled. They feel more resilient in their working lives because they affiliate with like-minded others, have a place where they belong, and have influence over their collective destinies.

In the years ahead we will also be focusing on two other important components. Firstly, we want to professionalise

“WHAT MAKES THIS SUCH A LOVELY BUSINESS TO WORK IN IS THAT WE ENABLE PEOPLE TO HAVE A GREATER IMPACT ON THE WORLD AROUND THEM IN A WAY THAT MAKES THEM HAPPIER AND MORE FULFILLED”

– TONY CRADDOCK, DIRECTOR GENERAL, THE PAYMENTS

payments. We believe that too often people acquire skills and expertise in our industry simply by doing work and we would like to accelerate the pace at which they can learn by providing additional professional learning opportunities and more training.

Secondly, we’re going to be accelerating the democratisation of our community. We want our members to be increasingly able to influence what it is that the community does, and the way in which it is delivered through regularly checking in with our members and allowing them to influence the day-to-day content and direction of what we do. This means that the

community is not only positioned as being for them, but they’ve been involved in creating it, and co-creating it along with my team.

In the end, however, it’s really about the people we have on our team that makes all this possible. You don’t generally wake up in the morning and say, I want to work for a financial services trade association. Instead, people have joined us who are brilliant at developing great content for events, superb at managing business-tobusiness accounts, inspired at shaping policy or excellent at marketing and business development. And they have come together with the collective purpose of improving lives everywhere through payments. As a result, we have a wonderful team of highly motivated people who love working together and doing well by doing good. It’s inspiring and the real secret of our success.

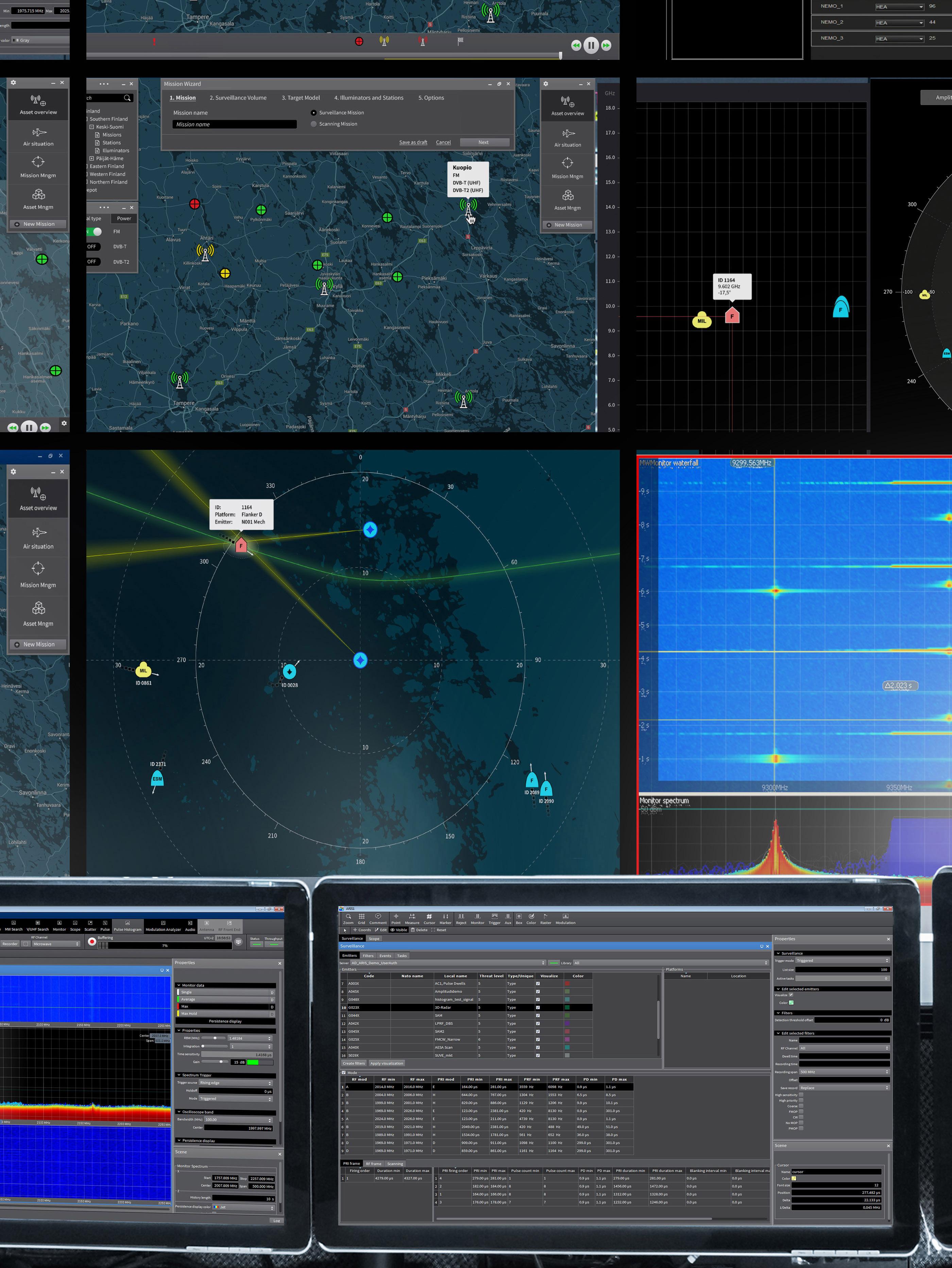

Finland is renowned for its technology and manufacturing industries.

The home of giants such as Nokia Corporation, Valmet Technologies, and reputable vehicle producers, the country is also a hub of activity for entities operating in the defence industry.

This is an industry firmly rooted in the nation partially a result of Finland’s own unique history. In 1917, the country gained independence from the Russian Empire following over a century of rule, and since that time has always held a defensive edge - quite literally - sharing a border of over 1,300 kilometres with the larger neighbouring superpower.

Three months after the beginning of the Second World

War, Finland was attacked by the Soviet Union (USSR) in a conflict that came to be known as the Finnish Winter War (First Soviet-Finnish War), with two preceding wars occurring within the timeline of the global conflict - against the USSR a second time and a smaller conflict against German forces in Lapland. Following this period, and with such a vast land border with Russia, national funding and support to Finland’s military and defence industry has remained steadfast.

Today, the defence sector is an ever-changing space where technologies are utilised in unprecedented ways; robotics and artificial intelligence (AI) autonomous systems, cyber warfare, and the latest in vehicle

technology are seen to merge traditional modern warfare with new frontiers.

The Finnish defence, aerospace and security industries focus on certain niche areas. Finland is home to global market leaders in armoured wheeled vehicles, turreted mortar systems, logistics, and command and control (C2) related systems. Finnish companies are also world leading within C5ISR (command, control, computers, communications, cyber, intelligence, surveillance, and reconnaissance). Dual-use products with security solutions and civilian applications are also becoming increasingly important.

With a few exceptions, most Finnish defence, aerospace

and security companies are privately owned small and medium enterprises (SMEs). One strength of these SMEs is that many also operate in alternative industrial sectors. Finland therefore benefits from a larger ecosystem of such companies with substantial R&D investment (15 percent of turnover). Turnover within defence, aerospace and security was approximately €1.9 billion in 2021, which was a slight increase from the previous years, with direct employment standing at around 9,500.

Due to the smaller scale of the Finnish domestic market, Finnish companies operating in the defence industry look abroad to supply products, systems and services to customers and partners.

Made up of member companies representing the Finnish defence, aerospace and security industries, we take a look at the organisation that forms a critical part of the country’s comprehensive security and military security of supply – the AFDA