Towards a Circular Economy Through Responsible REE Management

Recovery of Rare Earth Elements from magnetic waste in the WEEE recycling industry and tailings from the iron ore industry

European Union

This project received support from the European Union in the FP7 programme

REEcover

Recovery of Rare Earth Elements from magnetic waste in the WEEE recycling industry and tailings from the iron ore industry

Duration: 2013-2016

FP7 project

Grant agreement no: 603564

FP7-ENV-2013-two-stage

ENV.2013.6.3-1: Turning waste into a resource through innovative technologies, processes and services

Document date: January 2023

Towards a Circular Economy Through Responsible REE Management

Recovery of Rare Earth Elements from magnetic waste in the WEEE recycling industry and tailings from the iron ore industry

European Union

This project received support from the European Union in the FP7 programme

Abstract 7 Introduction 9 1 Critical Elements Everywhere 10 2 Two Resources 20 3 REEcover Processes 38 4 Impact 56 Credits 66 Imprint 68 Contents

6

The FP7 research project REEcover aimed to:

A) Improve European supply of the critical Rare Earth Elements Y, Nd, Tb and Dy

B) Strengthen SME positions in REE production and recovery value chain

C) Innovate and research two different routes for hydro/pyro metallurgical recovery of REEs: as Rare Earth Oxides (REO) or Rare Earth Oxy-Carbides (REOC) in electrolytic reduction

D) Demonstrate and compare viability and potential for these routes on two different types of deposited industrial wastes:

I) magnetic waste material from the WEEE recycling industry (low volume but high concentration REE)

II) tailings from the iron ore industry (high volume but low concentration of REE)

REE’s in WEEE-products end up in magnetic waste and subsequently in slag or dust from steelmaking or base metal smelters. During iron ore production of magnetite concentrates tailings are removed and deposited. Both waste streams have potential of becoming valuable feedstock.

REEcover developed numerous processes to transform the large mass of WEEE and apatite tailings into concentrated REEs that jointly present a valuable, secondary resource that is pure enough to re-use in a variety of applications.

The processes used to extract the REEs from the industrial waste streams are physical separation, followed by hydrometallurgical and pyrometallurgical upgrading. The resulting upgraded product was further purified using solvent extraction, and electrolysis.

In order to facilitate market-uptake of the processes developed in the REEcover project, the consortium has fostered links with relevant companies and prospective buyers. However, market conditions are of major importance for business case feasibility and process implementation into industry. Business case scenarios do indicate that multiples of the prevailing 2013-2016 market price levels are required for profitable applications.

7

Abstract

8

Introduction

At the beginning of the 21st century, the challenge to achieve global sustainability looks very complicated. Overpopulation, ecological degradation, climate change and widespread economic inequality collide, making the challenges regarding sustainability so complex that integrative, multidisciplinary approaches to innovation and research will necessarily play a major role in achieving progress.

Major challenges for humanity are resource depletion and ecological degradation. As the global population continues to grow, the existing stock of primary resources has to be distributed amongst increasing number of individuals. Reckless overconsumption of luxury products and ever-increasing cycles of production, usage, and discarding of electric and electronic products are intimately coupled to this looming scarcity.

One way of managing impending global scarcity (and economic recession) is to rethink the way in which we produce, consume and perform our economic calculations and predictions. Up until now, growth was achieved by exploiting new caches of natural resources and using them in producing more and more consumer products.

This model endangers the whole concept of sustainable development: the idea of future generations being able to meet their needs as easily as the current generation does. In order to become sustainable, a circular economy is needed. This means that the idea of waste should become redundant – waste should become the new input (re)source that minimizes the need for ever-increasing exploitation of primary resources.

REEcover is a step in the direction of the circular economy. Rare Earth Elements (REEs) are valuable and rare, yet they form an essential part of our technology-saturated societies. Both the current digital revolution and development of green technologies would be unthinkable if not for those elements. The effects of the 2011-2012 REE price spike (a result of supply constraints and the unbalanced market situation) provided incentives to develop technologies and processes for recovery of these critical raw materials.

Yet, a considerable amount of these elements end up in high-temperature smelters and their recovery rates are alarmingly low. The processes developed in REEcover aim to increase these recovery rates significantly, in an integrated processing chain. A more efficient recovery of REEs means that the necessity for exploiting new natural resources can be diminished, thereby contributing to ecological preservation and responsible handling of the global resource stock. Thus, REEcover contributes to solving the twin problems of ecological degradation and resource depletion outlined above.

The following pages illustrate the characteristics and applications of REEs in our everyday environment, followed by an exposition of the two waste streams that are central to REEcover concept. The processes that jointly make up the REEcover proposal are described in some detail, followed by a discussion on the impact we hope to achieve.

9

1CRITICAL ELEMENTS EVERYWHERE

Earth: common home to humanity

Earth is home to humanity - a home that is growing increasingly crowded. The global population is well on its way to 9 billion people, and this trend will not slow down till the middle of the 21st century. In the meantime, we consume more energy per person than we did 100 years ago. Thus, the time is here to act on these insights. An effective way of accomplishing this is to rethink how we handle the management of non-renewable resources.

We need to utilize our waste products and come to regard them as a valuable secondary source of resources. Particularly REEs (Rare Earth Elements) are critical in this regard. Though these elements are not rare in the earth’s crust, they are difficult to extract and unevenly distributed, and it is hard to

envision our technology-saturated lifeworld without them. As the demand for REEs will likely increase envisioning all the applications in our society, we need to have the technology to recover them from waste products.

12

Periodic system of elements

The periodic system of elements lists all the pure elements found on Earth. Some of them are extremely common. For instance, oxygen, carbon and phosphor can be readily found in the atmosphere and in the surface of the Earth’s crust.

Other elements are indispensable for technological applications. Iron, copper or zinc are an essential part for application in everyday and high-tech equipment. Yet others are exceedingly rare and valuable, gold and silver being paradigmatic examples.

With the rise of digital technology, REEs are increasingly used in particular for their magnetic properties in all kinds of electronic devices such as smartphones, hard-disks, windmills,

batteries, electro-motors and laptops. Consequently, the demand for them increases and as they are rare, we need to find ways to re-use them again and again if we are to maintain our current technological applications.

1 H Hydrogen 1.008 3 Li Lithium 6.94 4 Be Beryllium 9.0121831 5 B Boron 10.81 6 C Carbon 12.011 11 Na Sodium 22.98976928 12 Mg Magnesium 24.305 13 Al Aluminium 26.9815385 14 Si Silicon 28.085 19 K Potassium 39.0983 20 Ca Calcium 40.078 21 Sc Scandium 44.955908 22 Ti Titanium 47.867 23 V Vanadium 50.9415 24 Cr Chromium 51.9961 25 Mn Manganese 54.938044 26 Fe Iron 55.845 27 Co Cobalt 58.933194 28 Ni Nickel 58.6934 29 Cu Copper 63.546 30 Zn Zinc 65.38 31 Ga Gallium 69.723 32 Ge Germanium 72.630 37 Rb Rubidium 85.4678 38 Sr Strontium 87.62 39 Y Yttrium 88.90584 40 Zr Zirconium 91.224 41 Nb Niobium 92.90637 42 Mo Molybdenum 95.95 43 Tc Technetium 98 44 Ru Ruthenium 101.07 45 Rh Rhodium 102.90550 46 Pd Palladium 106.42 47 Ag Silver 107.8682 48 Cd Cadmium 112.414 49 In Indium 114.818 50 Sn Tin 118.710 55 Cs Caesium 132.90545196 56 Ba Barium 137.327 72 Hf Hafnium 178.49 73 Ta Tantalum 180.94788 74 W Tungsten 183.84 75 Re Rhenium 186.207 76 Os Osmium 190.23 77 Ir Iridium 192.217 78 Pt Platinum 195.084 79 Au Gold 196.966569 80 Hg Mercury 200.592 81 Tl Thallium 204.38 82 Pb Lead 207.2 87 Fr Francium 223 88 Ra Radium 226 104 Rf Rutherfordium 267 105 Db Dubnium 268 106 Sg Seaborgium 269 107 Bh Bohrium 270 108 Hs Hassium 269 109 Mt Meitnerium 278 110 Ds Darmstadtium 281 111 Rg Roentgenium 281 112 Cn Copernicium 285 113 Uut Ununtrium 286 114 Fl Flerovium 289 57 La Lanthanum 138.90547 58 Ce Cerium 140.116 59 Pr Praseodymium 140.90766 60 Nd Neodymium 144.242 61 Pm Promethium 145 62 Sm Samarium 150.36 63 Eu Europium 151.964 64 Gd Gadolinium 157.25 65 Tb Terbium 158.92535 66 Dy Dysprosium 162.500 67 Ho Holmium 164.93033 68 Er Erbium 167.259 69 Tm Thulium 168.93422 70 Yb Ytterbium 173.054 71 Lu Lutetium 174.9668 89 Ac Actinium 227 90 Th Thorium 232.0377 91 Pa Protactinium 231.03588 92 U Uranium 238.02891 93 Np Neptunium 237 94 Pu Plutonium 244 95 Am Americium 243 96 Cm Curium 247 97 Bk Berkelium 247 98 Cf Californium 251 99 Es Einsteinium 252 100 Fm Fermium 257 101 Md Mendelevium 258 102 No Nobelium 259 103 Lr Lawrencium 266 57 71 89 103 Lanthanide Series Actinide Series He Helium 4.002602 Ne Neon 20.1797 Ar Argon 39.948 Kr Krypton 83.798 Xe Xenon 131.293 Rn Radon 222 118 Uuo Ununoctium 294 2 10 18 36 54 86 9 F Fluorine 18.998403163 17 Cl Chlorine 35.45 35 Br Bromine 79.904 53 I Iodine 126.90447 85 At Astatine 210 117 Uus Ununseptium 294 8 O Oxygen 15.999 16 S Sulfur 32.06 34 Se Selenium 78.971 52 Te Tellurium 127.60 84 Po Polonium 209 116 Lv Livermorium 293 7 N Nitrogen 14.007 15 P Phosphorus 30.973761998 33 As Arsenic 74.921595 51 Sb Antimony 121.760 83 Bi Bismuth 208.98040 115 Uup Ununpentium 289 13

Frequency of four REEs in the Earth’s crust

Yttrium ~20 ppm

Neodymium ~35 ppm

Tb Dy

Terbium ~0.6 ppm

Dysprosium ~6 ppm

Au comparative values for gold and silver Ag

Aureum (gold) ~0.003 ppm

The frequency of elements is expressed in parts per million (ppm). For instance, if their is only 1 mg of substance A in 1 kg of substance B, the amount of A is expressed as 1 ppm. As is apparent, gold and silver are still more rare than the REEs that we are interested in. However, the demand for REEs is rising, and it seems that for the foreseeable future REEs will be widely used in a variety of applications.

Argentum (silver) ~0.08 ppm

14

Y Nd

Everyday, everywhere: some REE applications

REEs play crucial roles in everyday technological applications. Microphones, speakers, microwaves and washing machines would not function as effectively without these elements. Everyday life would look radically different without these seemingly simple applications.

Besides such mundane technological appliances, REEs are used in aircrafts, cars, energy storage, wind turbines, lamps, banknotes and cancer treatment drugs. The technological challenges surrounding the re-use of REEs touches not only on maintaining levels of comfort, but also on addressing global mobility, energy efficiency and medical treatment.

washing machines loudspeakers headphones magnets lasers microwaves smartphones

15

surgical supplies cancer treatment drugs aircraft wind turbines microphones camera lenses computer harddisks

importance

16

This display could not have been produced without REEs

17

Four core REEs in the REEcover project

REEcover is focused on recuperating four different REEs: Dysprosium (Dy), Neodymium (Nd), Terbium (Tb), and Yttrium (Y).

Dysprosium is used in permanent magnets in power generators and electric vehicles, lamp phosphors and laser metal but also in rods applied in nuclear reactors, as well as data storage applications due to its magnetic properties.

Neodymium, the most important REE in world market value is used in a wide variety of applications. As it is extremely magnetic, it is used in hard disks, loudspeakers, microphones and electric motors. Furthermore, it is used in laser technology.

Terbium is used in green phosphors for lamps and so-called trichromatic lighting applications that have a higher efficiency than regular incandescent lighting. In addition, it is used in sensors and naval sonar as well as fuel cells.

Yttrium is used to produce the red colour in lamp phosphors and displays, in near-infrared lasers, as strengthening material for aluminium alloys and in cancer treatment drugs.

18

Y Nd

Neodymium Terbium 65 60 39 66 Dysprosium Yttrium Tb Dy lasers microwaves displays smartphones headphones speakers displays magnets washing machines magnets nuclear reactor controls halide lamps

19 SOME REE’S THAT REECOVER WILL RECUPERATE PLAY CRUCIAL ROLES IN SUSTAINABLE TECHNOLOGIES, FOR EXAMPLE WIND TURBINES

2TWO RESOURCES

Resource 1: Waste Electric & Electronic Equipment (WEEE)

WEEE (secondary, urban mining)

The first resource for REEcover is called WEEE (Waste Electrical and Electronic Equipment). As our current lifestyle is heavily dependent on technology, WEEE is one of the fastest growing waste streams in the European Union and possibly globally, according to the European data.

Approximately 9 million tonnes were generated in 2005, and its is expected that around 2020, 12 million tonnes will be generated annually. This increase can be explained by population growth and the fact that we use an increasing number of devices per person. In addition, the ‘consumer cycle’ of buying, using, replacing and discarding a device is being repeated increasingly quicker.

WEEE scrap contains significant amounts of REEs, but the problem is that REE containing appliances are gathered and processed in bulk, and that selective processing is too labour intensive to be economically feasible.

To retrieve REEs, specialized processes are required to separate REEs from other elements, but due to the prevailing market conditions (such as depressed 2012-2016 price levels) costs are too high to invest in the retrieval of REEs in industrial processes, leading to a material loss of these critical raw materials.

22

Resource 2: Apatite tailings

tailings (primary mining)

The waste products of mining are called tailings, that remain after the extraction of the mined minerals. Once the valuable ore is removed from the surrounding rocks, these remnants are stored in sizable deposits. Ore extraction produces vast amounts of processed waste rock, and these depots can grow to enormous size, and typically positioned near large mining sites.

REEcover investigates the possibilities of mining these tailings, as they contain low concentrations of REEs. The mine tailings being investigated are from Kiruna, Sweden, where LKAB runs one of the largest iron mines in the world.

Although the absolute concentration of REEs is low in mining tailings, the volume of the material more than makes up for this. As there is a large amount of material to process, industrial processes are needed to retrieve the REEs from the tailings. Since the mine is located some 200 kilometres above the Polar circle, energy requirements play an important role into investment decision to process bulk quantities with low concentrations of REEs at the prevailing market conditions in the 2012-2016 period.

23

The consumer cycle: buy, use, replace, discard

A recurring problem for reaching sustainability in material usage are the short life cycles of REEs containing technological appliances which are often bought, used, replaced and discarded in rapid succession. The pace of this consumer cycle increases as new models of laptops, tablets and smartphones are introduced more frequently. As long as there are no effective processes for extracting all REEs from these devices, the increased production quantities will cause an accelerating depletion of REE supplies. In order to address this problem, REEcover aims to improve the extraction and re-use of REEs.

partial recycling discard

production new primary resources disappearing resources

buynew

usage

consumer cycle resource cycle

replace

25

Smartphone components and elements

speaker vibration motor tip ceramics condenser tip resistance tip coils LCD camera glass epoxy board solder crystal oscillator tip tantalum capacitor IC plastics button battery earphone jack, AC jack button contact material

Smartphones serve as paradigmatic example for the recycling problem in REEs. Every device contains a variety of elements, some of which can be retrieved. Current recycling procedures are not able to isolate the Neodymium from each device, as this would be too expensive and troublesome.

However, if an efficient process were to exist, all these small amounts of Neodymium could be relatively easily removed and utilized again. Taken together, all these amounts would jointly form a tremendous global resource distributed during their utilisation phase around the globe. REEcover aims at inventing processes for the effective retrieval from REEs from such devices, turning waste into resources.

ferrite

Nd

Ag, Ba, Ni, Pb, Pd, Ti, Zr

Ag, Cu, Fe, Ni, Pb, Zn

Cu In, Sn Au, Cu, Ni Br, Cu, SiO 2 Pb, Sn Cu, Ni, Si Ag, Mn, Ta Ag, Au, Cu, Si Sb Ag Au Ag, Cr, Fe, Ni

26

Electronic appliances as global resource

The fact that technological appliances are globally manufactured and distributed introduces a challenge: to collect and dismantle them in their end-of-life stage. To address this challenge, the EU has formulated the so-called WEEE directive, setting goals for the collecting and recycling rates of such appliances throughout the European Union. The goal of this directive is to increase the collection rates, so that the total mass of electronic appliances ends up in effective, sustainable recovery processes.

27

Modern life without compact and versatile communication technology is currently almost unimaginable

Around 2020 , there will be approximately 2.7 billion smartphone users globally Each smartphone contains only a speck of Neodymium

This is a potentially tremendous global, yet diluted resource

Some EU facts and numbers regarding production and collection

The EU produced 8.1 million tonnes of EEE in 2013

3.5 million tonnes of WEEE were recovered in 2013

The EU has now set a recovery goal for 4 kg per household

28

The challenge ahead: collecting a diluted resource

All these small amounts must be collected first in order to extract them

29

Tailings: mining the mining waste

The Swedish town of Kiruna is home to one of the largest iron ore mines in the world. The company LKAB – a partner in the REEcover project – undertakes mining activities here. When mining, large quantities of processed waste rock are produced. These are called tailings, and are being stored close to the mining site.

However, these tailings still contain valuable elements – REEs among them. The mine in Kiruna being one the largest iron mines in the world, it produces annually an immense amount of tailings that contain REEs fractions. By viewing these tailings as a new resource, we can start to appreciate the amount of REEs that is currently available for extraction, given effective extraction processes.

30

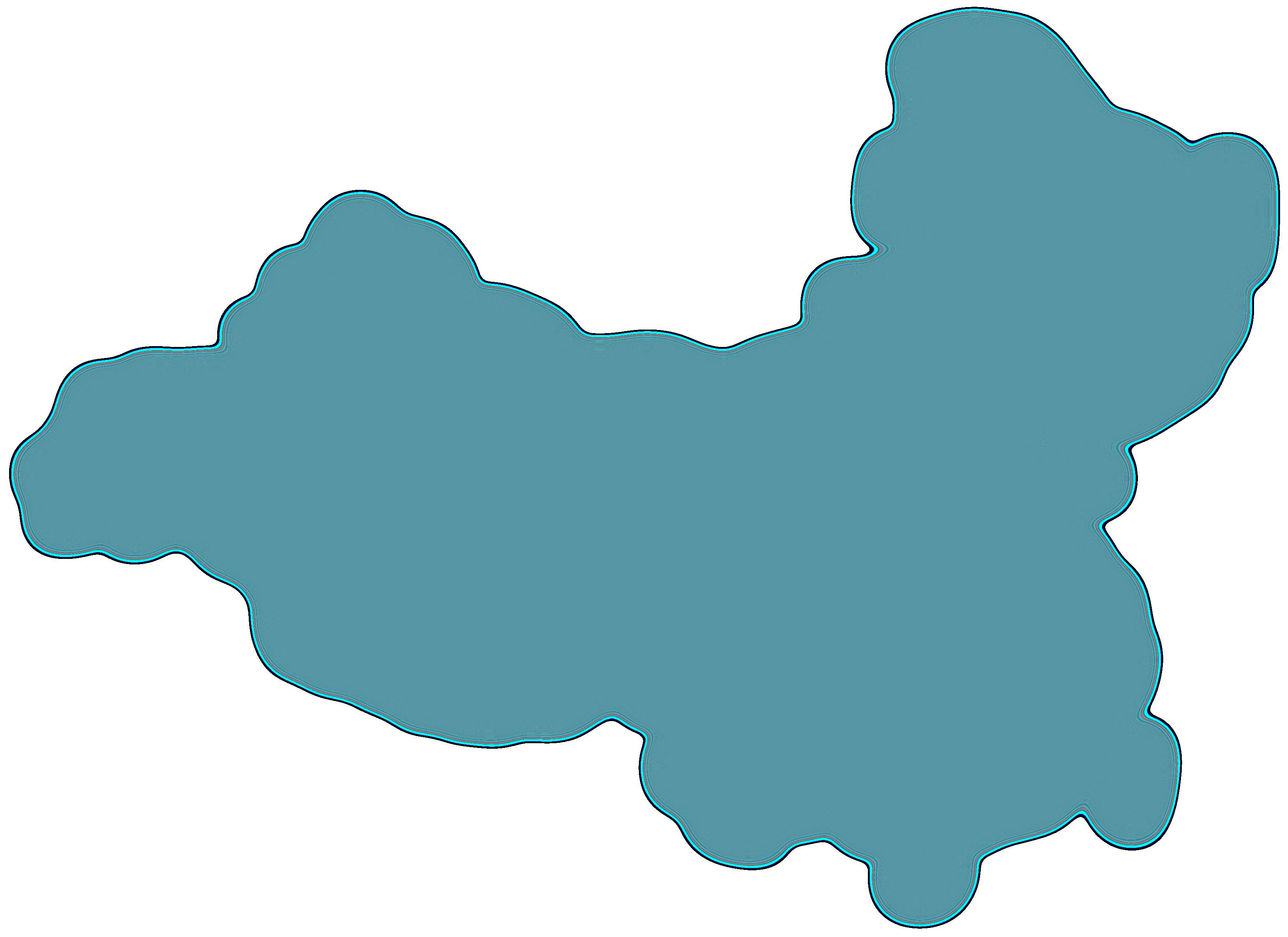

City of Kiruna and the LKAB mining site

The town of Kiruna is located well beyond the Arctic Circle, making mining activity challenging. The iron ore that is being extracted is shipped in the form of iron ore pellets to the port of Narvik in Norway, from where it is distributed globally. The mining tailings are stored in Kiruna itself, next to the mine.

As the mine is located in an ecologically vulnerable area, industrial process applied to the ore or tailings have to be carefully evaluated in order to prevent lasting ecological damage.

Kiruna Arkhangelsk

Norilsk

Trondheim

Reykjavik

Nuuk Helsinki St. Petersburg Moscow

Luleå

Narvik

Tromsø

Kiruna Arkhangelsk

Norilsk

Trondheim

Reykjavik

Nuuk Helsinki St. Petersburg Moscow

Luleå

Narvik

Tromsø

Mining and refining process explained

The mining process that LKAB utilizes in Kiruna consists of a series of consecutive steps that range from the actual mining activities to more refined process steps to retrieve magnetite –the mineral that largely makes up the iron ore. The amount of magnetite determines how valuable the iron ore is. The more magnetite, the higher the actual iron concentration.

After removing all the surplus material from the mining process, two products remain: magnetite pellets that are shipped to Narvik for transport, and apatite tailings, the waste product that is being stored in Kiruna. For REEcover, this waste product is a new resource.

32

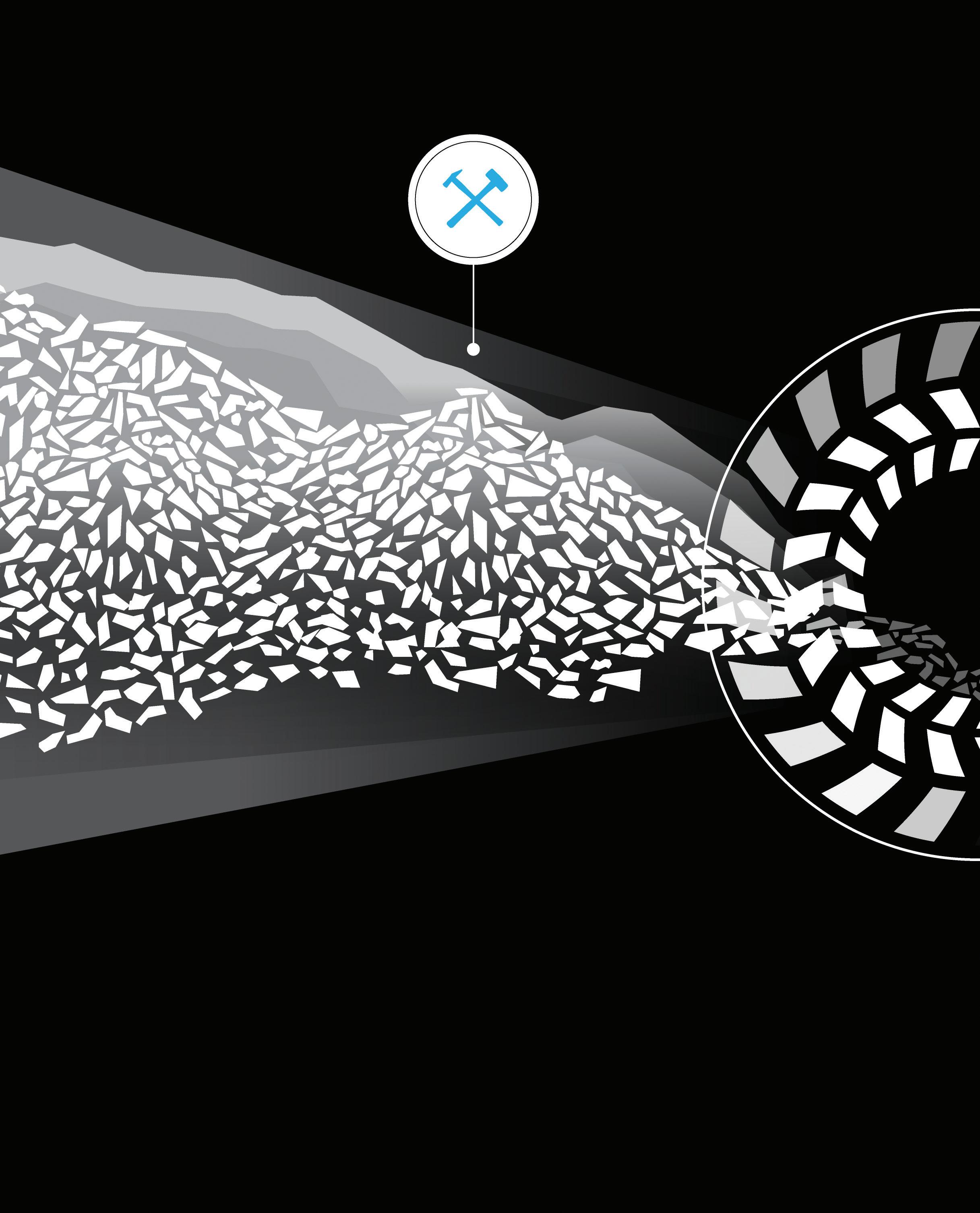

Ore is extracted from underground mines by means of sublevel caving whereby gravity is exploited to get ore to fall into the development drifts for subsequent transport on huge vehicles, trains and hoists up to the surface. The ore consists of magnetite, apatite and various type of rocks.

The total amount of extracted iron ore is transported to the surface to be entered in a sorting and refining process. At this stage, the iron ore consists of rather rough and large blocks.

When the iron ore exits the mines it is crushed down to a size of approximately 10 centimetres to make handling easier, more efficient and to get better access to impurities.

A quantity of waste from the rock surrounding the orebody follows the ore to the surface so the rock and ore must be separated, which takes place magnetically on large conveyor belts. This process is called dressing or sorting.

33

1 mining the iron ore body

3

grinding

2 transporting the ore 4 magnetic sorting

The aim of this subsequent grinding is to liberate the impurities in the magnetite such as silica, sodium, potassium and phosphorous.

Phosphorous, in the mineral apatite, is removed through flotation. Added reagents in the wet iron ore mixture attach to the apatite. When air is then bubbled through the slurry, the bubbles attach to the apatite and carry the apatite particles to the surface, where they are bound in froth that is removed.

Before the magnetite slurry can become pellets it must first be dewatered down to a moisture content of around 9%, and the binding agent bentonite is added. The slurry is shaped into spheres in large rotating drums where the iron ore particles clump together and grow ever larger in the same way as snowballs.

In REEcover, we are interested in the apatite that can be extracted from the LKAB process. It contains most of the REEs we are looking for, and there is a very large annual supply of this rest material (so-called tailings) that we can tap into.

34

5 grinding the magnetite 8 apatite feeds in REEcover 6 flotation 7 magnetite is pelletized

The mines in Kiruna produce annually 2.000.000 tonnes of fine tailings containing apatite.

Taken together, these tailings contain approximately 2.000-4.000 tonnes of REEs

35

Summary: two resources

WEEE (secondary, urban mining)

discarded consumer products mining waste

tailings (primary

mining)

input for a collection/ recycling process

input for industrial processes

large bulk, many small quantities of REEs

large bulk, many small quantities of REEs

diluted resource in need of collection storage in tailings deposits

Summarizing, REEcover focuses on two resource streams. First, WEEE, the rest product of the consumer cycle. Second, apatite mining tailings, the rest product of iron mining activity.

Both resources share a characteristic: they consist initially of a large bulk that has to be reduced towards a smaller, purer mass. REEcover aimed to develop processes to accomplish a stepwise purification process, with the product of each step containing higher concentrations of REEs.

The problem of resource dilution takes different forms for each resource: the WEEE has to be collected before retrieving the REEs can start. Once collected, the REEs are still diluted in multiple discarded appliances.

The apatite tailings are stored in a tailings dam, but the actual resources are in this case diluted throughout a tremendous amount of mass, necessitating effective retrieval processes to suppress the costs.

36

37 BOTH WEEE AND APATITE MINING TAILINGS CONTAIN DILUTED RESOURCES: THE WHOLE BULK OF INPUT MATERIAL HAS TO BE PROCESSED TO EXTRACT THE NUMEROUS TINY AMOUNTS OF REEs

3

REEcover PROCESSES

INPUTS

WEEE/apatite tailings scrap containing REEs mixed REOs

hydrometallurgical upgrading/ pre-treatment characterisation (continuous) solvent extraction pyrometallurgical upgrading of dilute REO streams

physical separation

scrap containing REEs mixed REOs single REOs solvent extraction input materials

PROCESS OUTPUTS 2a 1a 3 2b 1 1b 3

40

single REOs

electrolytic reduction (REO-fluoride) electrolytic reduction (RE-oxycarbide)

4 4 integral value chain development 41

dissemination/ knowledge management European security of REE supply

purified REEs

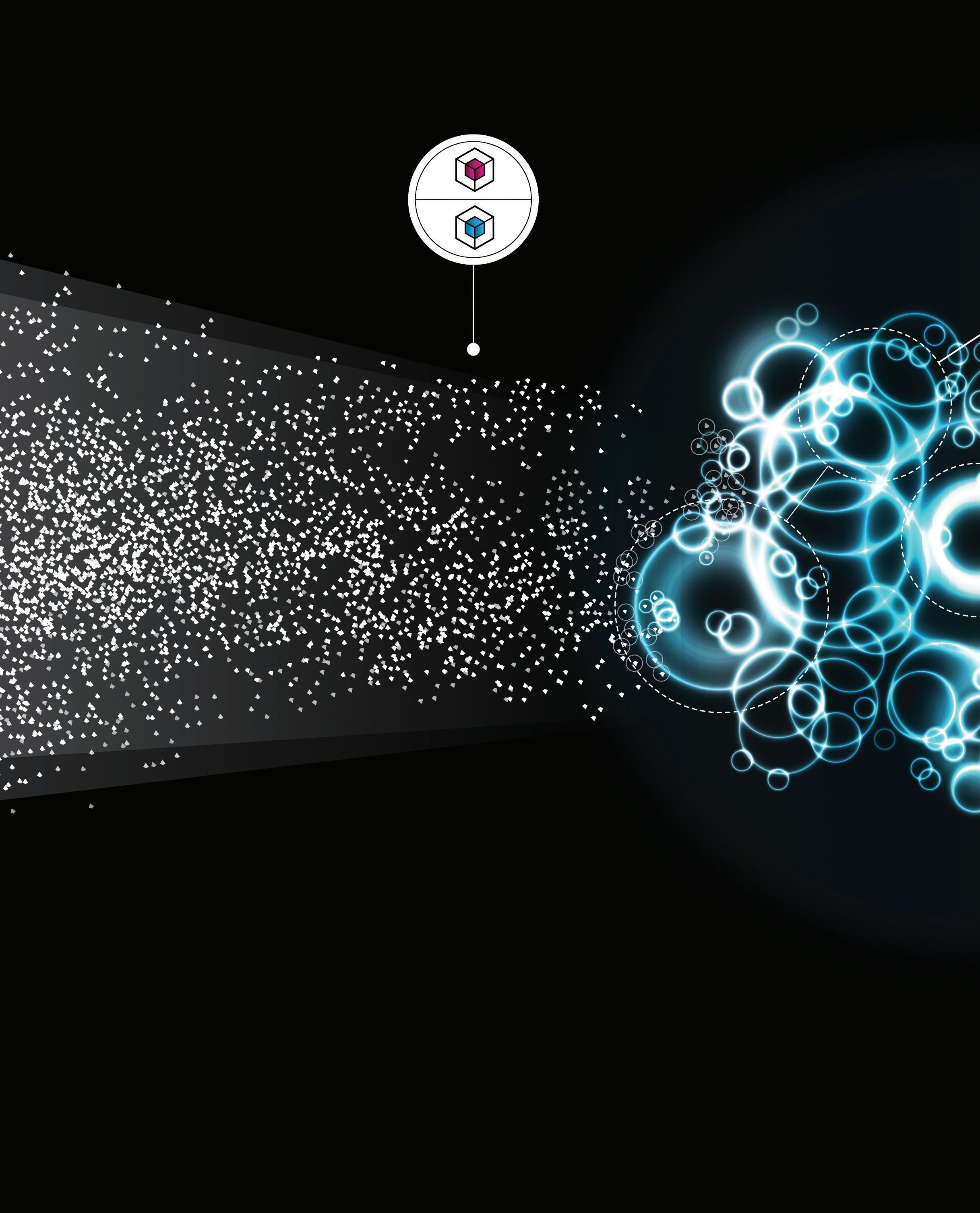

From lots to little: diluted resources

collecting sorting reducing extracting reducing

total bulk of input material

mass to be removed through consecutive REEcover processes valuable REEs

bulk decreases value increases

Each step in the REEcover processes upgrades its input material. For example, the input for hydrometallurgical upgrading is a type granulate that is made either from WEEE or mining tailings.

This granulate contains REEs, but in quite low concentrations, and mixed with impurities. The hydrometallurgical upgrading process is a first step in removing impurities. As a consequence, the total mass is reduced.

A good way of visualizing such upgrading processes is to imagine a simple high school chemistry experiment: cooking seawater in a petri dish. Once the water has evaporated, the total mass is reduced, but the salt (the valuable part) remains.

In an analogous way, REEcover uses multiple steps to refine the input materials, until the highest possible concentration REEs remains.

As pure REEs are very valuable, one can generally say that when the total bulk decreases, the value of the remaining product increases. The higher concentration of REEs per gram of mass makes some of the later half products of REEcover valuable goods.

Of course, the effectivity of the recovery processes plays a significant role. Expensive or ineffective processes affect the market value and the attractiveness of applying them on a large scale.

42

input input 1

2 3 4 scrap containing REEs processinputs

Value addition in the REEcover process

€ ^

scrapcontaining

mixedREOs singleREOs purified REEs

process inputs: large masses of WEEE and tailings 43

REEs

1 mixed REOs 2 single REOs 3 purified REEs 4

Progression of inputs and outputs

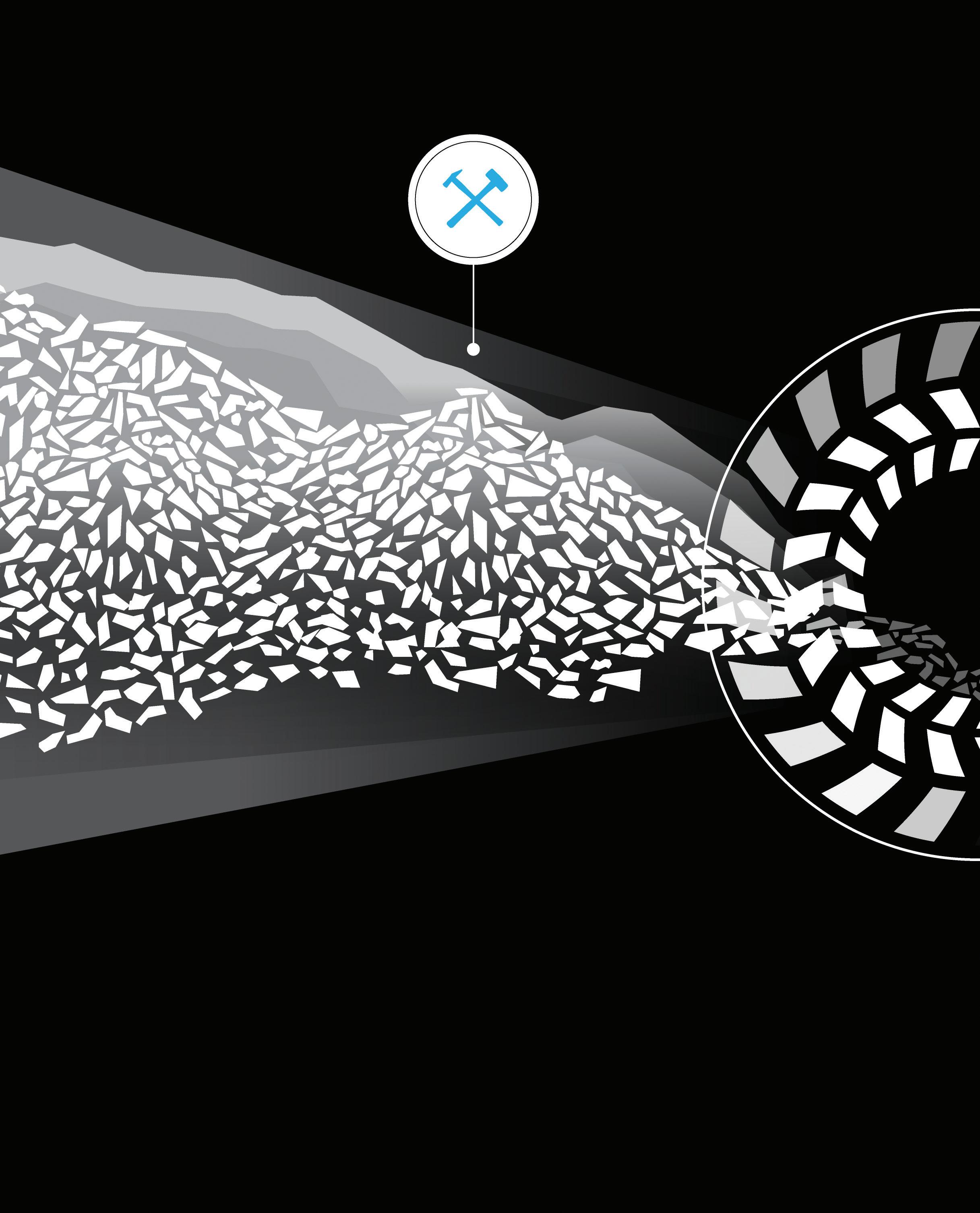

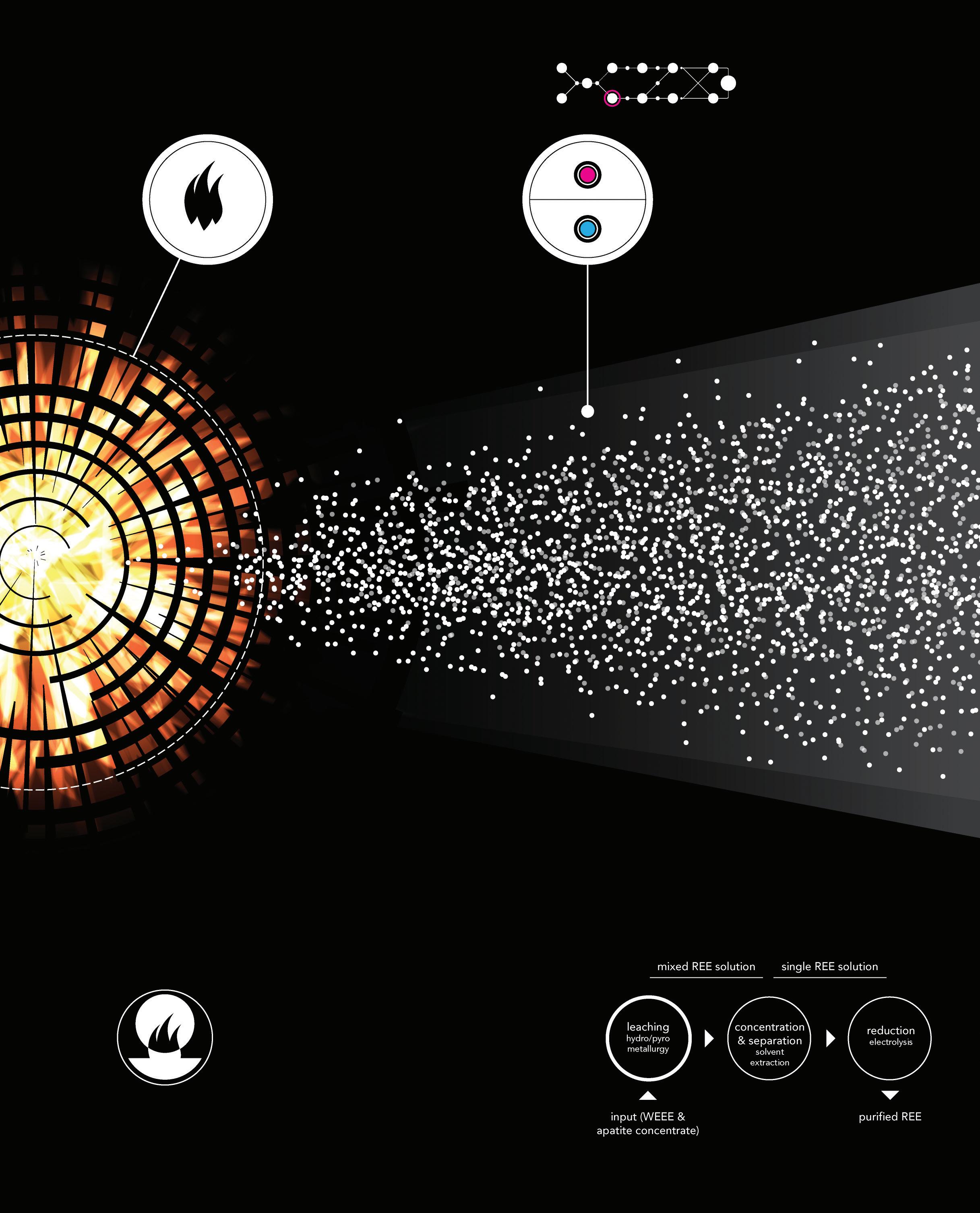

Step 1a: Physical Separation (WEEE)

Input: WEEE scrap

The bulk of WEEE scrap that is partially dismantled contains significant amounts of Dysprosium and Neodymium.

In order to extract it, a further grinding is necessary

WEEE containing REE is a mixture of plastics, printed circuit boards, metals, and in particular magnetic agglomerates from strong magnets. To get rid of the magnetic properties of the material, it is heated to high temperatures (>400°C), which also burns of the plastics.

Subsequently, the WEEE needs to be sieved with a circular motion to remove clean magnetic fragments from the coarse fraction. The next process step is to grind the particles down to a smaller size, but due to the ductile (soft, easily transformable) metals involved, this cannot be done by ordinary milling.

Therefore, the material is cooled down drastically (with liquid nitrogen), increasing its brittleness, and then milled into smaller particles. The cooling step makes the soft metals brittle, preventing them from being spread out as a paste during the milling.

The small, magnetic fragments are then concentrated to the smallest granulate in the mix and can be separated by sieving as an enriched product.

44

Operation: grinding

Melting the scrap would make it impossible to recover the REE’s. Therefore, a mechanical process of grinding is utilized.

Output: WEEE granulate

The resulting granulate contains REEs, but this central resource is still mixed with metals that are not needed. However, the size of the granulate makes it easier to process.

Principle: physical separation

Physical separation is an umbrella term for a number of methods used to sort, process, grind and mill raw input materials in formats that are suitable for subsequent process steps.

45

Step 1b: Physical Separation (Apatite tailings)

Input: apatite tailings

The bulk of apatite tailings contains significant amounts of Terbium and Yttrium. In order to extract it, a further grinding is necessary.

To increase the REE-concentration in mining tailings, the REEcover project uses various physical separation techniques. Firstly, the tailings are milled to get fresh surfaces.

Secondly, the apatite and some REE minerals are separated by a flotation process, where these are concentrated in a froth that can be scraped off. It has been discovered that the REE are only partly in apatite, but also in separate REE minerals (for example monazite) that can be won together with apatite.

Other REE minerals like allanite and titanate exist in tailings, but special treatment options for them can now be developed on the basis of knowledge obtained in REEcover.

46

Operation: grinding

A mechanical grinding process is utilized to be able to recover the REE’s.

Output: tailings granulate

The resulting granulate contains REEs, but this central resource is still mixed with minerals that are not needed. However, the size of the granulate makes it easier to process.

Principle: physical separation

Physical separation is an umbrella term for a number of methods used to sort, process, grind and mill raw input materials in formats that are suitable for subsequent process steps.

47

48

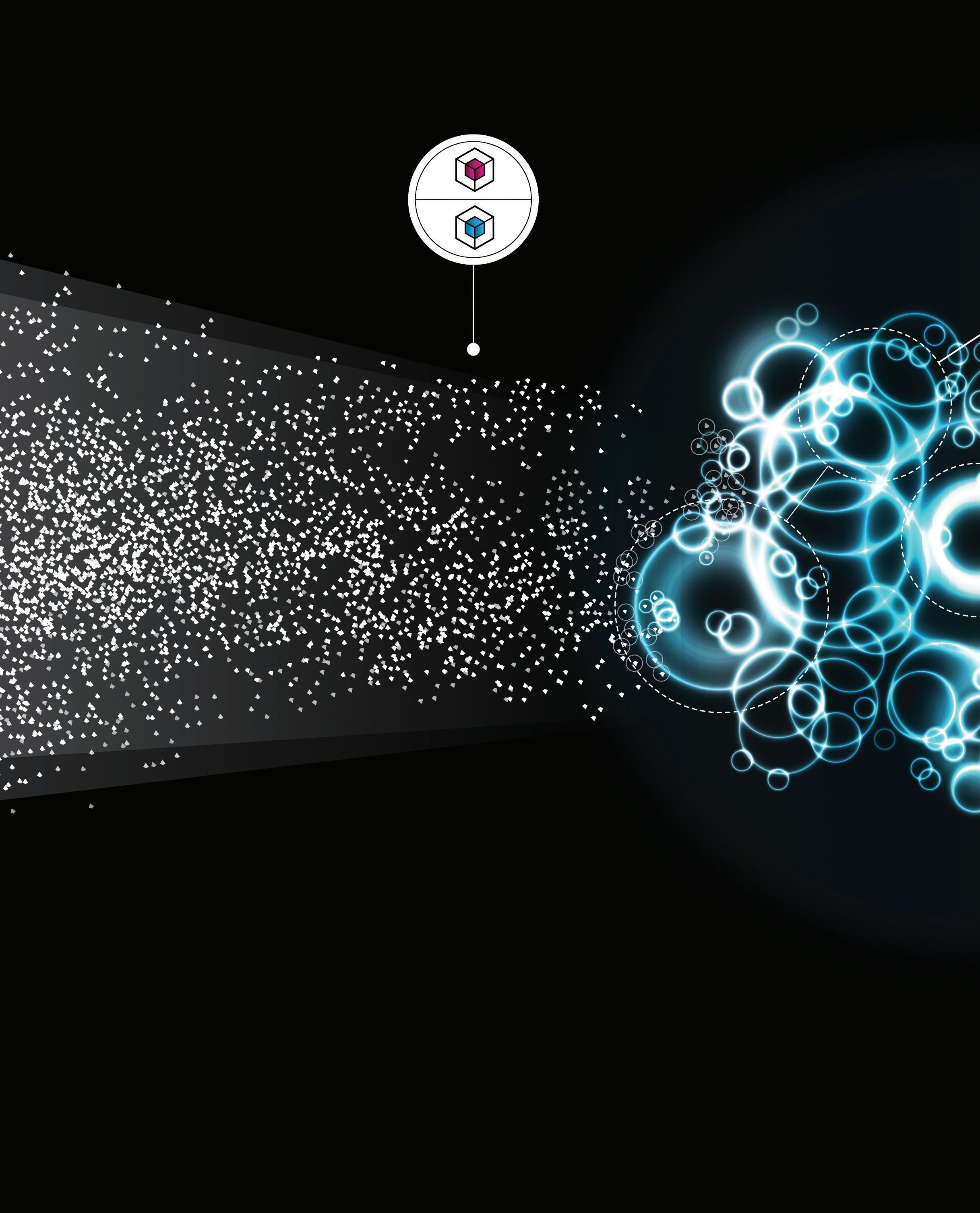

Step 2a:

Hydrometallurgical upgrading/pre-treatment

Input 1: WEEE granulate

Input 2: apatite granulate

The granulate from process steps 1a and 1b is now used as input in metallurgical processes. Itcontains the REEs, but is far too impure to be of much value yet.

By processing this apatite concentrates with inorganic acids at modest temperatures it is possible to recover a large part of the valuable REEs, together with phosphorous as valuable phosphoric acid. The mixture elements in the dissolved solutions can be separated and purified using traditional solvent extraction technique.

Electronic scrap from end-of-life (or discarded) computers and other IT products is currently subjected to physical separation by shredding and sorting after collection and transport, without REE recovery. In the REEcover project an isolated sieve stream containing small NdFeB magnet pieces can be subjected to two different processes each with its own advantages and disadvantages. The first is a

hydrometallurgical process where scrap is first corroded in water so that the magnets can be selectively dissolved using diluted acids, followed by an isolation process which recovers the REE as salts. The second process uses pyrometallurgical treatment for separating REEs present from the iron (ferrous) stream, followed by hydrometallurgical treatment using inorganic acids. The resulting Neodymium (Nd) dissolved in acids, can be separated with subsequent solvent extraction from non-REEs and possibly from other minor REEs such as Dysprosium (Dy) and/or Praseodymium (Pr). The REE mixture (Nd+Pr+Dy) or separate REEs in the solution can be further precipitated as oxides (REOs). These REOs will be used to produce rare earth metals or alloys through the subsequent electrolysis at high temperatures.

Operation: hydrometallurgical upgrading

A metallurgical process that works primarily with liquid solutions to split the REEs from other materials still present in the granulate.

Output: mixed REOs

The resulting REOs (oxides that with Rare Earth Elements) contain an increased amount of REEs.

Principle: hydrometallurgical upgrading

Hydrometallurgy is focused on forms of chemical/physical processing that use liquids or aquaceous solutions to isolate important components such as REEs.

49

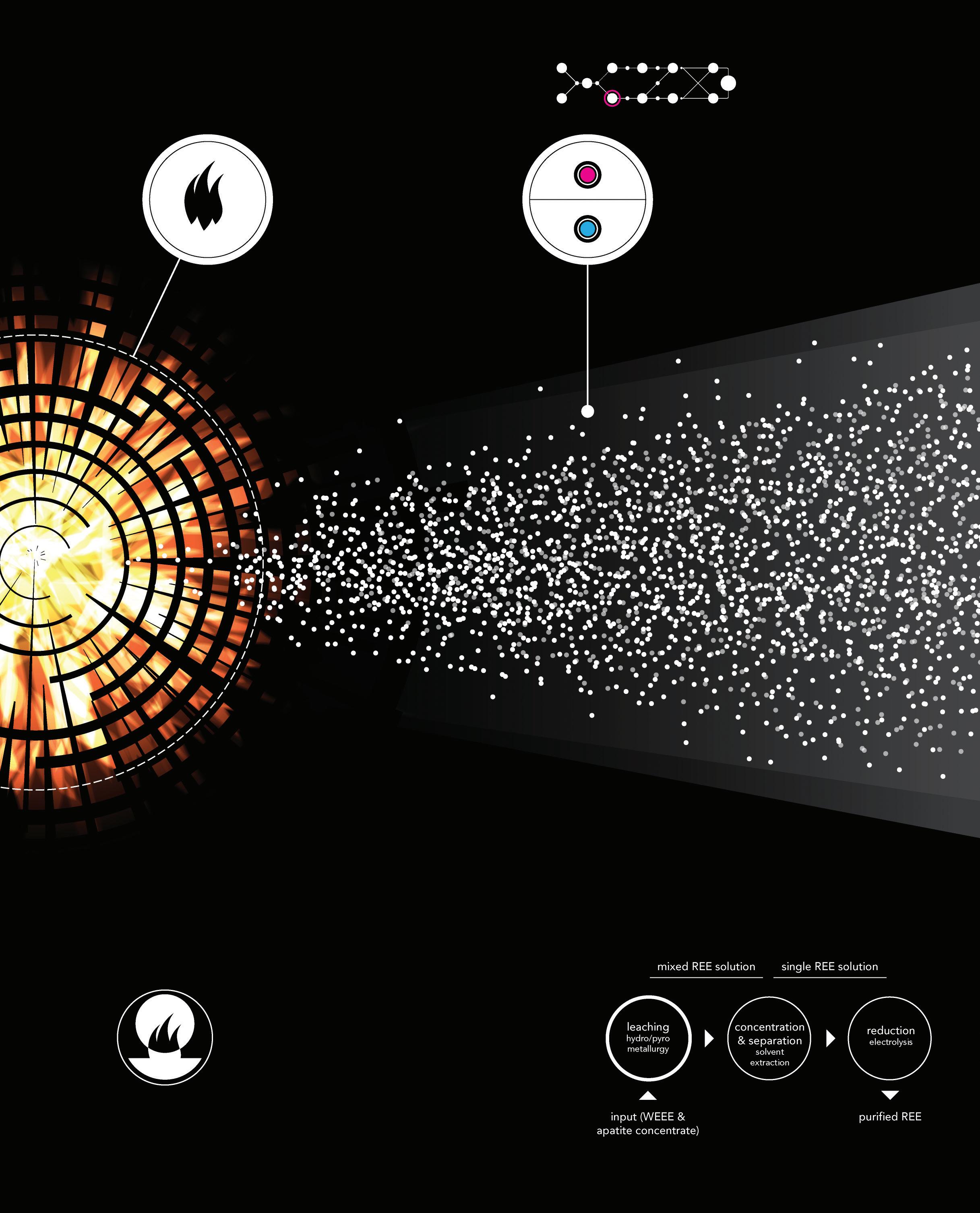

50 Step 2b:

Pyrometallurgical upgrading of dilute REO streams

Input 1: WEEE scrap

Input

2: apatite tailings

The granulate from process steps 1a and 1b is now used as input in metallurgical processes. It contains the REEs, but is far too impure to be of much value yet.

During pyro-metallurgical processing a high temperature furnace melts upgraded WEEE-output from the preceding physical separation step at temperatures typically exceeding 1600°C. Upon melting of metals, pure elements that have a high affinity to react with oxygen form oxides.

Oxides have a much lower density than metal and so these two components do not mix. Consequently, any oxides formed will be found as a separate phase on top of the metal. This is normally referred to as ‘slag’ in metals processing and can easily be separated.

The REE’s are among the strongest elements in the periodic table to form oxides and will do so also in this process by

sourcing oxygen from the air or already existing, weaker, oxides in the mix - such as iron oxides (rust).

By balancing the amount of oxygen entering the furnace, pyrometallurgical processing targets to oxidize all REEs with as few other oxides forming as possible, thus forming a REOrich slag. This will result in a REEs concentration in the slag several times higher than compared to the metal, but at a price; the REEs are now found in a form of REO’s which needs to be converted back to metals using subsequent steps.

Operation: pyrometallurgical upgrading

A metallurgical process that works primarily with heating processes to split the REEs from other materials still present in the granulate.

Output: mixed REOs

The

Principle: pyrometallurgical upgrading

Pyrometallurgy comes maybe closest to the popular image one may have metallurgical activity. In all forms of pyrometallurgy, adding heat or otherwise manipulating the temperature serves to isolate compounds or make new alloys.

51

resulting REOs (oxides that with Rare Earth Elements) contain an increased amount of REEs.

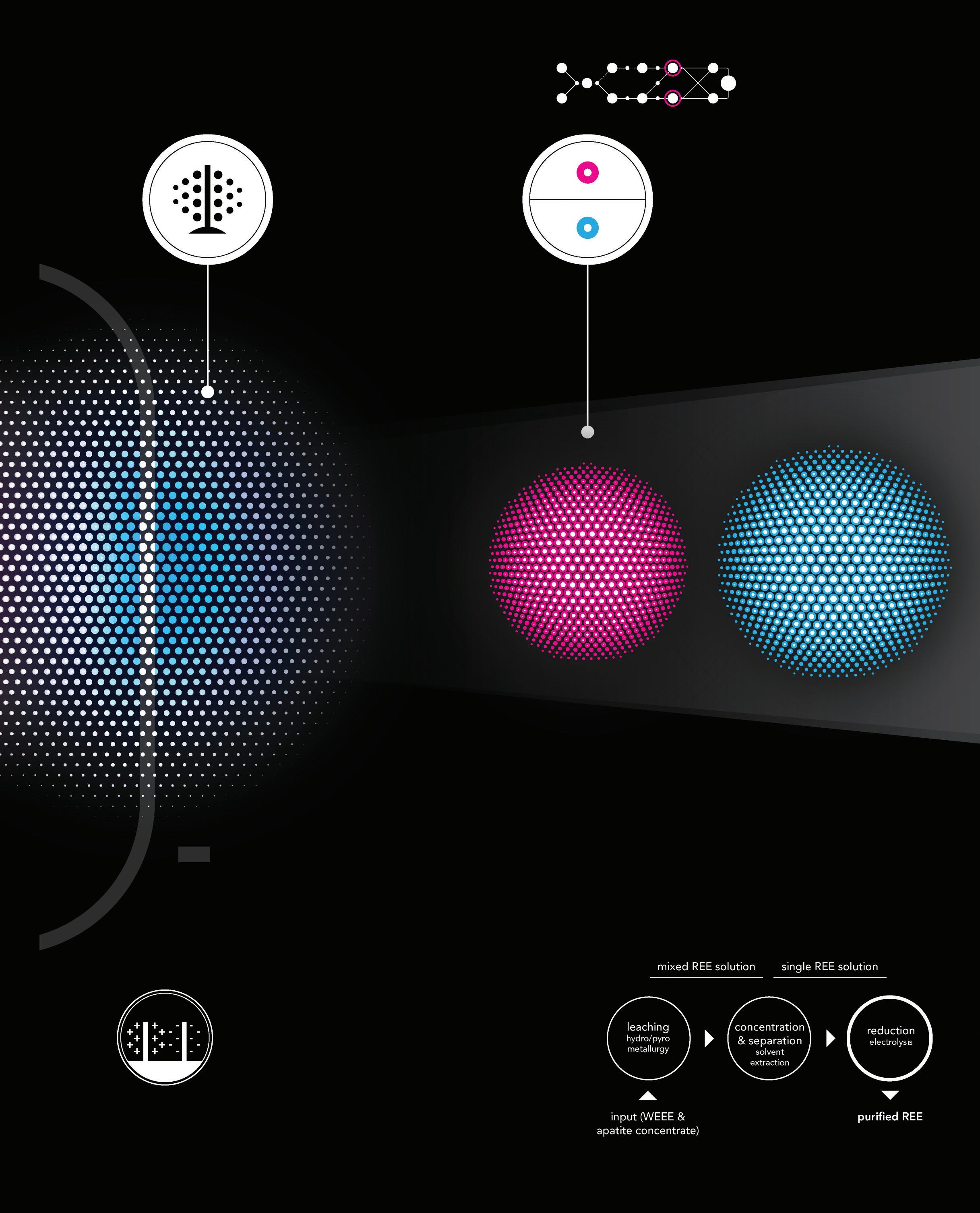

52 Step 3: Solvent extraction

Input 1: mixed REOs derived from WEEE

Input 2: mixed REOs derived from tailings

Metallurgical processes results in mixed REOs that are still in need of further concentration, and that need to be sorted into single REEs.

Following both hydro- and pyrometallurgical processes steps, the resulting REEs have to be concentrated further. As with every process step, the idea is to increase the amount of REEs in the total mass as much as possible. In solvent extraction, an aquaceous (liquid) mix with REEs is mixed with a so-called solvent.

Solvent extraction is a technique where two liquids that do not mix (for instance, oil and water) are mixed together in a first stage and subsequently mixed together before being allowed to separate again. This allows for specific chemicals present in the ‘oil phase’ to bind with the desired elements - here the REE - in the ‘water phase’. When oil and water separate again this splitting will draw the desired elements away from

the water and into the oil, achieving separation. However, in solvent extraction, one original input stream reacts with the other solving liquid (oil), draining the input stream largely from REEs. The remaining input material (water) can be treated again to extract as much REEs as possible.

Operation: solvent extraction

Solvent extraction is a process functioning through concentrating the level of REEs in a solution. In consecutive steps, the concentration of REEs is gradually increased.

Principle: solvent extraction

Solvent extraction mixes an input solution containing REEs with another liquid with which it does not mix. The REEs react with the second liquid, and the input source is largely drained of REEs. By repeating the process, the concentration of REEs in the second liquid increases.

53

Output 1: single REOs derived from WEEE Output 2: single REOs derived from tailings The solution that results from solvent extraction contains a quite high amount of REEs. In turn, electrolysis is needed to retrieve them in a still purer form.

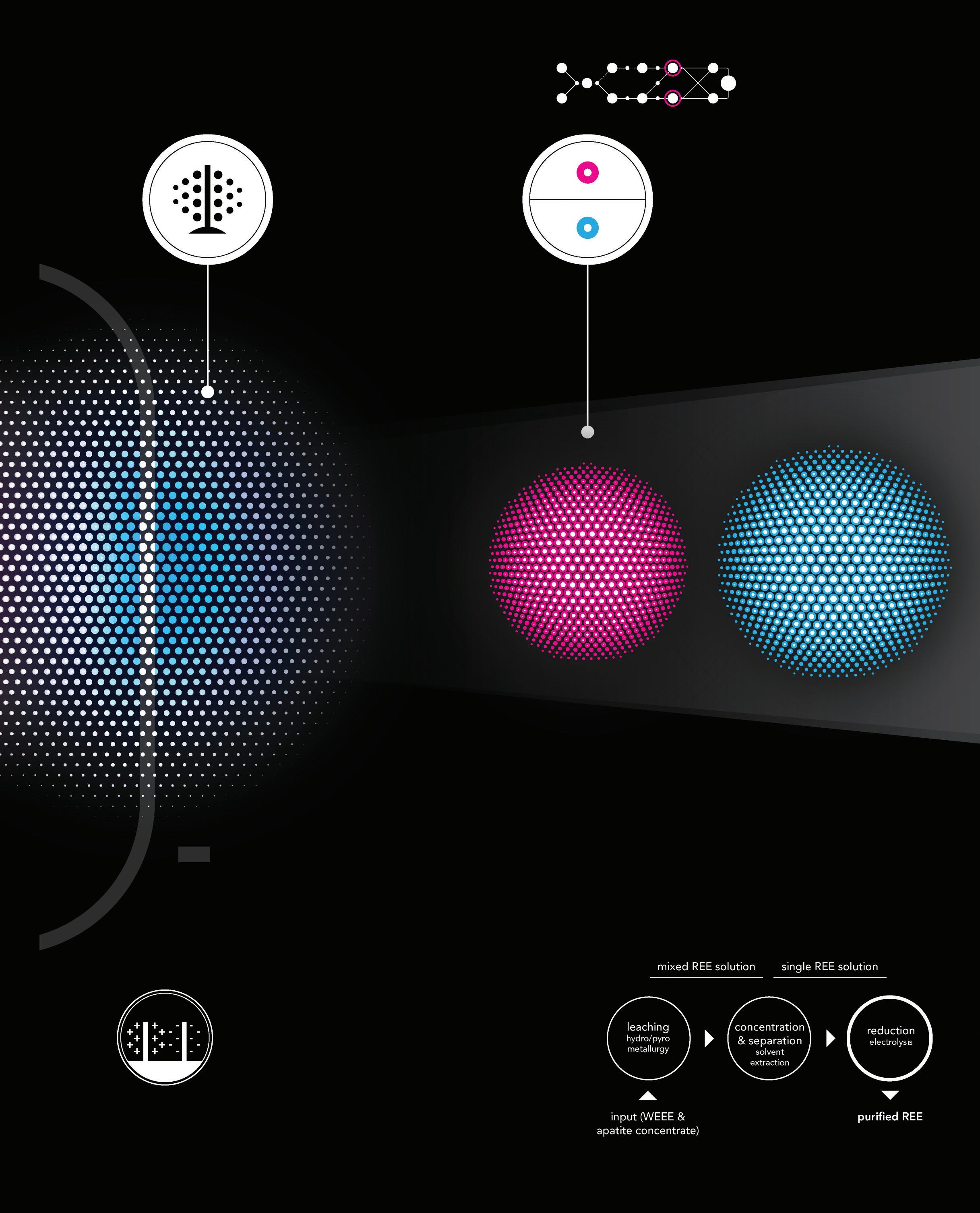

54 Step 4: Electrolysis

Input 1: single REOs derived from WEEE

Input 2: single REOs derived from tailings

The bulk of apatite tailings contains significant amounts of Terbium and Yttrium. In order to extract it, a further grinding is necessary.

Electrolysis is a reduction process in which a gel (electrolyte) containing mixed ions is sorted. The sorting process works by having an anode and cathode, one of which is positively charged, while the other is negatively charged. The electrolyte contains a RE oxide mix that needs to be sorted.

This mix consists of both negative and positive ions. By introducing them into a cell that contains the anode and cathode, a natural sorting process occurs. The negatively charged particles gravitate towards anode, the positively charged particles towards the cathode.

The cathode produces the RE metal in its purest possible form. By using a new electrolyte that contains less fluorinecontaining compounds, the process is made more effective due to more stringent control. Towards the end of the project, the technology is being demonstrated in a large laboratoryscale electrolysis cell in order to have a realistic idea of the efficiency and business potential of the technology.

Operation: electrolysis

A physical/chemical process used for retrieving the REEs by using the electrical charge of particles for sorting purposes.

Output: purified REEs

Purified REEs are valuable on the global resource market, or could be used in the production of new applications and consumer products.

Principle: electrolytic reduction

Electrolytic reduction exploits the fact that ions are either positively or negatively charged, resulting in a separation according to charge.

55

IMPACT 4

58 Current situation: dependency on global resource streams

Increasing pressure on the biosphere, resource depletion and pollution make responsible handling and processing of waste materials a pressing necessity. Particularly pressing is the problem of resource dilution: small quantities of primary resources are distributed over many products, making it hard to retrieve them afterwards. This leads to inefficient recycling and accelerates resource depletion, as resources disappear from the production cycle.

Increased global mobility has its advantages and disadvantages. One feature of global mobility is that knowledge is concentrated where facilities are concentrated. As of now, the relative lack of specialized recycling and processing plants in Europe may cause talented professionals to migrate,

taking their valuable knowledge with them. Roughly the same logic applies for business opportunities: by concentrating knowledge and facilities concentrated on the circular economy throughout Europe, business opportunities will ensue.

Strengthening the European position with regards to recycling and re-use expertise will be beneficial for the environment in the long term, as high-tech equipment and expertise will allow significant control over effective resource management, emissions and the ecological footprint of recycling processes.

unsustainable recycling transport costs&risks

resource disappearance

less chances for European business

migrating knowledge

global market dynamics

global resource streams risks and contingencies for the EU

1 2 3 4 5 6

Desired situation: strengthening the European position

6

1 2 3 4 5

Effective recycling and processing of REEs requires specialized knowledge. Given its educational standards and constituent technologically advanced societies, Europe is well placed to develop specialized knowledge that contributes to the integration of REE recovery as part of a circular economy.

The shift towards a circular economy offers chances for developing new industries around the processing of secondary resources, contributing to global sustainability. Redeveloping the traditional consumerist model of producing, buying, using and discarding products that contain valuable resources towards a circular, sustainable economy demands a vastly different business infrastructure – and Europe is well placed to develop such an infrastructure.

To address this issue, specialized knowledge is needed. Developing such knowledge on REE processing (and optimizing the recovery of waste streams in general) decreases resource depletion, but also generates new business opportunities, allowing Europe to remain competitive in the global economy. Expert knowledge can be used in rethinking waste handling processes, equipment manufacturing and the development of new business models that derive from and strengthen the circular economy.

59

invest in high-tech processing local re-use and recycling

Security of Supply develop European business base

develop European knowledge base

European industry and economy global resource streams solutions and possibilities for the EU

60 Current situation: dependency on global resource streams

With the global population growing, resources have to be divided in a fair manner. This implies that no country should use too much, disadvantaging others in the process. From this perspective, the large inequality in consumption levels leads to the situation that some countries export most of their resources to economies that rely heavily on unsustainable consumer patterns.

It also implies that global distribution and transport streams have to be critically evaluated. Local production and manufacturing is in the long run more beneficial for the environment, as concentrated mining of critically important REEs in distant regions of the world makes the EU crucially dependent on extraction circumstances and supply it cannot

manufacturing

control, on multiple transport contingencies and on the unpredictable dynamics of global markets. To avoid all these problems, processing REEs within the EU is an important strategic asset.

Principle of circularity: semi-closed resource loops

keeping the resource semi-closed increases Security of Supply

minimize the import of new primary resources

recycle consumer cycle

replace

re-use

re-use valuable elements repeatedly in a semi-closed loop

Recycling REEs increases Security of Supply (having a safe source of resource supplies at hand) and makes local re-use in manufacturing possible. The circular economy is a model of resource streams that consists of semi-closed loops. The consumer cycle runs in this model largely on resources that are re-used multiple times. The goal of the circular economy is to reduce the necessity for exploiting new pockets of primary resources, while simultaneously keeping the waste stream (resources disappearing from the loop) as limited as possible. While this economic model does not stop resource depletion all by itself, its main concept significantly delays the depletion process. This is beneficial for reaching global sustainability, as a decreased demand for primary resources may reduce ecological degradation.

minimize the waste of valuabe elements from discarded products

61

Current situation: dependency on global resource streams

effectuate smart circular economy Security of Supply European knowledge platform developing European competences

local manufacturing and recycling responsible handling and resource management

chances for European businesses developing European industries and opportunities

Impact

64

65

The photo’s on page 12 and 19 have been obtained from Shutterstock. The photo’s on page 30, 32 and 37 have been obtained from LKAB.com. Photographer: Fredric Alm.

Graphic design by Otto Paans/Boukje.com Consulting BV. Graphics may only be used with full attribution.

Recommended citation: REEcover - Towards a Circular Economy Through Responsible REE Management FP7 Project. Project Storyboard, p. [number] Boukje.com Consulting BV/Otto Paans

Special thanks to:

Karen van den Bos

Boukje Ehlen

Kees Nederveen

Marco Pieterse

Gabriella Tranell

visual design: (c) 2013–2023

66 Credits

67

NTNU

Ragnhild Aune Lars Jakobsson Mark Kennedy Ivar Ødegård Tianming Sun Gabriella Tranell (coordinator)

LTU

Bertil Pålsson Christina Wanhainen

LCM Chris Hall Trevor Jones David Murphy Kagya Nyanin

LKAB

Lars Nilsson Rickard Jolsterå

TU Delft

Xiaoling Guo Sebastiaan Peelman Yongxiang Yang

SINTEF Ana Maria Martinez Karen Sende Osen Kai Tang

METSOL

Mårten Görnerup

SIMTEC

Patrick Namy Alexandre Oury

ELEMETAL

Bert-Jan Kuipers Dirk-Jan Kooijman Silvan Thus

INDUMETAL Dorleta Guarde

CHEMCONSERVE

Kees Nederveen Marco Pieterse

BOUKJE.COM

Karen van den Bos Boukje Ehlen (project manager) Otto Paans

TECNALIA

Lourdes Yurramendi Sarasola

68 Imprint

Imprint

This project has received funding from the European Commission in the FP7 program.

2013-2106

FP7-ENV-2013-two-stage

ENV.2013.6.3-1: Turning waste into a resource through innovative technologies, processes and services

project partners

CHEMCONSERVE

69

Kiruna Arkhangelsk

Norilsk

Trondheim

Reykjavik

Nuuk Helsinki St. Petersburg Moscow

Luleå

Narvik

Tromsø

Kiruna Arkhangelsk

Norilsk

Trondheim

Reykjavik

Nuuk Helsinki St. Petersburg Moscow

Luleå

Narvik

Tromsø