It’s

MATTHEW BRADFORD

It’s

MATTHEW BRADFORD

s we look back on the past year, it’s impossible not to feel a sense of immense pride and excitement about the progress we’ve made. Our association has navigated a period of significant transformation, characterized by strategic innovations and key milestones that have set a strong foundation for future growth.

One of the standout moments was launching our new strategic plan and vision which is built on three pillars:

Building Enduring Relationships with decision-makers at Queen’s Park, Indigenous Communities, environmental NGOs, municipalities and infrastructure partners.

Elevate OSSGA’s Profile through sophisticated communication, member growth, engagement, and educational opportunities.

Champion Sustainability by achieving net-zero by 2050 and leading the circular economy in aggregate and restoration practices.

Navigating the current political climate in Ontario has been both challenging and rewarding. The landscape is constantly shifting, with new policies and regulations that impact our industry. We have embraced these changes with agility, ensuring that our initiatives align with governmental priorities and foster collaborative relationships with policymakers. Our renewed proactive approach has allowed us to advocate effectively for the interests of our members in matters as far reaching as property tax reform and for a new Provincial Planning Statement.

I am particularly excited for this edition of Avenues as we are welcoming a new section on advocacy at OSSGA. Read through and learn more about our initiatives at Queen’s Park, with local municipalities and Indigenous Communities. We also are addressing some industry hot topics including an in-depth look at the licensing process for aggregate sites, providing a comprehensive guide to navigating this complex regulatory landscape. Additionally, we offer practical advice for companies looking to achieve a healthy work-life balance, recognizing the importance of mental and physical well-being in our industry. Lastly, an inspiring piece on our industry’s road to net zero highlights the innovative steps we are taking toward a more sustainable future.

The past year has been exceptionally busy for OSSGA, and the upcoming year promises to be equally as dynamic. We are continuously reminded as an industry how much room we have for improvement, but also how imperative it is to promote the need for close-to-market aggregate and the importance of stone, sand and gravel. Each story in this issue reflects the dynamic and multifaceted nature of our work and underscore our commitment to progress and innovation.

Thank you for your continued support. I hope you enjoy this issue of Avenues.

– Jim Petrella

Avenues is published for

The Ontario Stone, Sand & Gravel Association

365 Brunel Rd., Suite 2 Mississauga, ON L4Z 1Z5

Tel: 905-507-0711 www.GraveFacts.ca

Publisher Mike McSweeney OSSGA Executive Director

Sharon Armstrong Vice President, Industry and Stakeholder Relations

OSSGA Editor Carly Holmstead Communications Manager

Sales Executive Sharon Headley

Designer Katrina Teimo

All rights reserved. The contents of this publication may not be reproduced by any means, in whole or in part, without the prior written consent of the association.

Published September 2024

PUBLICATION MAIL AGREEMENT #6118616

Please return undeliverable items to:

The Ontario Stone, Sand & Gravel Association

365 Brunel Rd., Suite 2 Mississauga, ON L4Z 1Z5

Is Ontario’s ambitious infrastructure plan at risk due to a looming shortage of high-quality licenced aggregates?

BY MATTHEW BRADFORD

Ontario has ambitious infrastructure plans in the coming years. From adding 1.5 million new homes to building critical healthcare facilities, laying stretches of road to conducting extensive belowground works, the Province’s pipeline is reaching capacity. Each project has the potential to impact the lives of Ontarians, but without access to high-quality stone, sand, and gravel, one wonders how they will make it off the ground.

“The simple story is that we are running out of high-quality licenced aggregate,” says Mike McSweeney, OSSGA Executive Director, citing research that indicates

without stone, sand, and gravel,” he adds. “But we’re having a lot of difficulty doing what we need to do as an industry because of that lack of understanding and the barriers that come with it.”

Hurdles at high levels

It is no exaggeration to say the aggregate industry is one of the most regulated industries in Canada. The industry is beholden to 25 pieces of legislation and countless regulations. All may have started with good intent but are nonetheless making it increasingly difficult to get pits and quarries up and running in places where they can produce highquality, close-to-market aggregate.

This all goes back to a lack of understanding and appreciation, says McSweeney, who adds, “It just doesn’t seem like the people who depend on aggregate but also regulate and legislate have a sufficient understanding of how important it is to their communities or our society as a whole.”

TOLD

INDUSTRY PLAYERS FACE A NUMBER OF BARRIERS TO SUPPLYING ONTARIO WITH THE MATERIALS IT NEEDS TO MOVE AHEAD WITH ITS INFRASTRUCTURE PLANS.

nearly four billion tonnes of aggregate will be needed to cover the Government of Ontario’s ambitious infrastructure plans—which the Province aims to hit by 2040. That’s no small order, McSweeney continues, and for the aggregate industry to even come close, it needs to be able to dig: “And that shouldn’t be a problem, right? All it means is finding good supply, setting up operations, and starting to dig. And yet, it’s much more complicated than that these days.”

Indeed, between extended licensing timelines, ballooning costs, political barriers, and the delays that come with addressing public misconceptions, the process of putting shovels in the ground is not as straightforward as it could be. And at the heart of the issue, says McSweeney, is a gap in public understanding: “Nothing gets built

“There are several municipalities that don’t like the idea of having a pit or quarry in their borders because they believe it’s going to negatively impact their communities, and that sentiment seems to get elevated the closer you get to Toronto,” says DeRuyter. “They may have good deposits, but they’re close to communities and housing, so they’re conflicted about giving the okay.”

There are ample examples of current policies prohibiting much-needed aggregate operations. For example, Neal DeRuyter, Partner with MHBC Planning, says the current policies prohibiting new aggregate extraction sites within the Province’s Natural Heritage System have created significant barriers to being able to set up operations in proximity to high-quality aggregates. “I’m often asked, what’s one policy that you think should be changed that would help overall aggregate supply, and it’s removing that prohibition on new aggregate operations within the natural Heritage system,” he says, noting, “Fortunately, the province has recently announced the approval of the Provincial Planning Statement coming into effect in October 2024 which does just that.”

Further hurdles can be found at the municipal level. Local governments are increasingly hesitant to approve pit and quarry operations, even when Ontario’s provincial policy statement encourages municipalities to provide opportunities for aggregates to be located close to the markets where they’re in demand.

All told, aggregate industry players face a number of barriers to supplying Ontario with the materials it needs to move ahead with its infrastructure plans. In addition to causing friction on the balance sheet, these obstacles are extending the licensing process to unsustainable lengths.

Waiting decades to dig The timeline between applying for a pit or quarry licence and starting operations stretches by the day. Where it may have taken two to four years to obtain a licence 25 years ago, today’s timelines are nudging north of a decade. To understand why the process is taking longer, it helps to have a refresher on the licensing process.

Essentially, getting approvals for pits or quarries requires obtaining a licence through the province via the Aggregate Resources Act and then approval through the host municipality. The licence application process begins by identifying a potential site and then pairing with third-party consultants to conduct technical studies to address a broad range of matters (e.g., environmental impact, noise, traffic, etc.). These studies can vary depending on several factors; for example, if the application is for a pit or

quarry, if the site is above or below water levels, if it’s Class A or B, and so on.

“Usually, you need to set aside 12 to 18 months to do the studies,” offers Matt Bertram, Senior Project Engineer with Skelton, Brumwell & Associates Inc. “So, more often than not, by the time you have everything bundled up and ready to go you’re probably in that 18 to 24-month window before you even can make your application to begin with.”

Next in the process is packing the studies into an application and sending it to the Ministry of Natural Resources (MNR), which has a legislated timeline to review the application’s completeness. Applicants that receive the greenlight then move on to the notification and consultation stage, which involves notifying all landowners within 120 meters of the proposed site as well as the local municipality, the Ministry of Environment, and a host of other stakeholders.

In addition are Indigenous Communities that must be engaged and consulted on for many proposed aggregate operations. This is a vital step to ensure plans address Indigenous communities’ concerns and align with their interests and values; however, with no hard and fast timelines to go by, these consultations can add significant time to the licensing journey.

“The process is open-ended, and you often don’t know what you’re getting into,” says Bertram. “You can be dealing with several communities with different and contradictory interests, so you really need to put aside the time and resources to help find a middle ground that makes everyone happy.”

DeRuyter agrees that this component of the consultation process is key but that it can be onerous for all parties. That includes Indigenous Community leaders themselves, who may be stretched thin consulting with organizations in any

number of sectors at the same time:

“Indigenous Communities are asked to review and comment on tons of things, not just aggregate. They have capacity issues, so it just takes time.”

Consultations can be tricky, no matter who the parties are. To move in the licensing process, applicants must prove they’ve done everything they can to engage stakeholders and address their concerns. Here again, says DeRuyter, this means dealing with many moving targets:

“If you talk to aggregate producers, one of the most difficult things for them is that they don’t know where the finish line is.”

After the consultation phase comes a 60-day notification period, during which time efforts are stepped up to inform the public through local media advertising,

These days, it can seem as though all licensing roads lead to the OLT. This isn’t far off from the truth, and it’s increasingly the result of politics getting in the way.

At issue is the fact that even when license applications engage in success consultations—and even though the provincial licence statement may favour close-to-market aggregates— municipalities tend to defer their approval in response to public opposition.

“What you’ll typically see now is that municipal council will vote against their staff recommendation and against the Provincial Policy Statement because they want to say to their constituents, ‘I voted against it, I protected you,’” says McSweeney. “I haven’t found a politician yet who doesn’t support aggregate, but they won’t vote for it openly because they fear it will cost them their seat, and they know the Ontario Land Tribunal will likely approve the licence anyways.”

I haven’t found a politician yet who doesn’t support aggregate, but they won’t vote for it openly because they fear it will cost them their seat, and they know the Ontario Land Tribunal will likely approve the licence anyways.

– Mike McSweeney, OSSGA Executive Director

signage, and public meetings. At the end of those 60 days, licence applicants have two years to work through any comments and see if they can resolve them or not.

And surely, says Bertram, “You’re always going to have opposition, no matter what. It’s a given. That’s why good community relations and early engagement go a long way at the end of the day.”

When the applicant is confident it has dealt with the feedback from the 60day notification period, the application process is sent back to the MNR for final approval. But while one would assume this is the final stop before getting the green light, more often than not the application is deferred to the Ontario Land Tribal.

The OLT has played an important role in the licensing process for nearly a half-century under various names (e.g., the Ontario Municipal Board). Under the Aggregate Resources Act and the Planning Act, it has the authority to deal with any disputes and objections relating to licence applications and municipal approvals for pits and quarries.

“Often, producers need to appeal to the OLT either because the council has refused the application or they haven’t made a decision on the application, and so the OLT then deals with the application and makes the decision,” explains Kim Mullin, Partner with Wood Bull LLP and OSSGA board member.

Mullin has practiced extensively before the OLT and represented many aggregate producers on their licence applications. Considering this part of the process requires more time and resources, it pays to go in prepared:

“My advice is to make sure you’re working with a good consulting team and that you’re preparing the application and all the studies with a view towards how well they’ll play in front of the Ontario Land Tribunal if we end up going there.”

For Ontario’s infrastructure plans to materialize, it will need aggregate producers who have the ability to deliver the goods. There is reason to be encouraged by the Province’s moves to support close-to-market operation, as there is confidence in the aggregate industry’s ability to address the public perceptions holding them back.

As DeRuyter notes: “A lot of aggregate producers do a very good job at building good relationships with the public because, at the end of the day, they are members of the community. They want to employ local people, help build the community through their business, and do their best to be good neighbours.”

Moving ahead, there are hopes that efforts to continue fostering relationships with the public and provincial decision-makers will bring licensing process times under control and, more importantly, let aggregate producers get to work.

STEP 1: SUBMISSION TO MINISTRY

Applicant prepares technical reports and site plan, and submits application to Ministry of Natural Resources (Ministry) for an aggregate licence or permit.

Ministry confirms if application is complete (within 25 days).

STEP 4: FINAL SUBMISSION TO MINISTRY

Applicant submits final information package to Ministry indicating how it has met all requirements and addressed all comments.

STEP 2: NOTIFICATION AND CONSULTATION1

Applicant notifies public by: writing to landowners within 120 m of property; posting signage on property2; and posting in local newspaper. Applicant sends complete application package to relevant agencies (e.g., conservation authority and other ministries).

Applicant holds public information session (10 to 50 days after notification) and makes application, site plan and technical reports available to public.

Members of the public and agencies may submit comments to applicant and Ministry within 60 days of public notification. Ministry also provides comments on application.

It’s time to think outside the box and try something different

BY KELLY PARKER

STEP 3: ADDRESSING COMMENTS

Applicant must attempt to address all submitted comments.

Applicant amends application to reflect consultation and submits consultation information to Ministry (within six months of public notification for aggregate permit or two years for licence).

Applicant provides commenters with an objection form for any comments that remain outstanding2

ICommenters may submit objection form to Ministry to formally object (within 20 days of receiving form); otherwise comments are considered addressed or withdrawn2.

STEP 5: DECISION PROCESS

Ministry staff review information and either recommend that the Minister approve or refuse the licence, or refer the licence application to the Ontario Land Tribunal. For permits, the Director may approve or refuse the application.

Minister approves, refuses or approves application with conditions.

Ontario Land Tribunal holds hearing and then directs Minister to approve, refuse or approve the application with conditions.

Applicant may request hearing with Ontario Land Tribunal if application is refused2

1. As licences and permits are prescribed instruments under the Environmental Bill of Rights, 1993, the Ministry is also required to conduct a separate consultation process pursuant to that law. 2. These steps apply to aggregate licences only (not to aggregate permits).

Note: This process does not include the requirement for zoning under the Planning Act, nor the requirement for producers to adequately consult with Indigenous Communities. This duty to consult and accommodate is assessed separately by the ministry.

n the corporate world, COVID-19 altered the fabric of our professional lives. A large majority of employees worked from home and were introduced to a new life-work balance that didn’t previously exist in their jobs. Working from home highlighted the potential for workplaces to foster a happier, more productive, and loyal workforce through flexibility. Yet, this adaptability never really hit the construction industry, particularly the aggregate sector, where employees cannot do their job remotely, and logistical demands are high—often requiring workers to begin at the crack of dawn and work a 12-hour shift.

But this new flexibility is what our workforce is searching for. Is achieving work-life balance feasible in an industry where frontline workers often face long hours with minimal time off? Not only did the pandemic force companies to explore flexible work options but because it disproportionately affected working women, it shed a light on the impact of gender inequality and how companies can reduce barriers for female employees—something the aggregate industry is currently tackling.

Recruitment and retention strategies are integral to the labour shortage problems

the industry is facing as an aging workforce is retiring. How do we solve these problems?

One way is to build relationships with training colleges so that you can speak to young workers and help them overcome any misconceptions they may have about the aggregate industry. “We have agreements,” explains Mike Andrighetti, Vice President of Ethier Sand & Gravel, “with some of the training colleges here locally where we’re able to monitor and have supervisors attend the training with the employees, so we have a relationship with them before they actually start work.”

“Any operator can go get a job working in construction or anywhere else where the piece of equipment will work,” continues Andrighetti. “But to attract them to quarrying and a pit setting is a lot different. It may be a kind of dirtysounding business, but it’s also a lot of fun. You have to make it exciting and engaging.”

One strategy to address this shift is to move away from the traditional 12-hour shift model. “You have to schedule your shifts and treat your people in ways that may be a lot different than what the old guard used to do,” stresses Andrighetti. “Especially in the quarry or pit setting. Trying different things that are not traditional to the industry, like removing the traditional night shift from the equation, is something that has worked for us. It allows us to have these young people who value time at home and life away from work more than maybe the 30-year employee has. I think that’s been a real driver for us.”

Ethier Sand & Gravel has transitioned from 12-hour rotations to a production day of two eight-hour shifts, a change that has yielded positive results. However, moving to three eight-hour shifts in a 24-hour production day could exacerbate staffing shortages. Andrighetti notes

IN LINE WITH THE INCREASED FOCUS ON WORK-LIFE BALANCE, COMPANIES ARE ALSO ENHANCING SERVICES TO SUPPORT EMPLOYEES’ OVERALL MENTAL HEALTH.

that effective recruitment messaging is crucial: “If you’re dangling the carrot out there that the worker is going to have more time at home and better work-life balance – which is the point – you’re attracting the group that’s opposed to the 12-hour shifts.”

The transition period when implementing this strategy may present challenges, potentially leaving the company shortstaffed until sufficient staffing levels are reached. “It’s tough. You just have to have the right people who create an environment where (new employees) will be welcomed,” Andrighetti explains. “And it’s a good place to work – a team environment. If you establish all of that, then you hope that transition period is easy on the employees and happens fairly quickly, obviously for the employer.”

Andrighetti emphasizes that feedback from employees has been overwhelmingly positive, as the changes have fostered the desired work-life balance. “Sometimes, in certain circumstances, you need to accommodate the employees. Everyone now, especially with this younger group, has different needs than employees have had in the past. Part of work-life balance is ‘Hey, my kid’s got a recital today,’ or a medical appointment, and that’s something that companies are increasingly trying to accommodate.”

Gone are the days when employees would spend their entire careers with one company. Today’s workforce anticipates

Despite

the presence

of many women in the aggregate industry, they remain significantly outnumbered by men, a disparity that presents additional challenges.

working for multiple employers and even changing careers, further complicating retention efforts. Additionally, their priorities have shifted from a work-first mentality to a significant emphasis on work-life balance.

The nature of work in pits and quarries— where teamwork is essential—may not allow for complete flexibility, but accommodations can still be made.

“Employees have to be mindful of where they’re working. Some situations may not be ideal to allow for that,” says Andrighetti, “But at the same time, if you want to be able to say ‘Okay, you do have a life outside of work and you can go to your kid’s recital,’ you have to be somewhat accommodating, and planning ahead certainly helps.”

In line with the increased focus on work-life balance, companies are also enhancing services to support employees’ overall mental health.

“We offer employees a pretty robust employee assistance program,” Andrighetti explains. “It gives all employees access to doctors, legal advice, counseling, and rehab if they need it. It’s a pretty comprehensive group of resources that these employees can access and get the help they need at any time with a phone call.”

To address these issues, Laronde’s firms established a Diversity, Equity, and Inclusion (DEI) Committee, which focuses on creating a more accommodating work environment. “Women need clean access to washrooms, which is important for everyone. One of the first things we did was to have an all-gender washroom or a gender-neutral washroom. Construction is reportedly the number one job for transgender men, so everyone needs a safe place to go to the washroom. It was a huge eye-opening experience for me. I thought I was well aware, but I realized come from a place of privilege. It’s important to speak not only for women but for other underrepresented ethnicities in our industry.”

Despite the presence of many women in the aggregate industry, they remain significantly outnumbered by men, a disparity that presents additional challenges. Lisa Laronde, President of RSG International and Powell Contracting, identifies harassment, discrimination, and isolation as primary obstacles. “We do a really good job of getting women trained to be able to get into the trades, but then they get on a job site and they’re the only woman there. They’re not prepared for that. It would be nice if we could at least prepare women, saying ‘this is the environment you’re going to enter into,’ versus pretending it doesn’t exist. We need strategies on how to deal with that.”

Childcare is another significant barrier for women in construction. “We don’t have nine-to-five hours. You have to be able to get to work early, sometimes before childcare is open. As part of the North American Women in Construction and the Canadian representative for the Global Women in Construction panel, I can say this is a global issue,” says Laronde. Access to clean washrooms and feminine hygiene products is also a critical concern.

people were praying in bathrooms, which is not a nice place to be.”

As the aggregate industry grapples with a labour shortage, it is crucial to consider these details. “Women represent 50% of the population but only 5% of the skilled trades. It’s crazy that we’re not attracting more women. If industry, unions, education, and government come together, we can attract more women, Indigenous people, and new immigrants into the construction industry. These are all opportunities for us to be successful,” emphasizes Laronde.

If industry, unions, education, and government come together, we can attract more women, Indigenous people, and new immigrants into the construction industry. These are all opportunities for us to be successful.

Additionally, the firm introduced a “quiet room.” “That allows you, if you’re nursing, a private place to pump breast milk or just a space for alone time if you need to gather your thoughts. It’s also used for prayer as we found some

It’s clear that introducing work-life balance practices, as well as ensuring your recruitment practices are attracting the full scope of potential employees will help solve these issues.

Andrighetti agrees, and concludes by providing the following advice: “Don’t be afraid to just think outside the box and try something different. It’s a pretty traditional industry that needs to think a little differently about how it wants to treat its employees.”

Rehabilitation is not usually the first word that comes to mind when considering mining or material extraction. However, rehabilitation is a significant part of the requirements for aggregate extraction in Ontario.

Under the legislative and regulatory environment in Ontario, when aggregate companies identify areas for material extraction, they are required to include a detailed plan for site rehabilitation after aggregate extraction has taken place. Rehabilitation means the restoration of the site to its former use, if possible, or changing the site to another use or condition that is compatible with the surrounding land.

Though minimum standards for rehabilitation exist as part of the provincial requirements and are identified on all licensed pit and quarry site plans in Ontario, CBM Aggregates (CBM) strives to achieve higherquality rehabilitation. Whether by encouraging biodiversity or restoring productive farmland, these efforts are geared toward promoting uses that blend with the surrounding landscape.

Aggregate companies often face community challenges when a new extraction site is identified.

Residents typically are unaware of the interim nature of an aggregate operation and the benefits that will be realized when rehabilitation fully occurs. In many cases, residents don’t even understand restoration efforts are required at all. Local communities can be anxious and generally unhappy with the prospect of an extraction site in their neighborhood.

In 1996, Cannington Pit received a license to operate through the Ministry of Natural Resources and Forestry (MNRF). Sand and gravel extraction began in the late 1990s and the pit operated intermittently, supplying material to CBM’s nearby Sunderland Pit and to Brock Township for local road projects. In 2020, the last truckload of gravel left the pit.

CBM worked with Glenn Harrington to rehabilitate the site. Under his guidance, progressive rehabilitation occurred at the pit and uniquely included a number of specific rehabilitated end uses on the property, including agriculture, open natural habitat, reforestation, and pond/wetland creation.

Glenn Harrington, was a founding partner and principal landscape architect at Harrington McAvan Ltd. For over 40 years, the firm has specialized in landscape architecture, earth sciences, and biology, with a focus on stream and wetland restoration and rehabilitation projects. Over his career, Glenn was widely known for his innovative approach to environmental landscape design and his skills as a facilitator in the public participation process.

Glenn had a knack for respectfully educating objectors about the benefits of site restoration to help companies gain approval for aggregate licenses. He treated all people—from municipal and agency staff to the public—with kindness as he represented his clients’ positions, spreading the value of soil bioengineering and landscape and rehabilitation design. By giving respect and providing science-based education, he also gained respect from these audiences, which typically are hard to win over.

As an expert in innovative bank stabilization and improvement to aquatic habitat, Glenn worked with CBM on many projects including the Cannington Pit, located in Brock Township, Durham Region, Ontario.

In 2013, CBM Aggregates and Glenn Harrington began restoring the Cannington Pit by establishing a wetland plant seed bank along the pond’s northern shoreline. By 2015, they stocked the pond with minnows, and in 2016, Glenn led an agricultural rehabilitation project, including land contouring, soil management, and the introduction of rainbow and brown trout. In 2017, Glenn added a spawning area and planted oak acorns and tallgrass prairie species.

In the following years, CBM and Glenn expanded their efforts, building wetland plant boxes, planting thousands of trees with Ethics Tree Creations, reshaping pond slopes, and conducting fisheries assessments, which confirmed healthy populations of minnows and trout. These projects also included erosion control and creating wildlife habitats.

The Cannington Pit was close to Glenn’s heart. In fact, Glenn loved the site so much that he purchased it in 2015, dubbing the area “Harrington Glen.” He planned to spend his retirement there, working the fields, canoeing, fishing, rambling, and sharing the bounty of his land.

Unfortunately, Glenn passed away before restoration was complete, but his commitment to rehabilitation—specifically at the Cannington Pit—will always be remembered.

The Cannington Pit, initially licensed in 1996 and operational until 2020, received a licence surrender from the MNRF in 2023, having met the approved site plans.

During its operation, CBM received multiple awards from the Ontario Stone, Sand, and Gravel Association (OSSGA) for their progressive rehabilitation efforts at the Cannington Pit.

Now surrendered, the former pit is now host to thriving agricultural areas, naturalized and wetland habitats - a lasting reminder of Glenn’s legacy.

BY OSSGA STAFF WRITER

The Ontario Stone, Sand & Gravel Association (OSSGA) has embarked on a new strategic direction, underpinned by a comprehensive strategic plan aimed at strengthening its influence and fostering enduring relationships with political leaders. This initiative took center stage on April 15th, 2024, when Queen’s Park was rockin’ with activity as more than 40 OSSGA members engaged in 42 crucial meetings with Ministers, Members of Provincial Parliament (MPPs), Deputy Ministers, senior political staff, and other key decision-makers at the Ontario Legislature.

“As we embark on a new strategic direction within OSSGA, it is clear that the future of Ontario’s infrastructure depends on timely access to quality, close-to-market aggregate, which was a clear message during our time at Queen’s Park” says Michael McSweeney, executive director, OSSGA.

OSSGA’s message was clear: the industry is in crisis. Without faster approvals for new close-to-market aggregate sites, Ontario’s ambitious infrastructure plan is in peril. Without aggregate, Highway 413, the Bradford Bypass, the twinning of the Garden City Skyway, the new Ontario Place/Science Centre, the Ontario Line, and the construction of 1.5 million homes will not be possible.

OSSGA’s ask was simple: significantly reduce the time it takes to get an aggregate licence approved by the Ontario government.

While members were pleased with the warm welcome, they received in each of their meetings, it was clear that continued effort is required to educate and communicate to politicians and their constituents on the importance of close-to-market, quality aggregate.

Ontario’s infrastructure plans, which include major projects like highway 413, the Bradford Bypass, the Ontario Place/Science Centre, and the construction of 1.5 million homes, will require a staggering four billion tonnes of aggregate by 2040. The GTHA is particularly at risk, with supplies of close-to-market aggregate dwindling rapidly. OSSGA emphasized that without faster approvals for new aggregate sites, these important projects could be in jeopardy.

The response from political figures was overwhelmingly positive. Minister of Natural Resources, Graydon Smith, acknowledged the need for close-to-market aggregate.

Several MPPs, including Brian Riddell, Sam Oosterhoff, Ric Bresee, and Ted Arnott, demonstrated a strong understanding of the industry’s needs. However, challenges remain, particularly regarding the pushback from constituents and the need for improved communication about the industry’s extensive rehabilitation work.

Michael Lindsay, CEO of Infrastructure Ontario, recognized the importance of having the right aggregate quality specifications in place and sought the industry’s assistance in implementing them. Discussions also highlighted the potential for transporting materials by rail or barge, despite existing infrastructure challenges.

A significant portion of the discussions focused on reducing the time it takes to approve new aggregate licenses. Currently, the process averages 7 to 12 years, and OSSGA aims to shorten this to 4 to 7 years. “One proposed solution was increasing the levy on aggregate, allowing municipalities and Indigenous communities to benefit more directly,” says McSweeney. However, this proposal faced resistance as it was perceived as a tax increase, conflicting with the Ford government’s low-tax stance.

Minister Smith suggested developing a strategy to enhance relationships with municipalities and Indigenous groups. There was also a call for reducing regulatory red tape, with Associate Minister for Small Business and Red

Tape Nina Tangri encouraging OSSGA to continue submitting proposals on this front.

Rehabilitation of aggregate sites was a recurring theme throughout the day.

Politicians, including Mike Harris and NDP MPP Catherine Fife, showed interest in the industry’s rehabilitation

practices and stressed the need for more public awareness. Discussions with Minister of Environment, Conservation and Parks Andrea Khanjin focused on recycling and the potential for a certification process for recycled aggregate.

Green Party MPP Mike Schreiner emphasized the importance of addressing noncompliance issues and

increasing inspections, aligning with concerns raised in the 2023 Auditor General’s report on aggregate management.

OSSGA members highlighted several industry challenges, including the lengthy and costly licensing process, which poses a barrier to investment, especially for smaller producers. Kent Williamson, senior advisor to the Minister of Economic Development, proposed the Northern Ontario Heritage Fund as a potential avenue for support.

The day concluded with a well-attended reception, featuring visits from several Ministers, reinforcing the event’s success and the need for it to become an annual occurrence. The OSSGA Lobby Day demonstrated the industry’s important role in

OEM equipment sales & rentals

All makes parts & service, including Sandvik, Metso, JCI, and Cedarapids

2 factory locations and 5 branches

Factory-trained field service personnel

OSSGA’S MESSAGE WAS CLEAR: THE INDUSTRY IS IN CRISIS.

Ontario’s infrastructure development and the necessity for ongoing dialogue and collaboration with government officials.

The OSSGA Lobby Day emphasized the importance of close-to-market, high-quality aggregate for Ontario’s infrastructure projects, the need for faster licensing approvals, as well as a better public and political understanding of the industry’s contributions and challenges. By continuing to foster relationships with government officials and advocating for practical solutions, OSSGA aims to ensure that Ontario’s infrastructure goals can become a reality.

Fully-equipped service bays Rebuild facilities Crusher wear parts Manganese and screen media Conveyor parts & components

Moreover, OSSGA plans to enhance its communication strategies, showing successful rehabilitation work and promoting the environmental and economic benefits of the aggregate industry. By increasing public awareness and understanding, OSSGA hopes to garner broader support for their initiatives. As they look to the future, the association is committed to continuous discussions, problem-solving, and sustainable practices, ensuring that Ontario’s infrastructure development remains robust and efficient.

“Our meetings at Queen’s Park reinforced that together, we can overcome the challenges facing our industry and ensure that Ontario’s ambitious infrastructure projects are not only realized but built on a foundation that supports our communities for generations to come,” closes McSweeney.

Engagement, education, and collaboration take center stage as OSSGA connects with municipal leaders to emphasize the critical role of aggregates in Ontario’s infrastructure and community development.

BY OSSGA STAFF WRITER

Each year, the Association of Municipalities of Ontario (AMO) hosts a conference that brings together thousands of municipal leaders, staff and delegates for three days worth of networking, concurrent sessions and plenary programming. As the Ontario Stone, Sand, & Gravel Association (OSSGA) works to achieve its new strategic vision under the leadership of Executive Director Mike McSweeney, this year, OSSGA upped its presence by not only attending AMO but also becoming a primary sponsor. This event provides a significant platform for our association to engage with key stakeholders and further the conversation around the importance of the aggregate industry in Ontario. Our presence was marked by a series of successful events and two days on the tradeshow floor, solidifying our commitment to advocating for the essential role that stone, sand, and gravel play in the province’s infrastructure and community development.

“It always surprises me how many local politicians are eager to learn more about aggregate. There’s an assumption that municipalities aren’t supportive of us, but I think the real issue local councillors face is that they need to be armed with evidence they can take back to their constituents—and that’s something we can help them with,” says Sharon Armstrong, Vice-President of Industry and Stakeholder Relations.

sponsored by OSSGA:

One of the highlights of our participation at the AMO Conference was hosting two caucus lunches: one for voting members and one for non-voting members. Both lunches were attended by more than 500 conference attendees. Through a combination of informative videos and compelling speeches, attendees were educated on the critical role that aggregate plays in the development of communities and infrastructure.

Building on the strong relationships we established with many of these politicians during our Lobby Day in April, we used these lunches as a platform to further amplify the critical message of our industry: we are running out of high-quality, close-to-market material. We emphasized the urgency of securing close-to-market aggregate resources, highlighting the increasingly difficult process of obtaining licenses and permits, and the prolonged timelines involved in these processes— underscoring the need for immediate action and streamlined regulatory procedures to ensure the sustainability and resilience of our industry.

Sarkaria, Liberal Leader Bonnie Crombie, Paul Calandra, Minister of Municipal Affairs and Housing of Ontario, Minister of Education, Jill Dunlop, and MPPs such as Stan Cho, Sam Oosterhoff, Lisa Thompson, Charmaine Williams.

The evening provided an invaluable opportunity for networking and facilitated important discussions on the future of the aggregate industry.

“The AMO conference provided a unique opportunity to engage directly with Mayors and Councillors from areas where we have ongoing projects, all in one place and in a relaxed environment,” says Rob Pierce, past chair for OSSGA.

“The informal setting made it easy to have meaningful conversations and build relationships. The lunches were also valuable, offering a chance to educate politicians about our initiatives and the impact we have on their communities. It was a fantastic way to foster collaboration and understanding across different regions.”

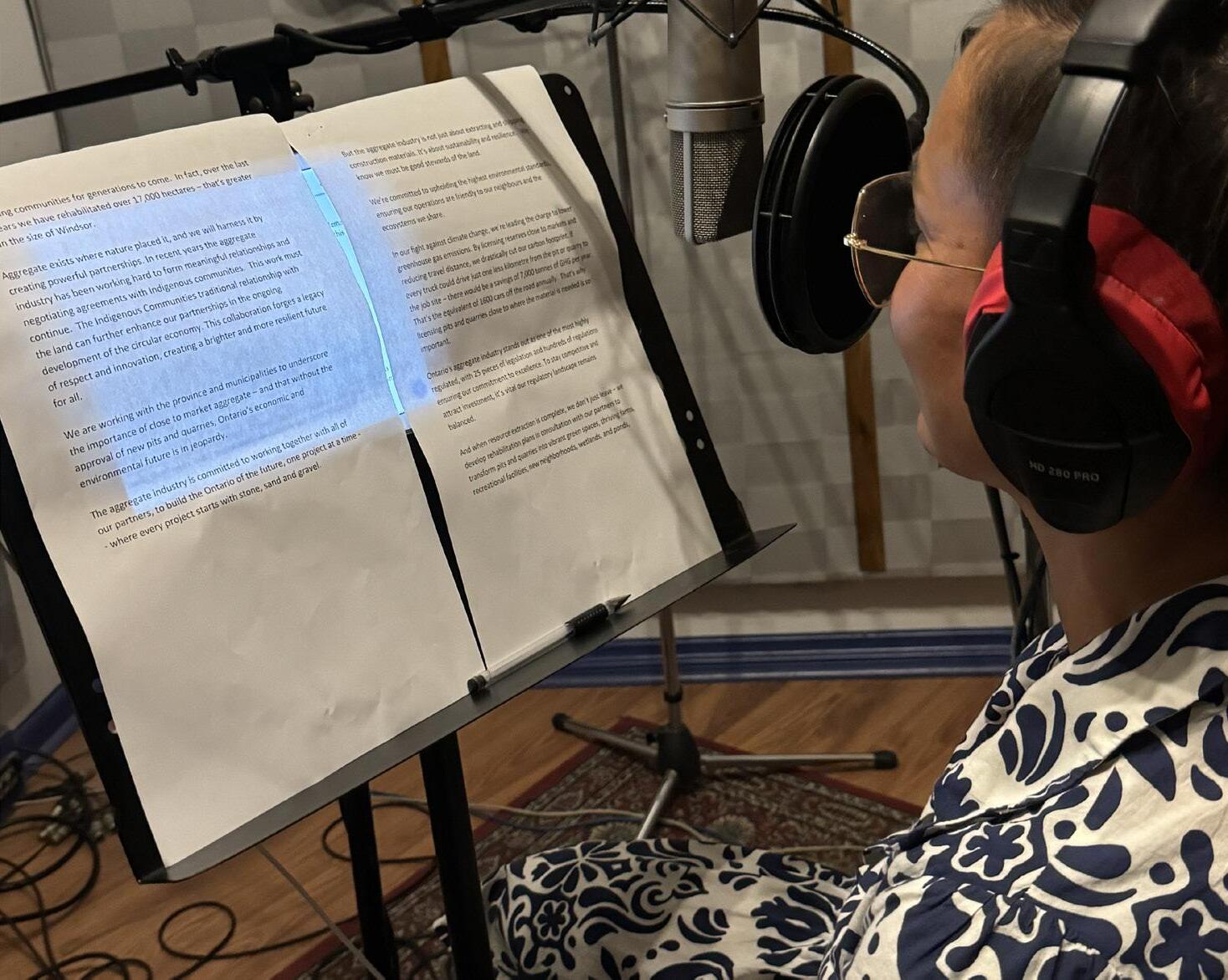

One of the most exciting moments of the conference was the unveiling of our newest video, which showcases a bold new direction for OSSGA. The launch of this video is a testament to our ongoing efforts as we adapt to the changing needs of our industry. It highlights the

strategic direction of OSSGA as we continue to advocate for the aggregate industry’s critical role in Ontario’s economic and social development. This video underscores our commitment to working closely with two key partners: municipalities and Indigenous Communities. By focusing on collaboration, we are positioning ourselves to address challenges, while ensuring the industry remains a vital contributor to the province’s ambitious infrastructure goals.

In conclusion, our participation in the 125th AMO Conference in Ottawa was a resounding success. The events we hosted, the discussions we facilitated, and the new initiatives we launched all served to advance the conversation around the importance of the aggregate industry in Ontario. We are proud of the strong presence we had at the conference and the positive impact we made. As we move forward, OSSGA remains committed to advocating for the essential role of stone, sand, and gravel in building and maintaining the infrastructure that supports our communities. We look forward to continuing our work with municipalities, Indigenous Communities, and other key stakeholders to ensure a sustainable and prosperous future for all Ontarians.

“Many councillors are surprisingly knowledgeable about the industry and recognize its importance to their communities. It’s great to see so much understanding and support in one place. The trick of course is to get them to think and speak that way when they are sitting at a Council meeting.”

On Monday evening, OSSGA organized a reception that successfully brought together nearly 750 attendees, including prominent figures such as Minister Graydon Smith, Minister Prabmeet

Aggregate producers have a responsibility to the land on which they operate, and to the Indigenous Peoples upon who’s traditional and treaty territories their sites are located. In fact, adequate consultation on licence applications is a legislative requirement under the Aggregate Resources Act. Which is why OSSGA, and its members, are committed to forming, strengthening, and maintaining relationships with Indigenous Peoples that are built on respect, trust and mutual understanding.

As the voice of Ontario’s aggregate industry, OSSGA’s Executive Director, Mike McSweeney is committed to ensuring the aggregate industry is working closely with key stakeholders and rightsholders to sustainably extract aggregate resources. This includes forging strong relationships with Indigenous Communities and working with the provincial government to develop innovative ways to contribute more resources to Indigenous Communities as part of the industry’s commitment to reconciliation. In August 2024, this renewed focus was underscored by the launch of OSSGA’s newest video which captured the association’s commitment to working closely with Indigenous Communities and Olympics. The music was also by Indigenous artists. (take a look at GravelFacts.ca/Video101)

“For an industry that is critical to Ontario’s growth and building of a circular economy, connection and collaboration with Indigenous Communities forges a legacy of respect and innovation, creating a better Ontario and a brighter and more resilient future for all,” says McSweeney. And McSweeney leads by example, by including Indigenous Communities wherever possible. OSSGA has been actively meeting with and learning from Indigenous Communities in treaty and traditional territories with significant aggregate resources, working with elders and elected band leaders on communicating effectively, and inviting Elder Whabagoon, with the Loon Clan, Keeper of Sacred Pipes, and a member Obishikokaang, Lac Seul First Nation to officially launch the OSSGA Conference and AGM in February 2024.

Indigenous Peoples are a link to the past and they must be partners in sustainable resource management moving forward. For reconciliation to happen, according to the Truth and Reconciliation Commission of Canada, “there has to be awareness of the past, acknowledgment of the harm that has been inflicted, atonement for the causes, and action to change behaviour.”

In June 2015, the Truth and Reconciliation Commission of Canada, which was created to inform Canadians about what happened in residential schools and lay the foundation for reconciliation across Canada, listed 94 Calls to Action to achieve true reconciliation. The 92nd Call to Action calls on the corporate sector in Canada to adopt the United Nations Declaration on the Rights of Indigenous Peoples as a reconciliation framework and to apply its principles, norms, and standards to corporate policy and core operational activities involving Indigenous peoples and their lands and resources. The call to action includes committing to meaningful consultation, building respectful relationships, and obtaining the free, prior, and informed consent of Indigenous peoples before proceeding with economic development projects. It also includes ensuring that Aboriginal peoples having equitable access to jobs, training, and education opportunities in the corporate sector, and providing education for management and staff on the history of Aboriginal peoples.

So how can OSSGA and its members strengthen relationships with Indigenous Communities and move towards full reconciliation?

Bob Joseph, member of the Hamatsa Society, who has inherited a chief’s seat in the Gayaxala (Thunderbird) clan, the first clan of the Gwawa’enuxw one of the 18 tribes that make up the Kwakwaka’wakw, shares in his book Indigenous Relations: Insights, Tips & Suggestion to Make Reconciliation a Reality, some of the ways the corporate sector can build relationships with Indigenous Peoples. They include understanding and using the proper terminology, recognizing and respecting the history and cultural diversity among Indigenous Peoples, understanding

For an industry that is critical to Ontario’s growth and building of a circular economy, connection and collaboration with Indigenous Communities forges a legacy of respect and innovation.

– Mike McSweeney, OSSGA’s Executive Director

governance structures and the election cycle (this includes learning

researching and understanding the Indian Act, residential schools and MMIWG, practicing Indigenous cultural appreciation instead of appropriation, taking Indigenous cultural competency training, supporting Indigenous authors, artists and businesses, and attending public cultural events (such as powwows).

The Indigenous worldview that all living things are connected and our actions and decisions impact one another is a powerful one. Which is why, says McSweeney, “We need to work together—governments, municipalities, Indigenous communities, and the aggregate industry—to ensure that we have the resources necessary to build the Ontario of tomorrow.”

The aggregate industry’s road to reducing GHG emissions.

BY WARREN HEELEY

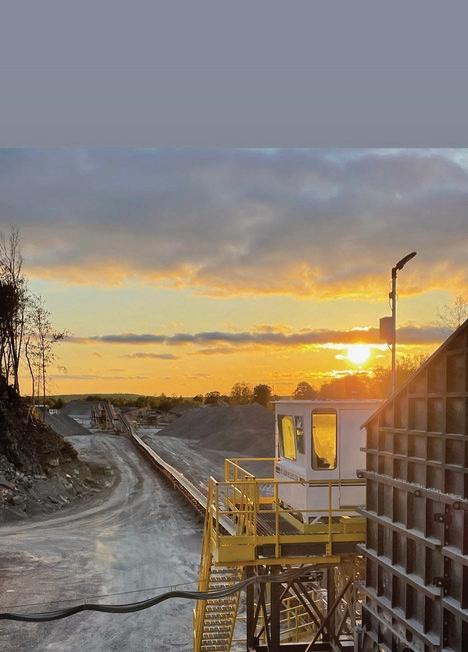

The Ontario Stone, Sand and Gravel Association (OSSGA) and the aggregate industry in Ontario is committed to reducing its carbon footprint to meet the federal government’s targets for net zero emissions by 2050. The industry plays a critical role in Ontario’s circular economy and is already a driving force contributing to carbon neutrality in many ways.

An industry plan to reach net-zero aggregates will capture these long-term and continuing business practices and chart a path towards net-zero. However, some OSSGA members have already started reducing emissions from their operations. Both small and large-scale companies are working on steps towards a more sustainable future, including operator Ron Brent, from Brent Quarries.

Brent Quarries: moving forward sustainably

“Our company is already on the road to net zero,” says Ron Brent of Brent Quarries. “We have implemented a series of sustainable solutions for our operations and will continue on this road until we meet the targets for 2050.”

Based in Port Carling Ontario, this member company was started in 1990 by the three Brent brothers. One of the brothers was a contractor and had an ongoing need for small to medium volumes of aggregates that were difficult to obtain from the larger aggregate suppliers. Starting Brent Quarries solved this initial challenge and opened up a whole new family business.

The company has steadily grown from 80 to more than 3000 acres of land and five quarry sites. “Our hook with customers is that we are close to clients so the congestion on main roads in the province did not impact us and we could guarantee quick and on time delivery at a better price,” says Brent.

He went on to say that the net zero targets will be difficult for the industry but they are achievable. Approaches like planting trees to offset carbon emissions for the aggregate industry is not going to work. Instead his company has already started down the sustainability path in a number of ways.

Here are the steps that Brent Quarries has taken or will be taking in the near future.

Super insulated buildings – The buildings on Brent’s properties are wood construction and the inside is super insulated with spray-on foam insulation on the walls, ceiling and under the floor. This makes these buildings stronger, quieter and better insulated than steel construction which is harder to insulate and therefore, more difficult to maintain a good thermal barrier. The building’s energy use is very low and it creates a good environment for workers when it is cold or hot outside.

Our company is already on the road to net zero. We have implemented a series of sustainable solutions for our operations and will continue on this road until we meet the targets for 2050.

–

Ron Brent, Brent Quarries

Buildings usable in winter – Property buildings have been designed to allow trucks to be kept inside during the winter which negates the need for truck warmup during colder weather. The buildings also create a better environment for workers when maintenance is needed on

company trucks and other equipment in the winter months.

Building heating – On company sites, all buildings on the property are heated by a central boiler system that connects to each building by underground insulated pipes. The system has two boilers connected to the loop; one to provide heat for the system and one as a backup. The boilers operate on wood waste

pellets which makes the system carbon neutral and includes a heat extraction feature in the system.

Electric property grid – All of the five sites have a 44,000 kilowatt line coming into the site that allows most operations (including crushing in the future) to be electrically run.

Solar farms – Three of the five sites have 500 kw solar farms that feed back into the property grid and provide 200 per cent of the ongoing energy needs for the property. The solar farms have been placed on land that is reclaimed, or land that is not presently being used.

Hybrid trucks – “We are proud to say that we have found a way to convert our dump truck fleet to electric hybrids,” said Brent. “A manufacturer in British Columbia makes available a kit that can be retrofitted into a dump truck to convert it to a diesel/electric hybrid. We are actively pursuing this for our fleet

THREE OF THE FIVE SITES HAVE 500 KW SOLAR FARMS THAT FEED BACK INTO THE PROPERTY GRID AND PROVIDE 200 PER CENT OF THE ONGOING ENERGY NEEDS FOR THE PROPERTY.

and expect to have the first hybrid truck on the road in 12 to 24 months. With transportation being the largest carbon emission challenge for our industry, we see this as a major breakthrough for emissions reduction”

Rail aggregate shipping – The fifth site opened by Brent was about 700 acres. Brent saw an opportunity in this site to create a better way to transport aggregate to markets around the province. The emissions from moving aggregate to distant markets by truck and the traffic gridlock created each day

in urban areas makes transportation by rail a preferred option.

The new site has access to both CN and CP rail lines through the property. Using rail would reduce shipping costs, energy use and GHG emissions. With maintenance costs rising for dump trucks and a shortage of dump truck drivers, rail makes sense especially considering the difficulty being encountered in shipping aggregate by truck to large urban areas like the GTA. “Rail is a good sustainable option, so we are preparing for it,“ stated Brent.

Brent concluded by saying, “Does our company agree with the net zero targets? Yes, we do. Fossil fuels are becoming a precious commodity and should only be used when there is no other alternative like the situation currently with aircraft. Putting aircraft use aside, there are so many other energy options in our industry where fossil fuels can be replaced with alternative energy sources that are more sustainable. It’s our job to implement as many of these options as possible to reduce the carbon loading in our environment.”

A plan to reach net zero by 2025 is currently being developed by the OSSGA Board and Environment Committee. It will entail establishing a series of key performance indicators (KPIs) to track progress within the industry and set goals for future targets. Most importantly, the plan will provide practical approaches and methods to make day to day aggregate processes sustainable,

recognizing that it may not be a “onesize-fits-all” solution for members.

Steps like switching to grid supplied electricity, fleet/equipment updates, utilizing alternative fuel sources, recycling, and switching from loaders to conveyors will all contribute to reductions in greenhouse gas (GHG) emissions in the industry. However, transportation emissions are the largest output of GHGs in the aggregate industry and will

obviously be a key target for reductions.

The transportation part of the plan will go hand in hand with the industry position on the need for “close to market” aggregate supply chains and the impact it will have on reducing emissions. To address this, the industry is also looking at alternative aggregate delivery systems and obstacles to transporting aggregate by rail in Ontario.

In the interim, OSSGA sees opportunities to raise awareness of the need to adapt processes to lower emissions, communicate best practices and new technologies to the membership, and develop industry environmental product declarations (EPDs). There is also a proposal to introduce a new OSSGA “net zero award” to help incentivize members to make their operations more sustainable and showcase examples of industry initiatives.

The road to net zero is going to be a challenge but it will also provide the aggregate industry with opportunities to audit their fleets, buildings, and processes and identify ways they can reduce emissions, improve waste recovery and even save money. For an industry that is so critical to so many aspects of people’s lifestyles whether it is the roads and bridges they drive on, the homes they live in or the buildings they work in, net-zero aggregates is a shared commitment to a more sustainable future.

building community relationships.

Tell us a bit about your job and your responsibilities.

As the Land and Resource Manager, I oversee license applications, site plan amendments, and compliance with license conditions. am also the main point of contact for community relations, including addressing public concerns through community groups, open houses, and site tours. Additionally, I work closely with our Operations team in the planning for stripping and rehabilitation projects, land use tax assessments, resource assessments, and special projects.

Describe a typical day on the job and how the work you do contributes to the company. Every day is different, which makes my job enjoyable. Mornings might involve meeting with contractors to plan new licenses or discuss upcoming activities. Afternoons could include meetings with neighbors to address concerns, or with consultants reviewing studies for license applications. In between, I attend various meetings on acquisitions, taxes, and lease renewals. The variety keeps each day unique and fulfilling.

What do you find most challenging in your work?

Dealing with the public can be challenging but also satisfying. Emotions play a big role, but consider myself a good listener who can generally find middle ground. Building relationships with our neighbors is crucial and something I take pride in.

What do you enjoy most?

I love developing internal stripping and rehabilitation projects with our Operations group. Transforming a depleted area into its final after-use is highly rewarding. Being able to be part of that life cycle and interim land use is very satisfying. can

show the public tangible examples of what we are doing as a company to create new habitats, or restore farmland etc. Not many industries can point to this kind of positivity with respect to land use.

How did you become interested in this work?

I have always enjoyed the outdoors and hoped for a job that would allow me to be connected with the natural environment. My job allows me to work in a big sandbox with a great bunch of people on projects that I enjoy, including most notably rehabilitation projects. The fact that we as a company rehabilitate land in such amazing ways really provides that connection in a unique way to nature that I would be hard pressed to find elsewhere.

What advice would you give a high school student unsure of the opportunities in the aggregate industry?

I would encourage them to visit an aggregate site through an open house or community event and talk to the people that work there. Learn about the industry and see if it’s the right fit for them. Our industry is the best kept secret. There is such variety and opportunity to be involved in amazing projects and tasks—the typical person wouldn’t imagine such a place to work has been near them their entire lives.

Is your current position the same as when you started in the company?

No, I started as the CBM Environmental Coordinator. Since then, I moved up to Land and Resource Supervisor and now Manager. I accredit my advancement to continued learning, being a team player and showing the company that I am a reliable employee that can achieve success with hard work. I

believe that have also shown integrity in my position, which I believe the company values greatly.

Detail your past and ongoing education and how it is relevant to your job.

I graduated from Trent University with a degree in Environmental Studies. I also attended Fleming College and graduated from the Ecosystem Management Technology program, both of which have tied in nicely with the job. University provided an understanding of environmental policy, while College gave a practical hands-on experience in resource management. Within our organization I have had the opportunity to take various courses offered to me, including, as an example, ones related to finance and conflict resolution.

If you could start over, would you change your career path?

Honestly, the answer to that would be no! For the most part, I feel I have the best job in the world. While there are challenges to be sure, I love going to work each day and wouldn’t change the path I have taken.

Tanika Greig leads safety and innovation as the Health, Safety and Environment Manager at Green Infrastructure

Tell us a bit about your job and your responsibilities.

As a Health, Safety and Environment Manager (HSE) at Green Infrastructure Partners (GIP), I help prevent workplace injuries and illnesses at our 19 pits and quarries in Ontario. My role involves providing HSE advice, developing safety plans, enforcing procedures, conducting inspections, running drills, responding to emergencies, and mentoring HSE coordinators. I also ensure compliance with regulatory standards.

Describe a typical day on the job and how the work you do contributes to the company.

I spend most of my day in the field, inspecting sites, identifying hazards, solving HSE issues, supporting staff, and training safety professionals. My work ensures everyone goes home safely, contributing significantly to GIP’s safety goals. The more incidents we can help prevent, the better.

What do you find most challenging in your work?

There are different challenges arising each day. Trying to stay ahead of the game and prevent future problems that may arise is probably the biggest challenge.

What do you enjoy most?

There are a lot of things I enjoy about working in this industry. I enjoy coaching and supporting field staff, helping them voice concerns, and mentoring new safety professionals. Seeing them grow and succeed is very rewarding. The changing view of safety at GIP, where it’s now embraced rather than hidden, is also gratifying.

How did you become interested in this work?

Being in quarries, pits and asphalt plants makes my heart sing. I really enjoy the equipment ballet as some may call it, when crushing, laying asphalt, paving in echelon or plowing in echelon, all the moving parts that have to come together safely to get the work completed. It is truly beautiful to watch.

I grew up in construction—my dad owns a construction company—and working in construction feels like home to me.

A lot of my family works in construction and in the trades, and I have seen how a workplace injury affects the injured worker, their family at home and the crew at work. wanted to be a part of preventing more people from being injured. Over 50% of men work in construction in their lifetimes, and I have two younger boys at home. It is likely that one, if not both, will work in construction and I hope construction becomes a safer place for them to work and that someone is looking out for them by the time they reach the age to work in construction.

Is your current position the same as when you started in the company?

I started as a HSE officer and advanced to HSE manager by learning from mentors, attending training, and working closely with operations to implement safety measures.

Detail your past and ongoing education and how it is relevant to your job.

I started my construction career about 10 years ago with another big aggregate company for many years, before working at a smaller company that builds parks, playgrounds and sound barrier walls, before joining GIP HSE team. I worked my way up from being a COR and driver record of training administrator, to a health and safety Manager.

I do have a degree, but it is not in health and safety, it is in Animal Biology, Microbiology and Zoology. For Health and Safety, I have over 50 different courses completed, from working at heights, first aid, incident investigating, naloxone, surface minor, air monitoring, confined space, asbestos etc.

Education is very vital for this job; legislation is changing year to year and there is so many different topics to learn about in construction

If you could start over, would you change your career path? No, I don’t think I would change my career path. All of my experiences have made me who I am today. I really enjoy my job—I find it rewarding and purposeful.

What advice would you give a high school student unsure of the opportunities in the aggregate industry?

I would give a school aged student is to work in the field—try out an entry role, a flagger, or administrator position to see if you like the industry. Look into trade schools, and different courses or degrees that can further your education. Find a mentor and someone you look up to and ask questions, ask how they got into the industry, how did they get to their position. Everyone’s path may be a little different, and that is okay.

What are some common jobs in the aggregate industry you don’t need a formal education to apply for?

Each company and site may require different minimum qualifications. Some jobs that you do not need a college or university degree may include, scale operator, truck driver, laborer, heavy equipment operator. This does not mean there isn’t training on site, or a certain license or equipment certificate isn’t required.

AERIAL PHOTOGRAPHY/SURVEYS

TEC Surveying Inc.

www.tec-survey.ca 21

AGGREGATES Ferma Aggregates Inc. 24

Hutcheson Sand & Mixes A member of The Muskoka Rock Family of Companies www.hutchesonsand.com 25

Lafarge Canada Inc. www.lafarge.ca 27

Rice Aggregates Limited www.ricegroup.ca 24

AGGREGATE CONSULTANTS Arcadis www.arcadis.com 30

AGGREGATE EQUIPMENT

ELRUS Aggregate Systems

www.elrus.com 20, 24

AGGREGATE PLANTS

R.W. Tomlinson Limited www.tomlinsongroup.com 25 Sunrock Canada www.thesunrockgroup.com 23

AGGREGATE PRODUCTS & SERVICES

Rice Aggregates Limited www.ricegroup.ca 24

AGGREGATE RESOURCES

Get Phil Inc. www.go.getphil.app 21

R.W. Tomlinson Limited www.tomlinsongroup.com 25

Southwestern Sales Corporation Limited www.southwesternsales.ca 25

Sunrock Canada www.thesunrockgroup.com 23

AGGREGATE & ROAD BUILDING EQUIPMENT HMA Equipment Company of Canada www.hmaequip.com 24

AGGREGATE WEAR PARTS

AM Cast, Inc www.amcastonline.com 40

ASPHALT PLANTS

R.W. Tomlinson Limited www.tomlinsongroup.com 25 Sunrock Canada www.thesunrockgroup.com 23

AUTOMATIC GREASING

BREAKERS, ROCK Sunrock Canada www.thesunrockgroup.com 23

CONCRETE MIXERS

R.W. Tomlinson Limited www.tomlinsongroup.com 25 Sunrock Canada www.thesunrockgroup.com 23

CONSTRUCTION EQUIPMENT Sunrock Canada www.thesunrockgroup.com 23

CONSTRUCTION MATERIALS

R.W. Tomlinson Limited www.tomlinsongroup.com 25

Rice Aggregates Limited www.ricegroup.ca 24 Sunrock Canada www.thesunrockgroup.com 23

CONSTRUCTION SOFTWARE Get Phil Inc. www.go.getphil.app 21

CONVEYORS

Assinck Limited www.assinck.com 3

CONVEYOR - ACCESSORIES Assinck Limited www.assinck.com 3

CONVEYOR - COMPONENTS Assinck Limited www.assinck.com 3

CONVEYOR - PULLEYS Assinck Limited www.assinck.com .................................. 3

CONVEYOR – REPAIRS & INSTALLATIONS Assinck Limited www.assinck.com 3

CONVEYOR – SCALES Assinck Limited www.assinck.com 3

CRUSHERS AM Cast, Inc. www.amcastonline.com 40

Frontline Machinery Ltd www.frontline-machinery.com 5 Sunrock Canada www.thesunrockgroup.com 23

Brandt Tractor Ltd. www.brandt.ca .............. Insdie front cover 2

CRUSHING Ault Industries Inc. www.ault.ca 25

CRUSHING/SCREENING Masaba Canada www.masaba.ca 15

CRUSHING & SCREENING PLANTS Powerscreen of Canada Ltd. www.powerscreencanada.com 31

CUSTOM CONVEYOR SYSTEMS Assinck Limited www.assinck.com 3

CUSTOM CRUSHING Joe Kerr Limited www.joekerrlimited.ca 24

CUSTOM CRUSHING & WASHING Sunrock Canada www.thesunrockgroup.com 23

Assinck Limited www.assinck.com 3

CUSTOM FABRICATION AND INSTALLATION Assinck Limited www.assinck.com 3

CUSTOM FABRICATION, INSTALLATION AND MOBILE WELDING Assinck Limited www.assinck.com 3

DRILLING PARTS & ACCESSORIES

Ame Drill Supply & Services Inc. www.amedrillsupply.ca 21

DRILLS Ame Drill Supply & Services Inc. www.amedrillsupply.ca 21

ECOLOGISTS

Skelton Brumwell & Associates Inc. www.skeltonbrumwell.ca 25

EQUIPMENT PRODUCTS & RENTALS

M-K Power Products M-K.com www.M-K.com 7

ENGINEERING

Skelton Brumwell & Associates Inc. www.skeltonbrumwell.ca 25

Assinck Limited www.assinck.com 3

ENVIRONMENTAL COMPLIANCE APPROVALS

Skelton Brumwell & Associates Inc. www.skeltonbrumwell.ca 25

ENVIRONMENTAL CONSULTING WSP

www.wsp.com 24

Aquatic Aeration Solutions www.aquatic-aeration-solutions.com 17

Skelton Brumwell & Associates Inc. www.skeltonbrumwell.ca 25

ENVIRONMENTAL EXPERTISE

Get Phil Inc.

www.go.getphil.app 21

Aquatic Aeration Solutions www.aquatic-aeration-solutions.com 17

ENVIRONMENTAL MANAGEMENT SYSTEMS Get Phil Inc.

www.go.getphil.app 21

EXCESS SOIL MANAGEMENT Get Phil Inc.

www.go.getphil.app 21

Rice Aggregates Limited

www.ricegroup.ca 24

FEEDERS

Assinck Limited www.assinck.com 3

FINE RECOVERY WASHING SYSTEMS

Powerscreen of Canada Ltd. www.powerscreencanada.com 31

FIRST NATIONS CONSULTANT

Skelton Brumwell & Associates Inc. www.skeltonbrumwell.ca 25

GEOGRAPHICAL INFORMATION SYSTEMS (GIS)

Skelton Brumwell & Associates Inc. www.skeltonbrumwell.ca 25

HEAVY CIVIL CONSTRUCTION

Sunrock Canada www.thesunrockgroup.com 23

INSURANCE SERVICES Cowan Insurance Group www.cowangroup.ca 24

JOBSITE INFRASTRUCTURE

Sunrock Canada www.thesunrockgroup.com 23

LICENCE APPLICATIONS

Skelton Brumwell & Associates Inc. www.skeltonbrumwell.ca 25

LOAD BROKER Get Phil Inc. www.go.getphil.app 21

MANUFACTURERS & DESIGNERS Brampton Brick Limited www.bramptonbrick.com 25

Assinck Limited www.assinck.com 3

MATERIAL HANDLING Assinck Limited www.assinck.com 3

Sunrock Canada www.thesunrockgroup.com 23

MATERIAL HANDLING & PROCESSING SYSTEMS

Assinck Limited www.assinck.com .................................. 3

Haver & Boecker Niagara https://haverniagara. com/?utm_source=OSSGA&utm_ medium=PrintLogo&utm_ campaign=Fallissue&utm_content=logo 24

MOTOR CONTROL SOLUTIONS Benshaw Canada Controls www.benshaw.com 25

MOTORS

Assinck Limited www.assinck.com .................................. 3

Haver & Boecker Niagara https://haverniagara. com/?utm_source=OSSGA&utm_ medium=PrintLogo&utm_ campaign=Fallissue&utm_content=logo 24

Sunrock Canada www.thesunrockgroup.com 23

PAVING, ASPHALT, PIPE & AGGREGATES

Green Infrastructure Partners Inc. www.gipi.com 35

PIT & QUARRY REHABILITATION Get Phil Inc. www.go.getphil.app 21

Skelton Brumwell & Associates Inc. www.skeltonbrumwell.ca 25

PORTABLE CUSTOM CRUSHING & SCREENING Assinck Limited www.assinck.com 3

Haver & Boecker Niagara https://haverniagara. com/?utm_source=OSSGA&utm_ medium=PrintLogo&utm_ campaign=Fallissue&utm_content=logo 24

The St. Mary’s Quarry operated from the mid to late 1800s until the 1930s when operations were shut down and the quarry was allowed to fill with water. During that time, limestone blocks from the quarry were used for construction on buildings in St. Mary’s (nicknamed “The Stonetown”) and surrounding towns.

In 1945, the Town purchased the property and later officially re-opened what is now known as Canada’s largest outdoor freshwater swimming pool. Today the site hosts cliff-jumping, an inflatable floating waterpark, a canteen and picnic areas. Various species of fish (Common Carp, Pumpkinseed, and Rock Bass) are also commonly found.

On July 14, 1983, OSSGA (then Aggregate Producers Association of Ontario) presented a Bronze Plaque to the Town of St. Mary’s and St. Mary’s Cement Limited to commemorate the transformation of these grounds from a quarry to an outstanding recreational area, recognizing the site as an asset to this community.