POWERFULLY BUILT

Matthew Bradford

Warren Heeley

Ashlee Zelek

Ashlee Zelek & Carly Holmstead

Kelly Parker

Sarah B. Hood

Viacore is committed to ensuring your material handling systems run efficiently and offer improvement through the various products and services we provide. Our aim is to increase productivity, grow your profitability, and decrease unscheduled downtime. Everything from solution support, site review, design, engineering and fabrication to project implementation and management is available with Viacore. We are your one-stop-shop for all your material handling needs.

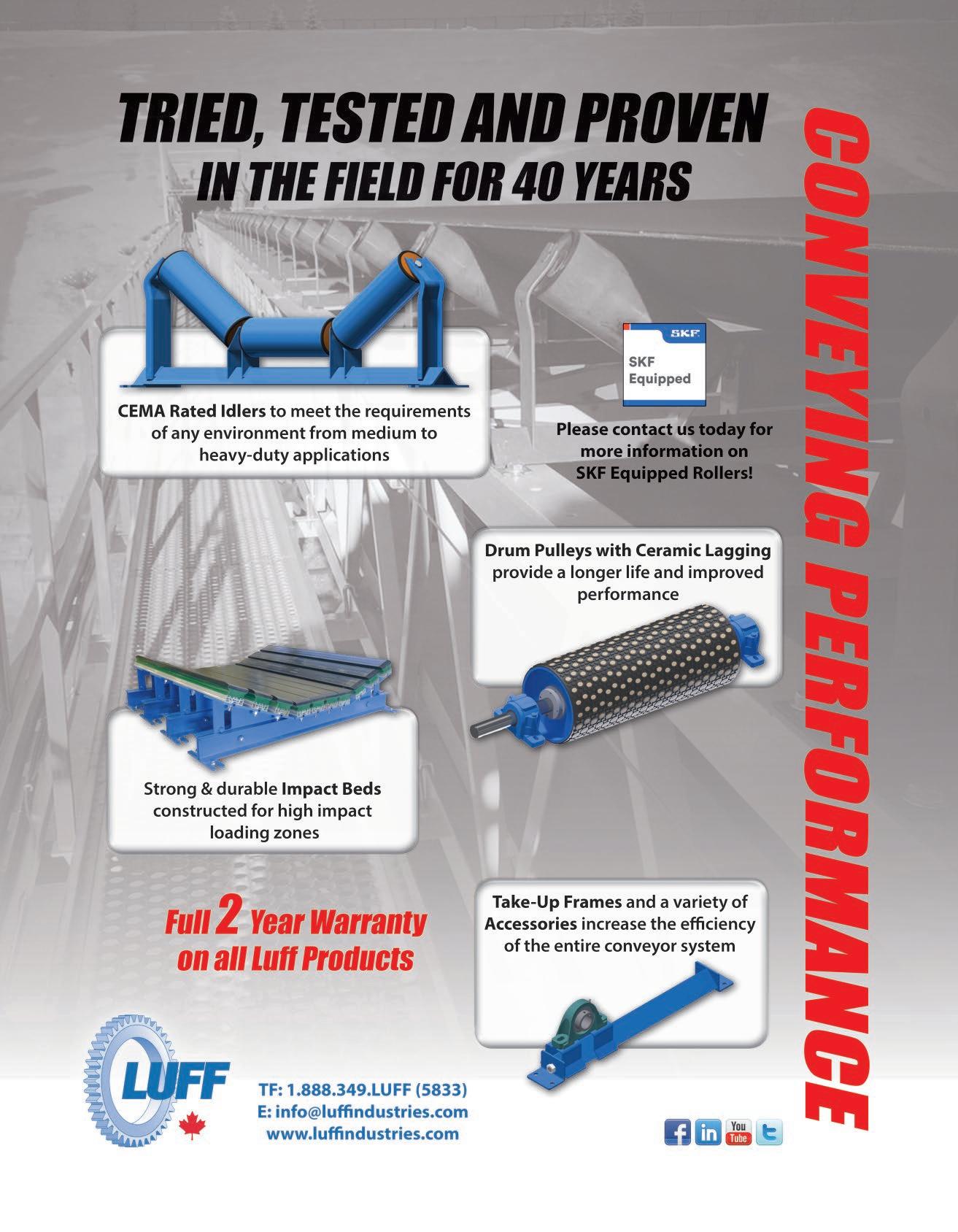

BELT SALES & SERVICE

Viacore is a leader in light to heavy duty conveyor belts. As a stocking supplier, we have the ability to provide the best planning, supervision, and quality control for all your belt installs and repairs. Utilizing a team effort from job scope review to on the site w k our skilled team has installed and replaced conveyor belts on some o most challenging conveyor systems safely and efficiently.

RUBBER MOLDING/LINING

With over 50 years of experience in the molding, lining and coatings industry, Viacore provides total wear solutions that solve problems We provide everything from hot vulcanized bonding (autoclave and environmental cures), to cold bonded applications that use a wide range of rubber compounds suited to site requirements.

Viacore provides a wide range of components for your material handling systems. Collaborating with customers, we identify issues and offer optimal solutions within budget. Viacore supports our component needs across the e system, standing firmly behind our products.

Over 50 years of experience, 6 locations in Ontario and over 30 locations across North America.

MECHANICAL SERVICES

’s mechanical services teams ocused on dealing with the mechanical oriented components of your material handling systems. Often working hand in hand with our belt technicians, a skilled team approach can be realized to enhance site repairs and changeouts, as well as larger project support.

Avenues is published for

Welcoming Mike McSweeney: OSSGA’sNew

ExecutiveDirector

From assisting Canada’s Leader of the Opposition (and future Prime Minister) to being elected as a City Councillor and Deputy Mayor of Ottawa, to serving as CEO of the Standards Council of Canada before taking on leadership positions at agri-food, environmental and construction organizations, Mike McSweeney has made a career of helping Canadian industries become more competitive and aligned with government agendas. He has also ensured that governments at all levels have a robust understanding of the industries involved.

Now, McSweeney is bringing his 40 years of public and private sector expertise to his new role as executive director of OSSGA. We recently sat down with him to learn more about his background and his vision for OSSGA moving forward.

Q: Take us through your journey to OSSGA.

I’ve been around politics/public affairs and the private sector my whole career. I entered the public sector in 1977 when I worked as a page in the House of Commons while earning my BA in Political Science and Law at Carleton University. After a few years of working with Members of Parliament, I sought election to the Ottawa City and Regional Councils, where my peers later elected me as Deputy Mayor. In addition to being on the City/Regional Council, I spent time as an executive assistant to Brian Mulroney and several cabinet ministers. After that, I was appointed CEO of the Standards Council of Canada, a Crown corporation that accredits all of the country’s standards and certification bodies while also representing Canada globally on the Board of the International Organization for Standardization (ISO).

The Ontario Stone, Sand & Gravel Association 5720 Timberlea Blvd., Suite 103 Mississauga, ON L4W 4W2

Tel: 905-507-0711 www.GravelFacts.ca

Publisher

Robert Thompson

OSSGA Editor Carly Holmstead

Editor Roma Ihnatowycz

National Sales Executives

Bill Biber, Derek de Weerdt, April Hawkes, Veronica Johnston, Dawn Stokes

Senior Design Specialist Marisa Giesbrecht

Design Specialist Bethany Giesbrecht

AVENUES is published for the Ontario Stone, Sand & Gravel Association by:

33 South Station Street Toronto, ON M9N 2B2 1-866-480-4717

Email: robertt@mediaedge.ca

531 Marion Street Winnipeg, MB R2J 0J9 1-866-201-3096

Fax: (204) 480-4420 www.mediaedgepublishing.com

President

Kevin Brown

Senior Vice President Robert Thompson

Director, Business Development

Michael Bell

Branch Manager Nancie Privé

All rights reserved. The contents of this publication may not be reproduced by any means, in whole or in part, without the prior written consent of the association.

Published February 2024

PUBLICATION MAIL AGREEMENT #40787580

Please return undeliverable items to:

The Ontario Stone, Sand &

Avenues is printed on 10% post-consumer FSC certified paper using soya based inks. When necessary to mail an issue in an enclosure, we use an environmentally-friendly, 100% oxo-degradable poly-wrap.

“Ensuring the competitiveness of Ontario’s stone, sand and gravel sector will guide all my actions as I work in this sector. Governments, stakeholders, allies and others in the construction industry must understand that the aggregate sector underpins all construction in our province”

It’s thanks to these public sector roles that I have become skilled in the art of persuading those who are outside of my direct control. These opportunities have also given me a deep understanding of how the government and its leaders work and the importance of codes, standards and specifications, which – as OSSGA members and staff well know – are very important to our industry and society.

My career has also taken me into the private sector. I worked for one of the world’s largest agri-food businesses, Archer Daniels Midland, based in the United States. After that, I returned to Canada and spent time in an environmental company that remediated contaminated soil in the mid-2000s. That was when I began developing a stronger appreciation and understanding of industry’s impact on the environment and learned how to work with governments to develop and implement marketbased solutions that reduced industry’s environmental footprint, while at the same time allowed industry to remain competitive. I carried that passion into my position as president and CEO of the Cement Association of Canada, where I served for 15 years. It also informed my subsequent role as CEO of the Ontario Road Builders Association (ORBA), where, along with the ORBA Board, we realigned, refocused, and re-branded the Association to better align ORBA’s objectives with government decision-makers and influencers.

I wasn’t sure about my next step after ORBA and whether or not I would fully retire. That’s when OSSGA and I started talking about my joining the Association and continuing my work on this side of the construction industry. It is an association I am familiar with and one in which I could be of value, so I said yes and consider it a privilege and honour to work for the members of OSSGA.

Q: What are your priorities as you settle into the role? Ensuring the competitiveness of Ontario’s stone, sand and gravel sector will guide all my actions as I work in this sector. Governments, stakeholders, allies and others in the construction industry must understand that the aggregate sector underpins all construction in our province. One aspect of our industry that is different from other sectors is we don’t have a choice of where to “set up” business; our industry establishes its sites where the raw materials are. It’s as simple as that.

In many cases, our operations are on the outskirts of communities, but communities have expanded and now we find

ourselves as close neighbours. From time-to-time, relationships become strained, but I can assure everyone that I will work tirelessly to ensure that we “sell our story” and, at the same time, listen to the concerns of our neighbours and the political leadership in those communities. It is important for the communities to understand that their homes, recreation, faith-based buildings, hospitals, roads, highways and wastewater facilities, etc., would not (and could not) exist without aggregates.

Worker health and safety is an ongoing and critical concern for our industry, so I want to ensure that OSSGA is providing the training and resources our members need to keep their employees safe – resources such as the operations health and safety seminar that we recently hosted. Every employee needs – and deserves – to get home safely at the end of the day. I want to make sure our industry uses the latest and best practices and technologies to ensure that happens.

I’m also really excited about developing relationships and working with First Nations communities. Given that our industry extracts from the land, it’s incredibly important to better understand First Nations’ issues and their concerns regarding how our members extract stone, sand and gravel. Practising reconciliation in everyday life is important to me, and I will bring that passion and those values to OSSGA members.

As such, we’ll develop a plan for members and myself to travel across the province to meet with First Nations communities, and gain their insights, perspectives and trust on extracting aggregates from Mother Earth. Recently I met with Elder Whabagoon, an Ojibway Elder whom I am getting to know better and whose counsel I’m seeking on the importance of opening our meeting with an Indigenous blessing. I started this practice last year at ORBA and look forward to continuing it at our convention. I hope I will be able to learn from her, and I’m seeking her counsel on how to build the relationships we need with Indigenous communities across Ontario. As I said, we each need to practise reconciliation on a personal level before we can achieve success provincially and nationally.

Another priority for me is to ensure the environment remains a top focus for our Association. I support Canada’s 2030 target of reducing greenhouse gas emissions by 43 per cent from 2005 levels within this decade. We also need market-based tools to help the industry meet its climate change goals. That’s why I’m committed to these goals and helping the aggregate industry understand its role in getting to net zero by 2050 and setting targets by 2030. I will

also be forging relationships with ENGOs (environmental nongovernmental organizations) so they better understand the role of aggregates in Ontario and why we need to mine aggregates close to where they are being used.

Q: What can members expect to see under your leadership?

The OSSGA team needs to offer a solid shareholder value proposition for every member, whether they’re a multinational, Ontario-wide, or entrepreneurial-led company. We need to be member centred and focused. I also aim to add value for members by drawing on my knowledge of the machinery of government and contacts within the public sector at the provincial and municipal levels of government, with municipalities, environmental groups, and First Nations leaders to remove some roadblocks and challenges that can slow the process of getting licences for new pits and quarries.

Q: How do you plan to broaden OSSGA’s network and raise its voice among Ontario decision-makers?

For an association to have success, it has to follow four simple rules when dealing with decision-makers: be a constant presence, be consistent with your practices, be coordinated with your members and allies, and have a compelling story to share. By following this ‘recipe,’ we will be well on our way to building reservoirs of goodwill with the decision-makers and influencers.

Secondly, I want to establish a solid relationship with TAPMO (Top Aggregate Producing Municipalities of Ontario) and AMO (Association of Municipalities of Ontario). I will work with AMO on a proactive basis so that they better understand our industry

and, for the first time, OSSGA will take a major sponsorship at the AMO policy meeting that takes place in August of each year.

I also look forward to launching OSSGA’s first lobby day at Queen’s Park this coming April. We plan to have 50 of our members participate in 50 meetings with elected representatives from the Premier, cabinet ministers, MPPs from government and the opposition to key civil servants. The lobby day’s goals are to broaden our audiences’ understanding of how important the aggregate industry is to Ontario. By the end of the day, we want them to know that nothing gets built in Ontario without aggregates.

In one sentence, what OSSGA needs is a greater voice for our industry and for our industry to be proactive and engaged in building broad and deep relationships with decision-makers in governments, environmental NGOs, First Nations, and allied industries in the construction sector, and ensuring that those stakeholders understand the importance of Ontario’s stone, sand and gravel industry.

OSSGA has a robust committee system, so I encourage members to participate. And if they have any questions, concerns or gripes, I want them to pick up the phone and let me know. I will be proactively reaching out to members, but I want them all to feel welcome to call me anytime to help with industry or individual member issues. That two-way communication and learning is key to what I do. While I have been in the construction industry for 17 years now, I still have a lot to learn, and we have giants in the industry from whom I want to learn.

Custom designed rod handler eliminates all hands-on contact with pipe, increasing safety & speed. No secondary unit cuts our footprint in half compared to full-size Sonic setup.

Sonic drilling has a wide variety of applications, including but not limited to:

• Environmental assessment & remediation

• Mineral & aggregates exploration

• Dam & levee investigation & rehabilitation

• Water resource profiling

• Dewatering projects

• Landfill investigations & expansions

• Geotechnical projects

• Geothermal loop installations

• Construction drilling

• Mining & tailing investigations

• Aggregate resources such as mineral sands & alluvial deposits

• Overburden core sampling

• Environmental well completions (903 Reg’s)

• Borehole Abandonment & Grouting

POWERFULLY BUILT

To meet its ambitious infrastructure goals, Ontario needs a strong and healthy aggregate industry

By Matthew Bradford

Shovels are in the ground across Ontario as work proceeds on critical infrastructure projects. Whether the goal is to improve transportation, build healthcare capacity, or relieve the housing crunch, every solution involves aggregate – or sand, stone and gravel.

“Nothing gets built without aggregate,” says Mike McSweeney, OSSGA’s executive director. “That applies to everything –transportation lines, schools, hospitals, recreational facilities, and all our public and private buildings. Stone, sand and gravel play a central role in developing all that.”

In Ontario, it is estimated that nearly 164 million tonnes of aggregate are consumed annually to keep pace with the province’s infrastructure needs. The Greater Toronto and Hamilton Area (GTHA) alone uses 73 million tonnes of that share, and the province is projected to consume another four billion tonnes of aggregate by 2041 as growth continues across the province.

“Federal and provincial governments are in an unprecedented time of investments into infrastructure, and much of that infrastructure will be built in municipalities,” McSweeney reports. “We have three levels of government commitment to a number of projects up and down Ontario, and they’re all going to be coming to the aggregate industry for materials.”

Much of that infrastructure is being built to meet the needs of a large influx of immigrants to the country. Canada is aiming to welcome half a million immigrants annually in the coming years, and many of them are expected to settle in Ontario, one of the country’s most popular destinations. In the first half of 2023, the province attracted 101,455 new permanent residents –around 38.5 per cent of the total for Canada (immigration.ca). The numbers are expected to be just as high for the second half of the year.

FOUNDATIONAL RESOURCE

There’s no overstating the importance of aggregates in building up the province’s cities and municipalities to accommodate this mass influx of new residents. Aggregates, after all, are crucial to the growth and evolution of any growing society. Indeed, as Kevin Powers, managing principal at Project Advocacy Inc., aptly states, “Building stone has been the foundation of civilized infrastructure since the time of the pharaohs, alongside a steady supply of clean water

and arable land. The same thing can be said today, where nearby stone, sand and gravel supplies are responsible for building Toronto and the GTHA.”

While they are no longer being used to craft mud brick houses, aggregate materials remain foundational for our built environment. Today, high-quality sand, stone and gravel are in increasingly in high demand across all construction sectors, particularly among residential builders working to alleviate the country’s housing crunch.

“We have a housing crisis upon us right now, and it’s telling us that we need to build a million-and-a-half new homes in the next 10 years,” says Greg Sweetnam, executive vice president of James Dick Construction Limited.

That’s a lot of houses, Sweetnam continues, and reaching this goal will require nearly 190 million tonnes of aggregate a year, not to mention the additional materials needed to build supporting residential infrastructure. “When you build a residential development, you’re not just building

Insurance for Ontario Stone, Sand and Gravel Association members since 2005

Real risk management solutions for everyday business risks

Exclusive member rates

Specialty coverage extensions

Expert advice from a dedicated team focused on your industry

Exceptional claims administration and 24/7 claims service

Other available coverages include automobile, including fleets, property, contractor’s equipment, builder’s risk, liability, umbrella liability, and pollution/environmental.

Contact us today to learn about our customized insurance programs.

programs@cowangroup.ca | Toll-free: 1-866-912-6926 cowangroup.ca/ossga

We care about what you care about.

Economic Outputs

OSSGA’s The Long Haul: Examining the Implications of Far-from-Market Aggregates is a study prepared by the Ontario Chamber of Commerce (OCC). It delves deep into Ontario’s aggregate demands and outlines the economic impacts of aggregate production on the province’s economy.

Using data from 2019, the report determined that $1.7 billion worth of total new aggregate production in Ontario generated the following estimated upstream and downstream economic outputs:

• $2.9 billion in gross output ($196 per capita)

• $1.6 billion in GDP ($107 per capita)

• $150 million in tax revenue ($10 per capita)

• $3.7 billion in gross output ($250 per capita)

• $1.8 billion in GDP ($124 per capita)

• $1 billion in labour income ($67 per capita)

• 14,000 jobs

houses; you’re building the streets, the sidewalks, the curbs, the gutters, the storm sewers, the sanitary sewers, the water mains, and the water systems that go with that, as well as any upgrades of any required wastewater treatment plants and stormwater management ponds and water filtration plants,” Sweetnam says.

SOCIAL INFRASTRUCTURE

Expansions to Ontario’s healthcare and education systems are contributing to aggregate demand. The province committed to building over 30 hospitals and 300 long-term care homes between 2016 and 2025 and earmarked $208 million between 2023-24 to support critical upgrades and repairs at 131 hospitals and 58 community healthcare facilities.

Ontario is also slated to spend $15 billion over 10 years for new school construction, with hopes of accelerating their development. In a December 2023 statement to the press, Ontario Education Minister Stephen Lecce noted: “Our government is taking new measures to ensure school boards are building schools in nearly half the amount of time it took before – cutting down the timelines by nearly 50 per cent through a transparent, accountable and clear process that prioritizes shovel-ready projects… [so] that we get schools built faster for Ontario families, and for the children of this province too.”

Ambitious plans for Ontario’s transportation infrastructure are also playing a part in straining current and future aggregate supplies. Specifically, the province is spending $25.1 billion over the next decade

to enhance the way its people and goods move. Major projects include creating Highway 413, expanding Highway 401, building the Bradford Bypass, and rehabilitating the QEW Garden City Skyway, among other key initiatives.

“Ontario is the economic engine of Canada, and we produce a lot of goods that need to be moved, and if they don’t go by rail, they go by trucks. Therefore, they need that road infrastructure,” insists McSweeney.

With these and other developments planned across Ontario’s residential, industrial and commercial sectors, one can see why aggregate producers are in high demand. With more initiatives getting the green-light each year, industry stakeholders like Sweetnam hope decision-makers recognize the importance of enabling access to high-quality aggregate materials. After all, he says, “Every time you approve development, you’re actually approving aggregate. Municipalities don’t often think about that. A lot of times they approve all this development, and aggregates are an afterthought. That leaves aggregate producers to figure out how to get the pits and quarries licensed to meet demand.”

SHRINKING SUPPLY

Aggregate has an undeniable and irreplaceable role in building Ontario. The question is if aggregate producers have what they need to keep pace. The answer, says Powers, is uncertain: “We’ve been lucky to have sources of high-quality limestone within 50 kilometres of the GTHA since its inception, but that abundance is rapidly coming to an end. More than 90 per cent of our existing limestone deposits in the GTHA have been sterilized by development, regulations or zoning, and the roads, condos and office towers that are being built right now are being supplied by quarries that were approved decades ago or nearly depleted.”

Moreover, Powers adds, the little remaining limestone in proximity to the GTHA that has not been excavated or sterilized is under threat by regulation, by NIMBY (Not In My Backyard) opposition, and other barriers: “This dwindling supply of close-to-market aggregate for a big stumbling block for the province’s transportation targets, for its housing targets, and its environmental targets.”

This issue is documented in The Long Haul: Examining the Implications of Far-from-Market Aggregates, a study commissioned by the Ontario Stone, Sand and Gravel Association (OSSGA) and prepared by the Ontario Chamber of Commerce (OCC). It raises concerns over the depletion of limestone quarries in close proximity to the GTHA. With supplies running out and fewer close-to-market operations coming online, the study predicts the region will become an “aggregate desert” within the next two years, leaving no other option than to bring in materials from over 150 kilometres away.

“The abundant supply of high-quality aggregate is rapidly coming to an end, and within the next decade, nearby supply is headed off a cliff with far-reaching implications for city building,” says Powers. “That’s largely because the number of pits and quarries data cited in the GTHA continues to drop while the population continues to climb. And if no quarries are licensed in the GTHA in the next 10 years, closeto-market supply of stone, sand and gravel will disappear.”

CLOSE-TO-MARKET

While mining activity in Ontario’s North bodes well for the province’s economy, to make good on its infrastructure plans, many believe that

closer-to-market aggregate supplies are vital. There are several reasons why mitigating the long haul of sand, stone and gravel makes sense. For one, says Powers, it is easier on the bottom line. “Transportation is the single biggest expense in aggregate production, absorbing up to 60 per cent of the cost. The farther it’s produced from the market where it’s consumed, the more expensive it becomes,” he says.

Naturally, adds McSweeney, reducing transportation requirements also has environmental benefits: “Yes, we can bring aggregate from North Bay or Parry Sound to Ontario’s waterfront, but think of how much greenhouse gas is being produced by all that transportation, not to mention the wear and tear it’s having on our roads and highways. I always say that if you believe getting your food close to home is a sustainable way of life, then you should believe in getting your construction material as close to home as well.”

There are logistical, financial and environmental advantages to supporting close-to-market aggregate production. Moreover, says Sweetnam, there is enough unlicensed rock resource in southern Ontario to supply regional developments for years to come. The key, he continues, is to convince decision makers to allow the industry to license these strategic, provincially significant resources. This often means convincing politicians and parts of the population that having a pit or quarry close to where they live is a benefit, not a disturbance.

“Pits and quarries can operate in close harmony with their communities and the environment without conflict,” explains

Sweetnam. “Look at the Town of Caledon, where we have the bulk of our operations. Despite the fact that it’s a major aggregate producer and one of the largest concentrations of aggregate sites in Canada, Caledon was just voted the ‘Happiest Community in Canada’ and residents’ property values have doubled in the last few years…. What more do you want as proof that aggregate extraction in close-tomarket locations does not have a negative impact on people?”

For now, the barriers to getting more pits and quarries online near the GTHA continue to be NIMBYism and red tape – both of which require ongoing public education and political support. Until then, there is an opportunity for recycled aggregates to help fill the supply need. “Recycled aggregates make up a small fraction of the amount of aggregate, and many municipalities have complete bans on using recycled aggregates because it is not as strong,” says Powers. “Still, recycled aggregate has a lot of basic uses and can be of help right now.”

There is no overstating the role aggregates play in building and maintaining our modern way of life. As Ontario continues to approve developments that will spur growth and accommodate its growing population, access to high-quality sand, stone and gravel materials will be essential.

As Powers observes, “If you believe in this province, and you believe that roads are the lifeblood of its economic prosperity, and that affordable housing, quality healthcare and strong education are the foundation of the Canadian dream, then you need to support the aggregate industry and its push for new quarry development.” •

TAX HEADACHE

In the face of massive tax hikes, OSSGA demands a more equitable approach to calculating taxes on aggregate sites

Land tax assessments on aggregate properties have been a problem for years – but never has the issue taken on such colossal proportions as it has today. In what can only be described as a rushed approach on the part of MPAC to revaluate all 3,200 aggregate properties in Ontario for the 2024 year, some operators have seen their taxes jump by 200 per cent – and as much as 900 per cent in at least one community.

Such crippling tax hikes stand to impact the economic health of province’s aggregate industry, with some smaller operators possibly forced to close shop. They could also significantly increase the cost of aggregate and hinder the government’s ambitious plans to dramatically increase housing stock in the coming decade.

By Warren Heeley

“The current path MPAC is following is undoubtedly going to raise aggregate costs to the customer,” explains George Lourenco, director, lands and resources at Capital Paving. “When you consider that the municipal and provincial governments are the largest aggregate industry customers, and that increases in taxes of this magnitude end up being passed to the customer, the issue has really become a circular issue.”

OSSGA’s response has been swift. Last November, we asked the province to put current MPAC revaluations on hold until a more “studied and thoughtful methodology” could be developed. OSSGA wants to see the province work together with MPAC (the Municipal Property Assessment Corporation) and industry representatives to work out a more viable assessment

methodology for aggregate sites – one that is fair and specifically suited to the industry.

SUITABLE APPROACH

To date, this type of methodology has been missing. Part of the problem is that aggregate properties cannot be assessed in the same manner as other properties using MPAC’s current value assessment method (CVA). This commonly used method involves comparing properties with similar classifications in the same region when they are sold. Finding sales of other aggregate properties in the same area as the aggregate property being assessed is clearly pretty difficult.

Earlier attempts by OSSGA and MPAC to settle on a more workable assessment method consistently came up against challenges. As the then OSSGA executive director wrote in his November letter to the Finance Ministry: “Appeals and reassessments have been going on for decades – with assessments and the resulting taxes swinging like a pendulum back and forth to one party’s advantage or the other.”

After a recent Wellington County aggregate assessment appeal case upheld a decision to establish a county per acre value rate for pits and quarries, MPAC applied a similar methodology across all aggregate sites in the province. It reassessed the sites based on local sales of all classifications of properties between five and 250 acres within a kilometre of the aggregate operation, using this approach to determine median assessment rates for each county.

The result for the aggregate industry was catastrophic, with valuations skyrocketing by as much as 1,000 per cent for some operators. Stepping back, MPAC then increased the minimum size requirement of local properties to 25 acres from five. Still, some operations saw their assessments double or triple. They were dismayed by the fact that the assessments failed to take into consideration the unique nature of their site in relation to other properties in the region.

“The historic challenge facing the industry for tax assessment is the unique aspect inherent with aggregate properties,” says James Bellaire, executive vice president, finance, and chief financial officer at Walker Aggregates. “For example, often only certain parts of our properties are being mined for aggregate at any specific time, while other areas could be rehabilitated

and/or farmed. The challenge in valuating aggregate properties for MPAC is that under the regulations, no value can be attributed to the unmined in-ground aggregate reserves in their valuation of the property. So finding sales of comparable properties excluding this component of the sales price is virtually impossible.”

Also, industry stakeholders say the MPAC process is not consistent with decisions reached by the province’s Assessment Review Board (ARB), which hears property assessment appeals. In particular, the Board had clearly stated that assessment values of aggregate sites should be compared with “like or similar properties.”

Another concern is the speed with which MPAC moved forward with its 2024 reassessments, bypassing an industry questionnaire that was sent out to aggregate operators in past years to determine land classifications. Instead, MPAC utilized drone images of sites and arbitrary land classifications. (MPAC has now agreed to re-introduce the questionnaires moving forward.)

WEAK UNDERSTANDING

OSSGA holds the general view that MPAC simply does not understand the aggregate industry and that it needs to take concrete steps to learn more about it if it is to ever conduct accurate valuations. This view is shared by the industry’s aggregate suppliers, large and small. “Many of the court appeals taken forward by aggregate producers [reveal] that MPAC really does not understand how to assess these properties,” confirms Glenn Lucas, principal of Property Tax Review Services.

What would help, adds Lucas, is to have municipalities more involved in the appeal process, but this too has been missing to date. “Until the most recent Wellington appeal, municipalities have failed to participate in any meaningful way in past appeals,” he says.

Regan Cox, president of Cox Construction, expresses similar concern over MPAC’s lack of industry insight. Combining large and small aggregate sites into one single tax bracket, for instance, is yet another misguided MPAC decision with grave consequences, especially for small operators. “MPAC’s approach to categorize large and small pits and quarries in one tax bracket is simply unfair. They should be differentiated based on size by using annual sales or licensing quota,” suggests Cox.

With the number of concerns being raised, many industry professionals feel it all comes down to MPAC’s lack of any true understanding of aggregate properties or the sector in general. What the province is facing as a result is the possibility of a financial disaster costing millions of dollars on appeals, increased aggregate costs for priority projects like housing and infrastructure, a dip in foreign investment, and the possible loss of small aggregate producers. There is a lot at stake.

To avoid this concerning scenario, OSSGA wants the province to put in place regulations that would ensure aggregate properties are taxed in a fair and responsible manner. We propose that the 2024 valuation rates be consistent with the earlier 2016 valuation rate and that inconsistencies in aggregate property classification be resolved. (The MPAC 2024 rates result in most aggregate sites being converted from a lower tax class for large site areas to the industrial tax class.)

OSSGA’s Board of Directors Executive met with Ministry of Finance officials and wrote to Minister Bethlenfalvy to express our concern and to call for a pause on the use of the recent valuation numbers in the next round of taxation. In early January, OSSGA received a letter back from the Minister indicating that, “the government is undertaking a review of the property assessment and taxation system that will focus on fairness, affordability, and business competitiveness. The review will also include exploring modernized administration tools. As part of the work on this review, the assessment and classification of gravel pits will be explored.”

This is good news, and we look forward to working with the Ministry and MPAC on a new methodology. That said, we still need to ensure that the recent valuation assessments are not used as the basis for the next round of tax invoices. OSSGA is asking members to file a Request for Reconsideration (RFR) with MPAC for each property that was reassessed as soon as possible. The deadline is March 31, 2024. Our continued work with the Ministry, and a strong response from members, will ensure the long-awaited fair property assessments the industry has been seeking. •

MINDING THE MYTHS

By Ashlee Zelek

“It’s virtually impossible to return farmland to its previous level of productivity.” Guelph MPP and leader of the Green Party of Ontario Mike Schreiner boldly declared this in March 2023 in reference to restoring former gravel pits to productive farmland.

This sentiment echoes similar assertions heard over the years from advocacy groups like Gravel Watch and Reform Gravel Mining Coalition, as well as from the Ontario Farming Association. The latter said that “once land is disturbed to extract aggregates, it is rarely rehabilitated to the level necessary to become productive agricultural land again.”

The problem with this sentiment is that it is not true, despite the reignited fervour in the “Agriculture vs Aggregate” debate across the province. This view is still being voiced notwithstanding the many

Industry stakeholders need to do a better job sharing their rehabilitation success stories

examples of gravel pits transformed into productive agricultural land, as well as sufficient resources and best management practices around agricultural rehabilitation.

For example, in the 1980s, Mackintosh and Mozuraitis conducted extensive work on sites in Southern Ontario to provide an inventory of locations rehabilitated to agriculture, evaluate the success of rehabilitation procedures, and to determine challenges. The study found that “if one uses pre-and post-extractive soil capability class as the criterion for success, 60-70 per cent of the sites studied can be considered successful in their rehabilitation programs.”

In 2013, The Ontario Aggregate Resources Corporation (TOARC) undertook a similar study and concluded that 67 per cent of surrendered sites in the study had no differences between the rehabilitated and undisturbed agricultural areas.

So why the increasing rhetoric purporting that it cannot be done? Well, while these studies tell us that complete recovery of prime agricultural production after aggregate extraction is possible, they also show that these success stories are not well documented, and more research may be needed to determine successful rehabilitation and management strategies.

This is why in the summer of 2023, guided by a steering committee comprised of members of OSSGA’s Rehabilitation Committee, the Ministry of Natural Resources and Forestry (MNRF) and the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), OSSGA undertook a study to fill in some of the gaps. It sought to document agriculture success stories and determine management strategies that increase the success rate of agricultural rehabilitation.

The study is being led by Dave Hodgson with D.B.H. Soil Services. Aggregate properties of various types and sizes across Southern Ontario were included in the study, which featured an interview process and background research review with the landowner/farmer to determine the type of operation, management, equipment, yields, fertilizer use, etc. The agricultural study also included soil sampling completed to the parameters set out by OMAFRA – looking at things like bulk density, particle size and soil fertility.

At the time of writing, field work was wrapping up and the results were not yet available, but there were already some takeaways from the initial findings:

WE NEED TO BETTER SHARE OUR SUCCESSES

In the 2023 Auditor General’s Report on the Management of Aggregate Resources, it was noted that a lack of publicly available data on the supply and demand of aggregates from MNRF may be helping to fuel claims from groups like the Reform Gravel Mining Coalition that there does not exist a shortage of high-quality aggregate reserves.

Data shows that there are an estimated 3,337 million tonnes of aggregate to meet demand for the next two decades (estimated to be 2,220 million tonnes). At first glance these numbers look promising; however, less than half of this aggregate is high-quality, which is critical for products like concrete and asphalt. Unfortunately, data related to material quality was not published, leading the Coalition to refute claims of a shortage of aggregate.

In some ways, the same can be said about rehabilitation back to agriculture. As an industry, we know that sites are being successfully rehabilitated to agriculture, but this message is not getting across. Part of the reason may be the availability and accessibility of data around agricultural rehabilitation. The more we can document this work, the easier it will be to combat the messaging claiming that it cannot be done.

This study will help, but it’s just one tool in the toolbox. Across the province, 15 per cent of aggregate sites are rehabilitated to agriculture use post-surrender, making it the most common post-rehabilitation land use of all sites. This amounts to more than 2,500 hectares of land in Southern Ontario alone and does not include does not include active sites that are progressively rehabilitating to agricultural use and may already be actively farmed.

Most members of the public may not realize that the soybean or corn field in their community may have been an aggregate pit that supplied the material to help build their community. Ongoing communication strategies by OSSGA and our members will be a critical part of telling our story.

ACKNOWLEDGE THE SUCCESSES; ADDRESS THE CHALLENGES

MNRF’s review in the 1980s found that most of the sites studied had a high level of success. TOARC’s 2013 study also found that rehabilitated agricultural sites can have a high similarity to undisturbed sites in soil characteristics, crop quality and yield. The study did identify room for improvement, however, with stoniness and slope being the two main challenges that make farming more difficult.

Soybeans being harvested from a licensed aggregate site rehabilitated to agriculture in Paris, Ontario

Initial findings from OSSGA’s study show that challenges remain around sloping/drainage and stoniness, but aggregate producers are being innovative in addressing these obstacles. These efforts include things like rock picking, contouring, using soil amendments, importing topsoil, soil testing, and planting cover crops for longer periods of time before moving to row crops. More time is being spent around developing and stabilizing the soil structure before returning to agriculture, and sites are being monitored for longer to determine long-term effectiveness.

PIT TO PRIME PARTNERSHIPS

Last year, a site in Cambridge, owned by the Edworthy family and operated by Heidelberg Materials, was awarded the 2022 OSSGA Judges’ Choice Award in Progressive Rehabilitation. An interview with John Edworthy highlighted the relationship between the farmer and aggregate operator and the importance of this partnership to achieving successful rehabilitation back to agriculture. When interviewed, the Edworthy family commented on their commitment to working with the aggregate company in rehabilitating their land and restoring it to the farmland it once was, not just for their family (who lives in that community) but for the generations to come.

OSSGA’s study survey looked not only at land management practices, it also queried landowners on when they became involved in the process and their level of involvement. We think that the results will highlight the significance of the relationship with the aggregate producer and landowner. We also believe that greater alignment of management strategies between the operator and landowner may lead to more successful rehabilitation outcomes.

The report is expected in the first quarter of 2024. We look forward to sharing the results once available. •

Drone footage from the OSSGA study showing gentle sloping of a rehabilitated aggregate site in Grey County

Corn crop on a former aggregate site in Huron County

Balancing growth and responsibility

By Ashlee Zelek and Carly Holmstead

“From highways and subway tunnels to hospitals, schools and houses, aggregates – such as sand, gravel, stone and rock – are essential for building much of Ontario’s infrastructure,” states the introduction to the Auditor General’s comprehensive 57-page Audit of the Management of Aggregate Resources.

Released in December 2023, the report not only sheds light on the vital role aggregate plays in our economy, it also raises several concerns about the management of the aggregate industry and provides suggestions for improvement.

While OSSGA supports the Auditor General in their efforts to improve the management of the industry, we think it is valuable to provide more detail around some of the report’s findings. Our objective is to continue working with the Ministry of Natural Resources and Forestry (MNRF) and communities across Ontario to create stronger programs and policies so that the long-term availability of valuable aggregate resources is protected and managed responsibly.

Following are the key findings of the report and OSSGA’s corresponding comments.

INSPECTIONS, NON-COMPLIANCE AND ENFORCEMENT

Understanding the Auditor General’s report on the MNRF’s management of the aggregate industry

Inspections are key to ensuring aggregate operators are meeting their approved operating conditions, rehabilitating their sites accordingly, and properly reporting any non-compliance issues.

The report correctly highlights the shortage of experienced aggregate inspectors, with the number increasing from 22 in 2022 to 34 in 2023. Furthermore, an additional 19 inspectors are currently undergoing training. Importantly, the context of this shortage is due to inspectors transferring to a new centralized branch of the Aggregate Section. Their valuable experience is now directed towards handling new licence applications and amendments, and reinforcing the team’s strength in that specific area. To bolster public trust, swift training and staffing initiatives are underway at the MNRF.

OSSGA and its members have raised concerns about the lack of technical and safety knowledge among inspectors within the MNRF. Some members have even offered training to help new aggregate inspectors understand the industry better.

“The lack of inspections can negatively impact the industry’s image as a whole,” explains Anne Guiot, partner and senior

planner at Skelton Brumwell and Associates. “We want communities to be able to trust the work the industry is doing to protect our neighbours and the environment, but a lack of inspections does not provide the necessary third-party assurances.”

OSSGA is pleased that MNRF is committed to hiring and training additional inspectors and understands the importance of this role.

The report also found that the fees to extract aggregates are insufficient to cover program costs. On this issue, OSSGA has advocated for the aggregate levy to go directly to supporting the Aggregates Program and enforcement and staffing.

“For years our industry has been saying the program is underfunded and understaffed,” says Guiot. “We hope that some of the recommendations and subsequent changes from this report will go into creating better implementation of the program.”

REHABILITATION

Under the Aggregate Resources Act, after extraction of a pit or quarry has ceased, the site must be rehabilitated. While the Auditor

General’s report found that many aggregate operators are properly rehabilitating their sites and returning the land to productive after-use, it also noted there are numerous sites across the province that have not been rehabilitated or surrendered. Some sites have been sitting dormant for over 25 years with no extraction taking place during that time.

There are valid reasons why a site may sit dormant, states the report. The reserves may be intended for future projects, or the specific type of material may not yet be in-demand in the market. But when sites remain dormant for long periods of time, it leaves the public questioning aggregate extraction overall as an interim land use.

For their part, OSSGA and its members pride themselves on their rehabilitation efforts and the work they do returning land to productive end uses. “If we as operators have done a good job rehabilitating the land, it may not even be recognized as a former aggregate site, which is the goal,” says Ken Zimmerman, land and asset manager at The Miller Group.

OSSGA looks forward to working with the MNRF to better understand the data, where the dormant sites are located, and what the challenges are. “Beyond the ARA requirements, rehabilitation of our sites is the right thing to do. It helps build public trust, shows that we are responsible stewards of the land, and that we do provide for the next generation,” says Zimmerman. “A focus of our industry should be to determine how we can do better to ensure more sites are being rehabilitated, and in a timely manner.”

“Beyond the ARA requirements, rehabilitation of our sites is the right thing to do. It helps build public trust, shows that we are responsible stewards of the land, and that we do provide for the next generation”

Ken Zimmerman The Miller Group

CRUSH. SCREEN. WASH. CONVEY.

• All makes parts & service, including Sandvik, Metso, JCI, and Cedarapids

• Factory trained field service personnel

• Rebuild facilities

• Fully equipped service bays

• Manganese for different makes and models

• Crusher wear parts

• Screen media

• Conveyor parts & components

SUPPLY AND DEMAND OF AGGREGATES

Another key finding of the Auditor General’s report is the lack of accurate supply and demand data, which leads community groups and stakeholders to conclude there is an oversupply of aggregates approved for extraction.

OSSGA supports accurate supply data, and the Association had already expressed concerns with the 2016 supply and demand study referenced in the report. Knowing the total quantity of material in a licensed site or in reserves across the province does not provide an accurate supply estimate – unless the quality of materials is also taken into consideration. This information was omitted in the 2016 supply and demand study.

As such, OSSGA was pleased to see the Auditor General’s report recognize that the 2016 study was inappropriately interpreted by different groups – such as the Reform Gravel Mining Coalition which claimed there was an oversupply of aggregate reserves.

As stated in the report, high quality aggregate is needed for products like concrete and asphalt, and the quality of material directly influences the structural integrity and longevity of infrastructure projects. It is in the MNRF’s best interest to communicate to the public how using high-quality material reduces the need for maintenance and replacement of infrastructure.

RECYCLED AGGREGATES

All recovered aggregate material should be reused as recycled aggregate wherever possible, so OSSGA was glad to see the report outline one of the biggest barriers to using recycled aggregate – the fact that municipal policies often prohibit or severely limit the use of recycled aggregate in construction projects.

Unfortunately, the MNRF has made little progress in encouraging the recycling of aggregate material. A significant barrier has been the lengthy and cumbersome approval process for producers looking to recycle aggregate, but this was not included in the Auditor General’s report. If the MNRF is looking to reduce barriers, they will need to work with municipalities to not only use more recycled material in municipal projects but to also make it easier for sites to import recycled material.

In 2023, the Ministry established a multi-stakeholder working group to remove such barriers. As a member of this working group, OSSGA looks forward to supporting the Ministry in removing barriers, and also in educating the public and stakeholders on the benefits of recycling aggregates.

OUTDATED POLICIES AND PROCESSES

As the Auditor General’s report points out, just over 25 per cent of active licences and permits have been scanned and digitized. As a whole, the Aggregates Policy and Procedures Manual has not been updated in 20 years and most of the databases used in the Ministry are not integrated.

OSSGA was not surprised to read in the report that outdated information systems make it difficult for MNRF staff and applicants to track submissions, or that outdated policies have caused confusion and delays in the approval process. On more than one occasion, we have heard from our members about lost Compliance Assessment Reports (CAR) after their submission to the MNRF.

Most of our members have experienced challenges related to outdated MNRF databases and polices over the years. OSSGA has worked diligently with the Ministry to provide recommendations on how the policy manual can be updated to better serve the industry and the MNRF as they issue aggregate approvals.

OSSGA members have also met with technical staff to provide feedback on how the Natural Resources Information Portal (NRIP) can meet industry needs by making it easier to submit CAR reports virtually and submit and view application details.

We hope the Ministry continues to prioritize updating the policy manual and integrating approval and compliance information into NRIP.

In conclusion, the Auditor General’s report highlights crucial challenges in the management of Ontario’s aggregate industry. OSSGA remains committed to collaborating with the MNRF to strengthen the aggregate resources program, as well as protecting and promoting the responsible management of aggregate resources within the industry. •

Love thy neighbour

By Kelly Parker

Taking a pro-active approach to developing good relations with nearby residents is essential and reaps

multiple rewards

Generally speaking, laypersons have a good grasp on the temporary inconveniences and noise involved in the expansion of housing in their neighbourhood, or in the construction of a building. But the notion of a pit or quarry nearby tends to bring out the NIMBY in people – the “Not in My Backyard” mindset.

That’s why working on good neighbour and community relations can go such a long way toward ensuring the smooth operation of an aggregate site. It’s about maintaining positive relations while simultaneously countering misconceptions, educating those who are leery, and enhancing a company’s reputation as an asset to the community.

For many, the first image that comes to mind when learning that a quarry will be operating nearby is a big, ugly hole forever replacing the present beautiful wilderness. Of course, that’s unavoidably going to be the case for a short time, but it needs to be communicated that it is just one part of an evolving process that ends with a complete site rehabilitation.

“Part of your plan for every site is your final rehab plan,” explains Cindy McCarthy, manager of transportation and compliance for Miller Aggregates. “A lot of those sites are turned back to agriculture, or become a water feature like a small lake, and might eventually be surrounded by residential homes. If we’re here for 50 or 100 years, I know it feels like a long-term use, but your children or grandchildren might be buying a house on a little Miller Lake.”

COMMUNITY ENGAGEMENT

Also important at the outset is engagement with Indigenous communities, stresses Chris Breen, vice president of government and community relations at Walker Aggregates. Breen notes that his firm will reach out and set up agreements with Indigenous groups to fund their participation. On-site, they’ll walk the land together and set up an archaeological monitoring program to determine if there is anything that is culturally significant on that land, and in turn that process may help in their efforts to trace their history.

With an eye to the future, notes Breen, “we gain a lot of help from (Indigenous)

communities with their traditional knowledge of the land, which comes in handy with quarry rehabilitation plans. At one point when the quarry is mined out, you want to return it to nature, and [you want to have] somebody who understands that land, who understands the features of the land, what grows well, what are the truly native crops, and how the wildlife likes to interact with that land. That’s an area that’s absolutely critical to not just Walker, but our industry in general.”

Neighbours rightly have concerns about how the daily operations of a quarry will affect them, both aesthetically and practically. Those reasonable issues can be addressed in a number of ways. McCarthy notes that Miller surrounds its quarries with earthen berms and tree blinds to conceal operations as much as possible. Unfortunately, however, there can be a downside to this approach. “People then get an idea that we’re trying to hide something behind our berms,” she says. “So we open the gate and invite people in to come on in to see what’s going on, and we’ll explain our processes.”

Tree Planting Day at Miller Aggregate’s Carden Quarry northeast of Brechin, Ontario

McCarthy emphasizes that an open-door policy at its quarries is key and constant. “Anytime someone wants to come in this door and have a tour of the quarry to see what we’re doing, we’ll have the operations manager and a site superintendent pop them into the truck, drive them around, and just show them what’s going on here,” she says.

Walker has a similar policy, and also hosts community gatherings on-site. “We’ll do a summer barbecue and a holiday gathering each year,” explains Breen. “These are opportunities for people to just show up at the quarry. The summer one in particular is quite popular because we’re at full operation and people can actually see quarry activities. The kids like to come and touch the truck and all that kind of stuff, and then we’ll do a barbecue lunch. It’s a good opportunity for people to be able to ask any questions very informally, and to give any feedback that they want.”

Breen says those events are supplemented by regular newsletters and other targeted communication, both through direct mail and occasional advertising in local media when there’s anything new happening at the quarry.

The robust communication can also help to illustrate how local aggregate operations can benefit the community. “Sometimes people forget or underestimate the importance of having a local aggregate source close to construction sites,” notes Breen, adding that a local quarry can point out the advantages of close-to-market

JGS100

aggregate versus trucking it in from a distance. “They sort of say, ‘Yeah, I get it.’ We don’t need higher costs of anything these days and we all need to do a better job with taking care of the environment.”

McCarthy is adamant that any aggregate firm going into a new community should make setting up a public engagement committee their first priority. “That’s really going to give you traction because you make yourself transparent and it gives you a conduit to the community,” she says. “People who are concerned can talk to that committee, and I think it really makes a difference.”

“Our neighbours understand the importance of quarries for building housing, schools, hospitals and roads,” adds Breen. “They also understand that having a quarry in their neighbourhood means that they are making an extra contribution, that they’re really stepping up with their neighbourhood to help build our communities. It’s critical for us then to be in touch with them proactively all the time, to keep the lines of communication open and support initiatives that are important to them.”

DAY-TO-DAY OPERATION

Regarding the day-to-day operation of the quarry itself, and any inconvenience it may cause neighbours, dust mitigation tends to be a priority. Miller recently purchased a piece of equipment that atomizes mist to capture and drop dust. It also employs a full-time employee whose only job is to drive a water truck around the quarry and up and down the road outside the gate to suppress dust. Miller also spreads a layer of calcium chloride a couple of times a year for the same reason.

Many, if not all facilities have extensive traffic studies attached to them as part of the licensing process, because this too can have an impact on nearby residents. “Those [studies] make sure that we pick the best route to support the heavy trucks that are coming in and out of a quarry,” says Breen. “That includes traffic rules and a lot of signage to remind the drivers what those rules are. We have a 25-kmper-hour limit inside our quarries to keep things safe and to keep dust down. We also employ retired police to help us enforce and monitor safety to make sure that the roads leading in and out of the quarry are safe for everybody in the community.”

The same berms that improve the view for quarry neighbours also help with noise, directing it upward instead of outward. Walker also puts rubber linings in its equipment to soften the noise when rock gets dropped into big containers on the back of trucks. It covers a lot of its stationary equipment and installs insulation inside to dampen the sound.

“Another thing that we do,” says Breen, “is when we have to blast, we only do that at midday, so no one’s in bed asleep, or at night when they’re home trying to have their dinner. We do it at midday because that seems to be the best time for folks and has the least impact on their day. Some people also like to get a phone call or a text before a blast just to remind them it’s going to happen, which we’ll do.” Walker also foregoes blasting on windy days to control dust.

Walker Aggregates team members helping out at a Habitat for Humanity build in Niagara

GIVING BACK

As with any business – but particularly in an aggregate operation that might experience more community resistance – community involvement is of paramount importance, and both Miller and Walker try to lead in that arena. They financially support community activities, sports leagues and charities, and they get their boots on the ground in the community whenever possible.

Miller sponsors a local soccer team every year with the Miller name on the players’ uniform, and it is front and centre at an event the league holds each season for sponsors. “One of the ladies here at the office made up a table,” details McCarthy, “took some of our products there to show, had a few little contests and a few little activities, and we just made sure we were there.”

Prior to the pandemic, the local historical society would hold a big annual event; Miller was present there as well. “We’d bring the old Miller truck and have a couple of people there to talk about it to show it off,” says McCarthy. “It’s that next step-up to engagement, as opposed to just financially supporting these things.”

McCarthy points to a recent tree planting day as another example of Miller’s efforts in the community. “I think we did about 300 [trees] that day,” she recalls. “These opportunities show that we are doing the right thing for the environment. Bringing out the community to help and be with us made it a good day.”

Walker Aggregates too is heavily involved in community initiatives and charities. “Habitat for Humanity is a big one for us, so we donate both employee time and building materials,” notes Breen. “I think we worked on six different builds in Niagara, Grey and Bruce counties in 2023, and that was done by allowing employees time to go and actually do the construction, and also through donations of aggregate and other related materials to the projects.”

The company gives every employee two paid days off a year to volunteer in the community, in whatever way appeals to them. Giving them this flexibility lets every Walker employee consider how best they can help and interact with the people living in region. “They can do pretty much whatever they want. That’s good because it gets the ball rolling, gets people focused, gets people thinking about where they want to do their volunteerism, and many of the employees then end up offering more of their own time to that organization,” Breen says.

By engaging in all of these efforts, stresses Breen, “these folks become our best advocates. Nothing says that we’re doing a good job with what we’re doing like a happy neighbour. We can say what we want, as much as we want, but when a happy neighbour is expressing that, it’s a really good indication for us that we’re doing the right thing.”

Perhaps trumping the desire to be a good neighbour and responsible corporate citizen is the fact that the people who work at the quarries are often community members themselves. “We’re neighbours. We’re people who’ve been born and raised here, too,” says McCarthy. “We’re just trying to make a living and do it in the most professional, most environmentally friendly way that we can, because we care about this stuff too, just like they do.” •

The annual community barbecue held at Walker Aggregates’ Duntroon Quarry

Miller Aggregates regularly sponsors local sports teams

Minnows & memories

CBM Aggregates’ McMillan Pond hosts kids and cops for an unforgettable day of fishing

By Sarah B. Hood

Do you remember catching your very first fish? If you grew up in Ontario, with its wealth of unspoiled freshwater lakes and rivers, chances are you’ve never forgotten the excitement of that tug on the line and the thrill of pulling a sparkling silver fish out of the water.

In 2023, CBM Aggregates hosted a Kids & Cops event that gave a group of children that same wonderful opportunity. The event paired children who might otherwise never experience fishing with police officers in a fun day at the rehabilitated McMillan Pond near Aberfoyle. The experience was made possible by the Fishing Forever Foundation, which supports the program whose aim is to open minds and build bridges.

“The McMillan site is a restored gravel pit in the Township of Puslinch, 15 or 20 minutes south of Guelph,” says Steve May, lands manager for CBM Aggregates. “It operated as a tip for approximately 10 years and was restored to a natural condition starting in 2002.” Naturalization contouring on the property, which is just under 100 acres, with a 65-acre lake, was completed in 2007. “At that particular area there’s very high-quality aggregate material located below the water table,” says May.

Once extraction was complete, the lake on the site was clean and clear but utterly bereft of life. After May joined the company about five years ago, new technology with floating raceways allowed CBM to put a controlled amount of nutrient into the pond. Essentially, May says, the system works via a network of docks that enclose the fish with screens on both sides. “Water is fed through on an airlift system and there’s an airstone, like what you would have in an aquarium system.”

Rainbow trout are the focal species, but CBM also stocks bluegills, which are a sunfish-type species, and some native minnows, and they have all flourished in the lake. Besides fish species, the pond has attracted numerous birds, including a pair of bald eagles, blue herons, common terns, diving ducks, osprey and a family of loons. In addition, the pond hosts turtles, frogs, salamanders and crayfish that have migrated on their own from the surrounding area. The dissolved fish waste used to encourage the rehabilitation process in the lake was sourced from Izumi Aquaculture, Inc., which also opened a fish production facility on the property.

The company’s president, Wayne Izumi, founded the Kids & Cops program with his brother Bob, who is well known as a professional angler and long-time host of Bob Izumi’s Real Fishing Show. “My brother and I started the Fishing Forever Foundation over 25 years ago, and for at least 20 years we’ve supported a Kids & Cops program,” Wayne says. “We wanted to put some of our money back into supporting fishing.”

CREATING CONNECTION

Multiple Kids & Cops events take place in different locations each year. “In our peak years, before COVID, we had up to 80 events a year –mainly in Ontario, but also in Saskatchewan,” says Izumi. The program was designed to create a community connection between youth and local law enforcement. All the equipment is normally provided to the young participants, and they receive some basic instruction in fishing techniques.

Holding the event at McMillan Pond was a natural idea because Izumi Aquaculture already had a presence there. “We produce steelhead trout for market consumption, and we are also vertically

integrated from egg to plate, so we also have a hatchery,” Izumi says. “We go right from eggs to fingerlings to mature fish for market. We have stocking programs; we sell fish for stocking private ponds.”

The event paired Guelph Police Service officers with youth from the Brant Avenue Neighbourhood Group. It was not the first time Guelph Police were involved. “We’ve been doing this since 2012,” says Inspector David Doxey, who works with the Neighbourhood Services Division of the Guelph Police Service. “It had always been a hobby of mine, and still is. I always enjoyed it. We work with kids who wouldn’t normally have the opportunity to enjoy a day of fishing. We always reach out to the youth centres or the neighbourhood groups that work with children.”

Besides simply creating an enjoyable day for all involved, pairing police officers with neighbourhood children has many added benefits for both the participants and their community. “All the studies say that fishing is one of the best activities for a kid because it’s one of the few activities where a kid can outperform an adult,” Doxey says. “Some of the kids who come out to that event can really use that. The expression on their faces and that sense of achievement make the entire event worthwhile.”

In addition, connecting with police in a relaxed and happy way may be something that stays with a child for a long time afterwards,

potentially bringing about positive changes for them, their families and the broader community. “It’s an event where cops and kids can bond together and just create a good relationship,” says Doxey. “This year we reached out to the Brant Avenue Neighbourhood Group. We had about 20 youth, and their parents came with them. Having that opportunity to mentor them allows the police service to increase that commitment to enhancing the quality of life while contributing to the positive growth of the community.”

NEW EXPERIENCES

It’s especially impactful, adds Izumi, for new Canadians. “This is increasingly important for new immigrants because many have had no exposure to sport fishing and some of them are coming from cultures where the sight of someone in uniform is a scary thing,” he says. “The reward is the smiles we see on their faces and the pride in being able to enhance the quality of their life.” Then there’s the fun of the sport. “At McMillan I think 80 per cent of them caught their very first fish, while 100 per cent of them caught fish,” Izumi says.

“I think every one of them caught at least a dozen fish,” adds May. “The bluegills were very accommodating. We fed them hamburgers and sausages, and it was about as good a day as you could get –sunny with a light breeze and about 20 degrees. It was a perfect day all around.”

Children and police officers enjoying a day of fishing at CBM Aggregates’ McMillan Pond near Aberfoyle

“It was really interesting to see young girls from Syria,” continues May. “I can’t imagine the changes they’ve experienced. To be out there and to see the smiles on their faces when they’re in a pretty environment and catching the fish, and then to have the stars align, to have the fish cooperating – the fishing was something that even very experienced fishermen would have appreciated.”

The police officers who helped out were keen anglers and they were very helpful, but the event would not have been possible without CBM Aggregates having successfully rehabilitated the pond and surrounding land. The work and effort to make this possible was appreciated by all involved. “It’s really nice to see a corporate partner

taking the steps to rehabilitate and populate a piece of land as they have, restoring it to a productive part of the ecosystem,” May says. “[It shows a] commitment to the community and a commitment to the environment.”

For CBM, it proved an excellent opportunity to showcase the immense possibilities that exist with the successful rehabilitation of a former pit or quarry, while simultaneously doing something good for young people who might otherwise never have the opportunity to learn to fish. “It really helps with our business sustainability, and we like to support local communities and local initiatives,” says May, adding that CBM is already planning to repeat the event in 2024. •

Many new immigrants took part in the Kids & Cops event at McMillan Pond - for most it was their first time fishing

Turning a vision INTO REALITY

CDE commissions its largest C&D waste plant in Canada for Calgary Aggregate Recycling

In recent months, concrete, asphalt and aggregate recycling firm Calgary Aggregate Recycling Inc. unveiled a new 250 tons per hour (tph) washing solution. Designed and engineered by CDE, the construction and demolition (C&D) waste plant is at the forefront of an industry that is adapting at pace and innovating sustainable means for managing resources.

Calgary Aggregate Recycling president Travis Powell says the aim of the plant is to disrupt “out-of-date practices” in the construction industry: “We set out to establish economical and viable solutions to position Alberta as a leader in sustainable and responsible construction.”

Helping to turn that vision into reality are washing experts CDE. The company’s business development manager Adrian Convery believes the Calgary Aggregate Recycling plant puts forward a strong case for the adoption of recycled materials. “The partnership is pioneering better ways of managing resources in Canada,” he explains.

Convery says the partnership highlights the “immense potential of C&D waste streams,” and the numbers are undeniable. Fuelled by CDE’s washing technology, Calgary Aggregate Recycling has almost doubled its processing capacity, increasing throughput at its recycling facility by 600,000 tons of waste. It now produces more than 1.25 million tons of construction sand and aggregate products every year.

The circular approach to resource management is also helping to reduce carbon emissions in Alberta by an anticipated 22,567 tons annually. “As well as landfill diversion, our solutions help to realize sustainability aims by reducing, or completely eliminating, the requirement to truck in sand and aggregate resources from other jurisdictions – an approach that generally comes at a significant environmental cost,” says Convery.

Commissioned with the backing of Emissions Reduction Alberta (ERA), the plant is supporting communities in the Calgary and Alberta areas to achieve their business and environmental goals.

“We have been very busy… and have received tremendous feedback,” Powell says. “We are strongly positioned to make significant strides forward in our mission to reduce the cost of construction – socially, environmentally and economically.”

Processing up to 250tph of raw feed material, the CDE solution is transforming C&D waste into a high-value suite of construction products, helping Calgary Aggregate Recycling to grow its business sustainably by boosting revenue while simultaneously addressing C&D and the waste burden.

Among the products being produced are 0-1mm fine and 0-4mm coarse sands as well as 4-10mm undersize, 10-20mm midsize, plus 20-40mm, 40-100mm and >100mm oversize aggregates.

Sold to the construction industry in the Calgary and Alberta areas, these products are actively supporting a range of major public works and infrastructure schemes, including a significant project with the City of Calgary. •

Investing in a better future

As president and CEO of Arro Crushing, Jared Kuepfer loves playing the long game

Q: Tell us a bit about your job and your responsibilities.

As the president and CEO of Arro Crushing Ltd., my job is to think and create a plan for our company’s future. Currently, I ensure our crews maintain profitability by having the correct people and equipment within reach. I create and manage systems to ensure our work is completed efficiently, safely and quickly, while maintaining the highest level of quality. I make sure we have a full schedule of work ahead of use. I spend a fair bit of time building industry relations to continue the growth of Arro along with bettering the industry.

Q: Describe your typical day on the job and how the work you do contributes to the company.

I like to spend my morning behind the computer, reviewing the past day’s reports and looking ahead to any issues that might affect our customer or the team. From there I try to visit a job site most days or meet with a client/vendor. The work I do daily is an investment into the future of Arro by building a better structure for the future.

Q: What do you find most challenging in your work?

One of the most challenging aspects is leading people and ensuring they have the knowledge needed to operate safely and effectively. Along with managing a fleet of equipment that likes to break down, throwing a wrench in the gears!

Q: What do you enjoy the most?

I love seeing people grow in our business, becoming strong leaders in their team and having their eyes opened to what this wonderful industry has to offer.

Q: How did you become interested in this work?

I grew up exposed to quarry operations and always loved the big machinery. I wanted to be an operator, so I joined an excavating company, but I missed the production aspect of a pit operation. I noticed a need for a concrete crushing contractor in my area and jumped on the opportunity to fill that need.

Education and advancement

Q: Is your current position the same as when you started in this company?

When I started the business with my business partners at the time, I was on the ground every day making the production happen as a foreman. Going from a foreman to a business operator was a big transition. One of the best things I have found to help further my career has been reading a lot of books on leadership. I highly recommend reading 10 pages a day; a lot can be learned, and it can be life changing both in your career and in your personal life.

Q: Detail your past or ongoing education and how it is relevant to your job.