Gary White: New president takes the reins of SAE-A Kevin Yardley: On VinFast, GM and understanding cultures Engineers’ Assessment: SAE-A accredited to assess engineers SAE-A AGM: Another successful year VEHICLE TECHNOLOGY ENGINEER September 2023 Issue 37 Representing mobility engineers since 1927 www.saea.com.au FSAE returns to a Revitalised Calder Park Formula SAE at Calder for 2023

VTE | Contents VTE | 3 www.saea.com.au 23 SAE-A was founded in 1927 to address the need for further education for all facets surrounding Automotive Engineering, and now encompasses all mobility engineering industries in the Australasian region. The SAE-A is a non-profit organisation that works to serve the needs of its members and to promote the relevance of mobility related technologies to governments, industry and the community in general. About the SAE-A 20 2023 Annual General Meeting Here and gone, VinFast Contents September 2023 Special Features 7 FSAE Calder – FSAE returns to a revitalised Calder Park 20 AGM 2023 – New board and President 23 Vinfast – Here and gone, very fast VTE News 10 General News 12 Truck & Bus News 14 Defence & Aero News 16 Automotive News 17 Overseas News Society News 4 Notes from the Chair - Welcome from Gary White 5 SAE-A News Technical Feature 27 Technical – Building an Autonomous Drive System for an Electric Shuttle Bus The editor, publisher, printer, the Society of Automotive Engineers – Australasia (SAE-A) and their employees, directors, servants, agents and associated or related entities (Publishing Entities) are not responsible for the accuracy or correctness of the text, pictures or other material comprising the contributions and advertisements contained in this publication or for the consequences of any use made of the products, services and other information referred to in this publication. The Publishing Entities expressly disclaim all liability of whatsoever nature for any consequences arising from the use or reliance on material contained in this publication whether caused to a reader of this publication or otherwise. The views expressed in this publication do not necessarily reflect the views of the Publishing Entities. The responsibility for the accuracy or correctness of information and other material is that of the individual contributors and the Publishing Entities do not accept responsibility for the accuracy or correctness of information or other material supplied by others. To the extent permissible by law, the Publishing Entities exclude all liability pursuant to the Competition and Consumer Act 2010 (Cth) or other applicable laws arising from statute or common law. Readers should make their own inquiries prior to the use of, or reliance on, any information or other material contained in this publication, and where necessary seek professional advice. All rights reserved. Reproduction in whole or part without the written permission of SAE-A is strictly prohibited. 16 Rose celebrates 40 years with the SAE-A AIC offers test facility for ADR98/00 braking SEA trucks with expanded SEA-DAS systems 13 6 FSAE returns to its roots –at a revitalised Calder Park About the cover

VTE Published By:

Society of Automotive Engineers - Australasia

ABN: 95 004 248 604

Address:

VACC House

650 Victoria Street, North Melbourne VIC 3051

Phone: 0403 267 166

Email: info@sae-a.com.au

Web: www.saea.com.au

Membership & Subscriptions

Rose De Amicis

Email: rose@sae-a.com.au

Events

Suzanne Nicol

Email: events@sae-a.com.au

Board of Directors:

Adrian Feeney – CEO

Gary White – President

Greg Shoemark – Vice President

Mohammad Fard – Technical Director

Noi Vera (Kotev) – Dir Events/Training

Paul Nation – Director Treasurer

Marth Oplopiadis – Director Membership

Bernie Rolfe – FISITA & SAE Liaison

James Soo – Autonomous/EV Vehicles

Richard Taube – Board Director

Michael Waghorne – Dir Truck & Bus

Magazine Production: Editor

Mandy Parry-Jones

Trading Terms Media

Email: mandypj@optusnet.com.au

Mobile: 0409 806 986

Design

Brigid Fraser

Email: fraseram@optusnet.com.au

Mobile: 0413 009 122

Advertising

Jill Johnson

Jill Johnson Media

Email: jj@jilljohnsonmedia.com.au

Mobile: 0409 217 624

VTE Industry

Partner: Excellerate Australia

Gary White President

Society of Automotive Engineers – Australasia

I am honoured to take up the role of Chairman and President of SAE-A, and I hope to contribute to the Society with as much enthusiasm as my predecessor Adrian Feeney. I am so pleased that Adrian continues as a director, CEO and leader of the Formula SAE program. Our Board Committee Chairs and all our members join in thanking Adrian for his wise leadership of more than a decade of service as President.

Adrian has been awarded Life membership of SAE-A at our AGM in June. This award is recognition of his significant contribution to the Society, its activities, and to the automotive industry.

I also warmly welcome our incoming new Board directors each also with important roles in the organisation. Paul Nation (as Treasurer), Noi Vera (Site tours and FSAE-A) and Martha Oplopiadis (Membership and Diversity). Their passion for automotive and their skillsets help them slot right into the team.

I note that Australian EV sales are accelerating, as consumers become more aware of the tangible benefits of EV ownership. Private owners can access EV purchase rebates, while companies and employees can benefit from the EV FBT exemption in salary packaging. I am seeing electricity suppliers offering very attractive plans tuned for EV owners who have in-home chargers. This all bodes well for continuing EV sales growth, now greater than expected by the more optimistic modellers of market growth. And good news, Australian EV manufacture is happening, beginning in the light to medium truck categories, and conversions. Those members who have attended our EV conversion seminars in WA and NSW got a glimpse of this

growing business model. Keep an eye out for a Victorian seminar in the coming months.

SAE-A is taking action in providing informative events that cover the EV phenomenon, but also many other aspects of automotive engineering that our members need to stay current. SAE-A has a full calendar of site visits, seminars, webinars and workshops the will excite members from all areas of the mobility industry. Please look at Suzanne’s announcements in this issue, and get yourself along to your favourites.

Please note that Rose is happy to receive your membership renewal payments, to keep you financially current, and giving you access to discounted member rates for all our events.

Professional Engineers Registration Schemes have been launched by various state governments, and we can announce that Society of Automotive Engineers – Australasia has been approved as an assessment entity for the Victorian Professional Engineers Registration Scheme (PERS). You can now contact SAE-A for assessment and registration for Victoria as a professional engineer. You have until December to begin your registration process so professional engineers can continue to offer services in Victoria, and similar requirements are in force for other states. I encourage you to read the article from Greg Shoemark, and act early to ensure no disruption to your business.

And don’t forget! Our annual Formula SAE-A event for 2023 is on at Calder Raceway! We have over 40 entrants, ICE, EV and novel automated vehicles. Visitors are most welcome on certain days, so please contact Suzanne or Rose for details.

I hope you enjoy this issue of VTE.

Introduction | Secretary, CEO and Chairman Society of Automotive Engineers 4 | September 2023

Adrian Feeney Life Member of the SAE-A

The Society of Automotive Engineers – Australasia (SAE-A) has conferred honorary life membership on its long-serving chairman and voluntary CEO, Adrian Feeney.

The honour was presented at the society’s annual general meeting in Melbourne for his conspicuous contributions to the society. In presenting the award, SAE-A Senior Vice-President Greg Shoemark, said Adrian Feeney’s contributions to SAE-A were greater than most members could imagine.

From 2001 to today he has been deeply involved in organising the Formula SAE-A university motorsport event, and he has twice served as president of SAE-A.

After serving from 2013 to 2016, he was part of the team that led SAE-A out of voluntary administration, and he returned as president from 2017 until his retirement due later this year.

Since 2017 he has also served as voluntary CEO and has made good on his stated objective of “rebuilding the society and ensuring it remains relevant into the future”.

Mr Shoemark said Adrian had shown a lifelong commitment to furthering the profession of mobility engineering which had formed the foundation of his working life.

“Adrian embodies an inspiring enthusiasm and relentless dedication that set an example for all of us involved in the running of SAE-A,” he said.

“In his 21 years in the Formula SAE-A organising team, he has seen it grow in importance and transform into a showcase of the latest EV and autonomous vehicle technology.

New board members

Three new board members have joined the SAE-A board for 2023.

Paul Nation is a serving Army Officer with accumulated experience as a military vehicle technician, maintenance manager, trainer and automotive engineer across multiple locations and roles in Australia, Asia, the Middle East and the United States. Lt Col Nation holds a Bachelor of Engineering in Automotive Engineering from RMIT University, a Master of Science and a PhD from the University of Maryland, USA. Separate from his military career, he has established several engineering consultancy businesses in the Northern Territory offering specialist advice and services to government stakeholders, and various industries.

He is a Certified Practising Engineer, a Member of Engineers Australia and the Institute of Automotive Engineers, and a member of the Standards Australia QR-005 Dependability Committee.

“He brought the same commitment to last year’s APAC21 engineering conference – it was Adrian more than anyone who refused to be defeated by Covid and led us to a great success.

“SAE-A is truly fortunate to have had such a leader in recent years, and I am happy to report that Adrian will remain at the head of Formula SAE-A.”

Adrian Feeney started his career at General Motors Holden in 1976 in the Future Model Engineering Department and held numerous management roles including proving ground manager and engineering program manager before taking early retirement in 2013.

Martha Oplopiadis is an electrical engineer, with a major in Electronics and Data Communications, and is a global leader with experience operating at senior levels developing strategies to drive project outcomes in a complex stakeholder environment.

Ms Oplopiadis’ career spans 26 years within the automotive and rail infrastructure industries through roles she has held with major projects in engineering, project delivery and business readiness.

She has worked at Alstom, General Motors-Holden, Ford Motor Company and is currently program manager –commercial and project controls with Metro Trains Melbourne on the Metro Tunnel Project.

Noi Vera (nee Kotev) is a mechanical engineer with a passion for vehicles and academic excellence, who received four scholarships for her academic performance, fuelling her drive to seek as much hands-on knowledge as possible. Ms Vera completed four internships, including one based in China and one with SAE-A working on the zero emissions emergency vehicles project, aligning perfectly with her interest in the future of automotive.

She was active in Formula SAE-A during her university years, and also presented a paper on the use of Augmented and Virtual Reality in engineering at the APAC21 conference hosted by SAE-A last year. She is currently working as a graduate mechanical engineer at Supacat.

SAE | News VTE | 5

Gary White our new president

The SAE-A elected Gary White as its president, taking over from Adrian Feeney in a unanimous vote by the board.

Dr Gary White is a Chartered Professional Engineer, a Fellow of Engineers Australia, and member of the Australian Institute of Company Directors.

He has held engineering and leadership roles at GM-Holden and Kenworth Trucks, and worked in R&D with Scalzo Automotive Research Ltd, AutoCRC Ltd and Excellerate Australia Ltd.

Mr White has a passion for vehicle electrification, automation and infrastructure, he helped establish multiple Australian cooperative research centres and their R&D programs, worth more than $240 million.

He has overseen the scholarship funding of more than 120 post-graduate researchers and is a advocate for delivery of industryready graduates.

Mr White has served on Swinburne’s Mechanical Engineering Course Advisory Committee for 16 years.

Rose celebrates 40 years with SAE-A

As the SAE-A is nearing its centennial the society celebrated its longest serving member, Rose de Amicis who has been working with the SAE for 40 years.

Rose started at the age of 18 and was the SAE-A’s second employee. She has remained loyal to the society and its members ever since.

During August SAE-A past presidents, CEOs and work colleagues met in Melbourne to celebrate the occasion and thank Rose for her many years of work with the SAE-A.

The lunch was a surprise for Rose and her joy at being recognised for her tireless work was evident.

Over the 40 years, Rose has worked with 17 presidents and 14 CEOs including Don Clarke, Phil Bourke, Angela Krepcik and current CEO Adrian Feeney.

It is difficult to imagine the SAE-A without Rose in the office and even more difficult to manage even everyday tasks without her help.

Forty years of service means that Rose has covered a myriad of jobs and responsibilities and has met and come to know so many members over those years.

In the early days it was Rose who was responsible for all manual data entry and

Engineer assessments to be conducted by SAE-A

The SAE-A has been approved by the Business Licensing Authority (BLA) to conduct an assessment scheme in the area of mechanical engineering.

Mechanical engineers in Victoria are required to be registered by 1 December 2023.

SAE-A president Dr Gary White said the society expected applicants to come from the broad range of mobility engineering disciplines it represented.

“In addition to automotive engineers, we expect to look after applications from engineers in the aviation, rail, defence and other mechanical engineering sectors,” he said.

“Registration is required for professional engineers based in Victoria, regardless of where their clients are located, and engineers anywhere in Australia whose clients are in Victoria.

“There are exemptions, such as when an engineer is supervised by a registered engineer, and we can assist applicants in determining their obligations as well as their eligibility.”

Full details of the SAE-A PERS assessment scheme, including an online application form, are available at https://www.saea.com.au/pers.

billing, mailing the magazine and maintaining all the society’s records as hard copy files, on top of looking after the SAE-A reception desk and organising all the society’s meetings and training classes.

Harry Watson, who was president of the SAE-A from 2002-2006, did the honours and presented Rose with flowers and a ruby necklace to commemorate the occasion.

In his speech he detailed some of the work

that Rose has done, always behind the scenes, to advance the society; from manually recording and looking after records in the ‘old’ days before computers to managing students participating in Formula SAE, to organising meetings and reception.

There is very little work of which Rose has not been an integral part.

As Harry Watson remarked, Rose was and is the hub of the SAE-A.

News | SAE 6 | September 2023

Formula SAE 2023 Returns to Calder Park

13-17 December 2023

After many discussions with Winton Raceway, it was untenable for the SAE-A to conduct the 2023 Formula SAE event at that facility, which was unfortunate but unavoidable.

Mid-August Winton organisers advised the SAE-A that they needed to change the date of the event from 6-10 December to 13-17 December. This was less than ideal for the SAE-A, but the change was accommodated and promoted to teams.

However, later that month Winton advised the SAE-A that the cost of the event had risen significantly and negotiations to come to a more affordable cost were not fruitful. It was not feasible for the SAE-A to continue to hold the event at the Benalla, Victoria facility.

Calder Park revitalised

Years ago, the SAE-A held the FSAE events at Calder Park, which had many benefits but also some downsides as the track and facilities were becoming very rundown and at that stage there was no indication that the facility would be upgraded. This has all changed. Calder Park is the phoenix rising as it is being transformed and given a new lease of life by owners Rodney and Kim Jane under the direction of circuit manager Rowan Harman. The first phase of the regeneration has already occurred with a better surface on the main track, new seating, signage, painting, new undercover areas, with more upgrades to come.

Regular race meetings have now been held on the repaved surface, which is overlooked by a modern spectator area, featuring a significant quantity of new seating. The facility has

been developed to the standard required by Motorsports Australia (nee CAMS).

The management of Calder Park has shown itself to be very open to making improvements both short term for this year’s FSAE, as well as in the long term, which is very encouraging for our event.

Conveniently located on the outskirts of Melbourne

Based northwest of Melbourne, a quick trip of less than 20 kilometres or half an hour from Tullamarine airport and just 30 kilometres from the CBD. Calder Park’s closeness to both the airport and the city of Melbourne make it much more user friendly for teams.

Local teams can easily access their own facilities and even those teams from out of town are able to more easily source parts and equipment from major suppliers if needs be. Calder Park has been in existence since 1962 with the main circuit retaining a very similar shape to the current one.

In the 1970s Bob Jane purchased the facility and it flourished. In its heyday the venue hosted international events such as the Australian Grand Prix on five occasions in the

1980s, and a round of the World Touring Car Championship as well as many other race formulas including Superbikes.

The national circuit is 2.280 kilometres long with a shorter club circuit that is ideal for FSAE.

Volunteers you’re closer now

Being a volunteer offers you an excellent opportunity to experience the action with the students and see the latest global automotive technologies in play.

Join industry leaders, automotive enthusiasts, and students at FSAE at Calder Park Raceway for one, two, three or all four days.

Volunteers are supplied with on-the-job training, and receive a commemorative polo top and meals throughout their participation.

For more information about volunteering contact isaac.j.baldry@gmail.com or call +61 475 517 244.

For more information about Formula SAE visit www.saea.com.au or email formulasae@saea.com.au or call +61 403 267 166

Photos: cover and on this page – Geoff Colson www.colsonphotography.com.au

SAE | News VTE | 7 www.saea.com.au

New Members

The SAE-A would like to welcome the following new members:

Professional Member

Fabian Alistair

Jacques Hickey

Shaun Holland

Martha Oplopiadis

Shahzad Qaisar

Amina Siskovic

Noi Vera

Liam Viskovich

Gary White

Timothy White

Student Members

Bhavinkumar Arya

Jim Belskyj

Daniel Bendotti

Akshaj Bhardwaj

Tim Bolton

Daniel Daldy

Ayden Davey

Declan Dooley

Has Gardige

Brenton Henry

Adil Ibrahim

Navod Imiya Arachchige Don

Grace Jopling

Harry Marshall

Lachlan Neville

Darby O’Meara

Michael Rotondo

Haw Ming Seow

Keeley Sermon

Charles Sewell

Lincoln Siu

Lucas Webb

Qingtai Wu

SAE International award nominations

Each year SAE awards celebrate exceptional individuals and teams for continually pushing the boundaries of technical excellence, innovation, and leadership.

The international SAE awards provide a powerful global platform to gain company recognition, boost team morale, and demonstrate your team’s technological and societal impact.

You can nominate an SAE-A member, nominations close on 30 September. Visit www.sae.org for more information.

Electric Vehicle Conversion Seminar WA

On Tuesday 22 August at Bibra Lake, WA

the SAE-A hosted an EV conversion seminar conducted by AEVA and Unique EVs. There were 35 attendees from the SAE-A. Then on 26 August ACE in Victoria hosted the SAE-A. “Thanks to you and the team

Coming events

at Kangan’s ACE for an excellent tour today. Everyone in the group was definitely impressed with the facilities and the professionalism of the training team, and I personally think ACE is one of Melbourne – Australia’s gems in education.” Gary White President SAE-A.

FEA & CFD Simulation Course Online – NOTE CHANGE OF DATES

Monday 16 October – Monday 23 October

An introductory course intended for all engineers and product designers who are new to simulation, or have an intermediate level of knowledge of the use of simulation.

Dolphin Products Facilities Tour

Tuesday 19 September 10.30am - 12.30pm Heidelberg West, Victoria

Dolphin specialises in plastic products. Dolphin provides turnkey solutions designing, tooling, manufacturing and assembling of complex products for medical, mining, defence, auto and industrial applications.

APV Test Centre Site Tour

Wednesday 4 October 6pm - 8pm Campbellfield, Victoria

APV has an advanced dynamic, static, crash and environmental test facility. Visitors will see the company’s indoor test track, the component laboratory, crash test dummy calibration, impact testing, and test equipment. There will also be a behind the scenes look at the SRS R&D specialist development such as air-bag compatible bull bars. For more information www.saea.com.au or events@sae-a.com.au

Melbourne EV show with FSAE

The SAE-A has a stand showcasing the Formula SAE-A cars at CarSales Melbourne EV show which is on from 22-24 September at the Melbourne Exhibition Centre.

RMIT and Swinburne are attending with their cars and a Formula simulator. They will also be highlighted on stage to talk about Formula SAE-A.

News | SAE 8 | September 2023

Hugh H Videion Honorary Life Member SAE-Australasia

Hugh Videion celebrates 90th birthday and 55 years with SAE-A

Hugh Videion joined SAE-A in 1968 and was awarded Honorary Life Membership of the Society in 2001 after a wonderful career in the industry he loved. This is the first part of a two-part story which starts in 1954 at GM-H. Hugh joined GM-H in September 1954 in the Experimental Engineering Department at Fisherman’s Bend as a technical report writer. Prior to that, he had worked at Paton’s Brake Replacements (PBR) from late 1950 to September 1954 in their Experimental Engineering Laboratory located in PBR’s headquarters in Leicester Street, Carlton. At the same time, he was completing his engineering studies at night at the Royal Melbourne Technical College (now RMIT), graduating with a Diploma of Mechanical Engineering in 1960.

Following his promotion in 1961 to Project Engineer- Research and Experimental, Hugh was made responsible for braking systems test and development on all Holden vehicles. The first model Hugh was engaged in was the 1956 FE Holden followed by its successorthe 1958 FC, and later models from the 1962 EJ and 1963 EH through to the 1968 HK.

Hugh’s engineering manager at this time was the Experimental Test Engineer Charles Paterson, a very experienced engineer and

one of the original three Holden engineers who had been assigned to GM Corporation in 1946 in Detroit to participate in the test and development of the prototypes of the first Holden – the iconic 48/215.

The other two GM-H engineers that accompanied Charles Paterson were Jack Rawnsley (Chassis Engineer) and Fred James (Engine Engineer).

In 1963, Jack Rawnsley, a committee member of the Institution of Automotive and Aeronautical Engineers (IAAE), the forerunner of SAE-A, was at that time the engineering manager responsible for the design and development of Holden suspensions, steering, braking systems, wheels and tyres. He encouraged Hugh to author a technical paper on braking systems as one of four papers to be presented by a team of engineers knowledgeable in braking systems, during a Lecture Series sponsored by IAAE in Melbourne.

The lectures were part of an education program offered by IAAE to members and other interested people such as VACC technicians working in the industry. The lectures were highly successful and well attended; they were repeated in 1966 and 1967.

IAAE had been founded in Melbourne in 1927 and later re-named SAE-A when it signed a Memorandum of Understanding with SAE in the USA. This arrangement allowed members of SAE-A to be eligible for joint membership in both SAE-A and SAE-Inc.

Part two will be featured in the December issue of Vehicle Technology Engineer.

SAE | News VTE | 9 www.saea.com.au

Briefs

Parent power by McLaren

Celebrating women in engineering with Romy Mayer

Nulon Racing celebrated International Women in Engineering Day by announcing that respected motorsport engineer, Romy Mayer, is joining the Arundel-based team.

Supercar maker McLaren released a new film to mark International Women in Engineering Day that highlighted the importance of parent power in encouraging young women to pursue science, technology, engineering and mathsbased careers. It featured McLaren automotive materials scientist Ella Podmore MBE and her father Bruce. The film features her chatting with her father while they build a Lego Mclaren F1LM together. You can see the film here: https://www. youtube.com/watch?v=R8kIxwsjvSM

CommBank Manufacturing Insights

The new 2023 CommBank Manufacturing Insights Report revealed that 72 percent of manufacturers in Australia expect to increase production levels in the next 12 months, while the same proportion are planning to increase capital expenditure.

The majority of Australian manufacturers surveyed are confident in the short-term outlook for business conditions, likely buoyed by a stronger than expected financial performance in the past year. Seventy percent of manufacturers reported profit growth in the past 12 months, compared with just 52 percent last year. Manufacturers are optimistic with 74 percent anticipating increased profits in the next 12 months.

Critical mass for critical metals

As more and more electric cars are travelling on the roads of Europe, this is leading to an increase in the use of the critical metals required for components such as electric motors and electronics.

With the current raw material production levels there will not be enough of these metals in future – not even if recycling increases. This was revealed by the findings of a major survey led by Chalmers University of Technology, Sweden, on behalf of the European Commission.

Electrification and digitalisation are leading to a steady increase in the need for critical metals in the EU’s vehicle fleet. Moreover, only a small proportion of the metals are currently recycled from end-of-life vehicles. The metals that are highly sought after, such as dysprosium, neodymium, manganese and niobium, are of great economic importance to the EU, while their supply is limited, and it takes time to scale up raw material production. Our increasing dependence on them is problematic.

Across a 13-year career, Mayer’s list of achievements specifically in Supercars is extensive and includes playing a key role in Jamie Whincup’s seventh career Supercars title and guiding Craig Lowndes and Declan Fraser to the best finish by a wildcard (eighth) in last year’s Repco Bathurst 1000. After working with Triple Eight Engineering in Supercars, Super2 and GT World Challenge Asia for eight years, Mayer says she is looking forward to joining the Nulon Racing team to support Jimmy Golding and Tim Slade. Mayer’s first job was in Germany at Mercedes Motorsport in the German Touring Car Championship (DTM). Working with the car manufacturer for four years, Mayer was heavily involved in the development of a GT3 car, with the project taking a year to complete. After five years at Mercedes, Mayer made the move to Australia to join Triple Eight Race Engineering in September 2015. As data engineer, Mayer worked alongside David Cauchi and Grant McPherson when Jamie Whincup claimed his seventh championship in 2017 before making the move to become a Race Engineer herself on Triple Eight’s Super2 entry for Kurt Kostecki, finishing second in the championship. That same year (2019), Mayer also worked on the GT3 team fielded by Triple Eight in Asia. Following the birth of her first child, Mayer returned to GT3 last year (2022), contesting the full season in Asia, with her entry winning the Pro AM Championship before the eye-

catching result as race engineer of the Lowndes/Fraser result at Mount Panorama.

Mayer is also a FIA Girls on Track Ambassador and Co-Founder of the Future Females program, and often presents to schools and universities to encourage women to pursue a STEM-based career.

“I think it is pretty cool that my joining the team has been announced on International Women in Engineering Day,” Mayer said.

“International Women in Engineering Day is all about raising awareness about the women pursuing engineering and transforming the world with their achievements, so I think the timing is quite fitting.

“Encouraging women and girls to pursue careers in STEM and motorsport is a real passion of mine, and I look forward to continuing my work in this area while being a part of the Nulon Racing team.”

International Women in Engineering Day is celebrated around the world, to honour women in the field of engineering. It focuses on raising the profile of women who are changing the field of engineering and has been recognised by UNESCO.

Plastics no longer fantastic

Most will be aware that the Federal Government is preparing for the next meeting of the UNEP Committee on the preparations for the Plastic Pollution Treaty in 2024.

The Federal Government has joined the High Ambition Coalition to End Plastic Pollution. This Coalition is a group of like-minded countries that will work towards an ambitious new global plastics treaty. This coalition aims

to end plastic pollution by 2040 and is going further than the Treaty envisages.

The Federal Government has also announced its intention to sign the Plastic Pollution Treaty in 2024. It might take one to two years to have this treaty converted into law and regulations in Australia. The Federal Government has also announced it will regulate the use of plastic in packaging most likely through a type of Extended Producer Responsibility (EPR) scheme or similar.

Although the first actions based on the Treaty will cover polymer materials and plastic products in the packaging industry, most members are affected because you use plastic packaging.

News | General 10 | September 2023

RMIT Online doubles down on upskilling

RMIT Online has extended its partnership with global education provider, Udacity, doubling down on its commitment to make upskilling in critical fields more widely accessible.

The unique collaboration between Udacity and RMIT Online was designed to address skill shortages.

Udacity, which has collaborated with Silicon Valley powerhouses including Google, Facebook and NVIDIA, gives students skills to advance their careers through a series of online courses in hands-on technologies in high-demand subjects.

Following a successful launch of courses in 2018, the newest suite of course offerings include Flying Car and Autonomous Flight Engineer, Deep Learning, Ethical Hacker, and Ethical AI.

Research from RMIT Online and Deloitte Access Economics, titled Ready, Set, Upskil, found the digital skills gap – the gulf between

our current industry skill set and realising the true potential of a resilient, agile, Australian workforce – is costing Australian businesses $3.1 billion annually.

RMIT Online remains the only Australian University to offer internationally backed courses

through Udacity. Courses include Flying Car and Autonomous Flight Engineer, Deep Learning, Ethical Hacker, and Ethical AI, for which students will receive a university-backed credential. All courses are open for enrolment at https://online.rmit.edu.au

CSIRO report shows Australia lags with hydrogen refuelling

A new report released by CSIRO and GHD Advisory calls for Australia to focus on hydrogen-powered transport alongside electric vehicles or risk being left behind our international counterparts.

The ‘Hydrogen vehicle refuelling infrastructure’ report sets out the opportunities and challenges for deploying refuelling stations for hydrogen-powered road vehicles in Australia.

CSIRO’s chief scientist, Prof Bronwyn Fox, said Australia needs to urgently decarbonise its transport sector, which currently accounts for 18.6 percent of our greenhouse gas emissions, if the country is to meet its net zero commitments. Heavy vehicles are a key contributor to these emissions.

“While we know hydrogen will play a critical role, we also know that much of the key infrastructure for storing, moving and distributing hydrogen for use as a transport fuel – including pipelines, storage tanks and refuelling stations is yet to be built,” Prof Fox said.

“That’s why this report is so important. It identifies priorities for action, including areas that would benefit from targeted research and innovation.”

The report compared the different hydrogen storage and dispensing options available and evaluated refuelling infrastructure options based on fuel demand and distance from the hydrogen source.

It found that while all Australian hydrogen refuelling stations currently have onsite hydrogen production, we will need to move to

centralised offsite production and distribution of hydrogen in order to refuel vehicles at scale.

Shawn Wolfe, Executive Advisor at GHD Advisory and lead author of the report, said Australia currently has only five hydrogen refuelling stations in operation, with 20 planned or under construction.

“The pace of the transition to hydrogenpowered transport is moving a lot faster internationally than in Australia,” Mr Wolfe said.

Meanwhile CSIRO, and corporate advisor RFC Ambrian have co-founded Hadean Energy, a new company to commercialise cuttingedge technology that can produce hydrogen with 30 percent less electricity and help to decarbonise heavy industry.

CSIRO will trial the technology at BlueScope’s Port Kembla Steelworks to demonstrate the equipment at pilot scale in an industrial environment.

CSIRO’s tubular solid oxide electrolysis (SOE) technology efficiently produces hydrogen by electrolysing water using a combination of heat and electricity and promises to significantly reduce hydrogen production costs and industry emissions through process efficiencies.

Dr Sarb Giddey, lead scientist on hydrogen research at CSIRO, said the development of tubular SOE technology at CSIRO is a key project aimed at producing more affordable and efficient hydrogen to help industry dramatically reduce emissions.

VTE | 11 www.saea.com.au General | News

RMIT Online CEO Nic Cola

Sarb Giddey, Gurpreet Kaur and Raj Ratnaraj with-SOE tubes

Truck & Bus Briefs

Cummins, Daimler and PACCAR battery cell production

Accelera by Cummins, the zero-emissions business unit of Cummins, Daimler Trucks & Buses US and PACCAR are partnering to accelerate and localize battery cell production and the battery supply chain in the United States. The planned joint venture will manufacture battery cells for electric commercial vehicles and industrial applications. The total investment is expected to be in the range of US$2-3 billion for the 21-gigawatt hour (GWh) factory. Accelera by Cummins, Daimler Truck and PACCAR will each own 30% of, and jointly control, the joint venture, which will initially focus on the lithium-iron-phosphate (LFP) battery technology family for commercial battery-electric trucks.

Triple tanker

Omni Tanker has launched a world-first composite triple road train, able to move almost 100 tons of payload in a single haulage run, while significantly reducing operational costs. Employing advanced composite materials and engineering practices commonly found in aerospace, Omni Tanker’s new triple tanker features world-first Mould-in-Baffles to better manage the movement of fluid (surge) in the road tankers, enhancing safety, while advanced fabrication techniques also reduce the weight of the trailer units.

Volvo adds to its executive team

Zero emissions bus rollout in Victoria

Victoria is one step closer in its drive towards a more sustainable bus fleet with the launch of a new consultation paper to industry to help support a transition to zero emissions.

All new public transport buses purchased from 2025 onwards will be zero emission as part of the Andrews Labor Government’s target of net zero by 2045.

Minister for Public Transport Ben Carroll launched a consultation paper that lays the groundwork for the transition plan set to be released in 2024.

Victoria is already leading the way through the Labor Government’s $20 million Zero Emission Bus trial delivered hand-in-hand with industry to inform the smooth transition of almost 4,500 diesel buses to zero emissions.

The three-year trial leading up to 2025 involves six operators across Victoria introducing 52 zero emission buses into

their fleets – 50 electric and two hydrogen –across Melbourne, Traralgon and Seymour. The trial has provided evidence about performance, depot charging needs, capacity, infrastructure and energy network requirements, environmental outcomes and customer expectations.

The consultation paper highlights the benefits of the trials with industry and invites their contributions on how a zero emission bus transition can slash emissions, improve passenger experiences and create secure jobs in the bus industry.

More than 100 hybrid and around 45 zero emission buses are already operating on public transport routes across Victoria.

Volvo electric truck to put out fires

Volvo Group has unveiled Australia’s first zero-emissions logistics vehicle, supplied to the ACT Emergency Services Agency (ESA), at the Australasian Fire and Authorities at the (AFAC) conference, the region’s largest emergency management conference and exhibition.

Volvo has added to its executive team with Lauren Pulitano appointed as vice president of public affairs. Ms Pulitano was serving as vice president of governmental sales and UD Trucks Australia and has held roles within the bus and trucks business areas across Australia, Sweden, and Singapore. Cameron Bettany, an accomplished expert in government projects, emergency services sector, and stakeholder management in the Asia Pacific region, has been promoted to the position of vice president, group governmental sales.

Marco Quaranta joins SEA

SEA Electric has appointed transport industry veteran Marco Quaranta as the company’s Sales Director for the Asia Pacific. Mr Quaranta brings to SEA Electric 35 years of experience from his previous roles at IVECO, with various tenures based in Australia, Korea, Thailand, Hong Kong and his native Italy. Mr Quaranta, held several roles over the last 17 years, including Institutional Relations and Alternative Propulsions Manager, National Product & Marketing Manager, Branch Manager, and National Sales Manager.

The purchase is a significant milestone in the partnership established between Volvo Group Australia and the ESA in July 2022.

The vehicle is a Volvo FL Electric, a solid and nimble truck designed for urban and city environments. With a superstructure designed and made in New Zealand, the FL Electric will be used for important tasks including operational support for Fire & Rescue teams.

“This is a significant milestone for the ACT. Transitioning emergency services operational support vehicles to zero emissions vehicles is a crucial step to achieving our government’s nation-leading

target of net zero emissions by 2045,” ACT Minister for Police and Emergency Services Mick Gentleman said.

Martin Merrick, President of Volvo Group Australia, said that transport accounts for 19 percent of Australia’s carbon emissions, and 38 percent of that is from road vehicles. With this project, government and the emergency services are leading by example in moving to net-zero vehicles. The vehicle has a range of 300 kilometres.

Volvo already has truck orders with the Queensland Fire and Emergency Services for heavy-duty electric FMZ 6x4 prime movers.

News | Truck & Bus 12 | September 2023

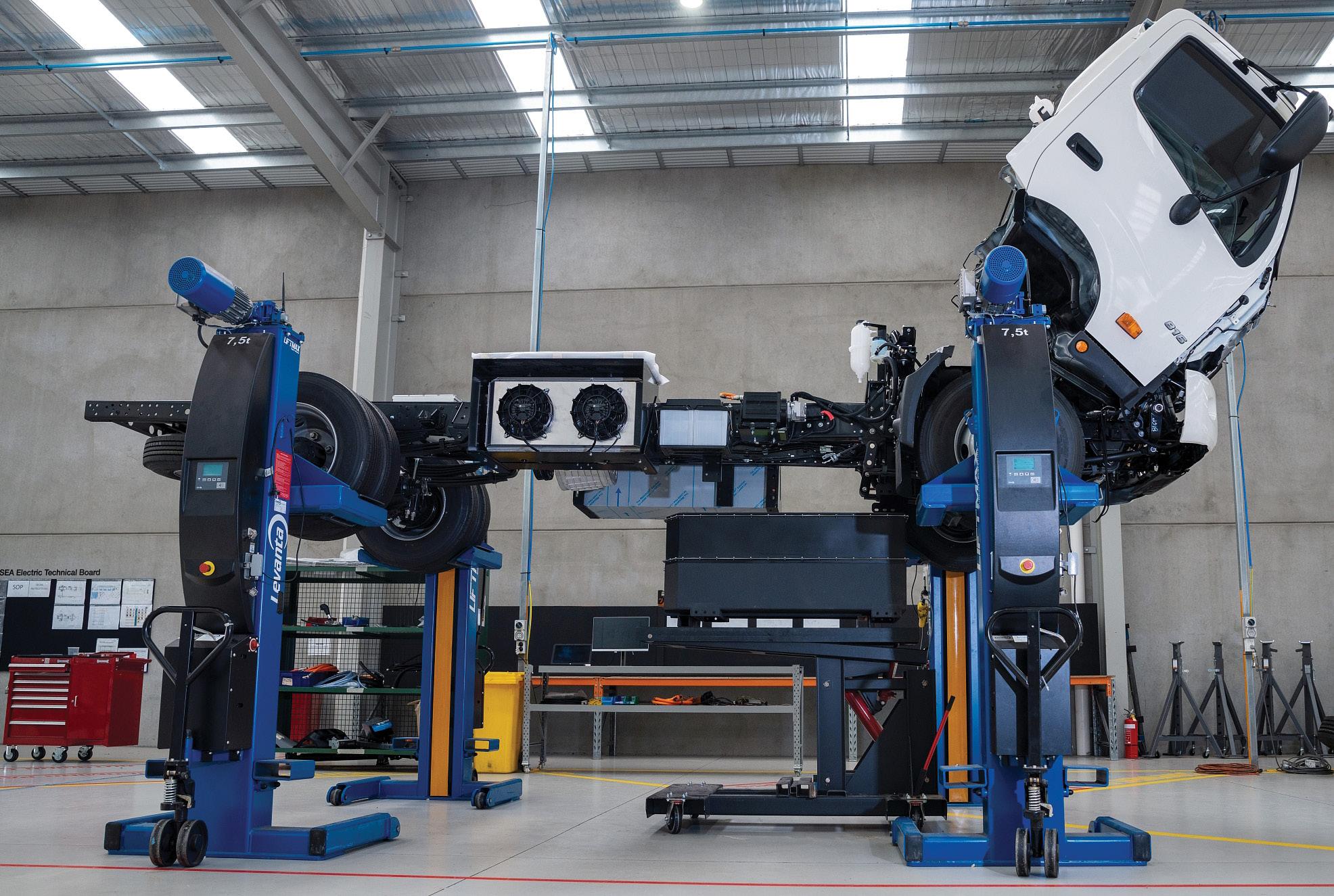

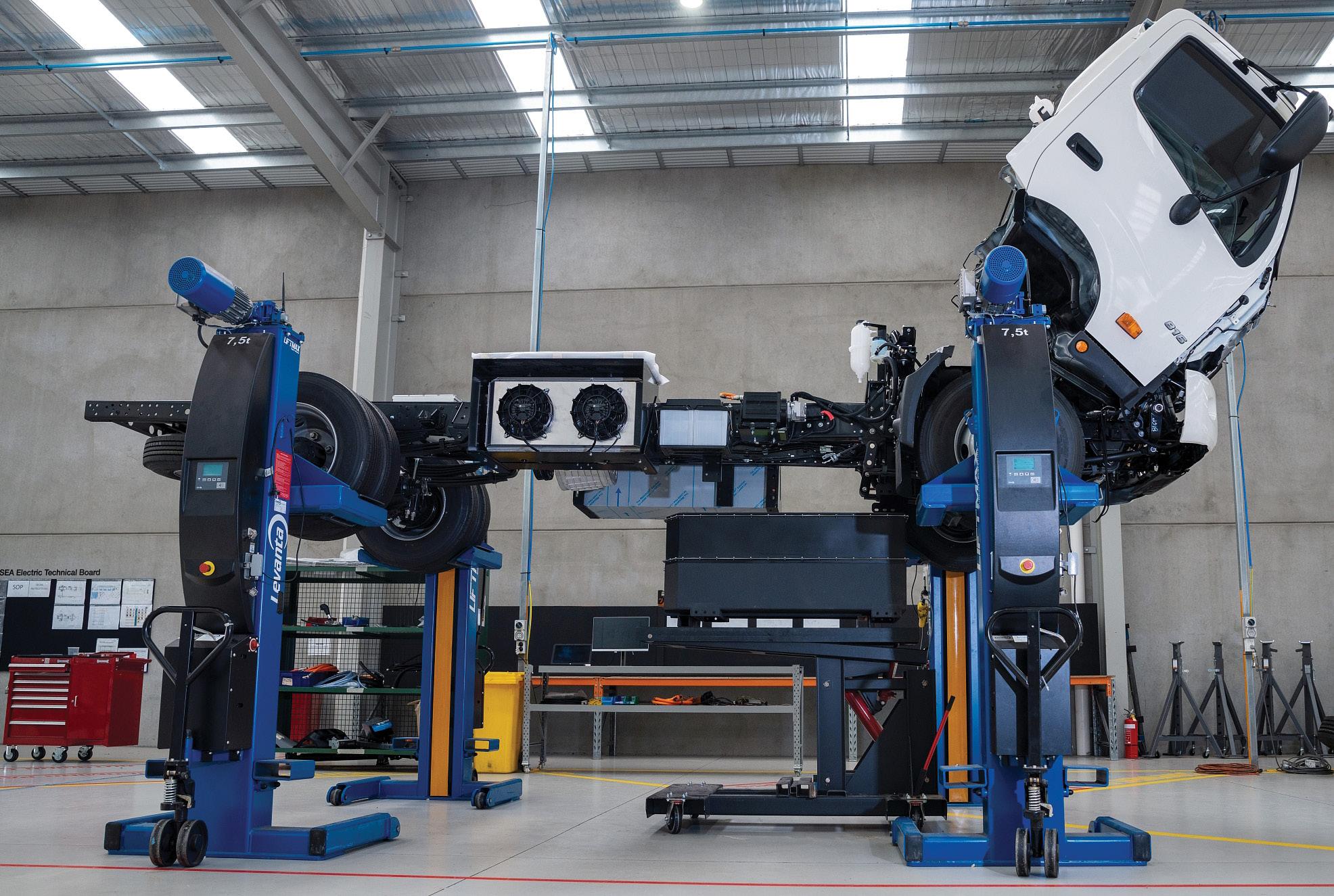

SEA trucks with expanded SEA-DAS systems

SEA Electric’s Australian-produced range of light and medium-duty trucks comes as standard with an expanded SEA-DAS (SEA Driver Assistance System) offering.

The array of features includes active systems and passive design features, such as Vehicle Stability Control, Automatic Emergency Braking, Pedestrian Detection, Lane Departure Warning, Traction Control, an Anti-lock Braking System (ABS), dual SRS airbags and dual SRS seatbelt pre-tensioners.

Tested to ADR standards, the SEA Electric compliance plated trucks have an ECE-R29 cab strength certification, a shock-absorbing and collapsible steering column, anti-side intrusion door beams, reversing camera with buzzer, and daytime running lamps.

The SEA 45e, SEA 85e, and SEA 225e cater for 4.5t car licence models through to 22.5t three-axle rigid configurations and a wide array of final applications, with the trucks engineered and assembled in Melbourne.

The SEA-Drive power-system architecture features innovative in-chassis mounted batteries, which improve battery protection and driving dynamics by centralising weight while maintaining front-to-rear weight distribution for optimal braking performance.

One of the key features of the SEA-Drive

Power System is the use of regenerative braking, which not only tops up battery levels while the truck is in motion, but also saves wear on the service brakes, preserving them for any possible emergency situations.

The first stage of the active and passive braking system is engaged by turning the electric motor into a generator when coasting without any pedals depressed, slowing the

Daimler launches new truck brand

Daimler Truck has launched a new brand, Rizon, dedicated to Class 4 and 5 medium-duty battery-electric vehicles for the US market.

Rizon will challenge established truck makers such as Isuzu Motors and Hino Motors as well as several start-ups in the mediumduty commercial-vehicle space. Rizon capitalizes on years of customer feedback and data amassed from Daimler’s existing electric trucks, including the Freightliner eM2 medium-duty truck, which will remain unaffected by the addition of this new brand.

The Gross Vehicle Weight Rating (GVWR) for the eM2 is 26,000 lbs (Class 6) or 33,000 lbs (Class 7). Rizon initially will offer three cabover model variants, the e18L, e16L and the e16M, with a wheelbase of 175 or 187 inches (4445 or 4750 mm) and various body options such as dry vans, flatbeds, landscape dumps and reefers.

These trucks will target urban retail logistics, last-mile deliveries and municipal work and

feature an “OEM proprietary powertrain with eAxle” and lithium iron phosphate (LFP) batteries supplied by CATL positioned below the frame.

Expected driving range is 177-257km for 124kWh L models with three battery packs and 75-110 miles (120-177 km) for the 83-kWh M variant with two battery packs.

Rizon trucks are capable of being recharged by Level 2 AC charging (J1772) in 5-6 hours, according to Deuschle, and CCS1compliant DC fast charging in 45-90 minutes. Consulting on AC and DC charging as well as factory-fitted telematics access will be available.

truck and charging the battery, in essence, similar to a diesel engine’s exhaust brake.

The second stage is engaged during the initial depression of the brake pedal, whereby additional negative torque is applied to the motor, with the traditional service brakes then only utilised when the brake pedal is fully depressed as the vehicle stops.

75,000 Volvos built in Australia

Gary Bone, Vice President Volvo Group Australia, handed over the keys to the 75,000th Wacol built truck to be built locally and delivered in Australia.

“This is a landmark for Volvo Group Australia,” said Mr Bone. “It perfectly demonstrates the company’s commitment to the Australian transport industry, and we’re particularly delighted to be able to deliver this truck to Hills Tankers, who are a long-standing Volvo customer.” Andrew Hill of Hill’s Tankers took delivery of the FH16. TrueGreen buys Sydney bus company

Sydney private coach charter company North Sydney Bus Charters has been sold to electric bus company TrueGreen acquiring the charter company for around $100 million. TrueGreen owns zero-emissions bus companies such as Foton Mobility, Gemilang Australia, Nexport and GoZero in Australia and is expecting to make more acquisition this year.

VTE | 13 www.saea.com.au Truck & Bus | News

New defence grants for Victoria

The Victorian Labor Government is supporting the state’s defence industry with new grants to help Victorian businesses compete for and win major contracts, growing local defence capabilities and creating jobs.

Minister for Manufacturing Sovereignty

Ben Carroll visited Amiga Engineering and announced round two recipients of the Victorian Land Systems Fund – Supply Chain Uplift Program, which will support Victorian companies to become part of Hanwha Defense Australia’s LAND 8116 supply chain.

A total of more than $275,000 in grants will be awarded to four local companies that specialise in land systems defence to grow their business competitiveness and capabilities, supporting them to become part of Hanwha’s delivery of the Commonwealth Government’s $1 billion LAND 8116 Self-Propelled Howitzer program.

Marand gets $50M extension to include Boxer

Marand Precision Engineering and Rheinmetall have announced a $50M extension to their manufacturing partnership to now include the Boxer Combat Reconnaissance Vehicle (CRV) in use with the Australian Defence Force and for export orders.

Hanwha has also secured the contract for the multi-billion LAND 400 Phase 3 program, the largest land defence contract ever awarded in Victoria.

Around 600 direct jobs will be created from delivering the defence projects and hundreds more indirect jobs across the supply chain.

Broadmeadows-based Integra Systems will receive a grant to purchase and install new equipment into its manufacturing facility. Other companies benefiting from the grants are Total Precision based in Bayswater North and The Smart Think in Geelong. Victoria’s defence sector supports around 24,300 jobs across the sector and contributes $8.4 billion to the Victorian economy each year.

Marand has an existing partnership with Rheinmetall to manufacture LANCE digital turrets, hull components and vehicle attachments in Geelong for export markets utilising Marand’s and Rheinmetall’s established Australian supply chain. The enhanced manufacturing partnership includes Geelong manufacture of Boxer CRV subassemblies including Citadel machining, turret hatches, turret baskets, doors and dismount hatches.

Marand has operations in Melbourne and Geelong and supplies sophisticated

engineering solutions to the defence, aerospace, rail, automotive and mining sectors.

It designs and manufactures complex innovative solutions for its customer base including Lockheed Martin, Boeing, BAE Systems, BHP and Rio Tinto.

The company will undertake design and development with manufacturing at the historic Ford Factory precinct in Geelong. Since opening its Geelong manufacturing division on Ford’s site 10 years ago, Marand has employed more than 80 staff.

CSIRO is Boeing’s Pathfinder

Boeing, the world’s largest aerospace company, has named CSIRO, Australia’s national science agency, a Supplier of the Year for the fifth time since 2010.

The ‘Pathfinder Award’ recognises the substantial value CSIRO has created for Boeing through technological breakthroughs across space, advanced materials, data analytics, energy, manufacturing, robotics and autonomy. CSIRO has partnered with Boeing to develop new lightweight and sustainable materials for both aircraft and possible space applications.

The companies have also invested over $200 million across a wide range of projects to advance production systems, improve safety, reduce waste, and increase environmental sustainability in aviation.

Boeing’s Supplier of the Year Award program is an industry-leading recognition program

that highlights the accomplishments of the company’s top-performing suppliers. CSIRO was previously named a Boeing Supplier of the Year in 2018, 2017, 2016 and 2010. Earlier this month, CSIRO and Boeing jointly released the Sustainable Aviation Fuel Roadmap, which charts a path for the decarbonisation of the aviation industry.

News | Defence & Aero

14 | September 2023

Up-lifting Australian small businesses

Australian small businesses participating in Boeing Australia’s first Capability Up-Lift Program have graduated with seven Boeing contracts, including agreements with three new suppliers.

The program participants graduated with tools they need to increase business maturity and improve overall program performance.

The year-long program is designed to support companies who may not have experience working in a defence environment and was delivered with partners, the Office of Defence Industry Support from the Department of Defence, AusIndustry and Defence Jobs Queensland. Together, they shared resources and access to industry experts to provide SMEs with advisory services, mentoring and major event access to enhance business readiness and defence maturity.

At the time of graduating, participants received the following grants and awards:

Two businesses – HINDSITE Industries and Raytracer received AUD $2.8 million in grants and funding to productise their technologies for aerospace, in the areas of virtual reality technology and on-orbit vehicle servicing, assembly and manufacture as part of Australia’s Moon to Mars Initiative. Three businesses – HINDSITE Industries, LOGiT and JRS Group received their first Boeing contracts. Seven SMEs received 10 industry awards at both state and national levels.

Another 200 new jobs in aerospace

Minister for Manufacturing Sovereignty Ben Carroll welcomed Boeing’s growth in Victoria, with the company creating more than 200 new jobs this year alone, an increase of almost 25 percent and bringing its workforce in the state to more than 1000.

These roles are supporting increased production of new commercial planes due to growing demand globally.

Based at Melbourne’s Fisherman’s Bend, the company has been manufacturing aircraft in the state since 1927.

The company is not only growing its workforce in the state but also encouraging more women into aviation trade roles through

Briefs

New Hercules for RAF

The Albanese Government will purchase 20 new C-130J Hercules aircraft for the Royal Australian Air Force for $9.8 billion. This will provide the Air Force with state-of-the-art C-130 Hercules to meet the air transport needs of the future. The new acquisitions will replace and expand upon the 12 Hercules aircraft currently operated by Air Force with delivery of the first aircraft expected from late 2027.

Neumann Space to test Australian propulsion system

its Female Apprenticeship Program to increase gender diversity in traditionally male dominated roles.

Boeing’s Victorian presence is one of the company’s largest outside the United States, bringing together a unique combination of research and development, engineering, and advanced manufacturing in the one location.

Thales opens new facility in NSW

Thales Australia officially opened the company’s new advanced manufacturing facility at Lithgow in regional New South Wales.

It’s a key milestone in the first phase of Thales’ ambitious industrial plan to transform its Lithgow Arms site into an advanced manufacturing 4.0 and integration hub for the precision manufacture of next generation Australian designed weapon systems.

The new facility will house a new purpose-built live firing test and evaluation capability to support systems qualification and integration, and the acceleration of research and technology development of digitised smallarms and weapon system platforms.

It will also support collaboration across research institutions, SME partners, and key industrial partners to create the soldier

systems and small arms of the future, as well as train the next generation of skilled advanced manufacturing workers in the central west of New South Wales.

Surrey Satellite Technology of the UK and Neumann Space announced that they have agreed to work together to test an Australian designed and manufactured in-space propulsion system as part of the CarbSAR In Orbit Demonstration Mission.

SSTL and Neumann Space will commence work this year to integrate the next generation Neumann Drive as an IOD payload on board the SSTL CarbSAR satellite scheduled for launch in the second half of 2024.

More Bushmasters

The Australian Government has signed a $160 million contract with Thales Australia to deliver an additional 78 Bushmaster protected mobility vehicles for the Australian Defence Force. Bushmasters will continue to be manufactured in Bendigo, Victoria, with the first delivery expected in 2024.

100 Boxers for Germany

When Prime Minister Anthony Albanese touched down in Berlin ahead of NATO talks, he revealed one of the biggest defence export deals in Australia’s history.

Australia will export more than 100 Brisbanemade Boxer heavy weapon carrier vehicles to Germany starting in 2025 under a $1 billion deal. The military vehicles will be produced in Redbank and will secure around 1,000 jobs and be worth in excess of $1 billion for the Australian economy. “This will be one of our largest-ever exports,” Albanese told reporters on the tarmac.

HDR appoints defence principal Global engineering, architecture and planning company HDR has appointed Tim Napper as its Defence Principal following this year’s Strategic Review. His previous role was in the Department of Defence, as a project director in the Capital Facilities and Infrastructure Branch.

VTE | 15 www.saea.com.au Defence & Aero | News

Briefs

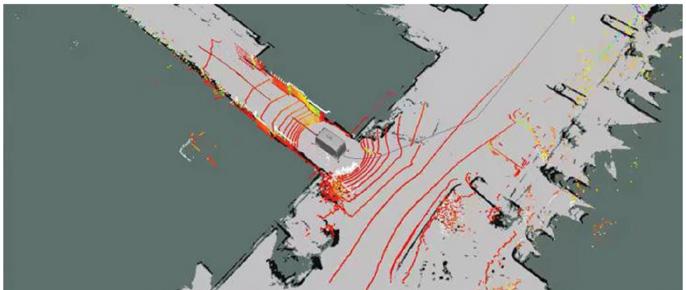

Coventry University’s self-driving Nissan

Premcar Bronco on US offroads

Premcar’s latest project was unveiled during this year’s Monterey Car Week in the US.

Coventry University showcased one of its selfdriving the Nissan ENV 200, which is a fully battery and electric operated vehicle. It was seen by the public driving around part of Coventry’s city centre. The vehicle, which is one of two self-driving research vehicles from the University’s Centre for Connected and Autonomous Automotive Research, was also demonstrated to the press.

“The vehicle’s purpose is to investigate a range of scenarios around self-driving, connectivity, cyber security and automated testing to create a resilient self-driving solution for our vehicles of the future,” Kevin Vincent, Director of Coventry University’s Centre for Connected and Autonomous Automotive Research, said.

The vehicle is fitted with a 360-degree scanning LiDAR, which shows where the vehicle is and builds a digital picture of the surrounding environment. It also has a series of cameras which help to localise it, a forward-facing radar, ultrasound sensors and a 5G development kit.

Bosch test centre for chips

Global demand for chips for the automotive and consumer goods industries remains high. That is why Bosch is continuing to expand its semiconductor business. The company has now opened a new test centre for chips and sensors in Penang, Malaysia.

The new test centre currently covers more than 18,000 square meters and includes clean rooms, office space, and laboratories for quality assurance and manufacturing. By the middle of the next decade, up to 400 employees will be working there. With the new factory and a total of 4,200 employees, Penang is now Bosch’s biggest location in Southeast Asia.

Nissan Node

Nissan Australia will launch an industry-first Circular Economy project in Victoria, with the Nissan Casting Australia Plant (NCAP) to use recycled Nissan LEAF batteries to power part of its production facility as reported by Manufacturers’ Monthly.

This is an important step towards Nissan Australia’s goal of carbon neutrality — the NCAP battery project, called Nissan Node, will see a new solar array installed at Nissan Casting Australia, as well as new EV chargers.

In its most simplified form, the Nissan Node will include the installation of a new battery energy storage system made of nine repurposed Gen 1 Nissan LEAF batteries at the Nissan Casting Australia Plant, which will be charged via the solar array.

The project is estimated to reduce Nissan Casting Australia’s annual C02 emissions by 259 tonnes, while saving 128 megawatts of energy every year.

Illinois-based Gateway Bronco teamed with the Australian new-vehicle engineering and manufacturing firm to develop the chassis, suspension and steering for its newest 1960s-inspired LUXE-GT model. Known internally by its project codename Pegasus, the Melbourne-based OEM automaker developed the ladder-frame structure with a 2350 mm wheelbase and 1623 mm (front)/1630 mm (rear) track width reminiscent of the classic Bronco. It has also been designed and developed to accept Ford’s latest 343 kW 5.0-litre ‘Coyote’ V8 engine, 10R80 10-speed automatic transmission, and two-stage shift-on-the-fly all-wheel drive system.

Gateway Bronco’s new Premcar-developed platform is also equipped with a suite of active safety systems, including Electronic Stability Control (ESC), Traction Control (TC) and Anti-lock braking (ABS), providing drivers with modern safety support as well as impressive current-day ride, handling and steering performance.

The chassis has been developed exclusively

for Gateway Bronco with US Patent(s) pending.

Beginning with specific attribute and performance targets, the two-year platformdevelopment program progressed through extensive CAD and FEA phases before prototype construction and testing. Specific suspension components were also newly developed for the program.

All engineering and development work was conducted at Premcar’s Engineering and Production Centre in Melbourne and included heavy-duty testing in remote regions of Australia.

AIC offers test facility for ADR98/00 braking

The Auto Innovation Centre (AIC) is now an approved ROVER Test Facility for the newly released ADR98/00 – Advanced Emergency Braking (AEB).

This new ADR98 service offering by the AIC will be an important test for vehicle modifiers developing frontal protection systems or producing GVM upgrade packages to ensure vehicle safety and compliance and is applicable to new model vehicles from 1 March 2023.

The AIC’s state-of-the-art testing capability features an ISO compliant foam vehicle target, custom tow fixture, plus specialised test equipment, forming an integral component of the AIC’s suite of vehicle testing services.

In addition to ADR98 testing, the AIC is a ROVER recognised testing facility for: ADR31 (Passenger Vehicle Brake), ADR35 (Commercial Vehicle Brake), ADR62 (Mechanical Connections – Tow Bars), ADR88 (Electronic Stability Control), ADR89 (Brake Assist Systems).

Product level testing is also a speciality of the Auto Innovation Centre with hydraulic durability, vibration, tensile testing and shock absorber testing available at the AIC’s Melbourne facility

News | Auto

16 | September 2023

Directed Technologies mobility innovation centre

Directed Technologies has a new $15m Connected Mobility Innovation Centre to fuel the rapid growth of connected vehicle technology and IoT solutions.

Briefs

Helixx new manufacturing system to deliver mini electric vehicles

The Centre will advance Australia’s capabilities in next-generation fleet vehicle digitisation and electrification while providing a foundation for Directed Technologies to scale its APAC solutions to global markets.

A Victorian-owned and operated company, Directed Technologies offers solutions for a variety of fleet and passenger vehicles including trucks, trailers, cars, motorbikes, and electric delivery vehicles.

The Connected Mobility Innovation Centre currently manages 200 terabytes of data, processing 20 billion probe data points a day, including live video feeds, vehicle and driver behaviour alerts and efficiency measures and vehicle fault codes. It provides customers with a live view and advanced analytical

insights of their people, vehicles, and assets across the global road network.

The new Connected Mobility Innovation Centre will double Directed Technologies’ local manufacturing capabilities in both telematics and IoT.

The company’s telematics devices, manufactured locally, are used in more than 2,500 vehicle fleets globally including truck brands like HINO, Mercedes-Benz, Kenworth, DAF and IVECO.

The company has seen rapid growth in Australia and New Zealand, with the homegrown technology now exported throughout 15 APAC countries including Japan, South Korea, Malaysia, Thailand, Singapore, Guam, Indonesia, and Vietnam.

Savvy research into the state of Australia’s view on EVs

As part of Savvy’s research into Australian consumer sentiment and economics, the company followed up its Electric Vehicle 2021 survey with a new poll seeing where sentiments are at present.

A new representative national survey commissioned has shown that over half of Australians intend to buy an electric vehicle (EV) in the future.

With 41 percent who said they intended to buy at some point and 10 percent primed to purchase within the next 12 months.

The 45–54-year-old cohort are the most likely to buy at some point with the 18-24s and 35-44s indicating they’re the most likely to buy within the next 12 months. The older demographics (55-64 and 65+) were most likely to prefer a internal combustion engine car.

Twelve percent said they would rather purchase a Petrol-Electric Hybrid vehicle instead and three percent of Australians already own an EV.

This is a slight increase over Savvy’s 2021 survey.

Prices seemed to have eased despite inflation and rate hikes, as only 17 percent said they couldn’t afford to buy an EV this year compared with 30 percent 2021. This may be influenced by greater choice and cheaper alternatives coming to market. Curiously, 23 percent of men say they cannot afford to buy an EV compared with 37 percent of women. When Australians were asked about their top three changes needed make EV ownership more enticing, men were more concerned about improved driving range compared with women being more concerned about electricity prices. Men also registered more concern about improved infrastructure.

Helixx, a new UK-based global technology company, has announced an innovative manufacturing system to deliver a range of affordable mini commercial electric vehicles. Engineered in the UK and designed to support sustainable economic development, the range of four advanced vehicles will be rapidly deployable virtually anywhere in the world through local manufacture.

The Helixx CARGO commercial delivery van will offer optimised cargo space, while the TRUCK pick-up is designed to meet the needs of construction businesses. The open-body TUK and the closed-body RIDE are designed as modern replacements for ride-hailing and taxi fleets. Through Helixx, regional businesses will be able to create and operate mobility hubs that within as little as 180 days can produce zero-emission commercial vehicles suitable for the megacities of today and tomorrow.

Tesla’s Model 3 just got better

VTE | 17 www.saea.com.au

Overseas | News

The Tesla Model 3 will now travel up to 629 km (WLTP) on a single charge with updated exterior styling optimised for maximum aerodynamics. The vehicle also has a new interior design with wraparound styling, premium materials and customisable ambient lighting. For the first time in Model 3, backseat passengers can adjust the climate or watch movies on an 8” rear touchscreen.

Society of Automotive Engineers

Australasia’s 2023 Annual General Meeting

On 27 June the SAE-A held its Annual General Meeting for 2023 at the Richmond Social in a private function room. SAE-A members started to arrive just before 6.30pm after which SAE-A Chairman and CEO Adrian Feeney officially opened the meeting.

At the start of his presentation, Mr Feeney concentrated on the reasons the SAE-A conducts reviews of its financial situation rather than audits explaining that ASIC does not require audits until a company reaches a threshold of about $500,000 and while the SAE-A is currently very financially stable and buoyant it has not reached that threshold. A review is substantially more cost effective than a full audit hence the SAE-A will continue with reviews.

Mr Feeney then reminded the audience of the SAE-A’s mission and vision statements which are:

1. Our mission is to advocate for, develop and connect Australasian mobility engineers for the future of global mobility

2. Our vision is to foster a thriving mobility engineering industry within the Australasian region. These are central to the operation of the SAE-A, as is the board which welcomed James Soo and Bernard Rolfe who were appointed during the year as replacements for two resignations.

After a snapshot of how the SAE-A had worked through the difficult COVID years Mr Feeney remarked on the welcome change to face-to-face meetings and the extremely successful APAC21 conference.

“We had an absolutely brilliant APAC21 conference last year attended by nearly 190 delegates over three days and it really made people realize just the capability we have,” he said.

Mr Feeney commented that due to COVID it went a little bit quiet last year saying there was not much choice, but now the events calendar is very strong,

thanks to Suzanne Nicol the society’s new full-time events manager, and to spice things up there are a lot of new events planned for this year.

Three board member positions were decided at the AGM and another big announcement was made.

“The big announcement, it’s a very sad moment for everyone I know, but I’m stepping down as chairman this year,” Mr Feeney said. “So, I’m stepping down, I will continue to help out, but we are looking for a new chairman and I think now is the right time to do so and to bring some fresh ideas in. Not that my ideas were all that bad, but I think we just need different ones. So, the SAE team for 2023 will have a new chairman.”

Mr Feeney will continue as CEO.

The SAE-A Board for 2022 was highlighted on the powerpoint presentation with Adrian Feeney as chairman, Michael Waghorne Finances, Greg Shoemark as Snr Vice President Government & Industry Liaison, Bernard Rolfe FISITA & SAEI Liaison – Director, Mohammad Fard Major Conference Technical – Director, James Soo Autonomous/EV Vehicles–Director, and Richard Taube and Gary White who is now President. It was time then to turn to the election of three vacancies on the board with nominations received from Lt Col Paul Nation, Noi Vera (Kotev) and Martha Oplopiadis, the three nominees were duly elected.

“I think it’s a great board. I mean the ones who are staying on have done very, very well and the new ones are going to bring some fresh ideas. So that’s all looking very bright,” Mr Feeney remarked. “Things

20 | September 2023 Feature | 2023 AGM

are changing in our world, in the automotive world so we’re looking for enthusiastic people to be part of that journey.

“We can’t look at just automotive in the old terms. The world is changing around us and so transport technology, off-site construction, defence and aerospace and autonomous and automated vehicle technology, they’re all areas which we need to move more and more into.

“We have started that process and we have assigned responsibilities within the board to look at that and to become experts in that field and that will continue to grow. So, we need to diversify as a bottom line.”

Finally, Mr Feeney touched on the Professional Engineers Association registration scheme saying that the focus was firmly on making that a reality for the SAE-A. Three years ago, the society approached the Victorian Government for a seat at the discussion table as the law was being developed. The SAE-A got that seat and had input and continues to do so. With that in mind there will be a need in the near future to employ a Professional Engineers Association assessor, which will be done once the new board settles in.

Three guest speakers were then introduced: Khesh Selvaganapathi – LEAP Australia, Prakash Shrestha – Ford Australia and Kevin Yardley, formerly VinFast Australia.

Mr Selvaganapathi graduated as a mechanical engineer from Monash University and with his passion for simulation is now Engineering Solutions Manager at LEAP AUSTRALIA, specialising in Computational Fluid Dynamics (CFD) and FEA. As an engineering solutions manager, he dedicates himself to assisting local companies in harnessing the power of simulation for product development processes.

Mr Shrestha has a Masters Degree in Structural Engineering and more than 10 years’ experience in product development, design, manufacturing and CAE, with nine world patents and a passion for advanced finite element analysis, structural dynamics, vibration analysis, data acquisition/analysis and CAD.

Mr Yardley was formerly Head of VinFast Engineering Australia. He graduated from Swinburne in 1993 and in 1995 he started with Holden. Mr Yardley progressed quickly up the management hierarchy until he left in 2019. His journey at VinFast started in 2019 and ended in 2021, but in that short space of time he experienced a great deal.

VTE | 21 www.saea.com.au 2023 AGM | Feature

Noi Vera

Paul Nation

Prakash Shrestha Interior CAE –

Ford Australia

Eight years ago Mr Shrestha started with Ford and has been working with the company in interior CAE – IP and console, soft and hard trim, door trims, air registers and air bags. Two years into his job at Ford the company closed down manufacturing in Australia, but they maintained the development of the Everest model here as well as the Ranger. These products are developed in Australia for the whole world so it’s a complex program. “At the moment about a hundred engineers are doing computer-aided engineering. That includes safety, NVH, durability, all kind of things,” Mr Shrestha explained.

“I work in the interior, so basically interior means the IP and console, the soft trim, hard trim, registers and airbags and you know the safety things.”

One of the important parts of the job is the NVH analysis – Noise, Vibration, Harshness which is done using Nastran software, which is a finite element analysis (FEA) program that was originally developed for NASA. The other part is the kinematics which is analysed using MSC Adams which is a multibody dynamics simulation software system. The simulation software solver runs mainly on Fortran and more recently C++ as well. According to MSC Adams it is the most widely used multibody dynamics simulation software.

The IP/Console – knee/head impact airbags, CFD, illumination and other structural elements are analysed using Ansys.

“It is quite complex, you know, because what has happened is you are driving on a road. The wheels are vibrating, and the body is vibrating, and you know, then the steering is vibrating and all the parts are vibrating. So, what we have to do is we have to make sure that there is no resonance between each of them,” Mr Shrestha said.

“You have to take into account everything. Although you are working in the interior, you still need to make sure it is not resonating with any other parts in the vehicle. If it resonates, then you know that part is going to fail. So, basically, the thing is in a car you might have thousands of parts, and you don’t want any of them to be resonating and failing within the life cycle.”

Mr Shrestha went on to explain the challenges facing his area which includes meeting criteria from different countries, different laws and regulations. In some countries you may have to put in single stage airbags, others dual stage or maybe low power or high power. He cited the example of North America where they need larger airbags because they don’t have to have seat belts in every state.

Regardless of the air bag type or deployment the systems all must work as intended.

“We have to make sure that it cracks properly,

Khesh Selvaganapathi Engineering Solutions Manager Leap Australia

Mr Selvaganapathi has been part of LEAP’s finite element team for the past four years and he was concentrating his talk on CAE.

LEAP assists local companies to reduce costs, improve product quality and increase productivity using engineering software from industry leaders such as ANSYS, PTC, nCode, Rocky & LSTC.

“Ansys has been around from 1970s. Initially the start was with the nuclear industry in a structural and a finite element sense. But ever since Ansys has grown into a huge multinational simulation company focusing on different physics,” he explained.

“We’ve been supporting a number of clients in Australia, and we’ve got a local team in all the major cities. We train, and we do consultancy as well.

“Apart from Ansys, the other things we offer, but I’m primarily from the Ansys team, includes CAD, as well as product of lifecycle management assistance.”

it opens up, it hits the windshield, and then by the time it’s fully open, the person hits. It looks very, very simple, but the simulation is fairly complex,” he explains.

“The last part is the CFD, that is the occupant, like how the person feels inside – you have to have an air conditioning system. We want to make sure that there’s enough air coming out. And then the demisters are working properly and it’s good enough to demist. For for that, we do the CFD.”

Mr Selvaganapathi went on to explain that nowadays the goal is to get products out faster and cheaper and so the solution is to use simulation in order to lower costs as well as to get testing done.

He also touched on how his company is working with phototonic simulation where with a computer you can render simulations of a foggy, or rainy or very sunny day, to see how a system performs within those parameters.

As Mr Selvaganapathi said in closing what he was able to talk about was just 10 percent of what Ansys has to offer.

22 | September 2023 Feature | 2023 AGM

Here and gone, VinFast

It’s tempting to call this VinFast, bin’ fast but we won’t however, the Vietnamese company did come and go in Australia at a very fast rate, quicker in and out than Alfa Romeo of times gone by.

VinFast set up shop in Melbourne in December 2019, officially opened its R&D centre in June 2020, purchased the Lang Lang proving ground from Holden in September 2020, in May 2021 it ‘temporarily’ closed its engineering centre in Port Melbourne and then pulled the pin completely in Australia in August 2021. The company blamed COVID.

Kevin Yardley ex-Holden and GM engineer had set up the local office and headed the company in Australia.

He had been with GM for 25 years and was an experienced engineer but also an experienced automotive executive. He resigned from VinFast after 18 months.

VinFast LLC is the brainchild of Vietnam’s richest man, Pham Nhat Vuong, who invested billions in his dream of developing a global car company based in Vietnam, for a while it did include Australia and while the company has said recently that it hasn’t put that dream aside it is unlikely in the near future.

“I went to VinFast in 2019, and I was there as head of product development for about 18 months. But what I’d like to talk about in all of that diversity is my learnings and experiences on how culture plays a really vital role in the auto industry. I mean, most people think it’s just technical,” Mr Yardley said at the SAE-A AGM where he spoke at length on his time with the company.

Australia, our culture and outlook is individual as is every country’s but what Mr Yardley reiterated was the need, the absolute need to understand the culture of the market you want to tap into.

An easy example is Great Wall Motors, any Australian could have told you the name would not work no-one in their right Aussie mind would want to say I drive a Great Wall. Hence, GWM was born.

Mr Yardley referred to what he termed the GM ‘cookbook’ which was essentially a recipe for building a car for a specific country that would fit the culture.

“In my opinion you have to have a company culture of trust and delegation of real

VTE | 23 www.saea.com.au 2023 AGM | Feature

g

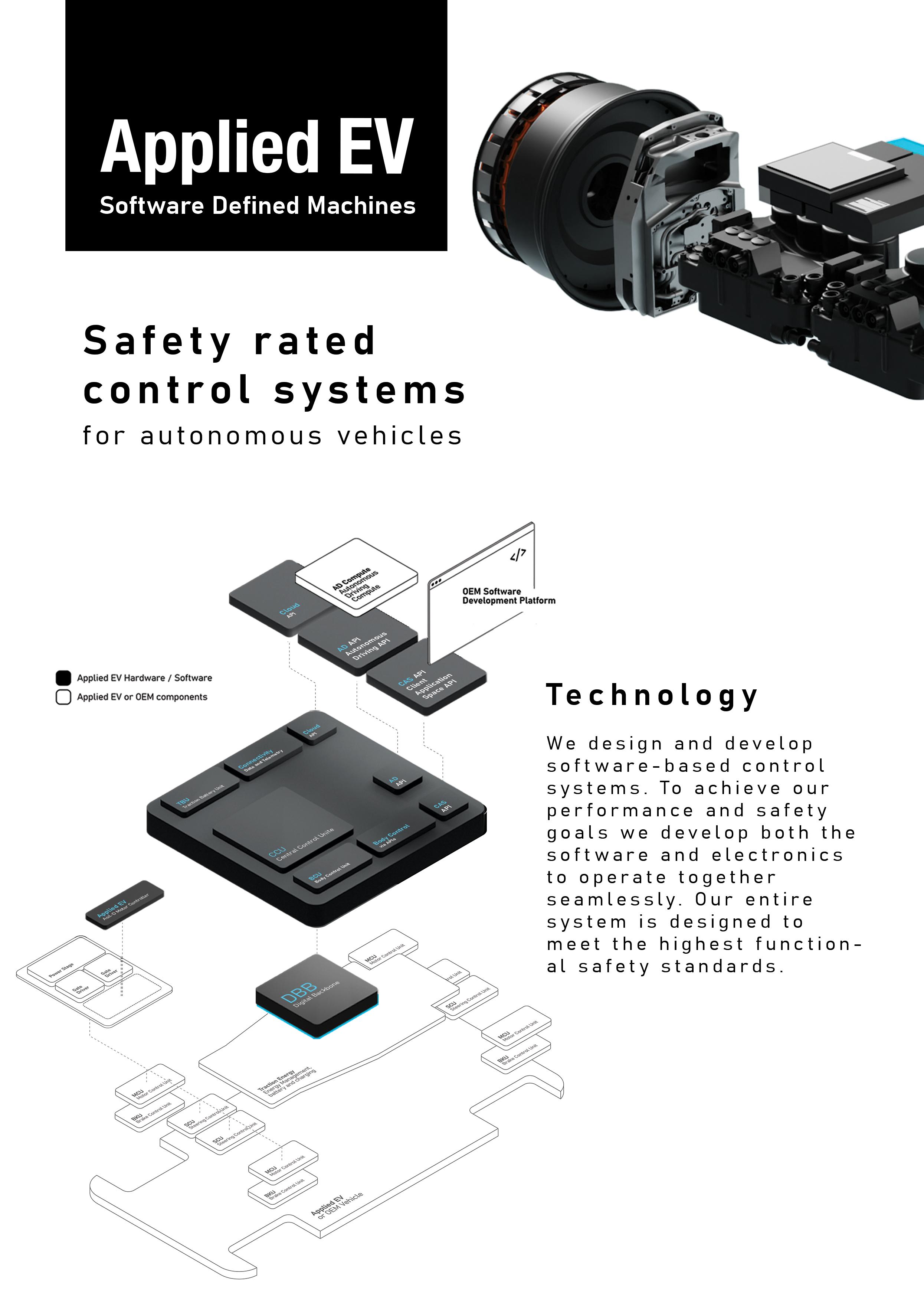

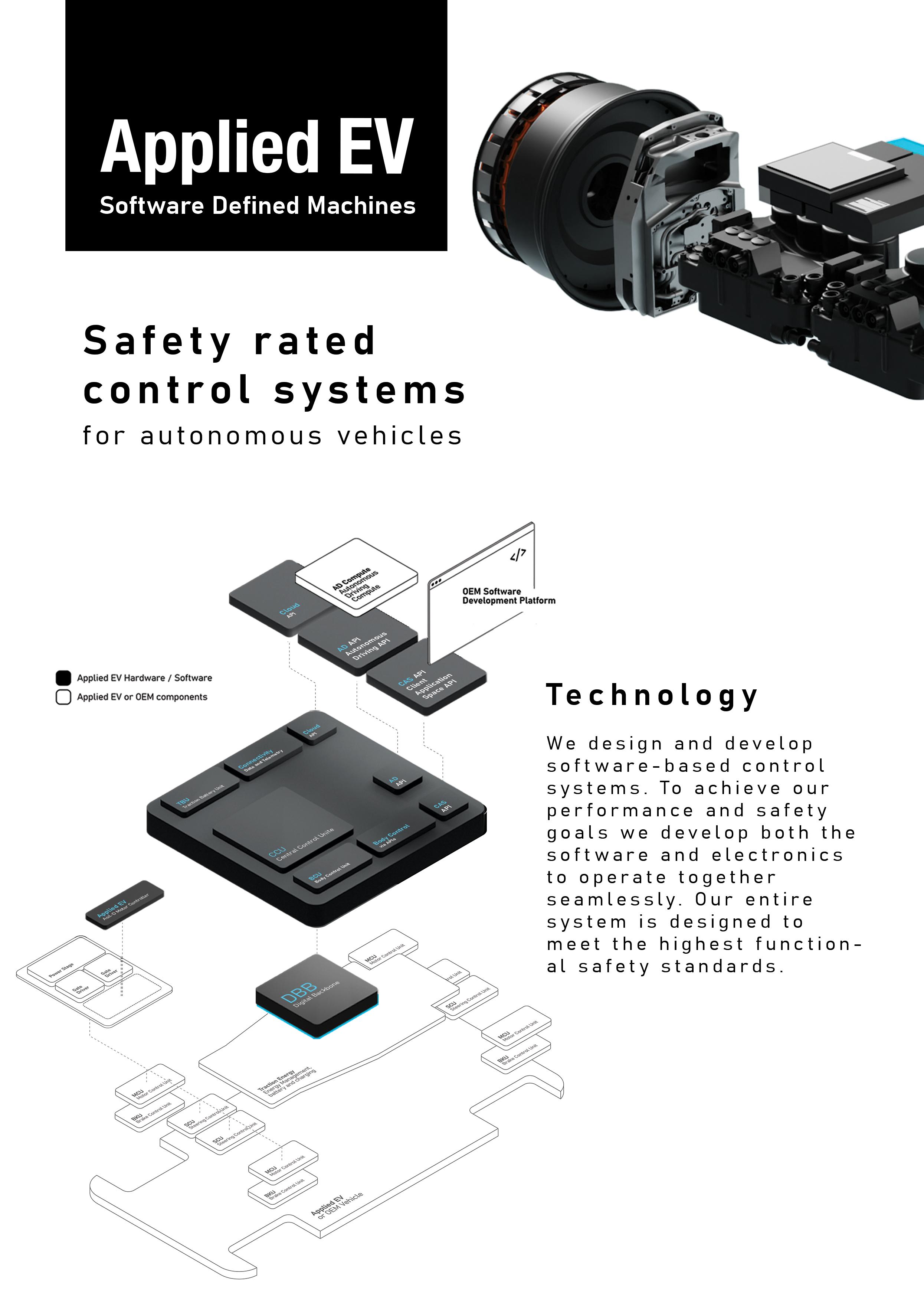

Kevin Yardley