Analog Devices delivers IMU sensor solutions that maintain high precision even while operating in the harshest conditions. Featuring robust accuracy, full calibration, and plug and play functionality, ADI’s IMUs provide the level of navigation and stabilization you need to deploy complex, high performance designs.

Small

Editor’s Perspective

7 Common MOSA, SOSA updates

By John McHaleTechnology Update

8 Workforce development a major piece of CHIPS Act investment

By Lisa DaigleMil Tech Insider

9 Safety-certifiable COTS lowers the cost of keeping the skies safe

By Gregory SikkensDefense Tech Wire

10

By Dan TaylorEditor’s Choice Products

38 By Military Embedded Systems Staff

Guest Blogs

40 IFF on U.S. drones: Is cost a factor?

By Glenn Mathias,Australian Maritime Consultancy

42 Industry 5.0: The digital transformation of A&D manufacturing confronts the next phase

By Matt Medley,IFS

45 The metaverse, AI, and space defense: Emerging tech transforming 2024

By PeteMorrison, BiSim

Connecting with Military Embedded

46 By Military Embedded Systems Staff

14 Inspiring future women engineers, a defense industry challenge Q&A with Maria Ho, Deputy Director for Government and Strategic Programs, Aerospace & Defense at Analog Devices

By John McHale, Group Editorial DirectorSPECIAL REPORT: Counter-UAS technology

18 Evolving UAS threats spur industry to get creative with C-UAS solutions

By Dan Taylor,Technology Editor

MIL TECH TRENDS: Reduced SWaP designs for UAS payloads

22 Developing CSfC secure data solutions: Waivers no longer required for storage devices

26

All

©

©

ISSN: Print 1557-3222

By Chris Kruell,CDSG

SWaP-optimized mission systems for unmanned platforms help expand capabilities

By Jeff Evans, Curtiss-WrightINDUSTRY SPOTLIGHT:

MOSA solutions for unmanned systems: SBCs, RTOS, connectors, backplanes, etc.

30 AI, MOSA, and the future of secure uncrewed warfare

ByTim Reed, Lynx Software Technologies

34 VITA Standards Organization high-profile projects

ByJerry Gipper, VITA Editorial Director

Published by:

ON THE COVER:

U.S. Marines walk an FIM-92 Stinger man-portable air-defense system to a firing point aboard the amphibious assault ship USS Boxer (LHD 4), while supporting a counter-unmanned aerial system exercise in the Pacific Ocean during late 2023. U.S. Marine Corps photo by Cpl. Amelia Kang. @military_cots

https://www.linkedin.com/groups/1864255/

Behlman introduces the first test-proven VPX power supplies developed in alignment with the SOSA Technical Standard. Like all Behlman VPXtra® power supplies, these 3U and 6U COTS DC-to-DC high-power dual output units feature Xtra-reliable design and Xtra-rugged construction to stand up to the rigors of all mission-critical airborne, shipboard, ground and mobile applications.

VPXtra® 1000CD5-IQI

> 6U power module developed in alignment with the SOSA Technical Standard

> Delivers 1050W DC power via two outputs

> VITA 46.11 IPMC for integration with system management

VPXtra® 700D-IQI

> 3U power module developed in alignment with the SOSA Technical Standard

> Delivers 700W DC power via two outputs

> VITA 46.11 IPMC for integration with system management

17 Abaco Systems – Elevate autonomy

15 AirBorn – TriMate next-generation circulars

2 Analog Devices, Inc. –IMU solutions for the harshest conditions

25 AUVSI.org – The technology event for autonomy (XPONENTIAL)

5 Behlman Electronics, Inc. –Behlman leads the pack again!

36 Dawn VME Products –Dawn powers VPX

37 Elma Electronic – Leaders in Modular Open Standards enabling the modern warfighter

48 GMS – X9 Spider. The world's most powerful full-featured wearable AI computer

13 LCR Embedded Systems, Inc. –VPX and SOSA aligned solutions for any mission

41 Phoenix International –Phalanx II: The ultimate NAS

21 Sealevel Systems, Inc. –Relio R1 Rugged Industrial Computer for Mission Critical Communications

33 Sealevel Systems, Inc. –Modern Aviation's Reliance on ACAS for Crewed & Uncrewed Deployments

3 Wolf Advanced Technology –Winning at the edge

embedded world Exhibition & Conference

April 9-11, 2024

Nuremberg, Germany

https://www.embedded-world.de/en

Sea-Air-Space

April 8-10, 2024

National Harbor, MD

https://seaairspace.org/

XPONENTIAL/AUVSI

April 22-25, 2024

San Diego, CA

https://www.xponential.org/xponential2024/ public/enter.aspx

SOFWEEK 2024

May 6-10, 2024

Tampa, FL

https://www.sofweek.org/

GROUP EDITORIAL DIRECTOR John McHale john.mchale@opensysmedia.com

ASSISTANT MANAGING EDITOR Lisa Daigle lisa.daigle@opensysmedia.com

TECHNOLOGY EDITOR – WASHINGTON BUREAU Dan Taylor dan.taylor@opensysmedia.com

CREATIVE DIRECTOR Stephanie Sweet stephanie.sweet@opensysmedia.com

WEB DEVELOPER Paul Nelson paul.nelson@opensysmedia.com

EMAIL MARKETING SPECIALIST Drew Kaufman drew.kaufman@opensysmedia.com

WEBCAST MANAGER Marvin Augustyn marvin.augustyn@opensysmedia.com

VITA EDITORIAL DIRECTOR Jerry Gipper jerry.gipper@opensysmedia.com

SALES/MARKETING

DIRECTOR OF SALES Tom Varcie tom.varcie@opensysmedia.com (734) 748-9660

STRATEGIC ACCOUNT MANAGER Rebecca Barker rebecca.barker@opensysmedia.com (281) 724-8021

STRATEGIC ACCOUNT MANAGER Bill Barron bill.barron@opensysmedia.com (516) 376-9838

STRATEGIC ACCOUNT MANAGER Kathleen Wackowski kathleen.wackowski@opensysmedia.com (978) 888-7367

SOUTHERN CAL REGIONAL SALES MANAGER Len Pettek len.pettek@opensysmedia.com (805) 231-9582

DIRECTOR OF SALES ENABLEMENT Barbara Quinlan barbara.quinlan@opensysmedia.com AND PRODUCT MARKETING (480) 236-8818

INSIDE SALES Amy Russell amy.russell@opensysmedia.com

STRATEGIC ACCOUNT MANAGER Lesley Harmoning lesley.harmoning@opensysmedia.com

EUROPEAN ACCOUNT MANAGER Jill Thibert jill.thibert@opensysmedia.com

TAIWAN SALES ACCOUNT MANAGER Patty Wu patty.wu@opensysmedia.com

CHINA SALES ACCOUNT MANAGER Judy Wang judywang2000@vip.126.com

PRESIDENT Patrick Hopper patrick.hopper@opensysmedia.com

EXECUTIVE VICE PRESIDENT John McHale john.mchale@opensysmedia.com

EXECUTIVE VICE PRESIDENT AND ECD BRAND DIRECTOR Rich Nass rich.nass@opensysmedia.com

DIRECTOR OF OPERATIONS AND CUSTOMER SUCCESS Gina Peter gina.peter@opensysmedia.com

GRAPHIC DESIGNER Kaitlyn Bellerson kaitlyn.bellerson@opensysmedia.com

FINANCIAL ASSISTANT Emily Verhoeks emily.verhoeks@opensysmedia.com

SUBSCRIPTION MANAGER subscriptions@opensysmedia.com

While it was officially released in the famous Department of Defense (DoD) Tri-Service Memo five years ago, the concept of a modular open systems approach (MOSA) has been around for some time and is not a new concept, said Jason Dirner, in his keynote address at the MOSA [Modular Open Systems Approach] Virtual Summit held February 22 and hosted by myself and Military Embedded Systems. What is new, however, Dirner said, is “common MOSA, [where] you have multiple programs and services conforming to the same standard,” which enables a greater level of reuse and portability across the community, he added.

MOSA has been used within a single program, where the modular architecture, key interfaces, etc. are defined, but the resulting solutions are specific to that program and have limited reuse across community, he explained.

Common MOSA strategies like the Sensor Open Systems Architecture (SOSA) Technical Standard, CMOSS [C5ISR/EW Modular Open Suite of Standards], and HOST [Hardware Open Systems Technologies], are actually more similar than they are different, Dirner said. They all want to increase competition, improve upgradeability and while they are separate efforts, “we are working together.”

Dirner noted this is especially true with SOSA, which has become a “standard melting pot, quickly becoming the de facto form to adopt and align government and industry standards to create a common DoD-wide open system architecture.” SOSA enables reuse across services, agencies, and programs; maximizes government investments; and capitalizes on the collective expertise of over 160 member organizations, he added.

The services have been collaborating for the better part of a decade on these standards, Dirner noted.

“If the Air Force procures a capability and matches what the Army needs, why shouldn’t the Army be able to take it and integrate it?” he said. “On the flip side, if a vendor gets a plugin card included in program X now, they can get it included in program Y and Z as well. [This creates] new opportunities and new reuse that wasn’t possible before.”

In his presentation, Dirner said the Technical Standard for SOSA Reference Architecture, Edition 2.0 (Snapshot 2) would be released any day; in fact, it was released the very next day.

Describing the latest release, Dirner noted some highlights:

› More support for EO/IR wide area search/surveillance

› Nav Data Service adoption of VICTORY

John.McHale@opensysmedia.com

› Security Services definition (providing authentication and authorization infrastructure for the sensor)

› Data model updates for EA, SIGINT, SAR, and EO/IR

› MORA V2.5 and VICTORY V1.10

“The data model underpins everything we do in SOSA,” Dirner noted.

For more from Dirner on Snapshot 2 and a preview of what will be in Snapshot 3, check out the MOSA Virtual Summit at https://resources.embeddedcomputing.com/series/mosa2024/landing_page?utm_bmcr_source=cal . To learn about Snapshot 2, visit https://publications.opengroup.org/s241.

As we ended the keynote session, I asked Dirner if he could share MOSA success stories and he replied with two. The first told how Army PM EW&C (Program Manager Electronic Warfare and Cyber) were early adopters of CMOSS. “I saw where they were able to pivot and change cards and share cards across programs, all of which would not have been possible if they had not used a common architecture,” he said.

In the second story, he mentioned CMFF [Common Mounted Form factor), which was born out of CMOSS. Dirner noted that “CMFF will replace mission-command comms, PNT [position, navigation, and timing], and EA [electronic attack] solutions on ground and airborne platforms with a common chassis and has a potential huge impact on how we field these systems in terms of competition and upgradeability. Those are two great success stories to reference.”

The same week as our MOSA Virtual Summit and the SOSA Technical Standard 2.0 Snapshot 2 release, Intel announced the launch of Altera, its new standalone FPGA [field-programmable gate array] company.

If you remember, Intel acquired Altera, a maker of the Stratix line of FPGAs and main competitor Xilinx at the time, which is now part of AMD. While it was quiet regarding product launches the first few years after the acquisition, Intel then started releasing new FPGA solutions – such as the Agilex family – that were leveraged by many military embedded systems companies like Annapolis Micro Systems and Mercury Systems; the latest such announcement was the Agilex 9.

I will be diving into the new Altera with its leadership in a podcast later this month. You’ll be able to check it out on https:// militaryembedded.com/.

The White House announced in February 2024 that it will invest more than $5 billion in semiconductor-related research and development (R&D) and workforce needs, including establishing the National Semiconductor Technology Center (NSTC), to advance the government's goals of driving semiconductor progress.

As part of the implementation of the CHIPS and Science Act of 2022, these investments are intended to advance U.S. leadership in semiconductor R&D, cut the time and cost of commercializing new technologies, enhance U.S. national security, encourage universities to develop engineering and semiconductorfocused programs, and support workers in gaining secure semiconductor and engineering jobs.

The recent announcement formally established a public-private consortium for the NSTC and laid out plans to invest hundreds of millions of dollars in the U.S. semiconductor workforce, along with specifics on the government’s plans to fund programs in packaging and metrology.

The NSTC, says the National Institute of Standards and Technology (NIST), is at the center of the CHIPS Act’s R&D effort. According to information from NIST, the NTSC is beginning the process of uniting government, industry, educational institutions, labor interests, customers, suppliers, entrepreneurs, and investors to accelerate the rate of semiconductor innovation and ultimately production. The NTSC will operate as a public-private consortium as it works to lower the barriers to companies’ participation in the semiconductor business and directly work to establish and facilitate a skilled, diverse semiconductor workforce.

The U.S. Department of Commerce oversees NIST, which is one of the nation’s oldest physical science laboratories and has as its mission to promote U.S.

innovation and industrial competitiveness by advancing measurement science, standards, and technology to enhance economic security and quality of life. Under the administration’s CHIPS for America effort, NIST manages the CHIPS Program Office, which is responsible for manufacturing incentives; and the CHIPS Research and Development Office, which oversees R&D programs.

On January 31, 2024, the Department of Commerce issued a Notice of Intent (NOI) to announce a competition for what it’s calling the CHIPS Manufacturing USA Institute, a program that will create a so-called digital twin center that will work on innovations in semiconductor and advanced packaging manufacturing.

In its NOI, NIST and the commerce department stated that the CHIPS Manufacturing USA Institute will strive to “… foster a collaborative environment to significantly expand innovation, bring tangible benefits to manufacturers of all sizes, strengthen diverse research institutions, and ensure a national reach in workforce development.”

The CHIPS Manufacturing USA Institute is expected to establish a facility where companies can experiment while protecting proprietary information, conduct relevant research projects, share tools and equipment that will enable large and small members to innovate at low cost, and participate in educational and workforce development programs.

This digital twin-style facility – as described in the White House announcement – will serve as a virtual manufacturing floor, simulating a physical floor in real time to discover ways to improve products and expedite processes. Whereas a shift in equipment or manufacturing processes can drastically slow down production on a physical floor, digital twin technology will enable users to assess techniques before making costly decisions, and thereby improve capacity planning, production optimization, facility upgrades, and real-time process adjustments.

“CHIPS research and development programs are at the core of our greatest innovations and help to find the solutions for the semiconductor industry’s most pressing challenges. With strategic investments in R&D complementing targeted industry incentives, CHIPS for America will not only bring semiconductor manufacturing back to the U.S. – it will keep it here for good,” said Commerce Secretary Gina Raimondo. “As we create opportunities for good-paying jobs, the workforce initiatives, such as the NSTC Workforce Center of Excellence, will help ensure a diverse, skilled, and prepared workforce across the nation.”

In a separate February 2024 address at Georgetown University, Secretary Raimondo emphasized the need for a trained technology workforce and urged chip manufacturers, construction companies, and unions to work toward the national goal of hiring and training another million women in construction over the next decade to meet the demand in chips and associated infrastructure projects. She also called on semiconductor companies to work with high schools and colleges to train 100,000 new technicians over the next decade through apprenticeships, career and technical education, and career-pathway programs.

“If we don’t invest in America’s manufacturing workforce, it doesn’t matter how much we spend,” said Raimondo. “We will not succeed. If we get this right, the U.S. semiconductor workforce will be the gold standard for other industries to follow.”

Every day, at peak operational times in the U.S., the Federal Aviation Administration (FAA) Air Traffic Organization (ATO) handles approximately 5,400 aircraft flying in 29 million square miles of controlled airspace. When the growing number of uncrewed air systems (UASs) and other commercial and military uncrewed aircraft are also considered, the total number of aircraft flying daily over U.S. airspace significantly increases.

The critical systems responsible for an aircraft’s safe flight are subject to stringent safety regulations. Adherence to these regulations must be proven before an aircraft is deemed airworthy. The level of danger posed by an aircraft system in the event of a failure and the associated acceptable probability of failure dictate the Design Assurance Level (DAL) that system must meet to be certified for flight. For example, flight-critical systems whose failure would result in catastrophic loss of life – the highest level of danger – must meet DAL A to demonstrate a probability of failure lower than one in one billionth (10-9) per flight hour.

To ensure that UASs are equipped to fly without an onboard pilot, two TSOs [technical standard orders] have been released specifically for unmanned aircraft. TSO-C212, in accordance with DO-366 (UAS Air-to-Air Radar), provides standards for the UAS’s scanning radar that serves to detect other aircraft while in flight. The complementary TSO-C211 invokes DO-365 (UAS Detect and Avoid Systems) and outlines requirements for an onboard system capable of computing an avoidance maneuver should an intruder enter the UAS’s flight path. All UASs weighing more than 55 pounds, flying in controlled airspace above 400 feet and out of view of their operators, should meet DO-365 objectives and obtain TSO-211 authorization.

For larger UASs, there is a separate set of DALs and failure probabilities they must adhere to based on their kinetic energy at ground impact. The calculations behind these DALs are detailed in TSO-C213 (Unmanned Aircraft Systems Control and NonPayload Communications Terrestrial Link System Radios).

Ultimately, the flight certification for an aircraft is authorized by the aviation authority in that aircraft’s country of origin, whether it’s the FAA, the European Aviation Safety Agency (EASA), or Transport Canada. Because multilateral agreements exist between many certification agencies, after an avionics system has been successfully safetycertified in one country, that certification is usually recognized as valid in numerous other countries (pending the completion of some additional paperwork).

To meet safety-certification requirements, system designers must provide data showing evidence of objectives identified by a means of compliance; this data is referred to as artifacts. Hardware and software components can be purchased from vendors who have experience and expertise in safety-certifiable COTS [commercial off-the-shelf] parts as an alternative to undertaking the rigorous, costly, and time-consuming process required to develop a custom safety-certifiable module from the ground up. Safety-certifiable COTS products are delivered with the full set of artifacts demonstrating certifiability to the objectives identified by a means of compliance, resulting in a significant reduction in the time and cost of certifying the complete system.

Military aircraft systems are often built using COTS modules. The reliability of COTS devices usually falls in the range needed to meet the far less stringent DAL C rating,

suitable for systems whose failure would result in discomfort or injuries to the occupants, but not loss of life or loss of the aircraft. To meet DAL-C, a system must be designed to have <1 failure in 10-5/flight hour, far short of the 10-9 required failure probability for DAL A.

For this reason, when COTS devices are used, redundancy is needed to meet the probability of equipment failure. The use of a dissimilar redundant architecture mitigates common mode failures and meets DAL A requirements. By running different operating systems and applications on dissimilar hardware, system designers can add an extra layer of protection against latent software defects that would impact the different hardware architectures in similar ways.

To help system designers build redundant architectures with a lower risk of common mode failure, Curtiss-Wright offers a family of safety-certifiable COTS modules that include processors powered by NXP Power Architecture and Arm processors.

For example, the V3-1708, a SOSA Technical Standard aligned, DAL A safetycertifiable processor features an NXP Layerscape LX2160A processor and supports Wind River’s VxWorks HVP safety-certifiable profile with a VxWorks 7 safety-certifiable profile guest operating system. It uses a rugged COTS singleboard computer developed using AC/ AMC 20-152A as a means of compliance – combined with off-the-shelf data kits for DO-254 and FMEA [failure mode and effects analysis] to support system architecture, Functional Failure Path (FFP) analysis, and certification.

Gregory Sikkens is Senior Product Manager, Curtiss-Wright Defense Solutions.

Curtiss-Wright Defense Solutions

www.curtisswrightds.com

By Dan Taylor, Technology Editor

By Dan Taylor, Technology Editor

Germany to obtain air defense system from Rheinmetall

The German armed forces chose Rheinmetall to supply the Skyranger 30 mobile air defense system in a €595 million ($646 million) contract that includes the delivery of a prototype and 18 series production vehicles, with an option for an additional 30 systems. In its contract announcement, Rheinmetall says that it expects the first prototype to be delivered by the end of 2024.

The Skyranger 30, a component of the newly developed shortand very short-range air defense system in Europe known as the NNbS, aligns with the European Sky Shield Initiative. The hybrid system, says the company, is intended to fill a capability gap in mobile air defense, as it combines a 30 mm x 173 KCE revolver gun, surface-to-air missiles, and accompanying sensor suite on a single platform. Depending on customer requirements, the system can be kitted out with various modern guided missiles such as the Mistral, Stinger, or special counter-uncrewed aerial system (C-UAS) missiles.

Saab won a contract from the Swedish Defense Materiel Administration (FMV) to supply four additional Gripen C fighter aircraft to Hungary. This development follows an amendment to a previous agreement between FMV and the Hungarian Government, initially signed in December 2001, which included 14 Gripen C/D fighters for the Hungarian Air Force. With this latest amendment, Saab reports that Hungary’s fleet of Gripen aircraft will total 18.

Saab has been a long-standing partner for Hungary, providing continual upgrades and support, with plans extending beyond 2035. The company says that in tandem with the aircraft order, Saab and the Hungarian Ministry of Defence have entered into a Memorandum of Understanding (MoU) focusing on high-tech industrial development and fighter aircraft capabilities, with the intent of facilitating the establishment of a center of excellence for virtual-reality technology in Hungary.

BAE Systems won a contract with the Space Systems Command (SSC) Space Enterprise Consortium (SpEC) to provide a prototype ground system for the U.S. Space Force’s SSC Future Operationally Resilient Ground Evolution Command and Control (FORGE C2) project. Under the terms of the agreement, BAE Systems will integrate proven capabilities into a prototype ground system that will enable the Space Force to provide command and control capabilities for Next-Generation Overhead Persistent Infrared (OPIR) GEO (NGG) and Next-Generation OPIR Polar (NGP) systems.

The announcement describes the FORGE C2 project as the attempt to integrate telemetry, tracking, command, flight dynamics, mission management, and ground resource management into a consolidated framework; the resultant framework will facilitate rapid integration of next-generation assets as they come online and enable a single capability that can operate the current and future OPIR constellation.

Figure 1 | Image courtesy Rheinmetall.

Figure 1 | Image courtesy Rheinmetall.

Hypersonic vehicle test flight completed by Stratolaunch

Stratolaunch completed the second captive carry flight of its Talon-A hypersonic vehicle, TA-1, marking a significant step toward its first powered flight, the company announced. The recent flight, involving the company’s launch platform Roc, is the 13th flight for Roc and the second time it carried a Talon vehicle loaded with live propellant.

The flight, which lasted 4 hours and 29 minutes, took place in the Vandenberg Western Range in California. It focused on evaluating the propulsion system of Talon-A and assessing flight environments with live propellant onboard. Another key aspect of the flight, the company reported, was to test the telemetry systems of both Roc and TA-1, in conjunction with range communication assets.

UK to invest £4.5 billion in drones for armed forces

The U.K. Ministry of Defense (MoD) launched what it calls the “U.K. Defence Drone Strategy,” a new initiative backed by a £4.5 billion ($5.71 billion) investment over the next decade. This approach – which the MoD termed “informed by the experiences in Ukraine” – seeks to accelerate the deployment of uncrewed tech across Britain's army, navy, and air force.

The MoD’s strategy emphasizes rapid experimentation, testing, and evaluation of uncrewed platforms, integrating efforts across the three military services, along with close collaboration with industry to stay abreast of evolving technologies and threats. The goal, say MoD officials, is to equip the armed forces with enhanced intelligence, reconnaissance, surveillance, strike, and logistical capabilities and move away from prolonged development timelines.

MH-60S helicopters to obtain video system support from Cubic Defense

Cubic Defense won a contract from Naval Air Systems Command (NAVAIR) for the ongoing maintenance, upgrade, and support of the Full Motion Video (FMV) System, dubbed KnightLink, for the MH-60 Sierra (MH-60S) helicopter fleet, the company announced.

The contract covers a range of services, including software enhancements, hardware reinforcement, and general maintenance for the KnightLink systems, which provide video support capabilities across various operational domains such as flight testing, maintenance, and laboratory assistance. The company says that the KnightLink hardware features Weapons Replaceable Assemblies (WRAs), necessary cabling, and additional hardware procurement, including Peculiar Ground Support Equipment (PGSE), to facilitate fleet introduction.

AI flight assistant pact signed between USSOCOM, Beacon AI

U.S. Special Operations Command (USSOCOM) awarded artificial intelligence (AI) aviation technology company Beacon AI a Phase 2 prototype Other Transaction Authority (OTA) agreement under which Beacon AI will enhance its AI copilot assistant to optimize aircraft operations and improve aircraft route selection. A Beacon AI announcement on the agreement stated that the company is tasked with developing and strengthening its AI copilot’s ability to analyze various factors, such as weather and flight path monitoring, with the aim of providing air crews with optimal route recommendations based on aircraft, user-specific requirements, and hazardous weather avoidance and enhancing situational awareness and mission execution.

According to information in the Beacon AI announcement, the AI copilot can help optimize the U.S. Department of Defense’s (DoD’s) annual consumption of 2 billion gallons of aviation fuel; moreover, the global commercial aviation industry is said to be able to use the same technology.

Figure 3 | Image courtesy Stratolaunch.

Figure 3 | Image courtesy Stratolaunch.

Hughes wins contract with SES in support of AFRL satellite internet trial

Hughes Network Systems (an EchoStar company) announced that it won a contract with SES Space & Defense to provide a flexible, software-defined, multi-orbit, autoPACE [primary, alternate, contingency, and emergency] solution and associated modems in support of SES Space & Defense’s and the Air Force Research Laboratory (AFRL) Defense Experimentation Using Commercial Space Internet (DEUCSI) program.

Under the terms of the agreement, Hughes is tasked with delivering its automated network management system (NMS) and enterprise management and control (EM&C) capabilities together with its “Smart Network Edge” software to be integrated by the SES Space & Defense team with Hughes next-generation, software-defined HM100 and HM400 satellite modems providing GEO/MEO [geosynchronous orbit/medium Earth orbit] connectivity. SES Space & Defense is working on integrating a LEO [low Earth orbit] solution into the Hughes auto-PACE offering, which is expected to add resilience to the end program.

Synthetic aperture sonar beamforming under development in Kraken Robotics, U.S. Navy deal

Kraken Robotics Inc. entered into a Cooperative Research and Development Agreement (CRADA) with the Naval Undersea Warfare Center Division, Newport (NUWCDIVNPT) to develop synthetic aperture sonar (SAS) sensor technologies and signalprocessing techniques, the company announced.

Under this agreement, Kraken Robotics and the U.S. Navy will jointly explore various aspects of sonar technology, including advanced signal processing, data fusion, image registration, multispectral image enhancement, and automated target recognition with a focus on enhancing both current and future SAS sensor capabilities. Kraken has collaborated with U.S. government agencies since 2012, with partnerships involving NUWCDIVNPT and the National Oceanographic Institute. These collaborations, the company reports, have enabled Kraken to validate and refine its underwater technology solutions, including the SAS, KATFISH actively controlled towed sonar, and pressure-tolerant subsea batteries, the company says.

Simulation/modeling/virtual training market to show strong growth to 2034, study predicts Global revenue for the military simulation, modeling, and virtual training market – standing at $14.2 billion so far in 2024 – is expected to show strong revenue growth through to 2034, according to a report from Research and Markets, “Military Simulation, Modelling and Virtual Training Market Report 2024-2034.”

The study authors state that market growth is bolstered by the increasing complexity of military operations necessitates advanced training methodologies, which then spurs the adoption of simulation and virtual training solutions; the global surge in defense budgets that amplifies investment in cutting-edge technologies and fosters development of sophisticated training systems; and the emphasis on cost-effective training solutions and the need for realistic battlefield simulations that thereby positions the market as a strategic asset for defense forces worldwide.

U.S. Navy selects Mercury to deliver electronic warfare combat training subsystems

Mercury Systems won a five-year, $243.8 million contract with the Naval Air Warfare Center Weapons Division to provide electronic warfare (EW) combat training subsystems that are reprogrammable, the company announced. The subsystems are intended to bolster U.S. pilot training initiatives with advanced near-peer jamming and EW capabilities. Mercury’s digital RF memory (DRFM)-based reactive jamming subsystems can simultaneously emulate multiple National Air and Space Intelligence Center (NASIC)-validated threats, enhancing training realism, the company says, adding that it has assisted with the Navy’s Airborne Threat Simulation Organization (ATSO) since 1987. Mercury had an initial $20.3 million DRFM production order from ATSO, which encompasses continuous engineering services to update the system’s threat library, ensuring alignment with evolving adversarial capabilities, the company noted.

Figure 5 | NASA image.

Figure 5 | NASA image.

Maria Ho Deputy Director for Government and Strategic Programs, Aerospace & Defense at Analog Devices

Maria Ho Deputy Director for Government and Strategic Programs, Aerospace & Defense at Analog Devices

Recruiting female minds to pursue degrees in electrical engineering and to work in the defense industry is a challenge that needs to be addressed by industry and government, Maria Ho, Deputy Director for Government and Strategic Programs, Aerospace & Defense at Analog Devices Inc. (ADI), told me in my podcast. Maria says that recruitment needs to start at the high-school level or even earlier to inspire young female students to select engineering as a degree and career path. Government programs, industry internships like those offered by ADI, mentorship, and even popular culture all play a role in solving this problem, she notes. Maria also talks about her own career in engineering and the defense industry while also addressing key technology trends in military RF and microwave designs. Edited excerpts follow.

MCHALE: Please describe your responsibility with ADI and your group’s role within the company.

HO: My group has a really unique role within ADI. We work strategically with the science and technology stakeholders in the government. For example, we engage directly with the DoD, the government labs, and other federally funded research and development centers. The idea is we want to provide them early access to technology and development platforms, so that they can prototype quickly and really aid in the technology transition for government programs.

Having this early technology alignment also helps ADI accelerate and really tune our roadmaps for government applications. If there’s a listener out there in a government lab or an R&D center, we’d love to work more closely with you. I'm going to give my shameless plug: Please email us at gov.analog.com.

MCHALE: What trends are you seeing from your military customers in the radar and electronic warfare world in terms of requirements?

HO: First of all, we’re always looking for ways to lower SWaP [size, weight, and power]. But in addition to that, a lot of the other major trends that we’re seeing include wider instantaneous bandwidth, wider tuning ranges, moves to higher frequencies, higher SFDR or spurious-free dynamic range. And we’re also seeing higher power levels and higher operating temperatures for all the electronics.

One of the other big things that we are also seeing from the application side of things is more phased array, both digital and hybrid phased arrays.

MCHALE: Where is innovation happening in military application?. What are your engineers working on that we might see a couple years down the road in RF and microwave technology that’ll be a game-changer for the applications we talked about?

HO: Well, I can’t really disclose our future product roadmaps. But I can tell you that ADI is really working hard to address many of the trends that I previously mentioned. We’re working across multiple process nodes and technologies, so we can continue to improve performance while reducing SWaP. But you’ll also start to notice that we’re including more programmable hardened DSP [digital signal processing] functions in a lot of our latest solutions. That really helps to lower the overall solution cost and lower DC power consumption.

What we’re really trying to do is start to get some of these DSP functions in our overall solutions such as our mixedsignal front-end solutions that that have been recently announced.

MCHALE: Speaking of engineering innovation, you and I had a long conversation where we talked about how to expand the pool of engineering talent in the U.S., especially the pool of female engineers. How do you enlarge the pool? Does it start at the college level or should we go a bit earlier to their high-school years?

HO: I definitely feel that we need to target them earlier. As an industry, we really need to provide more deliberate opportunities, and even consider modernizing the curriculum and coursework at the high-school level, so that we can attract and expand the pool of engineers. For example, the eighth and ninth grade summers [are] an amazing time to target virtual or in-person opportunity so that young women start to get a feel for all the careers in engineering, and then also continue to keep their interest in math and science, so that they can pursue higher levels of math and science curriculum.

Now, continuing on that momentum towards the 10th and the 11th grade,

one of the most crucial pieces is for young women to really have the access to real hands-on internships in specific fields of engineering, because they need that guidance as they are starting to pave their path towards college and beyond.

MCHALE: What is ADI doing to recruit engineering talent?

HO: ADI is doing a lot in this area. There’s a lot of different vectors. We’re very committed to investing in our people and their growth. So, we take different forms. For our normal recruitment, we utilize many of our university partnerships to attract the best talent from across the country. But we also have very focused and specialized partnerships with institutions, such as the University of Massachusetts at Lowell, where we actively recruit these students who are having more experience with the Analog Devices RF Microwave Learning Lab. We also have excellent partnerships with

TriMate’s performance meets or exceeds legacy MIL-DTL-38999 connectors yet they are manufactured in a smaller, lighter, and easier-to-install connector package.

TriMate is offered in three different forms to support different applications: Threaded, Push/Pull, & Break Away — all three plug styles mate with the same receptacles.

airborn.com

organizations that promote the advancement of underrepresented groups, so that we can attract diverse talent to ADI.

What’s near and dear to my heart is internships. ADI really has a cutting-edge internship program, not only at the college level, but at the high-school level. This is coupled tightly with a very strong mentorship program. So, when these programs are linked together, the combination really contributes to better recruitment, but ultimately, better retention success.

The long-term goal would be for us to be able to convert an intern into a full-time employee. Right now, we’re probably converting over 60% of our interns to full-time employees after graduation.

MCHALE: I’ve been in the defense industry nearly 30 years, and I think the number of women who are in senior positions – not just senior management, but senior engineering positions and young engineers – has definitely increased. But there’s still work to be done. In your career, what are the biggest challenges you faced as a woman engineer and as a woman in the defense industry? And how did you overcome them?

HO: Back in 2020 the entire world participated in [what turned out to be] the largest workplace flexibility experiment. We were all thrust into remote work environments. And it really proved that these work environments, being remote and hybrid, could actually be productive, and in many cases, more productive. [As] women we sometimes have added responsibilities. That requires additional flexibility [as] we may not be interested in compromising our career paths. These days I’m really excited that many of these organizations have flexible workplace policies that may not have existed in the past. But there’s still room for a lot of growth here.

One of the areas I feel that we as an industry really need to start thinking of improving is [regarding the] negative perceptions [applied to] someone who wants flexibility, [that] maybe they don’t want to climb up the career ladder or be assigned to the most interesting or challenging projects, which is typically not the case.

MCHALE: While there are many things industry and government can do to get young people more interested in engineering, often what inspires people toward a career is a personal connection with an engineer. Did you have an engineer or mentor who inspired you to get into defense industry or to be an engineer?

HO: Yes, actually, I did. When I was starting out, I was very grateful to have a female mentor who really guided me for years. She was not only a role model, but she helped me navigate my life from becoming a student, [then] becoming an employee. She guided me on how to grow within the organization. And she really personally empowered me to take chances. The one-on-one mentorship, that was priceless. It really helped shape my career.

Now, I have a little bit of a different pathway into defense: I actually spent the bulk of my career supporting the commercial industry. But there came a point where I was looking for a change in trajectory. I wanted to continue to learn. I wanted to be more challenged. But most importantly, what I was looking for was to be in an industry that was directly making a critical impact on society. That was the true inspiration for my transition to the defense industry.

MCHALE: I think that could be a good selling point to recruit young engineers into the defense industry – they can make an impact.

HO: Yes, absolutely. And that’s probably one of the [most fun] things about the job – that there is a direct connection to humanity. That’s what I was looking for and

I urge many people out there whether you’re beginning your career, or you’re looking for transitions in your career, this is a great place to be.

What's near and dear to my heart is internships.

ADI really has a cutting-edge internship program, not only at the college level, but at the high-school level. This is coupled tightly with a very strong mentorship program. So, when these programs are linked together, the combination really contributes to better recruitment, but ultimately, better retention success.

MCHALE: So, Maria, we talked about how to reach young minds through high school [and] college, but is there a way we can reach them beyond school? How do we get the culture to address this challenge?

HO: John, that’s an excellent question. I really feel we have an opportunity to really expand the pool of engineers in our industry [and] our nation. We need to look at it from a broad awareness perspective. When I think about public awareness, I think about Hollywood, the media and the entertainment industry, the content creators out there. They can be using their platforms to grow awareness and highlight these diverse role models in the field of engineering. For example, I grew up in this generation of watching “ER,” where the backdrop was a hospital. That got me thinking that I wanted to go into the medical field. And then when I watched the original

debut of the movie “Top Gun,” I imagined myself as a pilot. So, these images and these role models that that we see on the screen, they have a broad-based influence that could encourage people of all ages, all stages of life, all different backgrounds, to really pursue and consider engineering.

MCHALE: What advice would you give to a young woman trying to decide on engineering as a field today or even getting into the defense industry that you wish someone had given you all those years ago?

HO: When I think about this question, I say, okay, in hindsight, would I do this all over again? That’s typically the best way to think about it. And I would.

I would encourage every woman to consider majoring in electrical engineering. It’s a well-respected, well-paid field. It thrives on constant innovation. It offers you a tremendous amount of career

mobility. Every industry uses an electrical engineer. It’s one of the most broad-based engineering degrees that you could possibly have because electronics touch everything around us.

Just as an example, in my semiconductor-ish industry you can design and you can manufacture chips, you can be involved with test and verification, you can develop and build entire electronic systems, and you can move on to business aspects like product and program management, even technical marketing and sales. The core elements of what you learn as an engineer really allow you to solve problems. You’re balancing tradeoffs, you’re making improvements, you’re innovating everything around you. There really are limitless career opportunities with an electrical engineering degree. There’s just no limit to where that education can potentially take you. It can be across industries, across different roles. The base of having an electrical engineering degree has been a huge, huge lift for me in my life and my career.

MCHALE: As you say, engineering can also lead you to other careers seemingly unrelated to engineering like marketing. Many of the folks I speak to in industry are in technical marketing, but have engineering backgrounds. No one else can talk the talk like an engineer. Correct?

HO: Absolutely. When you look at my career, I started out in a technical field and I’ve slowly migrated on to other aspects of the business. I think that that’s the way careers should be, or at least that’s a good avenue, because a lot of times when you’re starting out you may not know exactly what you want. This degree allows you to have that flexibility to kind of migrate and pave a path, pave your own personal path. MES

Uncrewed systems once served merely a supporting role in the military – useful for certain niche tasks from explosive ordnance disposal to broad area surveillance, but not as a fundamental capability like tanks or aircraft. For more than a decade, uncrewed aerial systems (UASs) have delivered lethal capability, especially in the conflict in Ukraine. As the UAS threat evolves, so must countermeasures.

The capabilities provided by uncrewed aerial systems (UASs) to the U.S. military are force multipliers, but the same can be said for the technologies used by the U.S.ʼs adversaries. That reality is why industry must come up with creative solutions to keep pace with and counter UAS threats.

The landscape of UAS threats has undergone significant transformation, reflecting advancements in technology and shifts in their application.

The rapid advancements have taken place across all domains, from air to sea to ground, says Kent Savre, senior director of strategy for Northrop Grumman (McLean, Virginia). The wars in Ukraine, the Nagorno-Karabakh War, and the Hamas-Israel war are “driving change at an immense rate,” Savre says.

U.S. Marines walk an FIM-92 Stinger man-portable air-defense system to a firing point aboard the amphibious assault ship USS Boxer (LHD 4) during a counter-unmanned aerial system (UAS) exercise. U.S. Marine Corps photo by Cpl. Amelia Kang.

time, the increased usage for threats ranging from dropping contraband in prison yards, invading sporting event airspace, or worse, has become more commonplace,” says Jessica Beard, a business development executive at Benchmark Electronics (Tempe, Arizona). “For military threats, drone swarm simulations are beginning to take place ranging from a few drones to thousands, and the Pentagon recently began to focus on methods to neutralize swarms.”

Modern conflicts are not only testing grounds but also accelerators for UAS technologies, enhancing their autonomy, operational range, and destructive capabilities.

“The operational environment today is increasingly transparent – thousands of drones are in use in Ukraine and Israel today,” Savre says. “In the maritime domain, in a clear example of how fast evolution is occurring, one just needs to look how the Ukrainians have advanced the surface drone strike capability against the Russian Black Sea fleet.”

The rise of noncooperative drones further complicates the landscape, says Anne Stephan, vice president of critical infrastructure and networks for Rohde & Schwarz (Munich, Germany) – a challenge increased by a lack of open systems.

“Protective measures can only be taken after a threat is detected,” she says. “The importance of noncooperative drones with proprietary software and firmware has continued to grow in recent years. This makes detection for decoding systems more difficult. … To effectively counter the threat, early warning is necessary – every second counts.”

As UAS threats have grown more sophisticated, so too have the countermeasures designed to neutralize them. Beard says that Benchmark is focusing its efforts on systems that are portable, as well as on technology that allows for RF takeover on commercially sold drones to track both UAS and user.

“Militaries will most likely utilize a layered approach, including detection systems, landing and/or jamming technologies, and missile and laser countermeasures,” she says.

While raw capability is of course important to militaries, Stephan notes that operators are asking for more user-friendliness in the design, leading to the conclusion that the industry should not forget the importance of designing for operational practicality and ease of use.

Modern counter-UAS systems are more integrated now than they have been in the past, Savre says. “Highly automated, AI [artificial intelligence] and machine learning (ML)-enabled, full kill chain solutions are available with a flexible mix of long range/ short range sensors, network C2 connectivity, and kinetic and non-kinetic effectors,” he says. An example of this is Northrop Grumman’s Mobile Acquisition Cueing and Effector (M-ACE) system that is in development.

Any individual can buy a drone and use it to cause harm, but at the scale that nation-states can leverage the tech –think drone swarms – defeating them is a critical military priority.

“Although access to drones has been available to the general public for some

“The number-one challenge now is compressing the kill chain as AI and autonomy drivers increase in the marketplace,” Savre continues. “This is followed closely by having full mobile capability on a platform that can hide and not emit [signatures] as much as possible.”

There’s a growing need for more sophisticated countermeasures, including kinetic solutions like missiles and directed energy weapons, he adds. This evolution reflects an arms race between drone capabilities and counter-drone technologies, where advances in one domain spur developments in the other. [Figure 2.]

Figure 1 | SD filters from Benchmark remove potential radar altimeter interference without increasing size and weight.Early detection and an ability to scale are drone countermeasure challenges that industry is looking to solve.

Beard says regulatory and scalability issues can be problematic. Specifically, state and local government entities can be an obstacle in developing these solutions, and companies with the best solutions to protect the public are often smaller companies that don’t have the capability to quickly scale operations.

Beard says her company is providing supply-chain architecture, review, and design for production manufacturability, and creative inventory modeling to make it easier to scale C-UAS products and bring them to a wider market.

While speed of scale is an important procurement and production consideration, speed of detection may matter most on the battlefield.

Joint solutions that leverage partnerships between companies will create more sophisticated counterdrone systems with multiple levels of capability.

“When it comes to countering drones, time is of the essence,” Rohde’s Stephan says. “Malicious or noncooperative drones must be detected as early as possible to give decision-makers the maximum time possible to respond to threats and avert potentially disastrous consequences.”

Along those lines Rohde & Schwarz has built its ARDRONIS family of counterdrone technologies. The system detects commercial drone activity, automatically classifies the type of drone signal, determines the direction of the drone and its pilot, and disrupts the radio control link to prevent the drone from reaching its target. [Figure 3.]

Today, UAS and counter-UAS technology development points towards a future where automation, integration, and swarming technologies play central roles.

Northrop Grumman’s Savre sees a shift toward highly automated counter-UAS systems. “For C-UAS, it is about automating the kill chain and kill web to the point of decision for the human operator,” he says. “Faster decision-making

Figure 2 | Blue Thunder, Northrop Grumman’s gun truck concept armed with the company’s M230 Link Fed Chain Gun. (Photo: Northrop Grumman.)and systems that are in a nondedicated role … is the key to defeating unmanned threats that are becoming greater in number on the battlefield.”

Making counter-drone systems easy to use for military personnel should also be a priority as not everything can be automated.

“User-friendliness is becoming increasingly important and in the future automatic systems will also be used; these will not only detect and locate but also offer react possibilities,” Stephan says.

Joint solutions that leverage partnerships between companies will create more sophisticated counter-drone systems with multiple levels of capability. Beard says the industry will see companies integrating their separate solutions like Anduril and Epirus, who combined their Lattice and Leonidas systems in 2023 to demonstrate commandand-control tech to the Marine Corps Warfighting Laboratory. MES

SEA-SEA-24001 Sealevel R1 Rugged - Tech Briefs.pdf 1 2/13/24 3:08 PM

SEA-SEA-24001 Sealevel R1 Rugged - Tech Briefs.pdf 1 2/13/24 3:08 PM

Military and government agency program regulations require their sensitive data at rest (DAR) to be securely encrypted and stored in a variety of applications, including in uncrewed systems, servers, and other endpoint devices. Shouldn’t we be following the rules? Rules that call for highly sensitive information to be securely encrypted and stored? Unfortunately, it has been too easy to acquire exceptions to these regulations, especially when it comes to data-storage solutions, thus putting the nation’s data at risk. The NSA CSfC [National Security Agency Commercial Solutions for Classified] program was launched in 2016 to make it easier to secure data by using certified, off-the-shelf products. With the advent of new NSA-approved off-the-shelf secure storage solutions, waivers that skirt secure storage requirements no longer need to be granted.

Data security solutions developed with the U.S. government’s National Security Agency (NSA)-approved Commercial Solutions for Classified (CSfC) are used to protect sensitive information of all kinds and are built with commercial offthe-shelf (COTS) technologies. CSfC solutions have primarily been used by

the U.S. Department of Defense (DoD), the intelligence community, military services, and other government agencies, though those who are concerned about protecting confidential data should also consider implementing solutions built with CSfC-listed products and components. Occasionally and if deemed necessary, exceptions called waivers or deviations can be granted by a program authorizing official (AO), or someone who is chartered with accepting the risk of implementing a non-CSfC solution. As more products are added to the CSfC component list, waivers should not be granted as frequently as in the past.

Before CSfC: Type 1 encryption systems and GOTS products

Until the advent of the CSfC program, government program managers and others needed to procure expensive NSA Type 1 encryption solutions to protect top secret information. Government off-the-shelf (GOTS) products may sometimes meet the security standards required by a particular agency or application. GOTS products and Type 1 systems are typically for specific programs or agencies, and they contain specific NSA-approved encryption algorithms.

The usage of Type 1 systems is highly restricted. Because a Type 1 product is itself a classified system, it must be appropriately protected, and its usage properly guarded. (The NSA has also defined Type 2, Type 3, and Type 4 systems for less sensitive information.)

The usage restrictions, as well as the cost, have limited the propagation of

Type 1 systems, which is problematic as the rapid creation of sensitive digital information has more than tracked with the information explosion in the civilian world.

In the ever-evolving cybersecurity landscape, the NSA’s CSfC program is an innovative step forward to securely encrypt top-secret and other sensitive information. Once launched in the mid-2010s, CSfC revamped the approach to handling classified information by enabling the integration of commercial off-the-shelf (COTS) products to protect national security systems. To create a CSfC data security solution, the solution must be built using CSfC-listed components. If no such component exists, a waiver may be requested.

The CSfC framework enables government entities to access and utilize COTS products, provided they meet specific criteria outlined by the NSA. This approach is a significant step in addressing two problems: it enhances affordability and ensures a continuous influx of innovative products into classified data usage and storage. (Figure 1.)

In addition to being built from commercially available components, CSfC solutions require two layers of encryption, each from a different source, whether those sources are two different vendors or two different types of encryption.

Unlike traditional approaches in which cybersecurity solutions were developed for very specific applications, often taking years to materialize, CSfC enables government agencies to harness the expertise and resources of private companies and existing products.

Stringent standards and requirements set by the NSA govern the certification process for products seeking CSfC listing. The NSA has defined several capability packages (CPs) against which products are tested. CPs exist for securing data at rest (DAR), protecting information as it traverses an untrusted network, commercial device access of secure services over a campus wireless local network, and the like. Rigorous evaluations ascertain the suitability of these products for handling sensitive information, contributing to the creation of a trusted ecosystem of solutions designed to safeguard classified DAR.

CSfC’s approach to secure storage solutions involves the implementation of layered security, combining various components such as virtual private networks (VPNs), firewalls, intrusion detection systems (IDS), and cryptographic modules. Particularly in DAR applications, the program mandates the use of two layers of encryption to fortify the protection of classified national-security systems and other sensitive data.

Capability packages calling for two layers of encryption for classified information storage are often referred to as COTS end-to-end strategies. While there are advanced off-the-shelf SSD products that provide one layer of protection, CSfC mandates the incorporation of a second layer from another source, fostering a comprehensive security posture.

While CSfC has transformed the landscape of secure data solutions, waivers or deviations can be requested and approved for the use of non-CSfC products. A waiver, in this context, serves as an exemption granted by the government, allowing organizations to bypass specific CSfC requirements.

Historically, organizations could request waivers from the NSA for products not appearing on the CSfC list. This flexibility was crucial in situations where the urgency of implementing cybersecurity solutions outweighed the availability of CSfC-listed products. The increasing need for secure DAR solutions caused program managers to specify standard SSDs in computers and other devices since no SSDs in modern form factors (for example, NVMe M.2 2280 used in client devices such as laptops) existed on the CSfC Storage Component list.

However, with the recent inclusion of FIPS SSDs on the CSfC list, the need for waivers for secure SSD data storage has been eliminated.

Value of the CSfC program

1. Access to affordable, secure solutions: CSfC enables government agencies to benefit from cost-effective yet secure commercial technologies.

2. Enhanced flexibility: The program empowers government entities to adapt swiftly to evolving security requirements and technological advancements.

3. Rapid deployment of technologies: CSfC accelerates the integration of new technologies, fostering agility and responsiveness.

4. Catalyst for private-sector innovation: By encouraging collaboration with private companies, CSfC stimulates innovation and raises industry standards.

5. Cutting-edge cybersecurity products: Government agencies leveraging CSfC enjoy access to the latest and most advanced cybersecurity solutions.

6. Protection of national-security systems: CSfC employs cutting-edge technologies to fortify the security of national assets and classified information.

The impact

The milestone of the DIGISTOR CSfC listing for its FIPS 140-2 L2 SSDs (which also meet the international Common Criteria standards and as a result are NIAP-listed) is important since it enables off-the-shelf NVMe and SATA SSDs to be integrated into secure DAR solutions, including those used on the battlefield. In addition, the

With these drives now listed on the CSfC storage component list, the NSA has communicated its intention to discontinue issuing waivers for similar products, although this intent may not be widely known. This shift emphasizes the program’s commitment to promoting listed storage components and discouraging the use of unapproved products for classified information storage.

As CSfC continues to evolve, its impact on the realm of secure storage solutions becomes increasingly pronounced. The program’s emphasis on layered security, stringent certification processes, and collaboration with private-sector innovators positions it as a driving force in the protection of classified information. The elimination of cyber waivers for storage components underscores the program’s maturation and its pivotal role in shaping the future of secure communications within the realm of classified information. As organizations continue to navigate the complex landscape of cybersecurity, CSfC is an important sign of data security, providing a framework for the integration of cutting-edge technologies into the safeguarding of our national assets. MES

Marketing director

Chris Kruell leads the sphere of marketing activities at CDSG, including corporate branding, corporate and marketing communications, product marketing, marketing programs, and marketing strategy. In his spare time, Chris is an alpine climbing instructor and has served as president and board member of the Mazamas, a Portland-based nonprofit organization that fosters a love of the mountains. Chris holds a BS degree from Cornell University and an MA degree from Hamline University. Readers may reach him at ckruell@cdsg.com. CDSG https://cdsg.com/

Reduced SWaP designs for UAS payloads

Aerospace and defense systems integrators continue to push for reductions in size, weight, power, and cost (SWaP-C) to support advanced sensor/vetronics payloads onboard unmanned reusable and attritable platforms. Fortunately, advances in the miniaturization of mission-processor and network-switch subsystems are enabling designers of UAS (unmanned aerial system), UGV (unmanned ground vehicle), UUV (unmanned undersea vehicle), and USV (unmanned surface vehicle) platforms to expand their mission capabilities.

What constitutes optimal size, weight, and power (SWaP) specs for a particular electronics LRU [line-replaceable unit] varies greatly depending on the target platform and application. SWaP goals for unmanned aerial system (UAS) platforms, whether military or commercial, are typically dictated by the size of the payload that a platform can carry. The

platform’s mission is often driven by the capabilities brought by the payload. For example, in contrast to small commercial UASs, consider a military high-altitude/longendurance (HALE) platform that can carry 1,000 pounds (approximately 450 kg) of payload electronics and are often used for persistent intelligence, surveillance, and reconnaissance (ISR) use cases.

In comparison, the small commercial UAS more typically will have payload capability of a few pounds or less. Designers of these systems may be satisfied to get an HD [high-definition] camera onboard a UAS that flies for only about 30 minutes due to the

limitations of the aircraft’s battery. For such small platforms, both airborne and ground, micro-miniaturization of systems becomes very desirable. Systems integrators often look at the operational and logistical impact of the electronics that are added to an aircraft or vehicle platform, with some UAS suppliers going so far as to break down the cost of every pound (or kilogram) of payload weight in terms of cost-per-pound/kilo. Shrinking the physical size and weight of payload electronics not only delivers

Traditional system architecture might have previously factored in multiple separate components, whereas today system designers have SoC alternatives that combine processing, memory, other controllers, interfaces, and physical transceivers all in a single chip.

cost savings, but it also provides the ability to add more sensors and C4ISR [command, control, communications,computers, intelligence, surveillance, and reconnaissance] equipment to enhance operational mission capabilities for the end user.

To further illustrate how much SWaP impacts platform cost, consider three numbers: 1, 30, and 60: As a data point, one major North American UAS supplier has calculated that for every one (1) pound of weight they can eliminate from their UAS platform dedicated to ISR missions, they save approximately $30,000 in operational cost for the vehicle. For their combat UAS platform, they save even more, approximately $60,000 per pound.

In addition to cost impact, SWaP can affect feasibility for implementing mission capabilities. A major U.S. Army tactical UAS underwent a tech refresh to add an onboard network backbone, involving the integration of a fully managed Ethernet switch. Launched from a trailer-mounted pneumatic catapult and used for reconnaissance, surveillance, and targeting applications, this particular UAS has a rather small airframe and payload bay. The integrator performed a volumetric analysis and determined that the size available for a network switch LRU was limited to roughly the size of a pack of playing cards and about half a pound in weight.

Since the electronics payload area wasn’t generous in size, if a switch could not be found to meet this form-factor requirement, the UAS would have been unable to add the desired network readiness capability. This would likely diminish situational awareness and potentially lead to a costly redesign, since the switch was intended to link an onboard video encoder, mission processor, and warfighter communications devices via a common Ethernet network.

The miniature Ethernet switch has since been broadly deployed in not only UAS platforms, but also on far larger fighter-aircraft ISR sensor pods, helicopter sonar dipping systems, autonomous submarine networks, tactical ground vehicles, unmanned rotorcraft, and dozens of other SWaP- constrained platforms. The switch’s wide adoption is a testament to the need for ultra-small-form-factor (USFF) devices and the diverse applications that benefit from them; whether the platform is very small or much larger, low SWaP is advantageous.

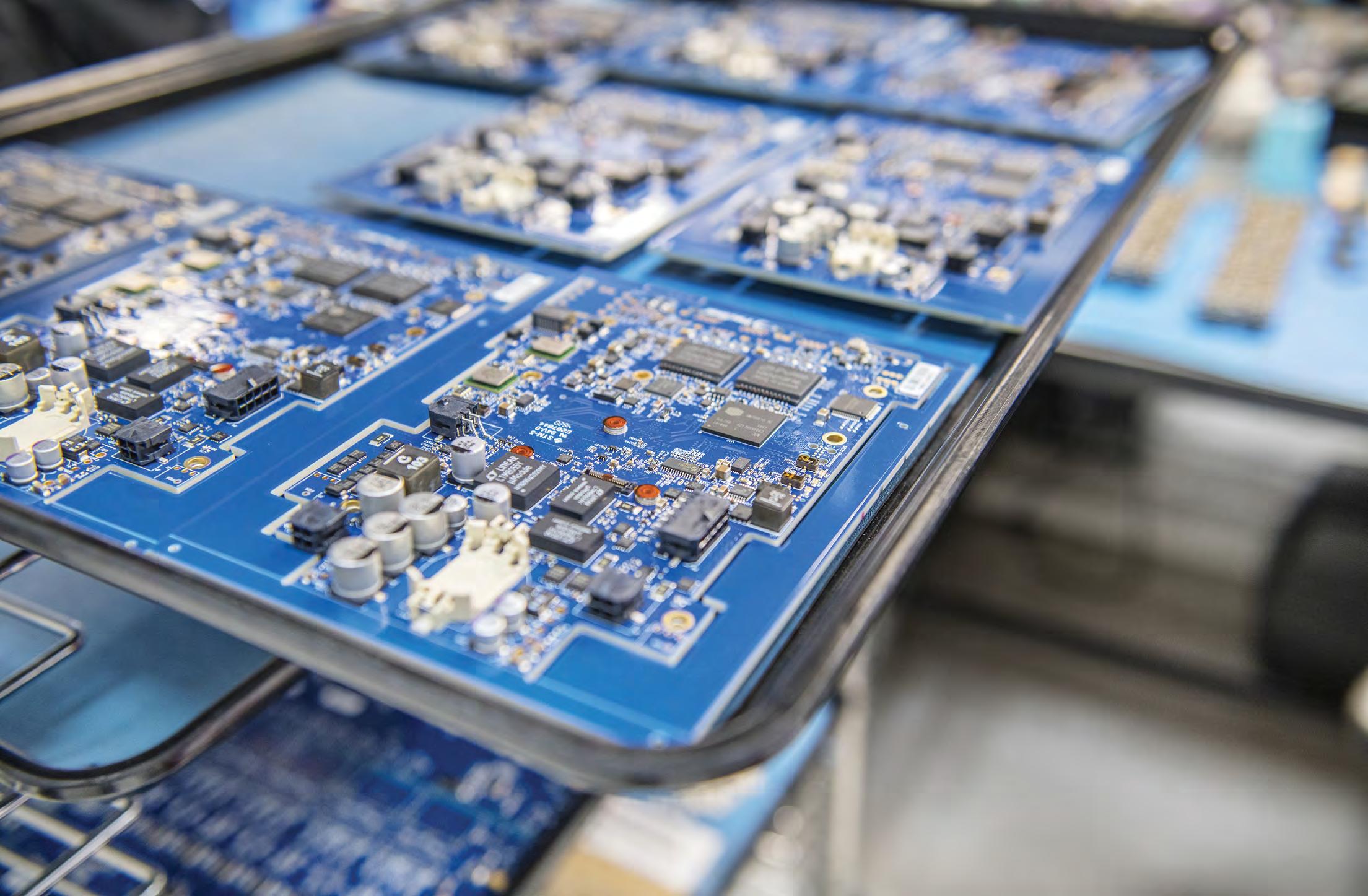

In large part, the miniaturization of electronics is made possible by advancements in commercial technology. Three notable enablers in this regard include system-on-chip (SoC) technology, intelligent power-management technologies, and mechanical component miniaturization. Semiconductor devices for computing and networking are more energy-efficient than ever before and are evolving to include more functionality in the same physical packaging. With fewer discrete components to integrate, printed circuit board assemblies (PCBAs) can be smaller. Traditional system architecture might have previously factored in multiple separate components, whereas today system designers have SoC alternatives that combine processing, memory, other controllers, interfaces, and physical transceivers all in a single chip.

In the case of the USFF Parvus DuraNET 20-11 20-port Gigabit Ethernet switch (Figure 1), its integrated switch SoC includes not only a nonblocking Ethernet switch fabric, but also a MIPS processor (for management), fully integrated copper PHYs (physical transceivers), DDR memory controller, and IEEE-1588 precision timing protocol

Figure 1 | The USFF Parvus DuraNET 20-11 20-port Gigabit Ethernet switch SoC combines processing, memory, other controllers, interfaces, and physical transceivers.(PTP) controller for accurate time stamping. This style of SoC approach has enabled the miniaturization of military electronics, particularly for low to mid-power devices.

Traditional MIL-C-38999 connector shell sizes and MIL- STD-1472 (Human Engineering) recommendations for connector spacing have conventionally driven the size of the connector panel and enclosure. Microminiature MIL-performance connectors provide the same or better physical, electromagnetic, and electrical performance as legacy “triple 9” connectors while providing higher-density contacts at roughly half the size and weight of traditional options. Consequently, there are now Ethernet switches and mission computers on the market today using these connectors that measure barely over one inch (around 3 cm) tall.

Also helping reduce SWaP in mission electronics for unmanned platforms is the shrinking of semiconductor die sizes and the addition of symmetric multicore processing (SMP) that boosts performance while reducing power consumption. Intel-based x86 processors use smart speed-stepping technologies to maximize performance, yet throttle back to save power when loads are lighter with the advantage of protecting the device from thermal damage.

Arm core processors similarly hone their own highly efficient power management capabilities in mobile devices. Further, Ethernet switch devices can now integrate advanced power-management technologies in the switch core and physical transceivers, such as Energy Efficient Ethernet (IEEE-802.3az) and ActiPhy, which put unused ports in a lowpower idle mode, keeping links active but consuming less power during lower data activity. These switches can also sense the length of the cable connection, limiting power for transmitting data, to say, 10 meters (32.8 feet), rather than defaulting to the 100-meter (328-foot) Ethernet specification. In total, these technologies can result in cutting power consumption by 50% or more from traditional levels.

As manufacturers of SoC devices reduce the thermal needs of the silicon, they are also reducing the power-dissipation requirements on the system, which means a smaller surface area required for cooling of the chassis. The mechanical size of the enclosure can also be smaller thanks to higher density connector technology.

Innovative x86 and Arm-based processor technologies continue to integrate more capabilities into ever-higher density semiconductor packages with optimized power management. These low-power CPUs are frequently used in SoCs that include not only multicore microprocessors, but also advanced peripherals, such as a graphics processing unit (GPU), without the need for separate discrete components, helping to reduce overall SWaP for embedded electronics. Intel’s Atom processor is an example of an x86 SoC that integrates a lower-power quad-core CPU plus high-definition Intel graphics and I/O chipset in a single package, enabling the mission computer to have a very small 5.2 by 5.4 by1.4 inch (39 cubic inch) footprint and weigh less than 1.5 pounds while drawing less than 25 watts.

Because of the reduced instruction set nature of Arm architectures, Arm delivers superior million instructions per second (MIPS)-to-watt ratio with fewer transistors than processors based on complex instruction set computing (CISC) like x86 CPUs. Arm processors also reduce power consumption by operating at a lower clock frequency than x86 processors. In addition, Arm SoC vendors have integrated low-power states, such as power gating and clock gating, into their processors. Arm’s lower power design lends itself nicely to SWaP-constrained applications by providing a reduced thermal solution in a low-weight processor.

A rugged small-form-factor mission computer designed for military and civil tactical processing applications is the Parvus DuraCOR 8044 modular mission computer workstation. It features a sealed and fanless IP67-compliant design that enables system

designers to meet compute-intensive requirements for applications deployed in the harshest environments. The ITARfree, U.S. Commerce EAR-controlled unit features an 8-core, 16-thread, 11th-gen Intel Xeon W (Tiger Lake-H) processor. Designed to meet or exceed MIL-810G and DO-160G environmental test standards, the mission computer weighs 5.6 pounds and measures 6.75 by 6.25 by 3.5 inches (135 cubic inches). Its Intel Iris Xe GPU supports OpenGL for graphicsintensive applications and OpenCL for GPGPU-accelerated data processingintensive applications. It also supports high-speed real-time Ethernet endpoint connectivity at rates up to 10 Gigabits for low-latency, on-time transfer of critical data. (Figure 2.)

The military and aerospace market maintains an insatiable appetite for smaller, lighter, and cheaper. As technology continues to advance, electronic device density and packaging improvements will continue to enable smaller and more cost-effective unmanned platforms. These factors will drive advancements in the SWaP optimization of rugged deployable small-form-factor mission computers and network solutions. MES

Jeff Evans has 20+ years in product management and serves as the Product Line Manager at Curtiss-Wright Defense Solutions for the Parvus DuraCOR, DuraNET and DuraMAR mission computers, switches, and routers.

Curtiss-Wright

https://www.curtisswrightds.com/

Military Embedded Systems focuses on embedded electronics – hardware and software – for military applications through technical coverage of all parts of the design process. The website, e-mags, newsletters, podcasts, virtual events, annual Resource Guide, and print editions cover topics including radar and electronic warfare, artificial intelligence/machine learning, uncrewed systems, C5ISR, avionics, and cybersecurity. Don’t miss any of it!

Military Embedded Systems is also the largest source for coverage of the Sensor Open System Architecture (SOSA) Technical Standard and the Future Airborne Capability Environment (FACE) Technical Standard. We exclusively produce the once-yearly SOSA Special Edition and FACE Special Edition.

MOSA solutions for unmanned systems: SBCs, RTOS, connectors, backplanes, etc.

Artificial intelligence (AI)-enabled autonomous systems have revolutionized military operations and modern warfare. These uncrewed systems are well-suited for dangerous and repetitive tasks, enhancing situational awareness and logistical capabilities while reducing risks to human personnel. However, their growing role raises significant security concerns: Uncrewed vehicles rely heavily on machine learning (ML) and can be vulnerable to cyberattacks that could jeopardize missions, troops, and critical technologies. While no system is unhackable, system architecture becomes critical in ensuring a device is as resilient as possible to cyberattack not just on the day of initial deployment but several years into its product life cycle. Because of this, robust safeguards are necessary throughout their development and deployment life cycles. Secure design principles, encryption, access controls, and secure communications can harden these systems against unauthorized access.

The aerospace and defense (A&D) ecosystem – including the military, private

sector, academia, and government – must consider a huge number of factors as autonomous systems become more common in the sea, on the land, and above the battlefield.

From the spear to the cannon to the tank, technological advances have long given militaries a tactical edge. Today, artificial intelligence (AI) is the next frontier promising to revolutionize warfare. Fulfilling that promise hinges on our ability to prevent these “thinking” machines from being turned against us.

The new spear: unmanned aerial vehicles (UAVs) and autonomous sentries

Autonomous technologies such as unmanned or uncrewed aerial vehicles (UAVs) and robotic sentry “dogs” are redefining the battlespace. These devices excel at surveying terrain, identifying targets, and detecting and disarming threats without endangering service members. Their

potential is vast, yet so are their vulnerabilities. Without rigorous cybersecurity measures baked into their designs, these self-guided systems could end up serving our adversaries rather than our troops.

Military UAVs and devices leverage cutting-edge AI technologies to operate with minimal human guidance. Computer-vision algorithms enable UAVs to navigate and detect objects, while natural-language processing analyzes speech and text data to extract insights. Reinforcement learning optimizes decision-making for complex missions with many variables, while deep neural networks identify patterns and make predictions from massive datasets.

However, the very technologies enhancing unmanned systems also introduce new cybersecurity risks. AI-enabled autonomous platforms rely heavily on data and machine-learning (ML) algorithms, which potentially exposes them to data poisoning, model theft, and adversarial attacks aimed at manipulating their behaviors.