Future-proof your designs with WINSYSTEMS’ rugged embedded computing solutions designed for highly reliable operation in harsh environments. Our products enable a wide range of applications from EV Charging to factory automation, robotics, industrial IoT, and Edge computing.

US-made COM Express Type 6 Compact and Type 10 Mini Modules and Carrier Boards

Rugged highly reliable COM modules featuring Intel® Atom® E3900 and 11 Gen CORE™ i3/i5/i7 processors with on-board discrete TPM 2.0 hardware security and industrial temp rating.

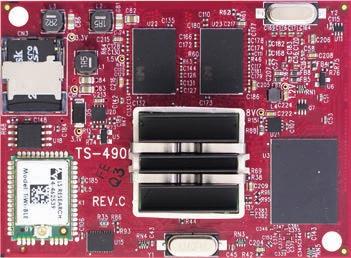

Tiny Pico-ITX SBC: ITX-P-C444

Low power industrial-rated SBC with NXP ® i.MX 8M series processor, on-board discrete TPM 2.0 hardware security, dual Ethernet, industrial connectors and I/O

PC/104-Plus SBC: PPM-C407

Low power industrial-rated SBC with Intel® Atom® E3800 series processor, Gigabit Ethernet

EMBEDDED COMPUTING BRAND DIRECTOR Rich Nass rich.nass@opensysmedia.com

SENIOR TECHNOLOGY EDITOR Ken Briodagh ken.briodagh@opensysmedia.com

ASSOCIATE EDITOR Tiera Oliver tiera.oliver@opensysmedia.com

ASSOCIATE EDITOR Taryn Engmark taryn.engmark@opensysmedia.com

PRODUCTION EDITOR Chad Cox chad.cox@opensysmedia.com

TECHNOLOGY EDITOR Curt Schwaderer curt.schwaderer@opensysmedia.com

CREATIVE DIRECTOR Stephanie Sweet stephanie.sweet@opensysmedia.com

WEB DEVELOPER Paul Nelson paul.nelson@opensysmedia.com

EMAIL MARKETING SPECIALIST Drew Kaufman drew.kaufman@opensysmedia.com

WEBCAST MANAGER Marvin Augustyn marvin.augustyn@opensysmedia.com

DIRECTOR OF SALES Tom Varcie tom.varcie@opensysmedia.com (734) 748-9660

DIRECTOR OF SALES ENABLEMENT Barbara Quinlan barbara.quinlan@opensysmedia.com

AND PRODUCT MARKETING (480) 236-8818

DIRECTOR OF MARKETING Eric Henry eric.henry@opensysmedia.com

OPERATIONS & AUDIENCE DEVELOPMENT (541) 760-5361

STRATEGIC ACCOUNT MANAGER Rebecca Barker rebecca.barker@opensysmedia.com (281) 724-8021

STRATEGIC ACCOUNT MANAGER Bill Barron bill.barron@opensysmedia.com (516) 376-9838

STRATEGIC ACCOUNT MANAGER Kathleen Wackowski kathleen.wackowski@opensysmedia.com (978) 888-7367

SOUTHERN CAL REGIONAL SALES MANAGER Len Pettek len.pettek@opensysmedia.com (805) 231-9582

INSIDE SALES Amy Russell amy.russell@opensysmedia.com

STRATEGIC ACCOUNT MANAGER Lesley Harmoning lesley.harmoning@opensysmedia.com

EUROPEAN ACCOUNT MANAGER Jill Thibert jill.thibert@opensysmedia.com

TAIWAN SALES ACCOUNT MANAGER Patty Wu patty.wu@opensysmedia.com

CHINA SALES ACCOUNT MANAGER Judy Wang judywang2000@vip.126.com

PAGE ADVERTISER

21 BlackBerry QNX –Enabling Safety, Security and Reliability in Embedded Software Development

1 Clarinox Technologies –The Simplified Embedded Wireless Ecosystem by Clarinox

1 Digi-Key Corporation –Development Kit Selector

27 Kontron – Speakout: Emerging Trends In the Module Industry

27 Kontron – Speakout: Motherboards that meet your every need: Kontron’s extensive line of high-performance boards

15 NI (National Instruments) –LabVIEW

56 Tadiran – IIoT Devices Run Longer on Tadiran batteries BlackBerry QNX

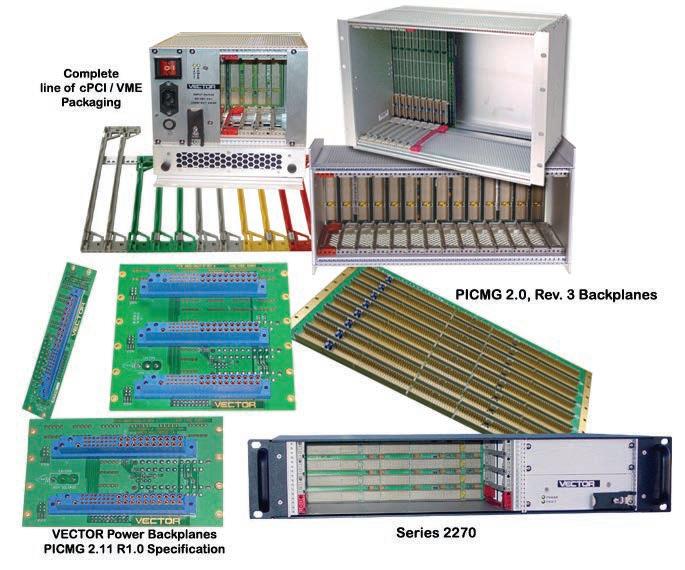

9 Vector Elect –VME/VXS/cPCI Chassis, Backplanes & Accessories

1 Wind River –

From the leading RTOS provider, new ways to buy

2 WinSystems –Embed Rugged Reliability

Facebook.com/Embedded.Computing.Design

@Embedded_comp

WWW.OPENSYSMEDIA.COM

PRESIDENT Patrick Hopper patrick.hopper@opensysmedia.com

EXECUTIVE VICE PRESIDENT John McHale john.mchale@opensysmedia.com

EXECUTIVE VICE PRESIDENT AND ECD BRAND DIRECTOR Rich Nass rich.nass@opensysmedia.com

VITA EDITORIAL DIRECTOR Jerry Gipper jerry.gipper@opensysmedia.com

MES ASSISTANT MANAGING EDITOR Lisa Daigle lisa.daigle@opensysmedia.com

TECHNOLOGY EDITOR – WASHINGTON BUREAU Dan Taylor dan.taylor@opensysmedia.com

GRAPHIC DESIGNER Kaitlyn Bellerson kaitlyn.bellerson@opensysmedia.com

FINANCIAL ASSISTANT Emily Verhoeks emily.verhoeks@opensysmedia.com

SUBSCRIPTION MANAGER subscriptions@opensysmedia.com CORPORATE

www.linkedin.com/showcase/ embedded-computing-design/

www.youtube.com/c/ EmbeddedComputingDesign

EMBEDDED COMPUTING DESIGN ADVISORY BOARD

Ian Ferguson, Lynx Software Technologies

Jack Ganssle, Ganssle Group

Bill Gatliff, Independent Consultant

Andrew Girson, Barr Group

David Kleidermacher, Google

Jean LaBrosse, Independent Consultant

Scot Morrison, Siemens Digital Industries Software

Rob Oshana, NXP

Kamran Shah, Klick Health

As the automotive industry faces escalating security regulations, there is a corresponding surge in the need for penetration testing, or “pentesting.” Utilizing remote penetration testing and automation tools represents a significant advancement in the realm of automotive security, as it leads to quicker pentest execution and reduced expenses. Read some of the different approaches for advancing the field of automotive penetration testing on page 10.

Executive Vice President How Software Redefines the Value of the Automotive Industry

Tune In: https://embeddedcomputing.com/ application/automotive/how-softwareredefines-the-value-of-the-automotive-industry

Exploited: Netgear Nighthawk RAX30

Read Now: https://embeddedcomputing.com/ technology/security/network-security/ exploited-netgear-nighthawk-rax30

Surviving the Semiconductor Shortage with SoMs

Tune In: https://embeddedcomputing.com/ technology/processing/compute-modules/ surviving-the-semiconductor-shortage-withsoms

Published by:

2023 OpenSystems Media®

© 2023 Embedded Computing Design

All registered brands and trademarks within Embedded Computing Design magazine are the property of their respective owners.

ISSN: Print 1542-6408

Online: 1542-6459

RISC-V is the hot thing in embedded these days, it seems, with news hitting every day. We’ve looked at some of the key tools and players in the RISC-V space, and even seen several major players make moves this week.

One of the bigger announcements in RISC-V news we’ve seen recently came from a recent partnership between some of the biggest automotive chip suppliers. According to this announcement, Infineon, Nordic Semiconductor, NXP Semiconductors, Qualcomm, and Robert Bosch have jointly invested in a new company based in Germany with the goal of advancing global RISC-V adoption.

It seems that the venture will act as an accelerator for the “commercialization of future products based on the open-source RISC-V architecture,” the release stated.

Now, nominally, the group is open to exploring all sorts of industries ripe for RISC-V, but this particular grouping begs the question: Is the automotive industry getting ready to move? Will the automotive OEMs, dare I say, take a ... RISC?

Research group Semico thinks the global automotive market is ready. According to a recent report from the firm, the interest in RISC-V stems partially from the semiconductor supply chain shortages that have been occurring for nearly 5 years now.

“Against this backdrop of architectural and functional exploration are the current supply problems of semiconductors aimed at automotive applications,” said Rich Wawrzyniak, Principal Analyst for SoC and ASIC Research at Semico. “In order to secure a steady supply of the semiconductors needed to produce their vehicles in a timely manner, most, if not all, of the automotive manufacturers have embarked on creating their own internal SoC design groups with the intention of using the silicon foundry network to supply the parts.”

Those internal SoC groups will certainly be looking at RISC-V as an option, and with the new German supergoup of chipmakers in play, that option will look even more viable. Bill Stewart, Vice President of Automotive Americas Marketing at Infineon, is optimistic about the possibilities for RISC-V.

“We see RISC-V as a potential alternative for future CPU core roadmaps. Obviously, we’re making an investment in it, so we see it as viable,” he said. “The automotive OEMs are going to a software-defined vehicle architecture. They’re all investing a lot in software right now.”

As they move into creating their own software and hardware, automotive OEMs are looking for reliable, certifiable standards, and RISC-V is diligently offering one that is paired with being an open architecture – and all the customization and (potential) cost-savings that go along with it.

RISC-V International, the organization driving RISC-V adoption and standardization globally, has been preparing to bring the automotive industry inside. In a blog post from March, it specifically calls out how the technology is suited to carmakers’ needs. “Designers can leverage RISC-V in creating Systems-on-Chips (SoCs) for automotive applications that not only meet performance/ cost/power requirements, but also have a high degree of code portability.”

The post goes on to advocate for RISC-V in safety systems like Advanced Driver-Assistance Systems (ADAS) and autonomous vehicles, in addition to in-vehicle infotainment (IVI) systems that are becoming ever-more sophisticated with advanced displays, connectivity, over-the-air updates, personalized experiences, and even gaming.

It’s not only the chipmakers that are getting in on the action, either. Lars Bergstrom, Director of Engineering at Google, announced in 2022 that Google will support RISC-V in Android ecosystems. And if you look into the existing RISC-V ecosystem, the major players have been building and getting loaded up for quite some time.

As an example, SiFive and IAR have partnered to target automotive with the mating of the SiFive RISC-V Automotive CPU IP and the IAR toolchain, which together offer a set of pre-certified development tools that can ease the rigorous certification process in the automotive sector.

It’s not all settled yet, though. “There’s still a lot to work out and a lot of uncertainty,” Stewart said. The main challenge, as he sees it, will be getting standardization established. “There are a lot of potential applications for RISC-V, and we can’t have RISC-V implementations coming from a bunch of different places. That not standardization.”

The interest and investment are certainly there on the embedded technology side, but the major OEMs have not been as vocal. No major manufacturer has announced a move to RISC-V yet, so we’ll have to wait and see.

Is automotive ready for RISC-V? Hard to say, but it can’t be denied that the RISC-V players are eager to hit the road.

By Dunstan Power, ByteSnap

By Dunstan Power, ByteSnap

The UK has committed to ban the sale of new petrol and diesel cars and vans by 2030 in line with its climate goal of net zero emissions by 2050.

The move to electric vehicles is unfaltering, but what kind of strain to the electrical grid will be created by at least 10 million more EVs in the next decade? Can the grid cope? How can there possibly be any synergy between climate goals and the need to charge millions of new electric vehicles?

These are prudent questions given that in 2022 the Russia-Ukraine conflict quickly resulted in energy supply concerns so severe that three-hour planned power cuts were expected during the winter.

There are currently over 660,000 batteryelectric vehicles (BEVs) in the UK and an additional 445,000 plug-in hybrids (PHEVs). Per LGV and the Energy Savings Trust (EST), it’s estimated there will be between 8 and 11 million electric or hybrid cars on UK roads by 2030. By 2040, this number could reach 25.5 million. This is gargantuan growth but moving to vehicles with net zero emissions is a critical part of the UK’s overall net zero goal. Similar transitions are planned elsewhere around the globe; the U.S. aims for half of all new vehicle sales to be electric by 2030.

Imagine the demand on the grid as 10 million more electric vehicles hit the road. What happens to the power grid if all those vehicles are plugged in to charge at the same time? Overload, right?

If the 32 million cars currently in the UK were electric, the demand for charging them, if they were all plugged in at the same time, would equate to 229GW. The capacity of the National Grid in 2020 was 75.8GW.

In reality, the chances of every EV charging at the same time are extremely slim, though not impossible. Some will be driven, parked, or used once in a while and charged much less often. Others will be charged at work, at the supermarket, or at home overnight. In the near future,

EVs may charge from renewable energy sources, serve as battery stores, and sell their power back to the grid when energy demand peaks.

Experts are not expecting electric vehicle charging to overload the grid and there are number of reasons for this confidence. In August 2022, the National Grid described the issue of the grid not being “able to handle the increase in EVs,” as a myth. The National Grid reiterated earlier commentary that the shift to EVs is gradual, renewable energy sources are being developed, and “we’re constantly evolving the electricity grid.” The issue of developing the grid, nationally and locally, is critical though. Local substations, transformers, and power distribution networks will all require significant updating.

According to the National Grid, electricity demand peaked in the UK at 62GW in 2002 and has fallen by around 16% since, because energy efficiency has improved. It estimates that a complete shift to EVs would only increase demand by around 10%, putting consumption still well below the 2020 peak.

There is another reasonable calculation, as per Forbes. This puts average EV consumption at 3.5 miles per kWh and an average user distance per annum of 7,400 miles, so each car will consume an average of 2,114kWh of energy per year. Multiplied by 32,697,408 vehicles gives total EV consumption of 69TWh. The UK produced 323TWh of power in 2019. EVs won’t draw all the grid’s power, but they may require additional capacity that could come from further energy efficiencies elsewhere or from renewables.

An additional problem for the power grid is that EV chargers are designed to deliver a controlled current to lithium-ion batteries. EV charge current isn’t flexed when demand to the grid is high, EV chargers continue to pull power at the same rate. This contrasts with traditional domestic high-energy appliances like ovens and kettles, which will reduce power draw in times of grid stress.

Balancing Demand to the Grid – Smart Charge Control and Charge Timing

Energy stakeholders are well aware of the theoretical strain on the grid should many EVs be charging concurrently, so regulations are being built in to prevent such a problem.

The UK government has introduced its Electric Vehicle Smart Charge Points Regulations for 2022 and beyond. The regulations cover private EV charge points and smart cables for EV charging, and they ensure EV charge points have smart functionality. This functionality allows for EV charging to happen when there is less demand on the power grid, and for charging to pause when demand is high. The U.S. has its Smart Chargers and Time of Use Rate programs to achieve similar results.

On January 17, 2023, the UK government and Ofgem published the Electric Vehicle Smart Charging Action Plan. The plan’s goal is to make smart charging the “preferred method of long duration charging by 2025.” The plan is supported by further investment of £16 million in funding from the Net Zero Innovation Portfolio (NZIP) for smart charging technologies. Based on the plan’s release:

“The government and Ofgem will seek to remove the barriers that currently prevent the full development of a diverse and competitive smart charging market, while making sure the energy system is ready to respond to the upturn in energy demand that electric vehicles will bring.”

We may be some way from an entirely smart grid scenario where the electricity grid communicates fluently with smart chargers to automatically manage charging times. A scenario where charging switches off when demand is high or supply low, and charging is enabled off-peak or when there is excess energy to the grid, will certainly be the ultimate goal.

Governments and energy stakeholders want to avoid high volumes of EV charging at peak times. In the UK, energy usage peaks between 5pm and 8pm as it gets dark and people return home from work, cook, and finish household tasks or plug in additional devices. Outside of EV regulations, energy companies are already rewarding households that can cut energy use during peak times.

UK electricity tariffs are cheaper at night, which will encourage off-peak charging and there are likely to be further incentives for off-peak charging as EV numbers grow. Peak charging could also be discouraged by the implementation of higher electricity tariffs during this time.

Overcoming EV charging problems, developing EV charging infrastructure, improving grid efficiency and local power infrastructure, and balancing charging demand to power grids are all important components to EV adoption and development. The UK has committed £1.3 billion to developing public and private charge points and has pegged up to £1 billion for the development and production of EV batteries. Ofgem plans to reinforce the UK power distribution network.

The proportion of energy generated by renewable sources is growing quickly. Some of these sources can generate additional grid capacity at certain points in time. Solar energy can pick up some slack from daytime demand. Windy periods, or windy nights, may be able to meet additional demand, or night-time demand from EV charging.

Effectively coordinating peaks in both energy supply and demand could be key to meeting EV charging requirements whilst balancing climate goals – without overloading the grid.

The Potential of V2H and V2G

Vehicle-to-Home (V2H)

Battery capacity must be substantial for EVs to “go the distance,” with petrol and diesel vehicles, and innovation in battery technology is pushing this capacity upwards.

This capacity means an EV battery has the potential to be used as a flexible energy storage device or home battery system that can help offset power supply and demand fluctuations. When there is excess or cheap power, EVs can be charged. When power demand is high, or expensive, EV batteries can give power back to homes and even back to the grid.

In a V2H scenario, an EV can be charged with excess solar power generated by the home. When it’s dark, or cloudy, the EV can give the stored power back, saving the household from purchasing electricity.

In 2018, OVO Energy and Imperial College London declared V2G could have the potential to save the UK energy network £3.5 billion per year. OVO Energy and Nissan conducted a three-year trial after installing 330 bidirectional chargers in UK homes. They concluded the homes could save up to £725 annually on their electricity bills if they gave (or sold) stored power from their EVs back to the grid during peak hours.

There are several barriers to V2H and V2G. Bidirectional chargers are large, unsightly, and costly. The number of homes generating their own power is still relatively few, and

few current EV models support bidirectional charging technology. Plus, given the complexity of power networks and the number of EV makers, the diversity of EV charging, and the number of electricity companies involved, coordinating energy price and exchange is an incredibly complicated operation.

Virtual power plants are pitched as a solution to managing grid pressure and would form part of a smart distribution network. The Power Potential R&D, a project run by UK Power Networks and National Grid ESO, plans for renewable power operators within a region to be able to produce energy but also to contribute to correcting problems with supply or voltage that occur within a network.

Virtual power plants can also consist of groups of EV chargers and enable V2G. EV energy is trialing such systems that shift loads away from evening peaks, or that prioritize charging when renewables are creating a surplus.

Our net-zero emissions future and shift to EVs may rely predominantly on the strength of the technology supporting this societal change. Energy distribution networks and entire power grids must become fully smart.

Eliminating energy waste, channeling surplus energy, and adjusting supply when demand is high can all be controlled automatically by integrated smart technologies.

This smart future is immediately possible. Bringing it to fruition, however, will rely on all stakeholders developing and implementing technologies that share the same design principles. Technologies must be able to easily communicate and work with one another, right from power plants down to EVs, chargers, and other devices at home.

Dunstan Power, Director at ByteSnap Design, is an experienced leader of electronic product design teams. His specialties include project and team management, architecting electronic systems, business development, digital hardware and FPGA design, Product design, and more.

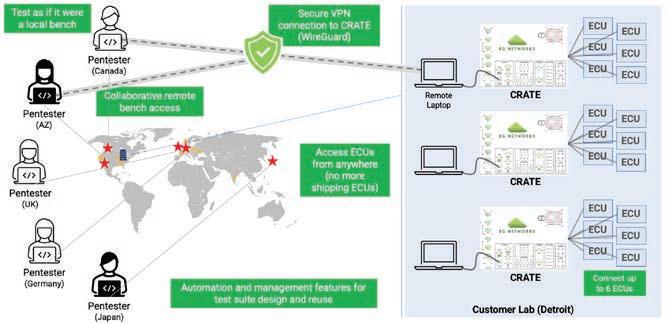

By Roman Lysecky, BG Networks

By Roman Lysecky, BG Networks

As security requirements and legislation for auto manufacturers continue to increase, so does the demand for penetration testing, or “pentesting.” Pentesting is becoming a requirement for all new Electronic Control Units (ECUs) that need to be cyber-secure, but the rising cost of pentesting is a major concern. This is due to the growing number of devices that must be tested, the limited number of available penetration testers with the appropriate skills, and the lack of automated tools.

Remote pentesting and automation tools are a game-changer for automotive security because it results in shorter times to complete pentests and lower costs.

The traditional approach requires pentesters to have physical access to the ECUs being tested. This can be timeconsuming and expensive. Remote pentesting eliminates these challenges by allowing pentesters to test ECUs from anywhere in the world and, when combined with automation, provides several other advantages. These benefits include:

› Eliminating the need to ship ECUs or for pentesters to travel.

› Sharing a single ECU between multiple pentesters.

› Around the clock testing with pentesters in different time zones.

› Fewer ECUs needed for testing.

› Automation of repeatable tests (e.g., fuzzing, scanning).

› Shift left. Run tests earlier in the development cycle including CI/CD regression testing.

› Validation and verification of security features.

› Real-time reporting of results.

› New automated ways of reporting vulnerabilities to management systems.

› Aligns with ISO SAE 21434 specified testing requirements.

› Integration of pentesting with incident response for vulnerability validation.

Remote pentesting allows skilled researchers to contribute from anywhere in the world, without being limited by time zones or distance. This helps to bridge the cybersecurity skills gap caused by a limited number of pentesters in a particular area.

Innovative solutions, such as BG Networks’ collaborative and remote pentesting platform, offer a new approach to address the challenges of automotive pentesting. This platform combines a software-managed remote bench with a collaborative testing framework, automation to re-run tests, and logging of results.

By using a remote bench, pentesters can collaboratively test multiple ECUs simultaneously, without the need for physical access. The flexibility of remote access means that testing can take place at any time of the day, providing maximum convenience for both testers and developers. Live reporting of testing results allows engineers to quickly reproduce any findings and address them more quickly.

The automotive industry has increasingly focused on cybersecurity in recent years. This focus has led to the staffing of expert product security teams and

the development of significant cybersecurity capabilities. Regulation has been a driver behind this development. When it comes to critical infrastructure, regulation is needed to ensure that the right level of cybersecurity is included to provide resilience against Advanced Persistent Threat (APT) groups and adversarial nation states.

The key regulations and security standards that have been the driver for cybersecurity in automotive systems are:

› UNECE Regulations UN R155 & UN R156 for Vehicle Cybersecurity

› ISO/SAE 21434 Road Vehicle Cybersecurity Standard, which is the reference implementation for R155 compliance

These regulations require companies to implement a full Cybersecurity Management System (CSMS). This includes development of security from initial stages of design, implementation of cybersecurity features to protect devices from cyberattacks, testing to validate and verify security has been implemented correctly, monitoring for newly exposed vulnerabilities, and an incident response team to quickly remediate any attacks that are detected.

At a high level, a secure development process requires the following steps:

› Performing security threat assessment/risk analysis (TARA) to identify potential vulnerabilities and to guide the implementation of security features. A TARA identifies the right amount of security for the given system considering potential threats and risks including financial, data, operational, and safety impacts.

› Implementing cybersecurity features such as secure boot, authenticated communication, secure key storage, secure software update mechanisms, and device security monitoring.

› Managing supply chain security to ensure vulnerabilities are not introduced when open-source software or commercial third-party solutions are utilized in developing a product.

› Penetration testing to uncover security vulnerabilities.

Without penetration testing, it is impossible to know if a device is truly secure. No one would consider releasing an automotive ECU without extensive testing of core features for functionality and safety. Penetration testing provides analogous testing for security features of an ECU.

Furthermore, ISO/SAE 21434 specifies testing for “unidentified weaknesses,” and cites penetration testing as a method for doing this. Given that all new vehicles in the EU need to be R155 certified by July 2024, there is an increasing need for pentesting.

Penetration testing is performed by personnel who have not been involved in the design of the product and that have a unique skill set. Pentesters essentially act as hackers and use the same techniques to identify cybersecurity vulnerabilities and potential attacks. This is a critical step in ensuring that security has been implemented correctly and there are no open security gaps. It is very easy to make a mistake that leads to a significant vulnerability such as:

› Not setting the secure boot mode bit in an embedded processor

› Forgetting to remove engineering test code from the production code release

› Using keys that were meant to be temporary and are not secure

› Forgetting to close all unused network ports

› Using default or easy to guess passwords

› Allowing root privilege in a shell

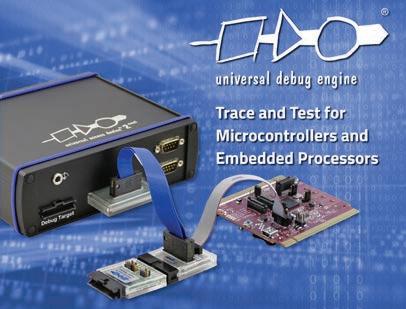

› Not locking JTAG

› Software buffer overflows

These are all common security mistakes that pentesting can uncover. A simple security mistake, such as these, can turn into a serious safety and operational problem.

Pentesters simulate real-world attacks and attempt to exploit vulnerabilities in the device’s firmware, software, and hardware. The goal is to identify weaknesses that could be exploited by hackers to gain unauthorized access to the ECU or its data, use it as a pivot point to attack other ECUs in the vehicle, or most seriously, compromise the integrity of an ECU that controls a physical actuator (steering, breaking, acceleration, ADAS, etc.).

Pentesting for automotive ECUs typically involves the following steps:

1. Reconnaissance: Gathering information about the device, such as its firmware version, supported interfaces, and software configuration.

2. Identification of vulnerabilities: using hacking tools and clever tricks of the trade to identify vulnerabilities and weaknesses. This can take many forms:

a. Privilege escalation: Attempting to gain administrative access to the device or its data.

b. Running tests/attacks against known protocols and interfaces using hacking tools.

c. Scanning vulnerability databases for known vulnerabilities in the software components running on the ECU.

d Reverse engineering the code running on the ECU to search for weaknesses and vulnerabilities.

3. Exploitation: Attempting to exploit vulnerabilities found during the identification phase. This includes chaining vulnerabilities that could lead to very significant exploits.

4. Post-exploitation persistence: Attempting to maintain access to the device, exfiltrate data from the device, or use it as a pivot point to attack other ECUs in the vehicle.

5. Reporting: Documenting the vulnerabilities found and providing recommendations for remediation.

Once vulnerabilities have been identified, these weaknesses can be remediated to eliminate the potential for adversarial exploitation to occur in the wild.

Pentesting for ECUs requires specialized knowledge and skills, including knowledge of ECU device architecture, firmware analysis, reverse engineering, software development, hardware, network, and automotive protocols. It is typically performed by experienced security professionals with specialized training in software, IoT, embedded systems, and automotive security.

Pentesting for ECUs presents several unique challenges, which can lead to high costs and long schedules, including:

1. Heterogeneity of ECU architectures: ECUs are built on a wide range of hardware and software platforms/operating systems, and utilize a variety of communication protocols and buses, some of which are unique to automotive ECUs. This makes it challenging to develop standardized testing methodologies that can be applied across all devices.

2. A large attack surface with many types of interfaces: Knowledge of a wide array of interfaces and associated software stacks is needed to test

for weaknesses. Interfaces include Ethernet, CAN, USB, JTAG, LIN, cellular, Wi-Fi, Bluetooth, SD Card, V2X, and EV charging interfaces.

3. Heterogeneity of ECU suppliers: Every vehicle has many ECUs, and ECUs within a given vehicle are often developed by numerous tier 1 suppliers. As a result, multiple software stacks for the same interface are often independently developed. Each implementation needs to be tested as it may have unique security vulnerabilities.

4. Limited processing power and memory: Many ECUs have limited processing power and memory, which can make it challenging to run vulnerability scanning tools or require more time to craft tests.

5. Components of a larger system: Automotive ECUs are designed to work as components of the overall vehicle. It is necessary to test these ECUs in isolation, but that is not sufficient. Penetration testing must also consider how these devices will be used in the vehicle and what attacks are possible at a system level. For example, what attacks are possible against ECUs connected to a common CAN bus if the infotainment ECU is hacked? This requires additional knowledge of how the overall system operates and what the most significant cyber-risks are at the vehicle level. Challenges are also presented in setting up and running a single ECU that is designed to operate in a large system (e.g., creating needed cable harnesses, providing power, providing the correct message sequences to have the ECU respond, etc.).

Overcoming these challenges requires specialized skills and expertise in automotive ECU security testing, as well as a thorough understanding of the unique characteristics of automotive systems. Pentesters must be able to work with a wide range of tools and techniques to

identify vulnerabilities and provide recommendations for remediation.

Automotive ECUs are subject to a variety of attack types (Figure 1). Attacks may originate on remote networks over a cellular interface. They may also originate from local networks, such as an automotive dealers’ network that is used to update and diagnose vehicles in an auto-shop. Other attacks require a local presence, such as attacks over a Bluetooth interface or physically gaining access to a CAN bus (e.g., removal of a headlight) to steal a vehicle.

Hackers can also compromise a local host, such as an infotainment or telematics ECU and then pivot and use the compromised ECU to find weakness in other ECUs or the automotive OEM’s cloud system. For example, certificates that allow cloud access to millions of vehicles have been found, without adequate cyber-security, in telematics units. Older remote keyless entry protocols have been shown to be insecure against man in the middle attacks. Finally, hackers can perform physical attacks by connecting directly to an ECU bus or memory and performing fault injection attacks or reading data directly from the device.

Pentesters must consider each attack type when assessing the security of automotive ECUs.

To enable pentesting at scale, better tools are required (Figure 2). BG Networks’ remote pentesting platform is designed to address these challenges. This platform

includes a remote workbench, supporting remote desktop access via VPN enabling pentesters to access an ECU as if it were in their local lab. The solution supports:

› Access to ECUs by local and remote pentesters.

› Automation of scanning and fuzzing tests.

› Remote access to debugger interfaces & buses (LIN, CAN, and Ethernet) on the ECU.

› Remote control of power to the ECU.

› Spectator mode for training and demonstration of discovered vulnerabilities.

› Logging of all activity during testing.

The solution also provides a testing framework that enables collaboration among pentesters, security engineers, and ECU hardware & firmware engineers.

The workbench is designed specifically for ECU pentesting and provides multiple automotive interfaces that can be utilized by pentesters. These include LIN, CAN, and Ethernet. It also supports standard debug interfaces, such as JTAG. This allows pentesters to execute tests and monitor interfaces, just as they would if they had physical access to the ECU.

The platform also allows tests to be scripted for repeatability. Once a test is developed, it can be added to a set of regression tests that are run each time a new version of the ECU hardware, firmware, or software is released. As more tests are developed, testing moves from custom testing of the new capabilities to an automated process in which known tests are automatically run.

Summary

The automotive industry is adapting to new legislation and industry standards requiring manufacturers to be proactive in adding security to their devices. Penetration testing is now a must-have for automotive ECUs, but current pentesting processes don’t scale to meet the growing needs of the industry.

Automated tools for pentesting are needed. Of particular importance are tools to allow remote penetration testing, and to automate execution of existing tests. A remote workbench to allow testing without physical access to an ECU combined with automation tools will dramatically increase productivity and collaboration, and enable repeatable testing.

Dr. Roman Lysecky is Co-founder and CTO of BG Networks and Professor Emeritus of Electrical and Computer Engineering at the University of Arizona. He is an expert on embedded systems, IoT security, medical device security, automated threat detection and mitigation, performance and energy optimization, and non-intrusive observation methods.

The BG Networks workbench enables pentesting of ECUs by local and remote teams. FIGURE 2 Multiple attack types must be considered when pentesting automotive ECUsThere is a seemingly endless number of RTOSes used with embedded MCUs, most of which have their own proprietary functionality as well as a unique API. Some of the APIs are good, and some not quite as good. In reality, the delta between a good and less-good RTOS API is quite small – most RTOS APIs will do the trick. As I look back on my last 30+ years, I’ve come to realize propriety RTOS APIs have had and continue to have a profound negative impact on embedded development and on our industry as a whole.

First and foremost, the proprietary RTOS API represents a lock-in for the application firmware. Code written using a proprietary RTOS API must be changed in order to move to a different RTOS. Worse, the changes required to move to another RTOS can be daunting. Some RTOS vendors have added an adaptation layer in an attempt to support other APIs. However, this solution is less than ideal as it often tries to fit a square peg in a round hole. Not to mention additional layers greatly increase overhead as well as complexity of the RTOS, which in turn can result in errors.

In any case, not being able to easily migrate application code can severely limit the evolution of a product. For example, if an application is dependent on RTOS XYZ and it doesn’t support the latest and greatest processor, the application either needs to modify their code base to move to another RTOS, wait until RTOS XYX adds support, or just give up. Similarly, migrating a RTOS XYZ-based application to embedded Linux (another very common situation), is difficult because multithreading in embedded Linux is based on the POSIX pthreads API. A standard RTOS API would help eliminate lock-in, thereby making embedded applications more portable and enhancing their future evolution.

Proprietary RTOS APIs also require extensive training. Most developers using an RTOS for the first time have to spend significant cycles learning the proprietary

RTOS API. Even embedded developers using FreeRTOS or Microsoft’s Azure RTOS ThreadX – both popular embedded RTOSes, each having their own proprietary API – represent a fairly small percentage of the total number of developers. The point here is that proprietary RTOS APIs necessitate learning, which costs companies time and money. An industry standard RTOS API would reduce training and, as a result, save money and improve device maker’s time-to-market.

Another issue is that some device makers have product families that span both MCU and MPU processors, typically with different functionality and price points. Their MPU-based products frequently use some flavor of embedded Linux. For these companies, having to maintain separate development teams (and code bases) because of a proprietary RTOS API is both difficult and costly. With a standard RTOS API, application code could be instantly shared between MPUand MCU-based projects, improving the entire development process, from coding and testing to product release.

What Should the Standard RTOS API Be?

Before we go further, credit should be given to Arm, since they identified this problem in the embedded industry many years ago and even tried to address it with the CMSIS-RTOS API. Unfortunately, the CMSIS-RTOS API is ultimately yet another proprietary RTOS API.

Back to what the standard RTOS API should be. Amusingly, the answer has been right in front of us for many years: The standard RTOS API should be the same industry standard POSIX pthread API, which is already part of every embedded Linux distribution, as well as every university computer science curriculum. Since embedded Linux represents 70% of the embedded designs, it’s easy to argue that the POSIX pthread API is already the RTOS API standard in the embedded space and what most developers are already familiar with.

Furthermore, the POSIX pthread APIs have been tested on UNIX/Linux systems for over 30 years. Coupling hard real-time capabilities with this industrial standard API promises embedded developers the best of both worlds. Our industry just needs the various RTOS providers to natively adopt it. Uniting the embedded industry on the POSIX pthread API standard would eliminate lock-in, accelerate embedded product evolution, reduce training, and instantly enable code sharing and migration between MCU- and MPU-class devices – all of which represents a significant step forward for the embedded industry.

Bill Lamie, President and CEO of PX5 RTOS, has been in the commercial RTOS space for over 30 years – first with Accelerated Technology (acquired by Siemens) and then with Express Logic (acquired by Microsoft). Bill was the sole author of Nucleus and ThreadX.

Accelerating

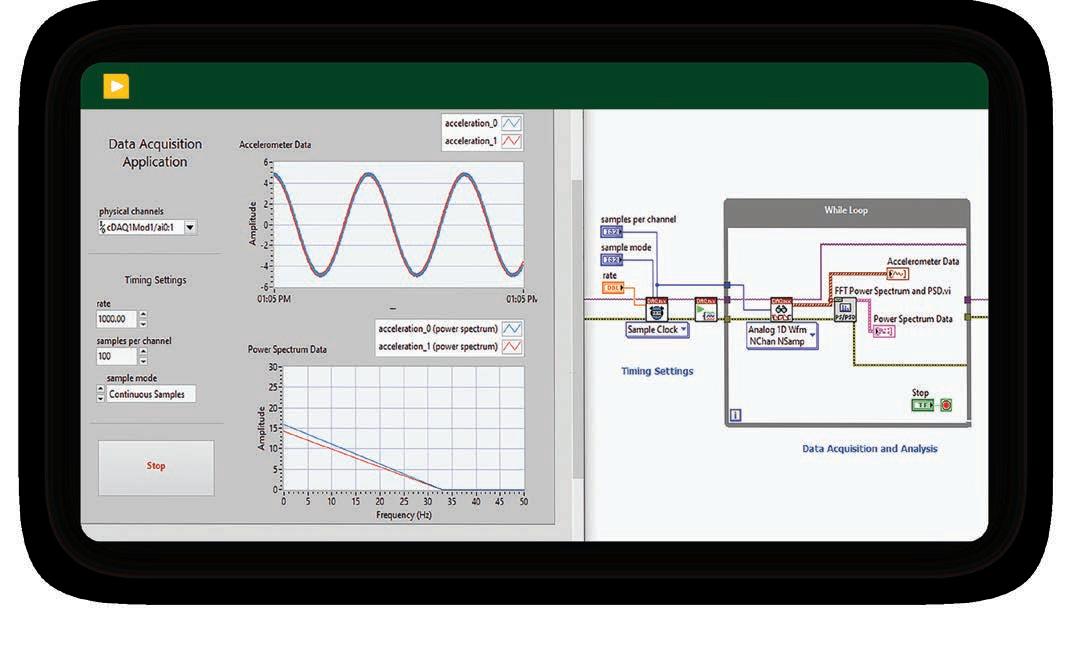

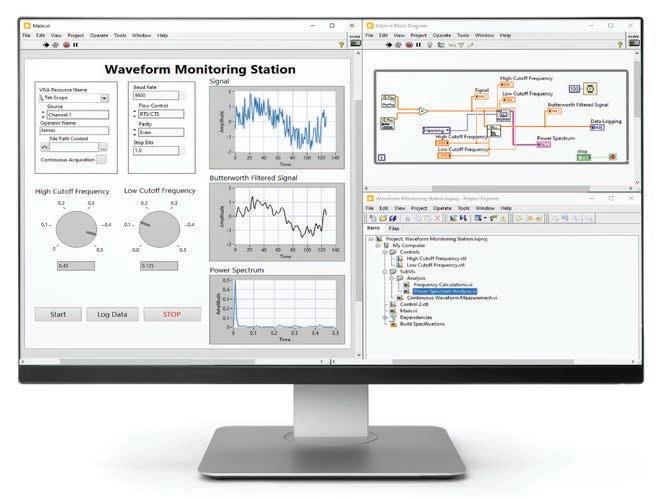

For over 35 years, engineers have turned to LabVIEW as their tool of choice for developing automated test systems.

Download today at ni.com/labview

Pytest is a command-line tool that finds, runs, and reports the results of tests you’ve written. It is suitable for all levels and types of the testing process. Pytest can be used by developers and designers, quality assurance teams, independent testing groups, and open-source projects.

Today’s modern businesses require faster software feature releases to produce high-quality products and to get to market quickly without sacrificing software quality. To ensure successful deployments, the accelerated release of new features or bug fixes in existing features requires rigorous end-to-end software testing.

While manual testing can be used for small applications or software, large and complex applications require dedicated resources and technologies like python testing frameworks, automation testing tools, and so on to ensure optimal test coverage in less time and faster quality releases.

Pytest is a testing framework that allows individuals to write test code in Python, enabling you to create simple and scalable test cases for databases, APIs, and user interfaces. Pytest is primarily used for writing API tests. It aids in the development of tests ranging from simple

unit tests to complex functional tests. According to a report published by Future Market Insights, the global automation testing market is expected to grow at a CAGR of 14.3% registering a market value of US$ 93.6 billion by the end of 2032.

Selection of the right testing framework can be difficult and relies on parameters like feasibility, complexity, scalability, and features provided by a framework. Pytest is the go-to test framework for a test automation engineer with a good understanding of Python fundamentals. With the Pytest framework, you can create high-coverage unit tests, complex functional tests, and acceptance tests (Figure 1). Apart from being an extremely versatile framework for test automation, Pytest also has a plethora of test execution features such as parameterizing, markers, tags, parallel execution, and dependency.

› There is no boilerplate while using Pytest as a test framework.

› Pytest can run tests written in unittest, doctest, and nose.

› Pytest supports plugins for behavior driven testing.

› There are more than 150 plugins available to support different types of test automation.

The diagram below shows a typical structure of a Pytest framework.

As shown in the Figure 1 structure, the business logic of the framework core components is completely independent of Pytest components. Pytest makes use of the core framework just like instantiating the objects and calling its functions in the test script. Test script file name should either start with `test_` or end with `_test`. The test function name should also be in the same format. Reporting in Pytest can be taken care of by Pytest-html reporting.

1. Pytest fixtures

The most prominently used feature of Pytest is Fixtures. Fixtures, as the name suggests, are decorator functions that are used in Pytest to generate a specific condition that needs to be arranged for the test to run successfully.

The condition can be any precondition like creating objects of the classes required, bringing an application to a specific state, bringing up the mockers in case of unit tests, initializing the dependencies, etc. Fixtures also take care of the teardown or reverting of the conditions that were generated after the test execution is completed. In general, fixtures take care of the setup and teardown conditions for a test.

Fixture scope

The setup and teardown do not have to be just for the test function. Scope of the setup may differ from a test function to as large as the whole test session. This means the setup-teardown is executed only once per defined scope. To achieve the same, we can define the scope along with the fixture decorator i.e., session, module, class, function.

Fixture usage

Pytest provides the flexibility to use a fixture implicitly or call it explicitly, with the autouse parameter. To call the fixture function by default, the autouse parameter value needs to be set to True, else to False.

2. Conftest.py

All the fixtures that are used in the test framework are usually defined in conftest.py. It is the entry point for any Pytest execution. Fixtures need not be autouse=True. All defined fixtures can be accessed by all the test files. conftest.py needs to be placed in the root directory of the Pytest framework.

3. Pytest hooks

Pytest provides numerous hooks that will be called in to perform a specific setup. Hooks are generator functions that yield exactly once. Users can also write wrappers in conftest for the Pytest hooks.

4. Markers

Pytest provides markers to group a set of tests based on feature, scope, test category, etc. The test execution can be auto-filtered based on the markers. i.e., acceptance, regression suit, login tests, etc.

Markers also act as an enabler for parameterizing a test. The test will be executed for all the parameters that are passed as the argument. Note, Pytest considers a test for one parameter as a completely independent test. Many things can be achieved with markers like marking a test to skip, skipping on certain conditions, depending on a specific test, etc.

5. Assertion

Pytest does not require the test scripts to have their assertions. It works flawlessly with Python inbuilt assertions.

6. Pytest.ini

All default configuration data can be put in pytest.ini and the same can be read by the conftest without any specific implementation.

Pytest supports a huge number of plugins with which almost any level of a complex system can be automated. A major benefit of Pytest is that any kind of implementation of the structure is done using raw Python code without any boilerplate code. It means implementing anything in Pytest is as flexible and clean as implementing anything in Python itself.

Amidst shorter development cycles, test automation provides several benefits that are critical for producing high-quality applications. It reduces the possibility of unavoidable human errors taking place during manual testing methods. Automated testing improves software quality and reduces the likelihood of defects jeopardizing delivery timelines.

Rahul Vala, Principal Engineer at Softnautics, is a solution-focused test automation engineer with 7+ years of experience in systems testing of different types. He possesses high level proficiency in end-to-end systems test automation and framework development of complete IoT ecosystem (web, mobile, end device, cloud) using different types of frameworks with Python.

LabVIEW, the graphical programming environment used globally by systems and test engineers (Figure 1), automates and simplifies what would otherwise be a tedious manual process. Developed and maintained by NI, LabVIEW is used to create applications that interact with real-world data or signals, such as measurement or control systems.

When using LabVIEW, users create programs by dragging and dropping different graphical elements onto a block diagram. This would otherwise be achieved by writing lines of code in textbased languages. These graphical elements are wired together to do things like acquire and analyze data and control instruments and processes.

A key benefit of LabVIEW is that it can reduce development time, partly due to its array of pre-built functions. In addition, a lot of the time savings comes from LabVIEW’s user interface and visualization capabilities. If you’re looking to monitor or interact with your test system in any way, LabVIEW has lots of functions for that. If you want to create charts, graphs, lights, or buttons, for example, that’s all readily available so the build is simple. You just drag, drop, move around, and resize as needed.

Candidates for LabVIEW include pretty much anyone doing test or measurement, or looking to connect to an instrument and acquire data. The beauty of LabVIEW is that it can scale from the smallest applications, even a one-time measurement, to a fully automated system with multiple devices.

This is where the tool really shines – when you’re connected to hardware and trying to measure and analyze at the same time, and when you are trying to connect multiple instruments at once. This eliminates the disconnect of going back and forth between tools, say a measurement program and then something else to handle the analysis. And that analysis occurs on the fly in LabVIEW, as the measurements are coming in. From that point, you create a report and automate it.

The “entry point” for LabVIEW occurs the second you need to take a measurement that’s beyond a basic temperature probe, essentially a measurement that needs to be logged at some point to validate and/or verify parts of your design.

While the learning curve for LabVIEW is quite short, unfamiliar or inexperienced developers should expect to take a brief training course, similar to starting any new language. But because the tool is graphical in nature, the training occurs very quickly. The real prerequisite is to understand algorithms and the test systems that are under development. Note that NI has lots of existing content that provide a jump start to just about any design. There’s also a trial version of LabVIEW that users might want

to test drive. And for those that may need a little extra or really want to get into the inner workings of LabVIEW, paid courses are available. It’s quite similar to getting started with a language like Python, to understand simple programming and how to formulate algorithms.

That’s not to say that having some basic programming knowledge wouldn’t come in handy. Keep in mind that graphical programming is somewhat different – easier, but different. It’s a little more intuitive, where you are dragging and dropping functions rather than writing your application line by line and needing to follow a very specific format and syntax (Figure 2).

The learning curve for a seasoned engineer should be a short one. In practice, every function has a help detail to walk you through specifically what that function is and how it should operate. And lots of detailed examples ensure that you’re usually not starting from point 0. While there may not be the exact example you’re looking for available, you can usually get pretty close, where it’s more about tweaking code than writing from scratch.

There is also a loyal community of LabVIEW users that scale across different industries, geographies, and languages that are quite passionate about the tool and typically lend a hand when asked. Note that this is external to NI, but extremely valuable, nonetheless.

The openness of LabVIEW allows it to keep pace with the latest and greatest technologies. Take AI, for example. If your code is already written in another language such as Python, it can be integrated into your existing LabVIEW application.

If you’re focused on one specific measurement using one device, then you may not realize the advantages of LabVIEW. But if you need to build upon that measurement, like connect to other devices, do analysis, or create reports, you can probably do it faster in LabVIEW. And LabVIEW works well if you’re operating with a team of multiple people, locally or in other parts of the world. You can track changes when modifying applications and compare results.

The bottom line is that, if you want to take measurements, analyze data, share results with your team and spend less time developing, LabVIEW is likely your best option.

“THE BEAUTY OF LABVIEW IS THAT IT CAN SCALE FROM THE SMALLEST APPLICATIONS, EVEN A ONE-TIME MEASUREMENT, TO A FULLY AUTOMATED SYSTEM WITH MULTIPLE DEVICES.”

By Michael De Nil, Morse Micro

By Michael De Nil, Morse Micro

The Wi-Fi blackspot problem inside the home has been largely solved by Wi-Fi 6 mesh access points that allocate some of their wireless bandwidth to establish connectivity between mesh network nodes, thus extending the reach of the wireless local area network (WLAN). While this works well in many domestic situations, and for some small offices, it’s not nearly a perfect solution.

On larger properties, Wi-Fi 6 mesh access points still struggle to reliably reach some garages, secondary dwellings, and outdoor locations. This limits reliable connectivity to new Internet of Things (IoT) devices such as remote locking systems and security cameras.

Overcoming the range limitations of current Wi-Fi standards is a major challenge for enabling the IoT applications of the future. The limitations in range come down to simple physics. Wi-Fi 4, 5, and 6 operate in the 2.4 GHz and 5 GHz frequency bands with the more recent Wi-Fi 6E adding the 6 GHz band to the mix. While these higher frequency bands allow wider channels with faster performance, lower frequencies offer better range and penetration. So, today’s Wi-Fi networks, including Wi-Fi mesh systems, are subject to the range limitations of the higher frequency bands.

Wi-Fi HaLow is the latest wireless protocol, certified by the Wi-Fi Alliance and based on the IEEE 802.11ah standard. Wi-Fi HaLow uses lower frequencies and narrower bandwidths, which enable ten times longer reach than conventional Wi-Fi networks that operate at

higher frequencies. While Wi-Fi HaLow removes the need for Wi-Fi meshing for new IoT deployments, especially in nondomestic environments, it also adds key benefits when combined with Wi-Fi 6, or soon Wi-Fi 7 mesh technology.

Operating at sub-GHz frequencies, Wi-Fi HaLow can transmit data over much greater distances and penetrate materials better than other Wi-Fi standards, such as Wi-Fi 4, 5, and 6.

While 5 GHz and 6 GHz Wi-Fi technology can provide multi-Gbps backhaul links between mesh nodes at short distance, the quality of the link quickly deteriorates as Wi-Fi mesh nodes are spaced further apart. In fact, most Wi-Fi mesh access point vendors recommend spacing units not further apart than 10 meters and they do not allow users to set up mesh nodes that are farther apart in order to guarantee reliable connectivity.

Wi-Fi HaLow enables mesh access points to reach farther, creating more robust and reliable infrastructure, even if mesh nodes are spaced further apart. The

sub-GHz link can be used as a secondary backhaul to enable Wi-Fi connectivity in places that are out of reach today.

And while the narrower channels do mean throughput is lower than Wi-Fi 5 and 6, Wi-Fi HaLow devices can still deliver throughputs in excess of 30 Mbps, which is fast enough for bandwidthhungry applications such as audio streaming, video conferencing, or even watching Netflix in HD.

Wireless mesh networking is inherently difficult because it involves the coordination of various nodes to create a reliable and robust network; each needing to adapt to the dynamic nature of wireless networking. Wi-Fi mesh networks are susceptible to interference from other neighboring Wi-Fi devices as well as various other wireless devices in the home, including Bluetooth headsets, Zigbee lightbulbs, or Z-Wave security sensors.

While Wi-Fi mesh access point vendors have helped mask these complexities for the end user, they still struggle when connectivity is lost or is intermittent

between nodes. For example, range issues, traffic volume, or interference can make diagnosing problems difficult or impossible.

Configuring and maintaining wireless mesh networks can be significantly simplified by splitting the high-speed data plane, which inherently relies on a functional mesh, from the control plane, which requires a reliable and robust link between nodes. Wi-Fi HaLow can provide an independent out-of-band radio in each mesh node, enabling direct communication between the master and any of the end nodes. This enables reliable network configuration, problem diagnosis, and recovery, thus enhancing ease of use and optimizing overall Wi-Fi management and performance.

Prepare for the Future of Mesh Networks

International Data Corporation (IDC) forecasts a massive growth in the number of IoT devices that will be connected to networks. It estimates that there will be in excess of 40 billion IoT devices by 2025, potentially generating up to 80 zettabytes of data. Connecting those devices to networks will become a major challenge in the coming years.

Wi-Fi HaLow can free up bandwidth in the higher frequency bands by moving IoT to the sub-1 GHz band and is starting to make its way into many IoT devices because of its advantages in power consumption and range. Therefore, adding Wi-Fi HaLow to mesh access points now will enable those devices to connect without the need for additional network equipment in the future. A mesh node equipped with both Wi-Fi 6

and Wi-Fi HaLow will enable enhanced connectivity for IoT devices while supporting traditional Wi-Fi applications.

The development of mesh networks and the continued evolution of Wi-Fi have been a boon for consumers. Whether people are working from home, enabling smart home devices, boosting coverage in offices, or starting to leverage IoT, extending networks using a standardsbased approach that avoids the costs of cabling and additional switches delivers significant benefits.

Michael De Nil is the CEO, co-founder, and a board member of Morse Micro. He played a key role in the digital chip development of the 802.11 Wi-Fi chips found in most modern smart phones and had 10 years of experience in low-power digital IC design at Imec and Broadcom before founding Morse Micro.

BlackBerry® QNX® is the embedded OS of choice for factory automation systems, medical robots, vehicles, ventilators, train controls, and more. Launch your critical embedded systems faster with our commercial real-time operating system (RTOS), hypervisor, development tools and professional services. Our hypervisor and middleware deliver performance and security and streamline safety certifications.

Embedded systems are more software-driven and complex than ever. BlackBerry® QNX® provides the software foundation and building blocks to help you focus on delivering value-added features and software.

If you’re looking to increase security or safety, or you want to streamline your cross-platform development process, we can help. We provide support for every stage of the product lifecycle and offer professional services and training to give you the additional expertise you need, when you need it.

• Foundation products include the QNX® Neutrino® RTOS, the QNX® Software Development Platform (SDP) with a POSIX-compliant development environment, and the QNX® Hypervisor.

• Safety-certified variants of our products accelerate your certification efforts. Accelerate time to market with software pre-certified to IEC 61508, ISO 26262 and IEC 62304, QNX® functional safety training, and safety services.

• Security – With a microkernel architecture, our RTOS and hypervisor are secure by design. Rely on our fieldproven cybersecurity experts to help protect your systems, including secure over-the-air updates.

• Reliability – The QNX microkernel architecture protects the OS and system from component failure and delivers exceptional performance.

• Scalability – Our fully-managed microkernel RTOS can be duplicated and used across all product lines, so your developers can focus on value-added features, not OS maintenance.

BlackBerry QNX offers customized professional services to bring safe, secure and reliable products to market on time, on budget and with excellent quality. We have decades of experience successfully delivering embedded systems for organizations in multiple industries.

By Sri Peruvemba, Marketer International

By Sri Peruvemba, Marketer International

I know 3D display technology has had its skeptics through the decades, and many in the industry have failed in this arena, but I believe 3D display technologies will touch just about every industry, further pushing the boundaries on the human digital experience – from entertainment to medical, military applications, engineering, graphic design, architecture, and more. Like rotary phones, we will forget that we had 2D displays.

However, I admit we are not quite there yet. While there has been significant progress in the display itself, we are not where we need to be to create a massive shift from 2D to 3D. For one thing, both the hardware and the

software need to be dramatically improved (think energy consumption, massive computing needs, for example). The entire industry needs to adopt this transition – from hardware to software to chip makers, and everything in between.

We also need higher resolution displays: 300 ppi to 500 ppi displays, from small to large sizes, to get the best results. Today, we have high resolution displays, but they

tend to be for phones with a notch for the camera or they have to be specially made, which renders them unsuitable for the mass market.

To make really good 3D light field displays, for example, you need large format displays with high resolution, which aren’t easy to come by. Even today, it’s hard to get any better than 8K, which is fine for smaller displays; but for an 85” display, even higher resolution is preferred. To clarify, 8K is plenty of resolution for 2D displays, but barely makes it for 3D.

In a future 3D digital world, our TVs will resemble the theater; the basketball game on TV will resemble that of courtside seats at the arena; the newest shoe or the newest piece of jewelry on a 3D display will resemble what you see in the physical store; flying airplanes during training to performing surgery will be more like the real thing. Our video conferencing will not look like we are talking to small glowing rectangular boxes – instead it will resemble an actual conference room. (We might even enjoy video calls. Ugh.)

There will also be less need for designers to mockup prototype cars made of wood or clay, or for architects to make a model out of Styrofoam because these will look realistic on a 3D display. Rather than walking around the model to get different views, you can rotate the image of the car or building on your 3D display, and multiple viewers can view and offer input.

Today, we have multiple companies chasing this space, including big players.

One example is the world’s first groupviewable 3D holographic displays by Looking Glass. This company, along with other innovators, is designing the highest resolution and most realistic experience technically available today.

The entertainment industry is currently the largest draw for 3D displays, followed by enterprise applications like 3D modeling, design, engineering, etc. The next biggest draw will be from brands wanting to showcase their product on a display that best resembles the real thing; the 3D light field display (hologram) does that.

There’s evidence that we are on the right track. The increased market supply and demand for 3D display technologies could breathe a whole new life into the entire display industry. It will impact all display technologies, from LCD to OLED to emerging ones like microLED.

But, much more innovation needs to happen. Today, everything is 2D and the transformation would mean that the current display hardware must be modified. The good news is that most of the existing infrastructure in terms of the factories, the production lines, the materials, and processes for current display technologies, can be reused. In most cases, you can insert additional films and system designs to make them suitable for 3D. Fortunately, these can be done relatively easily and don’t require massive design changes.

The industry has had to overcome some major hurdles in the ongoing shift to 3D, including:

Nausea: Since the design was poor, when you moved your head side to side, the image “chopped” and you got a reset of some kind. This issue has been solved by enabling the viewer to see multiple views at the same time, so there is no transition.

Single viewer: Many camera tracking 3D displays could only enable one person, so with a TV or monitor application where you expect multiple viewers, that does not work. This challenge has been solved with a multi-viewer system where several dozen people could view from a distance.

Glasses: Most people don’t like to wear glasses for extended periods of time unless you are like me. I have been wearing glasses since the fourth grade (I was the only kid with glasses in the entire school). All the new versions of 3D displays are glasses free. We will continue to see improvements in this space.

I’m excited and hopeful about the significant progress being made in the display tech space surrounding 3D. The good news is that the metaverse promoters have a huge appetite for 3D displays, and display makers are gearing up to feed the mass markets. Current products in the market are providing valuable feedback to the entire industry.

Like with previous new technologies, among the display makers, we will have the innovators and the fast followers, the laggards, and alas, some will be left behind. This will be an interesting race to watch – on a direct view, glasses-free display with my prescription glasses on.

Sri Peruvemba is the Chief Executive Officer at Marketer International. His 25 years of experience in the electronics industry include marketing LCD, CRT, TFEL, OLED, LED, Plasma and ePaper displays into the mobile, industrial, medical, signage and TV markets. He earned a BSEE, MBA, and a Post Graduate Diploma in Management. Previously, Peruvemba held senior level positions at E Ink, Sharp Corp, TFS Inc, Planar Systems and Suntronic Technology.

Smartphones have become ubiquitous, in everyone’s pocket, purse, and backpack, displacing many other household items. We rely on them for everything from email, banking, unlocking our front door, to even making the occasional phone call. Yet a quick glance around our homes and businesses will quickly reveal two things smartphones have yet to displace- buttons and a seven-segment display.

Buried deep within menus and button presses, many devices offer an incredible amount of information and customizability that requires cumbersome programming. With Bluetooth low energy (LE) featured in virtually every smartphone on the planet, it is time to break free from buttons and displays.

Imagine being able to program a pressure cooker by simply selecting the recipe

on a smartphone rather than manually pressing buttons and squinting at the display. By using Bluetooth LE with a smartphone app, designers can catapult their products into a premium user experience, improving customer satisfaction and product reviews.

Today’s Bluetooth microcontrollers and the Bluetooth standard have made tremendous strides in reducing costs, complexity, and power consumption. First, Bluetooth has evolved through the Bluetooth LE standard, which makes many improvements over Bluetooth classic. Bluetooth LE dramatically reduces power consumption through many optimizations, primarily by sending short bursts of data and then going into sleep mode. This is precisely how data typically flows for a user interface-small amounts of data are sent at regular intervals.

Bluetooth LE also simplifies the pairing process making it much easier and more reliable for end users to connect their smartphones to the end device. Finally, Bluetooth LE is designed around profiles, which structure the services and data exchange between the smartphone and the device, allowing software designers to focus on their application, not the Bluetooth connection.

A quick internet search reveals many resources explaining the details of how Bluetooth LE works. At its heart, Bluetooth LE is built around one device being the central and the other being the peripheral. The central scans for available peripherals, which advertise on specified channels. Once the central and peripheral devices establish a connection, the peripheral becomes the server, providing the central, now the client, with information about its available services and data.

Establishing this connection is handled by the Generic Access Profile (GAP) portion of the protocol, while the Generic Attribute Profile (GATT) manages the data exchanged between the two devices. The Bluetooth LE standard contains a multitude of predefined profiles for many common use cases and opens the door for custom profiles. For a user interface, one of the best places to start getting familiar with Bluetooth LE is with a simple wireless UART.

Most designers are familiar with using the universal asynchronous receivertransmitter (UART) protocol for debugging and diagnostic purposes. Sending data, status, and configuration information to a smartphone app over UART is relatively similar.

As shown in Figure 1, most Bluetooth microcontroller vendors, including NXP® Semiconductors, provide a wireless UART in their SDK that mimics a wired UART connection. With a wireless data path established, data flows between the Bluetooth device and the smartphone allowing the designer to carry

out all the functions of the display and buttons by passing data between the end device and the smartphone. The end user can now quickly and easily see information and access configuration options that used to be buried behind confusing menus and button presses.

With a basic understanding of how Bluetooth connections work and a simple way to wirelessly exchange data, the next step is to look at the hardware architecture of the end device. Many high-end devices require high-performance application processors (MPUs), such as NXP’s i.MX series, while others may only need a single MCU.

Based on the needs of the end device, there are three typical Bluetooth connectivity configurations that scale from standalone to hosted with network co-processor (NCP) and hosted with radio co-processor (RCP), see Figure 2.

In a standalone configuration, there is only one processor in the system, which runs both the Bluetooth protocol and the application. If more capability is needed, a host processor can be added, such as an NXP i.MX RT crossover MCU, which runs the application, while the wireless MCU acts as a network co-processor and runs the entire Bluetooth protocol.

For systems using a high-performance applications processor, the Bluetooth protocol can be cleanly split between the link layer and the stack, with the Bluetooth MCU running only the link layer. This split, and the required Bluetooth stack, are standard in most Linux distributions, making it easier to implement. Many processor providers, including NXP, offer software and products for all three configurations, opening Bluetooth connectivity to a broad range of end device types.

With a smartphone in every pocket, adding Bluetooth connectivity to a standalone end device opens the door to a rich graphical user interface through a smartphone app. No longer specialty devices, modern Bluetooth MCUs are more capable and easier to use than ever before. NXP’s latest K32W148 Bluetooth MCU, for instance, offers 96 MHz of performance, over 1 MB of flash, and advanced security features, all while minimizing power consumption.

Bluetooth MCUs like this offer the ability to add wireless and upgrade the entire end device with more speed, capability, and security. End device designers can easily upgrade their products by replacing buttons and the venerable seven-segment display with Bluetooth and a smartphone app. This, in turn, leads to happier users, better online reviews, and, ultimately, more sales.

Charlie Ice is a Wireless Product Marketer at NXP focusing on the company’s wireless MCUs. He joined NXP in 2022 with more than 10 years of experience managing products in the technology industry. His experience includes microcontrollers, digital motor control, digital power supply control, and test and measurement equipment. Prior to joining NXP, Charlie managed Silicon Labs automotive isolation products. He holds a master’s and B.S. in electrical engineering from Rice University.

“TODAY’S BLUETOOTH MICROCONTROLLERS AND THE BLUETOOTH STANDARD HAVE MADE TREMENDOUS STRIDES IN REDUCING COSTS, COMPLEXITY, AND POWER CONSUMPTION. FIRST, BLUETOOTH HAS EVOLVED THROUGH THE BLUETOOTH LE STANDARD, WHICH MAKES MANY IMPROVEMENTS OVER BLUETOOTH CLASSIC.”

What major trends do you foresee in the module industry for 2024?

With technologies such as artificial intelligence, machine learning/deep learning and 5G being implemented in a rapidly growing number of applications, we are seeing an accelerating increase in data collection. Kontron’s customers span a diverse range of applications from robotic surgery to autonomous vehicles and rugged computers for extreme conditions. We are also seeing most of our customers requiring much higher computing power, larger memory capacity and greater connectivity.

Another trend in the last couple of years is a significant demand for end-to-end solutions combining hardware and software for IoT edge. With an ever-increasing number of devices connected to the internet, there are exponential amounts of data generated from different sensors and devices. More of this data is being processed at the edge with applications such as vision inspection of production lines and autonomous vehicles.

How is Kontron preparing to meet these evolving demands?

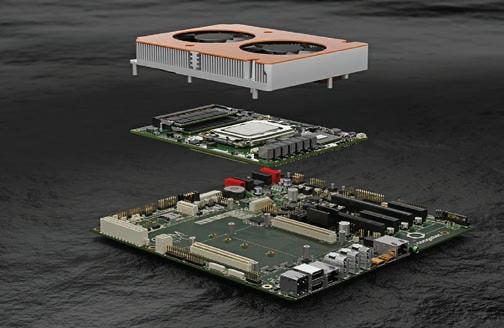

To meet these evolving demands, we have set up a working group in the PICMG® standardization committee, together with other leading manufacturers in the industry. The working group has developed a new module standard for High-performance Computing–COM-HPC®

COM-HPC ® expands our already comprehensive portfolio and bridges the gap between our COM Express® modules and our motherboard products. The larger footprint of COM HPC ® allows us to offer products with up to 512GB DDR4 memory, and 20 cores. COM-HPC® also supports the next generation of high-speed interfaces needed for edge devices. Kontron offers credit card-sized modules using low power, such as the COM Express Mini, up to COM-HPC® Server Class modules scalable up to 120 W TDB. Many of these products are also available in extended temperature version, providing great options for harsh environments.

With our numerous offerings, Kontron is well-suited to provide new solutions for embedded hardware for any kind of application.

The performance and lower power of current-generation processors have resulted in single board computers and motherboards being deployed in many products previously requiring highly specialized hardware. Modern embedded systems require a broad range of needs, including high-speed peripherals, networking and a secure platform. Expansion cards to support GPUs, frame grabbers, or other specialized functions often need to be added to increase the system’s functionality. These requirements and more are available in cost-efficient embedded boards from Kontron.

Kontron has long been known as a market leader in COM Express® modules, including the newest generation COM-HPC® form factor. Kontron also has a diverse range of board-level products used in both standalone scenarios and system-level products. Form factors from 3.5" single board computers and mini-ITX to ITX to full ATX server class motherboards are all part of Kontron’s product portfolio. Trade Agreements Act (TAA) compliance is being requested increasingly, and Kontron’s board products are all designed and manufactured in TAAcompliant countries.

Kontron’s diverse range of embedded form factors with embedded computing solutions with performance from Intel Atom class to high core count server-class processors in various markets, including industrial, medical and defense. Another key factor in embedded solutions is long life cycles. Kontron typically provides 7+ years of availability on board-level products, alleviating costly redesigns and/or recertifications triggered by frequent or unexpected EOLs. Demanding environments require high reliability, and Kontron’s focus on 24/7 operation ensures minimal maintenance costs.

The future of embedded boards is quite bright, and Kontron is well-positioned to support the diverse needs of this everexpanding market with Kontron’s diverse portfolio of boards and systems.

Artificial Intelligence has been enjoying another media resurgence since ChatGPT hit the scene earlier this year. ChatGPT is seemingly part of everyone’s vocabulary these days, and its popularity isn’t confined to our consumer lives.

Countless companies have been introducing ChatGPT into their products and product lifecycle. Microsoft uses the same large language models (LLMs) that power the ChatGPT chatbot to power its Bing search engine, and UK-based energy supplier Octopus Energy has built ChatGPT into its customer service channels, with it now responsible for handling 44 percent of customer inquiries.

Generative AI engines, such as GPT-4 that powers ChatGPT, hold enormous potential for insight and innovation around how products are designed and used by customers. But it also raises a few risks and legal questions, venturing into grey areas that have yet to be addressed.

ChatGPT is an advanced language model that uses artificial intelligence (AI) and natural language processing (NLP) to provide conversational responses to users. It’s trained on massive amounts of text data, enabling it to understand and generate human-like language.

For manufacturers, this can be a golden opportunity. Manufacturing companies generate their own specific data from customer usage and equipment performance, and it’s all unique to them. Until now, there have been limits on how companies can monetize and apply this data for development and innovation.