With compassion, clarity and commitment, Christina Giannone takes on the role of OHBA Chair

THIS IS BLACK

With compassion, clarity and commitment, Christina Giannone takes on the role of OHBA Chair

With the Residential Savings by Design program from Enbridge Gas, homebuilders can receive free expert help and financial incentives to build high-performance homes that reduce environmental impact.

From design to construction, we’ll help you continue to innovate and stand out in a highly competitive market.

Plus, you’ll meet buyers’ needs† with:

A plan for future renewable energy use.

Potentially lower environmental impact.

Reduced energy consumption.

Enhanced comfort.

Visit enbridgegas.com/sbd-residential to learn more.

Stay ahead of upcoming code changes.

Get customized design advice and assistance.

Reduce greenhouse gas (GHG) emissions.‡

Earn financial incentives.

Support your sustainability goals.

Preparing for the Storm

Getting out in front of impending climate-resilient construction measures

P30 Taking It All In

Listening is Christina Giannone's superpower. She'll put it to good use as OHBA’s incoming chair

9 Association News

Collingwood—and a host of engaging sessions—await at OHBA's Annual Conference, renovator news, Futures

Faster offers targeted training to address trades shortage, and you don't have to be a builder to be a member.

17 Frame of Mind

A groovy take on the granny pad from Seattle.

P50

Capital Squeeze With banks tightening up, it's harder than ever to find financing

19 Inside Storey

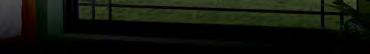

Aria is among builders taking advantage of augmented reality to avoid change orders and close deals faster.

23 Trending

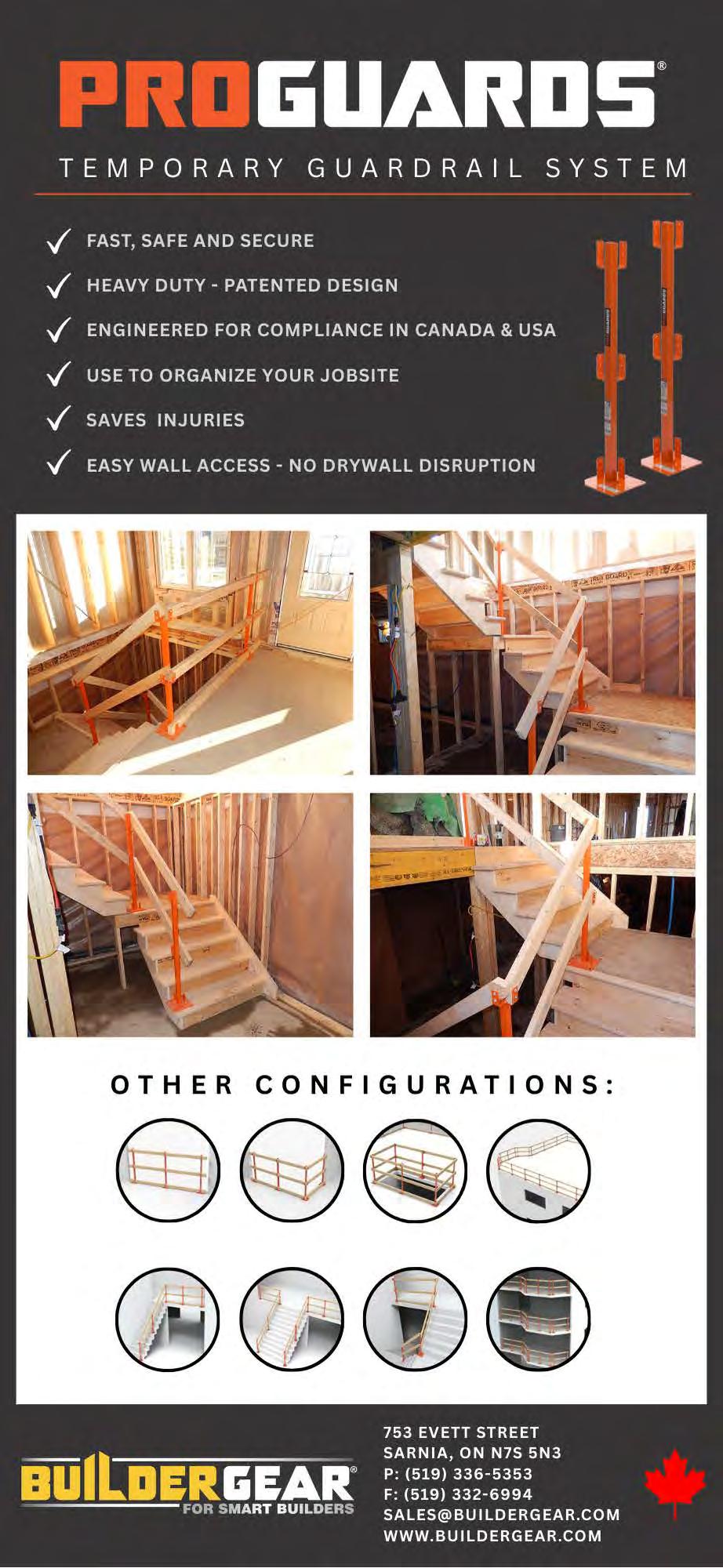

From stylish linear bricks and safer guardrails to tighter wall assemblies and black vinyl siding, here's what’s new in industry products and services.

59 Building Buzz

Ouroborus Deconstruction is an alternative to demolition, a massive development is planned for Woodbine, the rising costs of construction, the move to purpose-built rental land, and more.

70 Chapter Spotlight

Grand Highlands HBA CEO Melissa Jonker has helped bring two regions together.

EDITOR Ted McIntyre ted@laureloak.ca

ART DIRECTOR Ian Sullivan Cant

CONTRIBUTORS

Tamara Aspeling, Avi Friedman, Tracy Hanes

PHOTOGRAPHY

Josh Fee

ADVERTISING

Cindy Kaye, ext. 232 cindy@laureloak.ca

PUBLISHER

Sheryl Humphreys, ext. 245 sheryl@laureloak.ca

PRESIDENT Wayne Narciso

PUBLISHED BY Laurel Oak Marketing Ltd. laureloak.ca ohba.ca

Take a photo of our QR code and sign up for digital updates and news!

Ontario Home Builder is published six times per year (Winter, Early Spring, Late Spring, Summer, Fall, Awards).

Al l r ights reserved. No part of this magazine may be reproduced without the written consent of the publisher. © 2025

For address corrections please email info@laureloak.ca or phone: (905) 333-9432, ext. 245.

Si ngle copy price is $6.00

Subscription Rates: Canada $14.95 + HST per year, USA $29.95 USD

Order online at https://www.laureloak.ca/subscribe

CA NADIAN PUBLICATION MAIL AGREEMENT NO. 42011539 ISSN No. 1182-1345

Our phenomenal brick and stone selection, in very light tones, makes it simple to create the crisp, high-contrast look that homebuyers love. And when you choose high-quality masonry, you are delivering lifetime performance as well. Our unique calcium silicate products will never fade or need replacement, and offer superior storm protection as well.

OHBA news, views and events

The 2025 OHBA Conference is right around the corner, from September 28-30, at Blue Mountain Resort in picturesque Collingwood.

Meet us on the Mountaintop!

Join conference attendees on September 28 to enjoy the Opening Reception perched atop Blue Mountain. Reconnect with colleagues in this breathtaking setting after an exciting day of association business!

We have put together educational programming led by industry experts and government officials that are sure to bring you the latest and greatest from Ontario’s residential construction sector. There is something for everyone to enjoy in these sessions, including a panel on September 29 with Minister Flack, Ontario’s Minister of Municipal Affairs and Housing.

On Monday evening, September 29, OHBA will welcome its 2025/2026 Chair, Christina Giannone, VicePresident, Planning & Development, Brightwater-Port Credit West Village Partners. Christina will be the first female Chair in OHBA’s history. We will honour OHBA leadership, thank champions of the association and celebrate the incredible accomplishments of our industry.

Get ready to celebrate excellence in Ontario’s home-building industry at the highly anticipated 2025 OHBA Awards of Distinction Gala on Tuesday, September 30. Hosted by comedian, TV personality and writer Graham Chittenden, this celebration will surely be an unforgettable night!

The 2025 Ontario Home Builders’ Association (OHBA) Conference is set to deliver one of the most ambitious and comprehensive content lineups in the association’s history, offering attendees dynamic, relevant and solution-focused educational programming across the full spectrum of Ontario’s residential construction landscape.

With 12 expertly curated policy breakout sessions, the conference provides a unique opportunity to explore the most urgent and complex issues shaping the housing environment today. Whether you’re a custom home builder, low-rise or high-rise developer, renovator, planner, supplier, consultant, industry association or municipal stakeholder, this year’s programming is crafted with every corner of the industry in mind, to build on what you know and challenge you to think bigger.

Following the overwhelming success of last year’s Ministers’ Panel, we’re bringing it back and raising the bar. This high-profile session will once again kick off the conference programming, setting the stage for two days of discussion and insight. With Minister of Municipal Affairs and Housing Rob Flack already confirmed, and a stellar lineup of Cabinet colleagues to be

revealed in the lead-up to the event, this will be one of the most talkedabout events of the conference.

Moderated by renowned broadcaster Steve Paikin, expect a candid, highlevel conversation that will rival last year’s energy, delivering perspectives straight from the decision-makers shaping Ontario’s housing agenda.

At the heart of the conference’s educational program is a commitment to policy and thought leadership. Setting the Standard will take centre stage as a marquee panel featuring OHBA’s Policy Committee Chairs, kicking off the day on Tuesday morning. This session will officially launch our 2025/2026 strategic policy and advocacy focus, providing attendees with a clear view of the top priorities guiding OHBA’s engagement with Queen’s Park in the year ahead.

From there, sessions branch into critical and diverse focus areas. In Breaking Ground, a panel of all-female industry leaders will explore what it takes to lead across planning, development, law and energy in today’s challenging market. Rethinking Builder Protection explores lessons from Alberta and B.C. on alternate models to home warranty delivery, while

Unlocking Housing in Small-Town Ontario examines the unique barriers and untapped potential of small and rural Ontario.

We also bring municipal voices to the forefront. Leadership at the Limits and Then, Now & Next provide political and administrative perspectives on housing delivery, municipal finance and the realities of implementing provincial reforms at the local level. These candid conversations by a broad spectrum of leaders give attendees a deeper understanding of how decisions are made and where advocacy can drive results.

At the intersection of heritage and housing, Layered Landscapes unpacks how intensification can coexist with cultural preservation, while Margins Under Pressure offers a clear-eyed economic outlook, tackling cost escalations, tariffs and market shifts head-on. Builders looking to adapt to changing demand will find practical guidance in The Rental Reboot, focused on transitioning into the purpose-built rental market.

In addition, the program addresses the evolving expectations around indigenous consultation and archaeological processes in Respect, Risk & Readiness, technical challenges with utility rates and infrastructure in Power to Build, and includes a tailored Renovator Session developed in collaboration with Training Ontario to reflect the unique needs of the renovation sector.

Taken together, this year’s educational programming affirms OHBA’s role as a leading policy reform and advocacy voice for the home building industry. The sessions are designed not just to inform, but to equip attendees with the tools, strategies and insights they need to adapt, respond, and lead in a rapidly changing environment. And the extensive networking opportunities throughout the three-day event provides you with unparalleled access to leaders of change and innovation across our industry.

As the housing sector continues to navigate uncertainty, complexity and reform, the 2025 OHBA Conference remains the place to gather, learn and shape the future of building in Ontario.

APPLIANCES FOR YOUR

DO IT RIGHT WITH ONTARIO’S HOME TEAM.

Doing appliances right with a partner in your own backyard has never been easier. Founded in Stoney Creek, Ontario, we’re 100% dedicated to removing the appliance burden from your projects. Our responsive team will be there every step of the way from qualifying your needs, to dealing with your clients, to facilitating a smooth onsite delivery and quickly correcting issues. Do appliances right with Goemans and scan the code to connect with an experienced Commercial Account Manager.

Ontario’s current housing reality is undeniable: prices are soaring, supply is lagging and too many families can’t find a place to call home. OHBA is working with all levels of government to take the needed corrective action to create a policy environment that will allow builders to build homes that people can afford. Meanwhile, our sector is facing its own crisis—an acute shortage of skilled tradespeople at the very moment we need them most.

The province has set an ambitious target: 1.5 million new homes by 2031. Meeting that goal isn’t just about materials and land; it’s about people. We need a robust pipeline of trained, motivated workers to transform blueprints into communities. And we need every stakeholder—from experienced builders to newcomers to the trades—to pull in the same direction.

That’s where OHBA Futures Faster comes in. Futures Faster exists to help close this gap. By cultivating new talent and retaining experienced professionals through mentorship and targeted training, we’re helping ensure Ontario can overcome its housing challenge with strength, speed and collaboration. Together, we can make homes more attainable by investing in the people who build them.

This short-term, targeted, high impact, mentored upskilling program is designed to

support the growth and stability of Ontario’s residential construction workforce. Registration for this three-month program opens in September. Spaces are limited to 100 participants—50 mentors and 50 mentees—accepted on a rolling basis through to December 1.

The program is mentee-driven, meaning mentees will take an active role in identifying the next step in their career, setting goals and choosing the direction of their learning and growth with their mentor’s support. The program offers a library of industry-relevant micro-credentials curated by OHBA to support all participants with practical, targeted learning in the areas of industry skills, professional development and digital skills. Designed for a constantly evolving industry, the program also offers mentors the opportunity to upskill alongside their mentees to develop their own careers as well.

OHBA Futures Faster mentored upskilling program’s reach is broad. The program is open to anyone currently in or serving the residential construction industry in Ontario. Find out more about this valuable program at FUTURESFASTER.CA

OHBA is pleased to be the principal association partner for the Home Builder & Renovator Expo, which will be held as part of The Buildings Show December 3-5, 2025, at the Metro Toronto Convention Centre.

OHBA members can enjoy exclusive benefits, including 20% off show registration passes with code OHBA20, free Expo passes with code OHBAEXPO, and access to discounted rates on booth space. CONTACT events@ohba.ca.

Drawing on its 2025 Action Plan, the Ontario Renovator Council (ORC) has had a strong year of engagement, from hosting webinars on topics such as renovation rebates and AI in construction, to establishing live roundtable events and engaging with renovator members across the province.

We were thrilled to welcome Peder Madsen of CCR Build + Remodel Inc. as our new ORC Chair. We are excited to see an increase in renovators joining the OHBA and getting involved with the ORC and OHBA initiatives. Renovators and their hard work are also being recognized with awards throughout 2025 on the national stage. This year, ORC members were successfully represented across the Whole Home Renovation and Best Bathroom category categories of the CHBA National Awards for Housing Excellence, and at Enerquality’s Building Innovation Awards in the Green Renovation Project of the Year category. Ontario renovators also captured a CHBA Best Kitchen Renovation category.

Building on this momentum, we have planned a strong finish for 2025. On November 14, we will be hosting the inaugural Ontario Renovator’s Summit in downtown Toronto. Entitled Constructive Change:InnovationinAction, it will bring together renovators and other industry professionals to explore how technology, strategy and collaboration are shaping Ontario’s housing future. Check the OHBA website and social media channels for more information on registration.

And a special thank you to Concord Fireplaces for sponsoring our 2025 ORC Webinar Series!

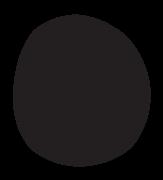

• True Inverter experience that provides the ultimate in comfort for a homeowner.

• 40% smaller, and 53% lighter than traditional cube style units.

• Environmentally friendly - Now available in R-32, using less refrigerant.

• Ultra quiet and best in class humidity control.

• Available in Air Conditioner, Heat Pump, and Dual Fuel (Hybrid) applications!

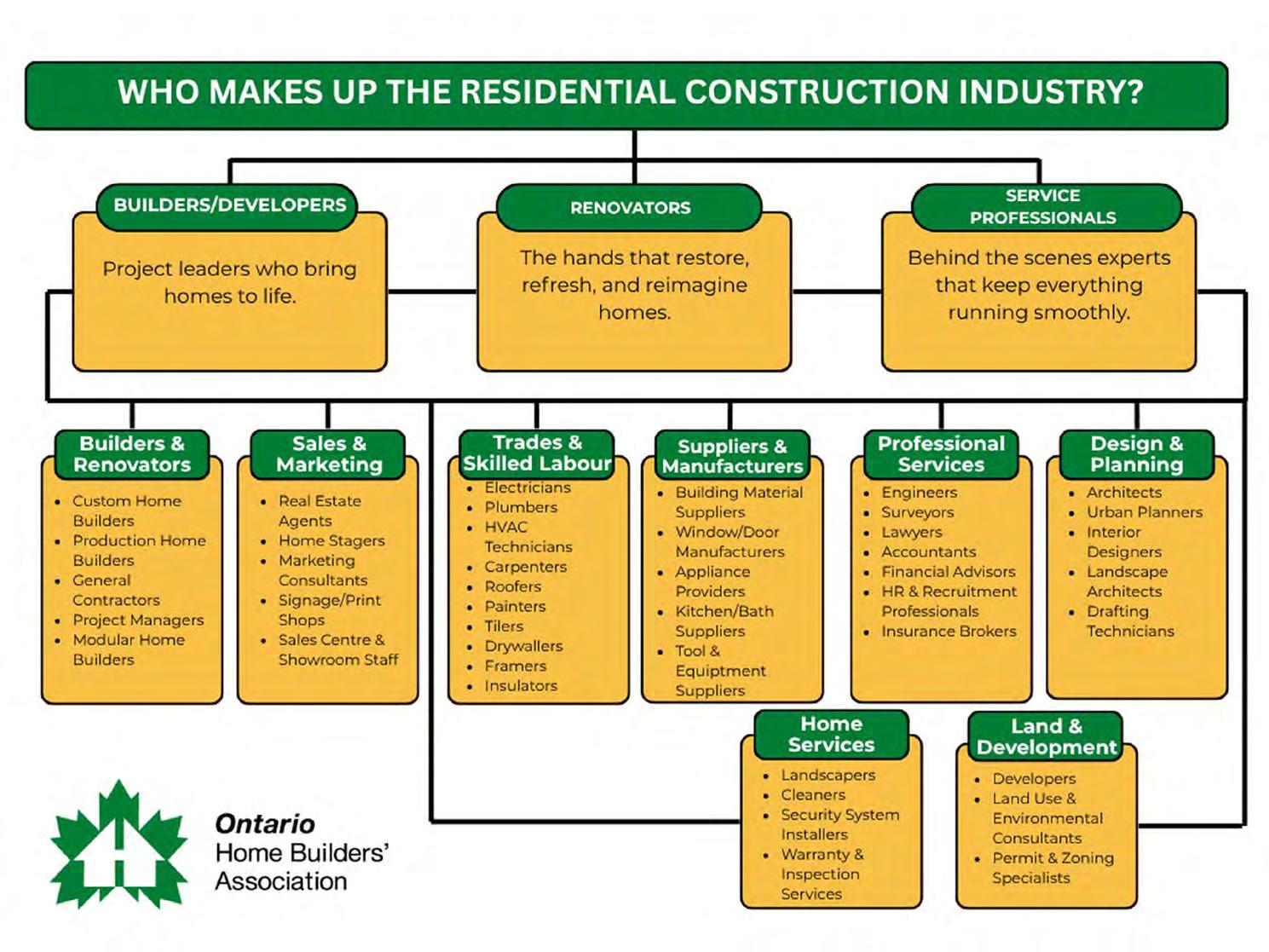

When people think of the Ontario Home Builders’ Association, the word ‘builder’ often comes to mind. But here’s the truth: You don’t have to be a builder to belong. OHBA is the voice of Ontario’s entire residential construction industry, and our membership reflects just that. From architects to electricians, marketers to manufacturers, and surveyors to stagers, the people who make up OHBA are as diverse as the homes we help bring to life.

From the first sketch on a blueprint to the final coat of paint, and everything in between, our association includes: architects, trades and contractors, interior designers, engineers and planners, suppliers and real estate professionals, renovators and landscapers, and more.

If you help shape how Ontario builds or renovates homes, you belong at OHBA. Whether you’re on the tools, behind the design or bringing homes to market, you’re building Ontario’s future. And you’re a vital part of our community.

AGING ALONE at home may be the preference of many seniors, but it’s not always practical or possible. Personal, medical or financial reasons often prompt seniors to seek alternative living arrangements. A common solution is moving in with family, which offers emotional comfort and reduced living costs.

Multigenerational homes have become increasingly popular after the COVID-19 pandemic highlighted the vulnerability of seniors in long-term care facilities and the high costs associated with such options.

To foster harmony in multi-gen households, homes must be designed to provide privacy, independence, personal space and minimal crowding. Proper planning helps prevent territorial disputes and promotes positive intergenerational relationships.

There are four main types of multigenerational housing:

• Side-by-side living: Adjacent units (such as row houses or semi-detached) share exterior walls but have no internal connection. Seniors maintain full independence while staying close to family for support or socializing.

• Plex houses: These include duplexes or triplexes, with each household occupying a separate unit on a single floor. This features a shared structure but with distinct private areas.

• Accessory apartments: Also known as in-law suites, these separate units are located within the same home, often with private entrances and kitchens.

• Garden suites: Also called granny flats, these smaller dwellings are built on the same property as the main home. They offer proximity with independence and can be repurposed for rental, adult children or guests. These units can be configured in clusters to promote community, especially if backyard fences are removed to encourage interaction. This reduces the risk of social isolation among elderly residents.

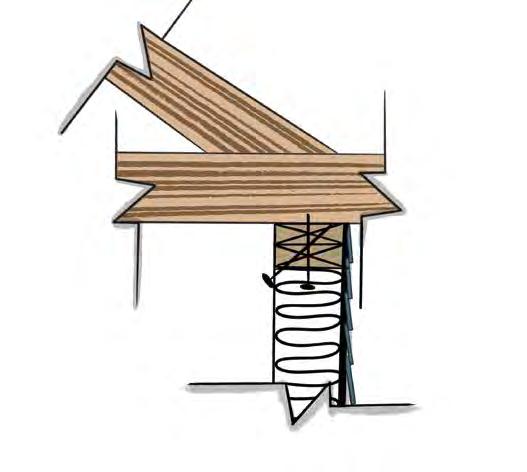

A standout example of the latter is the Granny Pad in Seattle, designed by Best Practice Architecture. Converted from a backyard garage into a 571 SF detached unit, it addresses urban density and affordability while supporting multigenerational living.

Granny Pad is characterized by its open, loft-like layout that maximizes the small footprint without sacrificing

functionality or aesthetic appeal. The design team focused on creating a single-level living area to accommodate decreased mobility, avoiding the need for segmentation into smaller rooms. The space features high ceilings with exposed rafters and is flooded with natural light from strategically placed windows and skylights. The original garage door was replaced with an entrance that leads into a combined kitchen and sitting room, seamlessly flowing into a bedroom, a closet with laundry facilities, and a bathroom. Above the bathroom, a lofted space, accessible via ladder, offers extra storage and the potential for other uses. Built into a hillside with a six-foot elevation change, the Granny Pad offers enhanced insulation and privacy. A private back deck connects the interior to nature, encouraging outdoor relaxation and family connection.

It’s an isolated example—figuratively and literally—but the Granny Pad demonstrates what creative design can accomplish. Not only does it meet the immediate needs of aging family members, but it also adds long-term property value. It can flexibly serve as a rental, studio or home office, making it a future-ready housing solution for evolving family dynamics. OHB

AVI FRIEDMAN IS AN ARCHITECT, PROFESSOR, AUTHOR AND SOCIAL OBSERVER. AVI.FRIEDMAN@MCGILL.CA

By Ted McIntyre with Behzad Ayon

WITH CONSTRUCTION ranging from slow to non-existent, and clients hard to come by, staying relevant demands innovation. Augmented reality (AR) coupled with VR headsets is quickly emerging as a must-have tool on this front. By allowing for immersive walkthroughs of 3D models, the technology is transforming how builders, architects and clients visualize and interact with projects before a single brick is laid.

In its Technology Transformation in Real Estate Development (2024) report, Proptech Collective observed that 71% of surveyed developers in Ontario are currently using or testing immersive technologies (including AR/VR) in the planning and sales phases. Further, projects that incorporated

AR for client walkthroughs saw a 25–30% increase in pre-construction approvals.

Behzad Ayon, managing partner of Toronto’s Aria Build, is among the OHBA members splashing into the AR waters. From streamlining workflows and enhancing client communication, to reducing costly errors, the technology appears destined to become a fixture in ARIA’s toolbelt.

OHB: When did you start employing augmented reality in your projects and why did you make the decision?

BA: “We’ve used it on a couple of projects so far. The first was in April 2024, a custom home in Whitby. The other is a new build in Etobicoke that broke ground in mid-July. The first

clients were having trouble visualizing the home, including the room sizes and floor plans. We teamed up with ADVU Studios and created an augmented reality experience of the home, featuring both interior and exterior views, as well as landscaping. It allowed them to walk through their home before it was built.

“Clients have two options. One is to review it on their iPad, computer or phone. We can place a virtual 3D model of the home on our conference table at the office, allowing the homeowner to spin the house around and view it from various angles inside and out. Or they can visit the property and visualize the house through a headset. It was important for our Whitby clients to see how the lighting would impact the property and illuminate the home at different times of day, particularly for their pool—when they’d receive sun, when it’d be shady, and what the views would be through various windows.”

Did it help close the deal?

“Definitely. We’re an innovative company and are always looking for what’s

new to make our jobs easier, and I think our clients like knowing that we’re on the cutting edge.”

How does it help clients with decisionmaking ?

“It absolutely expedites the design process from an interior, exterior and architectural standpoint. Because they get to walk through their home before we build it, it avoids costly changes after the fact.”

Can you provide an example?

“In the first project, the client, using AR, realized the ceiling in their main living area felt a bit too low. We were still in the design stage, so we adjusted it before anything was submitted for permits. That one tweak saved us from having to make a costly structural change down the line—and the client was thrilled with how it turned out.”

Numbers-wise, how many fewer change orders has it resulted in?

“It obviously depends on the client, but we’ve probably reduced changes by 70%-80% so far. So it has easily been worth the investment.”

When time is money, we build faster. Built with precision precast for quicker installs, lower labour costs, and earlier occupancy. FastTrack keeps your project on budget, on schedule, and ahead of the market — delivering the speed and quality you need to stay competitive.

What has been the most common change order avoided?

“Floor plans in general. There are always changes to the layout—the bedroom, moving closets around, etc. With kitchens, we’ve previously always spent a lot of time with our clients and done very high-end 3D renderings, but AR makes it so much easier.”

Have you taken advantage of it on the construction side as well?

“So far, we’ve mainly used AR on the design and client experience side, but we’re starting to look at how it can help on-site too. There’s huge potential. Being able to overlay digital plans onto the actual site can definitely help identify issues—such as spacing conflicts or structural misalignments—before they become expensive mistakes. We haven’t fully rolled that out to crews yet, but it’s something we’re actively exploring.

“You can catch mistakes early. Even during design reviews, AR has helped us catch small but important details. Things like door swings that might feel cramped in real life, or how furniture fits into a room—things that are hard to visualize on paper.”

Is there much of a learning curve for staff and clients?

“The great thing about AR is how easy it is to use. Clients don’t need any technical experience—most pick it up right away. We walk them through it once, and from there, they’re exploring their future home on their own. For our staff, there’s a bit of training to make sure everything is set up properly, but overall, the learning curve is pretty smooth.”

How do you ensure that the AR models reflect real-world constraints, such as structural requirements or building codes?

“We get the first draft from the architect and make sure that it meets all the building codes and city bylaw requirements, then feed that into the AR design. If the client wants changes, we take it back to the architect to implement them.”

Are there any limitations or areas that need improvement?

“We’re still learning how to make the most of it. One thing it’s important to have on hand is the client’s furniture design style. It takes the techies a while to create that. Fortunately, more and more furniture, tile and other finish companies are providing downloadable 3D models of their products. Rove Concepts, for example, allows you to take 3D furniture models from their website and place them into a room.”

Based on your early feedback, are you planning to incorporate this technology into the business, rather than contracting it out?

“Because it’s new for us, it takes a little while to put together, but I feel like we’ll have it streamlined by the end of the year and will be using it for all our projects. And yes, we’ll be bringing it in-house. I think everyone will be using this technology within a few years.”

Is there any funding out there to help builders adopting this type of tech?

“Yes, there are a few programs out there. We’ve explored options such as the Ontario Centre of Innovation and the Canada Digital Adoption Program. They can definitely help companies that are trying to innovate and bring in new technologies like AR—something I’d recommend to other builders too.” OHB

Creating a complete and unified exterior home design is simple with Brampton Brick. Our brick and stone products are developed to work together seamlessly and beautifully. Choose from a variety of textures, colours, and sizes that coordinate with each other, providing endless design possibilities.

Proudly made in Canada with homeowner satisfaction in mind, Regency® 400 Series windows stand alone with details designed for seamless installation, energy-saving comfort, and ongoing value.

• Glass Package Options: Tailor performance to specific climate conditions with a range of options, including EnergyPlus Quattro™, EnergyPlus™ and Solar Shield.

• 1-3/8" Triple Glaze: Optimized cavity spacing enhances gas performance and improves overall thermal resistance.

• 4-1/2" Thick Frame: Designed to position the insulated glass unit closer to the thermal envelope, helping maintain indoor temperatures and reduce heating and cooling demands.

• Integrated Brickmould: Provides a clean, modern finish with improved air and water sealing, simplified installation, and consistent design lines around the window.

• NEW! ARMOUR GUARD™ BLACK EXTERIOR WINDOW COATING: 7X harder than standard water-based paint for enhanced durability, plus “Instant cure” provides faster turnaround times.

• NEW! 80-sq.-ft. Window Assembly: Provides more natural light, expansive views, and added curb appeal.

Scan to learn more and see the full Regency 400 Series portfolio.

*Contact a Gentek representative for an energy-efficient glass package for your home and climate conditions.

You’ll love the easy assembly and thermal resistance of this OSB P.28

Talia stone from Brampton Brick adds a sleek and modern aesthetic to a home or building project. Its multi-length bundle and 57mm (2 1/4”) coursing height work seamlessly with modular and Norman brick sizes, allowing for a con tinuous linear look from brick to stone. Talia is available in six through-thebody stock colours (Mackinaw pictured) and is also compat ible with Brampton Brick’s Contempo and Granada stone, providing flexible design options.

BRAMPTONBRICK.COM

Jobsite safety just got better. ProGuards from BuilderGear are designed to protect your crew from falls and save you time. This temporary guardrail system is equipped with a built-in stacking feature that allows two posts to stack together, cutting your storage space in half. With its simple step-by-step installation process and an efficient, durable design, ProGuards are built for long-term safety on any construction site. BUILDERGEAR.COM

SlimWall 35 is the latest innovation—and slimmest profile to date— from Reynaers Aluminium. European-engineered and Canadianmade at Raven Fabrication, it delivers ultra-slim 35mm sightlines for expansive, unobstructed views and a clean, modern design. A fusion of beauty, performance and sustainability, it’s one of Raven’s most energy-efficient offerings. It’s Passive House certified for up to twostorey applications and is suitable for both high-end residential and light commercial. RAVENFABRICATION.COM

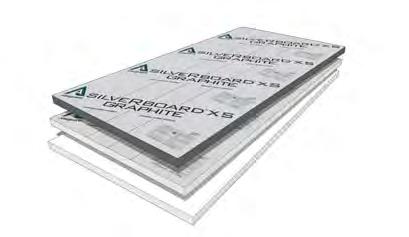

Alleguard’s AmBuck helps provide tighter, more efficient wall assemblies. The insulated window and door block-out system features stay-inplace buck formwork manufactured using Type 2 closed-cell EPS panels for ICF walls. Eliminating the need for wood and vinyl block-outs, it offers a costeffective and energyefficient solution while also reducing construction time thanks to its fast and easy assembly. In the long term, it prevents warping, cutting, bowing and splitting seen in most conventional wood-based block-out systems. ALLEGUARD.COM

Cladding, waterproofing, insulation, windows and doors, roofing and belowgrade—Convoy Supply has everything from the studs out. In this competitive market, home builders are seeking a one-stop shop with the expertise and on-time delivery they can count on—a partner that will overcome challenges and anticipate problems. Convoy has earned its reputation as an industry leader and is well-equipped to provide effective solutions. CONVOY-SUPPLY.COM

When it comes to making an impact, Al Ridley knows how to deliver. As an Outside Sales Representative at Convoy, he’s known for his dedication, attention to detail, and “can-do” attitude. Al approaches every project with the same precision and care he brings to his spectacular hobby—coordinating fireworks shows that leave audiences in awe.

With years of experience designing dazzling displays, Al has mastered the art of timing and flawless execution. That same commitment shines through in every project he takes on at Convoy, delivering exceptional results time after time.

We’re proud to have Al on our team. Whether he’s orchestrating pyrotechnics for crowds or solutions for his customers, Al is a true professional who knows how to make a lasting impression.

Navien’s new NWP500 Series Heat Pump Water Heater is now shipping across Canada, deliv ering ultra-quiet, energy-efficient performance with smart wifi connectivity. Featuring a durable stainless steel tank, five operation modes and a sleek matte finish, it’s installerfriendly and a Red Dot Design awardwinner. Available in 50, 65 and 80-gallon models, the NWP500 is built for modern homes and a greener future. NAVIENINC.CA

CertainTeed Canada’s Ecophon Fade is a high-performance acoustic plaster system that delivers superior sound absorption (NRC 0.80–0.90) with a seamless, sandable finish in smooth or fine textures. Ideal for curved ceilings, angled walls and complex architectural forms, it installs easily over gypsum, concrete or timber. Available in white, six standard colours, or custom tints, it resists discoloration and aging— perfect for modern spaces where acoustic performance and refined aesthetics are both essential. CERTAINTEED.CA

Mitten has launched what it’s terming “the first and only true black vinyl siding.” Made with PVDF film for superior fade resistance, its multiple benefits include unmatched durability and colour retention, effortless integration with various exteriors, heat resistance with no warping, low maintenance with no repainting or caulking, and a premium look at a fraction of the cost of wood or metal. Mitten Black Vinyl Siding is available with a complete set of matching trims. MITTENSIDING.COM/BLACK

Gentek Building Products has launched a full suite of colour-matched Align Composite Cladding accessories, designed to help Canadian contractors save time and deliver a pro-level finish without caulking or painting. This all-in-one siding system provides a timely solution for efficient, polished exterior builds. The new J-channel, trims and outside corner post profiles are offered in a wide range of classic and contemporary colours, and feature longer lengths, durable construction and lightweight handling. GENTEK.CA

Milwaukee Tool’s new M18 Fuel 3-in-1 Backpack Vacuum is built for jobsite durability, comfort, and performance. It delivers strong, sustained suction, over 40 minutes of runtime, and a filter that lasts 3.5 times longer thanks to a built-in debris separator. Designed for all-day use with an ergonomic harness and included accessories, it’s compatible with 275+ M18 tools. Ideal for pros who need efficient cleanup. MILWAUKEETOOL.CA

BTRboard OSB is a structural insulated sheathing panel composed of mechanically bonded layers of OSB, fire-resistant polyiso foam and mould-resistant fibreglass facer. Its unique one-piece composition ensures labour savings combined with superior airtightness, high R-value and structural stability for single-family and multifamily construction. It enables builders to achieve code-compliant, effective R-values using 2”×4” construction, or exceed it with standard 2”×6” construction. BTRBOARD.COM

Designed for versatility and efficiency, the new DeWalt 20v Max Atomic Multi-Head Drill/Driver features four quick-swap attachments—including right-angle and offset heads—for tackling tight corners and hard-to-reach spaces. Built for pros, it minimizes downtime and keeps jobs moving. It comes as a bare tool with belt hooks and a mountable organizer. DEWALT.COM

Trex has launched the Trex Deck Railing Designer, a mobilefriendly, 3D tool built to simplify railing selection for contractors and homeowners. With over 2,000 combinations, real-time estimates and dual-user modes, it streamlines planning and quoting—fast and error-free. Designed for jobsite or office use, it enhances accuracy, speed and collaboration. Railingdesigner.TREX.COM

Future-proof homes start at the panel with the QOTM Smart Panel Solution

Making your job easier

Easy Install: Save time and labour with faster installs

Modular & Scalable: Easily integrates into new builds and retrofits with a QOTM subpanel

Future-Ready: Meets the growing demand for connected, energy-efficient homes

Homeowner benefits

Save Money: Track and control energy use in real time

Smart Control: 24/7 monitoring and remote control with one app

Extend Backup Power Runtime: Prioritize essential devices during outages

Future-Proof Homes: Easily add solar, EV charging, and more

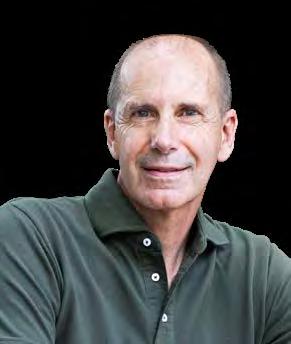

V.P. Planning and Development, Brightwater

Born: Feb. 10, 1985

Residence: Port Credit

Spouse: Kent Fenwick

Children: Jack (11), Emma (9)

From engagement to execution, OHBA’s next chair leaves nothing to chance

By Ted McIntyre

arly in her July photoshoot for this story, Christina Giannone posed near the front door of FRAM + Slokker’s head office at the corner of Lakeshore Rd. and Hurontario in Mississauga. The driver’s side window of a car awaiting a green light lowered, and a gentleman leaned out. “Hey, Christina!”

A smiling Giannone acknowledged the greeting. “Hi, Bob!” “A close friend of yours?” I asked.

“Not a close friend, exactly, but I went to high school with him,” she replied.

Later in the shoot, now relocated down the street along the waterfront trail, a young couple with two children in tow stroll past. “Christina!”

It was becoming clear that Norm Peterson was less recognized walking into Cheers than Christina is in her native hood of Port Credit.

The Giannone family is, shall we say, somewhat entrenched in the neighbourhood. You might even say they’ve been writing its DNA code for a quarter-century. Born and raised in Port Credit, Christina is V.P. of Planning and Development for Port Credit West Village Partners (Brightwater). Situated on the former Imperial Oil refinery site at the southwest corner of Mississauga Rd. and Lakeshore Rd., the 72-acre, 3,000-residential-unit Brightwater project will feature more than 300,000 square feet of retail and office space and 18 acres of parks and open spaces. The partnership includes Dream, DiamondCorp, Kilmer and FRAM + Slokker. Christina’s father, Frank, and grandfather, Giovanni, founded FRAM in 1982. In 1998, they purchased the old St. Lawrence Starch factory brownfield lands. A year later, their firm partnered with Slokker Real Estate and together transformed the property into Port Credit Village. (The original St. Lawrence Starch Company office building today serves as FRAM + Slokker’s head office, and as a tribute to the property’s heritage, the St. Lawrence name is still painted atop the entrance.)

A generation later, Christina and company have remediated another stagnant Port Credit site and are breathing that same vitality into the community just seven blocks to the west. When the opportunity arose to develop the property in 2017, come hell or high water, she was not going to be denied. “If I don’t get on this project, I’m going to have to move, because I will not be able to handle someone else developing my home!” she remembers thinking.

Giannone delivered the RFP in the second week of July 2017, then delivered baby Emma on July 28. So you might consider Brightwater her middle child.

Along with husband Kent Fenwick and children Jack (11) and Emma (9), Christina lives just a few blocks from the project. Being that close to a mega-development you’re spearheading, not to mention other local projects you’ve previously shepherded into existence, makes you a walking suggestion box. Feedback is as close as the playground, or the barista who asks, “So will those new condos block my morning sun?”

“There’s a lot of responsibility when you live here,” Giannone acknowledges over lunch at the lakeside Posta Italbar Cucina. “I was at my kids’ school and overheard someone say, ‘Imagine the traffic Brightwater is going to bring!’ I said, ‘I work there. Tell me your concerns and I’ll tell you how we’re going to work through it and the vision we have.’ I want to hear their worries, because it’s their home too. Even though I’m trying to proactively think of everything, it’s a long process, and we’re constantly adapting to changing needs.”

Giannone embraces meeting with ratepayers. She’s a little weird that way. “I think it’s a good thing to live where you develop, because I’m not going to create something and then walk away, leaving the community to deal with any consequences,” she says. “Homes, communities—they’re legacies. You can’t redo them. We spent a lot of time meeting with the many ratepayer groups in the area to understand their expectations and needs regarding Brightwater. We actually had focus group sessions with foam blocks, where we adjusted heights and moved density around. It was a very amicable process that could have gone a very different way had we not spent that amount of time.”

Count Mississauga’s Ward 1 Councillor Stephen Dasko among Giannone’s fans. “She is genuine,” he says. “Right after everything was approved for Brightwater, when a developer might feel inclined to shift their attention, I mentioned I had a park cleanup coming up. She said, ‘What’s the date and time?’ It turned out to be one of those bone-chilling spring days when the wind at the water’s edge cut right through. I figured, ‘OK, there’s no way Christina Giannone is going to be showing up to this.’ But there she was—with her kids—and they stayed the entire time, and got as dirty, if not dirtier, than everybody else.

“You can really tell when somebody cares about their craft and what they’re hoping to deliver to a community,” Dasko says. “When you’re remediating and then building— and it abuts two existing residential communities on a very

busy stretch of road—it’s not an easy thing to do. She has been out in front of a lot of things—dealing with the community and local businesses, and managing expectations. Some say, ‘Let’s just do this and we’ll talk about it later.’ She wants to get it done right. I don’t think it’s because she lives there; I think it’s just how she’s wired.”

Listening isn’t merely a skill for Giannone, “it’s her superpower,” says Kent. It is, without question, the leadership attribute others most cite as she prepares for her inauguration as OHBA’s first-ever female chair at OHBA’s Annual Conference in Blue Mountain later this month. It will also mark the first time in the association’s 63 years that an offspring of a former chair assumes the post. Her father held the position in 2008-2009.

Bianca Bruzzese, a partner with KPMG, Private Enterprise, and past president of the West End Home Builders’ Association, recalls her first meeting with Christina. “She was one of those people who you could see was actively focusing on what was going on in the messaging, and very thoughtful in her responses—not looking to dominate the conversation.”

“I’m a big believer that a good leader has to be a good listener,” echoes Peter DelFatti, retired director of construction at FRAM + Slokker. “When you’ve got all kinds of different groups at the table, you’ve got to pay attention to their concerns and then make decisions accordingly. Christina is

good at that. She’s someone who can get consensus.”

But don’t mistake Giannone’s sometimes quiet, observant nature for timidity. “I joke that she should’ve been a lawyer,” says Kent. “She loves reading contracts. She will go through a 200-page condo doc in one sitting—and actually really enjoy it! I’d hate to negotiate against her.”

Beneath that reserved boardroom persona, though, lies an onion of layers. This is a person who eats the same thing every day—two hard-boiled eggs in the morning, a fruit snack, a chicken salad with avocado for lunch, and a light protein with vegetables for dinner: “Life feels so busy sometimes that it’s nice just knowing what you’re going to eat.” Her musical appetites, on the other hand, have the variety of a smorgasbord. Having recently returned from Las Vegas to watch the Backstreet Boys, Giannone’s upcoming concert series included emotional pop artist Benson Boone, rock group Oasis and eardrum-splitting heavy metal band System of a Down. Like her OHBA brethren of West End HBA CEO Mike Collins-Williams and outgoing OHBA CEO Mike Memme, Giannone is not averse to the odd headbanging decibel storm. And so, when the duo invited her to experience industrial metal bands Ministry, My Life and Thrill Kill Kult at a Toronto concert in May, she leapt at the chance.

“We got Christina right up in front of the stage. Mike’s new plan is to have every new OHBA chair vetted in a mosh pit,” Collins-Williams jokes.

Ministry and company, though, were but a low-octane

garden party compared to some of Giannone’s wilder experiences—and we’re not talking about rollercoasters at Canada’s Wonderland or the annual charity Port Credit Polar Bear Dip.

“If you were to ask my brothers, they’d say it was the time a pickpocket was trying to rob my father in the subway in Rome during one of our family vacations, and I instinctively went into football mode and tackled the woman,” Giannone relates.

If you were to ask husband Kent, he might say it was a particular visit to the Giannone clan’s hometown of Pisticci, Italy. “We were at Europe’s longest zipline, and decided to take these donkeys up the mountain as part of the experience. No rails, no ledges—if the donkey slips, we’re gonna die. But Christina’s like, ‘Oh, this will be fun!’

But a side trip while on vacation in Hawaii takes the cake. “My dad half-jokingly suggested cage-diving with sharks,” Giannone shares. “Well, in our family, once one sibling says, ‘I’ll do it,’ everyone does. Except for my mom, who bailed when she saw how rough the ocean was. They tossed a chum bucket not simply near us but at us. It was chaos— dozens of sharks swarming inches from our faces. For the next 20 minutes, we tried to stay as far from the bars as possible, getting beaten up by waves, while my dad cheered us on from the comfort of the boat. When we finally got

back, we were bruised, shivering and hysterical. But the craziest part? I loved every shark-munching, chum-splattered, nausea-inducing second of it.”

Maybe that’s because there’s a little bit of shark in Giannone too—seemingly ageless, focused, hyper-aware of her surroundings, relentless in her pursuits. “I’m definitely a type-A personality,” she admits.

Her brothers John (39), Dave (37) and Rob (34) have seen it firsthand. “There was always a competitiveness amongst us—making rep teams, being on championship teams. ‘I won gold in my tournament. You won silver in yours. Haha!’ ”

Her competitive streak runs to fantasy football, Kent shares. “Last year, we were trying to indoctrinate our kids into NFL football, and she’s explaining, ‘Mommy needs this guy to get this short 30-yard field goal. It has an 87% chance to be successful.’ And, of course, the kicker misses it, and I have her reaction on video—the dramatic falling to her knees and screaming. The kids thought it was pretty funny. And that wasn’t even our favourite team, the New York Giants—just some team she’d bet on.”

The field of scholastics, however, was always a more predictable—and dominant—domain for Giannone, where she

The Navien NWP500 is built for efficiency, performance and durability with a stainlesssteel tank and aluminum refrigeration coils... no anodes needed. To learn more about all the advantages of the NEW NWP500, visit navieninc.com or scan the QR code.

Energy Star rating: up to 4.05 UEF.

Top and side connection options.

Built-in Wi-Fi powered by NaviLink® with over-the-air software updates.

Designed to meet NEEA AWHS Tier 4 requirements.

Quiet operation, less than 45dBA.

Ambient operating range of 41°F–113°F.

was as much straight-A as type-A. “We used to make fun of her in high school,” Kent recalls. “She was the person who before the test would be like, ‘Oh God, I don’t know if I know this stuff. I didn’t study enough!’ And then she’d get 100%. She seriously did get 98% and 99% in some of her courses.”

Kent had a front-row seat. He and Christina met in grade 9 at Lorne Park Secondary School in Mississauga and started seeing each other on a romantic basis a year later. “She’s the only girl I’ve ever dated,” he says.

“We work so well as a team, but we joke that if we didn’t meet at school, we probably never would have met, because we have such different interests,” says Giannone. That included post-secondary educational pursuits: “I took the business route at university, and he went into biomedical computing.” (Fenwick cofounded Agora three years ago. “It’s a web3 startup riding the crazy crypto wave that is building a decentralized platform for governance and collaboration,” he says, although quantum physics is probably easier to explain.)

Apart from the occasional classroom, Fenwick and Giannone also shared the same first employer—FRAM. “I started working on Frank’s sites when I was 15. I loved it,” Kent says. “I learned how to drive a backhoe and bobcat before I had a driver’s licence.”

Christina started a little younger—a 13-year-old summer student staring down an Everest of filing cabinets. She laughs about how she quickly traded manila folders for the sales desk at Port Credit Village, where real buyers with real questions taught her the value of saying, “I don’t know, but I’ll find out.”

At the University of Toronto, she continued to excel, earning a bachelor’s degree in commerce & finance in short order, but wasn’t yet married to the idea of real estate. She considered advertising and was about to enjoy a rare summer off when her father called: “One of our planners is leaving and we need someone to finish a project.”

“I shadowed the planner for a month and then took over his project—North Shore at Lakeshore Rd. and Hurontario, across the street from our current office,” Giannone

remembers. “It introduced me to development, and I instantly fell in love with it. It brought me back to being in the sales office and interacting with stakeholders, municipal staff, who were phenomenal, and ratepayer groups—seeing their anger and frustration when a 22-storey condo is going to be built in their community—and then learning how to work with everyone to build something that’s a win-win-win.”

While working full-time, Giannone knocked off her MBA at York University’s Schulich School of Business. Her education at the school of travel, on the other hand, continues to this day. Giannone adores seeing the world through her children’s eyes and hearing their questions, but has gleaned much on the professional front as well. From the Caribbean to the U.S. and throughout Europe, every vacation has doubled as global research. “From Italy, one thing our company has looked at is piazzas and promenades—places where you can gather, socialize and just people-watch,” she notes. “It’s one of the reasons I love the intent of OHBA’s international housing tours—it’s important to learn how other countries do things and see how other people live—especially when so many of our customers are immigrants.”

Closer to home, Giannone’s training had already included service on committees with BILD and the Urban Land Institute when then-OHBA CEO Joe Vaccaro reached out in 2019, looking to fill the position of secretary on the association’s board of directors. Her resume has since been augmented by the 2024 Connect CRE Canadian Women in Real Estate Award for Ontario, 2023 BILD Member of the Year, and 2021 Italian Chamber of Commerce Business Excellence Award for Next Generation.

But the path to here has also been paved by many mentors, Giannone notes. “My father pushed me out of my comfort zone, trusting me to run with big projects from the onset, challenging me to grow, learn and engage meaningfully with all stakeholders. His passion and leadership are reasons I became so involved with industry associations in the

CRAFTED HERE, CHERISHED HERE

JELD-WEN’S CANADIAN-MADE WINDOWS AND DOORS DELIVER BEAUTY, ENERGY EFFICIENCY, AND DURABILITY. DESIGNED FOR CANADIANS, BY CANADIANS

Canada’s diverse climate and building demands require solutions that adapt without compromise. JELD-WEN’s Canadian craftsmanship combines energy-saving innovation with precision engineering, ensuring every project meets the highest standards. From urban development to remote cabins, our windows and doors are built to last, offering flexibility to match your vision. We stand for quality, reliability, and a deep understanding of Canadian building needs. Partner with JELD-WEN to deliver homes that are not just built—but truly belong.

first place.” DelFatti, for his part, stressed teamwork: “Every individual has their specialty, but everyone chips in when there’s a jam.” Uncle Fred Serrafero, V.P. of Development and Construction at FRAM, taught her the importance of personal connection, and how “picking up the phone or visiting goes much further than sending an email.” From Bruzzese, she learned how to navigate boardrooms with poise and preparation, taking note of Bianca’s confidence and clarity during board meetings. And she credits her mother, Marina, “for instilling a family-first philosophy that has become a guiding principle in how I approach both leadership and life, helping me navigate the demands of my career while staying grounded in what matters most. And something all of them have given me is the self-assurance to push back if I see something I don’t think is right.”

While she is confident in her decisions—and the exhaustive research typically behind them cannot be questioned—a seed of self-doubt is buried so deep in Giannone that she might require an excavator to remove it. “Imposter syndrome,” she calls it. “My brothers and most of the previous chairs started with boots on the ground,” she laments. “I know all aspects of the industry, but I wasn’t the one with a hammer in hand.”

Her father waves off her anxiety: “Building is easy,” Frank says. “Getting a site approved—that’s hard. Christina is great at the most difficult stuff!”

Amid a President Trump-inspired trade war and a homebuilding market lying in a coma, she’ll require that talent as OHBA’s new chair. But battling through tough times is old hat for the Giannones. Frank was president of the Toronto Home Builders Association (now BILD), when it was proposed that GST be added to new-home sales. And it was under his term as OHBA chair in 2009 that the Ontario government introduced the HST, increasing taxes on new housing from 5% to 13%, during a major recession.

So perhaps the timing is actually perfect. “Christina has the technical knowledge to be in those discussions, which is huge to have in a chair,” says Bruzzese. “And she has the added capability to absorb input and to participate in HR

and financial discussions, which many don’t.”

And with respect to that “first woman” mantle, don’t expect Giannone to shine a spotlight on it. “On one hand, I understand that it’s a big deal, but it really shouldn’t be,” she says. “There are phenomenal women among OHBA’s board of directors and staff and throughout our membership.”

So what’s on her agenda as incoming chair? Much of the same as her predecessors, she notes. “Housing affordability, addressing skilled trades and labour gaps, rebuilding consumer confidence in the industry while tackling illegal building, and trying to have different key stakeholders within the province work together to streamline processes. We need government to modernize policies and processes, moving beyond siloed approaches among ministries and toward more interdisciplinary collaboration.

“And then there’s OHBA’s ‘one voice’ concept. We’ve got 4,000 members and 27 local chapters. I want to leave here having met and spoken with every executive officer. If I can be successful at anything, it would be to modernize that communication—how we work together as an industry to get our message out. We are one province. We are one industry. We should speak with one voice.”

Giannone admits she may bend the ears of outgoing chair Mike Memme and past chair Dave Depencier. “They both have this incredible energy and passion for the industry. They have demonstrated what strong association leadership looks like and have helped position OHBA to where it is today. I am honestly energized by our entire team. Their relationships have opened doors to speak to government that weren’t open before. I’m excited to be part of this era of OHBA to help affect change.”

Husband Kent also feels blessed. “You want to find someone who makes you want to be the best person you can be,” he says. “I’m still trying to impress her so that she knows she picked the right guy.”

Kent, incidentally, has also lived in Port Credit his entire life, so when he is greeted by locals, he’s proud to say that he is also well recognized.

“‘Hey,’ they say, ‘Aren’t you Christina’s husband?’” OHB

With Rinox’s ToneXclusive service, you can now offer your clients the ability to create a custom color that perfectly matches their vision. This unique feature allows you to personalize every detail of your project—whether it’s a residential build or a large-scale architectural design. Collaborate directly with Rinox’s expert team to develop bespoke shades that meet the highest standards of quality and durability. ToneXclusive ensures that your projects stand out, giving you a competitive edge and helping you deliver one-of-a-kind results that reflect your client’s style.

Climate-resilient construction measures are coming to a code near you

By Tracy Hanes

he City of Toronto earned a dubious honour on June 23, 2025. As the mercury hit 36°C, with a record-breaking humidex of 46°C, it made the list of the world’s hottest major cities.

On July 16, 2024, 10 cm of rain fell in just three hours, drenching the GTA and causing massive flooding that blew past $1 billion in insurable losses, with total costs likely three to four times higher, according to the Insurance Bureau of Canada. The Ottawa area, meanwhile, bore the brunt of a May 2022 derecho—a widespread, long-lived, straight-line windstorm associated with a fast-moving group of severe thunderstorms—that caused $720 million in damage in Ontario. Both events were among the top six most costly natural disasters in Canada in terms of insurance claims, according to Catastrophe Indices and Quantification Inc. (CatIQ)., Canada’s loss and exposure indices provider.

Extreme climate events such as these aren’t anomalies.

“I keep hearing, ‘Is this the new normal?’ But it’s just the start of how things will be,” says Ryan Zizzo, founder and CEO of fullservice climate consultancy Mantle Developments, and a professional engineer with extensive experience in climate-smart construction project management.

Adding to that concern is the fact that 1.5 million homes, or roughly 10% of Canada’s houses, can’t get insurance due to their locations, according to Dr. Blair Feltmate, head of the Intact Centre on Climate Adaptation (ICCA) at the University of Waterloo.

“This is a huge deal for insurance companies, and they are hoping to get others on side to mitigate the risks,” says Gord Cooke, president of Building Knowledge, which helps builders and developers design and construct homes with improved performance and indoor living environments.

Zizzo says there’s pushback from some home builders’ associations, as they view climate resilience as one reason why housing is so expensive. Still, many of those measures might soon be mandated. And many are trying to get ahead of the curve.

“There are some builders that have started down this (resiliency) path, and the Canadian Home Builders’ Association has launched a task force with the Institute for Catastrophic Loss Reduction to find evidencebased solutions, as some day, this will be in the Code,” says Cooke.

Currently, the OBC is roughly 85% the same as the National Building Code, Cooke notes. The latest published, but not yet adopted, edition, NBC 2025, does include a few new resiliency measures; however, it is unclear whether the OBC will adopt those sections, Cooke adds.

Feltmate, Zizzo and Cooke all say there are measures builders can take now to make homes more resilient, some at little cost. The ICCA has developed a series of infographics that address climate-related perils, including

“There are some builders that have started down this (resiliency) path, and the Canadian Home Builders’ Association has launched a task force with the Institute for Catastrophic Loss Reduction to find evidence-based solutions, as some day, this will be in the Code.”

—GORD COOKE

fire, flooding and heat, with costeffective measures that builders and homeowners can incorporate into new or existing homes.

As it stands, homeowners are paying dearly for climate change in more than one way, with premiums climbing much faster than inflation. The average cost of a typical homeowner policy in Ontario now runs about $1,565 per year (≈ $130/month), according to Rates.ca. Premiums in the province jumped 84% between 2014 and 2024, then another 5% in Q1 2025,

on top of double-digit increases for many 2024 renewals. And, as Global News reports, the 5.3% average hike projected for 2025 is more than twice the Bank of Canada’s 2% inflation target.

Of course, that all pales in comparison to climate-related damages. “The average flooded basement costs $54,000 to remedy,” says Feltmate. “It’s non-negotiable that you have to spend that money. If you experience a flood on

Monday and it remains unresolved by Wednesday, the house is deemed uninhabitable. It’s not discretionary spending.”

Depending on the market zone, homes with sump pumps should have battery backup and electrical panels that can easily be converted to run from a generator, advises Cooke. A kit from Home Depot costs about $500, Feltmate notes—a small price to pay given the average cost of basement flood damage.

Builders may want to reconsider building basements altogether and instead build up into the attic, Cooke suggests. His son has an older 1940s house near the Humber River that has experienced multiple basement floods, and if he rebuilds, he won’t include a basement.

One proven mitigating technology is the green roof, a standard the City of Toronto has had in place for 15 years. Noting that these roofs reduce flooding by absorbing rainfall, while providing a habitat for birds and insects, Zizzo believes that green roof standards “should be rolled out across the country.”

In the interim, new-home builders should avoid building on floodplains, Feltmate stresses. There are 36 areas in Ontario where conservation authorities regulate building, but in other regions, it’s at the discretion of the municipality. But Ontario’s newly passed Bill 17 will limit conservation authorities’ role in development approvals, and “that can be very dangerous, because perhaps you have a mayor who doesn’t believe climate change is real, or councillors who have lived there for 25 years and have never seen a drop of water in their basements,” Feltmate says. “Cheating the system is catching up, though, and that’s why 1.5 million homes in Canada are not insurable. In Quebec, Desjardins has stopped renewing mortgages for homes in flood areas.”

And expect it to get wetter. Environment and Climate Change Canada confirms an upward trend in heavy precipitation across Southern Ontario: intense rainfall events that once occurred every 10 years are now happening every five years or less in many regions. Large urban

Protect against extreme heat, wind, rain, wildfire and smoke — without breaking the budget

CLIMATE CONCERN: Extreme heat

BENEFIT: Reflects sunlight, reduces attic temps and AC loads

ESTIMATED COST: $5–$12/sq. ft. (White shingles also help, and at no added cost.)

4. Extended Downspouts and Proper Grading

CLIMATE CONCERN: Heavy rainfall and flooding

BENEFIT: Diverts water away from foundations

EST. COST: $10-$25 per downspout; $300$800 grading per lot

6. Low-E Glazing or Window Film

CLIMATE CONCERN: Heat gain, UV exposure

BENEFIT: Blocks infrared heat, lowers cooling demand

EST. COST: $6–$10/sq. ft. (film), $35–$55/sq. ft. (new glazing)

9. Reflective or Light-Coloured Siding

CLIMATE CONCERN: High heat

BENEFIT: Reduces heat load

EST. COST: Up to $0.50/sq. ft. over standard*

CLIMATE CONCERN: Increased frequency of severe hailstorms

BENEFIT: Engineered to withstand hail impact, reducing cracks, dents and replacement

EST. COST: 10-20% more than standard shingles

5. Wind-Resistant Roof Fastening (Clips & Straps)

CLIMATE CONCERN: High wind/storm events

BENEFIT: Prevents uplift and damage

EST. COST: $200-$300 incl. labour for screws; added labour cost for hurricane clips

7. Fine-Mesh Vents and Ember Guards

CLIMATE CONCERN: Wildfire embers

BENEFIT: Blocks embers from entering attic spaces

EST. COST: $100–$250 per home

BUILDER TAKEAWAY:

3. Metal or Class-A FireRated Roofing

CLIMATE CONCERN: Wildfire embers

BENEFIT: Resists ignition during fire events

EST. COST: $3–$15/ sq. ft., depending on material

8. High-Efficiency Air Filtration (MERV 13+)

CLIMATE CONCERN: Wildfire smoke, poor outdoor air quality

BENEFIT: Improves indoor air health during smoke events

EST. COST: $100–$200 per HVAC system

These upgrades are practical, build-stage-friendly, and increasingly relevant as municipalities and insurance providers look for climate-adaptive design. With many priced well below $1,000 per home, they offer high-resilience returns for modest investment.

centres such as Toronto, Ottawa and Hamilton report increases in one-hour and two-hour rainfall extremes—key drivers of flash floods through overwhelmed storm sewers and urban runoff systems. Municipal water authorities, meanwhile, report more frequent and intense drainage backups and basement flooding, even during what were once considered moderate rains.

According to the Insurance Bureau of Canada, wind caused $340 million in insured damages across Ontario in 2024. Doug Tarry Homes is, shall we say, blowing away the competition when it comes to mitigating potential damage.

The St. Thomas-based builder has participated in a pilot project with The Institute for Catastrophic Loss Reduction, aimed at enhancing home resilience to high-wind and tornado events, with a focus on the roof. At 100 new homes in St. Thomas, Tarry installed measures based on extensive research led by Western University, one of which involved longer roof sheathing nails and a second involving a special screw connecting the roof framing to the walls.

Company president Doug Tarry has witnessed the devastation that extreme weather events can wreak. As co-founder of the charity Hope Agua Vita, he helped rebuild homes in Puerto Rico that were destroyed by Hurricane Maria in 2017. It provided valuable insight into how to build more resilient homes in Ontario.

Measures on roofs provide the highest benefit at the least cost, says Tarry. He says hurricane ties aren’t costly, but it takes one minute to install one. A six-inch hurricane screw, on the other hand, can be installed in eight seconds. “You have to factor in the cost of labour,” he cautions.

Underlayment is another measure the company has taken, so that if shingles blow off, the roof still has some protection. “We’ve redesigned our gable overhangs too, as a high wind effect rips them up and water comes in,” Tarry explains. “We tie it back to the truss. We build the structure on the ground and crane

ABOVE: The Climate Risk Exposure Screen identifies and rates a property’s exposure to local climate hazards.

LEFT: The Climate Value at Risk Assessment estimates the cost of hazards on building systems.

For builders and developers looking to get serious about climate resilience, a new tool from Guelph-based engineering firm RWDI is making it easier to factor in local climate risks at the project planning stage.

“Resiliency is, to a large extent, a regional issue,” says Gord Cooke, partner at Building Knowledge Canada. “The risks to durability vary by geography—floods in some areas, wildfires in others, wind and hail, winter power outages, or extreme cold and overheating.”

That’s where ClimateFirst comes in. Launched in 2023, and led by Michael Williams—principal and VP of Climate & Performance Engineering at ClimateFirst—this new venture delivers fast, cost-effective climate risk analysis designed specifically for the real estate and development sector.

At the entry level, ClimateFirst’s Rapid Climate Risk Screens assess a property’s exposure to six major hazards: extreme heat, precipitation, drought, flood, wildfire, and wind. Delivered in 24 hours and scaled easily across multiple sites, these reports help developers prioritize which properties warrant deeper investigation.

For more detailed insight, the Climate Value at Risk (CVaR) Assessment

quantifies how climate hazards are likely to affect key building systems—roofs, HVAC, electrical, and more—over time. By comparing present-day performance with projected climate impacts, builders can anticipate maintenance costs, insurance challenges, and risks to asset valuation. CVaR reports are generated within 48 hours upon submission of a Building Condition Assessment (BCA).

Importantly, these assessments aren’t just about identifying risk—they also point the way to solutions. Each CVaR includes Resiliency and Adaptation Plans, complete with best-practice recommendations tailored to the property’s specific exposures. These measures draw on a database of over 250 engineering models to map out practical upgrades, from reinforcing roofs against wind to mitigating overheating and smoke infiltration from nearby wildfires.

“Institutional investors, insurers and lenders are increasingly expecting climate risk to be part of due diligence,” says Williams. “This kind of regionally specific, system-by-system breakdown makes it easier for builders to make smart, proactive decisions—not just for today’s code, but for tomorrow’s conditions.”

“it’s just a matter of time before there’s a major wildfire in southern Ontario. We should be preparing for this now.”

DR. BLAIR FELTMATE

it up. It’s more resistant to uplift and won’t sag. It’s standard with our homes, and we’ve shared this with the industry.”

While roof-to-wall hurricane ties and screws are not yet in the Code, and need to be more cost-effective for most builders, they’re standard in all Doug Tarry homes.

Despite the costs of resiliency, Tarry says his company has “done well” in the current market and met its targets for new-home sales. Net Zero Ready (NZR) homes offer significantly lower operating costs and are more resilient than OBC homes, with features such as a tighter envelope, low-solar-gain windows, and superior air filtration systems that help mitigate the effects of high heat events and wildfire smoke. Homes upgraded to full Net Zero could potentially store power from their solar panels in a battery to provide power during an outage. Tarry’s homes are either fully electric or dual-fuel hybrid models, which help reduce carbon emissions that contribute to climate change.

“Lots of builders are pulling back on Net Zero/NZR and Energy Star because of the cost,” Tarry notes. “But that’s not a choice we’ve made. We have customers come to us because of our better-value product. We’re a little bit boutique and have chosen a different path. Someone has to get out in front and figure out how to do it. That’s our role, and we’re happy to share what we’ve learned.”

Wildfires are not just a western Canadian problem, notes Feltmate, as Ontario’s boreal forests are at risk. “Areas such as Muskoka, Haliburton and the Kawarthas are vulnerable, and it’s just a matter of

time before there’s a major wildfire in southern Ontario,” he says. “We should be preparing for this now.”

The ICCA, for its part, suggests solutions such as integrating 30-metre-wide zones, or fire breaks, with ignition-resistant materials, including mowed grass, roads and ponds, into community design. Builders can consider using fireresistant building materials such as Class-A roofing, non-combustible siding and non-combustible decking materials.

With regard to landscaping, Tarry cautions, “No wooden decks, and no shrubs around the foundation perimeter in fire-interface zones. And there should either be no eaves, or they should be covered.”

A growing concern in Ontario has been wildfire smoke. Protecting against pollutants such as those from wildfires is one of the reasons Zizzo believes there also needs to be more effective air filtration in buildings.

Extreme heat is also of concern to Feltmate, who says that between 2050 and 2080, the average summer temperature is expected to increase by three to five degrees above current temperatures. Furthermore, the number of hot summer days per summer is increasing throughout southern Ontario.

While most new-home builders don’t currently install AC in new homes as a standard feature but make provisions for it, “We’re starting to see a movement to make air conditioning a requirement,” says Zizzo, who believes it should be mandated in the NBC, noting that a 5,000 BTU window unit costs only $150 and will typically last 10 years, incurring about

$5 a month in added hydro costs during the summer.

“Houses are getting much hotter, as builders are putting in way more windows that have 50% heat gain,” Cooke says. “This becomes even more problematic if there’s a lot of west-facing glass without proper shading or overhangs, or wall-towall glass that leads to a whole new level of air conditioning.” And if there are power outages, “you’re going to have a problem in a tall building.”

Other measures could include awnings, strategic placement of trees, and storm shutters that protect against heat and wind.

Simply building to NZ/NZR or Passive House standards includes resiliency elements such as highly insulated building envelopes, high-performance windows and air filtration. Cooke says the first step for builders is to simply follow welldocumented methodologies, such as proper water management for roofs, walls and basements—elements that have been in the Code for at least 25 years. For example, it’s well-known how to anchor roofs. “We know about screws and how to install them on rafters. These measures are in the Code but are not being enforced. You need best-practice guides, and you need training, such as how to properly install windows.”

Cooke says the Local Energy Efficiency Partnerships (LEEP) program, managed by Natural Resources Canada, is one resource builders can access for training and guidance.

While Canada’s next building code, set to take effect in 2030, will incorporate climate resilience for the first time, few details have been released yet.

At least 14 Ontario municipalities, including Toronto and Markham, have adopted green building standards that incorporate some resiliency measures, although Ontario’s Bill 17, as mentioned, will limit

CARPENTERS’ REGIONAL COUNCIL HEAD OFFICE: 830 EDGELEY BLVD, CONCORD, ON L4K 4X1 JOIN US

cities’ ability to set their own green standards.

At the Community Resilience Recognition Day during the 2024 National Climate Adaptation Summit last October, cities making exceptional strides were highlighted. Hamilton Housing was honoured for its Ken Soble Tower in the category of Resilient Housing. Earning Passive House Canada

EnerPHit Certification, the 2017-to2021 transformation rehabilitated a post-war apartment tower to reduce greenhouse gas emissions by 94%. It laid the groundwork for industrywide, ultra-low-energy retrofits needed to maintain and upgrade apartment buildings.

The tower features R38 overcladding and Passive House windows. Its Juliet balconies offer enhanced natural light and improved natural ventilation, reducing reliance on artificial lighting and heating and cooling systems, and avoiding the thermal bridging that conventional balconies can cause.

Dufferin County, meanwhile, was recognized at the event for its Hurricane Clip Rebate Program in the Disaster Resilience and Emergency Management category. “Normally, we think of how walls hold a roof up. In a severe storm, we need to consider how the walls will hold the roof down,” the county notes. The rebate

program provides property owners with $4.50 for each installed and inspected hurricane clip used to secure the roof rafters or trusses to the top plate of the wall on your new construction project.

These thin metal straps (or ties) may have the word “hurricane” in their name, but they could just as easily be referred to as tornado clips. Ontario, Canada’s most active tornado zone, averages 18 tornadoes per year, according to Western University data. There were a whopping 60 last year, however, 10 of which occurred over water, according to the Northern Tornadoes Project. Most are rated EF0 or EF1 on the Fujita scale (98% of all tornadoes in Canada measure EF-2 or less, with winds less than 252 km/h). That’s the sweet spot where Tarry’s measures can make all the difference.

Feltmate says almost every major city in Ontario offers weathermitigating subsidies that you can direct homeowners to, such as for disconnecting a downspout from the eavestrough to divert water away from the foundation, or for installing backwater valves.

“The backwater valve installation costs about $2,800 to $3,000, and 70% is covered in most Canadian cities,” Feltmate advises. “Ten to 15 years ago, people were unaware of their existence, or they were

difficult to find on a website, or too complicated. Cities are now making the process more user-friendly and better advertised. But a lot of people don’t use them, and the uptake has only been 7-9% so far.”

On a broad level, the next steps require “cooperation between insurance companies, municipalities, builders and different levels of government. There has to be a carrot and stick,” Tarry says. For example, insurance companies could provide a reduced rate for homeowners who incorporate resiliency measures into their homes.

Zizzo calls for provincial guidance on climate-smart construction, as he says the OBC currently contains nothing related to carbon footprint or climate resiliency. The federal government has a good climate policy, he notes, but the province hasn’t adopted it.

In the meantime, Tarry recommends taking proactive measures. “Determine the highest (climaterelated) priority in your area, and work at getting good at that detailing,” Tarry says. “High-fire interface area? Look at non-combustibles. High potential winds? Keep the roof on! High flood or rain potential? Keep water away from the home.

“But for all homes, the two commandments are moisture management and airtightness.”

“When you don’t do sustainable and resilient design up front, it becomes more expensive in the long run,” Zizzo cautions. “Things you can do to the roof and basement are a small investment, with large savings in the long term.”

Cooke is also an advocate of hedging against the future. “Do I think these measures will end up in the Code in 10 years? Yes.”

“The good news is that, to a large extent, we know what the problems are and have developed very good guidance in Canada with various agencies, providing practical, costeffective advice,” Feltmate says. “The problem is, we need to deploy these solutions and preparedness much more rapidly. There’s not much we can do when a house is on fire or a basement is full of water.” OHB

With banks pulling back, alternative financing is picking up

By Tamara Aspeling

sually, when you’re writing about financing construction projects, the first source is big banks, or “A lenders,” as they’re also known. However, despite reaching out to several contacts and media liaisons at Canada’s big five banks multiple times, none were inclined to be interviewed.

It’s not hard to read between the lines.