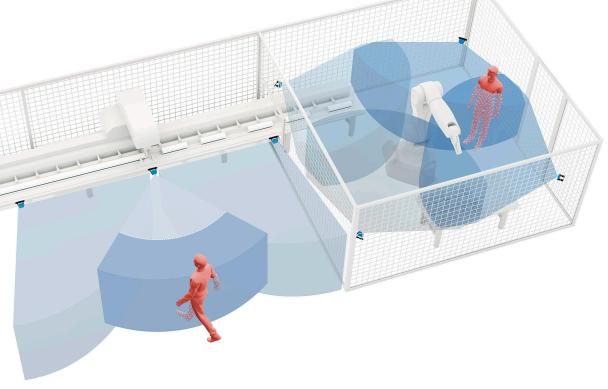

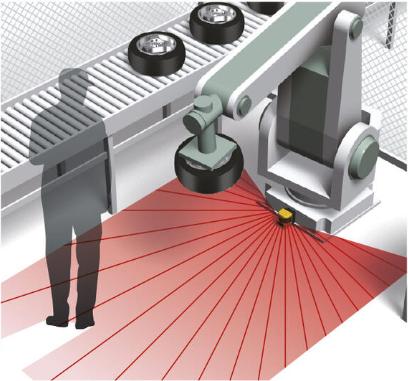

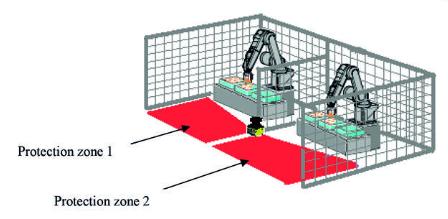

Access & Presence Detection

Presence Sensing Unexpected Start Up

Inxpect Radar Sensors are resistant to any disturbances stemming from smoke, dust, shavings, sprays or machining residues.

The sensors can work at high sensitivity and can even detect the micro-movements of a person breathing to prevent accidental machine restart. This radar monitors the space in 3D, providing volumetric coverage of the dangerous area. Two of the above application types Presence Sensing Unexpected start up & Safeguarding are only available from Inxpect and non of the brand label partners.

This product could be used as an alternative to both Safety Light Barriers & Safety Laser scanners, both solutions are affected by the environment that they are used in with regards to dust etc.. The Radar product is not affected by its environment. The Radar should improve the customer productivity as there should be less down time due to nuisance tripping.

Do you use Safety Light Barriers or Safety Laser Scanners?

Do you have any issues with your current solution? Do you have areas within the machine that you need to monitor from a safe perspective? What sort of environment do you operate in? Is there dust, water mist / sprays, smoke, shavings?

The competitors are all brand labelled by Inxpect. The competition do not have access to the full product range currently available from Inxpect, the new products are normally delayed to enable Inxpect to enter the market first.

The Inxpect product is also distributed in the UK by Scattergood & Johnson ForTop Automation Via Dutch Head Office

Super Compact Design, the unit has the “Smallest Footprint” on the market. 80mm x 80mm and a hight of just 95mm.

Simple GUI (Graphical User Interface), very simple software, when configured it confirms wiring config for the customer.

The unit comes with “All Features As Standard”, our unit comes fully loaded with most features that are available on the market. some competitors have multiple units within their range which require you to pay for the top of the range unit to get all features. Ethernet versions available for remote monitoring.

The product can protect an area and can have static objects in the protected area.

You can have warning zones so that the machine can keep running in a slower controlled way, so the process does not have to stop until it becomes unsafe.

Do you use Safety Light Barriers or Safety Radar Sensors?

Do you have any issues with your current solution?

Do you have areas within the machine that you need to monitor from a safe perspective?

Do you have space / mounting limitations?

Finger (14 mm), hand (30 mm), or body protection

300mm-2250mm Protection Height

Compact profile (35 x 40 mm)

No Dead Zone(Complete active face)

Basic functions, Standard or Advanced versions

Advanced version programmable by Wi-fi (and can be monitored remotely Via App)

Dynamic muting(on advanced version)

Low temperature operating range(-30°)

Cascade-able

Palletisers

Shrink-wrap machines

Woodworking machines

Presses

Conveyor systems

Robot cells

Can cover a large range of protection heights with no ‘dead zone’

Nuisance tripping can be detected remotely if required advanced version only.

Able to function right down to -30°

Who’s safety light curtains do you currently use?

Detection required(Finger/Hand/Body)?

Protection height required(300-2250mm +Cascade option)?

Any additional functions required(muting, blanking etc)?

Complete range of Interlocks, Solenoid Locking Switches, Non-Contact Safety Switches, Hinge Switches, Rope Pull switches and Emergency Stop devices which can be linked in series(or back to a distribution box) to one contact of a standard safety relay while still achieving the highest safety category possible.

Applications

Packaging machines

Food and Beverage

Food X-Ray machines

Conveyors

Materials handling

Lifting equipment

Pharmaceutical

Possible to connect multiple devices to one input of a safety relay saving wiring time and the purchase of additional safety relays or a more complex safety controller/PLC

Eliminates fault masking (occurs when one fault in a system obscures or hides the presence of another, potentially more serious, fault)

Current supplier/manufacturer?

Type of safety devices used (e.g. Solenoid interlocks + non-contact safety switches)? Plastic, metal or stainless steel.

Rockwell/Guardmaster

Phoenix Contact

Pilz

Wide product portfolio, with different types of sensing technology. E.g. Photoelectric, Inductive, capacitive, ultrasonic etc.. from one manufacture.

Standard sensors for simple applications as well as application specific sensors.

Global presence, the products are available globally for spares etc..

Using a family of sensors from one manufacture give a nice harmonised look to the machine all similar colour and design.

We have some application sensors that are market leading the TL print reg and luminescence sensors are market leading.

Manufacturing applications; Food & Beverage

Pharmaceutical

Processing & Packaging Machinery

Woodworking

Metalworking

Textile

Ceramic

Glass

Stones

Paper

Logistics Applications

Material Handling

Conveyors

Storage & Retrieval

Automated

Warehouses &

Distribution

Centers

Who do you currently use for your sensor solutions?

What type of Sensors do you use?

Inductive

Photoelectric

Capacitive

Ultrasonic

Radar

Do you use plastic or metal bodied unit?

Do you need any special type of protection e.g. Atex, IP69K?

Insensitive to dust, wind, rain, fog, temperature fluctuations and ambient light. Simple commissioning thanks to graphical user interface. Extremely robust.

Compact M30 design for simple mounting. Long range up to 40m.

Mobile Automation including cranes and lifting. Steel industry. Any level application. Water, liquid, wood shavings, sand, grain etc. Agriculture industry.

It can be used where photosensors and ultrasonics cannot. Not many competing products, only Baumer. Very easy to use software making set up times short. Ideal for complex applications such as condition monitoring of machines or bridges.

Is this a product you use today, or can imagine using?

Have you used Radar before?

Do you have issues with any other types of sensors in wet or dusty environments?

Would you like a demo of how easy it is to set up?

20 image learning. 20ms response time.

Teach by Machine and GUI.

Bright and visible Red LED pointer.

Machine Learning assisted setting.

Ethernet point to point communication available.

Labelling. Packaging lines. Cosmetic and Pharmaceutical.

Beverage and Brewing.

Fast and easy set up, no need for a skilled installer.

Green/Red LED Spot for Good read/Bad read making it easy to see the performance.

NEW Smart-VS Plus can now take 20 images rather than 6 images on the standard.

Simple free web-based software.

Is this a product you use today, or can imagine using?

Do you have a current solution? What is it?

Have you used Smart sensors before?

Would you like a demo of how easy it is to set up?

Demo cases available.

Demo is key to showing the sen bili i s.

Cognex

Keyence