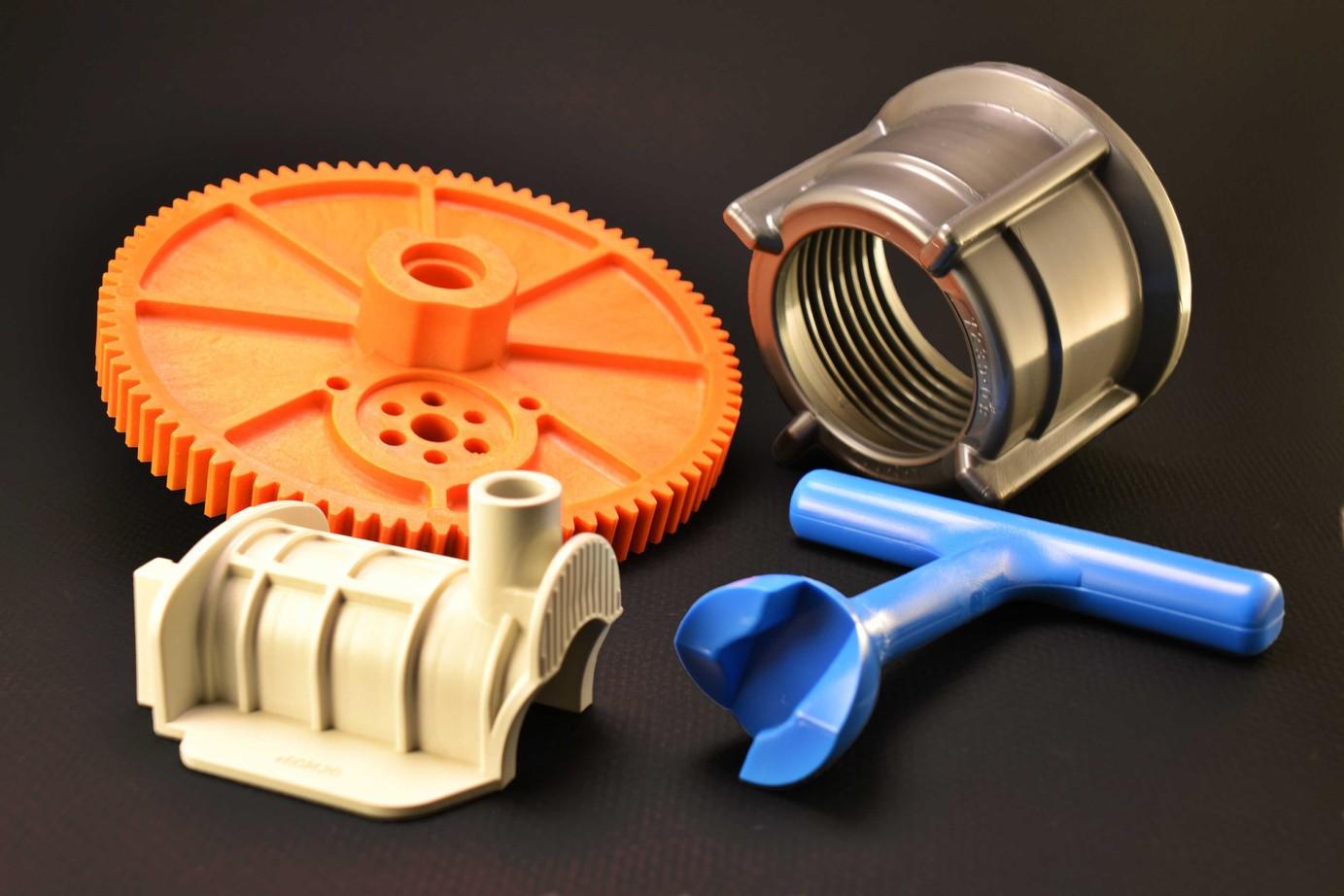

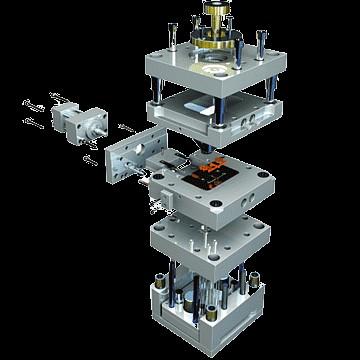

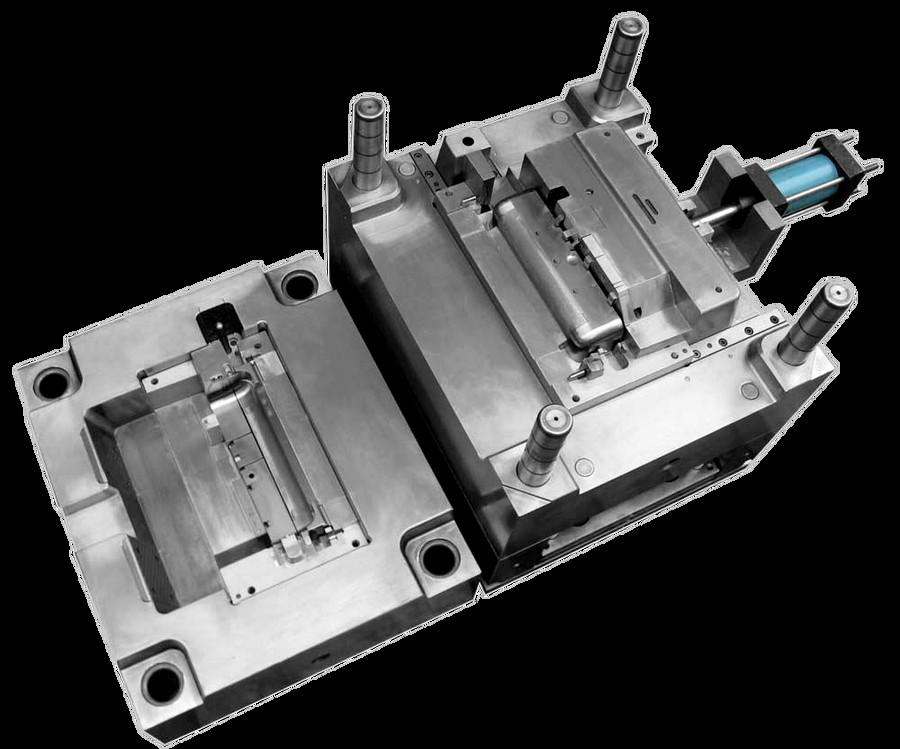

use the well-known technique of injection molding, which involves injecting molten plastic parts into a mold cavity. The final product is then, taken by the mold manufacturers once the plastic has cooled & become rigid. Injection molding is a reliable way for making solid plastic parts with a high-quality finish, despite the critical and difficult mold design process (a poorly designed mold might result in flaws).

yRepeatability, or the capacity to reliably make similar components, is essential in the automotive sector. The final molded car parts produced using the mold are almost identical to automotive plastic injection molding which is durable metal mold.

Due to the price of the mold, the process of creating an injection mold can be costly. As the High Quality Injection Molding manufacturers produce more components, the process' total cost falls, but it is still very scalable.

The large variety of rigid, flexible, and rubber plastics that the method is suitable for makes using injection molding for producing cars well. In the automotive sector, techniques are a wide variety of different polymers for various uses, including ABS, polypropylene, acrylic, acetal, nylon, and polycarbonate.

Molding Company , plastic items with relatively basic shapes may be formed with good surface finish quality. When creating parts, workers can choose from a wide range of finishes, including various surface textures like glossy, rough, or matte, which they apply directly to the mold rather than the molded item.

It is simple to change the colors of molded car parts in automotive plastic injection molding to match the color scheme of the vehicle. As injection molding is often used by automakers for the bulk production of automotive parts, it is also used as a prototype tool.