ReThink Waste Challenge

What idea will you contribute to a zero-waste future?

What idea will you contribute to a zero-waste future?

What idea will you contribute to a zero-waste future?

All rights reserved: no part of this document may be reproduced, stored in an automated database, or published in any form or by any means, be it electronic, mechanical, by photocopying, recording or otherwise, without the prior written permission of the publisher.

Publisher: Wageningen University & Research (studentchallenges@wur.nl)

Texts: Anna Celli (WUR), Harm ten Napel (WUR)

Editing: Anna Celli (WUR)

Photos: Guy Ackermans

Design: GAW, Marieke Eijt

Printing: Drukkerij Modern, Bennekom

We thank our partners and sponsors for their generous contributions. Their support has been invaluable in making the ReThink Waste Challenge an unforgettable and inspirational event, educating the game changers of the future and contributing to innovations for a sustainable future.

Impact partners

Business + partners

Business partners

Supporting partners

Media partner

With the world’s growing population and increasing prosperity, global consumption is skyrocketing. Unsustainable production processes and products based on finite resources and linear consumption processes have led to devastating consequences, ranging from waste and environmental degradation to accelerated climate change and depletion of natural resources. We urgently need approaches to development that limit these negative effects; sustainable and circular approaches that minimize waste, and utilize renewable resources. Addressing these challenges requires out-of-thebox designs, solutions and collaboration. Which is exactly what we aim for with our ReThink Waste Challenge.

As a leading institution in the field of sustainability, agriculture and food, we set out to educate and inspire young people, to become the changemakers for a sustainable and resilient future. We provide them with the knowledge and skills to contribute to key global transitions. This Challenge is one of the ways to achieve this. Twenty-seven teams with close to two hundred students from sixty seven different universities in thirty three countries started on this journey at the end of 2022. After nearly 6 months, 10 teams made it to the finals.

I am very proud of the students that have participated in this edition of the ReThink Waste Challenge. They have developed amazing concepts and innovations for limiting the amount of waste, and speeding up the transition to a circular biobased economy and society.

I am full of admiration for the teams who dedicated so much of their time and energy to make a positive impact on our world. Congratulations to you for your creativity, innovation, hard work and persistence!

Working together is crucial in tackling the global challenges we all encounter, and this Challenge is no exception. My colleagues at Wageningen University & Research, along with our partners worldwide, have collaborated on this project. I am immensely grateful for their support and would like to express my heartfelt thanks.

I hope the content of this magazine will provide inspiration to anyone interested in contributing to a more sustainable future.

Arthur Mol Rector Magnificus/Vice President of the Executive Board Wageningen University & Research

Text: Harm Ten Napel

The student teams competing in the ReThink Waste Challenge have received essential advice from industry experts. It has taken their ideas to the next level by honing in on the essence of their innovation, challenging them to communicate their ambition or even pushing them to change direction. Meet some of the students and their coaches and learn about their experience during the Challenge.

Central to the WUR Student Challenge philosophy is bringing together academic and industry experts with prospective innovators: the students competing in the Challenge. The ReThink Waste Challenge is no different. The student teams - hard at work to present the ideas that will chime in the zero waste future our planet needs - have met with several coaches out of the partner network.

Marco Nieto Lojo of Team ElectOlive was activated when the Universidad de Santiago de Compostela encouraged its students to compete in the Challenge.

“I immediately contacted my brother, Anxo. He started working on the economic side of the concept, together with his friend Larisa. Miriam, an old friend and a biologist, agreed to work with me on the research side of the project. I study biochemical engineering myself.”

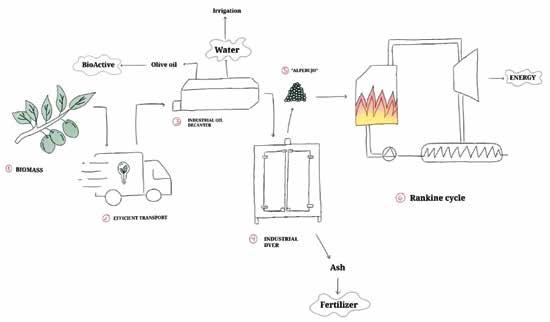

“We want to turn waste into electricity. Electricity is already important, but it will surely become more important in the future. We’re focusing on organic side streams of the olive oil industry, right now, proposing ways in which the industry could turn those into energy.”

“The olive oil industry produces enough suitable biomass for our concept, but our concept will be suitable to different industries.” The coaches the students spoke, honed in on their numbers and asked about their calculations. Could they really produce those amounts of energy?

“We’re pretty confident,” says Marco, “but we did listen to their comments.” The team realized they should think about where those questions came from. “We’ve made it a point to explain ourselves better, so interested parties will not only know that our idea works but also how it works. It’s up to us to communicate our confidence.”

“I served as a reality check for the students, while they gave me a fresh perspective.”

Heiko Oertling, R&D hub manager at CJ CheilJedang

“Focus, focus, focus - that has been my number one advice,” says Heiko Oertling, R&D hub manager for CJ CheilJedang, a leader in Korea’s food industry. “Some teams get distracted by complexity or expanding their idea. From my experience in innovation, usually it is beneficial to hone in on the strength of a core idea. You need to find the essence of your innovation - that is it what you’re selling in the end.” He emphasizes that a main skill in innovation is curation. “You need to filter the insane amount of information everyone has access to.”

“CJ CheilJedang is a major distributor and manufacturer of Asian food, with an extensive portfolio of items and ingredients.” Heiko is a chemist by training but has experience in many different areas from supply chains to innovation. “What drew us to the ReThink Waste Challenge was the chance to meet new minds. Our daily work is very often, unsurprisingly, concerned with everyday´s

harsh reality. My conversations with the student teams have been about the future.” He described those meetings with the word ‘friction’. “I served as a, sometimes unpleasant, reality check for the students, while they provided me a fresh perspective.”

“I think it’s really important to connect with the next generation,” Oertling says. “I personally love to see how far the teams can take their ideas.”

The focus that Oertling advises can also lead student innovators to discover not the essence of their current project, but a new direction. “Our project went through a couple of iterations, but we started out interested in treating digestate,” tells Daniel Balutowski of Team Waste^2. “Digestate is a liquid waste product of biofuel production - a kind of waste of waste, hence our teams name.” The team wanted to use hydrothermal carbonization to turn this problematic Rethink

by-product into a new solid and liquid energy stream, both of which provide green alternatives to the current situation.

“We did the work and started looking at, for example, chicken manure,” explains Balutowski. A hot topic in the Netherlands, manure, as it is tied up with problems surrounding nitrogen emissions. “Our current proposition is a technology that creates biochar out of excess manure.” This is a very useful product that could be applied to soil to store carbon, reduce emissions, and help retain water and nutrients.

“The coaches were really knowledgeable and helpful,” says Daniel Loreggia, a member of the same team. “They kept us focussed on the overarching details. Is this doable, not just economically, but chemically as well?” So the team dove in. “Going deeper and deeper into our proposition, taking the Dutch context into account as well, our initial idea, we concluded, didn’t work thermodynamically,” explains Balutowski. Using a water based processing method initially made sense, but the outputs were contradictory when considering the carbon balance. “So we took a step back.”

“IFF’s reason to partner with the ReThink Waste Challenge, and provide coaches, is threefold,” says Wilbert Heijne, Global Product Manager at International Food & Fragrances (IFF). He continues with a clear summary. “First, IFF is interested in networking within the upcycling community.” The Challenge also brings its partners together. “Second, we’re always on the lookout for business opportunities. Are there interesting waste streams or technologies we should know about? And lastly, there is the talent. I want to get to know the young innovators, but also: I want them to get to know IFF.”

“I want to get to know there young innovators, but also: I want them to get to know IFF.”

Wilbert Heijne, Global Product Manager at International Food & Fragrances

So what was his experience in coaching the young talent? “Valorisation came up frequently. The student teams were often motivated by their ideals, and assumed their potential customers would be too. But the challenge is to find that customer base and to communicate your sustainable proposition in a way that attracts them to your product. Otherwise you’re competing with the current baseline.” Heijne emphasized, like Oertling, that the Challenge served as a ‘sandbox for pioneering’ where there is a lot of room for creativity. “IFF comes in to professionalize those big ideas. We can’t invent everything ourselves, you know.”

Text: Anna Celli

Text: Anna Celli

Terms like ‘circular economy’ and ‘biobased products’ have nowadays become buzz words, but how far are we truly in the transition to a biobased economy? Though the chemical and packaging industry were initially reluctant to this change due to the technical challenges given by biobased ingredients, a change in public perception has pushed many industries to take action and develop fossil fuel free solutions. To achieve this, many companies have joined forces with experts and scientists from research institutes.

Among these, Wageningen University and Research (WUR) has been instrumental to the energy and material transitions by sharing its expertise with the private sector. Barneveld-based Paperfoam is an example of this partnership. Paperfoam produces high quality packaging for phones and egg cartons out of natural fibres, starch and a “magic mix”. The final product is 40% lighter and production emits 90% less CO2 than traditional packaging.

More recently, WUR researchers developed a circular binding agent for asphalt from lignin (a side-stream of paper production) to substitute bitumen which is a crude-oil product. Currently this invention is used in 30 roads in the Netherlands and options to develop a fully lignin-based asphalt binder for European highways are being developed. This technology is also suitable in other applications such as roofing. Over the past 30 years, WUR has co-developed many new circular products such as circular packaging coatings, pet toys, planting pots, biobased car tires and green insulation materials. But also safe biobased and biodegradable alternatives to fossil based surfactants in shampoos to prevent microplastics finding their way to the environment. Of these, many are still in the market 1020 years after launch.

With this proof of already many successful market introductions, the next step is scaling up. For this reason, a program for the National Growth Program addressing “BioBased Circular – BBC” was submitted to the Dutch government. The program focuses on scaling up and accelerating the development and production of

circular plastic materials based on carbohydrate rich biomass to large-scale applications in everyday products such as food, packaging, furniture, building materials and coatings. The proposal also includes another key factor addressed by the participating companies: human capital.

WUR already offers the MSc study program “Biobased Sciences” specifically focusing on the transition from fossil fuel technologies to a circular economy, and numerous MOOC courses for professionals. However, according to Gerlinde van Vilsteren, Project manager Value Creation at WUR “no true transition to a fossil-free society is made if we leave the human factor aside. Changes in education, learning models and new types of transdisciplinary expertise are needed.”

Such experimental ways of learning have already been used for extracurricular programs, such as the student competitions organised by WUR Student Challenges for students worldwide. This year the ReThink Waste Challenge is taking place on Wageningen Campus and online and involves 27 international student teams working on creative solutions to bring new solutions to the circular economy. One key aspect of these initiatives is collaboration between the student teams and a network of partners who coach the students through the process of developing a product. In addition, students learn about entrepreneurial skills and learn how to work in a multidisciplinary team by sharing their expertise and teaching others in an informal setting.

Muskan Mathur, lead of team Bridging Buildings and Bins (BB&B) thinks participation of partners set apart the ReThink Waste Challenge from other programs: “As students we are skilled in looking into literature and write about it”-says Mathur – “but partners constantly pushed us and ask us practical and insightful questions to push our innovative product idea to where it is. At the beginning of the challenge we wanted to create a sustainable insulating material from plum pits, but thanks to the expertise and guidance of our coaches, we realised it was not going to work and decided to start from scratch and use rapeseed stalk instead!”. Multidisciplinarity was also key to their process: “whenever I felt stuck or did not know how to do something, someone else in the team would step up and explain to me how.”

Multidisciplinarity also seems to be pivotal to the development of the new era of education for a biobased economy, as different professional profiles are needed to revolutionise the current industry. To put it in van Vilsteren’s words: “Developing a product is a start, but we also desperately require policy makers, designers and business model developers to make a biobased future a reality.”

The first edition of the ReThink Waste Challenge focused on bringing new and innovative solution to the biobased circular economy. In short, the proposed innovations should provide an approach to prevent, reduce, reuse, recycle or recover biomass side-streams. The participants were tasked with the arduous assignment of identifying a market for the proposed product and producing convincing prove that the innovation is viable, original and fills an existing gap in the industry. Fortunately, participants were assisted, coached and advised by a diverse network of coaches from 26 different partner companies who provided essential expertise and support to the teams. Moreover, participants were offered tailored trainings and workshops to achieve the best possible results by challenge organizers, WUR Student Challenges.

The Challenge kicked off on 18 January on WUR campus and was live streamed worldwide. Over 70 people participated in person and around 50 joined it online. The kick-off was a joyous event with a variety of activities and speakers sharing their personal experience with the Challenge and biobased economy. After the event, students took part in Sprint 1, an entrepreneurial training organized in collaboration with WUR start up incubator, Starthub. The Challenge was joined by 190 students in 33 different countries.

After almost two months of hard work, the teams delivered their first milestone report where they explained their ideas and highlighted how their innovation solves the problem of waste. Of the 27 teams, 18 made it to the next round and had a chance to make it to the finals. The selection was a difficult process, but according to Frank Mejier, Senior Food Designer at IFF and selection committee member: “When the students put the whole picture together, waste suddenly seems to be worth gold. Still with this nice feeling of doing more good for the planet”.

During the course of the Challenge, participants participated in Sprints, full day of entrepreneurship trainings and fun activities to get to know each other. The events took place in WUR Student Challenge’s Exploration Space in Plus Ultra II and were also livestreamed for participants abroad. Dingming from team Live Twice commented about Sprint 3: “I learnt quite a lot. We learnt how to validate our ideas and our assumptions with appropriate tools and were able to ask some questions to two brilliant companies”. In addition to the Sprint days, participants had the option to join a few workshops on the topics of personal branding, patents, pitching and prototyping. Coaching by the Challenge’s network of partners was also prominent: two online consultations events were organized as follow up event to the Sprint days. Muskan Mathur found these events incredibly helpful to the process of her team BB&B. “Every time we talked to the partners we got little bits of useful information and practical questions that we hadn’t thought of.”

On 1 June, The finalists of the challenge were announced. After 2 months of hard work, the teams delivered their second milestone complete with an artist impression of their idea and a social media pitch. The finalists had then some time to perfect their pitches before entering the dragon’s den with the Jury at the Grand Finals on 21 June.

During this full day event on Wageningen Campus, the finalists entered the dragon’s den and discussed their project with our Jury. The finalists were also given a chance to pitch their ideas to the audience to win the audience award. During the award ceremony the top 3 teams were announced and we also got to hear from some inspiring speakers: Ugne Dirdaite, EU Bioeconomy Youth Ambassador and Cees Leeuwis, professor of Collaborative Research, Communication and Change. After 6 months from the start of the challenge, the winner of the ReThink Waste Challenge was finally announced: Congratulations team Afterlife!

Edgar Suarez Garcia is the co-founder and CTO of Revyve (formerly FUMI Ingredients), a scale-up that is dedicated to transforming microbial biomass into functional ingredients.

Revyve is currently scaling-up the production of functional proteins and fibres from brewers spent yeast, but is also actively working with several spent microbial biomasses. Edgar has worked on biorefineries and valorization of various types of biomasses (agricultural streams, algae, waste streams) for over a decade at industrial, academic, and start-up level.

“The ReThink Waste Challenge could not be a better fit to my interests and ambitions. Firstly, I firmly believe that urgent action is needed to avoid waste and to transform it into valuable products. Secondly, we need fresh

ideas, creativity and innovation both, at student and corporate level. Thirdly, to achieve it, companies, universities and the government need to work together. I’m impressed with the energy and creative ideas that have been put forward by the teams. Unfortunately, only a handful of projects will be recognized as winners, but I really hope that most student teams can continue their development and become successful.”

currently one of the partners and works as a European and Dutch patent attorney in the field of chemistry. In his position, he supports a wide range of clients including start-ups, medium size enterprises, and multinational companies.

“The ReThink Waste Challenge allows young students to pursue their new ideas and develop a business proposition. It is a great pleasure to help them grow and flourish. One of the nicest aspects in my work is to see start-ups with exciting new technologies grow into valuable companies.”

V.O. patents & trademarks

Huub Maas studied Molecular Sciences at Wageningen University, after which he did a PhD in physical chemistry at the University of Berne, and held a postdoc position at the University of Amsterdam. In 2005, he joined V.O. patents & trademarks, where he is

Ernst-Jan Mul is innovation manager at Renewi. Together with the innovation team, he works every day on recycling more, and recycling better. Within Renewi he has a specific focus on organic, food and wood streams, and the upcoming possibilities to make more out of residual streams. Part of Renewi’s innovation strategy is

to cooperate with startups and universities to co-develop and scale these solutions.

Biobased circular products are key to reducing emissions, to keep CO2 fixed in materials rather than floating in the air, and above all, are the feedstock of choice for high value products. There are limitless opportunities in this field. But which ones to develop first? “With the ReThink Waste Challenge, I’m looking forward to be inspired by ambitious student teams, and to discover the next big innovation in this field.”

chemists and engineers. We have to deal with multiple transitions, such as, an energy-transition and a raw material transition. Furthermore, raw materials are getting scarce and recycling becomes an essential part of our economy.

“The ReThink Waste Challenge is important for two reasons. Firstly, because students work together in interdisciplinary teams to innovate and create new ideas. Secondly, because they prove that waste doesn’t exist. Actually, it might be the most important raw material of the chemical industry of the future. It is wonderful to learn ideas and solutions of the various teams.”

for almost two years, focusing on innovative start-ups in the Food & Agriculture and Energy Transition industries. SHIFT Invest is a Dutch venture capital fund with 13+ years of experience in impact investing aiming to bring back the balance between nature and society by investing in innovative companies.

Peter Berben is the managing director of the TKI Green Chemistry and Circularity. He has spent more than 30 years in research in industry, the last company being BASF. In that role he was responsible for developing innovative new catalysts and materials. The time period we live in is a very interesting one for young

Sophie van Weede has a background in Neurobiology and Econometrics. After starting her career in strategy consulting, she made the switch to venture capital. She has been working at SHIFT Invest, an early-stage impact investor

“This Challenge is a wonderful way to get bright students involved with entrepreneurship. We are currently facing several tremendous challenges, and I firmly believe technological innovations will play a major role in tackling these challenges. But unfortunately, technological innovations alone are not enough. A team bringing such technological innovations to the markets must also be business savvy, understand the market and be able to communicate the promise of their product to customers, partners and investors. This Challenge allows teams to think about the whole picture, the technological feasibility and the product-market fit. The WUR and SHIFT have always had a close relationship and are amazed continuously by the innovations coming out of this University. This Challenge is no exception, as the level of the proposal, and the diversity of the solutions, was very high.”

Afterlife aims to revolutionize the way we feed the world while protecting the planet. Our innovative solution harnesses the abundant agricultural food waste found in the Netherlands and converts it into a valuable resource. Through fungal fermentation technology, we unlock the power of these overlooked resources, creating a sustainable protein ingredient that is both functional and delicious. This approach not only addresses the inefficiencies of our current food system but also meets the skyrocketing demand for ecofriendly plant-based alternatives. Join us as we create a future that is secure in food, protects the environment, and is filled with delicious, protein-rich foods.

Afterlife offers a versatile mycoprotein as a solution to challenges faced by food manufacturers, particularly of meat alternatives. Plant-derived proteins have unwanted flavors, colors, and lack functional properties, leading to increased costs and compromised quality. Additionally, they require extensive land and water usage, resulting in a high environmental footprint. Afterlife’s mycoprotein addresses these issues with a neutral taste, color, and unique functional qualities. The magic happens inside a bioreactor, reducing land and water requirements, and lowering scope 3 emissions. Moreover, it caters to the rising trend of soy and nut allergies. Overall, Afterlife’s mycoprotein

provides an opportunity for innovative, sustainable, and allergy-friendly food products.

All of us Afterlifers are master students at Wageningen University with different backgrounds. We individually bring to the table specialized skills in biosystems engineering, biotechnology, food technology, sustainable business, and environmental sciences. We are dedicated to revolutionizing the food industry by offering versatile and sustainable protein alternatives that meet evolving customer needs, fostering a healthier and more sustainable future.

‘’This challenge made us discover the power of creative problem-solving, sustainable thinking, and the boundless opportunities that lie within our discarded materials’’

Team members:

Tijmen Visser

Giulio Mornati

Marisol Calderon

Tim Bongers

Kristina Smieskova

Energy efficiency is an important way to reduce carbon emissions from buildings and thermal insulation is an easy and effective means of achieving this. Our vision is to make housing more sustainable, affordable, and less damaging to human health by providing insulation materials with a low carbon footprint from up-cycled rapeseed stalks. We plan to launch our business in Europe, then expand globally. Our goal is to create a direct clean waste stream from rapeseed stalk agricultural companies and farms to insulation production and to give people the choice to be part of global change for a sustainable construction economy.

The project aims to utilize rapeseed stalk as an ingredient for insulation materials. Lower thermal conductivity indicates a better insulation material. Conventional insulators cause skin and airway irritation due to small pieces or chemicals getting released. This is not an issue with our more natural, nontoxic, allergen-free product which can be safely handled and installed without extra safety equipment required for the installation of conventional insulators. Moreover, while conventional insulators are often only onetime use and need several human lifetimes to degrade, causing health hazards while doing so, our product can be reused and recycled, and are fully biodegradable. The rapeseed stalk

will be collected from agricultural companies, farms and trials will be made to achieve a more sustainable and affordable insulating board.

BB&B is a group of five international students from different universities with backgrounds in Environmental and Biobased Technology, Biobased Sciences, Plant Biotechnology, Food Technology, and Environmental Technology. This mixture of knowledge enables us to see from various perspectives how to process food waste into construction materials that result in lower carbon emissions. We want to contribute to a cleaner, more sustainable future.

“The ReThink Waste Challenge opened our eyes to the immense possibilities within the circular biobased economy.”

Team members:

Muhammad Haikal

Larissa Markus

Muskan Mathur

Florence Ignatia

Kingdavid Ozobodo

At Cult Factor, our goal is to reduce waste and lower the cost of growth factors in cultivated meat production. By developing an engineered strain of Pichia pastoris, we aim to economically produce fibroblast growth factor (FGF2). Additionally, we propose a novel approach to recycling FGF by expressing Fc-tagged FGF through fermentation and chromatography. This process could significantly decrease the production cost of cultivated meat, bringing us closer to price parity with conventional meat. Our research provides a theoretical framework for further experimental exploration, contributing to a more sustainable and costeffective cultivated meat industry.

Our solution is to produce growth factors (GFs) for cultivated meat production with an innovative approach that includes incorporating an Fc-tag for multiple usage, implementing a waste reduction strategy, and ensuring a reliable source of supply. This presents an opportunity because existing competitors offer recombinant GFs at a high cost that can only be used once, while our solution provides a cost-effective and scalable alternative. What makes our solution unique is the combination of recycling high-quality GFs, maximizing the value derived from waste reduction, and offering a reliable supply, positioning us as a leader in the market.

With backgrounds in biology, food technology, biotechnology, agriculture, and animal science, our team brings together a range of expertise, accompanied by a common interest for cellular agriculture technology. This diverse combination of disciplines is necessary to find novel solutions for waste reduction in cellular agriculture applications. We strive to use our combined skills to find innovative solutions for the cultivation of meat by utilizing wastes from the agri-food sector.

“The ReThink Waste Challenge provided us with the tools to approach future challenges with a more sustainable approach, right from the start.”

Team members:

Tin Rudnički

Paul Steinhardt

Adrian Hirt

Bernard Prasetyo

Nike Schiavo

“Our perspective on waste has significantly changed as a result of the ReThink Waste Challenge”

EcoLiving’s vision is to become an eco-friendly startup that focuses on sustainable food waste management. EcoLiving addresses the lack of food waste management from households which leads to higher carbon emissions and carbon footprints thus becoming one of the causes of climate change. We aim to become a zero-waste pioneer in food waste management by collecting, identifying, managing, and processing the waste through an easy-to-use digital platform. Our food waste bank website system is based on four core values: living sustainability, innovation through creativity, strengthening the community, and working collaboratively.

At EcoLiving, we are developing a digital food waste bank as an integrated food waste management solution that connects households, food waste managers, and customers. This digital food waste bank provides website-based waste collection, waste processing, and product marketing facilities. EcoLiving features a blockchain system to ensure data security and integrated smart sorting to identify food waste from households. Food waste will be sorted based on the level of product defects allowing to rescue 10-20% of defective food which will be utilized in the food industry and more than 20% will be used as organic fertilizer, compost, worm feed, and maggot feed.

The EcoLiving team consists of students majoring in agribusiness and agroecotechnology. Zulfikar as CEO has experience in organizing tasks and coordinating programs. Christoforus and Wahyu as COO have experience in fertilizer processing and worm cultivation. Ni Wayan as CFO has experience in managing transactions and budgeting. Hafiz and Risa as CTO have experience in website development. The EcoLiving team is committed to educating and empowering women as zerowaste pioneers.

“Throughout our project, we learned that raising awareness of the waste issue is an integral part of our mission as social entrepreneurs.”

Team members:

Zulfikar Dabby Anwar

Ni Wayan Atik Sarmila Dewi

Risa Salsabilla

Wahyu Rizki Pratama

Christoforus Kalo Bello Puyanggana

Hafiz Okta Ramadhan

“We realized how important it is to develop new and innovative ideas, while also learning how to protect and grow them.”

A large amount of exudate is produced in the process of slaughtering and deep processing in the meat industry. Currently, there is no systematic method to make efficient use of such meat processing by-products which results in waste of muscle protein and additional environmental pollution. We aim to recycle exudate protein for the development of degradable membrane materials, providing a new idea for the high-value utilization of meat by-products.

After evaluating the composition and protein components of meat exudate, we used pH drive technology to recover high-quality proteins and studied the functional characteristics of gel emulsification of recovered proteins. This knowledge was then applied to develop a new degradable packaging membrane material from the recycled exudate protein. This animal-based raw material combined with extraction in an innovative way can bring a new biodegradable packaging experience to the market.

Our team used the pH drive technology to recover high-quality proteins from the recycled exudate and transformed it into biodegradable packaging membrane materials. During the ReThink Waste Challenge, our team members worked together to better understand food science and protein research. As a team, we

were happy to share our ideas for a better future with our international friends in different continents and universities.

“The Challenge was more than just writing a report, we developed our communication skills by talking to partners and learned to pitch.”

Team members:

Yu Chen

Hui Zhang

Yinghan Jiang

Rongguang Gao

Qian Xiao

Xinrui Xu

“Collaboration is fundamental in today’s workplaces, working on our project helped us develop these skills for our future careers.”

Electricity is the energy of the present but especially of the future. For this reason, one of the main problems in the agricultural sector is the amount of energy that is consumed but also the pollution resulting from these processes. Our team, ElectrOlive, aims to reduce emissions from this industry through a self-sustaining and environmentally friendly process.

Could you imagine being able to reinvent the electricity industry through a process that maximizes the amount of energy generated from biomass through an intelligent network monitoring the process? This is just what ElectrOlive proposes: create clean and selfsustaining energy through surpluses from agricultural industries. An innovative process that is one step closer to achieving the sustainable future that you can imagine.

We are a multidisciplinary team, made up of students of chemical engineering, biology, marketing and business management. With work experience in different sectors, we can easily adapt to different challenges and work together, complementing our expertises. We hope to take advantage of this great opportunity to validate our skills, improve as professionals and grow as people.

“The Rethink Challenge was a great opportunity that has shown us the importance of getting our hands dirty in generating a positive change.”

Team members:

Anxo Nieto Lojo

Larisa Birsanu

Marco Nieto Lojo

Miriam Vilarnovo Allal

“Working with experts from various sectors has given us a great professional insight in our work.”

We envision a new era of fermentation, where the utilization of pineapple by-products will contribute to the production of a sustainable, healthy, and tasty fermented beverage, increasing global environmental awareness on the existing food waste problem! The pineapple has a world production of 25.4 million tons annually. Pineapple by-products include the core, peels, stem, crown, and leaves, which all together account for about 50% (w/w) of general pineapple weight. Consequently, this industry generates a significant amount of waste divided into two main categories, pineapple on farm waste and pineapple peel waste. The waste usually ends up in landfills, producing gasses such as methane, which contributes towards environmental issues. Additionally, the disposal of pineapple waste occupies valuable space and due to microbial spoilage can pollute soil and water. Thus, this issue represents a challenge for the pineapple waste management, which will further lead to extended problems in the food chain, if not successfully utilized.

Fermentera will offer a naturally carbonated fermented beverage, based on pineapple waste by-products (PWBP) from the pineapple processing industry, making the drink environmentally friendly. Our beverage will be made with only natural ingredients and as a fermented product, it will contribute to gut health through probiotics. The process will be highly monitored and standardized, ensuring a safe and tasty treat in every bottle.

By consuming our product, customers will be raising awareness of the current food waste problem and allowing Fermentera to acquire more PWBP, therefore making an environmental impact and benefitting both Fermentera and themselves. Similar products in the market such as kombucha and kefir water utilize primary raw materials for their fermentation process, meanwhile, in Fermentera we will use a secondary food stream to start our fermentation, contributing to the production of a more sustainable, and environmentally conscious beverage.

Hello world! This is Fermentera introducing the new era of fermentation. Our team consists of two members, who are currently Master students of Food Technology at Wageningen University, specializing in Product Design and Ingredient Functionality & Food fermentation, biotechnology, and Gut health. The connecting factor of the team members is our love for fermented products, which is coupled with unique flavours, functionalities, and health benefits. Over the past few years our team has observed a fast growth in the fermented products market. The redirection of the food system towards higher awareness on environmental and health issues made us reconsider the strategy towards our personal and professional development. Our love for the environment, health and food is the combination which will make us reach our goal, contributing towards the change we want to see in the world.

Team members:

Panteleimon Agianidis

Samara Hernandez Arteaga

“During the Challenge, we experienced that collaboration and developing a network are important skills to young entrepreneurs.”

The Netherlands, a global leader in greenhouse construction and plant cultivation, generates a significant amount of biomass waste from high-wire crops. This waste, mostly stems, leaves, and subpar fruits, is typically composted or used for energy production with unseparated plastic tools. Given the rising costs of biomass disposal associated with plastic contamination, we aim to design advanced biomass waste treatment methods that can add value and improve circularity in the greenhouse industry. By effectively repurposing waste, growers can offset increased production costs, operate more sustainability, and maintain competitiveness, thus benefiting themselves and other stakeholders.

We utilize tomato biomass from the greenhouse, a widely available horticulture waste, to extract fibres and convert them into bio-degradable twines. This distinctive approach tackles two key issues: waste management and sustainable production. The extracted fibers are transformed into eco-friendly rope and provide a greener alternative to synthetic fossil-based products for greenhouse use, reducing environmental footprints. This opportunity capitalizes on the increasing demand for sustainable solutions within the horticulture industry. Its uniqueness lies in recycling a typically discarded resource, demonstrating a closed-loop system that both

benefits the environment and offers economic advantages, setting a precedent for future sustainable horticulture practices.

Live Twice is an international team of Master’s students and PhD candidates from Wageningen University. Thanks to our expertise in Food science, Plant science and Landscape architecture, we believe the best way to find the solution is to bravely cross the border of different disciplines and learn from each other. One thing we share in the team is our love and passion for lives, no matter small or big, young or old.

“We learnt to always trust in your team and be confident about your idea.”

Team members:

Haoyu Yang

Sijia Chen

Qing Ren

Dingming Rao

Apostolos Tavlaridis

“Meeting experts from various domain really expanded our vision and network.”

Our long-term goal is to build sustainable value chains in which apple and other fruit pomace wastes are directed in a circular fashion back into the food processing stage as sources of vital ingredients. Our vision is to preserve and exploit the natural value of different pomace wastes as well in the future to transform the pomace disposal problem into a value-added pomace opportunity for food industries. The global apple pomace quantity roughly varies between 4 to 7 million metric tons per year. However, the major problem associated is the loss of a natural and cheap food-grade starting material. Food industries are in need of novel food-grade ingredients for flavour formulation. Hence with the help of fermentation-based techniques, we aim to create a problem solution for natural ingredients from apple pomace.

Our solution is to use the biotransformation technique to produce environmentally friendly and sustainable natural aroma compounds for food flavour formulations. We believe that there is a need for a high food-grade source for the extraction or production of natural ingredients. Currently, it is dependent on low-quality natural sources. Switching to novel natural sources may increase the costs of production and the final product. Turning the pomace into valuable flavor compounds fit for human consumption is our solution to the pomace valorization problem. The unique selling point of the proposed idea is the fully natural and biobased production

of natural 2-PE. Our proposed product is not extracted based on the fixed content in the feed, but it is biotechnologically produced with bio-based sources allowing us to go for a higher yield.

Team Pomace has a clear drive to redefine the value of apple pomace in the food industry. We are currently a team of four students bringing certain expertise in food technology, biochemical engineering, and sustainability. In our previous work experiences, each of us has noticed the immense disposal problem of fruit pomace from industries. This has led us to think if there is a better way to tap the underlying functionality of pomace wastes and develop an appealing business case for pomace valorization.

“Not only did we learn a lot about our idea and how to develop it in practice, but we also gained a lot of knowledge on the business and legal side of starting a business.”

Team members:

Aiganym Abduraimova

Nurdana Orynbek

Steven Weijkamp

Ajinkya Sawant

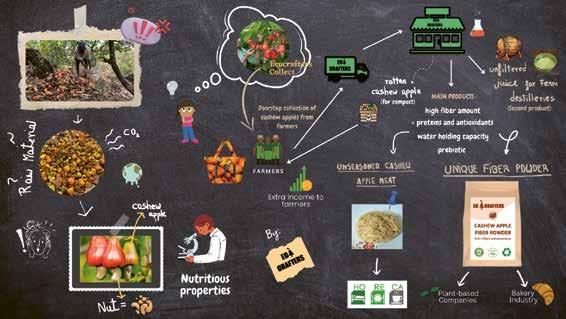

With EcoCrafters we hope to have a real impact by offering Indian farmers a new source of income while decreasing the food loss of 90% of cashew apples which are highly produced for cashew nuts. Our goal is providing a product for customers as bakery, plant based meat retailers or hospitality industry. We aim to demonstrate that cashew apples can be used for more than for small scale beverages or jams and we want to generate a competent product, satisfy our customers and create a product that meets the new challenges of this century, sustainability.

Ecocrafters aims to tackle food loss of cashew apples by processing the juice and drying the remaining fruit to create two core productscashew apple fiber powder and unseasoned versatile plant based alternative. The fiber powder is ideal for bakery and plant-based companies, and the unseasoned versatile plant-based alternative is ideal for the HoReCa (Hotels Restaurants Cafes) that serve Vegetarian or Vegan food. Additionally, our unique production process supports a circular economy and generates extra income for farmers. By using our sustainable ingredients, businesses can enhance their brand image and reputation, while also meeting the demands of environmentally conscious consumers. By choosing our product, businesses can promote sustainability and attract a growing number of eco-conscious customers.

We are Mia Djula, a Food Engineering graduate from Croatia, Manasi Nachankar, an International Agribusiness graduate from India, Alba Ochando and Marta Cerdá from Valencia, specializing in Biotechnology and Food Science and Technology. We bring diverse expertise and have acquired cross-disciplinary skills to collaborate seamlessly. Our objective is to maintain integrity and transparency while delivering a sustainable and safe product that meets the highest quality standards expected by our customers.

“The Challenge helped us develop an action plan to reduce food waste in our daily life, and we are excited to continue our waste reduction journey.”

Team members:

Alba Ochando Martínez

Manasi Nachankar

Marta Cerdá Bernabé

Mia Đula

“We gained a deeper understanding of the environmental, social, and economic implications of food waste.”

“The ReThink Waste Challenge is a great platform to engage with inspiring, talented young scientists and entrepreneurs.”

“If

Packo Lamers, Corbion

I had a time machine, I would go back to my university years and take the chance to attend this amazing challenge. Now, as coach, I love seeing the enthusiasm of participants and I hope to be an useful partner to make them realize their dreams.”

Ilaria Sangalli, Kerry

“I was impressed by the many good ideas of the student teams.”

Patrick Ballast, Ballast-Nedam

“Coaching the different teams has been a journey and an adventure. I am curious to learn which of the ideas will materialize.”

“Joining the ReThink Challenge for the third time and again amazed by all the great ideas and motivation of the students. It was very inspiring to be part of this Challenge again!”

“This Challenge is a wonderful way to get bright students involved with entrepreneurship.”

Sophie van Weede, Shift Invest

Yvette Muskens, Dalco Foods

Heiko Oertling, CJ Cheiljedang

“The ReThink Waste Challenge allows young students to pursue their new ideas and develop a business proposition. It is a great pleasure to help them grow and flourish.”

Huub Maas, V.O.

Rethink