Topics in Modal Analysis & Testing, Volume 8: Proceedings of the 37th IMAC, A Conference and Exposition on Structural Dynamics 2019 Michael L. Mains

Visit to download the full and correct content document: https://textbookfull.com/product/topics-in-modal-analysis-testing-volume-8-proceeding s-of-the-37th-imac-a-conference-and-exposition-on-structural-dynamics-2019-michael -l-mains/

More products digital (pdf, epub, mobi) instant download maybe you interests ...

Topics in Modal Analysis Testing Volume 8 Proceedings of the 38th IMAC A Conference and Exposition on Structural Dynamics 2020 1st Edition Brandon Dilworth

https://textbookfull.com/product/topics-in-modal-analysistesting-volume-8-proceedings-of-the-38th-imac-a-conference-andexposition-on-structural-dynamics-2020-1st-edition-brandondilworth/

Special Topics in Structural Dynamics & Experimental Techniques, Volume 5: Proceedings of the 37th IMAC, A Conference and Exposition on Structural Dynamics 2019 Nikolaos Dervilis

https://textbookfull.com/product/special-topics-in-structuraldynamics-experimental-techniques-volume-5-proceedings-ofthe-37th-imac-a-conference-and-exposition-on-structuraldynamics-2019-nikolaos-dervilis/

Dynamics of Civil Structures, Volume 2: Proceedings of the 37th IMAC, A Conference and Exposition on Structural Dynamics 2019 Shamim Pakzad

https://textbookfull.com/product/dynamics-of-civil-structuresvolume-2-proceedings-of-the-37th-imac-a-conference-andexposition-on-structural-dynamics-2019-shamim-pakzad/

Nonlinear Structures and Systems, Volume 1: Proceedings of the 37th IMAC, A Conference and Exposition on Structural Dynamics 2019 Gaetan Kerschen

https://textbookfull.com/product/nonlinear-structures-andsystems-volume-1-proceedings-of-the-37th-imac-a-conference-andexposition-on-structural-dynamics-2019-gaetan-kerschen/

Special Topics in Structural Dynamics, Volume 5: Proceedings of the 36th IMAC, A Conference and Exposition on Structural Dynamics 2018 Nikolaos Dervilis

https://textbookfull.com/product/special-topics-in-structuraldynamics-volume-5-proceedings-of-the-36th-imac-a-conference-andexposition-on-structural-dynamics-2018-nikolaos-dervilis/

Model Validation and Uncertainty Quantification, Volume 3: Proceedings of the 37th IMAC, A Conference and Exposition on Structural Dynamics 2019 Robert Barthorpe

https://textbookfull.com/product/model-validation-anduncertainty-quantification-volume-3-proceedings-of-the-37th-imaca-conference-and-exposition-on-structural-dynamics-2019-robertbarthorpe/

Sensors and Instrumentation, Aircraft/Aerospace, Energy Harvesting & Dynamic Environments Testing, Volume 7: Proceedings of the 37th IMAC, A Conference and Exposition on Structural Dynamics 2019 Chad Walber

https://textbookfull.com/product/sensors-and-instrumentationaircraft-aerospace-energy-harvesting-dynamic-environmentstesting-volume-7-proceedings-of-the-37th-imac-a-conference-andexposition-on-structural-dynamics-2019-chad/

Dynamics of Coupled Structures Volume 4 Proceedings of the 34th IMAC A Conference and Exposition on Structural Dynamics 2016 1st Edition Matt Allen

https://textbookfull.com/product/dynamics-of-coupled-structuresvolume-4-proceedings-of-the-34th-imac-a-conference-andexposition-on-structural-dynamics-2016-1st-edition-matt-allen/

Sensors and Instrumentation, Aircraft/Aerospace and Energy Harvesting, Volume 8 Proceedings of the 36th IMAC, A Conference and Exposition on Structural Dynamics 2018 Evro Wee Sit

https://textbookfull.com/product/sensors-and-instrumentationaircraft-aerospace-and-energy-harvesting-volume-8-proceedings-ofthe-36th-imac-a-conference-and-exposition-on-structuraldynamics-2018-evro-wee-sit/

Michael L. Mains · Brandon J. Dilworth Editors

Topics in Modal Analysis & Testing, Volume 8 Proceedings of the 37th IMAC, A Conference and Exposition on Structural Dynamics 2019

SeriesEditor KristinB.Zimmerman,Ph.D. SocietyforExperimentalMechanics,Inc., Bethel,CT,USA

Moreinformationaboutthisseriesat http://www.springer.com/series/8922

MichaelL.Mains•BrandonJ.Dilworth Editors

Proceedingsofthe37thIMAC,AConferenceandExposition onStructuralDynamics2019

Editors

MichaelL.Mains

MechanicalandMaterialsEngineering CollegeofEngineeringandAppliedSciences FacultyAdvisor,BearcatMotorsports UniversityofCincinnati Cincinnati,OH,USA

BrandonJ.Dilworth LincolnLaboratory MassachusettsInstofTechnology Lexington,MA,USA

ISSN2191-5644ISSN2191-5652(electronic)

ConferenceProceedingsoftheSocietyforExperimentalMechanicsSeries

ISBN978-3-030-12683-4ISBN978-3-030-12684-1(eBook) https://doi.org/10.1007/978-3-030-12684-1

©SocietyforExperimentalMechanics,Inc.2020

Thisworkissubjecttocopyright.AllrightsarereservedbythePublisher,whetherthewholeorpartofthematerialisconcerned,specificallytherights oftranslation,reprinting,reuseofillustrations,recitation,broadcasting,reproductiononmicrofilmsorinanyotherphysicalway,andtransmissionor informationstorageandretrieval,electronicadaptation,computersoftware,orbysimilarordissimilarmethodologynowknownorhereafterdeveloped. Theuseofgeneraldescriptivenames,registerednames,trademarks,servicemarks,etc.inthispublicationdoesnotimply,evenintheabsenceofaspecific statement,thatsuchnamesareexemptfromtherelevantprotectivelawsandregulationsandthereforefreeforgeneraluse.

Thepublisher,theauthors,andtheeditorsaresafetoassumethattheadviceandinformationinthis bookarebelievedtobetrueandaccurateatthedate ofpublication.Neitherthepublishernortheauthorsortheeditorsgiveawarranty,expressorimplied,withrespecttothematerialcontainedhereinorfor anyerrorsoromissionsthatmayhavebeenmade.Thepublisherremainsneutralwithregardtojurisdictionalclaimsinpublishedmapsandinstitutional affiliations.

ThisSpringerimprintispublishedbytheregisteredcompanySpringerNatureSwitzerlandAG. Theregisteredcompanyaddressis:Gewerbestrasse11,6330Cham,Switzerland

Preface TopicsinModalAnalysis&Testing representsoneofeightvolumesoftechnicalpaperspresentedatthe37thIMAC,A ConferenceandExpositiononStructuralDynamics,organizedbytheSocietyforExperimentalMechanicsandheldin Orlando,Florida,January28–31,2019.ThefullproceedingsalsoincludevolumesonNonlinearStructures&Systems; DynamicsofCivilStructures;ModelValidationandUncertaintyQuantification;DynamicsofCoupledStructures;Special TopicsinStructuralDynamics&ExperimentalTechniques;RotatingMachinery,OpticalMethods&ScanningLDV Methods;andSensorsandInstrumentation,Aircraft/Aerospace,EnergyHarvesting&DynamicEnvironmentsTesting.

Eachcollectionpresentsearlyfindingsfromexperimentalandcomputationalinvestigationsonanimportantareawithin structuraldynamics.TopicsinModalAnalysisrepresentspapersonenablingtechnologiesformodalanalysismeasurements andapplicationsofmodalanalysisinspecificapplicationareas.

Theorganizerswouldliketothanktheauthors,presenters,sessionorganizers,andsessionchairsfortheirparticipationin thistrack.

Cincinnati,OH,USA

Lexington,MA,USA

MichaelL.Mains

BrandonJ.Dilworth

Contents 1ModernModalTesting:ACautionaryTale ..........................................................................1 JamesC.Akers,KimD.Otten,JoelW.Sills,andCurtisE.Larsen

2VibrationTestingofLaparoscopicSurgicalInstrumentsUnderVaryingGripPressures ......................9 AndrewR.Hutchins,SabinoZaniJr.,RobertoJ.Manson,andBrianP.Mann

3CombinedQualificationVibrationTestingandFixedBaseModalTestingUtilizingaFixedBased CorrectionMethod ......................................................................................................13 JamesP.Winkel,VicenteJ. Suárez,andJamesC.Akers

4PressureStiffenedModalCorrelationofaCylindricalPressureVessel ...........................................31 EmilyA.JewellandIsamYunis

5PretestAnalysisforModalSurveyTestsUsingFixedBaseCorrectionMethod .................................39 PeterKerrianandKevinL.Napolitano

6FixingDegreesofFreedomofanAluminumBeambyUsingAccelerometersasReferences

KevinL.Napolitano

7SignalReconstructionfromMobileSensorsNetworkUsingMatrixCompletionApproach ...................61 SoheilSadeghiEshkevariandShamimN.Pakzad

8AllVibrationIsaSummationofModeShapes .......................................................................77 BrianSchwarz,PatrickMcHargue,JasonTyler,andMarkRichardson

9ModalTestingUsingtheSlinkyMethod ..............................................................................93 BrianSchwarz,PatrickMcHargue,andMarkRichardson

10NumericalandExperimentalModalAnalysisofaCantileverBeamAxiallyLoadedbyaTendon WhichIsAttachedinaSingleSpanwiseLocation ...................................................................107 VaclavOndraandBranislavTiturus

11DesigningaModalTestPlanBased onFiniteElementMethodResults ..........................................117 YanCaoandLiuJinming

12MaximizingtheQualityofShapeExtractionsfromBaseShakeModalTests ....................................123 KevinL.Napolitano

13NewApproachestoInverseStructuralModificationTheoryUsingRandomProjections ......................127 PrasadCheema,MehrisadatM.Alamdari,andGarethA.Vio

14ModalAnalysisofWindTurbineBladeswithDifferentTestSetupConfigurations .............................143 E.DiLorenzo,S.Manzato,B.Peeters,V.Ruffini,P.Berring,P.U.Haselbach,K.Branner,andM.M.Luczak

15ModalExcitationofCircularRotatingStructuresUsinganInnovativeElectromagneticDevice ..............153 ThomasHoffmann,MartinJahn,LarsPanning-vonScheidt,andJörgWallaschek

16ModalAnalysisofa7DoFSweetPepperHarvestingRobot .......................................................163 TobiasF.C.Berninger,SebastianFuderer,andDanielJ.Rixen

17CharacterizingDynamicsofAdditivelyManufacturedParts ......................................................171 GaryAdkins,ClaytonLittle,PeterMeyerhofer,GarrisonFlynn,andKyleHammond

18HowLinearIsaLinearSystem? .......................................................................................185 D.Roettgen,B.Pacini,andB.Moldenhauer

19AnInterpolationAlgorithmtoSpeedUpNonlinearModalTestingUsingForceAppropriation ..............193 MichaelKwarta,MatthewS.Allen,andJosephJ.Hollkamp

20EstimatingAppliedLoadsandResponseAccelerationsonaDynamicSystemUsingVibrationData ........197 ErenKoçak,CanerGenço ˘ glu,BülentAcar,andKenanGürses

21AnalysisofCouplingRelationshipBetweenCar-BodyandFlexibleHangingEquipment ......................209 XiaoningCao,XiugangWang,QintaoGuo,AiqinTian,ShaoqingLiu,WeiXue,andJiancaiZou

22Imager-BasedCharacterizationofViscoelasticMaterialProperties ..............................................215 HowardBrand,TiaKauppila,KaylaWielgus,BridgetMartinez,NathanMiller,TrevorTippetts, YongchaoYang,andDavidMascareñas

23DevelopmentandValidationofDataProcessingTechniquesforAircraftGroundVibrationTesting

SilviaVettori,EmilioDiLorenzo,BartPeeters,andAntonioCarcaterra

24StructuralHealthMonitoringwithSelf-OrganizingMapsandArtificialNeuralNetworks

OnurAvci,OsamaAbdeljaber,SerkanKiranyaz,andDanielInman

25ANovelTechniquetoExtracttheModalDampingPropertiesofaThinBlade

T.Mace,J.Taylor,andC.W.Schwingshackl

26FiniteElementModelUpdatingoftheUCFGridBenchmarkConnectionsUsingExperimental ModalData ...............................................................................................................251 MiladMehrkashandErinSantini-Bell

27StructuralHealthMonitoringonIndustrialStructuresUsingaCombinedNumerical andExperimentalApproach ...........................................................................................263 FabianKeilpflug,RobertKamenzky,DanielJ.Alarcón,TarunTejaMallareddy,andPeterBlaschke

28ValidationofAutomaticModalParameterEstimatoronaCarBody-in-White

N.Gioia,Pieter-JanDaems,andJ.Helsen

29ModalAnalysisofRotatingTiresinStationaryandRotatingFramesofReference ............................285 MohammadAlbakriandPabloTarazaga

30CombiningMachineLearningandOperationalModalAnalysisApproachestoGainInsightsin WindTurbineDrivetrainDynamics ...................................................................................293 N.Gioia,P.J.Daems,T.Verstraeten,P.Guillaume,andJ.Helsen

31ModalTest-AnalysisCorrelationUsingLeft-HandEigenvectors ..................................................301 RobertN.Coppolino

32ATheoreticalStudyontheGenerationandPropagationofTravelingWavesinStrings .......................311 IsilAnakok,V.V.N.SriramMalladi,andPabloA.Tarazaga

33ShapingtheFrequencyResponseFunction(FRF)ofaMulti-Degree-of-Freedom(MDOF)Structure UsingArraysofTunedVibrationAbsorbers(TVA) .................................................................317 CampbellR.Neighborgall,KaranKothari,V.V.N.SriramMalladi,PabloTarazaga,SaiTejParuchuri, andAndrewKurdila

34ExperimentalStudyonTireVibrationsandInducedNoise ........................................................327 SterlingMcBride,SeyedmostafaMotaharibidgoli,MohammadAlbakri,RicardoBurdisso,PabloTarazaga, andCorinaSandu

35OntheAdaptiveVibrationSuppressiononaFlexibleSpatialStructure .........................................333 OscarA.Garcia-Perez,LuisG.Trujillo-Franco,andGerardoSilva-Navarro

36EvaluationoftheHuman-Structure-SoilInteractiononaTwo-WheelTractorUsingModalAnalysis Techniques ................................................................................................................341

E.Velazquez-Miranda,G.Silva-Navarro,J.Bory-Reyes,O.A.Garcia-Perez,andL.G.Trujillo-Franco

37ReproducibleModalTestingUsingaFlexure-BasedImpactExcitationSystem

ShivangShekharandO.BurakOzdoganlar

38ModalAnalysisandCharacterizationofMountingCartUsedforTestingintheCombined EnvironmentAcousticChamber .......................................................................................353 MelissaA.Hall

39EffectsofSensorCountonDampingEstimatesfromOperationalModalAnalysis .............................357 EsbenOrlowitz

40AmbientVibrationTestsandModalResponseAnalysisofanOldAgeHigh-RiseBuilding inDowntownVancouver,Canada ......................................................................................365 M.Motamedi,C.E.Ventura,P.Adebar,andR.A.Murugavel

41SystemIdentificationofaFullScaleWoodFrameBuildingSpecimenSubjectedtoShakeTableTests ......369 M.MotamediandC.E.Ventura

42EstimatingRotorSuspensionParametersfromRunoutData ......................................................373 BrianDamiano

Chapter1 ModernModalTesting:ACautionaryTale JamesC.Akers,KimD.Otten,JoelW.Sills,andCurtisE.Larsen

Abstract Overthepast50years,greatadvanceshavehappenedin bothanalyticalmodalanalysis(i.e.,finiteelement modelsandanalysis)andexperimentalmodalanalysis(i.e.,modaltesting)inaerospaceandotherfields.Withtheadvent ofmorepowerfulcomputers,higherperformanceinstrumentationanddataacquisitionsystems,andpowerfullinearmodal extractiontools,today’sanalystsandtestengineershaveabreadthanddepthoftechnicalresourcesonlydreamedofbyour predecessors.However,someobservedrecenttrendsindicatethathardlessonslearnedarebeingforgottenorignored,and possiblyfundamentalconceptsarenotbeingunderstood.Thesetrendshavethepotentialofleadingtothedegradationofthe qualityofandconfidenceinbothanalyticalandtestresults.Thesetrendsareamakingofourowndoing,anddirectlyrelated tohavingevermorepowerfulcomputers,programmaticbudgetarypressurestolimitanalysisandtesting,andtechnical capitallossduetotheretirementoftheseniordemographiccomponentofabimodalworkforce.Thispaperendeavorsto highlightsomeofthemostimportantlessonslearned,commonpitfallstohopefullyavoid,andpotentialstepsthatmaybe takentohelpreversethistrend.

Keywords Analyticalmodalanalysis·Bimodalworkforce·Experimentalmodalanalysis·Finiteelementanalysis· Finiteelementmodel·Lessonslearned·Modaltesting·Retirement

1.1Introduction Analyticalmodalanalysis(i.e.,finiteelementmodellingandanalysis)andexperimentalmodalanalysis(i.e.,modaltesting) haveadvancedgreatlyoverthepast50years.Today’spowerfulcomputers,highperformanceinstrumentationanddata acquisitionsystems(DAQ’s),andpowerfullinearmodalextractiontoolscanprovidetoday’smodaltest/analysisengineer thetechnicalresourcesneededtocompeten tlytacklemost,ifnotall,linearstructuralissues.However,evenwiththisbreadth anddepthoftechnicalresources,today’smodaltest/analysisengineerisstillonlyasgoodastheirtechnicalexpertise.Forus “seasonedveterans”thistechnicalexpertisewasgainedduringthecourseof30+ yearsofworkingandstudyintheaerospace fieldandthroughtheexceptionalmentoring wereceivedfrommanyseniorknowledgeableprofessionals.Itwasthroughthis exceptionalmentoringthatwewereabletoleveragetheexpertiseofthe“seasonedveterans”thatcamebeforeusandavoid makingmanypoor(andquitefranklysimple/unwise)mistakes.Itissaid“Goodjudgementcomesfromexperience,and experiencecomesfrombadjudgement[1].”Unfortunately,ormaybefortunately,organizationsdonothavetheluxuryof beingabletoallowtheirengineerstomakebadjudgements. Thatsaid,recenttrendsobservedinbothindividualengineers andinengineeringorganizationsindicatethehardlessonslearnedoverthepast50yearsarebeingforgottenorignored, andpossiblyfundamentalconceptsarenotbeingunderstood.Thesetroublingtrendshavethepotentialofleadingtothe degradationinthequalityofandconfidenceinbothanalyticalandtestresultsandincreaserisktotheproject.Ifthishappens thecredibilityandefficacyofourengineeringprofessionwillcomeintoquestionandmissionsmaypotentiallysuffer.

Tosomeextent,theseproblemsareamakingofourowndoing.Withtheadventofmodernportablehighpowercomputers anduserfriendlyautomatedsoftware,itisrelativelyeasyforanoviceengineertogenerateacomputeraided-design(CAD) modelofastructure,automeshittogenerateafiniteelementmodel(FEM),andperformstaticandmodalanalysis

J.C.Akers( )·K.D.Otten

NASAGlennResearchCenter,Cleveland,OH,USA e-mail: james.c.akers-1@nasa.gov

J.W.Sills NASAJohnsonSpaceCenter,Houston,TX,USA

C.E.Larsen

DepartmentofEngineering,TexasChristianUniversity,FortWorth,TX,USA

©SocietyforExperimentalMechanics,Inc.2020

M.L.Mains,B.J.Dilworth(eds.), TopicsinModalAnalysis&Testing,Volume8,ConferenceProceedingsoftheSocietyfor ExperimentalMechanicsSeries, https://doi.org/10.1007/978-3-030-12684-1_1

(i.e.,computestresses,strains,modalfrequencies,andmodeshapes).Alsoanoviceengineercancollecttestdata(i.e., force,acceleration,andstraintimehistories),postprocessit,andextractmodalparameters(i.e.,modalfrequencies,mode shapes,andmodaldamping).Inaworkforcewherethereareampleseasonedengineeringprofessionalshelpingtoguide andmentorlessexperiencednoviceengineerstoavoidcommonpitfallsandreinforcetheunderlyingengineeringtheoretical concepts,thesemoderncapabilitiesareatrueasset.Eveninorganizationsthathaveabimodalworkforcewherethereare mostlyveryseasonedandverynoviceengineers,amplementoringcanhelptomakeupfortheshortfallofnothavingmany, ifany,mid-careerengineers.Howeverinorganizationswherethecurrentandforeseeableprogrammaticbudgetarypressures arelimitingtheamountofanalysisandtesting,combinedwiththeirtechnicalcapitallossduetotheretirementoftheirsenior seasonedprofessionals,whichcurtailsmuchneededmentori ng,theearlycareernoviceengineersareleft“notknowingwhat theydon’tknow”.Whilethefocusofthispaperisonaerospaceengineersperformingmodal/vibrationtestingorperforming analysiswithFEM’s,theconcernsdiscussedhereapplytomanyengineeringdisciplines.Thegoalofthispaperistoprovide earlycareernoviceengineerswithsomekeyconceptstohelpavoidthemostcommonpitfalls,andtoprovideboththem andeveryoneintheirorganizationpotentialstepsforensuringtheirorganization’stechnicalexpertiseremainsviableandthe aerospaceengineeringprofession remainsvibrantandrelevant.

1.2Pitfall#1:ConfusingComputerJockeysandEngineers Asengineerswemustunderstandthekeyfundamentalphysicsbasedconceptsthatunderpinouranalysisandtestingand realizethatsoftwareandhardwarearetools,notcrutchestomakeupforourlackofunderstanding.Wemustbeableto notonlyprovideresults,butbeabletoverifyandvalidatethoseresults.Beingabletomake“simplebackoftheenvelope calculations”isofparamountimportancetoprovidesanitychecks.Thisisevenmorecritical intoday’sworkenvironment whereengineersareincreasinglyoperatingasan“armyofone”andthedoublechecksandfactcheckingthatoccurredin thepastarehappeninglessandlessfrequently,ifatall.If youcandrawthefreebodydiagramofasingledegreeoffreedom (SDOF)oscillator,deriveitsequationofmotion,solveforits impulseresponsefunction,solveforthefrequencyresponse function,beabletoplotthesefunctionsandunderstandthem,youare90%ofthewaytounderstandingmostvibration problems.Theoldadage“KeepItSimpleandStraightforward”(KISS)isasrelevanttodayasinthepast.Startsimplyin youranalysis/testingandonlyaddcomplexityasneeded.Don’tconfusecomplexityforsophistication.Manytimesthemost sophisticatedsolutionmethodisthesimplest.Remember,wewenttotheMoononFEM’shavingonlycenterlinegridpoints andbeamelements,morecommonlyreferredtoas“ball-stickmodels.”TheSaturnVlaunchvehiclewasinitiallymodeled inthismannerduringtheApolloprogram[2, 3].Somehowmilliondegreeoffreedom(DOF)FEM’swerenotrequired(and neitherwastheInternet).

1.3Pitfall#2:TooMuchBlindFaithinFEM’s “AllMODELSAREWRONGBUTSOMEAREUSEFUL[4].”Thisblindfaithisthedirectresultofhavingextremely powerfulcomputersallowingrelativelynoviceengineerstogenerateCADmodelsthatlookexactlylikethehardwareand inturnusingautomeshfeaturestogenerateFEM’sthatlookexactlylikethehardware.“Prettypicturesdonotagood modelmake.”ThishasledsomedecisionmakerstobelievethataccurateCADmodelsandFEM’scanbeaccomplished withinexperienced(a.k.a.inexpensive)engineers.This issimplynottrue.AfinelymeshedFEMdoesnotguaranteeit accuratelycapturesthestructuralcharacteristics(i.e.,loadpaths)oftheactualhardware.Itonlymeansthesamemodelling assumptionshavebeenmademany,many,manytimesandiftheseassumptionsareincorrectthentheresultingFEMwill stillbeinaccurate.AlsothereisacurrenttrendofusingthestressFEMastheloadsFEM.ThestressFEMhasveryfine meshingtoaccuratelycapturetheintricaciesofstressfieldsaroundjointsandfasteners.TheloadsFEMdoesnotrequireas fineameshingsinceitisintendedtocapturethestructural dynamicpropertiesandneedstoallowreasonablemodalanalysis runtimes.ThevalidityofCADmodelsandFEM’sishighlydependentupontheproficiencyandexperienceoftheengineer generatingthem.TheengineergeneratingtheFEMneedstousetheappropriateelementsinsteadofsimplyrelyingonautomeshingthatpickselementtypesbaseduponeaseofmeshinginsteadofthebehavioroftheunderlyingstructure.Similarly, theFEMautomaticsinglepointconstraint(AUTOSPC)featureshouldbeavoidedsotheengineerisforcedtounderstand whatDOFareconstrainedandunconstrainedintheFEMandwhy.RememberthatuntilaFEMhasbeen“grounded”to testdata(i.e.,correlatedtostaticandmodaltestdata),itsaccu racy/validityisuncertain.Incorporationofstatictestresults intoaFEMcorrelationtoobtainthecorrectstiffnessishalfthebattle—neverforgetthedynamicsideoftheequation

(i.e.,squareroot(k/m)).Formodaltestingpretestanalysis,thismeanshavingahealthyskepticismoftheFEMaccuracy andalwaysincorporatingmarginintotestpreparations(e.g.,skewingshakerstohelpensurethatallTargetModeswillbe adequatelyexcited,instrumentationattheboundarytoverifytheboundaryconditionsduringtesting,usingengineering judgementalongwithsuchtoolsasiterativekineticenergytoselectinstrumentationlocations).

1.4Pitfall#3:ConfusingBeingBusywithBeingProductive Avoidconfusingbeingbusywithbeingproductive.Peoplenaturallywanttofeelthattheyaremakingprogresstowards reachingtheirendgoalanditisnaturaltoassumethatiftheyarebusydoingsomethinginsteadofbeing“idle”,thentheyare surelymakingprogress.Nottrue.Takethenecessarytimetoplan,prioritize,anddefinetheobjectives,goals,andsuccess criteriaofthetask.Thiswillallowyoutofocusyourtimeand resourcestogiveyouthehighestprobabilityofsuccessfully completingyourtask.Notetherearenocertaintiesandyoumustrealizethatyoudonotcontroleverything.Hence,wecan onlyspeakofprobabilitiesandlikelihoodsofsuccess.

1.5Pitfall#4:AvoidRushingtoAnalyze Itisverytemptingwhenfirstgivenamodelordatatowanttojumprightinandstartperformingyouranalysis.SeePitfall #3.However,itisimportanttoperform“sanitychecks”onanymodelsordatapriortoperforminganyanalysisinorder toavoidworkingforweeksonlytodiscoveritwasallfornaughtbecauseofeitherafaultymodelorcorrupteddata.Be skepticalofFEM’sprovidedtoyouandperformyourownstandardmodelchecks,especiallyifthepreviousFEManalysis residesinadifferentversionofsoftwarethanyouareusingbecausedefaultsettingscanchange[5].BesuretheFEMhas beenvalidatedtomatchtheCADoras-builthardware.AFEMisnotvalidjustbecauseithasbeen“correlated”tomodal parametersextractedfromamodaltestorresultsfromastaticstiffnesstest.TakingthetimetomatchtheFEMtotheCAD oras-builthardwareisabsolutelycritical foraccuratelycapturingtheloadpathsandbeingabletopredictinternalloads[6]. Moreover,whentheFEMmatchestheCADoras-builthardware,90–95%ofthemodelcorrelationeffortisachieved.Ifthe FEMdoesnotaccuratelyrepresenttheCADoras-builthardware,themodelcorrelationeffort, whilebeinginaccurate,most likelywillalsobeextremelydifficultandtimeconsumingandprobablyleadtounmetrequirementsandscheduleconstraints. BesureyouunderstandtheunitstheFEMisinandthedataunits.Eventhoughitisthetwenty-firstcentury,manyFEM’s generatedandusedbyUScompaniesstillhavemassinunitsofslinchesandslugsandaccelerationdatacanbeinunitsof in/s2 org’s.Don’tforgetfrequenciescanbeinunitsofrad/sorHz.Whendoingyourchecks,ifyouareoffbyafactorof 9.8,thisisprobablyanaccelerationunitsissueandifyouareoffbyafactorof6.3(i.e.,2π),thisisprobablyafrequency unitsissue.

Similarlybeskepticalofdataprovidedtoyou,andifpossible,performtime-domainand frequencydomaindataquality checksasappropriate.Askquestionstotheentityprovidingthedataforpoofofitsvalidity.Forexample,iftimehistorydata hasbeensuppliedandhaseitherbeenclippedorisinthenoisefloorofthedataacquisitionsystemthatwasusedtorecord it,blindlypostprocessingitintospectrawillleadtoverymisleadingspectra,whichisnotself-evident.

Taketimethroughoutyouranalysistoperformintermediatechecks.Withtoday’ssoftwareitisveryeasytoplotresults andgeneratetabularlistings,whichprovidequickandinsightfulcheckingmethods.Forexampleifyouarefilteringtime histories,besuretocomparethefrequencyresponsefunctionofthefiltertothePowerSpectralDensity(PSD)computedon broadbandrandomwhitenoisethathasbeenpassedthroughittoverifythefilter.Itisveryeasyintodesignfiltersthathave verytightpassbands,butarenumericallyunstable.Itisofcriticalimportancetobeabletocompute“backoftheenvelope” calculationsforprovidingatleastcursorysanitychecksofanalyticalresults.Sometechnicalreferencestoconsiderarelisted in[7–24].Documentingtheseintermediateandfinalchecksconstitutetheimportantportionofyouranalysisreportthat verifiesthevalidityofyouranalysisresults.Attheendoftheday,itisyournameandreputationthatisontheline,and itonlytakesoneortwobadanalysestogiveyouanegativereputationinyourorganization,whichcanbeveryhardto overcome.

1.6Pitfall#5:AvoidRushingtoTest Settingupamodaltestandperformingit,canbebothaveryexhilaratingandstressfultime.Itinvolvesphysicalexertion (e.g.,movingshakers,mountingaccelerometers,runningcabling,beinginanunfamiliarlocale),uppermanagementand programmaticpersonnelbeingpresentto“witness”thetesting(i.e.,lookingoveryourshoulder,beinginafishbowl),and havingaverylimitedtimewindowtoaccomplishit.Becauseofthis,itisverynaturaltowanttostartcollectingdataas quicklyaspossible,andinturntostartextractingmodalparametersasquicklyaspossible.However,aswithanalysis,itis importanttotaketimetoverifythetestsetupandthevalidityofthedatabeingcollected.BesuretheDAQhasanti-aliasing filteringengagedandoperating.Withtheadventoffasterandfastercomputers,acommonmisconceptiongoingaroundis thatyoucansamplesofastthataliasingisnolongeranissue.Nottrue.Aliasingwillalwaysbepresentwhateverthesampling rateisandoncetherecordedtimehistorieshavebeencorruptedbyaliasingitisimpossibletocorrectthem.Takethetime toperformtime-domainandfrequency-domaindataqualitychecksduringtestingtoverifythehealthofthechannelsand validityofthetestsetup.

Timedomainchecksshouldincludevisualinspectionofthetimehistories,lookingfordatadropouts,digitizationerror (i.e.,fullscalesettingoftheDAQsettoohigh),clipping(i.e.,fullscalesettingoftheDAQsettoolow),adequatelycapturing peaksinthefrequencyrangeofinterest,andimpulsivespikes indicatingrattlingand/orimpactingtakingplace.Computing standardstatisticssuchasmean,standarddeviation,kurtosis,andcrestfactoronrandomexcitationtestrunsprovideaquick andusefulchecktodetermineifnonlinearbehaviorispresent[25].Keepinmindthatcrestfactors(i.e.,peakdividedby standarddeviation)duringvibrationtestingcanreachashighas 5ormore.However,extremelyhighcrestfactorsandkurtosis mayindicateimpulsivespikesinthetimehistoriesofchannelsgoingbadormeasuringsignificantrattling/impactinginthe testarticle.Itisimportanttomonitorchannelsinrealtimeastheyarebeingacquiredtocheckforunderflow,overflow, excessivemean,signaldrift,andimpulsivespikes.IftheDAQgeneratesanautomaticchannelfaultlog(i.e.,deadchannel, overflow,underflow,etc.)takeadvantageofthisimportantfeature.

Frequencydomainchecksshouldincludeverifyingthedrivepointfrequencyresponsefunction(FRF)hastheexpected phaseanglebehavior(i.e.,foraforcetoaccelerationFRFiftheaccelerometerhasthesameorientationastheloadcellthe phaseanglestaysbetween 180◦ and 360◦ overthedesiredfrequencyrange).ChecktheinputexcitationforcePSDand comparetheresponsePSD’stotheirambientbackgroundlevelstoverifytheexcitationhassufficientfrequencybandwidth andlevel.Checkthecoherenceplotstoverifytherearelinearrelationshipsbetweeninputexcitationforcesandresponses confirmingtheadequacyoftheinputexcitationforcelevel.ChecktheFRFforexcessivehashiness,indicatingeithertoo lowaninputexcitationforceleveland/ornonlinearbehaviorinthetestarticle.AretheFRFresonancepeakssymmetric andwell-shapedoraretheytippedtotherightorleft(i.e.,“sharkfin”pattern)thatindicatesnonlinearbehaviorinthe testarticle?PSDorFastFourierTransform(FFT)waterfall plots(alsocalledspectrograms)areaveryusefultoolfor determiningiftestarticleisbehavingnonlinearlyoritsstructuraldynamicsaretimevarying,whichmayindicatedegradation ofitsstructuralhealth(i.e.,damageisoccurring).KeepinmindthatPSDorFFTwaterfallplotscomputedonsinesweep datamayhavesubharmonicorsuperharmoniccomponentsthatareduetothenonlinearbehavioroftheinputexcitation. Whileelectrodynamicshakerscanbepredominantlylinear,astheyaredriventohigherforcelevelstheywillalsobecome nonlinearduetolargedisplacementoftheiralignmentflexures.Hydraulicshakers,whichhavetheadvantageofbeing abletoprovidehigherforcelevelsatlowercostthanelectrodynamicshakers,typicallyhavesignificantlyhighernonlinear behaviorthanelectrodynamicshakersgiventhesamedrivesignal.However,pre-distortingahydraulicshaker’sdrivesignal cansignificantlyreducetheamountoftotalharmonicdistortionintheforceitgenerates.

Besuretoinstrumentthesupportstructurethetestarticleismountedtoinordertoverify/measurethetestboundary conditions.Thisistrueforbothmodalandvibrationtesting.Whilefloors,strongbacks,sliptables,andexpanderheadsmay beverystiff,theytypicallydoexhibitsomeflexingorrigidbodymotionduringtesting.Withoutthisboundarycondition information,deflectionsinthesupportstructurecannotbeseenintheextractedtestmodeshapesandanysubsequentFEM modelcorrelationwillerroneouslyattributesupportstructureflexibility/dynamicstothetestarticle.

Acquiringambientbackgroundlevelsatleastatthebeginningandendofeachtestday,andpriortoeachnewtest configuration(e.g.,movingofshakersoraccelerometers,reconfiguringthetestarticle)isvitalinbeingabletounderstand theambientbackgroundlevelandtoverifythehealthofthetestsetup.Havingtheambientbackgroundlevelwillalsohelp determineminimuminputexcitationlevels,whichavoidswastingtimeperformingmodaltestingwithinputexcitationlevels beingtoolow.Keepinmindthatiftheresponsesignalsareinthenoisefloor,noamountofaveragingisgoingtoclean themup.Manytimeshighambientbackgroundlevelsareduetoflorescentlighting,heating,ventilation,andairconditioning (HVAC)running,andpumpsandmotors operatinginadjacentrooms.Turningtheseoffortestingwhentheyarenotin operationcansignificantlydroptheambientbackgroundlevels.Thisiswhymanymodaltests,sincetheyneedtomeasure verylowlevelresponses,areconductedduringoff-shifthoursand/oronweekends.

OnceapreliminarysetofFRFhavebeen computed,ifpossibleextractanoperatingdeflectionshapeatafrequency wellbelowthelowestresonancepeakfrequencyandanimatethiswithyourTestDisplayModel(TDM).Thisprovidesa quickvisualcheckthattheaccelerometershavebeensetupcorrectly(i.e.,location,orientation,sensitivity).Itisstrongly recommendedthatallofthesechecksbedoneatthestartofthemodaltesttoverifythevalidityoftheentiretest setup.Ifthesechecksarenotfirstcompleted,typicallywhathappensisthaterrorsarediscoveredafewatatimeover thecourseofseveraltestruns.Thisinturnquicklyleadstoabookkeepingheadacheofhavingtogoback,ifpossible, andcorrectnotonlytheoriginaltestdata,butallofthepostprocessedresultsgeneratedfromthatcorruptedtestdata (i.e.,FRF,modeshapes,etc.).

Performlowlevelrandomorsinesweepcharacterizationtestrunsbeforeandafteranyhighlevelmodalorvibration testingtomonitorthestructuralhealthofthetestarticle.Thisisnecessaryinordertobeabletodetermineifobservedshifts intheFRFresonancepeaksatdifferentinputexcitationlevelsisduetoapermanentchangeinthetestarticle(e.g.,damage, settling)orisduetononlinearbehavior(e.g., jointsbreakingfreeandslipping).These preandpostcharacterizationtestruns alsoanswertheimportantquestionofwhetherthemodal/vibrationtestaffectedthestructuralhealth/characteristicsofthe testarticle.

Whenperformingamodalhammersurvey,startwiththesoftesthammertipandonlygoontostiffer/hardertipsifneededto obtainthedesiredfrequencybandwidth.Stiffer/hardertipsexcitehigherfrequenciesandmorestronglyexcitenonlinearities inthetestarticle,whichdegradestheFRF,andproducesresponseswithhigherpeakresponses,whicheatsupdynamicrange ontheDAQ.

1.7Pitfall#6:LackofDocumentation Forboththeanalystandtestengineeritisvitaltokeeparunninglogofyourwork.Fortheanalystthiscanbearunning summarymemothatdocumentsyourdailywork,whichshouldincludethemodelsused,theresultsgenerated,filelocations, andimportantfindings.Forthetestengineerthiscanbeatestlog,whichincludesthedataacquisitionandpostprocessing parameters,channeltable,testrunlog,andfilelocations.Photodocument(includinglabels)asyougothroughoutthetest. ThereisNOexcusewiththeproliferationofexcellentdigitalcamerasandcellphonecamerastoNOThaveanabundanceof photographicevidence.Generatingquicklookmemos/reportsaftereachmajortestingphasehelpstokeepallstakeholders informedastotestingstatus/progress.Startwritingthedraftofthetestreportandtestpresentationasyougoduringthetest sothatkeyresults,lessonslearned,andkeyinsightsarecaptured.Thesedraftsshouldbe90%completebytheendofthe test.Itisverydifficulttorememberdetailssometimesevendayslater,letaloneweeksafteratesthaswrappedup.Forboth theanalystandtestengineer,thisdocumentationformsthefoundationofyourpersonaltechnicalencyclopediaoftechnical knowledgeandaccomplishments,whichyoucandrawandbuilduponasyourcareerprogresses.Youtypicallywillencounter manysimilartasksthroughoutyourcareer,andyourtechnicalencyclopediawillbeaninvaluableassettoyou.

1.8Pitfall#7:DesigningOnlyforDesignLoads Hardwareneedstobedesignedforalloftheenvironmentsitwillbeexposedto,whichincludesnotonlydesignloads(i.e., maximumexpectedflightenvironment(MEFL)),butalsotestingloads,whichinthecaseofvibrationqualificationtesting maybeMEFL +3dB[26].Ideallytheassociateduppertesttolerance(e.g.,forrandomvibrationtestingtheacceleration PSDtesttoleranceis +3dB)shouldalsobeincludedinthedesignsothatiftheachievedtestlevelexceedsthenominaltest level,whichoftenoccurs,testingdoesnotneedtobesuspendedwhileananalyticalassessmentofthehardwareismade. Inadditionthehardwareneedstobedesignedsothatitcan bemountedfortesting,whichmeansdiscussionswiththetest labandthedesignerofthetestfixturing.Manytimesthetestfixtureisnothingmorethananadapterplatethatgoesfrom thebolt-holepatternofthehardwaretothebolt-holepatternofthesliptable/expanderheadofthefacilityshaker.Formore complicatedtestfixturing,verifythetestfixturedoesnotintroduceunwanteddynamicsduringtesting(i.e.,theintegrated hardwareandfixturehavemodesdifferentfromthefixed-basehardwareoverthetestfrequencyrange).Modesintroducedby thetestfixturehavetwodetrimentaleffects.First,isthatthesemodesmayproducenarrowbandvibrationenvironmentsthat significantlyexceedwhatthehardwarecanwithstand.Second,is thatthetestfixtureactsasalowpassfilterandattenuates thevibrationenvironmentthehardwareseesabovethefrequenciesofthesemodesandthereforeleadstoundertesting.For forcelimitedvibrationtesting,thehardwaremountingtabsneedtonotonlymeetstiffnessrequirements,butalsoneedtobe ofsufficientsizetoproperlyinterfacewiththeloadcellsusedtomeasurethetotalamountofforcegoingintothetestarticle.

1.9Pitfall#8:ModalAnalysisNotAccountingforOut-of-BandDynamics

Residualvectors,orequivalentlyamodeaccelerationapproach,needtobeincludedinanyanalysisuntiltheyareshown tobeunnecessarytoaccountforstructuraldynamicsthatlieout-of-bandthefrequencybandofinterest.Notaccountingfor structuraldynamicseitherbeloworabovethefrequencyrange ofinterestcanleadtowildlyinaccurateFEMresults.Inmodal testingpretestanalysiswhereinitialshakerlocationsandorientationsareselected,residualvectorsareneededtoaccountfor potentiallysignificantcomplianceinthetestarticleattheshakerdrivepoints.Notincludingresidualvectorscanerroneously leadthemodaltestengineertooverpredicthowwellthetargetmodeswillbeexcitedandthereforeleadtopoorlychoosing theinitialmodalshakerlocationsandorientations,whichinturnwillleadtomajorchangesintheshakersetupsduringthe modaltestandpossiblynotbeingabletomeetscheduleorexcitealltargetmodes.

Ifpossible,considertherealenvironmentsuseddoderivethedesignloads.Dotherealenvironmentshavesignificant frequencycontentoutsidethefrequencyrangeofthedesignloads?Isthetypeofdesignloadconservativewithrespectto thetime-domaincharacteristicsoftherealenvironments(i.e.,istheenvironmentrandomandstationaryorisittransient)? Doestheanalysisproduceresultsthatareconservativeenough, butnottooconservative,toaccountforout-of-bandenergy anddifferencesbetweentherealenvironmenttypeandthatofthedesignloads?

1.10Pitfall#9:AskingforHelporSeekingAdviceIsaSignofWeakness Acommonmisconceptionisthataskingforhelporadviceisasignofweaknessandincompetence.Nottrue.Nooneknows everything,especiallynewerandlessexperiencedengineers.Eventhemoreexperienced“seasoned”engineersfallintothis category,buttheytypicallyunderstandwhatquestionstoask.Alwaysunderstandthatyou“donotknowwhatyoudon’t know”.Askingcolleaguestolookoveryourworkoraskingforadviceisanexpectedandwelcomedbehaviorinahealthy organization.Seniorengineerswanttosharetheirexperience,knowledge,andinsights.Unfortunately,duetocurrentand foreseeablebudgetarypressures,noviceengineersaremanytimesnotbeingpaireddirectlywithseniorengineersleadingto thenoviceengineersnothavinganaturallyoccurring“apprenticeship”periodearlyintheircareers.Therefore,unfortunately theburdenfallsonthenoviceengineerstoactivelyseekouttheadviceoftheirseniorcolleagues.Apprenticeshipisimportant andneedstoonceagainbecomeanorminengineering.Makethatconnection!

1.11Pitfall#10:StovePiping:SeparatingAnalystsandTestEngineers Thisisquiteacommonpracticethatleadstotensionandpotentialdisconnectsbetweentheanalysisandtesting groups/personnel,diminishesthetechnicalprowess/capabilityof theorganization,andaddsrisk toprograms.Havinganalysts supportingtestingprovidesthemwiththemuchneededaccesstotheactualhardwareandtheabilitytogainadeeper appreciation/understandingfortheassumptions/simplificationstheyhaveincorporatedintotheirFEM.Italsoprovides analyststheopportunitytoseefirsthandthechallengesthetestengineerfacesconductingvibration/modaltesting(e.g., mountinginstrumentationandshakers,obtainingvalid/qualitytestdata,extractingmodalparameters,etc.)Theanalystalso gainsinsightintothefundamentalstructuraldynamiccharacteristicsofthehardwareinitstestconfiguration.Likewise, testengineersperforminganalysisgainanappreciationoftheworkthatwentintogeneratingtheFEM’s,particularlythe assumptionsaboutjointsandconnections,whichheavilyinfluencethemodalcharacteristics.Thetestengineersalsogain insightintothechallengesassociatedwiththecomplexityandsophisticationoftheanalyticalwork.Iencourageyou,ifgiven theopportunity,todobothtestandanalysiswork.Itwillonlymakeyouamoreexperiencedandknowledgeableengineer andtechnicallystrengthenyourorganization.

Anotherrelatedpoorpracticeisnothavinginterdisciplinaryteams(i.e.,“TigerTeams”)incorporatedintoprograms, particularlyattheirstart.TigerTeamscoverallaspectsofapieceofhardwareincluding:design,analysis,testing,operation, anddecommissioning.Thisunfortunatepracticeisagainpartly duetocurrentbudgetarypressuresandthemisconception thatTigerTeamsaremorecostly.WhileitistruethatTigerTeamsmaycostmoreduringtheinitialphaseofaprogram,they actuallyreducetheoverallprogramcostbyhelpingtoensurea goodinitialdesignandawelllaidoutplanforthesubsequent analysis,testing,operation,anddecommissioningaredeveloped.Startingwithapoorinitialdesigncanbeverycostlyto remedy,especiallythelaterintheprogramitsshortfallsareidentified.Ifyouarepresentedwithanopportunitytoserveona TigerTeam,doso!Thiswillhelpyoudeveloptheabilitytoeffectivelycommunicateandworkwithotherdisciplines,which iscriticaltobothaprogram’sandorganization’ssuccess.

1.12Pitfall#11:TestIsaFourLetterWord Duetoacombinationofcurrentbudgetarypressuresanddecisionmakersbecominglesstechnicallyknowledgeable, thereistremendousschedulepressuretoreducetheamountofanalysisandespeciallytheamountoftesting.Acommon misconceptionisthattestingincreases aprogram’scost,whichisnotaccurate[27].However,becauseatesthasawelldefinedresourceallocation(i.e.,cost,personnel,andschedule),thismakesitveryeasyfordecisionmakerstobelievethat cuttingtestingwillsavetheprogramtimeandmoney.Unfortunatelytestingprovidesinformationaboutthehardwarethatis simplynotavailablefromunverifiedandunvalidatedFEM’s.HencetheresidualriskintheFEM,whichmanytimesisnot wellunderstood,mustbecarriedalongandtypicallyresultsinhavingtoincorporatinghigheruncertaintyfactors.Manytimes thesehighuncertaintyfactorsinturnleadtopredictednegativestructuralmargins,whichleadstoredesignorde-scopingthe hardware’sperformance.

Ifpossible,piggyback“mini-modal”hammerorbasedrivemodaltestsontoexistingplannedcomponentandsubassembly vibrationteststogaininsightearlyintheprogram.NotonlywillthisallowtheseFEM’stobetestcorrelated,butitservesas avitalcheckonthedesignandidentifiesproblemsearlywhentheyarelesscostlyandtimeconsumingtofix.Alwaystryto implementthephilosophyofbuildfromthefoundationUP,notfromthefinalconfigurationtopDOWN.However,becareful ofnotfallingpreyto“testsofopportunity”andthe“somethingisbetterthannothing”approach,whereshortcutsaretaken duetolackoffundingandscheduleresultingintestsbeingpoorlyplannedandexecuted.Decisionmakersmaysee“testsof opportunity”providingriskreductiontotheprogram,wheninrealitytheirresultsmaybeatbestconfusingandmostlikely misleading.

Becauseofthiscurrentenvironment,engineersneedtonotonlycommunicatetodecisionmakersthe who, what, when, and where,butmostimportantlybeabletosuccinctlyexplain why themodalorvibrationtestisneededandthevaluethey bringtotheprogramintermsofreducingrisk(i.e.,increasingconfidencethesystemwillsatisfactorilyperformgiventhe program’sriskprofile).Risk,schedule,andcostisthelanguageofdecisionmakersandengineersneedtobecomfortable andproficientintalkingintheseterms.Beingabletosuccinctlyconveyessentialconceptsineasilyunderstandablelanguage iscriticaltothesuccessofbothyou,yourorganization,andthe project/programyouareworkingon.Beabletoadvocatefor the“right”testandtoconveytheassociatedriskwitha“testofopportunity”.Alwayshavea“30secondelevator”speech inthebackofyourmindreadytogo.Youcanbepulledintohighlevelmeetingsatamoment’snotice,andnoneofthe attendeesmayhaveanytechnicalknowledgeinyourarea.

1.13Pitfall#12:UnrealisticSuccessCriteria Whetheritbeforananalysistaskorforamodal/vibrationtest,ifatallpossibledefinethesuccesscriteriaatthevery beginningandgetagreementfromallstakeholders.Alongwiththesuccesscriteriaidentifythereceivables,taskscope,task schedule(i.e.,milestones),andthedeliverables.Formodalpretestanalysisthesuccesscriteriaincludesproperselectionof theTargetModes,excitationmethods(i.e.,shakerandhammer)andlocations,testDOFset(i.e.,ASET-NASTRANanalysis setofconstrainedboundaryDOF)andtheassociatedTDM,typesofinstrumentation,DAQothercomputerresources, andtheformatthemodaltestresultswillbedeliveredtothecustomer.Ifmodalshakerswillbeused,thisalsoincludes thecoordinationofhowtheseshakerswillbesupported/suspendedduringthemodaltest,whichmanytimesisthemost challengingaspectofanymodaltest.Alwaysleavealittlemargininthetestschedule(i.e.,successoriented)becauseno testgoesexactlyaccordingtoplanandtasksalwaystakelongerthanexpected.Atooaggressivetestschedulecanresultin needingtosupportlongtestinghours,whichleadstoincreasedstress,whichleadstosleepdeprivation,whichleadstothe testteammakingmistakes,whichleadstotestingdelays,whichleadsbacktolongtestinghours.Notagoodsituation.

Sometimestherereallyarenofirmrequirements.YouhavebeencalledinbytheCustomer,whoonlyknowsthatthey haveaproblem,buttheydon’tknowthecausenorhavetheyseenitbefore,butneeditfixedrapidly.Ifpossibleacquiredata duringoperationwhentheproblemisoccurring.Bemindfulthecauseoftheproblemmaybespatiallyand/ortemporally separatedfromthepartthatisfailing.Inthecaseofelectroniccomponents,eventhoughfailureoccurredduringavibration fatiguetest,thecauseofthefailurecanbeduedamageincurredduringtheprecedingthermaltest[20, 21].

ManytimestheCustomerhasatestingrequirementlevieduponthemfromacompanyorprogram,buttheythemselves donotfullyunderstandnorappreciatetheeffortneededtomeetthisrequirement.Asthetestengineer,youprovidethatvital roleof“technicalrequirementstranslator”informingtheCustomerofthetypeandscopeoftestingthatisrequiredandhow thisfitsintotheoveralltest/analysisprogramrequirements.Besuretoaccountforthisinyourworkestimate,becausethis cantakesignificanttime(e.g.,needtosupportreviewpanelsandtechnicalmeetings).

Modaltestingextremelylargehardwaremayalsorequireaforcedresponseanalysistoensuretheselectedexcitation methodandlocationscanproduceresponselevelsthroughoutthetestarticlethatare“significantly”abovetheambient

background.Theambientbackgroundisacombinationoftheambientvibrationlevelsinthetestarticle,sensorand DAQnoiseandsignaldrift,andtheambientelectromagneticenvironment.AsstatedearlierinPitfall#5,thismayrequire performingthemodaltestduringoff-shifthoursand/oronweekends.Itmayalsorequireusingagreaternumberofexciters (e.g.,modalshakers),largerexciters,orinstrumentationthatismoresensitive.Understandingboththeambientbackground andthetestarticle’smodaldampingcharacteristicsarecriticalinthisassessment.

Inallpretestanalysis,thereneedstobeahealthydoseofskepticismandsomeconservatismaddedbecausethepretest analysisisbaseduponanuncorrelatedFEMandassuming perfecttestboundaryconditions.Theselectionofthetest DOFneedstobedonejudiciouslyandsparinglybecausemoreinstrumentation doesnotguaranteebetterself-orthogonality (ORTHO)/cross-orthogonality (XORTHO),infactinmanycasesitcausessignificantdegradation.Alsomoreinstrumentation requireslongerinstallationandremovaltime,moreeffortduringtestingtokeepthemhealthyandfunctioning,extracostto purchase/renttheextrainstrumentationandtheassociatedDAQchannels,andincurstheextraburdenofhandlinglarger sizedfiles.Always,asafinalcheckoftheselectedtestDOF,displaytheTargetModes(i.e.,selectmodesofinterestthat containthefundamentalcharacteristicsofthetestarticleneededtoachieveawell-correlatedFEM)withtheTDM.TheTDM shouldonlycontainthegridpointswhereinstrumentationisinstalled.IftheTDMdisplayoftheTargetModesdoesnotmake intuitivesense,thenthetestDOFset(i.e.,ASET)needstobefurtherrevised.

1.14Conclusion Theadvancementsmadeinbothanalyticalandexperimentalmodalanalysisintheaerospacefieldisbeyondamazing.This isanexcitingtimeforcollegestudentsstudyingtogointoandnewengineersenteringthisfield.Thispaper,byidentifying 12specificpitfalls,willhopefullyserveasaguidetobothgroupstohelpensuretheyhaveasuccessfulcareerbypointing outsomeofthemostcommonpitfallsandmisconceptions.Wellinformed,theirenergy,enthusiasm,anddrivewillleadto theaerospaceengineeringprofessionremainingviable,vibrant,andrelevant.

References 1.Brown,R.M.:AlmaMater.RandomHousePublishingGroup,NewYork(2001)

2.Grimes,P.J.,McTigue,L.D.,Riley,G.F.,Tilden,D.L.:AdvancementsinStructuralDynamicTechnologyResultingfromSaturnVPrograms. NASA-CR-1539,VolumeI(1970)

3.Grimes,P.J.,McTigue,L.D.,Riley,G.F.,Tilden,D.L.:AdvancementsinStructuralDynamicTechnologyResultingfromSaturnVPrograms. NASA-CR-1539,VolumeII(1970)

4.Box,G.E.P.:Robustnessinthestrategyofscientificmodelbuilding.In:Launer,R.L.,Wilkinson,G.N.(eds.)RobustnessinStatistics.Academic Press,NewYork(1979)

5.Rose,T.:Yourmodeliswrong.NESCLoads&DynamicsTechnicalDisciplineTeamFacetoFace(2018)

6.Kabe,A.:Modesurveytestsandmodeshapeorthogonalitychecks.NESCLoads&DynamicsTechnicalDisciplineTeamFacetoFace(2018)

7.Avallone,E.A.,BaumeisterIII,T.:Marks’StandardHandbookforMechanicalEngineers,9thedn.McGraw-Hill,NewYork(1987)

8.Bayer,W.H.:CRCStandardMathematicalTables,24thedn.CRCPress,BocaRaton,FL(1974)

9.Beer,F.P.,JohnstonJr.,E.R.:MechanicsofMaterials.McGraw-Hill, NewYork(1981)

10.Bendat,J.S.,Piersol,A.G.:EngineeringApplicationsofCorrelationandSpectralAnalysis.JohnWiley&Sons,NewYork(1980)

11.Bendat,J.S.,Piersol,A.G.:RandomData:AnalysisandMeasurementProcedures,2ndedn.JohnWiley&Sons,NewYork(1986) 12.Blevins,R.D.:FormulasforNaturalFrequencyandModeShape.KriegerPublishing,Malabar,FL(1995) 13.CraigJr.,R.R.,Kurdila,A.J.:FundamentalsofStructuralDynamics,2ndedn.JohnWiley&Sons,NewYork(2006) 14.Ewins,D.J.:ModalTesting:Theory,PracticeandApplication,2ndedn.ResearchStudiesPressLTD.,Philadelphia,PA(2000) 15.Greenwood,D.T.:PrinciplesofDynamics.Prentice-Hall,EnglewoodCliffs,NJ(1965) 16.Harris,C.M.:ShockandVibrationHandbook,3rdedn.McGraw-Hill,NewYork(1987) 17.Horn,R.A.,Johnson,C.R.:MatrixAnalysis.CambridgeUniversityPress,Cambridge(1991) 18.McConnell,K.G.:VibrationTestingTheoryandPractice.JohnWiley&Sons,NewYork(1995) 19.Oppenheim,A.V.,Willsky,A.S.:Signals&Systems,2ndedn.PrenticeHall,EnglewoodCliffs,NJ(1997) 20.Steinberg,D.S.:VibrationAnalysisforElectronicEquipment,3rdedn.JohnWiley&Sons,NewYork(2000) 21.Steinberg,D.S.:PreventingThermalCyclingandVibrationFailuresinElectronicEquipment.JohnWiley&Sons,NewYork(2001) 22.UniversityofMassachusetts:Lowell“ModalSpace”. https://www.uml.edu/Research/SDASL/Education/Modal-Space.aspx 23.Wirsching,P.R.,Paez,T.L.,Ortiz,K.:RandomVibrations:TheoryandPractice.JohnWiley&Sons,NewYork(1995) 24.Young,W.C.:Roark’sFormulasforStressandStrain,6thedn.McGraw-Hill,NewYork(1989) 25.Bendat,J.S.:NonlinearSystemsTechniquesandApplications.JohnWiley&Sons,NewYork(1998) 26.NASA-STD-7001B.PayloadVibroacousticTestCriteria,11Nov2017

27.Juranek,J.B.,Wright,C.P.:ImprovingEfficiencyinSpaceVehicleAssembly,Integration,andTest(AI&T).30thAerospaceTestingSeminar, March2017

Chapter2 VibrationTestingofLaparoscopicSurgicalInstrumentsUnder VaryingGripPressures AndrewR.Hutchins,SabinoZaniJr.,RobertoJ.Manson,andBrianP.Mann

Abstract Manydevicesusevibrationtoprovidesensorycuestoahumanuser.Inapplications,suchassmartphones, thevibratorysensorycueissomewhatsimpleandneedsonlytoexceedaknownthresholdtosignaltheuser;however, applicationsthatrequireanindividualtocontrolormanipulateaninstrumentwhilebeinggivenavibratorysensorycuemust alsoconsidertheexcitation,whoseprimarypurposeistoprovidevibrotactilefeedback,whichcanaltertheuser’sability toproperlycontrolormaneuvertheinstrument.Anotherconsiderationformanyhandheldinstrumentsisthatauser’sgrip pressurecandrasticallyaltertheinstrument’sdynamicresponse.Tothisend,predictingtheinstrument’sresponseismade difficult,becausetherelationshipsbetween grippressureandtheequivalentinterfacialdampingandstiffnessiscomplex.To addressthisresearchgap,thispaperexplorestheideaofperformingexperimentalvibrationtestsonalaparoscopicinstrument whilebeingheldatvaryinggrippressures.Thisresearchismotivatedbytheideaofprovidingvibratoryfeedbackthrough laparoscopicsurgicalinstruments.Agapintheliteratureexistsinunderstandinghowsurgeongripcharacteristicsimpactthe optimalfrequencyforwhichthisexcitationshouldbesupplied.Resultsfromthisstudyindicatethatexcitationfrequencies shouldbegreaterthan175Hzforbothweakandstronggripconfigurations.Lowerfrequenciesresultinalargeramplitude responseattheinstrumenttipforallgrippressures,whichcouldresultinpatientharmastheinstrumenttiposcillates uncontrollably.

Keywords Laparoscopicsurgery·Hapticinterface·Gripforce·Vibrotactilefeedback·Vibrationtesting

2.1Introduction Thenumberofminimallyinvasivesurgicalcasesworldwide(ex.laparoscopicsurgery)continuetoincreaseasthese procedureshaveaddedbenefitssuchaslesspost-operativepain,fasterrecovery,lowermorbidityrates,andlesstrauma [1].Oneoftheprimarydrawbacksassociatedwithlaparoscopicsurgeryisthelackofhapticfeedbacktosurgeonsthatis relieduponduringopensurgerytechniques(i.e.tissuepalpation).Thedesignoflaparoscopicinstrumentationlimitsthe amountofhapticfeedback,particularlytactilefeedback.Toaddressthisconcern,therehavebeenattemptsataddinghaptic capabilitiestolaparoscopicinstruments;however,animportantstepbeforesimplyaddingvibrotactilecapabilitiestosurgical instrumentationistostudythefundamentalvibrationresponseoftheinstrumentfromvarioustypesofexcitation.Thisis essentialastheinstrumenttipshouldbelocatedatanode,whilethehandleatananti-nodetoensurethatthetipisnot movinguncontrollablyinsideofthepatientandthatthesurgeoncanperceivethefeedback,respectively.Toaddressthis researchgap,thisstudyinvolvedavibrationtestofalaparoscopicinstrumentwhilebeingheldatvaryinggrippressuresand simultaneouslybeingexcitedbyavibratingmotorlocatedattheinstrumenthandle.Gripforcesweremeasuredbyusinga seriesofforcesensorsattachedtotheinstrumenthandleandtheinstrumentresponsewasmeasuredatboththehandleandat theinstrumenttipusinguniaxialaccelerometers.Resultsfromthisstudyhaveimplications,notonlyinsurgery,butalsofor manyhand-heldtoolsorinstrumentswithhapticinterfaces.

A.R.Hutchins( )·B.P.Mann

DepartmentofMechanicalEngineeringandMaterialsScience,DukeUniversityPrattSchoolofEngineering,Durham,NC,USA

e-mail: andrew.hutchins@duke.edu

S.ZaniJr.·R.J.Manson DepartmentofSurgery,DukeUniversityMedicalCenter,DukeUniversity,Durham,NC,USA

©SocietyforExperimentalMechanics,Inc.2020 M.L.Mains,B.J.Dilworth(eds.), TopicsinModalAnalysis&Testing,Volume8,ConferenceProceedingsoftheSocietyfor ExperimentalMechanicsSeries, https://doi.org/10.1007/978-3-030-12684-1_2

2.2Background Muchresearchandmedicaldevicedevelopmenthasaddressedtheneedofaddinghapticcapabilitiestolaparoscopicsurgery instrumentation.Mostofthispriorwork,however,hasprimarilyfocusedoneithersurgeonperceptionofaddedhaptics[2]or performanceofsurgeonsattaskswithhapticinterfacesaddedtoinstrumentationduringtraining[3, 4].Somepriorresearch hasinvestigatedtheimpactofaddingpneumaticactuatorsattheinstrumenthandletocommunicateinstrumentjawcontact forcetothesurgeon[5].Inthisstudy,theauthorsfoundthatnovicesurgeonsgreatlyreducedtheiraverageandpeakgripping forcewhenthepneumaticactuatorswereactivated.Thesefoundationalstudiesprovideevidencethattheadditionofhaptics inlaparoscopicsurgerycouldexpeditesurgeonlearningandresultinusefultechnologiesthatcouldbeimplementedintolive proceduresbutfailtoinvestigatethemechanicsoflaparoscopicinstrumentationundervibratoryexcitation.

Asfullcontrolofsurgicalinstrumentationisessentialinprovidingoptimalpatientcare,surgicaltoolsequippedwithhaptic interfacesshouldbedesignedinsuchamannerthattheinstrumenttipsarelocatedatnodeswhenvibrotactilefeedbackis activated.Likewise,tomaximizehumanperceptionfromasignal,instrumenthandlesshouldbeatanti-nodes.Tothisend, experimentalvibrationtestsshouldbeperformedforallsurg icalinstrumentsthathavehapticinterfacestobetterunderstand theimpactofvaryinggrippressuresontipandhandleresponse.

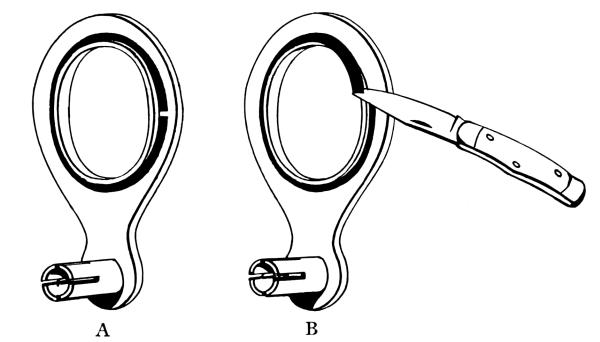

2.3Analysis TheexperimentalsetupincludedanEndoDissectlaparoscopicsurgeryinstrument(Medtronicplc,Dublin,Ireland),a2.7mm vibratingmotor,fiveFlexiForce™sensors(Tekscan,Inc., Boston,MA),andtwopiezoelectricaccelerometers(Handle: J352C34,Tip:352C42,PCBPiezotronics,Inc.,Depew,NY).TheFlexiForce™sensorswerecalibratedusingahandheld forcegauge(DFG35-10,OmegaEngineering,Norwalk,CT).Dataacquisitionfortheforcesensorsandaccelerometerswas madeusingaNationalInstrumentsUSB-6251andMATLAB2018B.Figure 2.1 showsanimageoftheEndoDissectwith theforcesensors,vibratingmotor,andaccelerometersaffixedtotheinstrument.Theforcesensorswereattachedatcontact pointsalongtheinstrumenthandletomeasurethecontactforceofeachfinger.Anelectronicallycontrolledresistancebox (ohmSOURCEOS-250,IETLabs,Inc.,Westbury,NY)wasconnectedinserieswiththevibratingmotorandwasusedto controlthemotorfrequency.

Theinstrumentamplituderesponsewasmeasuredatboththehandleandtipundervaryingmotorfrequenciesandgrip pressuresfor10sateachiteration.FrequencyresponsesatthetipandhandlewerethenextractedfromtheFastFourier Transformoftheaccelerometerdata,alongwiththevoltageamplitudeatthosefrequencies.Finally,theamplituderesponses ofthetipandhandlewerecompared(Fig. 2.2)todeterminethefrequencyrangeswhereasmallresponseoccursatthetip, butasomewhatlargerresponseoccursatthehandle,i.e.toensurevibrotactilefeedback.

InobservingFig. 2.2,itcanbeseenthatforfrequenciesgreaterthan175Hztheamplitudeatthetipislowerthanthat ofthehandle.Thisfindingindicatesthatforlaparoscopicsurgicalinstrumentswithahapticinterface, thevibratorymotor shouldrotateatthesehigherfrequenciestoensurethatthe tipoftheinstrumentisstaticwhilethehandleisvibrating.

Figure 2.3 illustratesthegrippingforcesforeachofthecontactpointsontheinstrumenthandleasafunctionofthemotor frequency.Theweakgripconfigurationresultedinamoreconsistentgrippingforceforeachfinger,whilethestronggrip configurationwasmoreunpredictable.Furthertestsarewarrantedfortestinggrippingpressuresofsurgeonstodetermine thedistributionofcontactpressurefromeachfingeralongtheinstrumenthandleandhowvarying grippingstylesimpactthe frequencyresponseattheinstrumenttipandhandle.PreliminaryresultsfromFigs. 2.2 and 2.3 indicatethatthetipandhandle

Fig.2.1 ExperimentalsetupoftheEndoDissectwithfiveFlexiForce™A101sensorsattachedatthehandle,avibratingmotorattachedatthe handle,andtwoPCBPiezotronicsaccelerometersattachedatthehandleandtip

2VibrationTestingofLaparoscopicSurgicalInstrumentsUnderVaryingGripPressures11

Fig.2.2 Normalizedamplituderesponsevs.vibrationmotorfrequencyplotsfortheinstrumenttipandhandleresponseatvaryinggrippressures. Responseisnormalizedbythesquaredfrequencytoensureconstantamplitudeacrossfrequencysweeps

Fig.2.3 Averagecontactforcefromeachfingerfortheweakandstronggriptrialsacrossallfrequenciestested.Errorbarsindicatestandard deviations responsesarecomparableregardlessofgrippressure;however,asindicatednear285Hzinthestronggripconfiguration,a larger-amplituderesponsemaybeafactortoconsiderwhenholdingtheinstrumentwithanincreasedgripforce.

2.4Conclusion Thisstudyinvolvedvibrationtestsonalaparoscopicsurgicalinstrumentheldatvaryinggrippressuresandexcitedbya motorwitharotatingmassimbalance.Resultsfromthisstudyindicatethatlowerfrequenciesshouldbeavoidedwhen providingexcitationtolaparoscopicinstrumentstoensurethathandleresponseexceed stipresponse,leadingtoanincreasein instrumentcontrolandprovidingandecreasedrisktopatients.Furtherworkisbeingcompletedtotestexcitationwaveforms withtheplantotrainaneuralnetworktoalterthemotorfrequencyinreal-timeusinggrippressure.Additionally,wewillbe testingthegripsofmultiplesurgeonsattodeterminetheoptimalgripconfigurationandmotorfrequencycombination.

Acknowledgements WewouldliketoacknowledgetheDepartmentofMechanicalEngineering&MaterialsScienceatDukeUniversityandthe DepartmentofSurgeryatDukeUniversityMedicalCenterforprovidingthenecessaryfundingtosupportthisresearch.

References

1.Berguer,R.,Forkey,D.,Smith,W.:Ergonomicproblemsassociatedwithlaparoscopicsurgery.Surg.Endosc. 13(5),466–468(1999)

2.Koehn,J.K.,Kuchenbecker,K.J.:Surgeonsandnon-surgeonspreferhapticfeedbackofinstrumentvibrationsduringroboticsurgery.Surg. Endosc. 29(10),2970–2983(2015)

3.Panait,L.,Akkary,E.,Bell,R.L.,Roberts,K.E.,Dudrick,S.J.,Duffy,A.J.:Theroleofhapticfeedbackinlaparoscopicsimulationtraining.J. Surg.Res. 156(2),312–316(2009)

4.Basdogan,C.,Ho,C.H.,Srinivasan,M.A.:Virtualenvironmentsformedicaltraining:graphicalandhapticsimulationoflaparoscopiccommon bileductexploration.IEEE/ASMETrans.Mechatronics. 6(3),269–285(2001)

5.Wottawa,C.R.,Cohen,J.R.,Fan,R.E.,Bisley,J.W.,Culjat,M.O.,Grundfest,W.S.,Dutson,E.P.:Theroleof tactilefeedbackingripforceduring laparoscopictrainingtasks.Surg.Endosc. 27(4),1111–1118(2013)

JamesP.Winkel,VicenteJ.Suárez,andJamesC.Akers

Abstract Vibrationtestingspaceflighthardwareisavital,buttimeconsumingandexpensiveendeavor.Traditionallymodal testsareperformedatthecomponent,subassembly,orsystemlevel,preferablyfree-freewithmassloadedinterfacesor fixedbaseonaseismicmasstoidentifythefundamentalstructuraldynamic(modal)characteristics.Vibrationtestsare thentraditionallyperformedonsingle-axissliptablesatqualificationlevelsthatenvelopethemaximumpredictedflight environmentplus3dBandworkmanshipinordertoverifythe spaceflighthardwarecansurviveitsflightenvironment.These twotestscurrentlyrequiretwosignificantlydifferenttestsetups,facilities,andultimatelyreconfigurationofthespaceflight hardware.Thevisionofthisresearchistoshowhowtraditionalfixed-basemodaltestingcanbeaccomplishedusingvibration qualificationtestingfacilities,whichnotonlystreamlinestestingandreducestestcosts,butalsoopensupthepossibility ofperformingmodaltestingtountraditionallyhighexcitationlevelsthatprovidefortest-correlatedfiniteelementmodels tobemorerepresentativeofthespaceflighthardware’sresponseinaflightenvironment.Thispaperdocumentsthefirst stepstowardsthisvision,whichisthecomparisonofmodalparametersidentifiedfromatraditionalfixed-basedmodal testperformedonamodalfloorandthoseobtainedbyutilizingafixedbasedcorrectionmethodwithalargesingle-axis electrodynamicshakerdrivingasliptablesupplementedwithadditionalsmall portableshakersdrivingonthesliptableand testarticle.Toshowrobustnessofthisapproach,thetestarticlechosenisasimplelinearweldment,whosemass,size,and modalparameterscouplewellwiththedynamicsoftheshaker/sliptable.Thispaperwillshowthatalldynamicsduetothe shaker/sliptableweresuccessfullyremovedresultingintruefixed-basemodalparameters,includingmodaldamping,being successfullyextractedfromatraditionalstylebase-shakevibrationtestsetup.

Keywords Modaltesting·Pretestanalysis·Modelupdating·Base-shake·Environmentaltesting·Fixedbase

3.1Introduction Testingspaceflighthardwareisavital,buttimeconsumingandexpensiveendeavor.Traditionaldynamictestmethods presentlyrequiretwoseparatetests;thefirst,amodaltestperformedonaseismicmass,andthesecond,aflightlevel verificationtestperformedonashakertable.Thevisionofthisresearchistocombinetwoseparatestructuraldynamic testsrequiredforspacehardwareverificationintoone,whichwouldallowperformingmodaltestingtountraditionallyhigh excitationlevelsthatcouldapproachflightlevels.

Severaldifferentmethodshavebeenproposedtoextractfixedbasemodesfromstructuresmountedonshaketables[1–9]. AuthorsofthispaperwereabletobeinvolvedwithutilizingoneofthesemethodsdevelopedbyATAEngineering,which utilizestheshaketableaccelerationsasreferenceswhencalculatingtheFrequencyResponseFunctions(FRFs)[8, 9].Itis theintentofthisresearchtostartwherethesetwopapers leftoffandfurtheradvanceutilizationofthesemethods.

Currentlyonlythefirststageofamulti-phaseresearchefforthasbeencompleted.Thispaperdiscussesthetestsetup,trade studiesperformedpriortothetestingontheshakertable,describingthechallengesandlessonslearnedthusfar,andfinally disclosingtheplanforcompletingtheremainingtwophasesoftheresearcheffort.Inthenextphase,theprimaryobjective willbetoprocessallthedatacollectedinthefirstphaseandformulateatestplanthatincorporatesanynecessarychanges.In thethirdandfinalphase,theplanwillbetocarryouthighlevelvibrationtestingandextractingfixedbasedmodalparameters fromthissametest.

J.P.Winkel( )·V.J.Suárez·J.C.Akers

NASAGlennResearchCenter,Cleveland,OH,USA

e-mail: james.winkel@nasa.gov

©SocietyforExperimentalMechanics,Inc.2020

M.L.Mains,B.J.Dilworth(eds.), TopicsinModalAnalysis&Testing,Volume8,ConferenceProceedingsoftheSocietyfor ExperimentalMechanicsSeries, https://doi.org/10.1007/978-3-030-12684-1_3

3.2SimpleBeamPathfinderStudy Asapathfindertoverifythatthemethodology ofusingaccelerationsasreferencesto removebasemotionwasbeingproperly implemented,asimplefree-freebeamwasused[10].Thesetupofthissimplefree-freebeaminvolveda2 square6061-T6 aluminumhollowrectangularcross-sectionbeamthatwas87 longandhadawallthicknessof0.125 thick.Asshownin Fig. 3.1,thebeamwassuspendedfroma1tonoverheadcranehangingover12ft.abovethetopofthebeam.Athinnylon stringwasuseddirectlytiedtothetopofthebeam.Inbetweenthestringandthechainofthehoist,arubberbungee cordwasaddedtoisolateanymodesfromthecraneinfluencingthebeamaswellaslowertherigidbodysuspension modesofthebeamtofrequenciesmuchlowerthantheflexiblebodymodefrequenciestosimulateafree-freeboundary condition.

Thebeamwasdividedintosixequalsectionsandsevenuniaxialaccelerometerswereplacedalongthebeamineachofthe twolateralbeamdirections.Asingleuniaxialaccelerometerwasplacedatthetopof thebeamorientedintheaxialdirection tobeabletomeasuremotionalongthebeamsaxialdirection.Thistotaledupto15channelsofaccelerometerdataforthe test.Asmallimpacthammerwithawhitevinyltipwasutilizedfortheexcitation.Atotaloftenimpactswerecollectedat eachofthe15accelerometermeasurementlocations.

Themethodwasexercisedtoverifythatthemodalparametersofthissimplebeamwiththefollowingthreerestrained boundaryconditions:pinnedat oneend,pinnedatbothends,andpinnedattheendsaswellasinthemiddle,couldbe extractedfromitsfree-freemodalhammersurvey.Afiniteelementmodel(FEM)wasgeneratedutilizing2Dbeamelements withatotalfourboundaryconditions,thefree-freeboundaryconditionsofthetestandthethreerestrainedboundary conditions.ThefirstfourFEMmodalfrequenciesandmode shapesofthefourboundaryconditionswerecomputedand comparedtothemodesextractedusingthe fixed-basemethodandareshowninFig. 3.2

Timehistorieswerepostprocessedintofrequencyresponsefunctions(FRF)byconcatenatingtheimpacthammerdata intoonelongtimehistoryfiledependinguponthespecificlocationsneededtoextractthedesiredboundarycondition.For example,insimulatingtheboundaryconditionofthebeambeingpinnedatbothends,theimpacttimehistoriesfortheX (lateral)directionsatbothendlocationwereconcatenatedtogether.Thenthetimehistorieswerepostprocessedusingdrive pointaccelerationsatthoseimpactlocationsasreferences.TheHvFRFmethodwasutilizedduetothefactthatthenoise levelonthereferenceaccelerometerandresponseaccelerometerwasequalinmagnitude.ComparisonsoftheFEMand extractedfixed-basefrequenciesandavisualinspectionoftheFEMandextractedfixed-basemodeshapeswasperformed andareshowninFig. 3.2.Figure 3.3 illustratesthecrossorthogonalitycomparisonbetweentheFEMandtestresultsfor thesedifferentboundaryconditions.Thisstudyverifiedthatafixed-basecorrectiontechnique,inthisspecificcaseusingdrive pointaccelerometersasreferences,couldbeusedsomewhateffectivelytoextractmodalparametersfordifferentboundary conditionsfromafree-freemodaltest.Itwasdefinitelymoredifficulttoextractcleanmodesshapeswhentheboundary conditionsthetestdatawasbeingcorrectedtobecamemorecomplicated.Thus,whentryingtosimulatethepinned-pinnedpinnedcondition,whilethedeformationshapesandfrequenciesappearedtobecorrect,thecross-orthogonalitywasnotas clean.Moreworkisplannedtobedoneusingthisdatatohelpmakemoresignificantconclusions.Itisthehopethatpriorto usinganyotherfixedbasedcorrectiontechniquesontheshakersliptable,thesetechniquescanfirstbeappliedtothissimple free-freebeamdata.

Fig.3.1 Simplebeampathfindersetup

Fig.3.2 Simplebeampathfinderfixedbasedcorrectionmodeshapeandfrequencycomparison

Therewereafewchallengesencounteredwiththesetupofthispathfinderstudythatifitwereredonewouldbeavoided. Thetestarticlehadasymmetricsquarecross-sectionmeaningthatthereweretwolateralbendingmodesateachresonant frequency,whichwerealignedwiththeaxesofthecross-sectionandthereforeoccurringinorthogonalplanestoeachother. Thecloselyspacedandhighlysimilarmodeshapesmadeitmuchmoredifficulttoextractthemodescleanly.Thesecond wasthatrunningalltheaccelerometercablestapeddownthelengthofthebeamcreatedasignificantamountofmassloading andadditionaldamping.Thisstudyisfarfrombeingfullycompletedandthehopeistospendmoretimewiththisdatagoing forward.

3.3TestArticleSelection Forthefirststageofthisresearch,developmentofanappropriatetestarticlealongwithalltheinfrastructureneededto performthemodaltestingwasthefirststep.Initially,itwasplannedthatatestarticlewouldbedesignedandfabricatedthat wouldmeetthefollowingrequirements:simpledesignandfabrication,behavelinearly,havesufficientweighttoinfluence thecurrentshakertabledynamics,andhaveitsfundamentallowestfrequencymodesinthesamefrequencyrangeasmost aerospacestructures.Shortlyintotheprocess,itbecameclearthatmeetingalltheserequirementswouldbecostprohibitive andwouldexceedthefirststagescheduleconstraints.As acompromise,anexistingmagnesiumbookendusedinthe dynamicslabwaschosenbecauseitwouldmeetthefirstthreerequirements.However,unfortunatelyitslowestfundamental

Fig.3.3 Simplebeampathfinderfixedbasedcorrectioncross-orthogonalitycomparison

Fig.3.4 Selectedtestarticle

modesaresignificantlyhigherinfrequencythantypicalaerospacetestarticles.Atthetimeitwasfeltthatthislimitation wouldnotbeanissueforthefirststageofthisresearcheffort.

Themagnesiumbookendweighed217lbandwasexpectedtobehaveextremelylinearsinceitwasafullywelded magnesiumstructure.Thebookendutilized 3/8in.diameterfastenersina4in. × 4in.squareholepatterntoholditdownto thefloor.MoredetailedinformationonthearticlecanbeseeninFig. 3.4

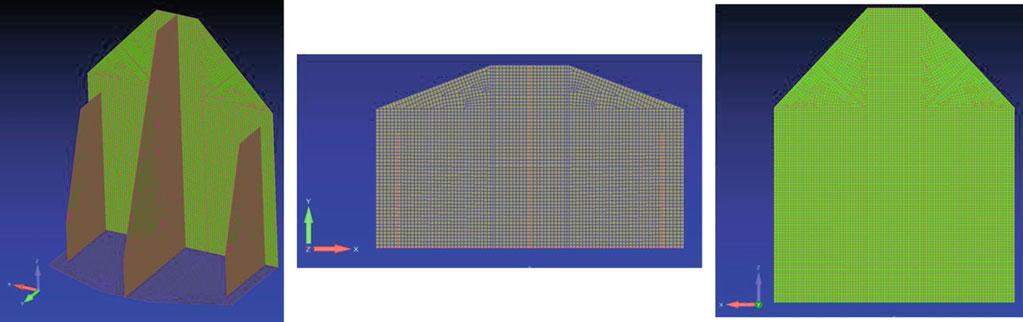

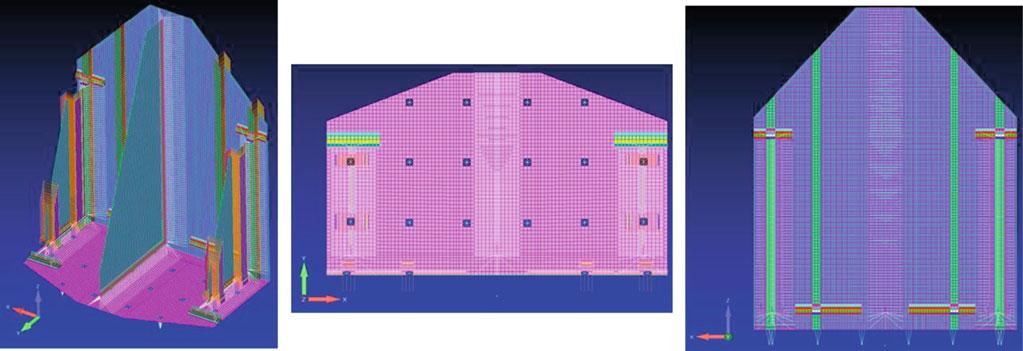

3.4FEMConstructionandSensorPretestTradeStudy AFEMofthismagnesiumbookendwascreatedtosupportthisresearcheffort.ThreedifferentFEMsofthebookendwere generatedusingthreedifferentmodelingtechniquestraditionallyutilizedinmodelingaerospacestructures.Thefirst,and mostsimple,modellingtechniquewastomodelthebookendusing2Dshellelementsovertheentirebookend,whichis typicallydoneinaerospaceloadsFEMs,andisshowninFig. 3.5 andwillbereferredtothroughoutthispaperastheSimple

2DShellFEM.TheadvantagesofthistypeofFEMareitisthesimplestFEMtogenerate,analyze,modify,andithasthe shortestsolutionruntimes.Thedisadvantageofthismodelingtechniqueisthatsimplefeaturessuchasholesandweldsare nottakenintoaccountandthereisalotofduplicationofmassatthejoints,whichwasespeciallythecaseduetotheextreme thicknessoftheplates.

ThesecondmodellingtechniqueutilizedwastoautomeshtheCADrepresentationofthebookendusing3Dsolid tetrahedralelements,whichhastheadvantagethatveryfinedetailcanbeaccuratelycaptured.Theobviousdisadvantages ofthistechniqueisthatsolutionruntimesaresignificantlylongerandtryingtomodifyortroubleshoottheFEMcanbe extremelycumbersomegiventhenumberofelementsandnodesthatareinternaltotheoutersurfaceandnoteasilysorted out.ThebookendFEMutilizingthissecondmodellingtechniqueisshowninFig. 3.6 andwillbereferredtoastheSolid3D FEM.

Thefinalmodellingtechniqueusedisahybridapproachwherethestartingpointwasthesimple2DshellFEMandthen makingmodificationstoeliminatetheoverlappingelementsatjointsandaddinginmoredetailtocapturedetailssuchas holesandwelds.ElementoffsetsandRBE2spiderelementsareutilizedthemakethisaddeddetailpossible.Theadvantages ofthismodelingtechniqueisitallowsfortheincreasedaccuracyofthemassdistributionandstiffnesschangeswithoutgoing tothefullextremeofsolidelements.However,thedisadvantageisitisthemostdifficultandtimeconsumingFEMtocreate. ThebookendFEMutilizingthisthirdmodellingtechniqueisshowninFig. 3.7 andwillbereferredtothroughoutthispaper astheComplex2DShellFEM.

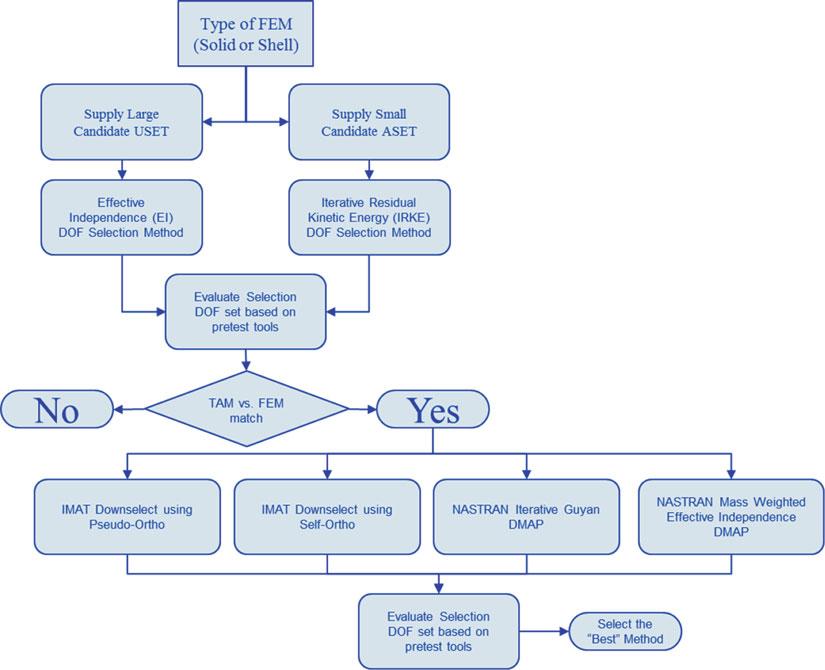

Atthispoint,thereadermaybewonderingwhythreedifferentFEMswerecreatedforthisresearch.Itwasdoneasa sidestudytoallowtestengineerstoabilitytoinvestigatewhichfiniteelementmodelingtechniquewouldmostcloselymatch therealdynamicsofthebookend.Intheprocessoffindingouttheanswertothis,testengineerscouldalsolookintowhich FEMmodelingtechniquewouldbethemostefficienttoutilizeinmodalpretestanalyseswhicharedonetoseehowmany accelerometersarerequiredtoindependentlycapturethetargetmodes.Modalpretestanalysiswasperformedutilizinga customizedsetofMATLAB-basedtestDOFselectiontoolsthatdrawextensivelyuponATAEngineering’sIMAT® software

Fig.3.5 Simple2DshellFEM

Fig.3.6 Solid3DFEM

FEMmodalfrequenciesandshapeprofiles

packages.AsimpleCBUSHspringwasattachedtothetopofthebookendrepresentingthetestverifiedaxialstiffnessofa bungeecordthatwouldbeusedtoholdthebookendsuspendedinthesubsequentmodalsurvey.Thefirstnineelasticbody modesforeachFEM(i.e.thesixrigidbodysuspensionmodeswereexcluded)wereusedastargetmodesinthesepretest analyses(Fig. 3.8).

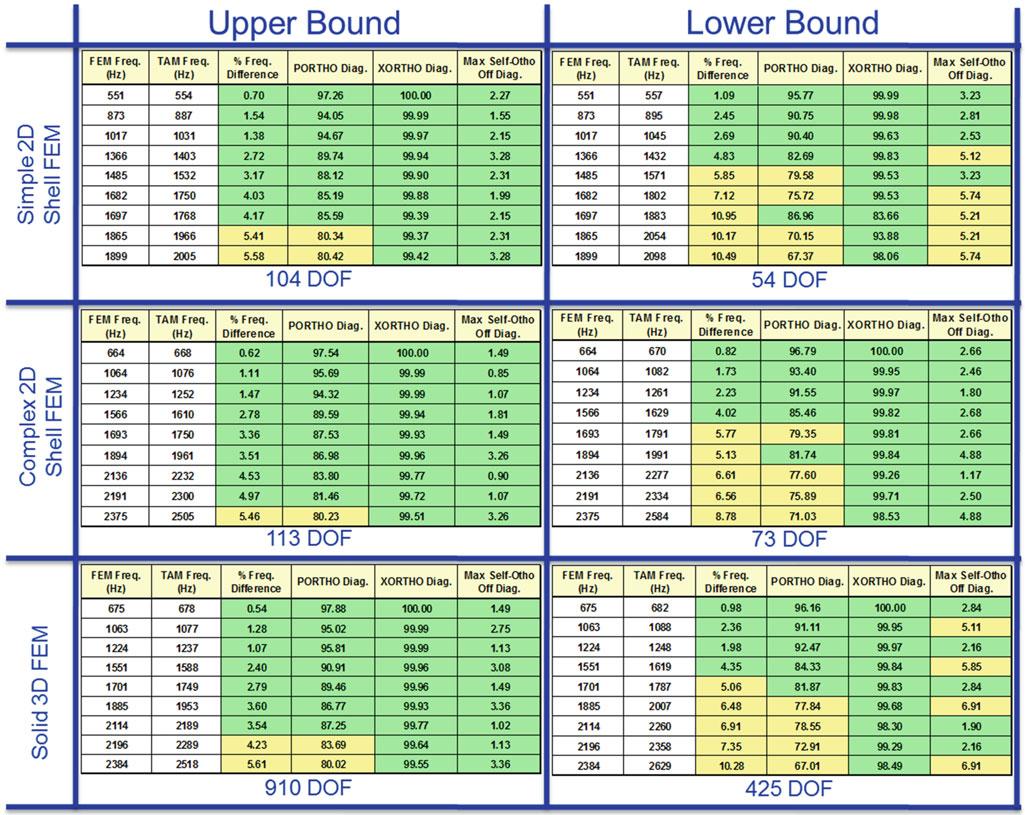

Aninitialset34testDOFwasutilizedthepretestanalysis ofeachFEM.Thissetwasbaseduponengineeringjudgement togivethepretestanalysisagoodstartingpointforcapturingtheshapeandmassdistributionofthetargetmodeset.The IterativeResidualKineticEnergy(IRKE)wasutilizedtoidentifyadditionaltestDOFresultinginatotalof2500testDOF. ThenadownselectionalgorithmcreatedbyATAengineeringwasutilizedtoincrementallyremovetestDOFtoachievea minimaltestDOFsetthatmetthefollowingcriteria(numberedbydesignatedimportance):

1.<5%frequencydifferencebetweenTAMandFEMfortargetmodes

2.<5%onoffdiagonalofthe Self-OrthogonalityMatrices

3.>90%onthediagonalvaluesand<10%onoffdiagonaloftheCross-OrthogonalityMatrices

4.>80%onthediagonalvaluesPsuedo-OrthogonalityMatrices(Usedtoestablishupperboundonly)

ThesummarytablesforeachofthepretestanalysisofeachFEMisshownTable 3.1.Therearetwotablesshownfor eachFEMwiththeUpperBoundbeingwherethePseudo-OrthogonalitycriteriaisnolongermetandtheLowerBound beingwheretheSelf-Orthogonalitycriteriaisnolongermet.TheoptimalsetoftestDOFisbetweenthesetwoboundsand isusuallymuchclosertotheLowerBound.

Thisstudyshowsthattheuseof3Dtetrahedralsolidelementsisnotconducivetothistypeofsensorselectionapproach.It shouldbemadeclearthatfortheSolid3DFEM,theonlytestDOFthecomputerwasallowedtoselectwereontheexternal surface.Thiswasdoneduetothefactthataccelerometerscannotbe placedinsidethetestarticle.Itisunderstoodthata2D

Fig.3.7 Complex2DshellFEM

Fig.3.8

Table3.1 FEMpretestanalysiscomparisons

ShellelementsexhibitsimilarissuesinthatthetestDOFselectedaretechnicallyonthecenterlineofeachsurfaceandcan alsonotbeselected,however,allthemassoftheFEMisdistributedtothosesamenodesina2Dshellelement.Withasolid 3Delement,themassisdistributedinamuchfinerfashionandmuchmoredifficulttocaptureusinglimitedinstrumentation. BoththeSimpleandcomplex2DshellFEMsdoareasonablejobofselectinganoptimizedsetoftestDOF,withtheSimple 2DShellFEMdoingaslightlybetterjob.

Afterseeingtheseresults,itwasquestionedaboutwhethertheappropriateDOFselectionmethodwasbeingutilizedor not.ThereforeasimpleplantoevaluateotherDOFselectionprocesseswascreatedandcarriedout.Theflowchartshownin Fig. 3.9 describesthisprocess.

AfterfinishingthisprocessonallthreeFEMs,theresultsclearlyshowedthattheIRKEselectionmethodoutperformed theEffectiveIndependenceselectionmethod.Theotherfindingwasthatnomatterthemethodused,thesolid3DFEM alwaysrequiredmuchhigherDOFcountstoachieveresultswithinthestatedguidelinesabove.Thisstudyservedasagood confirmationthatthestandardwaytheengineershadbeendoingpretestsensorsselectionsforpastmodaltestwasindeedthe mostefficientwaytodothem.

ThefinalstepwastoutilizetheSimple2DShellFEM,whichinthestudiesaboveshowedthebestabilitytopredictan optimalsensorset,tofinalizethenumberandlocationofthesensors.Asetof75DOFwasselectedwhichmettheoverall majorityofthepretestguidelinesweremetandcanbeseenindetailinFig. 3.10

Fig.3.9 Pretestanalysismethodologyevaluationflowchart

Simple2DshellFEMfinalpretestresults

Fig.3.10

3.5BookendFree-FreeModalTestandModelCorrelation ThetestarticlewassuspendedfromasoftbungeecorddisplayedinFig. 3.11 thatresultedinabouncemodeat3Hzand alloftheremainingsuspensionmodes(e.g.firstandsecond pendulummodes)below3Hzsothatallsuspensionmodesare morethantwoordersofmagnitudebelowthefirstflexiblebodymode.

Animpactmalletwithahardblackvinyltipwasutilizedtoexcitethestructure.Thistipwasabletoproducehighquality excitationwithgoodcoherenceupto1400HzshowninFig. 3.12.However,theFRFsseemtoholdtheirqualityof2300Hz. Becausethisisnotanactualtestofflighthardware,itwasconsideredacceptabletoignoretheguidelinesinthisspecificcase andusethemodalparametersextractedupto2300Hz.

Nowthattestresultshadbeenobtained,itwaspossibletodeterminetheanswerstothenewfewquestionsaboutwhich FEMconstructiontechniquewouldbestpredicttheactualtestresultswithoutmodelupdatingandtheFEMengineersshould continuetoutilizegoingforwardintheresearch.

1.Whichmodelisthemostaccuratecorrelationwithoutanymodelupdating?

2.IsmodelinginsomuchdetailwiththeComplex2DShellFEMrequiredorwhatsubsetofmodelingfeaturesarereally necessary?

3.Whichmodelwouldbethe“best”touse?“Best”meaninga goodbalanceofbothaccuracyofthehardwarewhilealso beinguserfriendly.

TheSolid3DFEMwasnotabletobeincludedfullyinthispartofthestudybecausethereducedmassandstiffness matricesgeneratedusingthechosensetofDOFwassoinsufficient,itcorruptedthecross-orthogonalitymatrices.However, thefrequencycomparisonfortheSolid3D FEMwasgeneratedforreferenceinFig. 3.13

OnecanseetheresultsinFig. 3.13 thattheComplex2DShellFEMdoesthebestjobpredictingtherealtestresultswhen consideringitcanbebetterutilizedinapretestsensoreffort.TheSolid3DFEM,asexpected,doesaverydecentjobin predictingtheresults.Itonlyslightlyoverpredictsthestiffnessofthetestarticle.TheSimple2DShellFEMunderpredicts thestiffnessofthemodelandthusissimulatingatestarticlethatistooflexible.

Inanormalmodaltestingeffort,testengineerswouldprobablynotseeaneedtoupdateanythingwitheithertheComplex 2DShellFEMortheSolid3DFEM.However,inthisresearcheffortitwasdesiredtoknowwhatfeaturesintheComplex 2DShellFEMwerereallynecessary.BystartingwiththeComplex2DShellFEMandslowlyremovingonecomplicated featureafteranother,itwasrevealedthatreallyonlyonecomplexfeature,thespiderRBE2elementsconnectingtheplates together,isnecessaryinmakingany2DshellFEMmostaccuratelysimulaterealtestresults.InFig. 3.14,onecanobserve thecomparisonbetweenthestartingComplex2DShellFEMtothemuchsimplercorrelatedversion.

Another random document with no related content on Scribd:

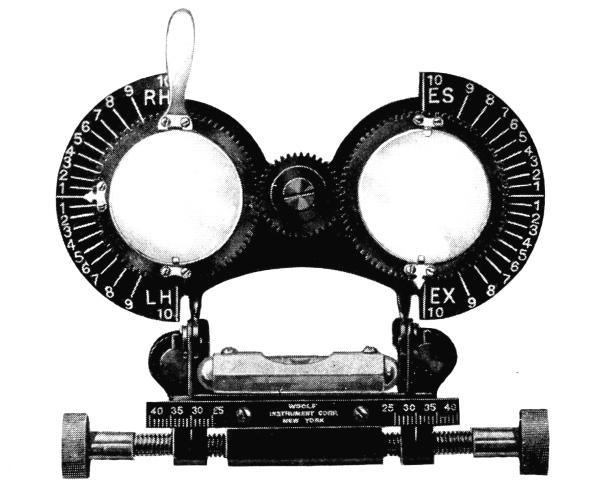

in place. Concave cylinders are then employed in quarters until the final results of +1.D. spherical, combined with -1.D. cylinder axis 180° is secured. This necessitates the change of but four cylindrical lenses as shown in routine “A” as follows:

ROUTINE “A” ROUTINE “B” (Made with minus cylinder) (Made with plus cylinder) Sph. +1.D. Cyl. Axis Sph. +1.D. Cyl. Axis

Step 1 +1.D. = -.25 ax. 180° equal to +.75 = +.25 ax. 90°

Step 2 +1.D. = -.50 ax. 180° equal to +.50 = +.50 ax. 90°

Step 3 +1.D. = -.75 ax. 180° equal to +.25 = +.75 ax. 90°

Step 4 +1.D. = -1 ax. 180° equal to 0 +1 ax. 90°

In brief the method of using minus cylinders exclusively in an examination, as explained in routine “A”, necessitates the change of the cylinder lenses only after the strongest plus sphere is secured.