the loop

Circular investments for forward-thinking companies

Contents Page

Circular investments for forward-thinking companies

Contents Page

In today’s competitive landscape, sustainable packaging goes beyond environmental responsibility. It has become a smart business strategy that delivers measurable returns on investment.

This edition of Packaging Review showcases how forward-thinking South African companies are discovering that sustainability and profitability go hand in hand. From Fuchs Lubricants’ energy-efficient solutions that promise to reduce operational costs to Bidvest Labels’ FSC-certified materials that meet evolving regulatory requirements, the message is clear: sustainable practices drive bottom-line results. For procurement specialists, Packaging Review features innovations present compelling value propositions. CCL Label has developed a new pressuresensitive label specifically for improved recycling of single use glass bottles. The EcoShear® adhesive technology ensures residuefree label removal, supporting circular economy compliance whilst enhancing recyclability credentials.

Nissei ASB’s latest innovations promise to reshape how the industry thinks about sustainable plastic bottle manufacturing. At the upcoming K 2025 exhibition, the Japanese machinery giant will showcase its all-in-one sustainable bottle solutions.

Innovation leaders will appreciate how companies like VR Print are integrating AR-enabled labels and RFID technology, optimising supply chains whilst meeting consumer demands for interactive, environmentally conscious packaging.

As South Africa’s packaging industry evolves, the companies featured in our 2025 edition are demonstrating that sustainability isn’t an operational burden. Instead, it’s become their competitive advantage to help clients reduces costs, ensures regulatory compliance and build brand credibility in an increasingly eco-conscious marketplace.

Enjoy the read!

The team

EDITORIAL

EDITOR: Abby Vorster

+27 (0)71 359 4519 abby.vorster@media24.com

LAYOUT & DESIGN: David Kyslinger

ADVERTISING

SALES EXECUTIVE: C àndida Giambò-Kruger

+27 (0)71 438 1918 candida.giambo-kruger@media24.com

INTERNATIONAL SALES

Germany/Austria/Switzerland: Eisenacher Medien

Erhardt Eisenacher +49 228 249 9860

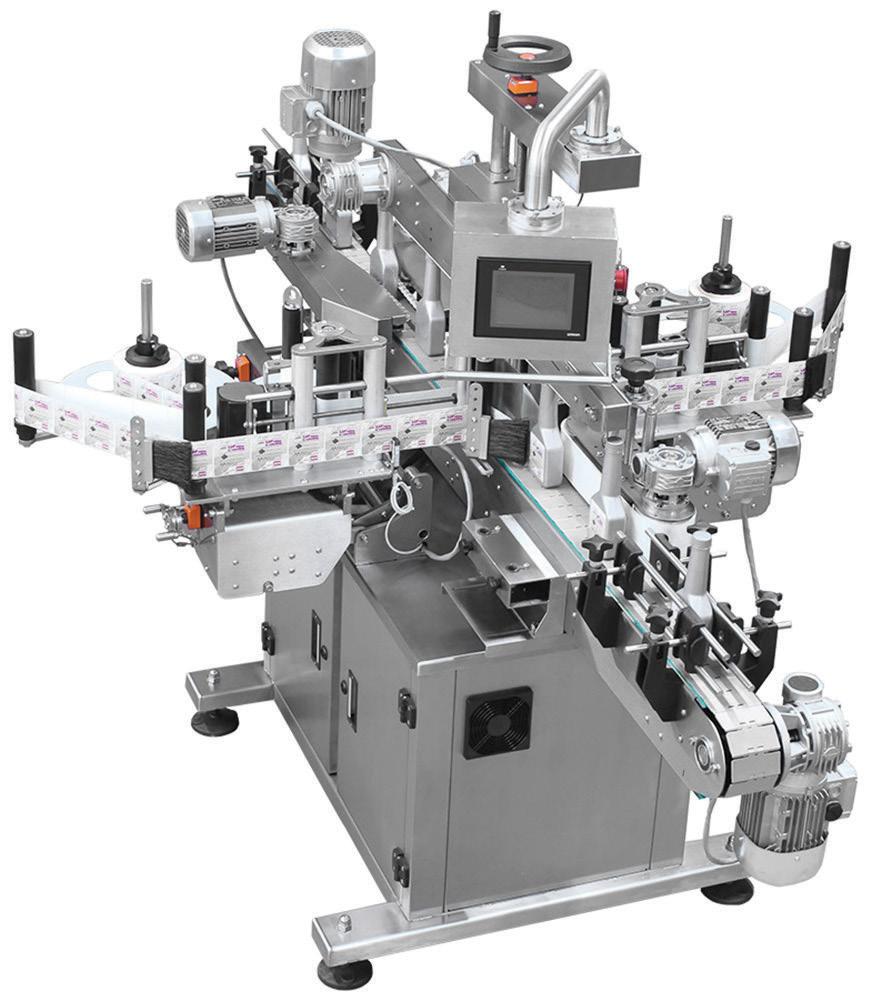

ISW’s got it covered

CFO: Lana Goliath

MEDIA24 CORPORATE

CEO MEDIA24: Raj Lalbahadur

CFO MEDIA24: Nelmarie Beyers

JOHANNESBURG OFFICE

Media24 B2B, Building 13, The Woodlands Office Park, 20 Woodlands Drive, Woodmead, Sandton

PO Box 784698, Sandton 2146 Tel: +27 11 867 6111

POSTAL ADDRESS

PO Box 784698, Sandton, Johannesburg, 2146

Published by Media24 (PTY) Ltd

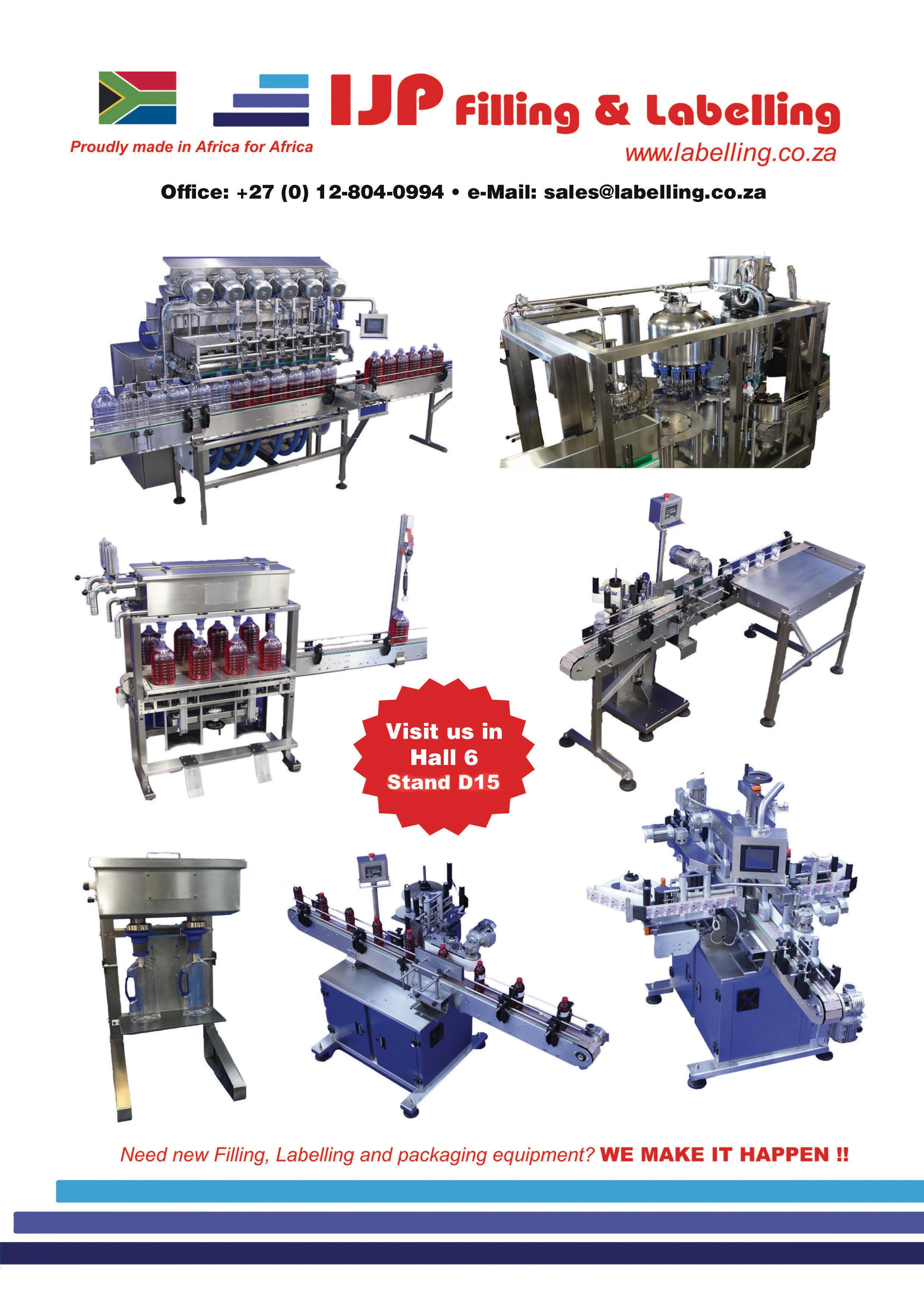

Through an innovative and out the box approach to our clients needs we are able to provide practical, efficient and cost saving solutions to almost every challenge.

Tel: +27 (0)11 609 1488

Email: sales@iswshrink.co.za www.iswshrink.co.za

16 Edendale Rd West, Eastleigh, Edenvale

With the manufacturing plant consisting of 10 colour and 8 colour MPS EPW560’s and a full compliment of the latest offerings in finishing equipment for the conversion and inspection of our shrink sleeves, multi-layer sachets and wrap around labels, ISW is one of only a handful of narrow web printers capable of producing wide Lay Flat shrink sleeves, achieving a L/F of 276mm from a printed web width of 575mm.

K 2025 will set the stage for something big – the premiere of the Plastic is Fantastic Association. This is the first global movement dedicated to reshaping how the world sees plastic. With a clear message to consumers: Facts, not prejudice. Its public debut in Düsseldorf sends a strong signal: Plastic isn’t the problem – it’s part of the solution.

The Plastic is Fantastic Association, initiated by the ALPLA Group, will provide a voice and network for the global plastics industry. It challenges clichés, dismantles myths, and shows what plastic is truly capable of – and what it means for the world. The association’s mission is clear: no excuses, just relevance. No opinions, just facts. And clear answers to future-facing questions – from next-gen materials to waste management and sustainability.

Powerful Material. Powerful Voice – The slogan says it all. International experts and producers have joined forces to highlight the benefits, perspectives and solutions that plastic offers in modern life. Grounded, objective and science based. From 8 to 15 October, the association will introduce itself to the public at K 2025 (Stand N05/North entrance) – inviting people to learn more, ask questions, and join the conversation. The Plastic is Fantastic Association isn’t an ivory tower – it’s a

is Fantastic Association

hands-on, get-involved community.

Dominic Fiel, chairman and executive director of the Plastic is Fantastic Association, will welcome a top-tier lineup of guests to the stand – including Philipp Lehner, CEO of the ALPLA Group and one of the association’s earliest supporters. International guests such as Joseph Tayefeh, secretary general of Plastalliance is also expected. He will be signing 100 free copies of his book “Plastic Bashing, Fake News” on 9 October 9 at 13:00. The association also has a mascot, Captain Plasto, who will be at the trade show. K 2025 marks the launch of a global communications campaign. The goal is to spotlight the positive sides of plastic – because too often, its real advantages are lost in emotional debate. Plastic is safe, lightweight, hygienic, recyclable, and often the most sustainable option. The knowledge exists – it simply needs to reach public awareness. That’s the task and the mission of the association. •

UPM Adhesive Materials has received recognitions from RecyClass for its releasable general purpose RW85C adhesive. In addition to the previously acquired approvals, label materials with RW85C adhesive are now recognised to be releasable in high density polyethylene (HDPE) container recycling and alkali/water releasable adhesive in PET bottle recycling*. This means that the approved label materials can be recycled in HDPE natural and white and PET bottle recycling streams, further enhancing recyclability and supporting the circular economy.

“Thanks to the immense research of RecyClass, label

material producers can now transparently prove their labels do not hinder the recyclability of HDPE and PET packaging. The quality of the highly valued natural and white recyclate can be secured with the right label material, along with the right adhesive technology innovations, which enable the circular economy and enhance sustainability performance.

Brand owners will be able to utilise the UPM Adhesive Materials technology approvals to certify their packaging with RecyClass,” says Santeri Marjamäki, manager, ecosystem, EMEIA, UPM Adhesive Materials.

“As packaging regulations like PPWR evolve and sustainability expectations grow, we’re staying ahead of the curve by collaborating with RecyClass to deliver label solutions that meet strict recyclability criteria by design. Our label solutions help brand owners hit their sustainability targets and lead the shift toward a circular packaging economy,” comments Przemysław Sawa, director, consumer label solutions, EMEIA, UPM Adhesive Materials.

*Specific conditions of the approval can be found in the RecyClass Technology Approval Letters: Letter 1 and Letter 2

‘Plastic is fantastic’ – ALPLA has been proving this for seven decades. Founded in 1955 in a laundry room in Hard by Lake Constance in Austria, the family owned company has grown into a global player with 200 locations in 46 countries.

As a ‘family of pioneers’, at ALPLA more than 24 000 employees develop, manufacture and recycle safe, affordable and sustainable packaging solutions – close to the customer.

ALPLA packaging touches the lives of billions of people daily. In Europe, North and South America, Africa and Asia, it ensures affordable consumption and supports numerous industries with safe solutions for consumer goods.

When the company was founded by brothers Alwin and Helmuth Lehner in 1955, its rise to become a global player was not yet foreseeable – but it was anything but a coincidence. With a passion for technology, pioneering spirit and strong teamwork, the company grew from a small family business to a global technology market leader for rigid plastic packaging. Numerous innovations, visionary

concepts, bold expansions and family cohesion have shaped the past 70 years. Milestones include the legendary Alplamat extrusion blow-moulding machine (1958), the first in-house plant located directly at the customer’s site (1985), the world’s first two-step PET bottle (1985) and the early use of post-consumer recycled material (1990). More recent highlights include the industrialisation of bio-based paper bottles and biodegradable coffee capsules.

To this day, ALPLA continues to shape progress in the packaging industry and sets quality standards in development, production and recycling. As a system provider, the company implements packaging solutions from a single source – tailormade and optimised in seven development centres and four one-stop shops for product design (STUDIOa) worldwide. With strong commitment and based on facts, ALPLA is also actively promoting the appreciation of plastic through its ‘plastic is fantastic’ initiative, educating consumers about the many benefits of the material. •

Discover the future of skincare packaging with Quadpack’s rolling dropper applicator. The Freedom Dropper is an innovative packaging solution combining a dropper, a rolling applicator, and a massager in one versatile tool. Specifically designed by Quadpack’s Creative Hub for cosmeceutical products, it transforms the skincare experience while elevating the user journey.

The Freedom Dropper is perfect for low-viscosity products, such as facial oils, serums, and products with active ingredients. Its precise rolling applicator tip ensures user-controlled application with minimal wastage, enhancing product performance and customer convenience. A purpose-built wiper removes excess formula, keeping the rod and applicator clean before releasing the drops, for a mess-free experience.

“It’s a brand new concept,” says Quadpack’s category specialist, Alejandra Isern. “Bringing a dropper and a rolling applicator together creates just the kind of value-added solution required by premium brands. For users, it’s a new experience that puts them in control. Unscrew the top, apply a drop on

your hand or directly to the face and spread it out with the soft, rolling tip. Use it like a dropper or a beauty tool – you have the freedom to use it however you like!”

The massaging effect of the Freedom Dropper not only improves formula absorption but also adds a delightful sensory dimension. Designed to deliver mess-free application, the wavy applicator makes every moment a seamless self-care ritual. Brands can customise the design, making the roller dropper an ideal packaging choice for differentiation.

Sustainably crafted with Quadpack‘s tall and elegant 30ml Skin-Up glass bottle, Freedom Dropper is a perfect choice for brands focused on sustainability without compromising quality. Its stylish design enhances any luxury skincare line, positioning the product as premium in the fiercely competitive skincare market. •

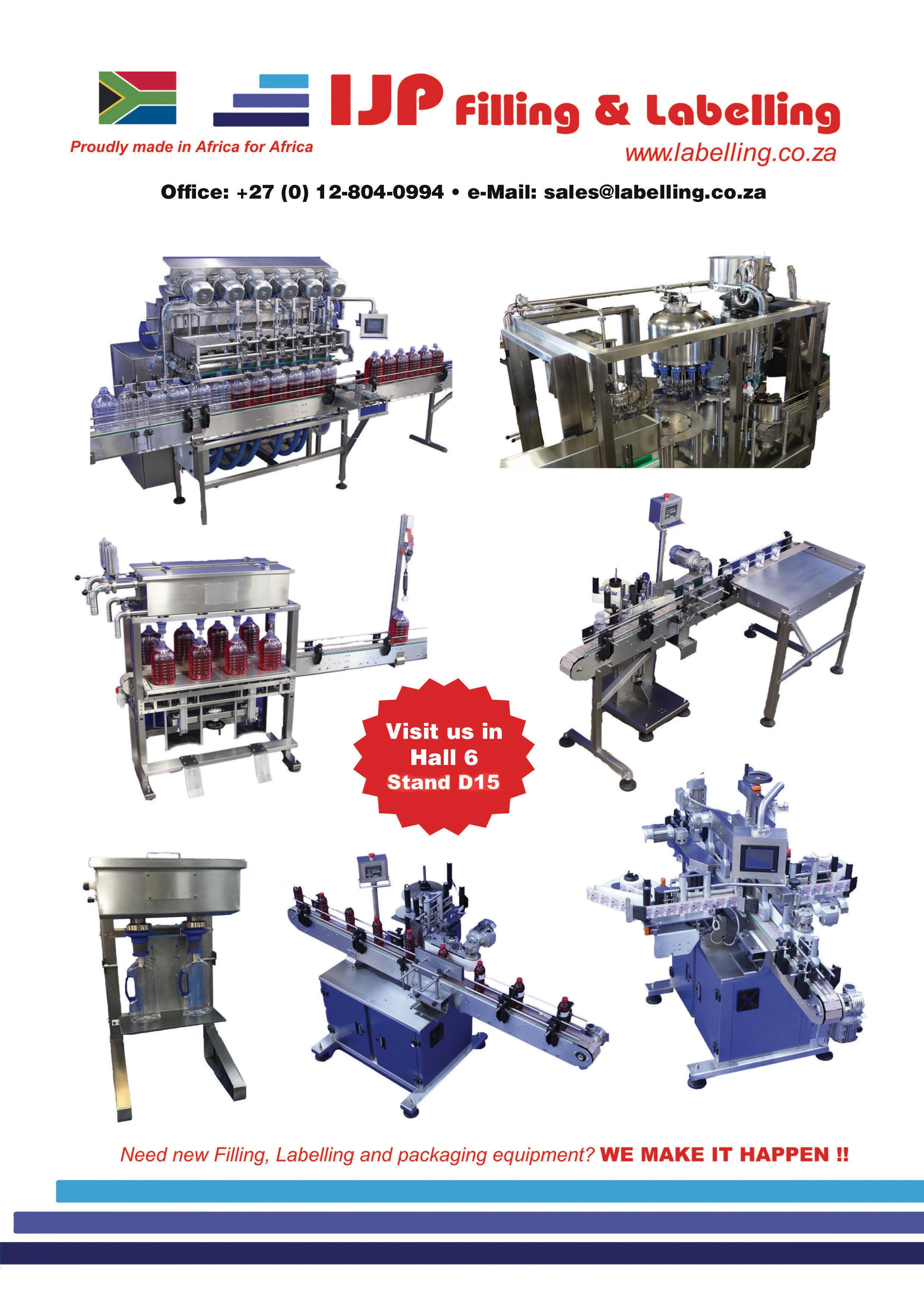

Bidvest made a significant industry announcement at Propak Africa 2025, unveiling the launch of Bidvest Labels, a move that cements its position as a leader in the labelling sector.

The new entity brings together Rotolabel, S&N Labels and Spec Systems, following the recent acquisition of Spec Systems, a respected specialist in labelling, barcoding and thermal transfer ribbons.

Colin Adendorff, CEO of Bidvest Data, Print & Packaging, emphasises the importance of this consolidation: “The formation of Bidvest Labels represents a strategic step forward in our commitment to delivering cutting-edge labelling solutions. By uniting these three companies, we have created one of the largest label businesses in South

Africa, offering a national footprint, an extensive product range and a single point of contact for all labelling needs.”

With a shared commitment to quality, innovation and exceptional service, Bidvest Labels is set to redefine the labelling landscape across Southern Africa.

The acquisition of Spec Systems strengthens Bidvest’s capabilities, allowing the company to offer expanded technical expertise, enhanced product innovation, and

seamless nationwide service delivery. With over 32 years of experience, Spec Systems brings valuable industry knowledge and customer-focused solutions that align with Bidvest’s commitment to quality and innovation.

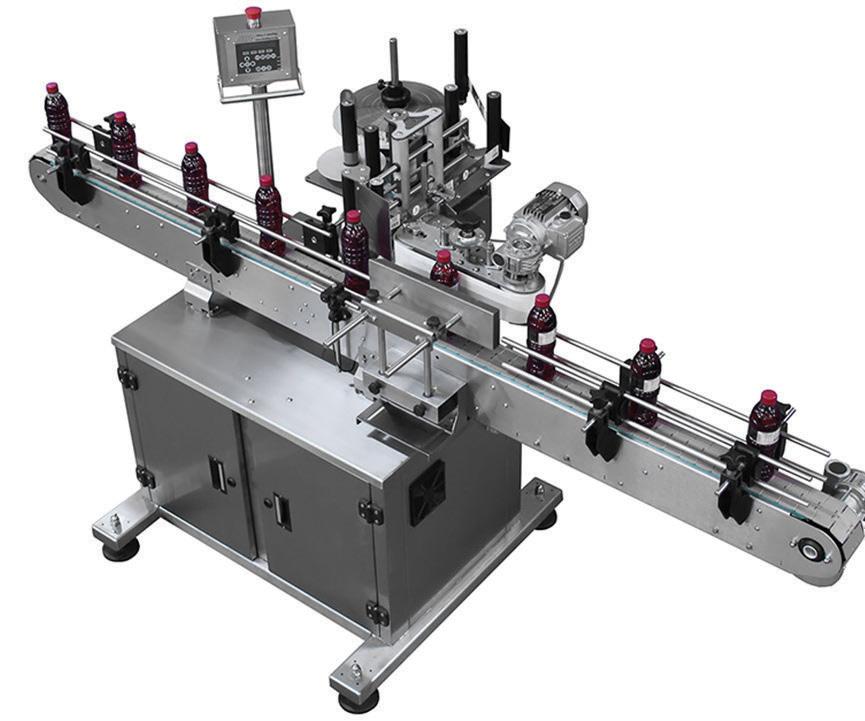

Bidvest Labels offers high-quality product labels for the food, wine, pharmaceutical and hygiene sectors, as well as functional labelling solutions, including price-marking and thermal transfer systems.

The new entity is positioned to offer an unmatched combination of expertise, product diversity and industry leading technology. With a workforce of skilled professionals, cutting-edge printing technology and a commitment to sustainability – including FSC® certification for responsible forestry practices – Bidvest Labels will continue to push the boundaries of excellence.

Customers will benefit from expanded capabilities, enhanced service offerings and greater efficiency. Whether

customers need large-scale label production, specialised security labelling or premium wine labels, Bidvest Labels provides a one-stop solution.

The introduction of Green Home Products to the Bidvest Packaging portfolio is another major highlight for the business. As a pioneer in plant-based and compostable packaging, Green Home is leading the way in sustainable alternatives with a product range that includes bagasse and bioplastic solutions free from PFAS chemicals.

“We are thrilled to welcome Green Home Products to the Bidvest Packaging family,” says Adendorff. “Their commitment to sustainability and innovation aligns perfectly with our vision for responsible packaging solutions. The demand for environmentally friendly packaging continues to grow and Green Home is at the forefront of driving meaningful change in the industry.”

“Whether customers need large-scale label production, specialised security labelling or premium wine labels, Bidvest Labels provides a one-stop solution”

In addition to launching Bidvest Labels and introducing Green Home to the stable, Bidvest Packaging includes three other companies, each demonstrating innovative solutions tailored to specific sectors:

1. Aluminium Foil Converters (AFC) is a leader in aluminium foil, film and paper flexible packaging. It supplies lidding, closures, and wrapping to top brands in the dairy, food, wine, pharmaceutical and agrochemical industries. AFC offers flexographic and gravure printing, laminating, punching, embossing, guillotining and slitting. The company prioritises food safety, holding ISO 22000:2018 certification, and maintains strong partnerships with customers to enhance packaging safety and quality.

2. Lufil Packaging specialises in fast-food packaging and is known for its commitment to sustainability. The company ensures its products are either repulpable or biodegradable and sources exclusively FSC-certified materials. With 90% of its products already eco-friendly, Lufil aims for 100%. It actively participates in the Extended Producer Responsibility (EPR) system and collaborates with suppliers to enhance sustainability. An aqueous-coated paper for takeaway chicken bags is in development and paper prescription bags for a major pharmaceutical chain are launching soon.

3. Masterpack produces advanced folding carton designs, blister cards, paper bags and package inserts, offering enhanced branding and functionality for various industries. Masterpack Cape excels in primary and secondary food packaging, backed by its AA+ BRCGS certification, FSC and PEFC accreditations. The company focusses on sustainability and innovation, recently investing in a six-

colour UV press for instant-dry packaging. It is also a member of the Fibre Circle EPR programme, reinforcing its commitment to responsible sourcing and ecoconscious manufacturing.

Masterpack Gauteng specialises in folding cartons and package inserts for the healthcare, personal care and confectionery industries. It offers six-colour offset printing, UV options, embossing and PET windows. The company is ISO 9001, FSSC 22000, and FSC certified and is approved by pharmaceutical customers under SAHPRA guidelines. As a member of the Global Packaging Alliance (GPA), Masterpack Gauteng collaborates globally for innovation and efficiency. Its sustainability efforts include rainwater harvesting, LED lighting migration and promoting biodegradable paperboard packaging.

Adendorff concludes: “With sustainability, quality and innovation at the heart of our operations, we look forward to continuing our commitment to responsible packaging solutions that meet evolving industry demands.” •

Connect with Bidvest Labels online:

In a market where packaging choices can make or break product success, Bright Packaging & Raw Materials has established itself as the go-to partner for companies seeking quality, flexibility, and sustainability without compromise.

Based in South Africa with physical stores in Centurion, Pretoria and Cape Town, Western Cape, the company represents a refreshing approach to packaging procurement – one that prioritises clients’ needs over rigid corporate structures.

For many South African businesses, particularly emerging brands and start-ups, accessing premium packaging solutions has traditionally meant navigating complex minimum order quantities and inflexible supplier terms. Bright Packaging & Raw Materials (Brightpack) has fundamentally challenged this approach by eliminating minimum order requirements entirely. Whether a pharmaceutical company needs a single prototype bottle or a cosmetics manufacturer requires bulk quantities, the company accommodates every scale of operation.

This flexibility extends beyond order quantities to product customisation. Brightpack’s extensive range of glass dropper bottles, available in sizes from 5ml to 100ml and in colours such as amber, clear, blue, green and black, provides formulators and brand managers with the creative freedom to match packaging precisely to their product requirements. For brands developing premium serums, essential oils, or pharmaceutical tinctures, this level of choice translates directly into enhanced shelf appeal and brand differentiation.

Whilst sustainability often carries a premium price tag, Brightpack demonstrates how environmental responsibility can align with commercial pragmatism. The company’s focus on glass packaging addresses multiple market pressures simultaneously – from consumer demand for eco-conscious products to regulatory requirements for chemical-resistant containers.

Glass offers compelling advantages that resonate particularly well in South Africa’s diverse climate conditions. Unlike plastic alternatives, glass maintains complete chemical inertness, ensuring product integrity across temperature variations and extended storage periods. For pharmaceutical companies dealing with sensitive formulations or cosmetics brands using active ingredients, this stability represents added quality assurance and regulatory compliance. The recyclability factor provides additional commercial value. As South African regulations increasingly focus on packaging waste reduction, companies partnering with Brightpack position themselves ahead of compliance curves whilst appealing to environmentally conscious consumers.

The company’s dual-location strategy reflects a sophisticated understanding of South African market dynamics. It has physical

stores in Centurion and Cape Town, coupled with nationwide online availability. For procurement specialists managing multiple product lines, the ability to physically examine packaging options before committing to orders provides invaluable peace of mind. Brightpack’s local presence extends beyond convenience to genuine market insight. The company understands the unique challenges facing South African manufacturers, from fluctuating exchange rates affecting imported packaging to the need for robust solutions that withstand local distribution networks. Its dual offering of glass and plastic solutions acknowledges that different products require different approaches. For example, premium cosmetics might demand glass’ elegance, whilst household products benefit from plastic’s durability.

Perhaps most significantly, Brightpack addresses one of procurement’s persistent headaches, which is supplier consolidation. By offering primary packaging solutions (bottles and jars) and complementary closures in a single relationship, the company simplifies vendor management whilst ensuring compatibility across components. For quality managers, this integration reduces the risk of component mismatches that can compromise product integrity or delay time to market. For procurement teams, it streamlines purchasing processes and provides greater negotiating leverage through consolidated spending.

Brightpack’s approach to business is of great benefit to the dynamic South African market, where businesses often evolve rapidly from start-up concepts to established brands. Its scalable solutions accommodate this growth trajectory without requiring procurement relationship changes that can disrupt operations.

For cosmetics brands and manufacturers developing product ranges, pharmaceutical manufacturers expanding formulations, or nutraceutical brands testing market acceptance, the ability to maintain packaging consistency whilst adjusting volumes provides operational stability during critical growth phases.

What distinguishes Brightpack in an increasingly commoditised market is its recognition that successful packaging procurement extends beyond product specifications to partnership quality. The company’s customer-centric approach acknowledges that

“Brightpack’s local presence extends beyond convenience to genuine market insight ”

packaging decisions often involve complex considerations, such as regulatory compliance, brand positioning, cost management and sustainability targets.

By combining premium products with flexible terms and local expertise, Brightpack provides South African businesses with packaging solutions that enhance rather than constrain their market opportunities. In industries where packaging increasingly influences purchase decisions, such partnerships represent genuine competitive advantages. •

Packaging, Equipment & Raw Materials Made Simple

Your one-stop partner for packaging, equipment & raw materials.

At Brightpack, we make it easy for businesses of all sizes to create, package and scale their products. From glass and plastic packaging to production equipment, white label products and raw materials, we’ve got everything you need under one roof. Whether you’re a small start-up or an established brand, our goal is to help you take your product from idea to shelf - with quality, reliability and support every step of the way.

www.brightpack.co.za

hello@brightpack.co.za

Centurion: 012 0040 183

Cape Town: 021 3000 684

Buckle Packaging is driving sustainable growth across Southern Africa. The company continues to lead the charge in sustainable packaging innovation, helping manufacturers across diverse industries transition to eco-friendly solutions without compromising on performance.

For over four decades, Buckle Packaging has been a trusted partner to the food and beverage, pharmaceutical and agricultural sectors, delivering highquality packaging machinery and consumables that keep African businesses competitive.

Founded in 1979 and still proudly family-run, it has grown to become Africa’s largest supplier of industrial bag-closing and heat-sealing equipment, with a portfolio that blends proven reliability with forward-thinking innovation. As we look to 2025 and beyond, the packaging industry faces a dual challenge: meeting increasing consumer demand for quality and convenience, while also embracing the shift towards more sustainable, responsible packaging practices. Buckle Packaging believes that success lies in marrying efficiency, sustainability and adaptability – helping customers future-proof their operations.

Each sector the company serves – be it food and beverage, pharmaceuticals, chemicals or agriculture –has unique requirements, regulatory considerations and production demands.

Food and beverage manufacturers often face highvolume production with strict hygiene standards. Buckle Packaging’s stainless steel bag-closing systems, such as the Fischbein MFS range, are designed for all environments, ensuring robust performance in poultry plants, grain mills and coffee roasteries.

Pharmaceutical producers need precision and compliance with GMP and safety standards. Buckle Packaging’s heat sealing and continuous band sealing solutions deliver secure, tamper-proof packaging for powders, capsules and medical devices.

Agricultural operations require rugged, versatile equipment that can handle bulk products like animal feed, fertilizer and seed. The heavy-duty stitching and sealing systems from Buckle Packaging are built to withstand demanding environments and ensure consistent, presentable and longlasting seals.

Many of Buckle Packaging’s customers in the chemical, mineral and construction materials sectors handle abrasive, heavy or moisture-sensitive products such as cement, salt,

or powdered chemicals. Paired with heavy-duty conveyors, the robust closing systems from Buckle Packaging are engineered to withstand tough conditions, ensuring a secure seal that protects product integrity during transport and storage.

By tailoring solutions to the specific conditions and compliance requirements of each sector, Buckle Packaging helps businesses avoid downtime, reduce wastage and optimise production flow.

Sustainability is no longer optional – it is a strategic imperative. As the packaging industry pivots towards greener practices, Buckle Packaging is actively expanding its range of eco-friendly solutions. It is also helping customers make the transition without compromising on performance or profitability.

Buckle Packaging’s approach to sustainability includes:

• Poly-woven and recyclable bag compatibility – the supplier’s machines are optimised to handle recyclable poly-woven and paper-based bags, enabling businesses to reduce reliance on single-use plastics while maintaining packaging durability.

• Sustainable materials and consumables – they supply a range of eco-conscious consumables and premium thread made for minimal environmental impact, helping customers reduce their packaging footprint.

• Minimised wastage in operation – their machinery is engineered to reduce unnecessary loss during production, whether it’s preventing bag damage during testing or using precision stitching to limit excess thread consumption. This not only lowers costs, but also supports sustainable production practices.

• Durable, long-life equipment – a key aspect of sustainability is longevity. By supplying machines that last for decades, with locally available spare parts and technical support, Buckle Packaging helps reduce waste from premature equipment disposal.

Did you know?

Buckle Packaging brings stability and innovation to its clients’ businesses. The company has more than 45 years of experience in packaging, coupled with strong supplier relationships and deep industry knowledge.

By aligning with global sustainability standards and offering adaptable machinery that works with recyclable and biodegradable packaging formats, Buckle Packaging is positioning African manufacturers for long-term compliance and competitive advantage.

The African packaging industry is on a rapid growth trajectory, fuelled by expanding consumer markets and increased exports. Buckle Packaging is responding to this growth with new technology, enhanced automation and service innovations that help customers scale up efficiently. For the remainder of the year, customers can look forward to:

• Next-generation automated bagging lines that are faster, more precise and more efficient. These systems integrate bag guiding, folding and conveying in a streamlined flow – ideal for high-volume food processing, bulk agricultural goods and industrial products.

• Enhanced after-sales service from Buckle Packaging’s fully equipped Johannesburg workshop and skilled technicians. They offer fast turnaround on repairs and spares, while extensive stockholding ensures machinery, consumables and parts are readily available.

• Customised industry solutions – whether you need a compact sealing station for a small-scale mill or a fully automated poultry plant system – Buckle Packaging tailors solutions to fit your specific capacity and compliance needs.

Buckle Packaging is more than a supplier; it is a partner invested in your operational success. The Buckle Packaging

“Buckle Packaging is more than a supplier; it is a partner invested in your operational success”

team works closely with customers from machine selection to installation, training, and ongoing maintenance, ensuring a smooth and productive packaging process.

As African industries navigate the twin demands of growth and sustainability, Buckle Packaging is ready to deliver reliable, future-focused solutions that keep production lines running, protect product quality, and meet evolving environmental expectations.

If you are looking to upgrade your packaging operations, embrace sustainable materials, or scale your capacity for Africa’s growing markets, Buckle Packaging has the equipment, expertise, and commitment to help you succeed.

Contact them today to discuss how Buckle Packaging can tailor a solution to your needs and support you on your journey towards sustainable growth. •

Connect with Buckle Packaging online:

Packaging automation has transformed many manufacturing processes, yet manual loading operations remain a bottleneck for productivity. CAMA’s innovative ACL system is designed to finally bridge this automation gap.

Packaging is a highly automated industry with high-speed processes and solutions that drive ongoing technological innovation.

However, even with all the advances in automation, there are still a few operations that are predominantly manual. These include magazine loading, reel loading, semi-finished product loading and quality inspection – all of which present issues relating to ergonomics, safety and repeatability.

One operation that can prove challenging for operators is the loading of carton blank magazines on packaging machines.

Carton blanks are often produced by paper mills located hundreds of kilometers away, transported on trucks, unloaded by forklift drivers and stored in the warehouse for weeks or months at a time. These continual logistical operations often result in pallets with misaligned products, excessive folding or carton blanks that exhibit different consistencies and moisture content depending on the season.

This inherent variability in carton blank specifications creates challenges for automated packaging lines, which require the visual adaptability, selective judgement and handling flexibility that human operators naturally provide.

“The ACL system never gets tired”

Collaborative robots can replace the arm of an operator, with even greater strength, reach and agility, while grippers equipped with distance, torque sensors and customised gripping systems can mimic an operator’s hand.

Collaborative robots can also be complemented with vision systems, based on 2D/3D or AI-based technologies, to replicate an operator’s view.

These integrated robotics and vision systems free operators from repetitive, time-consuming and burdensome tasks, allowing them to focus on higher-value activities while simultaneously boosting overall productivity.

CAMA presents automatic carton loading (ACL) as a viable solution. Comprising a collaborative robot, equipped with specialised interchangeable product-specific gripping tools, smart cameras and advanced programming, the ACL system automatically recognises the pallet pattern, its orientation, the cartons stacks and removable interlayer sheets. It can then grip and automatically load carton blanks into a machine’s magazine. It can also handle closed boxes and can be augmented with multiple smart tools and functions, including straps removal, case lid tear-off, and automatic size changing. If for some reason a pallet cannot be processed, the ACL system can request operator intervention.

The technology integrates seamlessly with CAMA machines, where it can be adapted to available factory real estate. For modern integrated packaging operations, the ACL system can communicate with upstream and downstream machines, so it can prepare to receive pallets transported by AMR (mobile robot).

It also works in harmony with the operator, sharing space in total safety according to all current regulations. The ACL system never gets tired. It is maintenance free, thanks to the fully electronic technology, it can be monitored remotely. It also feeds essential operational data and statistics into analytics systems.

Traditional fixed robotics aren’t always the optimal solution. When facilities have multiple storage locations with slower cycle times, installing individual robots at each point becomes economically unviable. Similarly, space constraints or the need to relocate depalletising operations to warehouse areas can make fixed installations impractical.

In these scenarios, autonomous ACL systems offer a compelling alternative. By moving freely throughout the production environment, these mobile solutions deliver

automation benefits where traditional approaches fall short – providing the flexibility to adapt to changing layouts whilst maintaining operational efficiency. •

Pactech is the local agent for Cama Group.

Technology inspired by human talent

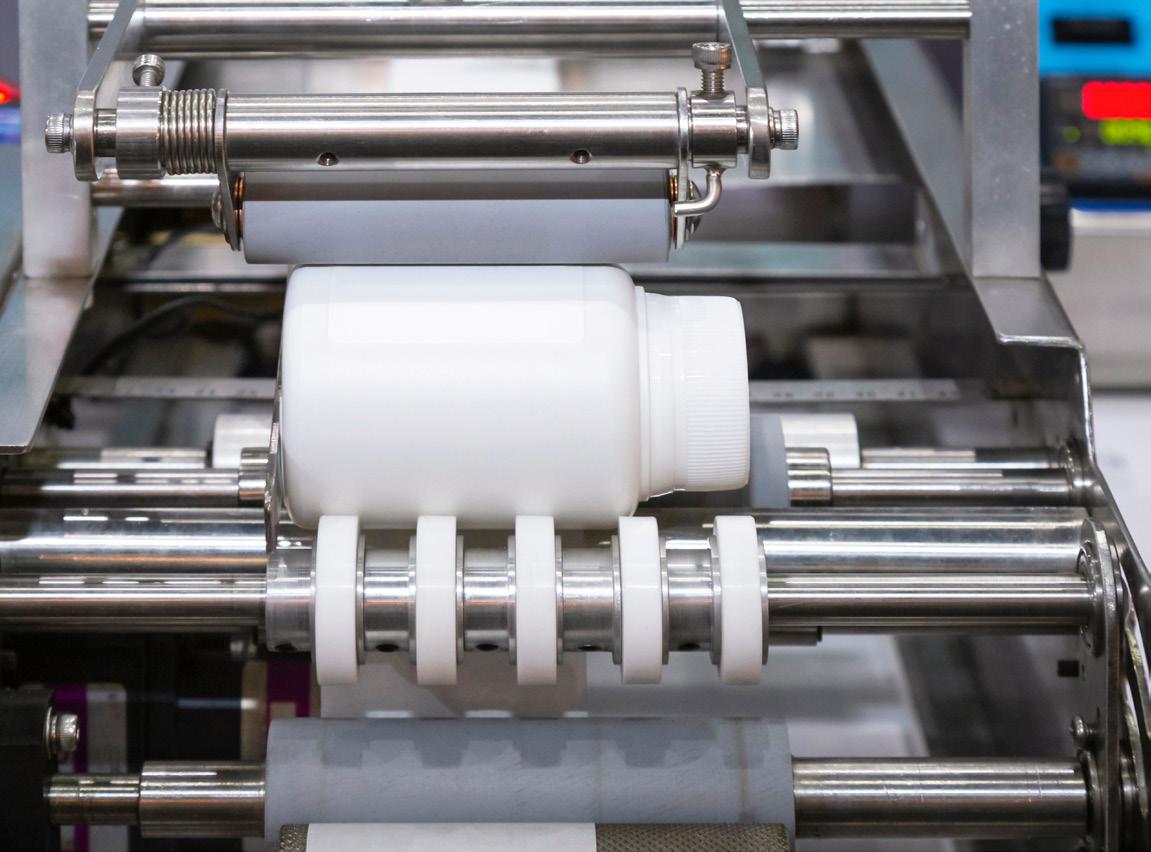

CCL announces a new pressure-sensitive label developed specifically for improved recycling of single use glass bottles.

CCL Label’s strategy is to help customers meet their sustainability targets while reducing the impact of its own manufacturing processes, materials and products.

As a world leader in specialty label, security, and packaging solutions, CCL Label has introduced a new adhesive technology developed specifically for single-use glass bottles. This new solution will be marketed under the product name, EcoShear®. In 2024, the average glass packaging collection for recycling in the EU was 80.2%. This figure represents the amount of glass packaging collected for recycling compared to the total amount placed on the market. Although the collection rate for one-way or single-use glass bottles and jars is relatively high, picking the right label for glass packaging can make a huge difference if the glass gets recycled or ends up being downcycled or even ends up in landfill.

“EcoShear® maximises glass recovery, minimising waste and supporting environmental goals ”

CCL Label’s EcoShear® is a breakthrough adhesive technology engineered specifically for single-use glass bottles. It enables virtually residue-free label removal, dramatically improving the recyclability of glass packaging.

“While glass recycling has proven to be successful, there remain additional ways you can continue to improve the recycling yield, starting with glass decorations such as labels,” explains Anja Rockstroh, development and technology at CCL Label in Meerane, Germany. “With EcoShear®, CCL introduces a revolutionary adhesive technology developed specifically for single-use glass bottles and jars and other containers.”

Self-adhesive film labels are premium and widely used for glass packaging in the beer, beverage and food industries. The moisture-resistant material provides an attractive clear-on-clear appearance, offering unlimited design possibilities and increased shelf appeal.

Standard filmic labels can impair the quality of recycled glass or adhere so strongly to glass shards that they are rejected during the sorting and recycling process. However, EcoShear® enables nearly residue-free removal during recycling. This reduces glass waste and significantly increases the yield of high-quality recycled glass.

EcoShear® maximises glass recovery, minimising waste and supporting environmental goals. It also supports energy efficiency with reduced waste and contamination contributing to lower energy consumption, helping brands meet sustainability benchmarks. •

Automated inspection technology from EyeC is shifting packaging quality control from reactive to predictive in line with sustainability developments.

The packaging industry faces challenges that are reshaping quality assurance priorities. Rising consumer expectations for safety and visual perfection coincide with increasingly stringent regulatory requirements across the pharmaceutical, food and beverage, personal care, and beauty sectors. The shift toward sustainable packaging introduces new complexities, as recycled materials often exhibit unpredictable optical and structural properties. Traditional manual inspection methods struggle to keep pace with accelerating production speeds and today’s quality standards. Human inspectors face inherent limitations in detecting microscopic defects consistently. Quality failures can result in product recalls potentially costing manufacturers millions while damaging brand reputation. These pressures demand an evolution in quality control. The idea is to shift from reactive to predictive inspection with intelligent systems that can adapt to changing production environments and emerging packaging technologies, while maintaining a competitive advantage and ensuring consumer trust.

Since 2002, EyeC has been at the forefront of print inspection technology, delivering systems that safeguard product integrity and ensure compliance. The company’s modern inspection solutions accommodate vastly different quality criteria across all sectors of packaging. While pharmaceutical applications demand absolute precision in detecting minute variations requiring resolution capabilities that can identify

defects measured in micrometers, personal care and beauty packaging focuses heavily on aesthetic consistency, with colour uniformity and surface finish variations invisible to untrained eyes.

Intelligent classification through AI EyeC’s comprehensive portfolio of in-line and offline inspection solutions addresses these challenges, detecting microscopic defects to ensure compliance in regulated industries. The company’s latest generation of systems represents a fundamental shift from traditional defect detection to intelligent classification and analysis. The EyeC ProofRunner Web series utilises artificial intelligence to not only identify print defects but to also understand and categorise them. While traditional solutions categorise similar defects under broad classifications – this leads to unnecessary production stoppages when irrelevant variations trigger alarms.

The EyeC solution addresses one of the industry’s most persistent challenges by distinguishing between defects that require immediate intervention – like colour deviations, misalignments, or blurred images. It also distinguishes between those that are acceptable within production tolerances like dust particles or substrate inclusions.

The training methodology behind this intelligent system involves datasets consisting of thousands of actual print jobs. Through extensive image library analysis, EyeC’s AI learns to differentiate between errors requiring attention and those that don’t impact product quality. By minimising false alarms, the system ensures smoother workflows while maintaining rigorous quality standards. This proves particularly significant in high-volume production environments where even minor interruptions can impact on overall equipment effectiveness metrics. At the same time, this approach minimises material waste and reduces the likelihood of creating secondary quality issues.

However, the integration of intelligent defect classification extends beyond immediate quality control to encompass predictive maintenance and operational optimisation. It provides valuable defect insights that strengthen equipment maintenance strategies, reducing unexpected breakdowns while extending the machinery’s lifespan. Yet, realising these benefits in practice requires addressing the added complexity of diverse manufacturing environments. EyeC’s systems demonstrate adaptability in integration scenarios,

with solutions that fit seamlessly into existing production workflows.

The next step is extending quality intelligence beyond individual facilities. Manufacturers are turning to connected, cloud-based inspection systems that make quality control accessible across entire production networks. SaaS-based prepress inspection systems like the new EyeC Proofiler Graphic Connect enable multi-site manufacturers to benchmark quality across facilities and standardise successful approaches. With its seamless integration into workflow systems like Esko’s Automation Engine or Hybrid Cloud Workflow, EyeC’s system ensures that quality checks are carried out in real-time without disrupting existing work processes.

The modular architecture of EyeC ProofRunner Web also allows starting with a base configuration and gradually upgrading the system to the more powerful HighLight or HighLight UHD variants as a manufacturer’s needs evolve. This capability proves particularly valuable for pharmaceutical and food manufacturers operating under strict regulatory frameworks, where consistency across production sites is both operationally critical and legally mandated.

The technologies are not only about compliance and efficiency, but also play a pivotal role in advancing sustainability objectives. By identifying defective items before they progress through subsequent packaging stages, EyeC proves that intelligent inspection systems serve as critical gatekeepers in waste prevention strategies. These systems prevent the accumulation of additional material costs, lower energy usage through decreased false rejects, and improved environmental impact scores across packaging operations. This early intervention approach significantly reduces total waste generated, as materials, inks, adhesives and energy investments are minimised when problems are detected at the earliest possible stage. Success in packaging landscape of tomorrow will increasingly depend on the ability to balance stringent

quality standards with sustainable practices and operational efficiency. These systems, by delivering measurable benefits in quality, cost and sustainability, exemplify how intelligent automation has become a pillar of modern manufacturing operations. •

The packaging industry is discovering that the right lubrication strategy can be a game-changer for manufacturing efficiency and environmental impact. FUCHS LUBRICANTS SOUTH AFRICA offers innovative lubrication solutions that not only extend machinery life and reduce energy consumption, but also help packaging operations achieve their green goals.

The growing demand for sustainability adds pressure to the packaging industry to find innovative solutions that reduce environmental impact without compromising performance.

FUCHS LUBRICANTS SOUTH AFRICA is dedicated to offering lubrication solutions that enhance the efficiency and longevity of packaging machinery. These products provide significant operational advantages to the food and beverage, pharmaceutical, personal care, and beauty packaging sectors.

Pioneering sustainable lubrication solutions

Proper lubrication ensures that packaging machinery operates smoothly and with minimal wear. FUCHS recognises the opportunity to offer solutions that align with global sustainability goals without compromising performance.

The FUCHS CASSIDA range of food-grade lubricants – NSF certified for incidental food contact – delivers superior performance under the demanding conditions of high-speed packaging lines. By reducing friction and wear, these lubricants extend machinery lifespan and reduce waste.

Enhancing machinery performance and sustainability

Sustainability in packaging extends beyond materials – it includes how products are manufactured. FUCHS lubricants optimise machinery efficiency, reduce energy consumption, and lower maintenance requirements, helping companies reduce their carbon footprint.

“Proper lubrication ensures that packaging machinery operates smoothly and with minimal wear”

food safety risks associated with traditional mineral oils.

• Paper and cardboard: FUCHS mitigates the use of harmful chemicals in inks and hydrocarbons, supporting safer, sustainable printing.

• Plastic packaging: Biodegradable lubricants from FUCHS address environmental concerns while maintaining protective qualities.

FUCHS LUBRICANTS SOUTH AFRICA supports clients through collaborative projects, technical expertise, and its LCCP (Lubrication Critical Control Point) Audit. The company’s extensive network of experts ensures each solution is

aligned to customers’ needs, driving innovation and operational excellence.

FUCHS is committed to providing comprehensive solutions that address the unique challenges faced by the packaging industry.

For more information on how FUCHS lubrication solutions can benefit your packaging operations, visit the FUCHS LUBRICANTS SOUTH AFRICA website. Together, we can enhance efficiency, sustainability, and safety across your processes. •

The RENOLIN CLP range, for example, offers exceptional protection against wear and corrosion, even in extreme conditions. These gear oils are formulated to enhance energy efficiency, contributing to lower electricity usage and reduced emissions.

To reinforce its commitment to the packaging sector, FUCHS LUBRICANTS SOUTH AFRICA leverages the specialised expertise of LUBCON within the FUCHS brand. The LUBCON range delivers tailored lubrication solutions for high-speed, high-precision packaging environments. From metal forming to plastic and glass applications, LUBCON’s advanced formulations ensure optimal performance, reduced downtime and enhanced sustainability, solidifying FUCHS as a trusted supplier to the dynamic packaging industry.

FUCHS has invested heavily in R&D to meet the highest environmental standards. Its lubrication solutions cater to metal, paper, cardboard, plastic and glass packaging applications, offering efficiency, safety, and sustainability.

• Metal packaging: Its lubrication solutions control wear and friction in forming processes, avoiding

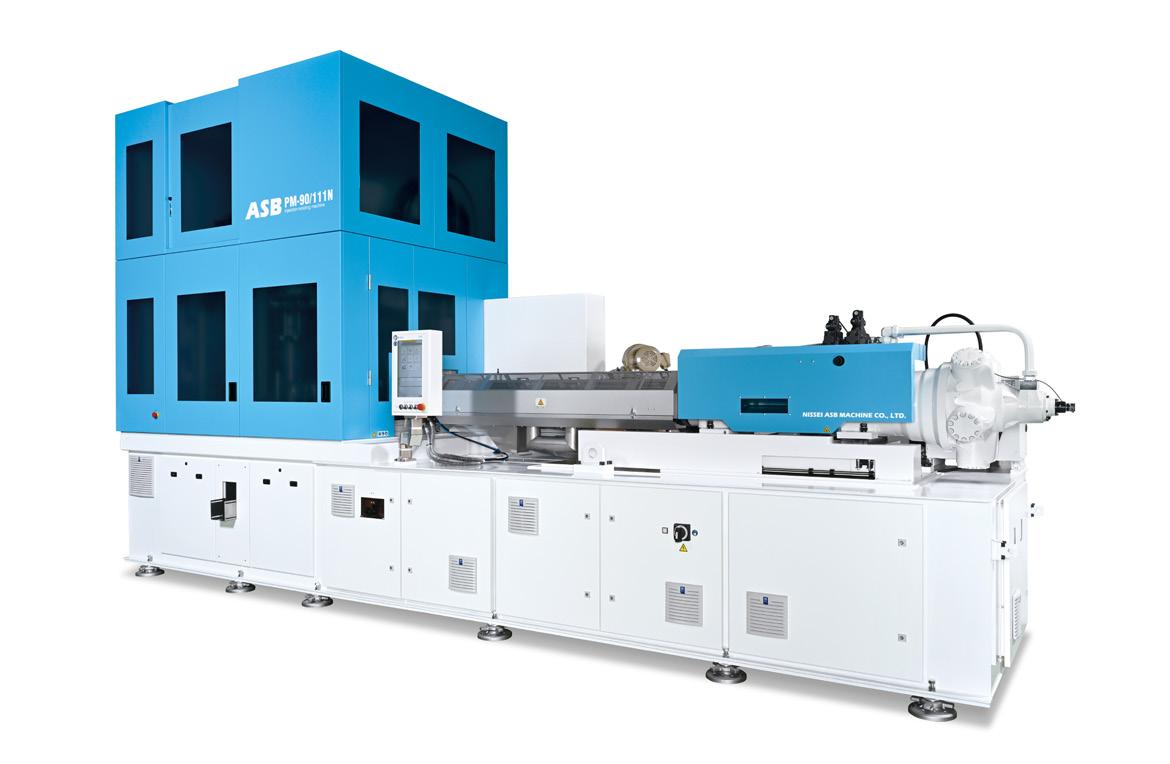

Japanese innovation meets environmental responsibility as Nissei ASB debuts revolutionary machinery at K 2025.

Pivotal changes are happening in the packaging industry, driven by sustainability, which has gone from a buzzword to being an operational necessity. For procurement specialists and innovation leaders across Africa’s food and beverage, pharmaceutical and personal care sectors, the challenge of balancing environmental responsibility with production efficiency has never been more pressing.

In line with these developments, Nissei ASB Machine Co.’s latest innovations promise to reshape how the industry thinks about sustainable plastic bottle manufacturing. At the upcoming K 2025 exhibition, taking place from 8 to 15 October in Düsseldorf, Germany, the Japanese machinery giant will showcase its all-in-one sustainable bottle solutions. This comprehensive approach addresses the packaging industry’s most critical challenges whilst delivering impressive production capabilities. These developments come at a time when many South African manufacturers are grappling with increasing environmental regulations and consumer demand for sustainable packaging.

Perhaps the most significant breakthrough comes from Nissei ASB’s PF36/36-600 machine, which produces 500m l water bottles using 100% recycled PET (rPET) without compromising on quality. Operating at a staggering 18 000 bottles per hour, this 1.5-step injection stretch blow moulding system demonstrates that sustainability and productivity need not be mutually exclusive. The implications for the South African beverage industry are substantial, particularly as local manufacturers seek to meet stringent recycling targets whilst maintaining competitive production costs.

+ Preform Molding

The machine achieves notable efficiency gains – up to 20% energy savings compared to conventional systems – whilst requiring a smaller factory footprint. For manufacturers operating in South Africa’s competitive market, where utility costs and facility space directly impact profitability, these advantages translate to tangible bottom-line benefits.

Three of Nissei ASB’s four machines making their global debut at K 2025 address specific market needs that resonate well with African packaging requirements. The PM-90/111N preform injection moulding machine offers a compelling proposition for smaller manufacturers. It delivers high-speed production in a compact design that reduces investment costs by 40% and floor space requirements by 30%. For the personal care and beauty industry, which is growing rapidly across Africa, the ASB-70DPH/50E hybridelectric machine produces thick-walled cosmetic bottles with 25% energy savings. This technology particularly benefits producers of packaging for household cleaning and personal care products, where container durability and costeffectiveness are paramount.

Presenting a world-first at K 2025, Nissei ASB’s HSB124N/111N can produce returnable and refillable PET bottles

“For African packaging manufacturers, Nissei ASB’s innovations offer a pathway to competitive sustainability”

through 1.5-step double blow technology. These bottles can withstand 25+ refilling cycles whilst being 7.5% lighter than traditional alternatives.

For South African beverage companies exploring returnable packaging systems – particularly in rural markets where container collection systems are feasible – this technology offers a genuine alternative to single-use packaging without the weight and breakage concerns of glass.

The environmental mathematics are compelling –returnable PET bottles significantly reduce the carbon footprint compared to single-use alternatives, addressing regulatory pressures and consumer environmental consciousness.

Nissei ASB understands that modern manufacturers need integrated solutions. This, coupled with their innovative machinery, set them apart in the industry. For example, the Vision1™ control systems enable remote monitoring and diagnostics, which are crucial capabilities for South African manufacturers operating across multiple sites or requiring technical support across vast distances.

For African packaging manufacturers, Nissei ASB’s innovations offer a pathway to competitive sustainability. As regulations tighten and consumer preferences shift towards environmentally responsible packaging, manufacturers equipped with advanced production capabilities will find themselves well-positioned for growth.

As the packaging industry continues evolving towards greater sustainability, Nissei ASB’s comprehensive approach – combining recycled materials, energy efficiency and innovative designs – provides a blueprint for manufacturers ready to embrace the future of responsible packaging production. •

As Africa’s packaging industry evolves to meet changing market demands and sustainability goals, innovative solutions are becoming essential for businesses across multiple sectors. In this article NSI Label shares insights into ecofriendly, industry-specific packaging that supports economic growth and environmental responsibility.

Across Africa’s food and beverage, pharmaceutical, personal care and beauty sectors, packaging is undergoing a major transformation. No longer just about product protection, packaging today must deliver sustainability, innovation and growth. Decisionmakers and procurement specialists are seeking trusted partners who can help future-proof their operations with eco-friendly solutions that also unlock new market opportunities.

NSI Label is proud to play a role in this transformation – delivering sustainable, innovative, and growth-driven packaging solutions tailored to Africa’s evolving markets.

Sustainability, which was once an option, has now become a key driver of procurement and brand positioning. With rising regulatory requirements, growing consumer demand for eco-friendly solutions and corporate commitments to lower carbon footprints, manufacturers across Africa are rethinking their packaging strategies.

In line with these changing demands, NSI Label offers:

• Biodegradable films and compostable options for food and beverage packaging.

• Recyclable mono-material solutions for pharmaceuticals and cosmetics applications.

• Lightweight packaging formats that reduce raw material use without sacrificing performance.

The company’s approach aligns with the circular economy, helping clients reduce waste, extend packaging lifecycles and meet global sustainability benchmarks. For instance, NSI Label’s new packaging solutions reduce plastic use by up to 40% while maintaining the protection required for sensitive industries such as pharmaceuticals and beauty.

NSI Labels serves multiple sectors, each with its own unique demands:

• Food and beverage – modified-atmosphere packaging (MAP) extends shelf life and reduces food waste, while plant-based materials offer renewable, compostable solutions.

• Pharmaceutical – tamper-evident, child-resistant and traceable packaging enhances compliance and safety.

• Personal care and beauty – lightweight jars, refillable containers and eco-friendly pouches align with consumer values and improve shelf appeal.

Through collaborative design workshops and R&D partnerships, NSI Label works together with its clients to tailor innovations that meet regulatory, market and sustainability demands.

Africa’s packaging market is expanding rapidly, driven by urbanisation, a rising middle class, and increased demand for branded products. This growth brings opportunity, but also responsibility. For example, packaging must enable businesses to scale while remaining environmentally responsible.

NSI Label is committed to supporting this growth by:

• Investing in local manufacturing and skills development.

• Strengthening supply chains to ensure accessibility and affordability.

• Championing homegrown packaging innovations that respond directly to Africa’s market realities.

By building capacity locally, the company reduces reliance on imports and creates solutions designed for African businesses and consumers.

NSI Label is proud to introduce new offerings that redefine packaging for the future:

• Smart packaging technology in the form of QR-code-enabled packs that allow consumers to verify authenticity, trace sourcing and engage directly with brands.

• Recyclable barrier films to replace nonrecyclable, multi-layer materials with fully recyclable structures.

• Lightweight packaging in the form of optimised secondary and tertiary packaging that reduces logistics costs while cutting emissions.

These innovations highlight NSI Label’s commitment to customer-centric design, sustainability and growth.

The coming decade will define Africa’s packaging industry. Companies that invest in sustainability and innovation today will be tomorrow’s leaders. NSI Label aims to be more than a supplier. It is your strategic partner in achieving growth, compliance and sustainability goals.

Eddie prints full-colour photographs and text directly onto the surface of food like cookies, lollipops, chocolate, wafers, marshmallows, macarons, crackers and many other suitable food items.

The world's only GMP and NSF® certified food printer. Perfect for corporate events, parties, weddings and other occasions.

✓ Prints directly onto food

✓ Easy to use

✓ Custom made Trays ✓ Ink cartrdige

Together, NSI Label and its clients can shape a packaging industry that protects products, delights consumers and preserves the planet. •

Technical Specifications

PMD Packaging has launched an innovative range of small pack machinery, targeting African entrepreneurs. The range addresses portion control hygiene challenges across diverse markets.

PMD Packaging (PMD) is constantly investing in new solutions for packaging systems to suit the food and beverage manufacturing industry, as well as the pharmaceutical and nutraceutical manufacturing industries. Furthermore, the economic profile of Africa is of great interest to the business.

“Many end users of common domestic products simply don’t have the resources to purchase the big packs and the result is often manual interference in order to satisfy the need for small packs,” explains Mike Spencer, managing director of PMD Packaging.

Small entrepreneurs have no choice but to do their best and measure portion size as best they can and manage their hygiene issues accordingly. This naturally introduces the consumer to hygiene risks coupled with the possibility of being over charged.

These trends reveal rising pressures to make small packs available, which are produced in compliance with health and safety and to meet the needs of the modern world.

In response, PMD has launched a new range of machines to complement its very successful range of VFFS machines with a multitude of special dosing systems, plus auto baling, shrink-wrap and many other unique solutions where the company enjoys assistance from its European partners.

This move is designed to satisfy many markets including, small entrepreneurs and large companies that need to offer small portions.

Three machines, multiple applications

PMD’s range of small pack machines includes:

1. Taurus is a mini VFFS machine for three side seal or pillow pack requirements. The Taurus is available with quick change over dosing capability for liquids, powders or granules.

2. Sigma 1 is a high speed VFFS machine for small packs, producing up to 100 packs per minute.

3. Apollo is a horizontal sachet machine for three or four side seal requirements and either single or twin lane capacity.

“We design them, we build them, we maintain them, we improve them, we develop them,” says Mike Spencer. “And above all we have technical support for everything we make.” • “We design them, we build them, we maintain them, we improve them, we develop them. And above all we have technical support for everything we make.”

Connect with PMD Packaging online

– Mike Spencer”

Tournaire’s nearly two-century journey of innovation offers South African manufacturers an alternative to conventional packaging solutions.

Represented locally by Sensetek, the French aluminium packaging specialist brings cuttingedge technology that transforms how industries approach product protection, sustainability and regulatory compliance.

Packaging performance can determine a product’s success or failure. For procurement specialists managing sensitive products – from pharmaceutical actives to essential oils – traditional packaging materials often present frustrating compromises. Glass brings fragility concerns and transport complications. Multi-material composites create recycling challenges. Plastic solutions may lack the barrier properties crucial for product integrity. Yet Tournaire’s monobloc aluminium technology eliminates these trade-offs entirely.

The company’s seamless construction approach, perfected since the 1930s, creates packaging that combines exceptional protection with practical durability. Unlike welded or assembled containers, these monobloc canisters eliminate weak points that compromise product safety. For South African companies dealing with extreme temperature variations during transport and storage, this structural integrity translates directly into reduced product losses and enhanced reliability.

Tournaire’s SYSTEM PLUS® closure technology exemplifies how technical innovation addresses everyday packaging challenges. Developed in the 1980s and refined continuously since then, this aluminium-plastic hybrid sealing system provides airtight protection even under the most demanding conditions. This reliability represents cost savings and regulatory compliance assurance when transporting temperature-sensitive compounds or for chemical manufacturers dealing with volatile substances.

The recently introduced OMNI+® closure range takes innovation a step further by addressing sustainability requirements without compromising performance. These 100% recyclable aluminium containers

Nearly 75% of all aluminium ever produced is still in use today, making aluminium one of the most sustainable packaging materials. Did you know?

feature detachable plastic tamper-evident rings, enabling effective separation for recycling whilst maintaining security features required by brands. This forward-thinking approach provides futureproof packaging solutions when navigating increasingly complex environmental regulations.

Tournaire’s approach is distinguished in its recognition of the unique packaging challenges faced by different industries. The company’s pharmaceutical-specific Type 8 closures, featuring chlorobutyl elastomer stoppers, demonstrate a deep understanding of the storage requirements of APIs. For South Africa’s growing pharmaceutical manufacturing sector, such specialised solutions eliminate the complexity of managing multiple supplier relationships whilst ensuring regulatory compliance.

In the cosmetics and fragrance sectors, where barrier properties directly impact product quality and shelf life, Tournaire’s aluminium containers provide exceptional protection against light, oxygen and humidity. For local manufacturers developing premium product lines or international brands establishing South African operations, this protection translates into extended product life and reduced waste, which are critical factors in markets where distribution networks may be extended.

Tournaire’s commitment to circular economy principles addresses one of the most persistent challenges in modern packaging – balancing environmental responsibility with practical performance. Aluminium’s infinite recyclability without quality degradation provides a genuine alternative to downcycling approaches that characterise many conventional packaging materials.

The company’s eco² innovation philosophy, combining ecological responsibility with economic value creation, resonates well in the South African context, where businesses increasingly face pressure to demonstrate environmental stewardship whilst maintaining competitiveness. Life Cycle Assessments backing Tournaire’s

Through its partnership with Tournaire, Sensetek brings international packaging expertise to South African markets. Tournaire’s continuous innovation programme, evidenced by developments like the OMNI+® closure range, ensures that partnerships remain relevant as regulatory and market requirements evolve.

In markets where packaging decisions increasingly influence brand perception, regulatory compliance and environmental impact, Tournaire’s comprehensive approach provides the technical excellence and strategic foresight that forward-thinking companies require. A select range of Tournaire’s packaging is available locally from Sensetek, giving South African manufacturers access to packaging solutions that don’t just meet today’s requirements – they anticipate tomorrow’s challenges. •

As African markets continue evolving towards greater sophistication and sustainability, partnerships with innovators like VR Print become essential for long-term success. This is their story.

In an industry where every millimetre of package space tells a story, VR Print has carved out a reputation as the label technology partner that transforms complex packaging challenges into competitive advantages. For procurement specialists and brand managers across Africa’s pharmaceutical, beauty and FMCG sectors, the company represents more than just another label supplier – it embodies the future of intelligent packaging solutions.

The modern packaging landscape presents a minefield of challenges. Pharmaceutical companies grapple with increasingly complex regulatory requirements whilst fighting for precious on-pack real estate. Beauty brands seek the perfect shelf appeal that drives consumer choice. Meanwhile, sustainability pressures mount across all sectors as recycling targets become non-negotiable business requirements. VR Print has built its business around solving these exact pain points. The company’s flagship Attach-A-Leaflet® extended content labels exemplify this problem-solving approach. Where traditional pharmaceutical packaging struggles to accommodate extensive regulatory information without compromising brand visibility, these innovative booklet-style labels

provide up to five pages of space in a single, elegant solution. The result? Compliance without compromise.

Sustainability that makes business sense

Whilst many suppliers talk sustainability, VR Print delivers tangible environmental solutions that improve bottom-line performance. The company’s wash-off adhesive technology, featuring products like Avery Dennison CleanFlake™ and UPM Wash-Off, addresses one of the recycling industry’s most persistent challenges – label contamination that prevents effective PET bottle recycling.

Did you know?

For clinical products, VR Print’s clever MedTrace Labels feature detachable sections for patient records. This simple innovation offers significant practical benefits for healthcare providers.

But sustainability at VR Print goes beyond materials. The company’s innovative Labelling by Banding® system reduces material usage whilst maintaining visual impact. Its transition to LED curing technology and extended colour gamut (ECG) printing delivers up to 90% reduction in ink waste compared to conventional processes, providing a win for both environmental responsibility and cost management.

For procurement teams balancing sustainability mandates with budget constraints, these solutions represent the sweet spot where environmental responsibility meets operational efficiency.

In an era where packaging must work harder than ever, VR Print’s technology portfolio reads like a wish list for innovative brand managers. The company’s augmented reality-enabled labels transform static packaging into interactive brand experiences, whilst its RFID smart labels provide supply chain visibility that procurement specialists increasingly demand. Brand protection remains equally critical, particularly in Africa’s diverse market landscape. VR Print’s security solutions, including exclusive Scantrust® secure QR codes, holographic embossing and covert inks, provide multi-layered protection against counterfeiting. For brands operating across multiple African markets, where product authenticity can significantly impact consumer trust and patient safety, these security features represent essential brand insurance.

What sets VR Print apart in the African context is its deep understanding of regional market dynamics. The company recognises that solutions developed for European or American markets don’t always translate effectively to African conditions. Whether it’s designing labels that withstand extreme temperature variations or developing cost-effective anti-counterfeiting measures suitable for emerging markets, VR Print’s approach reflects genuine market insight. This regional expertise extends to regulatory understanding. As African pharmaceutical regulations evolve and harmonise across different markets, VR Print’s regulatory compliance

“ VR Print’s technology portfolio reads like a wish list for innovative brand managers”

expertise becomes increasingly valuable. The company’s ability to navigate complex multi-country labelling requirements saves clients significant time and reduces regulatory risk.

Perhaps most significantly, VR Print positions itself as a development partner rather than a supplier. Its collaborative approach involves working closely with clients from concept through to production, ensuring that labelling solutions align with broader marketing and operational objectives.

This partnership mentality extends to strategic relationships with material suppliers like Avery Dennison and UPM Raflatac, ensuring clients benefit from the latest material innovations without the complexity of managing multiple supplier relationships.

This recent client feedback captures VR Print’s market impact: “(We) didn’t expect to see this level of innovation in label tech”. This sentiment reflects a broader industry recognition that labelling technology has evolved far beyond basic identification to become a crucial component of brand strategy, regulatory compliance, and supply chain management.

For packaging decision-makers seeking solutions that combine innovation, sustainability and practical functionality, VR Print offers a compelling proposition. In a market where differentiation increasingly depends on intelligent packaging solutions, the company provides the technological sophistication and local expertise that drives real competitive advantage. •

Connect with VR Print online: