Highperformance plant proteins

Extend shelf life naturally Gold Pack 2025 winners revealed

One ingredient, multiple functions

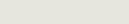

Fit-for-purpose packaging machinery that meets the needs of the product.

From horizontal and vertical form-fill-seal-machines and boxing systems to customized transfer and flow systems that provide efficiency and traceability. Fuji is the industry leader in automated packaging machinery technologies.

7

WHAT’S NEW

Showcasing the latest products on South Africa’s shelves

Bühler presented smart silo technology solutions

Bizerba makes big announcement

Organisations warned about

Gold Pack 2025 Awards celebrates innovation excellence

GELITA at Fi Europe 2025 –Paris

SA leads recycling while global talks stall

Clean label umami solutions revealed

One ingredient, multiple functions

Ingredient innovation reshaping the future food industry 28 INDUSTRY TALK

Spray dynamics symphony in-kitchen in seasoning solution

CARTON AND BOARD

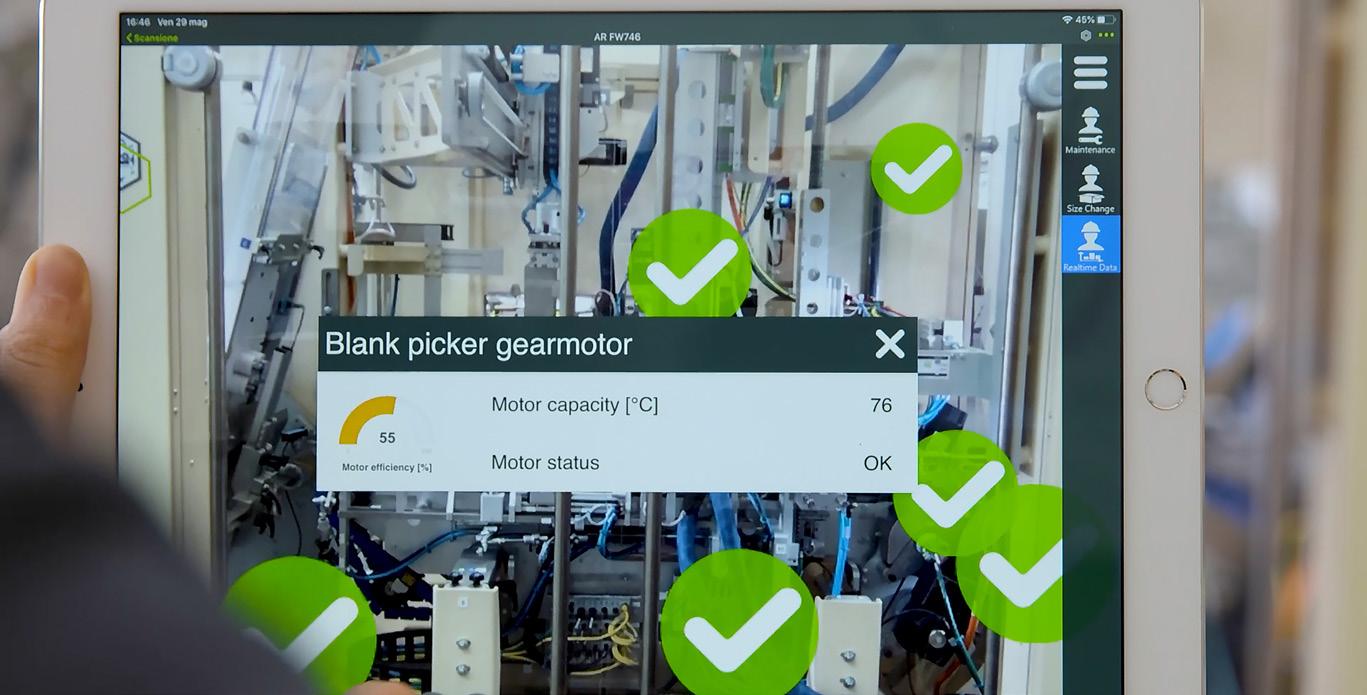

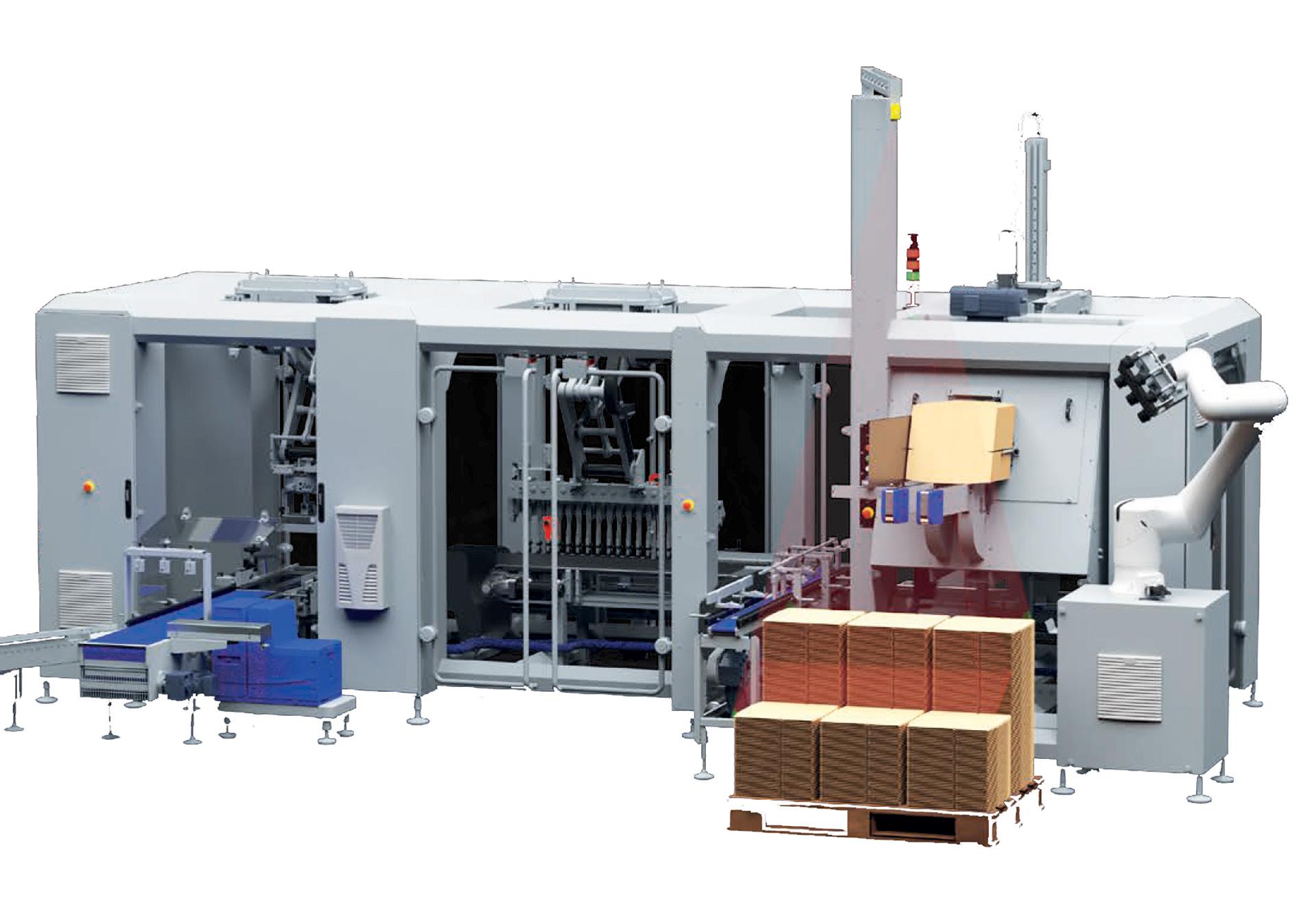

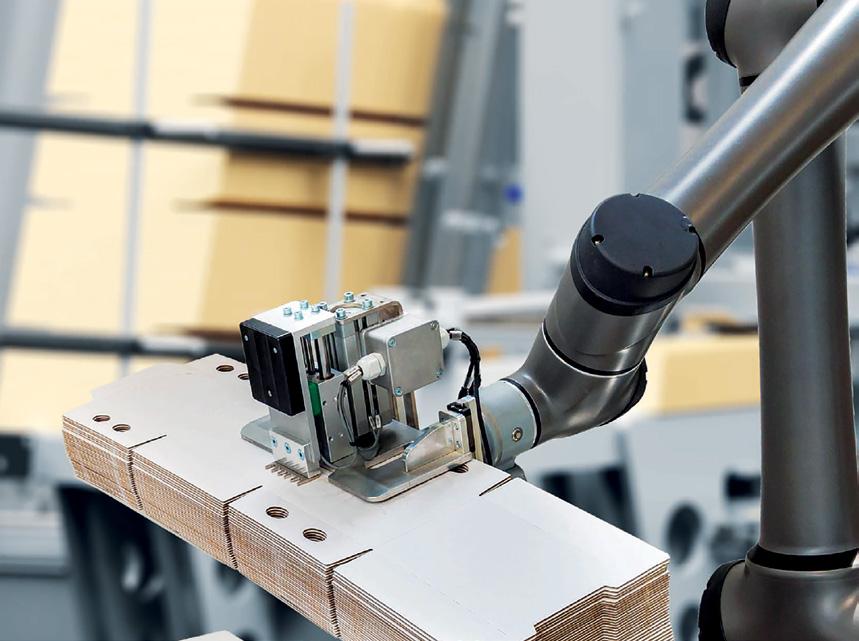

Collaborative robots transform carton loading

BEVERAGE PROCESSING TECH

AECI Food & Beverage rebrands as Lake International

CCL Label launches sustainable dairy product portfolio 20 ALTERNATIVE INGREDIENTS & PROTEINS

EDITORIAL

Editor: Kelebogile Nondzaba

+27 (0)78 175 9632

kelebogile.nondzaba@newmedia.co.za

Layout & Design: Tumi Kunene

Sustainable innovation takes centre stage

Welcome to our Nov/Dec 2025 issue, this month we explore the transformative technologies and sustainable practices reshaping the food and beverage industry. This edition showcases how innovation is driving meaningful change across four critical areas that define our sector's future.

Alternative ingredients innovation takes centre stage as manufacturers seek cleaner, more functional solutions. From Savannah Fine Chemicals' sustainable materials to Biospringer's clean label umami solutions, the industry is embracing yeast-based ingredients that enhance flavour while reducing sodium. The spotlight on alternative proteins, prebiotic fibres, and multifunctional ingredients like SANACEL® demonstrates how manufacturers are meeting consumer demands for healthier, more transparent products.

Waste management emerges as a cornerstone of operational excellence. Extrupet's groundbreaking bottle-to-bottle PET recycling facility in the Western Cape exemplifies South Africa's commitment to circular economy principles. Combined with Heat and Control's zero waste seasoning systems, these initiatives prove that environmental responsibility and business efficiency can thrive together.

Carton and board packaging solutions showcase the power of automation and sustainability. Our coverage of collaborative robotics in carton loading processes reveals how Industry 5.0 technologies are streamlining operations while supporting environmental goals. These innovations demonstrate that smart packaging extends beyond materials to encompass intelligent manufacturing processes.

Beverage processing technology continues evolving with CCL Label's sustainable packaging portfolios leading the charge. From monomaterial pouches to resealable formats, these solutions balance functionality with recyclability, addressing both consumer convenience and environmental concerns.

As we celebrate winners of the Gold Pack 2025 Awards, this issue underscores how sustainable production and bold design thinking are no longer optional—they're essential. The convergence of alternative ingredients, waste reduction, intelligent packaging, and advanced processing technologies positions our industry for a more sustainable and innovative future.

Cover Image and current page: Courtesy of Getty Images

ADVERTISING

Key Account Manager: Càndida Giambò-Kruger +27 (0) 71 438 1918

càndida.giambò-kruger@newmedia.co.za

INTERNATIONAL SALES

Germany/Austria/Switzerland: Eisenacher Medien

Erhardt Eisenacher +49 228 249 9860 info@eisenacher-medien.de

Italy: Ngcombroker

Giacomo Rotunno +39 370 101 4694 g.rotunno@ngcombroker.com

Taiwan: Ringier Trade Media

Sydney Lai +886 4 2329 7318 sydneylai@ringier.com.hk

CIRCULATION

Circulation Manager: Felicity Garbers felicity.garbers@newmedia.co.za

PUBLISHING TEAM

General Manager: Dev Naidoo

Production Controller: Mandy Ackerman

Art Director: David Kyslinger

JOHANNESBURG OFFICE

Building 13, The Woodlands Office Park, 20 Woodlands Drive, Woodmead, Sandton PO Box 784698, Sandton 2146 +27 11 867 6111

POSTAL ADDRESS PO Box 784698, Sandton, Johannesburg 2146

Published Media24 (Pty) Ltd

Càndida Giambò-Kruger

COMMUNICATE & CONNECT

ISW’s got it covered

Through an innovative and out the box approach to our clients needs we are able to provide practical, efficient and cost saving solutions to almost every challenge.

Tel: +27 (0)11 609 1488

Email: sales@iswshrink.co.za www.iswshrink.co.za

16 Edendale Rd West, Eastleigh, Edenvale

With the manufacturing plant consisting of 10 colour and 8 colour MPS EPW560’s and a full compliment of the latest offerings in finishing equipment for the conversion and inspection of our shrink sleeves, multi-layer sachets and wrap around labels, ISW is one of only a handful of narrow web printers capable of producing wide Lay Flat shrink sleeves, achieving a L/F of 276mm from a printed web width of 575mm.

Plant Based World Expo

Javits Center, New York, NY

2-3 December

www.plantbasedworldexpo.com

Food Africa Cairo Cairo, Egypt 9-12 December www.foodafrica-expo.com

February

Sweet/ISM Cologne, Germany

01 – 04 February www.ism-cologne.com

Fruit Logistica

4 – 6 February Berlin, Germany www.fruitlogistica.com

January

Dairy forum California, USA 25 – 28 January www.idfa.org

Gulfood 2026

Dubai World Trade Centre and Dubai Expo City, UAE 26-30 January www.gulfood.com

IPPE (International Production & Processing Expo) Atlanta, Georgia, USA 27-29 January www.ippexpo.org

BASF AROMA INGREDIENTS LAUNCHES NEW NATURAL LIME FLAVOUR

INGREDIENT

Isobionics®, the innovative BASF Aroma Ingredients biotechnology brand, is launching a new natural product on the flavor market. Isobionics® Natural alpha-Farnesene 95 is the latest addition to the company’s natural flavour ingredient portfolio for lime applications. “We are excited to introduce our new flavor

ingredient, Isobionics® Natural alpha-Farnesene 95, to the market,” says Steffen Götz, Senior Vice President of Aroma Ingredients at BASF. “This product represents our strong commitment to providing our customers with innovative high-quality aroma ingredients. Like all Isobionics® products, Isobionics® Natural alpha-Farnesene 95 is fermentation based and produced from renewable resources. This means it has reliable availability, independent of weather or harvest conditions. The product boasts an outstanding purity of more than 95% and provides exceptional new opportunities in our customers’ formulations.”

For more contact: FoodReview.co.za

NESPRESSO’S NEW AFRICANINSPIRED RANGE

Celebrate the season with a vibrant collection that captures the spirit of African artistry and the joy of shared moments.

This festive season, Nespresso invites you to uncover Magic in the Making, a celebration of the beautiful rituals, flavours, and craftsmanship that make every joyful gathering so special.

This year’s collection brings together an enchanting selection of limited-edition coffees, a new African-inspired blend, and thoughtfully designed festive accessories, all wrapped in vivid creations by Kenyan artist Thandiwe Muriu. Inspired by the African coffee flower, her work bursts with colour, energy, and warmth, perfectly capturing the essence of a South African summer in full swing.

Whether you are brewing your morning cup before a sun-soaked day, relaxing poolside after a festive feast, or sharing laughter over dessert, these indulgent new coffees are made

DENNY LAUNCHED NEW DRY SAUCE RANGE

South African consumers are reimagining their approach to home cooking, with flavour and convenience taking centre stage. WhyFive’s BrandMapp data reveals that 68% of South Africans keep dry stock as a pantry staple, a clear indication of the growing preference for shelf-stable, flavour-packed solutions that offer value, versatility, and convenience in challenging economic times. Responding to this evolving demand, DENNY®, one of South Africa’s most trusted food brands, has introduced a new range of dry cook-in sauces, pasta sauces, and stock powders. Designed for today’s busy households, the range combines robust flavour with practicality, offering long shelf life, simple

to add a touch of magic to every moment.

Gabriel Nobre, CEO of Nespresso South Africa, shares his excitement for the new collection:

“Coffee forms a part of so many joyous occasions during this time of year, and this collection celebrates that beautifully. Each blend was crafted to bring people together, to turn everyday rituals into something truly special, and to honour the craftsmanship and creativity that make the festive season so meaningful.”

A Taste of Celebration: Irresistible Coffees for a Limited Time

Inspired by the spirit of the festive season,

preparation, and affordability without compromising on taste. With retail pricing under R20 for dry cook-in and pasta sauces, and under R35 for stock powders in ready-to-use sachets, the new range provides accessible solutions for families seeking convenient, flavour-rich cooking options. From creamy pasta sauces to hearty Trinchado, the dry formats are tailored to South African cooking habits, allowing home cooks to elevate vegetables, stretch proteins, and create comforting meals with minimal effort. Each product is free from artificial colourants, packaged in recyclable materials, and requires only a few fresh ingredients and water to create satisfying, homecooked dishes.

Nespresso unveils a trio of limited-edition coffees, crafted to surprise, delight, and awaken the senses.

At the heart of the collection is the Festive Espresso for Original and Festive Double Espresso for Vertuo, a captivating Arabica blend of African coffees from Rwanda, the Democratic Republic of Congo, and Kenya. Expect a symphony of cereal and fruity notes, enriched with delicate caramel and woody undertones, an ode to the depth and diversity of African coffee. Enjoy it pure or transform it into a luxurious Latte Macchiato.

Visit: FoodReview.co.za

BIZERBA ANNOUNCES THE RENAMING OF BIZERBA LUCEO TO BIZERBA IMAGING SYSTEMS.

Product inspection is one of Bizerba’s core technologies – developed and managed entirely in-house. Bizerba Imaging Systems plays a crucial role in this area, particularly in product and packaging inspection. Its advanced systems make a significant contribution to food safety and support the automation of production processes across many industries worldwide.

Under its new name, Bizerba Imaging Systems will further expand its role as the competence center for vision-based product inspection within the Bizerba Group. “The site develops new technologies and tailored solutions precisely designed to meet the needs of our customers. This makes it a key driver of innovation, engineering excellence, and practical customer solutions within the Bizerba Group,” says Fred Köhler, managing director of the Business Unit Industry at Bizerba.

The team focuses on the development and manufacturing of both customised systems and catalog products. With state-of-the-art expertise in vision-based product inspection, Artificial Intelligence, and automation, Bizerba Imaging Systems delivers innovative solutions that meet the highest standards of product and food safety, process quality, and efficiency.

With this initiative, Bizerba continues to consistently pursue its long-term strategy: investing in future-oriented technologies, strengthening market and customer focus, and further developing core competencies.

For customers and partners, the renaming primarily means continuity with added value: existing contracts, contacts, and services remain unchanged. At the same time, the closer integration of the site into the global Bizerba structure ensures improved access to innovative solutions, faster development processes, and an expanded service offering.

BÜHLER PRESENTED SMART SILO TECHNOLOGY SOLUTIONS

Smart silos and grain storage technology was the focus of a key presentation by Marco Sutter, managing director of Bühler Southern Africa, at the 8th edition of the African Agri Investment Indaba (AAII), which took place from 24 to 26 November 2025 at the Cape Town Convention Centre.

The event brought together over 800 stakeholders, including investors, project developers, and government officials, who discussed the critical trends driving the future of African food and agribusiness over the next ten years and analysed the economic forces impacting the sector in the coming decade.

Bühler's participation underscored the vital role that advanced grain storage technology played in addressing Africa's food security challenges. Smart grain storage silos used sensors, monitoring systems, and

control mechanisms to optimise grain storage conditions and prevent losses due to pests, moisture, and other factors. Advanced technologies such as Internet of Things (IoT) devices, artificial intelligence (AI), and machine learning were being integrated into grain silos to optimise storage operations.

ORGANISATIONS WARNED ABOUT DIABETES CRISIS

For more, visit: foodreview.co.za

"The African Agri Investment Indaba provided an essential platform for Bühler to engage with key stakeholders across the agricultural value chain," said Marco Sutter. "As Africa grappled with the dual challenges of feeding a growing population whilst minimising post-harvest losses, smart silo technology represented a critical solution. We were excited to share how these innovations could transform grain storage across the continent."

Visit: Foodreview. co.za for more!

November 14th marked World Diabetes Day and civil society organisations warned that the cost of inaction on non-communicable diseases (NCDs) such as diabetes was already being paid for in lives, livelihoods and lost potential. The Healthy Living Alliance (HEALA) called on the South African government to increase the Health Promotion Levy (HPL) on sugary drinks from 11% to 20%, to help curb sugary drinks consumption and reduce the financial burden on the health system from rising non-communicable diseases. "Diabetes was the second leading cause of death in South Africa,¹ yet every year we allowed preventable diseases to claim more lives," said

Nzama Mbalati, CEO of HEALA. "Raising the Health Promotion Levy was one of the simplest, most effective steps government could take to protect people's health, especially children, who were consuming sugar at dangerous levels." Since the introduction of the HPL in 2018, beverage companies had reduced the sugar content of their drinks, leading to cuts in average per-capita sugar consumption. But the gains had stalled. HEALA and its partners warned that without further cuts in consumption, the policy's impact would fade, while rates of diabetes would continue to climb. South Africa's obesity rate was already twice the global average, and even one sugary drink a week raised a child's risk of obesity and diabetes.²,³ One in four diabetes cases in the country was caused by sugary drink consumption.4

These numbers were not just statistics; they represented real people and families forced to navigate lifelong illness and financial hardship.

Visit:foodreview.co.za for more!

Building a strong food safety culture

Ensuring food safety is crucial in today’s complex industry. From farm to fork, every step matters. Implementing robust measures requires more than regulations; it demands a shared commitment to a food safety culture.

Afood safety culture is a shared set of values, attitudes and behaviour that prioritise food safety at every level of an organisation. It goes beyond simply adhering to guidelines and regulations; it involves a collective commitment to continuous improvement and vigilance in identifying and mitigating potential risks. Here are some key steps to help you create and maintain a strong food safety culture in your organisation.

LEADERSHIP COMMITMENT

Building a food safety culture begins at the top. Leaders within the organisation must demonstrate a genuine commitment to food safety by making it a top priority. This includes allocating resources, providing training, and leading by example. When employees see that food safety is taken seriously by leadership, they are more likely to prioritise it themselves.

Education and training: Proper training is essential for ensuring that all employees understand the importance of food safety and know how to implement best practices in their daily tasks. From factory staff to management, everyone should receive comprehensive training on topics such as proper hygiene, safe food handling procedures, and identifying potential hazards. Regular refresher courses can help reinforce these principles and keep everyone up to date on the latest developments in food safety. Clear communication: Effective communication is essential for maintaining a strong food safety culture. Employees should feel comfortable reporting any concerns or observations related to food safety, and there should be clear channels for doing so. Whether it is a suggestion box, regular meetings, or an open-door policy with management, employees should know that their voices are heard and that their feedback is valued.

ACCOUNTABILITY AND RECOGNITION

Holding employees accountable for their actions regarding food safety is crucial for maintaining standards. This includes implementing clear protocols for addressing violations and ensuring that consequences

“Building a food safety culture begins at the top. Leaders within the organisation must demonstrate a genuine commitment to food safety by making it a top priority.”

are consistent and fair. At the same time, it is essential to recognise and reward employees who demonstrate exemplary adherence to food safety protocols. This can help reinforce positive behaviour and encourage others to follow suit.

Continuous improvement: The food industry is constantly evolving, with new challenges and risks emerging all the time. As such, it is essential to foster a culture of continuous improvement within your organisation. This means regularly reviewing and updating food safety protocols in response to new information, technological advancements, and changing regulations and actively seeking out opportunities for improvement can help ensure that your organisation stays ahead of the curve.

Lead by Example: Employees take cues from their leaders, so it is crucial for managers and supervisors to lead by example when it comes to food safety. This means consistently following protocols, practicing hygiene, and prioritising food safety in all their work. When employees see that their leaders take food safety seriously, they are more likely to do the same.

INVEST IN TECHNOLOGY

Technology can be a valuable tool for enhancing food safety in your organisation. From temperature monitoring systems to automated hygiene monitoring, there are a variety of technologies available that can help streamline processes and identify potential risks more efficiently. By investing in the right tools and systems, you can improve overall food safety while also saving time and resources.

Collaborate with partners: Food safety is a shared responsibility that extends beyond the walls of your organisation. Collaborating with chemical and raw material suppliers, distributors and other partners in the food supply chain can help ensure that everyone is aligned on food safety standards and protocols. By working together, you can identify potential risks more effectively and implement measures to mitigate them before they become problems.

In conclusion, creating a strong food safety culture in your organisation requires commitment, communication and continuous improvement. By prioritising food safety at every level in your organisation, investing in education and training, and fostering a culture of accountability and collaboration.

Gold Pack 2025 Awards celebrates innovation excellence

The Institute of Packaging SA hosted the prestigious Gold Pack 2025 Awards, celebrating groundbreaking packaging innovations across diverse industry categories.

On Thursday evening, November 6th, the packaging industry’s finest gathered at a spectacular blacktie affair that epitomised elegance and innovation. As a member of the Food Review team, I had the privilege of witnessing an extraordinary celebration where South Africa’s most innovative packaging solutions were recognised during an evening that seamlessly blended sophistication with sustainability consciousness.

The venue was transformed into a showcase of excellence, with attendees dressed to the nines in formal evening wear. Industry leaders, designers, and innovators filled the elegantly decorated space, creating an atmosphere of anticipation and celebration.

The black-tie dress code was embraced wholeheartedly, with guests donning their finest formal attire, reflecting the prestige and importance of these awards within the packaging community.

As the evening unfolded, a meticulously crafted three-course dinner was served, providing the perfect backdrop for the awards presentation. The culinary experience was nothing short of exceptional, featuring locally sourced ingredients presented with the same attention to detail and innovation that characterised the packaging solutions being celebrated. Each course was artfully presented, creating conversations around the table about the intersection of food presentation and packaging design.

SUSTAINABLE INNOVATION TAKES CENTER STAGE

The Gold Pack 2025 Awards, organized by The Institute of Packaging SA (IPSA), demonstrated a clear shift toward sustainability and environmental responsibility. Throughout the evening, it became evident that the packaging industry has embraced the challenge of creating solutions that are both functional

and environmentally conscious. The winning entries showcased remarkable innovation in materials, design, and production processes.

Freshmark’s Potatoes Kraft Bag emerged as a standout winner in the Food Non-Perishable category, earning the gold medal for its revolutionary approach to potato packaging.

The bag, crafted from semi-ex tensible wet-strength kraft paper, represents a perfect marriage of durability and en vironmental responsibility. This recyclable solution addresses the growing consumer demand for sustainable packaging while maintaining the functionality required for potato storage and transportation.

The innovation extended beyond mere material selection. The Fishaways Sushi Carton, which captured gold in the Food Perishable category, demon strated how plastic-free design could be achieved without compromising food safety or presentation. The carton features water-based coatings that provide necessary barrier properties while remaining completely biodegradable, setting a new standard for takeaway food packaging.

TECHNOLOGY MEETS ELEGANCE

The evening showcased how technology and aesthetic ap peal could converge to create truly remarkable packaging solutions. The KWV VS Brandy bottle, which won gold in the Beverages Alcoholic category, exemplified this principle with its single-contact area design

and elegant embossing. The bottle’s sophisticated appearance reflected the premium nature of its contents while incorporating technical innovations that enhanced both functionality and visual appeal.

Perhaps one of the most impressive technological innovations was the Clinique High Impact Shadow Play Seeding Box, which integrated LED illumination with rechargeable batteries to create an unforgettable unboxing experience. This entry demonstrated how packaging could transcend its traditional role to become an integral part of the customer experience, using technology to create emotional connections between brands and consumers.

The LabelSeal® Coca-Cola 2L Wrap Around Label represented another breakthrough in packaging technology. This

EVENT

water-based OPV solution offered reduced application volumes and lower retail costs while maintaining the high-quality appearance expected from such an iconic brand. The innovation demonstrated how cost-effectiveness and quality could be achieved simultaneously through thoughtful engineering.

STUDENT INNOVATION SHINES BRIGHT

One of the evening’s most inspiring segments was the Student Gold Pack Competition, which highlighted the next generation of packaging innovators. The competition featured entries across four catego ries: Food Science, Graphic Design, Packaging Technology, and Industrial Design. These young talents brought fresh perspectives and bold ideas that challenged conventional thinking about packaging design.

Nomï by Stellenbosch University students won the Food Science category, presenting an innovative approach to food packag ing that prioritized both functionality and sustaina bility. The Nutventures de sign by Delné Pottas from Potchefstroom Academy captured the Graphic De sign award with its creative visual communication and brand storytelling capabilities.

EcoBrew Coffee Slice by Cara-Lee Whitaker demonstrated excellence in Packaging Technology, while Braai Mate by Sibusiso Mokhoana from TUT won the Industrial Design category. These winning entries represented the future of packaging innovation, combin ing technical exper tise with creative vision to address contemporary challenges in the industry.

DID YOU KNOW?

The Freshmark Potatoes Kraft Bag is made from semi-extensible wet-strength kraft paper that is completely recyclable, representing a groundbreaking shift from traditional plastic potato packaging while maintaining superior durability and moisture protection properties.

CIRCULAR ECONOMY CHAMPIONS

The awards ceremony placed significant emphasis on solutions that support the circular economy. Lipton Ice Tea’s bottles, made using 100% recycled PET, demonstrated how large-scale circularity could be achieved in the beverage industry. This innovation represented more than just material selection; it showcased a comprehensive approach to sustainability that considered the entire lifecycle of the packaging. Detpak’s Renewable Food Wax Wrap earned recognition for its compostable design made from plant-based wax. This solution addressed the growing concern about food packaging waste while providing the necessary functionality for food preservation. The

innovation demonstrated how traditional materials could be reimagined to meet contemporary environmental standards.

The Comfort 800ml Fabric Con ditioner bottle showcased light weight design principles while maintaining durability through the use of recycled HDPE. This approach demonstrated how environmental responsibility could be achieved without compromising product protection or consumer convenience.

AFRISTAR RECOGNITION

The evening also celebrated continental excellence through the AfriStar Awards, recognizing outstanding packaging produced both in South Africa for the African market and in other African countries. The Amarula Gift Pack won gold in the “Produced in South Africa for Africa” category, demonstrating how local innovation could serve broader Af-

“The packaging industry has embraced the challenge of creating solutions that are both functional and environmentally conscious, with winning entries showcasing remarkable innovation in materials, design, and production processes that address contemporary market demands.”

rican markets while maintaining cultural relevance and technical excellence.

The Share-a-Coke Labelling: East Africa 2025 project captured gold in the “Produced in Africa (Outside South Africa)” category, highlighting the growing capability of African packaging industries to deliver world-class solutions. These awards emphasized the importance of continental collaboration and the recognition of African innovation on the global stage.

INDUSTRY EXCELLENCE ACROSS CATEGORIES

The diversity of winning entries across various categories demonstrated the breadth of innovation within the South African packaging industry. From household products to health and beauty items, each category showcased unique approaches to common packaging challenges. The Oh So Heavenly Roll On Deodorant Container exemplified innovation in the Health, Beauty & Pharma category, combining user-friendly design with manufacturing efficiency.

Woolworths Laundry Pods represented innovation in household products, demonstrating how premium retailers were pushing boundaries in packaging design to meet consumer expectations for convenience and sustainability. The Playbuddy Pet Toy Range

showed how packaging could enhance product appeal while providing practical benefits for both retailers and consumers.

FUTURE-FORWARD THINKING

As the evening progressed, it became clear that the packaging industry was not merely responding to current trends but actively shaping the future of consumer packaging. The innovations on dis play represented a fun damental shift toward solutions that prioritized environmental responsibil ity, user experience, and technical excellence in equal measure.

The judging criteria em phasized innovation, sus tainability, functionality, and tech nical execution, with particular attention to Extended Producer Responsibility (EPR) obligations. This comprehensive evalua tion approach ensured that winning entries represented holistic solutions rather than single-dimensional improvements.

quality and diversity of entries demonstrated that local companies and designers were capable of competing on the global stage while addressing uniquely African challenges and opportunities.

CELEBRATING WELL-DESERVED WINNERS

Each award presented during the evening went to thoroughly deserving winners who had demonstrated exceptional creativity, technical expertise, and market insight. The winners represented a cross-section of the packaging industry, from established multinational corporations to innovative local companies and emerging student talent. The recognition extended beyond individual products to acknowledge the teams and companies that had invested in research, development, and sustainable practices. Companies like Shoprite Freshmark, KWV South Africa, PepsiCo, Unilever SA, and Nestlé were recognized not just for individual products but for their commitment to packaging innovation and

The success stories shared throughout the event highlighted the importance of cross-industry partnerships in driving innovation forward.

The Gold Pack 2025 Awards evening stood as a testament to the South African packaging industry’s commitment to innovation, sustainability, and excellence. As the last course was served and the final awards presented, it was clear that the industry was not just keeping pace with global trends but actively leading the conversation about the future of packaging. The combination of elegant presentation, cutting-edge innovation, and environmental consciousness created an event that will be remembered as a defining moment for packaging excellence in South Africa.

The evening concluded with a sense of optimism about the future of packaging innovation in South Africa. The

The evening demonstrated how collaboration between brand owners, packaging manufacturers, and technology providers could result in solutions that exceeded the sum of their parts.

YOUR PACKAGING SOLUTIONS PROVIDER

For more than 30 years, Goldpack Packaging has been the leading provider of packaging solutions in Cape Town, Durban, Johannesburg, and throughout Southern Africa and Sub-Saharan Africa. We specialise in end of line packaging solutions, offering a comprehensive range of packaging machinery, packhouse supplies, and packaging consumables. From packaging machinery supplies to packaging machine spares, we provide everything you need to optimise your packaging process.

SA leads recycling while global talks stall

Despite the recent breakdown in UN-led talks on a global treaty to stem plastic pollution, South Africa is forging ahead with its efforts to continue building a circular economy for postconsumer PET beverage bottles.

On October 6, the country's plastics recycling infrastructure received a major boost with the official launch of Extrupet's second PET bottle-to-bottle recycling facility – and the vacunite first of its kind in the Western Cape.

This state-of-the-art facility, at the company's Propet plant in Cape Town, started commercial production in March this year, and is set to add 15 000 tonnes of recycled Food Grade (rPET) plastic to the market per year.

LEADING BY EXAMPLE ON GLOBAL STAGE

Speaking at the launch, the Minister of Forestry, Fisheries and the Environment, Dr Dion George, said plastic pollution was not only an environmental crisis, but also a public health emergency that harmed communities and threatened ecosystems. The Minister said South Africa was at the forefront of the global process to end plastic pollution.

"Through the Intergovernmental

"With our increased Food Grade rPET capacity, we will be able to process more plastic waste and strengthen South Africa's position as a circular economy leader in Africa and the world."

Negotiating Committee, we are advocating for a legally binding instrument that covers the full life cycle of plastics, from design and production, through consumption, reuse and disposal."

TURNING CRISIS INTO OPPORTUNITY

Although these negotiations had stalled, he said South Africa would lead by example, with the government creating an enabling regulatory environment, and industry players like Extrupet making it real through investment in increased recycling capacity.

"This facility is more than bricks and machinery, it is a symbol of how South Africa can turn a crisis into an opportunity. It shows

that with clear policy, vision and partnership, plastic crisis waste can be transformed from a burden on our environment into a driver of jobs, innovation and inclusive growth."

He said that PET was one of the most visible and valuable plastics in the waste stream, providing an income and dignity for many South African waste pickers and small businesses.

EXPANDING RECYCLING CAPACITY

"If we collect PET properly, it supports livelihoods and builds enterprises. If we do not, it ends up in landfills, rivers and oceans. That is the choice before us, and this facility tilts the balance towards opportunity."

In 2009, Extrupet established its first bottle-to-bottle line at its Johannesburg plant, with the second and third following in 2014 and 2020 respectively.

Extrupet's joint managing director, Chandru Wadhwani, said the latest addition marked the first of a two-phase expansion that will double the recycler's food-grade rPET output capacity.

BUILDING CIRCULAR ECONOMY SOLUTIONS

"This line represents phase one, which takes our total output from 30 000 to 45 000 tonnes this year. Next year, we are hoping to launch phase two with new machinery, which

Building a circular economy for PET plastic.

Petco, South Africa’s leading Producer Responsibility Organisation is proud to continue our partnership with Extrupet, one of SA’s largest recyclers, to ensure PET plastic packaging is collected, recycled and kept in circulation for as long as possible.

Extrupet, one of our eleven recycling partners, has recently launched a new bottle-to-bottle recycling plant in the Western Cape. The new plant has the capability to add 15 000 tonnes of recycled food-grade PET that meets international standards. This increases Extrupet’s total annual output from 30 000 to 45 000 tonnes per year.

Together, we’re proving that when the industry invests in infrastructure and takes responsibility through Extended Producer Responsibility, sustainability becomes reality.

To become a Petco member, email Junaid.francis@petco.co.za. Visit www.petco.co.za and www.extrupet.co.za for more information.

to launch phase two with new machinery, which will see us producing 60 000 tonnes of Food Grade rPET countrywide that meets international food-grade standards."

Wadhwani explained that PET, or polyethylene terephthalate, commonly used to package soft drinks and bottled water, was one of the few truly circular, commercially viable plastic recycling solutions – where bottles could be processed safely back into new food-grade products, keeping the material in circulation at its highest value for as long as possible.

"With our increased Food Grade rPET capacity, we will be able to process more plastic waste and strengthen South Africa's position as a circular economy leader in Africa and the world. So, we're pleased that our new plant can act as a beacon of hope in finding solutions to mitigate plastic pollution."

TWO DECADES OF PARTNERSHIP

Wadhwani added that Extrupet had been

"This facility is more than bricks and machinery, it is a symbol of how South Africa can turn a waste crisis into an opportunity."

working with the country's longest-standing producer responsibility organisation (PRO), Petco, for more than two decades to facilitate and balance the collection and recycling of PET, and stimulate market demand for the end-use products.

With roughly 70% of the PET beverage bottles that Petco members place on the market currently recycled, he said there was much to be positive about, despite the failure of the Intergovernmental Negotiating Committee (INC-5.2) session to develop a legally binding global instrument to deal with the growing volumes of plastic waste worldwide.

"For the past three years, the United

DID YOU KNOW?

Roughly 70% of PET beverage bottles placed on the South African market are currently recycled.

Nations has been trying to get member countries to agree on the measures we need to put in place to mitigate plastic pollution. Because we still don't have clarity on the way forward, it has put the onus back on individual countries and companies to do what is required," said Wadhwani.

REGIONAL IMPACT AND FUTURE GROWTH

"We are proud that South Africa is one of the countries that has created extended producer responsibility [EPR] legislation to deal with this issue. This means that, by law, producers and brand owners must take responsibility for their packaging waste across its entire life cycle – from design to disposal."

Petco CEO Telly Chauke explained that the organisation's primary function was to support the implementation of EPR legislation and to help its producer members meet their legislated targets for collection and recycling.

"Key infrastructure investments like this one ensure the availability of food-grade rPET at scale for local producers, who must also meet increasing targets for including recycled content in their packaging."

CONSUMER ROLE IN SUCCESS

Chauke said the new Western Cape facility would have a positive impact for the province's agricultural producers, whose export punnets destined for the European market need to contain at least 25% certified rPET under new EU regulations.

She said it was encouraging to see the regional recycling value chains strengthened by investments such as these.

"The economics need to work for recycling to succeed. So having facilities in key regions like the Western Cape will have a big impact as it is costly to collect bottles locally and then transport them across the country for reprocessing."

Chauke added that it was not only up to business and government to act, but that consumers could play a role by buying products in recyclable packaging, wherever possible, and separating recyclables from their general household waste to create clean feedstock for these recycling plants.

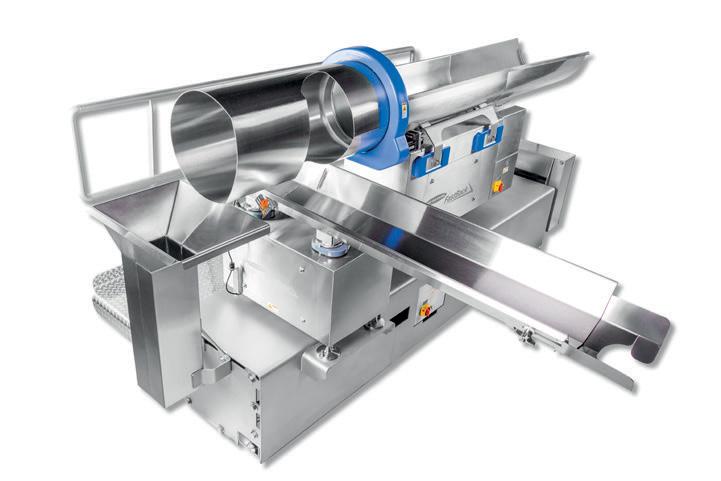

FastBack WeighBack continuous weighconveyor

Heat and Control's Symphony In-Kitchen Seasoning System delivers precise seasoning control with reduced waste and enhanced hygiene standards.

The FastBack® WeighBack Weigh

Conveyor a stand-alone, fully integrated weighing and conveying solution designed to enhance productivity in weigh-conveying operations. It offers superior accuracy, gentle handling to reduce product breakage, and lower maintenance compared to standard weigh belts. Ideal for the snack food industry, it can be easily retrofitted into existing production lines. FastBack’s patented horizontal motion technology and smooth pan design ensure gentle handling, minimising breakage and product buildup for easy cleaning. The nonslip pan enhances travel rates and accuracy,

allowing for precise load cell measurements. A weighing capacity of up to 32 feet per minute (10 meters p/m) is achievable, with 1 gram resolution and +/- 2-gram accuracy on most applications.

ELIMINATING TRADITIONAL BELT PROBLEMS

Unlike traditional weigh belts, FastBack’s slow-forward, fast-back motion eliminates the need for belts — preventing issues like stretching, tearing, and product buildup. This innovative design requires no preventative maintenance and is backed by a 5-year drivetrain warranty for long-term reliability. Daily

Less Waste, More Profit

maintenance is streamlined with tool-free load cell calibration and a pull-out electrical cabinet. Built with durable stainless steel and IP65-rated flush doors, FastBack is designed to perform in dusty or wet environments. A user-friendly touchscreen interface provides real-time operational data, automatic taring, load cell readings, and step-by-step instructions. Ethernet connectivity allows seamless integration with downstream equipment for processing, seasoning, or packaging.

Heat and Controlwww.heatandcontrol.com

Rely on Urschel for rugged, high-powered slicers and dicers to maximise capacity.

Precision, targeted cuts throughout production runs to maximise yield.

The sharpest knives team up with rugged components at powerful speeds to deliver the highest quality cuts.

In today’s world, where sustainability, food security, and waste reduction are more urgent than ever, finding smarter ways to store food has become a necessity, not a luxury. Enter O Buster Oxygen Absorber Sachets — a small, deceptively simple innovation that’s quietly transforming how we store and preserve food, both in households and across industries. Whether you're a home cook, an artisanal food producer, or a large-scale business, the challenge of spoilage is universal. Dry goods can attract insects. Biltong and nuts may turn mouldy or rancid. Confectionery items often go stale far too quickly. These are not just minor annoyances — they are costly problems. That’s where O Buster comes in.

WHAT IS AN O BUSTER OXYGEN ABSORBER?

At its core, an oxygen absorber is a small sachet filled with iron powder, salt, and occasionally activated carbon. When placed in an airtight environment, the iron within the sachet reacts with oxygen, forming iron oxide — essentially, rust. This reaction reduces the oxygen level inside the packaging to below 0.01%, creating a hostile environment for mould, bacteria, and other spoilage organisms. The beauty of this solution lies in its simplicity. With oxygen removed, food items retain their colour, flavour, aroma, and nutritional content significantly longer than

“Distributed exclusively in South Africa by Kubepac, O Buster sachets offer a game-changing approach to long-term food preservation.”

Oxygen absorbers transform food storage solutions

O Buster sachets from Kubepac use simple iron powder technology to preserve food naturally, eliminating spoilage without artificial preservatives or chemicals.

they would otherwise. From biltong and dried fruits to spices, tea, nuts, pet treats, and artisan goods, a wide range of producers trust O Buster sachets to maintain the integrity of their products. In a time when consumers are seeking “clean label” products — foods free from artificial preservatives and unnecessary chemicals — O Busters present a natural, residue-free alternative. They preserve food using a physical process rather than a chemical one, making them especially appealing for organic and health-conscious brands.

A SOLUTION FOR FOOD WASTE ON A GLOBAL SCALE

According to the United Nations Food and Agriculture Organization, about one-third of all food produced for human consumption is lost or wasted each year. A significant portion of this waste occurs after production, due to poor storage conditions. This is where oxygen absorbers can have a global impact. By simply extending the shelf life of stored goods and preventing premature spoilage, O Busters help reduce food waste at every level — from households to large distribution chains. This not only saves money and resources but also helps lessen the environmental impact associated with producing and discarding spoiled food. In short, they are a small tool with a surprisingly large role to play in improving food security and sustainability.

PRACTICAL, SAFE, AND EASY TO USE

One of the standout features of O Buster sachets is their practicality. Using them is straightforward: simply place the correctly sized sachet into an airtight container with your food product, and seal it. They work especially well in vacuum-sealed bags, mason jars, Mylar pouches, and other forms of low-oxygen packaging. O Busters are food-

safe and non-toxic, although they are not meant to be ingested or opened. With clear labelling and safety instructions, they’re perfectly suited for everyone — from biltong manufacturers, confectionery items, pet treats or dried nuts and fruit.

A GAME-CHANGER FOR MODERN LIFESTYLES

As more people embrace preservation, self-reliance, and eco-conscious living, oxygen absorbers like O Buster have become increasingly relevant. Whether you're are a manufacturer, running a business or preserving seasonal harvests, or trying to extend the shelf life of your products, O Busters align with the values of sustainability and smart consumption. For businesses, they offer a reliable way to deliver products that stay fresher longer, enhancing customer satisfaction and reducing return rates due to spoilage. For consumers, they offer peace of mind — the knowledge that your food investment is protected for the long haul. Food storage may not be the most glamorous topic, but it is undeniably crucial. Every O Buster sachet represents a simple, cost-effective solution to a much larger problem — food waste and spoilage. So, the next time you seal a bag of biltong, store your favourite loose-leaf tea, or stash away some dried fruit and nuts, remember what’s quietly working behind the scenes. A humble O Buster is in there, absorbing oxygen and keeping your food fresh, delicious, and ready whenever you are. Distributed exclusively in South Africa by Kubepac, O Buster sachets offer a game-changing approach to long-term food preservation.

Kupepac – www.kubepac.com

Yeast innovation transforms modern snack food development

Biospringer's three yeast-based product lines help snack manufacturers create bold flavours while meeting clean label and nutritional demands.

In the dynamic world of snack food development, meeting consumer demands for bold flavours, clean labels, and nutritional benefits has become increasingly crucial. As a leading provider of yeast-based ingredients, Biospringer is proud to offer a range of innovative solutions that empower snack manufacturers to create products that truly stand out on the shelves. At the heart of Biospringer's portfolio are three distinct product lines: Umami, Reveal, and Signature. Each of these offerings harnesses the power of yeast to deliver unique properties, allowing formulators to elevate their snack creations.

UMAMI: UNLOCKING THE SAVOURY POTENTIAL

The Springer® Umami range from Biospringer is a game-changer for snack developers seeking to amplify the savoury appeal of their products. The umami and typical savoury flavours of the range highlight and strengthen flavours to improve taste profiles of foods. Derived from natural yeast fermentation, these ingredients tap into the inherent umami notes that consumers crave bringing that lingering sensation, so specific to the 5th taste, to the overall profile.

FAST FACT

Biospringer's Signature range offers 4 distinct flavour families - meaty notes (chicken, beef), cooked notes (roasted, smoked, grilled), brown notes, and cheese notes.

"Umami is the 'fifth taste' that provides a rich, meaty, and satisfying sensation on the palate," explains Bénédicte PETTON, Biospringer's EMEA marketing director.

Beyond enhancing the overall taste experience, Biospringer's Umami ingredients also offer functional benefits. This yeast extract range rich in natural umami contributes efficiently to salt reduction, by

SIGNATURE: CRAFTING DISTINCTIVE SNACK IDENTITIES

For snack brands looking to develop a truly unique and memorable identity, Biospringer's Signature products range offers a compelling solution. These specialised yeast-based ingredients are designed to impart distinctive, signature flavours that set products apart in a crowded marketplace. Today's snack consumers are increasingly seeking out products that offer a sense of authenticity.

Biospringer provides a wide spectrum of specific flavour profiles through its rich range of yeast based specific flavour notes. Springer® Signature offers 4 main families of specific flavour notes:

• Meaty notes: chicken, beef

• Cooked notes: roasted, smoked, grilled

• Brown notes

• Cheese notes

Biospringer's Signature solutions enable snack manufacturers to craft a true flavour identity. These ingredients can be seamlessly integrated into a wide range of applications, from savoury crackers and pretzels to indulgent baked goods.

compensating the loss of intensity in taste when diminishing the quantity of salt in a recipe. It allows manufacturers to clean up their labels without compromising on taste.

REVEAL: BRINGING OUT THE BEST IN SNACK FLAVOURS

For snack producers looking to showcase the true essence of their flavours, Biospringer's Reveal range is a game-changer. These yeast-based solutions act as flavour "revealers," amplifying and balancing the taste profiles of a wide range of seasonings and coatings. Our Reveal range helps bring out the natural richness and complexity of spices, herbs, and other flavour components, creating a more satisfying and enjoyable snacking experience.

Formulated to be highly versatile, Springer® Reveal solutions can be seamlessly integrated into a variety of snack applications, from potato chips and extruded snacks

"Umami is the 'fifth taste' that provides a rich, meaty, and satisfying sensation on the palate."

to nuts and popcorn. They not only enhance the overall flavour impact but also help to improve mouthfeel and texture.

EMPOWERING SNACK INNOVATION

By leveraging Biospringer's comprehensive portfolio of yeast-based solutions, snack producers can unlock a world of new possibilities. Whether the goal is to enhance

"Our yeast-based solutions are designed to be the building blocks of snack success, helping brands deliver the flavours, textures, and experiences that today's discerning consumers demand."

savoury appeal, amplify authentic flavours, or develop a truly distinctive brand identity, these innovative ingredients provide the tools needed to stay ahead of the curve.

“At Biospringer, we're passionate about empowering snack innovators to create products that captivate consumers and stand out in a competitive market," says Bénédicte PETTON. "Our yeast-based solutions are designed to be the building blocks of snack success, helping brands deliver the flavours, textures, and experiences that today's discerning consumers demand."

As the snack industry continues to evolve, Biospringer remains committed to pushing the boundaries of what's possible. According to manufacturers challenges, our yeastbased solutions can help to enrich protein content thanks to our Springer® Proteissimo range, or to block bitterness and neutralise various off-notes with our Springer® Mask range. By collaborating closely with our customers and staying attuned to emerging trends, we're poised to deliver the next generation of yeast-based innovations that will transform the snack landscape.

Biospringer – www.biospringer.com

EXPLORE THE POWER YEAST PROTEIN

Five world class ingredient Themes Shaping 2026

Savannah Fine Chemicals reveals five ingredient innovation themes that will reshape South African food manufacturing in 2026.

As the food and beverage landscape continues to evolve, manufacturers face intensifying pressures: cleaner labels, smarter nutrition, cost-effective formulation, and consumer demands for sensory experiences that eclipse “just functional.” At Savannah, we work as your local partner in South Africa to bring worldclass ingredient from global manufacturers into your applications – supporting everything from bakery and beverages to dairy, snacks, and specialised nutrition. Along with our global partners and market insights, here are five ingredient themes set to define 2026 – and what R&D and innovation teams need to know.

STEADY ENERGY CARBOHYDRATES & GUT SMART FIBRES

Consumers increasingly understand carbohydrates are not simply energy—they’re about how that energy is delivered. That’s why innovative products like low-glycaemic carbohydrates and true prebiotic fibres are gaining popularity amongst consumers. Palatniose™ and Orafti Chicory root fibres from Beneo are perfect examples the types

"2026 will be defined by smarter stacks, not just smarter single ingredients."

of innovative carbohydrates. Palatinose™ (isomaltulose) as a slow-release sugar solution, offering balanced glucose responses and functionality in beverages, nutrition bars and dairy products. The Orafti chicory root derived inulin/oligofructose portfolio enables dual claims of reduced sugar and prebiotic health, while offering body, mouth-feel and sugar-replacement performance. For South African manufacturers: this means you can craft sustained energy and gut-friendly products without sacrificing taste while relying on science backed ingredients.

FAST FACT

The era of one-trick ingredients is coming to an end as more ingredient innovations deliver multiple benefits simultaneously.

FRUIT & CEREAL-DERIVED FIBRES

Texture is now a defining dimension in food innovation. At Savannah, we supply ingredient selections from CFF (SANACEL® fibres) and Herbafood (highly functional citrus fibres) to deliver clean-label structural benefits. SANACEL® fibre range enables water-binding, textural enhancement and fat-replacement in bakery or extruded snacks, while Herbafood’s highly functional citrus fibres deliver emulsification, freezethaw stability, and clean label alternative to hydrocolloids in dressings, desserts and plant-based products.

The benefit of this is that these fibres are simply declared as oat fibre or citrus fibre, and ingredient customers can understand, but that acts behind the scenes to enable the product to hit sensory targets customers enjoy. Savannah will guide you with technical support to choose the correct fibre for your application and desired outcome.

BIOAVAILABLE MINERALS & MODERN ACIDULANTS

Fortification is moving beyond tick-box addition. Modern consumers expect ingre-

"Instead of choosing between taste or function, development teams should be routinely asking: Can this ingredient reduce sugar and provide texture?”

dients they can feel, and formulation teams need systems that integrate well without compromising taste or stability. Savannah is proud to partner with Jungbunzlauer where we can offer mineral salts (e.g., calcium lactate gluconate, potassium/ magnesium salts) that combine solubility, taste neutrality and claim potential. As well as acidulants and lactate systems that support pH-control and shelf-life. South African beverage and dairy manufacturers can now easily design hydration drinks, and fortified offerings with ingredient names that resonate with customers.

FERMENTATION-DERIVED TOOLS

Fermentation isn’t just for probiotics anymore. Yeast-derived ingredients are quietly enabling major advances in flavour, sodium reduction and process efficiency. Through Savannahs partnership with Lallemand Bio-Ingredients, Savoury Ingredients division, Savannah offers a range of yeast extracts, inactive yeasts and yeast protein concentrate that support savoury depth enhancement, sodium reduction, nutritional protein fortification, enhanced mouth-feel, taste masking and speciality top notes for flavours such as

chicken, roasted meats and allergen free soya sauce. With an application range from savoury to sweet the Lallemand Bio-Ingredients can improve the overall taste, nutritional and functional performance of products with added clean label benefits.

PROTEIN SYSTEMS BUILT FOR FUNCTION

Protein remains a pillar, but the focus is shifting—from sheer grams to system performance: heat stability, dispersibility, flavour neutrality and compatibility with other functional systems. Savannah represents Tirlán Ingredients, that supply world class Irish dairy-based proteins, engineered for RTD beverages, nutritional powders and high-function formulations. These systems allow fortification, hybridisation (dairy-plant) and integration with other functional ingredients such as Palatinose™ from Beneo, Engivita

HiPRO Beyond (Yeast protein concentrate) from Lallemand Bio Ingredients and Mineral fortification with Jungbunzlauer mineral salts. Tirlán Ingredients flag ship Truly™ Grass Fed Instantised Whey Protein Isolate is the cleanest tasting whey protein on the market along with being sustainably sourced is truly the gold standard for nutritional applications and instant protein applications such drinks and desserts. In the South African market, manufacturers can use Savannah’s value-driven support to explore “high-protein” claims in snack bars, RTDs or complete-nutrition formats, while ensuring process stability and sensory quality. This is where the above prod-

WHY THESE THEMES, WHY NOW

The era of one-trick ingredients is coming to an end and more ingredient innovations that deliver multiple benefits. Innovation teams will need to shift priorities and gain deeper innovation understanding to ensure they are at the forefront of customer satisfaction by driving innovation that gets results. Instead of choosing between taste or function, development teams should be routinely asking:

• Can this ingredient reduce sugar and provide texture?

• Will this fibre perform in plant-based systems and contribute gut health?

• Does this mineral salt integrate with your protein system and stabilise pH?

• Can this yeast-derived flavour tool reduce sodium and keep processing robust?

ucts fit in beautifully, as they have the following common attributes:

• Multifunctionality: Ingredients pull double or triple duty (e.g., fibre + texture + prebiotic).

• Claim-readiness: Each offers label-friendly names and strong scientific evidence.

• Formulation resilience: Modern supply chains and processing lines demand ingredients that tolerate variability and deliver repeatable performance.

• Regional relevance: South African consumer trends (clean label, sugar reduction, plant-based, fortification) align with what global manufacturers are pushing; and Savannah global and local technical support, regulatory insight and sourcing logistics.

At Savannah our mission is simple, we want to make our customers lives easier and better by providing Ingredients to Create Brilliance and inspire creativity with support systems that make sense for your business. Savannah believes that 2026 will be defined by smarter stacks, not just smarter single ingredients. With our exclusive key suppliers like Beneo, Jungbunzlaue, Lallemand Bio Ingredients, CFF, Herbafoods, and Tirlán Ingredients, local support and global insight, we stand ready to equip South African food manufacturers for that future.

Savannah Fine Chemicals –www.savannah.co.za

Driving the growth of plant proteins on menus

South African restaurant trends are expected to mirror those in the USA (and globally) as the demand for plant-based food continues to grow. Restaurants, cafeterias and corporate catering services will play a pivotal role in meeting the needs of a growing ‘flexitarian’ consumer base, creating a fertile ground for meat-free food choices to thrive.

PUSHING FLEXITARIANISM FORWARD

Embracing this opportunity, many food spaces are adding plant-based meat alternatives to their menus. Earlier this year, the Plant-Based Food Association in the US released a report titled State of Plant-Based in Food Service While not South African focused, the findings are a great starting-point to understanding what the local food service industry can expect in the adoption of plant-based foods on menus.

The opportunities for plant-based options in restaurants are rapidly expanding. The report quells any doubts arising from media speculation and paints a strong picture of sustained and continuous growth. Currently, plant-based foods can be found in 48% of restaurants across the United States, and this number has consistently grown over the past decade, even during challenging times like the Covid-19 pandemic.

This growth trend has also been seen in the UK. According to a study released by Lumina Intelligence, UK food service has experienced a notable shift as restaurants respond to the impact of inflation and the increasing popularity of Veganuary. According to Lumina’s menu tracker data, only 33% of main courses at major UK restaurant chains now include meat, and only 12% of starters have meat.

CATERING TO CHANGING CUSTOMER TASTES

Katherine Prowse, senior insight manager at Lumina, emphasised that this trend is significant and driven by two factors: the desire to cut costs and meet the demands of customers. Rising restaurant dish costs, which saw a 7.9% increase in just three months, prompted restaurants to explore less expensive options.

The impact of Veganuary is very clear in UK restaurants. The annual pledge to avoid animal products over January has

gained serious significance since its start in 2014. Veganuary works because it makes the shift to meat-reduction accessible. It’s about adopting a flexitarian approach, which means reducing meat consumption, not eliminating it.

An embracing of flexitarianism is being seen in South African food service too, with more establishments capitalising on the growing trend of healthier living through reduced meat consumption. By aligning their menus with these preferences, they are not only catering to changing customer tastes but also able to manage costs effectively.

options, plant-based meats have gathered significant attention from food service operators, aligning with the growing flexitarian market. In the US the on-going success of the ‘good old’ veggie burger has paved the way for more innovative plantbased meat options. Despite a temporary dip in penetration during the pandemic, plant-based burgers have showed continued growth. Predictions point to plant-based meat burgers doubling their penetration in the US by 2025.

EMBRACING PLANT-BASED TRENDS

The momentum for introducing new innovations and diverse plant-based meat options onto menus is here to stay, according the PBFA’s research. Approximately 60% of operators agree that plant-based meat is a long-term trend, and four times as many food service operators plan to add more plantbased meat options to their menus this year rather than reduce them.

Plant-based foods can become a driving force of innovation for food service operators. Partnering with local plant-based brands like Fry Family Foods to introduce exciting and delicious new offerings not only allows consumers to experience fresh menu items but also allows operators to integrate them strategically into their overall brand strategy. This alignment with plant-based trends can elevate the identity of food service brands, setting them apart in the competitive South African restaurant scene and attracting a broader consumer base.

The plant-based food trend continues to show an upward trajectory, globally and locally. As the demand for plant-based menu options grows here in SA, and we see more and more success with innovative plant-based meat varieties.

The key to successful adoption of plant-based foods on menus is quality of product. Research points to the importance of innovation when it comes to consumer engagement. Among the plant-based Fry Family Foods – www.fryfamilyfood.com

Ingredient innovation reshaping the future food industry

Brenntag Food & Nutrition addresses ingredient shortages and rising costs while helping manufacturers meet consumer demands for healthier, sustainable products.

Ingredient innovation is reshaping the food industry. With some ingredients becoming short in supply and prices increasing to a point where alternatives are required in formulation, finding the right blend of ingredients can be a massive hurdle to overcome. Consumers are also increasingly seeking products that are healthier, cleaner and more sustainable, with manufacturers under growing pressure to evolve fast. From plant-based proteins and natural sweeteners to functional fibers and next-generation emulsifiers, alternative ingredients are opening up exciting possibilities. True innovation goes beyond discovery – it’s about making these ingredients work, delivering the right taste, texture and stability that consumers expect.

THE REFORMULATION SOLUTION

This is where reformulation becomes essential. Reducing sugar, fat or additives while keeping the same sensory appeal is one of the biggest challenges in product development today. It requires technical know-how, creativity and a deep understanding of ingredient functionality. Reformulation is not simply about removing or replacing – it’s about rebalancing, rethinking and recreating products that meet new expectations without compromise.

That’s where Brenntag Food & Nutrition comes in. With deep formulation expertise, a broad ingredient portfolio and a local South Africa based Innovation and Application

"True innovation goes beyond discovery – it's about making these ingredients work, delivering the right taste, texture and stability that consumers expect."

center that is closely connected to our global network of Innovation & Application Centers, we help partners turn trends into market-ready solutions. Our local based technical teams support every step of the process –from concept and ingredient selection to pilot trials and scale-up. Whether it’s developing a cleaner label recipe, optimising texture in plant-based alternatives or improving nutritional profiles, we bridge the gap between creativity and technical precision.

Our collaborative approach allows partners to test, learn and refine quickly, accelerating innovation and reducing time to market. By combining technical expertise with market insights, we help translate global trends into solutions that fit local tastes and regulations.

INNOVATION WITH PURPOSE

Innovation today also means responsibility. Choosing the right ingredients is not just about performance but about shaping a more

resilient and sustainable food system. At Brenntag Food & Nutrition, we guide partners in selecting ingredients that deliver functionality while supporting sustainability goals – from responsibly sourced raw materials to solutions that minimise waste and improve shelf life.

Reformulation and ingredient innovation are two sides of the same journey – both driving the evolution of a food industry that’s healthier, more sustainable and more adaptive to change. At Brenntag Food & Nutrition, we’re committed to co-creating the next generation of food solutions – combining science, insight and collaboration to help our partners stay ahead in a fast-changing market. Whether there is a need to use hydrocolloids to extend fat for bakery applications or fibers in hybridised meat applications, we are bound to find a viable solution for your developmental challenge.

FAST FACT

Brenntag Food & Nutrition's local South Africa Innovation & Application Center is directly connected to their global network of Innovation & Application Centers, enabling rapid translation of global trends into locally tailored food solutions.

Brenntag – www.brenntag.co.za

Unleash food and beverage innovation

Spray dynamics symphony in-kitchen in seasoning solution

Heat and Control's Symphony In-Kitchen Seasoning System delivers precise seasoning control with reduced waste and enhanced hygiene standards.

Heat and Control has introduced a breakthrough in in-kitchen seasoning. The Spray Dynamics® Symphony In-Kitchen Seasoning (IKS) System is purpose-built to simplify the seasoning process, delivering smarter, cleaner results with greater accuracy, efficiency, and sustainability. In-kitchen seasoning presents a unique set of challenges. Processors must manage complex flavours, allergens, hygiene standards, and labour constraints — all while maintaining product quality and consistency. The Symphony IKS meets these challenges head-on, ensuring precise seasoning control and reliable performance in demanding production environments.

SEASONING SMARTER FOR THE FUTURE OF FLAVOUR

In-kitchen operations require a system that can do it all — reduce waste, enhance

INNOVATION WHERE IT’S NEEDED MOST

• More accurate seasoning – Integrated load cells and proprietary controls deliver consistent, repeatable results

• Even distribution, no build-up – FastBall applicator improves coverage and reduces cleaning time

• Fewer parts, less downtime – Frameless drum design enables faster maintenance and sanitation

• Cleaner working environment – No fugitive dust, improved allergen control, and greater operator comfort

• Lower costs over time – Reduced labour, fewer parts, and improved performance translate into long-term savings

Developed in response to the growing complexity of in-kitchen operations, the Symphony IKS helps processors achieve consistent, high-quality results with less waste and effort. More than just an upgrade, it’s a practical solution for improving seasoning performance in compact, high-demand environments.

hygiene, manage allergens, and simplify daily operations. The Symphony IKS delivers on all fronts through innovation where it matters most. At its core is patent-pending seasoning capture technology that draws airborne particles back through the product stream so seasoning lands exactly where it should — on the product. The result is better coverage, less waste, and a cleaner, safer working environment.

RAISING

THE STANDARD IN SEASONING PERFORMANCE

With the Symphony IKS, Heat and Control sets a new benchmark for cleaner, safer, and more efficient in-kitchen seasoning. Whether you’re running high-volume production lines or flexible small-batch systems, this

ABOUT HEAT AND CONTROL

Established in 1950, Heat and Control is a privately-owned company with a global team that has built an extensive knowledge bank and developed a wealth of experience and expertise. Access to production and technical support from a network of engineers, food technicians, field service technicians, skilled tradespeople, and support teams provide food manufacturers with confidence to achieve production goals.

technology delivers precision, performance, and hygiene — at every scale.

HISTORY: LEADING THE WAY SINCE 1950

Experience matters when it comes to engineering and manufacturing equipment for complex and highly specialised food and other industry processes. Founded in 1950 by five engineers that saw an opportunity to modernise processing equipment, Heat and Control has consistently pursued our founders’ original passion for helping customers improve their products ever since and has been a leader in science, technology, and service from the start. Our organisational knowledge and experience allow us to approach a strategic solution most efficiently, and the level of our commitment to service and partnership is unmatched.

DID YOU KNOW?

The Symphony IKS features a frameless drum design that enables faster maintenance and sanitation while reducing downtime.

Smart and flexible conveying that keeps your line running smoothly. We provide a wide variety of innovative and dependable conveying and product handling systems to move product through the line as efficiently as possible.

Ideal applications: Everything you need to move your product from A - Z

• Snack foods

• Prepared foods

• French fries

• Fresh produce

• Pet food

• Nuts & Trail Mix

• Crackers

• Confectionery

GELITA at Fi Europe 2025 – Paris

GELITA, the global forerunner in Bioactive Collagen Peptides (BCP®), invites Fi Europe visitors to Be Active! and explore how collagen innovation is shaping the future of functional nutrition.

On December 2–4, 2025, at the Paris Expo Porte de Versailles (Booth 40H91), GELITA will present pioneering concepts for healthier, tastier, and more effective functional foods and beverages.

ELEVATE BARS TO FUNCTION AND FLAVOUR

For developers of high-protein and reduced-sugar bars, OPTIBAR® is redefining next-generation functional snacking. With its unique performance in texture, stability, and taste, it allows product developers to create protein and cereal bars that not only deliver nutritional benefits but also meet consumer expectations for indulgence and clean labelling.

Collagen that fuels active living: Under the umbrella theme Be Active!, GELITA showcases its comprehensive portfolio of Bioactive Collagen Peptides, including VERISOL®, PeptENDURE®, FORTIGEL®, FORTIBONE®, TENDOFORTE®, and BODYBALANCE®, each supporting targeted benefits from beauty-from-within and muscle strength to joint health, recovery, and longevity. Visitors can explore ready-to-market prototypes such as beauty drinks, sports performance beverages, and healthy ageing concepts — and experience them firsthand through onsite tastings.

VISIT GELITA – BOOTH 40H91

Whether your goal is to formulate the next best functional snack or beverage, or to explore sci ence-based collagen innovations that enhance performance and well-being, GELITA is your partner in creating products that help people Be Active!

ABOUT GELITA

strong requirement for innovation is the driving force of the family-owned company that is always looking for new solutions for food, pharmaceutical, health & nutrition as well as for technical applications.

Within its portfolio of collagen proteins, GELITA supplies collagen peptides with proven body-stimulating capabilities, tailor-made gelatines, and non- or partly-water soluble collagens. This holistic range of products in combination with its vast experience in developing solutions for different applications makes GELITA first choice for its customers.

"OPTIBAR® is redefining next-generation functional snacking with unique performance in texture, stability, and taste."

COMPREHENSIVE PRODUCT PORTFOLIO

In today’s landscape of highest consumer demands, manufacturers of food products have to rely on natural, healthy, non-allergenic ingredients for their developments. Collagen proteins from GELITA are the perfect match for this as they fulfil all of these requirements, a particular plus being the fact that they are foodstuffs in their own right (i.e. no E-numbers). They also possess a set of unique technical and physiological properties.

Besides the traditional use of collagen proteins as natural stabilisers and emulsifiers for countless products, they enable manufacturers to provide their products with other properties which are becoming more and more important. GELITA has intensified its research in developing solutions for physical mobility, weight management, and beauty-from-within.

GELITA is the leading company for manufacturing and marketing collagen proteins. Coordinated from headquarters in Eberbach, Germany, GELITA provides customers around the world with products of the highest standard, comprehensive technical expertise, and sophisticated solutions. More than 20 sites and a global expert network ensure that state-of-the-art know-how is always available for customers.

150 years of experience in the field of collagen proteins are the basis of GELITA’s performance. A

FAST FACT

GELITA has 150 years of experience in collagen proteins and operates more than 20 sites globally, making it the world's leading family-owned company in bioactive collagen peptide innovation.

Gelita - www.GELITA.com

New chapter begins for established supplier

Lake International officially launches as independent organization following management buyout, marking new chapter for established African food supplier.

Lake International, formerly AECI Food & Beverage, has officially launched as an independent organisation following its acquisition by the management team and Sana Partners, a South African private equity investor. The move marks the start of a significant new chapter for one of Africa’s most established and trusted food and beverage ingredient suppliers, with Lake International now set to operate as a standalone organisation with its own capital, identity and strategic direction, gaining the autonomy required to accelerate its growth.

LEADERSHIP PERSPECTIVE ON INDEPENDENCE

“We are an established and trusted South African business and this move, one that came about as our former group company centralised its focus on mining operations, gives us the freedom to operate in a more entrepreneurial environment,” says Roger Falck, Managing Director of Lake International.

UNIFIED IDENTITY UNDER ONE BANNER

The acquisition also presented an opportunity to unite the organisation’s three established divisions – Lake Foods, Infigro