2023 Start-up showcase

PIONEERING THE WAY TO NET ZERO

FOREWORD

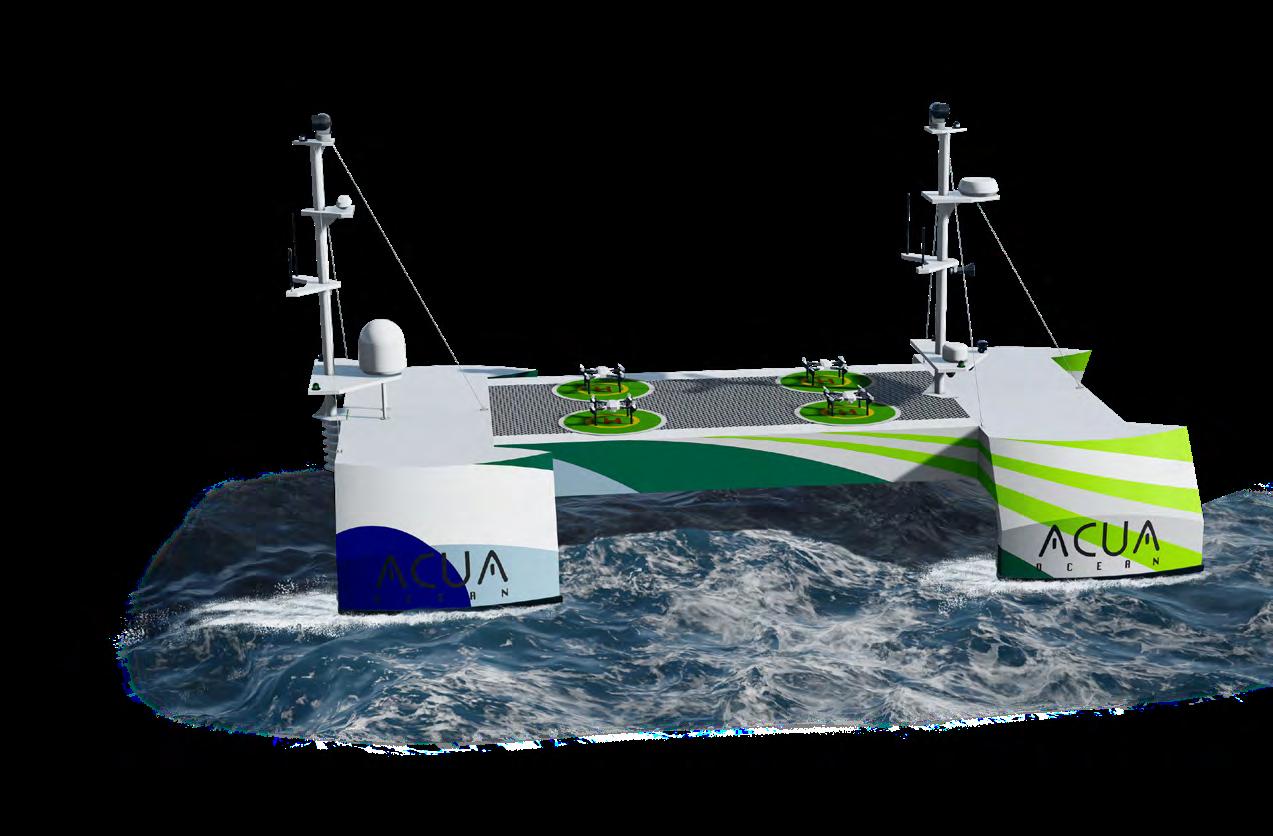

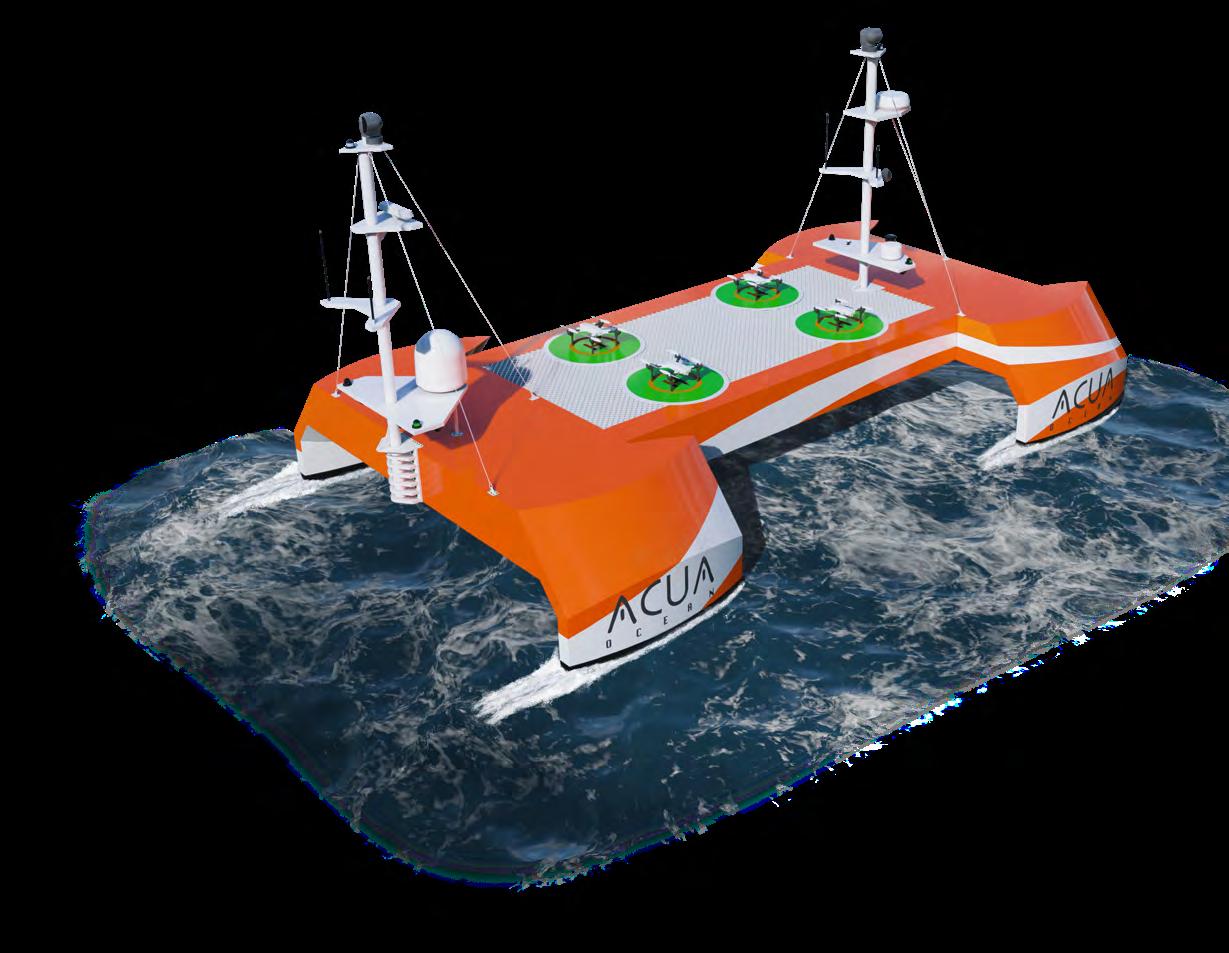

ACUA OCEAN

Neil Tinmouth, Chief Executive Officer, Mike Tinmouth, Chief Operations Officer, Eddie Davidson, Head of Delivery

ELECTROGENOS

Augusto Bartolome, Chief Executive Officer, Alfredo Saenger, Chief Operations Officer

FLUXART

Paul Perera, Chief Executive Officer, Professor Weijia Yuan, Chief Operations Officer

HYDROWHEEL

Ken Morrow, Chief Executive Officer

MESPAC

Andrea Gulisano, Co-Founder and Chief Executive Officer, Giuseppe Giorgi, Co-Founder and Chief Technology Officer

MYRIAD WIND ENERGY SYSTEMS

Adam Harris, Chief Executive Officer, Paul Pirrie, Chief Technology Officer, Peter Taylor, Chief Operations Officer

PARALLEL CARBON

Ryan Anderson, Chief Executive Officer, Aránzazu Carmona Orbezo, Chief Technology Officer

PURIFIRE LABS

Neel Shah, Chief Executive Officer, Dr Matt Pearce, Chief Technology Officer

WASTEWATER FUELS

Dr Daniel Carlotta-Jones, Founder and Chief Engineer

WATERWHELM

Dr Alireza Abbassi Monjezi, Founder and Director, Dr Richard Wood, R&D Engineer

WAVEX

Olivier Bourdin, Founder and Chief Executive Officer, Clement Puech, Chief Sales Officer

WINDSWEPT.ENERGY

Roderick Read, Founder and Chief Executive Officer

Foreword

In the midst of the climate crisis and the global shift towards clean, secure and affordable energy, there is a need for forward-thinking companies that are embracing disruption and change. Here at the Net Zero Technology Centre (NZTC), we see start-ups at the forefront of innovation. The entrepreneurial mindset is a force to be reckoned with; their agility and risk-taking mentality are needed to develop and deploy new technologies that will make a meaningful impact in accelerating net zero energy.

Mark Anderson Chief Acceleration Officer & TechX Director

Following a competitive application process, this year NZTC welcomed 12 high-potential start-ups to take part in our award-winning TechX Clean Energy Accelerator programme. Each of these pioneering companies are developing trailblazing solutions that can help transform the energy sector.

The progress our 2023 cohort has made has been nothing short of inspiring. They have been exposed to a diverse network of mentors and forged valuable relationships within industry. From enhancing their business models, to gaining customer validation and technology expertise, they have grasped each and every opportunity that comes with TechX.

We are delighted to continue supporting them on their journey. I look forward to seeing the impact they make, which in turn will help us advance a thriving clean energy ecosystem for a brighter, more sustainable future.

Discover the next-generation of start-ups and the solutions that will help us reach net zero, faster.

www.acua-ocean.com

ACUA Ocean is developing a hydrogen-powered uncrewed surface vessel (H-USV) for ocean monitoring and protection. The long-endurance USV is designed to operate in open ocean sea states of over 3 metres, increasing safety at sea and operational capabilities, whilst reducing the need for large costly, diesel-powered crewed vessels.

With critical infrastructure being deployed further offshore in more remote locations and extreme conditions, industry needs cost-effective and scalable solutions for managing and protecting these sites. Traditionally the solution has been expensive diesel-powered crewed vessels. These vessels use tens of thousands of litres of diesel per day and cost upwards of $30,000-50,000 (£24,146 - £40,243) per day to crew and operate. Recently there has been a move towards USVs, but due to their smaller size these platforms have lower weather limits, reducing the operational time at sea.

Alternative long endurance USV designs include wind, wave and solar autonomous vessels but they lack power for speed, communications or sensor payloads and therefore have limited applications within the offshore infrastructure and offshore renewable energy sectors.

ACUA Ocean’s patent pending hydrogen-powertrain technology provides reliability and stability for long endurance missions, with the power for payload to deploy a multitude of commercial and environmental sensors.

The company has worked with ORE Catapult on market sizing and Zero-Emission Marine Technology (ZEM-Tech) to validate its greenhouse gas (GHG) emissions calculations as part of the Department for Transport Clean Maritime Demonstration Competition. By reducing GHG emissions by 99.1%, ACUA Ocean’s H-USV offers a promising solution for the industry to directly reduce emissions by 111,940 tonnes CO2e by 2030 across all market segments, with the potential to reach almost a million tonnes depending on adoption rates.

Electrogenos

www.electrogenos.co.uk

Electrogenos is bridging the gap between academia and industry in hydrogen production, driven by the need for cost-efficient, scalable and sustainable solutions in a rapidly growing market. The company’s aim is to revolutionise the electrolyser manufacturing process while maintaining a competitive edge and promoting a cleaner energy future.

Electrogenos’ technology addresses the challenges of high capital investment, long lead times and limited scalability within the hydrogen production industry. The company’s unique alkaline electrolysers employ soft-tooling methods, substantially reducing capital costs and manufacturing time compared to traditional hard-tooling techniques.

Their proprietary electrolyser architecture incorporates a powerful, durable hydrogen catalyst without scarce rare earth metals, ensuring sustainability and minimised supply chain risk. The technology’s adaptability enables seamless integration of new catalysts, novel electrode architectures and ultrasonic excitation, potentially enhancing efficiencies by up to 20%. With a four-fold reduction in electrolyser stack costs - $70K/ MW (£56k) compared to the current $270K/MW (£217K) - and the capacity to deploy 200MW factories in under a year, Electrogenos accelerates net zero by addressing the two year backlog on electrolysers and providing an affordable, scalable hydrogen production solution.

The technology could enable substantial greenhouse gas emissions reduction. The displacement of steam methane reforming (SMR) produced hydrogen with an emissions factor of 11kg CO2e/kg H2 by electrolysis-produced hydrogen with an emissions factor of 1.95kg CO2e/kg H2 results in significant emissions reduction, contributing to the acceleration of net zero goals.

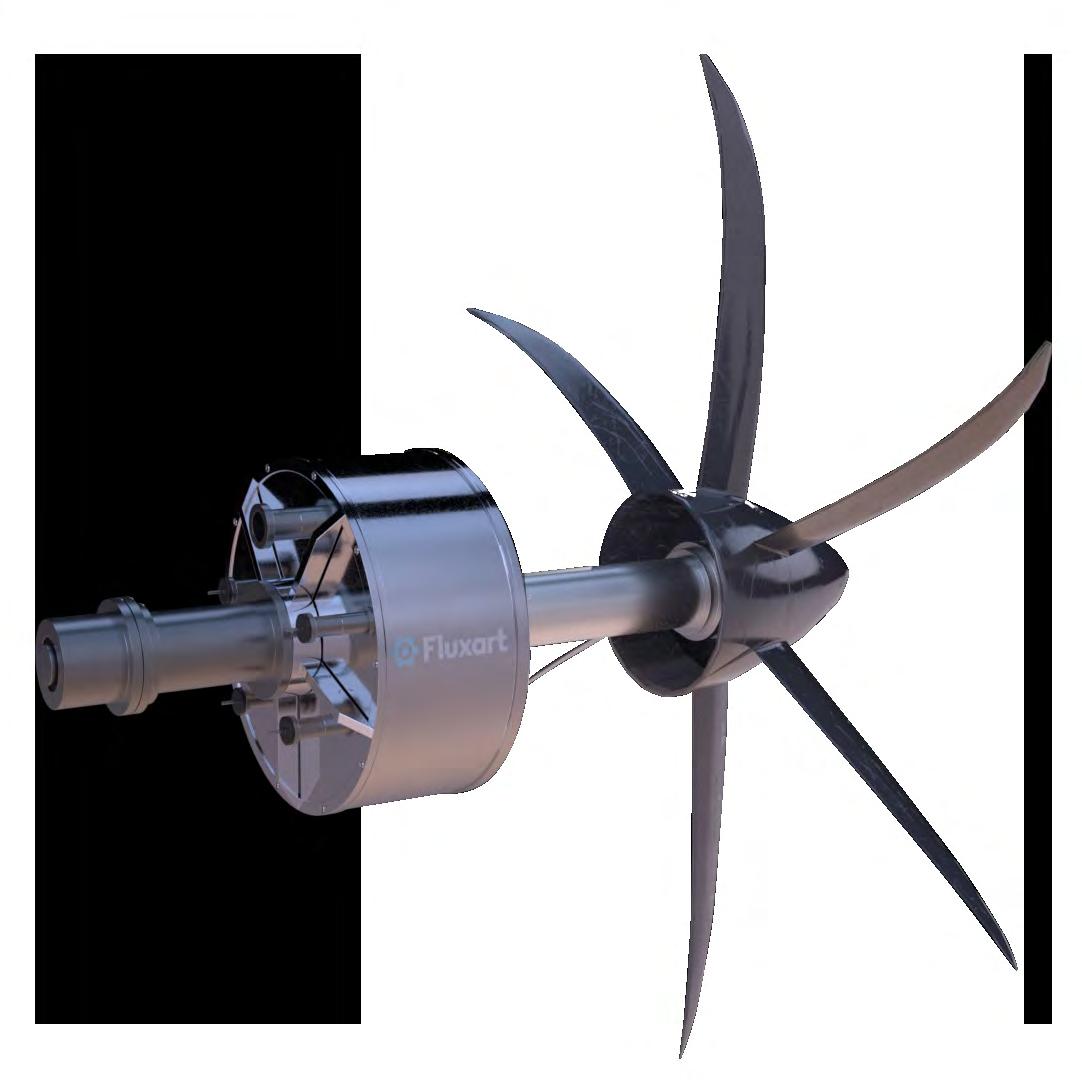

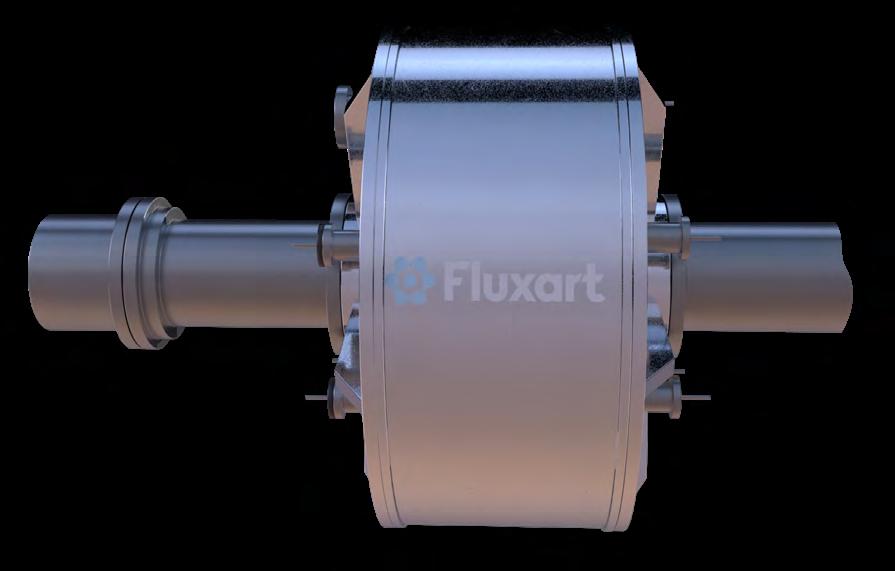

Fluxart was formed in response to the aviation sector’s need to deliver growth whilst remaining sustainable. According to the International Energy Agency (IEA), multiple additional measures will be needed to promote the technologies, operations and market conditions necessary to reduce the emissions associated with aviation to below 900 Mt CO2 by 2030, in line with the IEA’s Net Zero Emissions by 2050 scenario milestones.

To combat this, Fluxart is enabling a true zero emissions electrical aircraft propulsion system by developing a family of superconducting hydrogen motors and drives. Compared with current aviation fuel (kerosene) and sustainable aviation fuels, Fluxart’s solution not only eliminates CO2 but goes further by reducing the non-CO2 effects of aviation, including water vapour contrails, NOx and other sulphides associated with combustion. Its motors are designed to be four times lighter for a given power output than conventional motors and 98% efficient, both factors being key parameters in the optimal design of aircraft.

These benefits are achieved due to superconductivity which is realised by using the onboard cryogenic liquid hydrogen fuel to cool the motors and drives to very low, cryogenic temperatures.

As other industries address climate change i.e. through electrification, the relative GHG emissions contribution from aviation will increase. This problem is compounded by increasing demand for air transport which, according the International Civil Aviation Organization, will increase by an average of 4.3% per annum for the next 20 years. This underpins Fluxart’s passion and focus in decarbonising the aviation industry, although the technology has other applications too, including in heavy goods vehicles.

www.hydrowheel.co.uk

An affordable transition to sustainable, renewable energy is essential for our world to meet its carbon reduction requirements. Although there have been considerable cost savings in wind power, supply is intermittent. Tidal energy is renewable and dependable but, until now, it has been too expensive. Sophisticated engineering in a harsh environment creates high capital expenditure (CAPEX) and operational expenditure (OPEX).

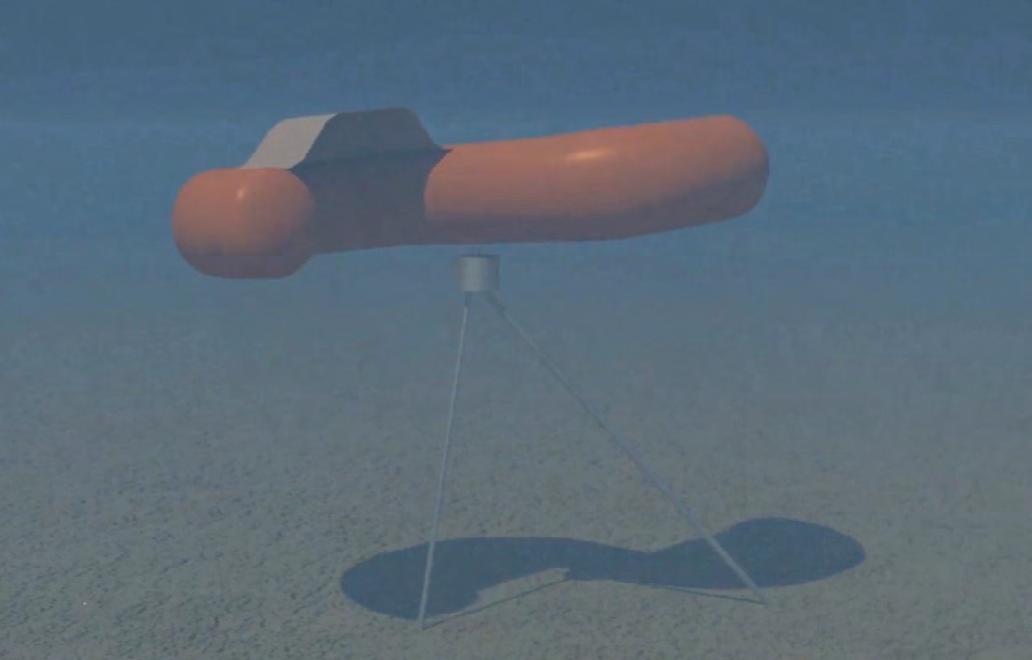

Hydrowheel is developing a unique solution in the form of its novel inflatable waterwheel technology to generate renewable energy from tidal power. The ‘Hydrowheel Ocean Turbine’ is an inflatable fabric structure reducing CAPEX with quicker, easier manufacturing and less demanding transport and installation requirements that minimises supply chain problems. Its inherent buoyancy also allows turbine maintenance to be carried out on the surface to reduce OPEX. Lowering the upfront and operational costs in this way finally makes tidal energy competitive with offshore wind with a projected levelised cost of electricity below £45 per megawatt hour.

When inflated on site and tethered to the seabed using standard subsea anchoring systems, the Hydrowheel technology takes the form of a large “Savonius” turbine which extracts energy from the tidal flow. The chambers of the turbine expand as the current flows into them to increase the open surface area and increase efficiency in a cost effective way. This then turns the gearbox and generator harnessed beneath the turbine and generates electricity to charge local batteries, or feeds back to local equipment or grids onshore.

As Hydrowheel’s solution lowers costs, it is suitable for a wider range of locations without the strongest tidal currents. This allows the energy to be generated closer to communities and infrastructure that consume the power. This means more installations and lower carbon emissions. 100 hydrowheels, installed individually or as closely packed arrays, have the potential to power 90,000 homes.

www.mespac.space

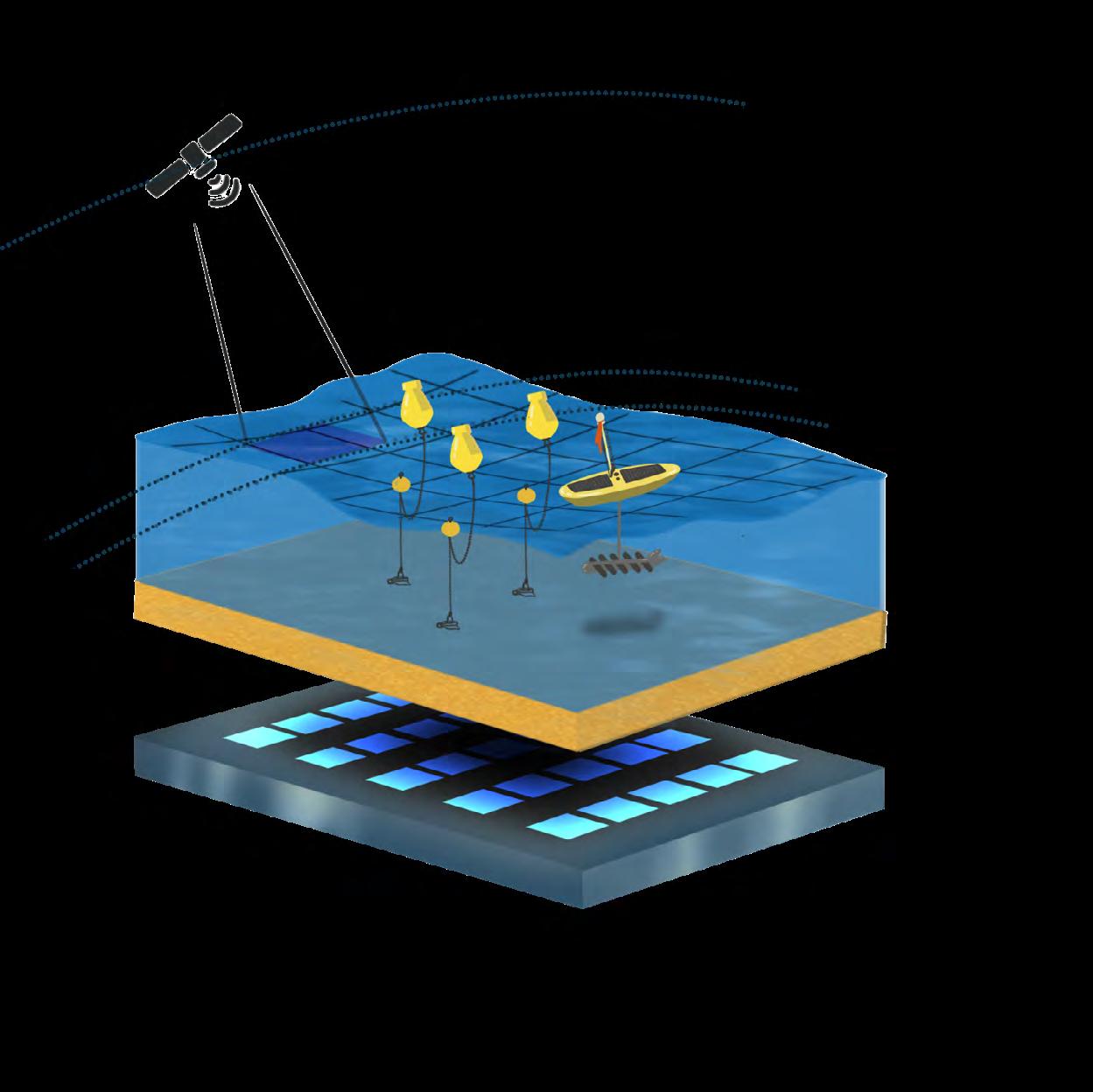

With 50 years of cumulative experience in the offshore renewable energy sector, MESPAC’s team has collectively seen the problems in obtaining metocean data to meet marine requirements in terms of granularity, accuracy, reliability and resolution. Developers in the renewables sector need accurate metocean surveys. Current methods install in-situ devices to gather this data, which cause delays due to lengthy permitting processes and loss of devices. They also produce unnecessary greenhouse gas emissions.

To solve this challenge, the company is developing offer a solution that utilises satellite data to collect real-time information on the ocean waves and winds, providing a quicker, more cost-effective and lower carbon solution than current methods. Designed for the offshore wind and ocean energy sectors, the service suite delivers highly accurate, continuous and spatially-refined wind and metocean information for project development, financing and operation. Using earth observation satellites, the quality of the data provided is suitable for bankability, advanced design activities, monitoring and control of operations for offshore energy projects.

In order to shorten metocean surveys, MESPAC uses in-situ measurement campaign data to train and validate the company’s algorithms and deliver the same accuracy as in-situ surveys. By combining this data, the solution can shorten metocean survey time by at least 50%.

According to the Impact Forecast methodology, taking into consideration the ability of MESPAC to accelerate the deployment of new offshore wind and other ocean energy installations, the platform will enable greenhouse gas emission reductions of 2.9 Mt (mega tonnes) CO2e per year by 2030, having contributed to a reduction of 6.4 Mt CO2e over that time period.

Myriad Wind Energy Systems

Team

Adam Harris Chief Executive Officer Paul Pirrie Chief Technology Officer Peter Taylor Chief Operations Officerwww.myriadwind.com

Myriad Wind Energy Systems is designing the next generation of wind turbines with its high-performance multirotor design. Instead of a single large rotor, Myriad’s design has a large number of smaller rotors which produce the same amount of power.

The solution eliminates the need to manufacture and transport long blades of more than 100 metres, but instead its blades on standard Heavy Goods Vehicles. When there is a need to scale up the power rating, the design simply requires more modules to be added. This can be achieved using the existing supply chain.

Myriad’s multi-rotor wind turbines are more cost-effective, with higher energy capture than conventional wind turbines. At the same time, just one of Myriad’s 3MW turbines can offset 3,000 tonnes of CO2e emissions from the electricity grid per year.

The company has stated that net zero is at the core of their mission. Myriad aims to take its innovation to the utility-scale market, in support of the transition to 100% renewable energy generation.

Minimising global warming requires immediate decarbonisation, as well as rapidly scaling the nascent carbon dioxide removal (CDR) industry. Scaling CDR is necessary for companies and countries to achieve net zero commitments. Direct air carbon capture (DAC) is a fundamental tool for achieving gigatonne-scale CDR. However, affordable DAC does not exist today, and new DAC-based CDR solutions will take decades to scale to climate-relevant supply volumes.

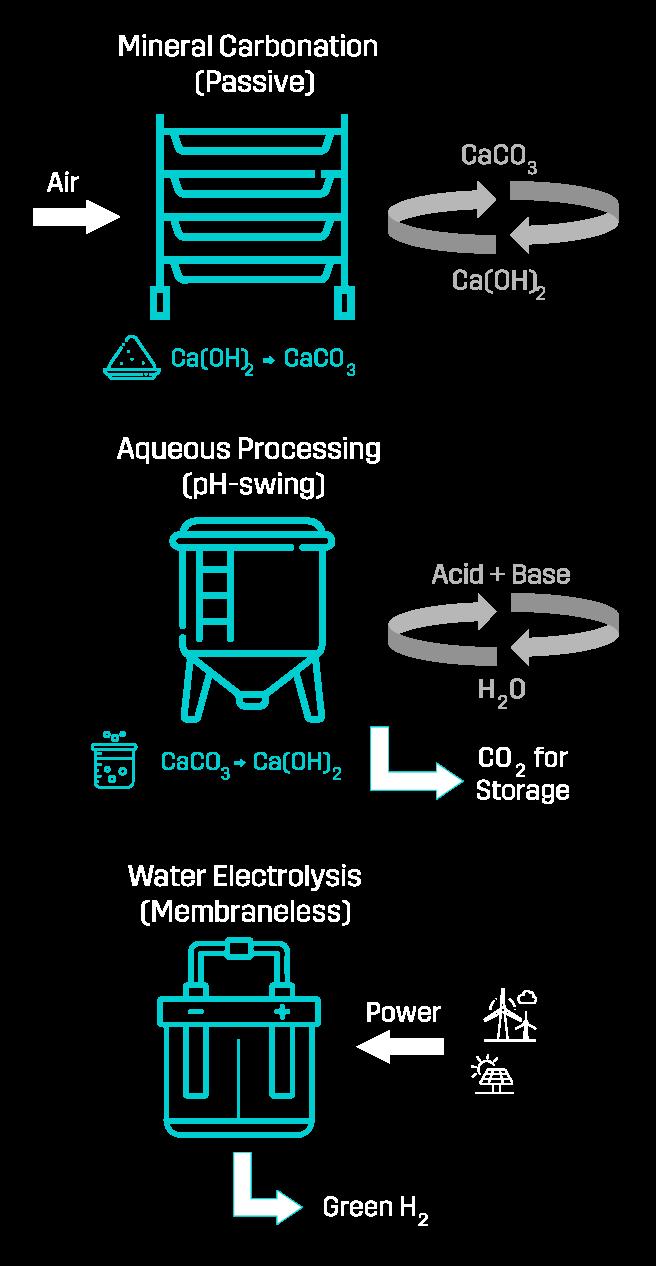

Parallel Carbon presents a solution with their affordable and scalable direct air capture process to permanently capture tonnes of carbon dioxide from the atmosphere, relying only on water, wind, sunshine and abundant minerals. The technology uses a unique combination of DAC and water electrolysis to produce high-quality CDR credits alongside green hydrogen.

Parallel Carbon’s patent-pending system passively captures CO2 from air using minerals that transform their chemical structure while doing so. To regenerate the capture medium and to liberate and permanently store captured CO2, these minerals are processed using aqueous, acid-base reactions. The acids and bases used are produced by water electrolysis which also generates green hydrogen.

By leveraging well-developed supply chains, inexpensive equipment and process integration, the company’s DAC technology will rapidly scale while producing highquality CDR credits. The technology is designed to rely on intermittent renewable power, eliminate fossil fuel demand with hydrogen, and significantly reduce the cost of mitigating climate change.

By 2030, the technology could have removed 2.1 million tonnes of CO2 from the atmosphere, while producing more than 94 tonnes of green hydrogen.

www.purifirelabs.com

Purifire Labs is passionate about addressing the climate crisis through innovation at the intersection of science, engineering and sustainability. The company aims to reduce anthropogenic emissions through their carbon capture and conversion technologies to prevent millions of tonnes of greenhouse gas emissions from entering the atmosphere.

At present, carbon capture solutions are expensive, energy-intensive and use toxic chemicals. These systems also have a large footprint and cannot be retrofitted onto existing polluting assets. For these reasons, fewer than 1% of polluting assets have any carbon capture systems.

To combat this, PuriFire Labs is developing gas separation technologies that eliminate the need for complex equipment from existing carbon capture systems, such as absorption and stripping columns, resulting in a cheaper and more energy-efficient carbon capture system.

By integrating its carbon capture technology with its proprietary hydrothermal gasification reactor (which generates hydrogen), PuriFire provides a unique, low-carbon and cost-effective pathway to producing green methanol through catalytic upgrading.

Green methanol is a clean, biodegradable fuel. It is an attractive alternative for powering vehicles and ships, cooking food, and heating homes and can reduce CO2e emissions by 83% compared to using diesel.