2024TechX Start-upShowcase

Contents

Foreword

About Airspection

Apleum

Frontier Robotics

H2CHP

HyWaves

INERGIO

Kali Technology

MECHAPRES

Modjoule

Reaforma

Soltropy

SurreyH2

Foreword

MarkAnderson

Chief Acceleration Officer & TechX Director

Every day start-ups are challenging traditional paradigms and unlocking new solutions to change the world. Their tenacity, ingenuity and technical prowess make them key in the transition to clean, affordable and secure energy.

At the Net Zero Technology Centre (NZTC), we continue to harness this entrepreneurial spirit to pave the way for industrial decarbonisation, while accelerating a thriving clean energy ecosystem. This year, we welcomed 12 pioneering companies to TechX, who have since undergone a transformational journey. Our 2024 cohort have advanced their technologies which promise impact, while growing their businesses to take advantage of the ever changing market landscape.

The solutions set to emerge from this year’s TechX cohort are ground-breaking, and will actively support us in making our vision a reality: a net zero world powered by technology innovation. The progress they have made has been remarkable, and their journey is only just beginning.

Entrepreneurs,assemble.

Countries

16 Finalists

NZTC’s TechX Clean Energy Accelerator is an intensive 15-week programme, equipping start-ups with the funding, tools and resources they need to evolve and grow, accelerating their path to commercialisation and beyond.

Through TechX, NZTC is unearthing new solutions, propelling CCUS and carbon removal, low carbon hydrogen, renewable power, alternative fuels, decarbonised heat and digital innovations.

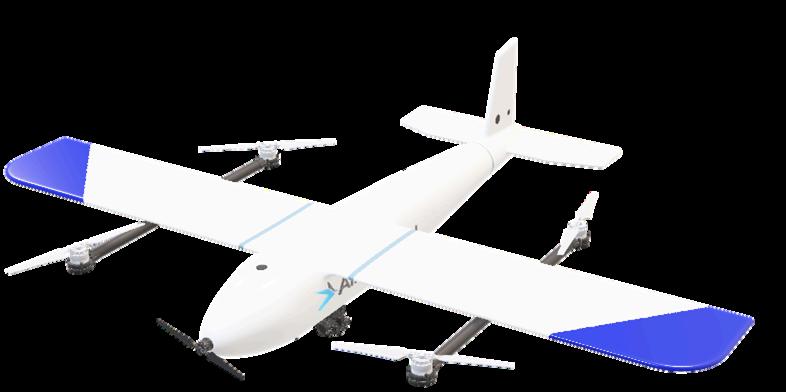

Airspection

Team:

Matthew McLean, MD and Chris Fowler, Technical Director

Location: Glasgow, UK

Website: https://airspection.co.uk

Technology focus area: Digital solutions

Technology readiness level: 6

Accessing remote infrastructure such as offshore wind turbines for inspections and maintenance poses challenges in terms of unreliability, time consumption and hazards, with up to 80% of the associated costs attributed to access. Currently, vessel launched drone inspections are required, which are infrequent, leading to high repair costs, operational inefficiencies and even risk of blade failures.

Airspection is developing a remote launched drone service, flying tough endurance drones from accessible locations to remote infrastructure. This solution provides reliable and safe inspections, with the ability to navigate challenging environments, and can inspect up to 3x faster than conventional methods, allowing for predictive maintenance.

Airspection has recently demonstrated a successful prototype drone inspecting a turbine blade, and has filed a patent.

Apleum

Traditional fuel sources continue to contribute to environmental degradation and the looming threat of climate change. This has resulted in industries such as aviation and shipping facing increasing pressure to reduce associated carbon emissions.

To address this, Apleum is developing a solution that utilises renewable energy to convert carbon dioxide into liquid fuels. The company achieves this through use of cutting edge proprietary technology in the areas of electrolysis and heterogeneous catalysis. The carbon neutral fuels are direct substitutes for those currently utilised in the shipping and aviation sectors. This creates a pathway for these industries to rapidly decarbonise without having to invest in the development of completely new designs of energy propulsion and support infrastructure.

Apleum was founded in late 2022 through the Carbon13 venture builder, securing early investment from the accelerator. By mid-2023, prototype development was successfully completed. This year Apleum joined the TechX accelerator, securing further investment and support. Currently, the company is focused on business development and constructing a demo unit.

Team: Kris Anderson, CEO, Alma Zhanaidarova, CTO, Tayeb Belhocine, COO

Location: London, UK

Website: https://www.apleum.com

Technology focus area: Alternative fuels and green chemicals

Technology readiness level: 4-5

Frontier Robotics

and David Wavell, COO

Location: Edinburgh, UK

Website:

https://www.frontierrobotics.ai/

Technology focus area: Digital solutions

Technology readiness level: 5-6

The number of offshore assets is set to increase significantly. Inspection of this infrastructure is challenging due to hazardous conditions and cost, but it is critical to the continued safe, reliable and sustainable operation of the marine economy. A new approach to subsea inspection is necessary to address this growing need.

Frontier Robotics has developed software that provides Remotely Operated Vehicles (ROVs) with autonomous and advanced inspection capabilities. The solution easily integrates onto almost any ROV, enabling a plug-and-play upgrade to the global fleet of thousands of ROVs. The solution improves inspection speed and quality, scales inspection quantity, and reduces safety risk and carbon emissions.

Frontier Robotics was started in 2023 to commercialise technology developed at Edinburgh’s Heriot-Watt University in collaboration with industry. The company has received almost £550K of public innovation funding, which has supplemented almost £1M university research funding received for the technology, carried out several field trials and has strong interest and engagement from several potential customers.

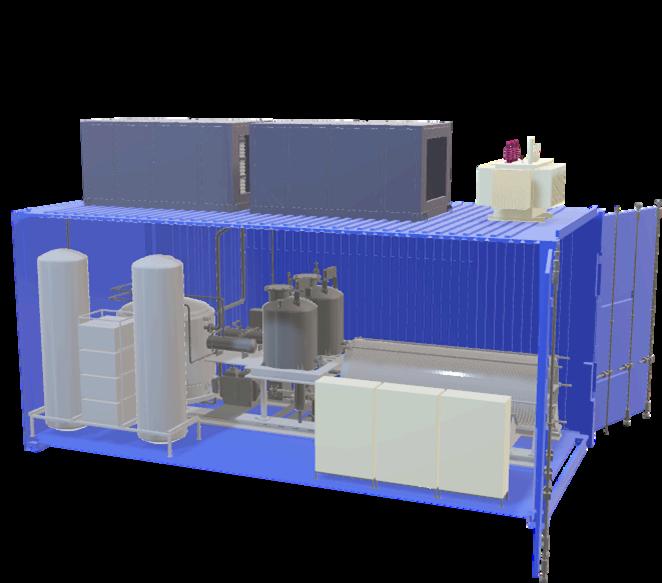

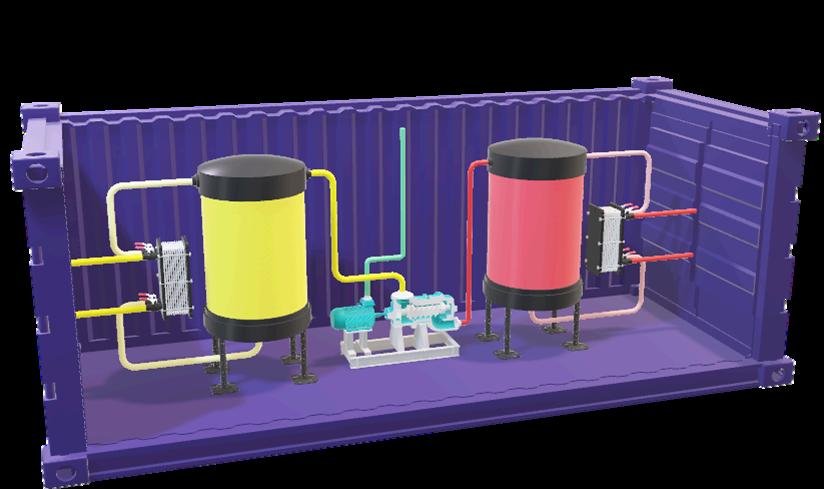

Many commercial and industrial clients, along with ports, seek clean and dependable power generation, with the flexibility to transition to 100% renewable fuels such as biogas and hydrogen as they become accessible.

H2CHP addresses this demand by developing a highly efficient, fuel-flexible generator tailored for industrial and maritime use. Unlike traditional reciprocating generators constrained by mechanical linkages, the company's generator is software-controlled, delivering efficiency surpassing 45% with zero emissions. The system seamlessly toggles between two and four-stroke modes, adapting to both liquid and gaseous fuels, even mid-operation.

Team:

Dr. Stephen Hampson, Managing Director, Professor Tony Roskilly, Technical Director

Location: Aberdeen, UK

Website: http://www.h2chp.co.uk/

Technology focus area: Low carbon hydrogen

Technology readiness level: 4

Team:

Dr. Thomas Delaney, CEO, Ugo Manfredi, CTO, and Niall Haughian, COO

Location: Bedford, UK

Website: http://www.hywaves.com/

Technology focus area:

Low carbon hydrogen

Technology readiness level:

5-6

Producing hydrogen by electrolysis requires multiple electric power conversion steps, resulting in significant efficiency losses and high costs. Renewable energy sources and the hydrogen production plants are often separated by long distances, resulting in the use of the electrical grid to deliver power to the plant. The net efficiency loss between the PV plants and the electrolysers amounts to approximately 10%, with high grid connection costs.

HyWaves has a novel power management and control architecture for connecting electrolysers to renewable power sources, designed for maximal production of green hydrogen and offering a significant reduction of up to 25% LCOH (Levelised Cost Of Hydrogen) over current technologies.

The company promotes the end-to-end use of direct current, which makes it possible to eliminate many hydrogen system CAPEX elements, while the absence of DC-AC and AC-DC power conversions maximises the overall system performance while minimising energy losses.

HyWaves has raised a total of £1.15M funding to date. Pre-seed

INERGIO

Fuel cells represent highly promising clean technologies poised to replace the likes of diesel generators, potentially offering 10x more autonomy than batteries, with zero emissions. Despite these advantages, they are not yet readily available in the market due to their high costs, low maturity and limited accessibility.

INERGIO is producing fuel cells that are fuel-flexible. This capability enables the company to merge the accessibility advantages of diesel generators with the efficiency, noise reduction, and emission-free benefits of fuel cells. The technology can currently utilise commercial fuels like propane and natural gas, with seamless adaptation to future green energy carriers such as hydrogen, biogas and ammonia once they become available in the market. Importantly, no additional technical adjustments are required for this transition.

A spin out of Ecole Polytechnique Federal de Lausanne (EPFL) from Switzerland, INERGIO recently launched a pilot test in January 2024 demonstrating their fuel flexible power generators in the field.

Team: Mahmoud Hadad, CEO and Luc Conti, CTO

Location: Lausanne, Switzerland

Website: http://www.inergio.ch/

Technology focus area: Alternative fuels and green chemicals

Technology readiness level:

5-6

Team: Andrew Anderson and Rahul Shivaram, Co-Founders

Location: London, UK

Website: Follow on LinkedIn

Technology focus area: Decarbonised heat & cooling technologies

Technology readiness level: 2

Pre-seed

A significant portion of overall industrial heating demand results from processes that require heating to reach temperatures of up to 120°C. The use of gaspowered steam generators is often favoured for this application. Heat pumps, however, can achieve this temperature threshold yet their widespread adoption is constrained due to the associated expenses and complexities involved in their installation.

To address this, Kali Technology is currently in the process of developing a heat pump solution tailored to seamlessly integrate into these industrial processes. Through the application of advanced manufacturing techniques in the redesigning of the heat pump, the solution aims to achieve a 10-fold reduction in capital expenditure. This significant cost reduction will pave the way for these processes to transition towards decarbonisation in a manner that remains competitively priced against natural gas alternatives.

MECHAPRES

Solutions to produce fossil fuel free steam either require the equivalent space of a tennis court, or are very costly. The burning of natural gas to raise steam for drying processes in industries like paper machines incurs significant expenses, primarily in fuel, labour, insurance and safety.

MECHAPRES is developing a high-temperature heat pump with integrated thermal storage. The system generates fossil-free steam by recycling waste heat. The novel components allow for high efficiency and low manufacturing costs, resulting in a payback time of under five years. Due to the embedded storage, the system can take advantage of on-site renewables or off-peak electricity, contributing to shortening the payback time. The compact patented design, operational flexibility and low safety requirements make it easy to integrate without causing any disruption to the plant’s operations.

Team: Anastasios Vasilopoulos, Marianna Digka, and Fabio Giunta, Co-Founders

Location: Cambridge, UK

Website: Follow on LinkedIn

Technology focus area: Decarbonised heat & cooling technologies

Technology readiness level:

4

Team: Sean Puchalski and William Etheridge, Co-Founders

Location:

Canada and London, UK

Technology focus area: Alternative fuels and green chemicals

Technology readiness level:

2

Diesel generators, commonly utilised to power refrigerated shipping containers during land transport, present considerable challenges due to their high operational costs and emissions of harmful pollutants. This not only contributes to environmental degradation but also poses health risks, particularly in areas near transportation corridors where air contaminants are prevalent.

Modjoule offers zero-emission power packs for refrigerated shipping containers (reefers) with three times the lifespan, one and a half times the power, and one-third the weight of a diesel genset. The Modjoules will be fully IoT-connected and provided on an energy-as-a-service (EaaS) basis to minimise customer switching costs and our company’s product support expenses.

A recent spin-out of Deep Science Ventures, Modjoule was founded by entrepreneurs with vast experience and a fervent commitment to transitioning industrial transportation away from fossil fuels. Modjoule has already secured £350K in equity and grant funding and is in negotiations for a technology evaluation agreement with a European multi-modal shipping company.

Reaforma

Concrete is the second most consumed material by humans after water, with cement being the key component that makes concrete possible, however it contributes 5% to global GHG emissions. The challenge is replacing the raw material cement with an alternative material that is accepted by one of the oldest and most risk adverse industries, meets required standards, reduces carbon footprint yet achieves cost parity with current solutions. The decarbonisation of cement is difficult as the fundamental science requires 1450 °C of process heat.

Reaforma proposes a solution by substituting traditional cement with clay. Clay requires significantly lower temperatures of 600-800 °C for processing, thereby reducing process emissions. This innovation enables the utilisation of low-carbon hot gas generation for the conversion process to clay, a feat otherwise unattainable with traditional cement production. Moreover, carbon capture occurs upstream; this early capture helps ensure that the final product -clay-cement - is net-zero in emissions because the CO2 is managed from the beginning rather than trying to capture it after it has been released.

Reaforma is currently in the developmental stage, refining their prototype system to demonstrate the production of carbon-neutral cement.

Team: Munraj Sembhi, CEO

Location: Peterborough, UK

Website: https://www.reaforma.co.uk

Technology focus area: CCUS & carbon removal

Technology readiness level:

3-4

Team: Stuart Speake, Founder and CEO

Location: Glasgow, UK

Website: http://www.soltropy.com

Technology focus area: Decarbonised heat

Technology readiness level:

7

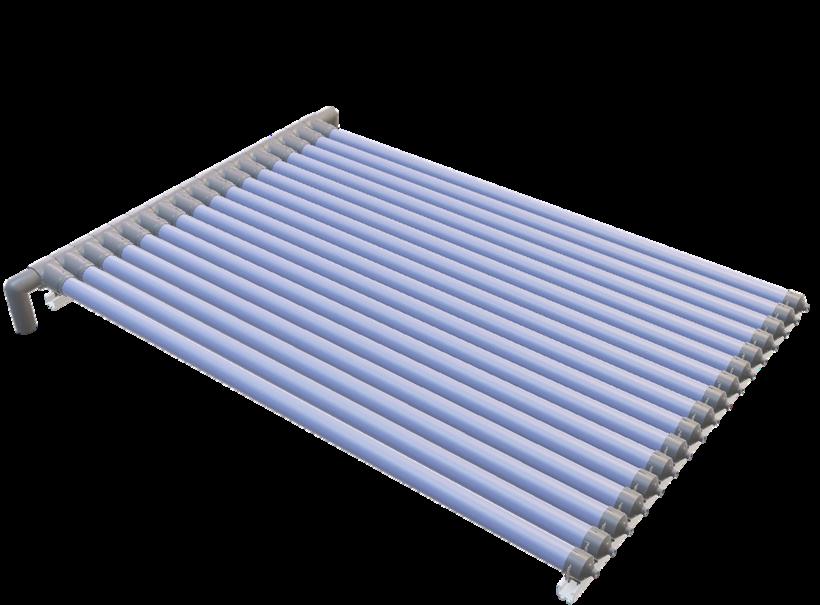

Heat contributes more than 40% of global energyrelated CO2 emissions, making it pivotal to decarbonise in support of net zero targets. One tried and tested solution in this space is solar thermal panels. While they often exceed 60% efficiency, they suffer from a number of problems. Multiple plumbing connections in larger systems lead to increased installation time and more failures; and the use of antifreeze means that systems are undersized for much of the year because they are sized for the sunniest days to prevent the antifreeze from overheating, which degrades it.

Soltropy’s technology solves these issues. Its novel approach to mounting the tubes reduces installation time by 50% while significantly reducing failure rates. The technology uses no antifreeze, which means that the system can be correctly sized, leading typically to a tenfold increase in energy generation. This results in a lower levelised cost of heating and therefore more carbon savings.

With over £50,000 in minimum viable product sales, Soltropy is poised to launch its next-generation solar thermal technology in Q4 2024.

Surrey H2

Currently, green hydrogen production poses significant cost challenges both in terms of capex and opex. Alkaline systems offer low capex but suffer from reduced efficiency at around 70%, whereas proton-exchange membrane (PEM) systems boast higher efficiency (by approximately 80%) but come with 40% higher capex. Additionally, dynamic response, such as the ability to cope with variable power from renewables, remains inadequate for alkaline systems.

SurreyH2's pioneering "SurreyLoop" innovation uses a cheap metal catalyst such as zinc, free of rare earth metals in a reduction oxidation loop. In an electrolyser the metal catalyst reduces and in a hydrolyser the metal catalyst oxidises. Both stages of the loop produce hydrogen, enhancing overall efficiency to over 90%. The capex is also reduced by up to 68% due to the fact that at least 50% of the hydrogenproducing capacity is provided in the hydrolyser which is a substantially cheaper piece of equipment at scale compared to the electrolyser.

Furthermore, this set-up serves as a substantial flow battery, facilitating dynamic response and storage capabilities. This is achieved by the addition of a sump to store the ionic zinc solution, which can be reacted in the hydrolyser with water to generate hydrogen even when there's no power input. Emerging from the University of Surrey, SurreyH2 has successfully secured two rounds of funding and received grants totalling £900k. Currently, the company is advancing towards the construction of a TRL 6 demonstrator.

Team: Dan Somers, CEO and Hasan Ozcan, CTO

Location: Guildford, UK

Website: www.surreyh2.com

Technology focus area: Low carbon hydrogen

Technology readiness level:

4