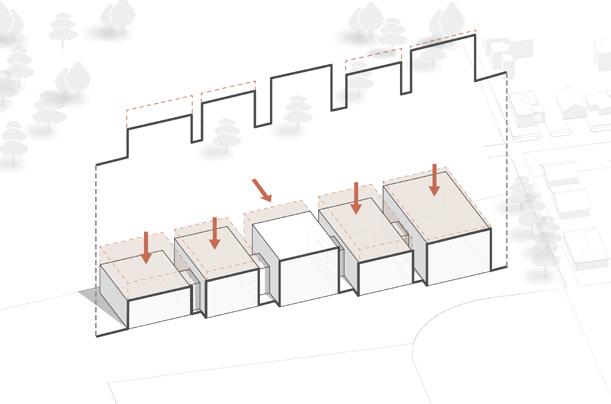

01 Rhythm

Architecture Studio III | December 2024

Category: Music Community Center

Instructor: Christopher Reinhart

Duration: One Semester

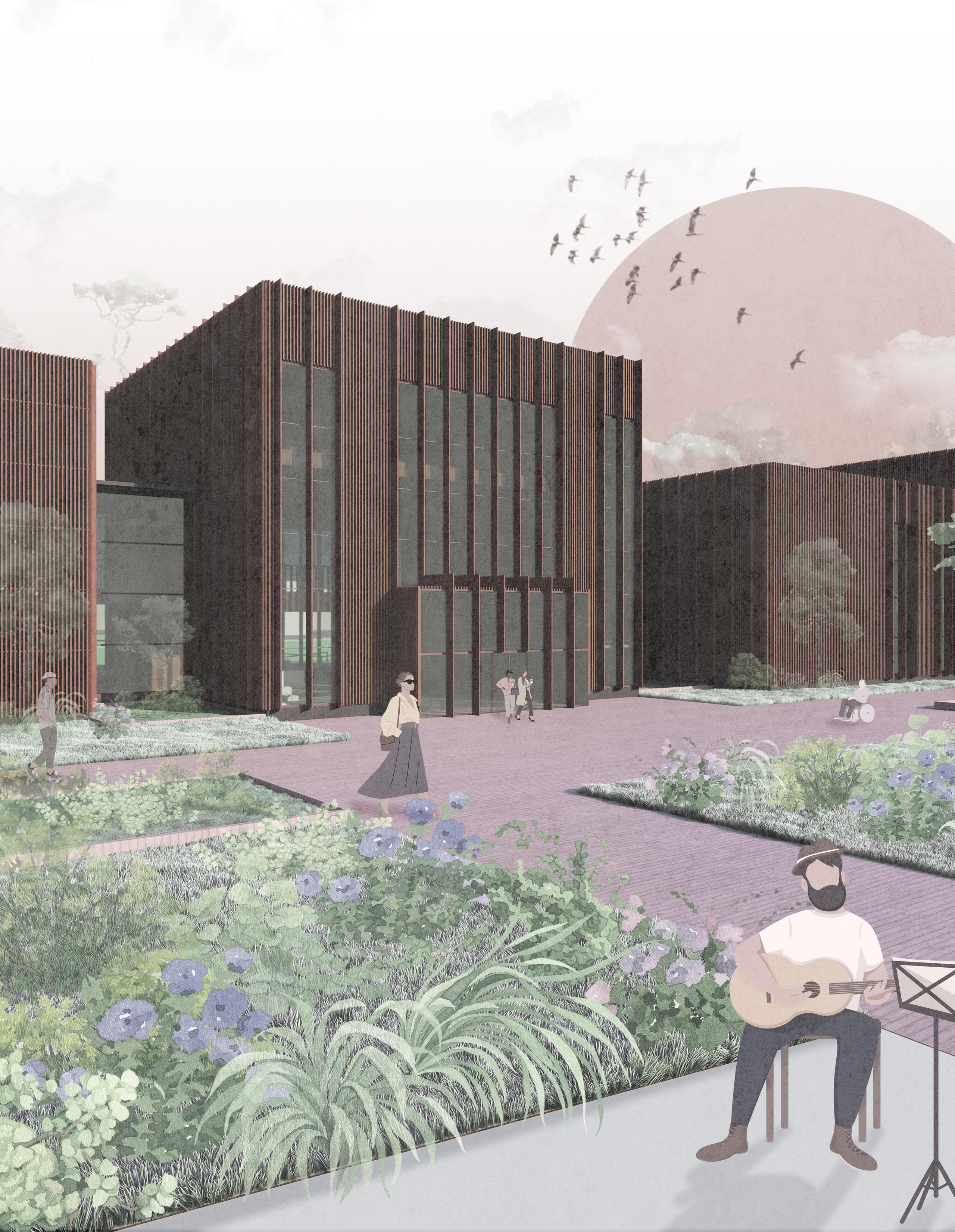

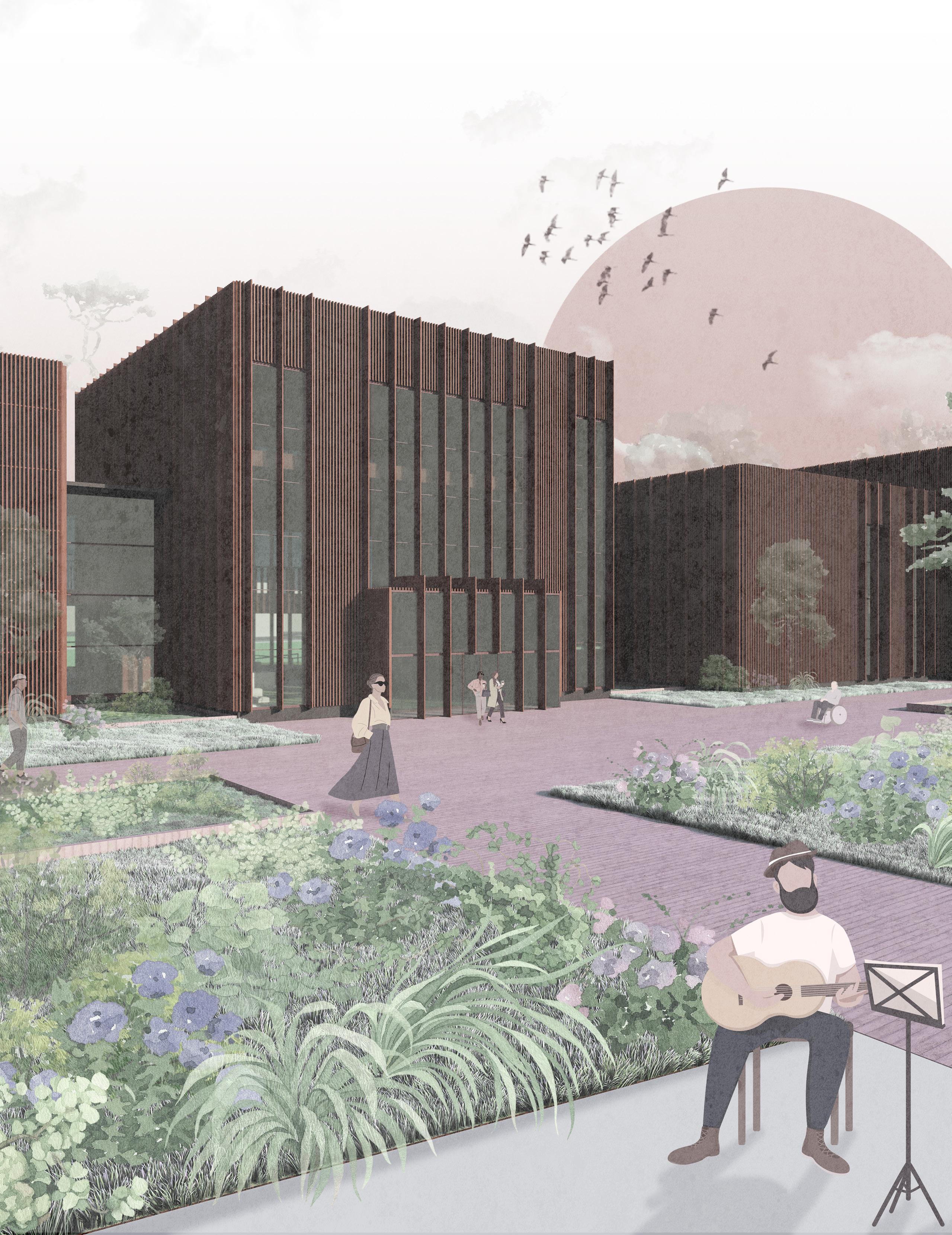

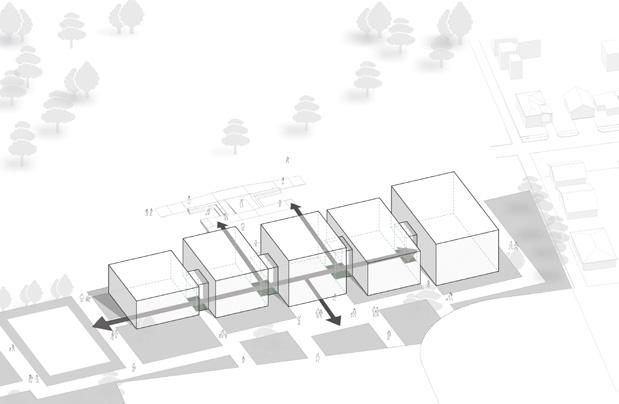

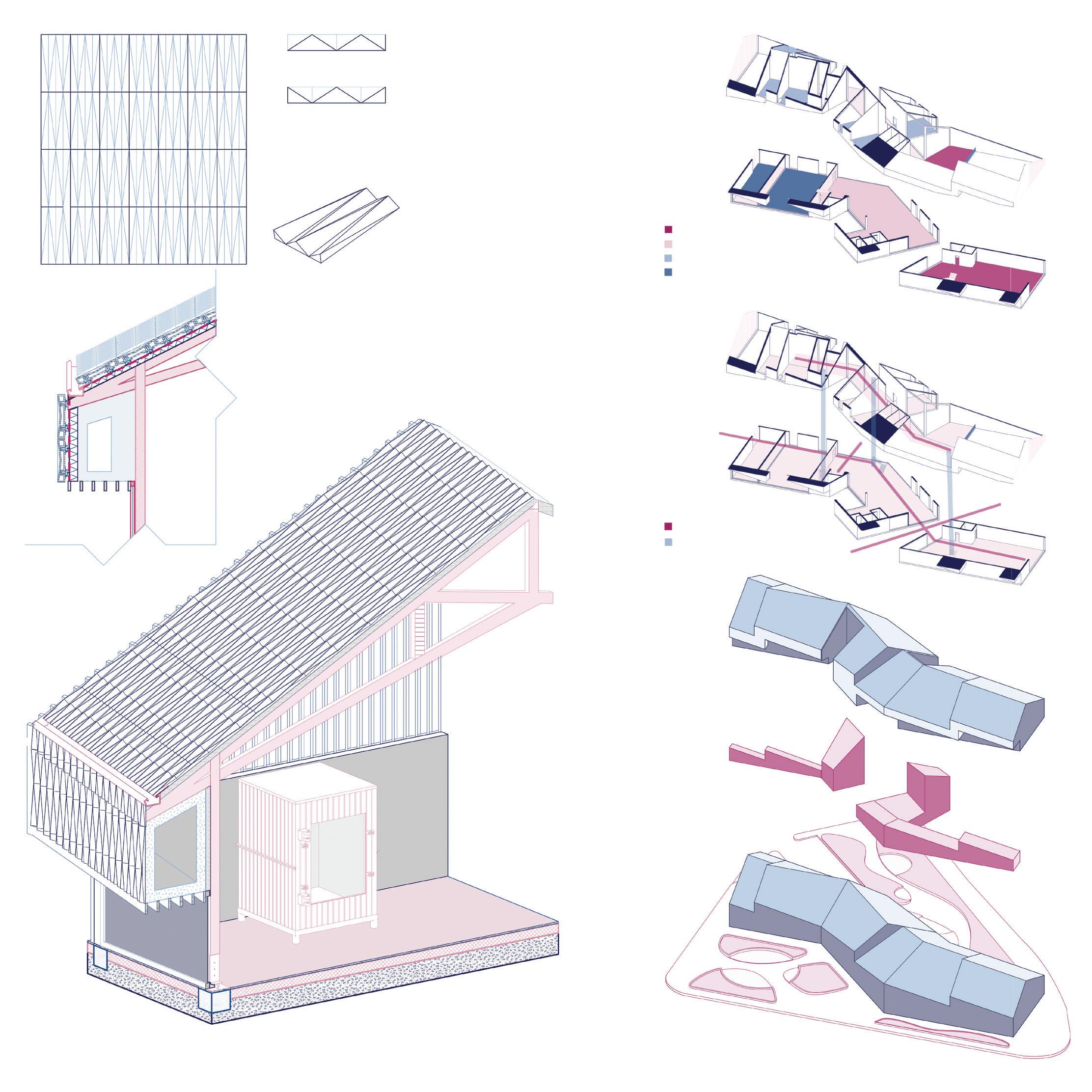

Rhythm threads between space into nature’s embrace

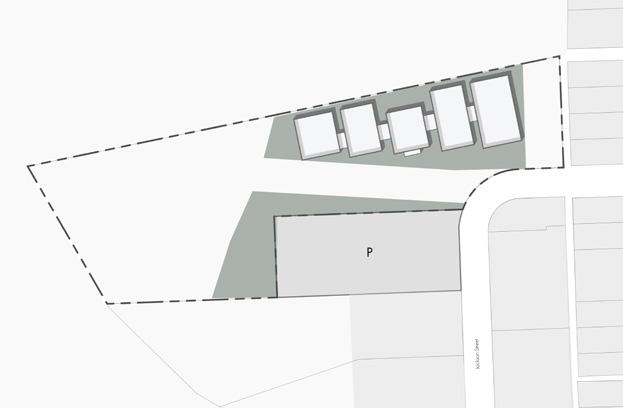

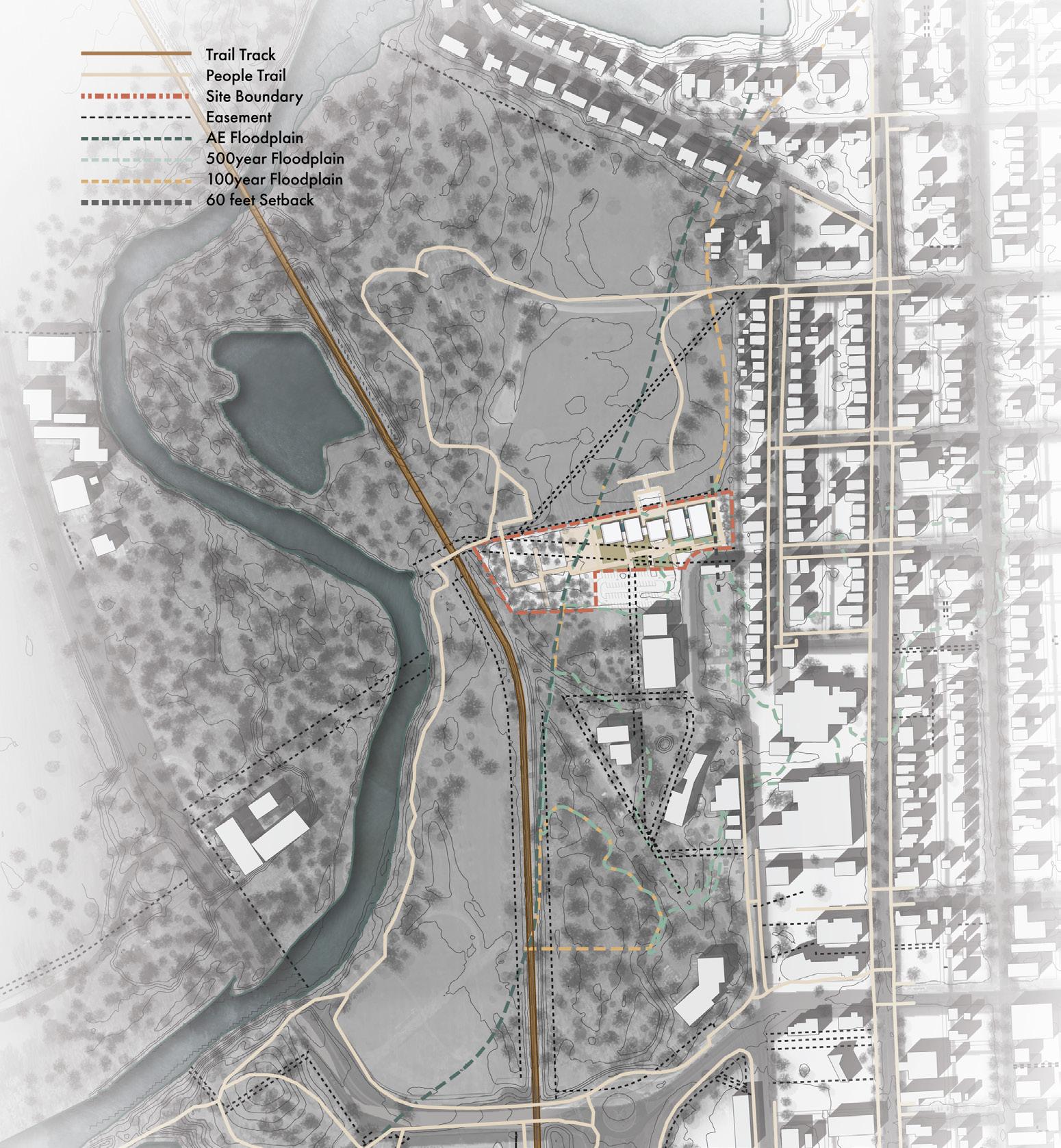

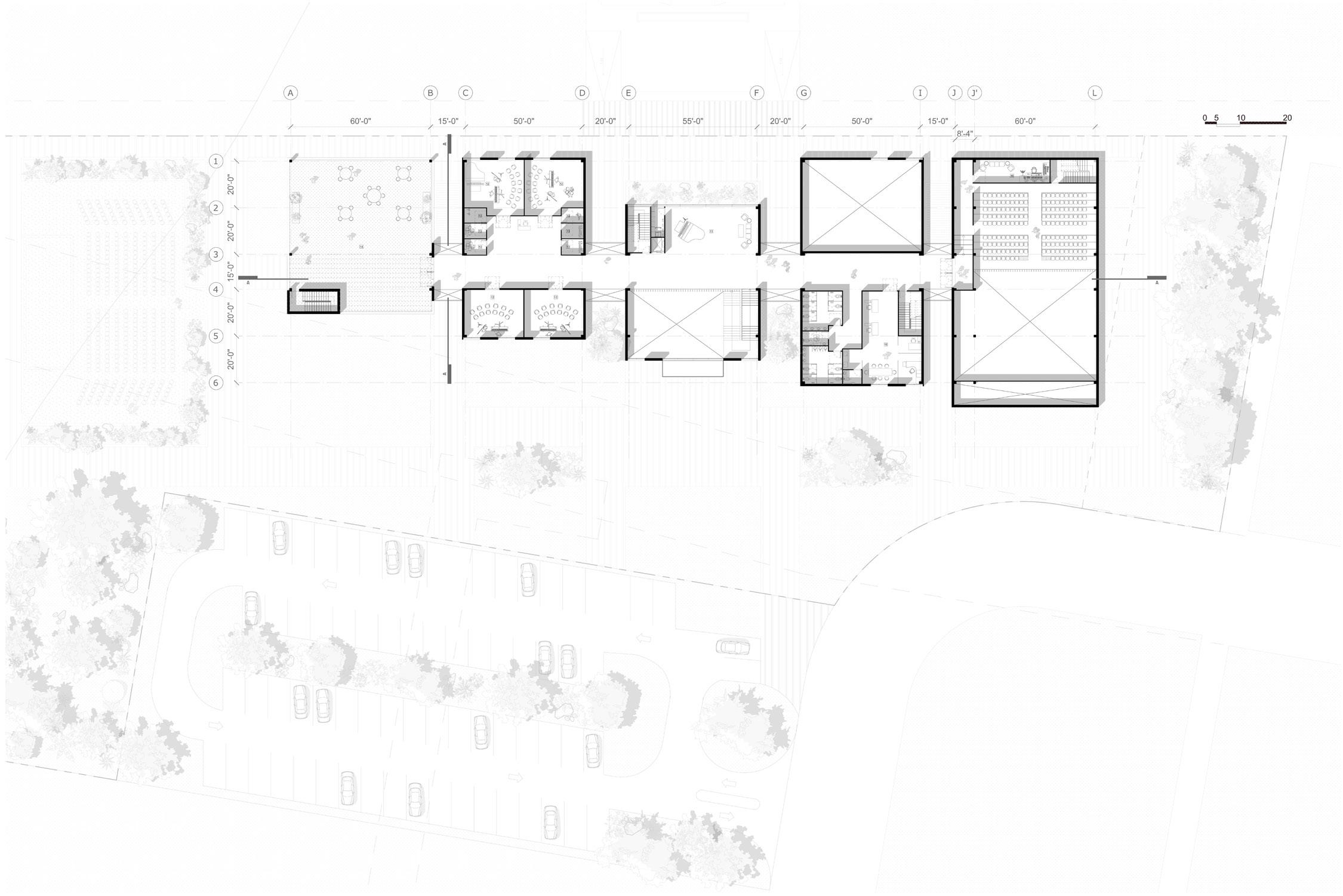

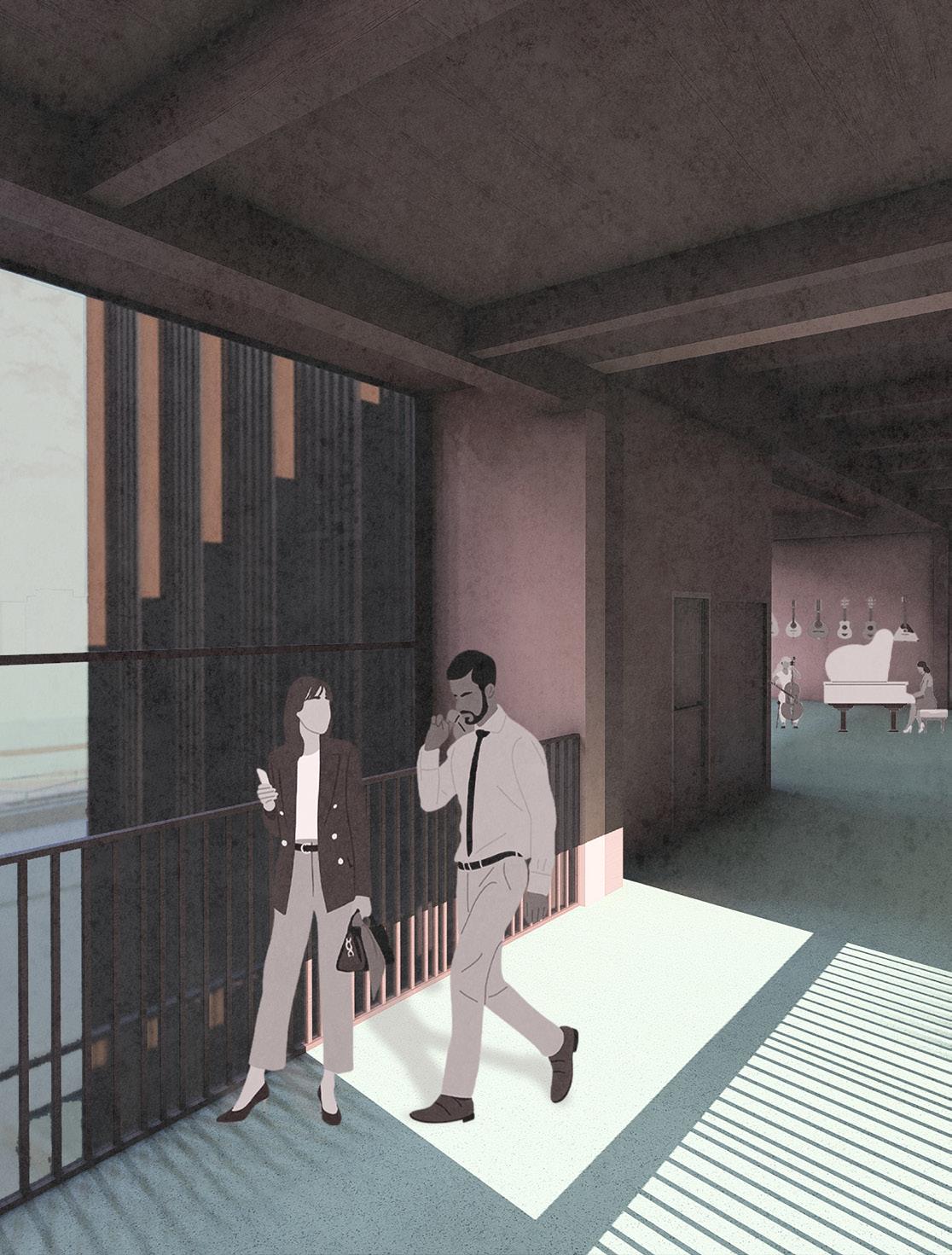

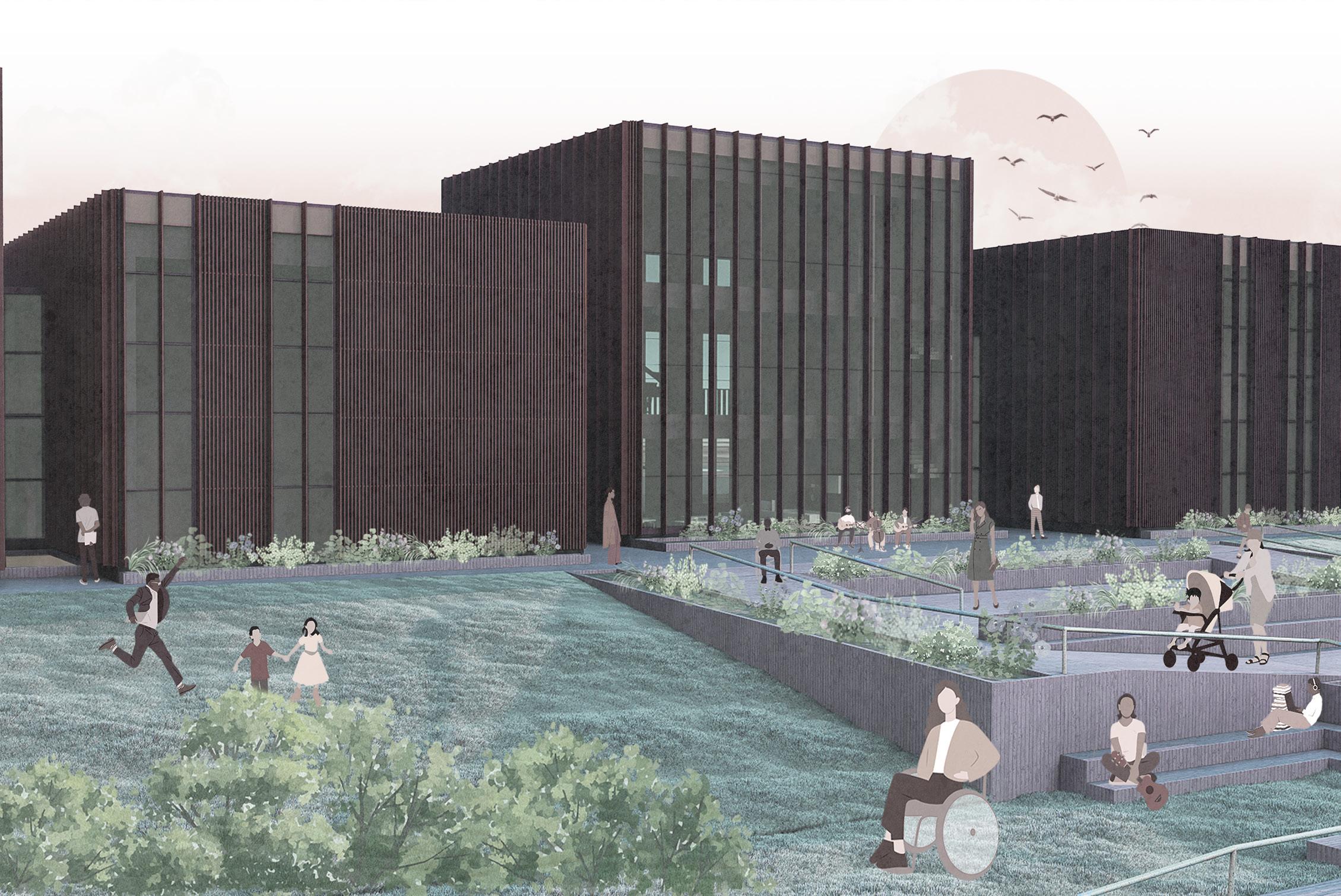

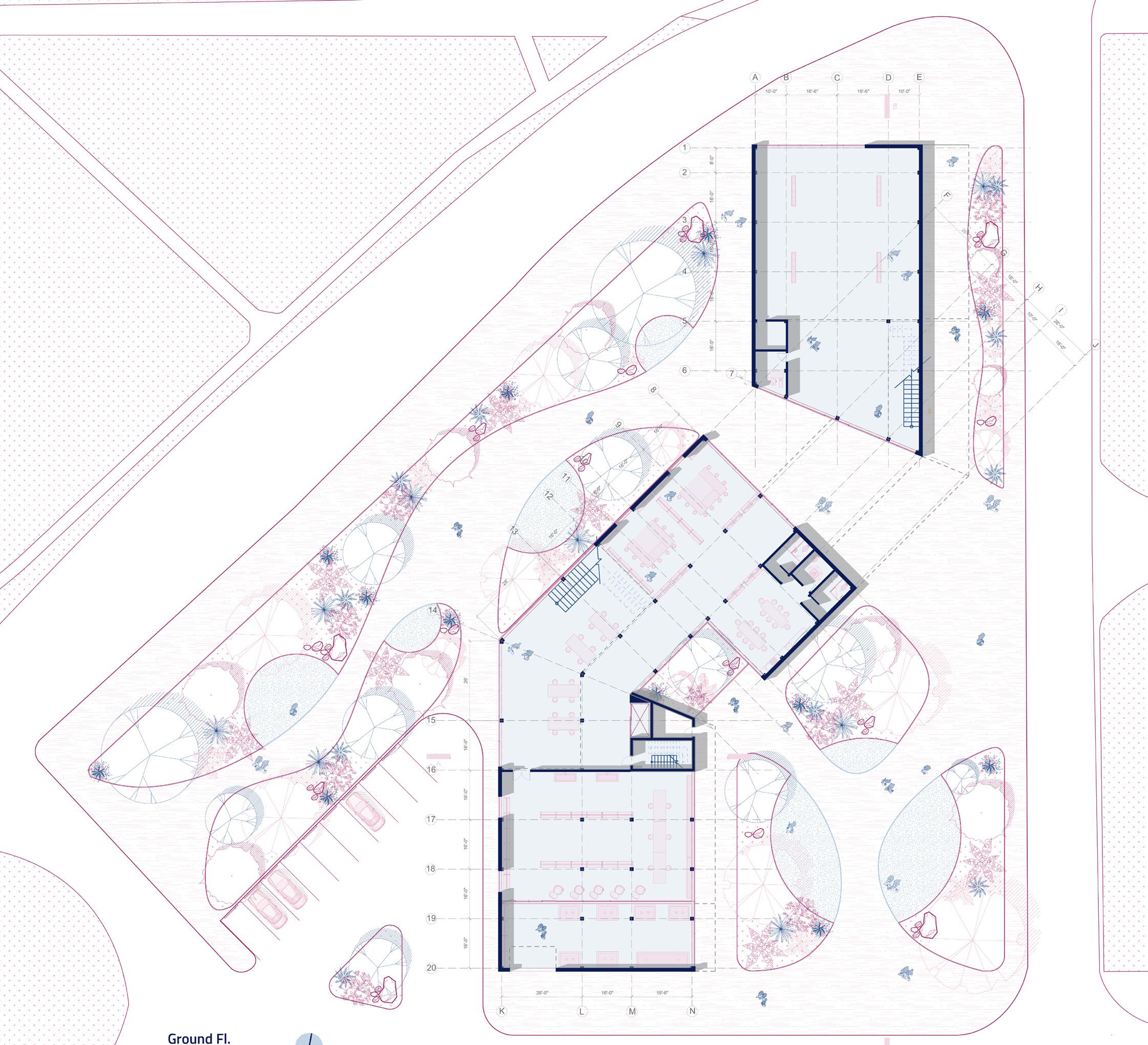

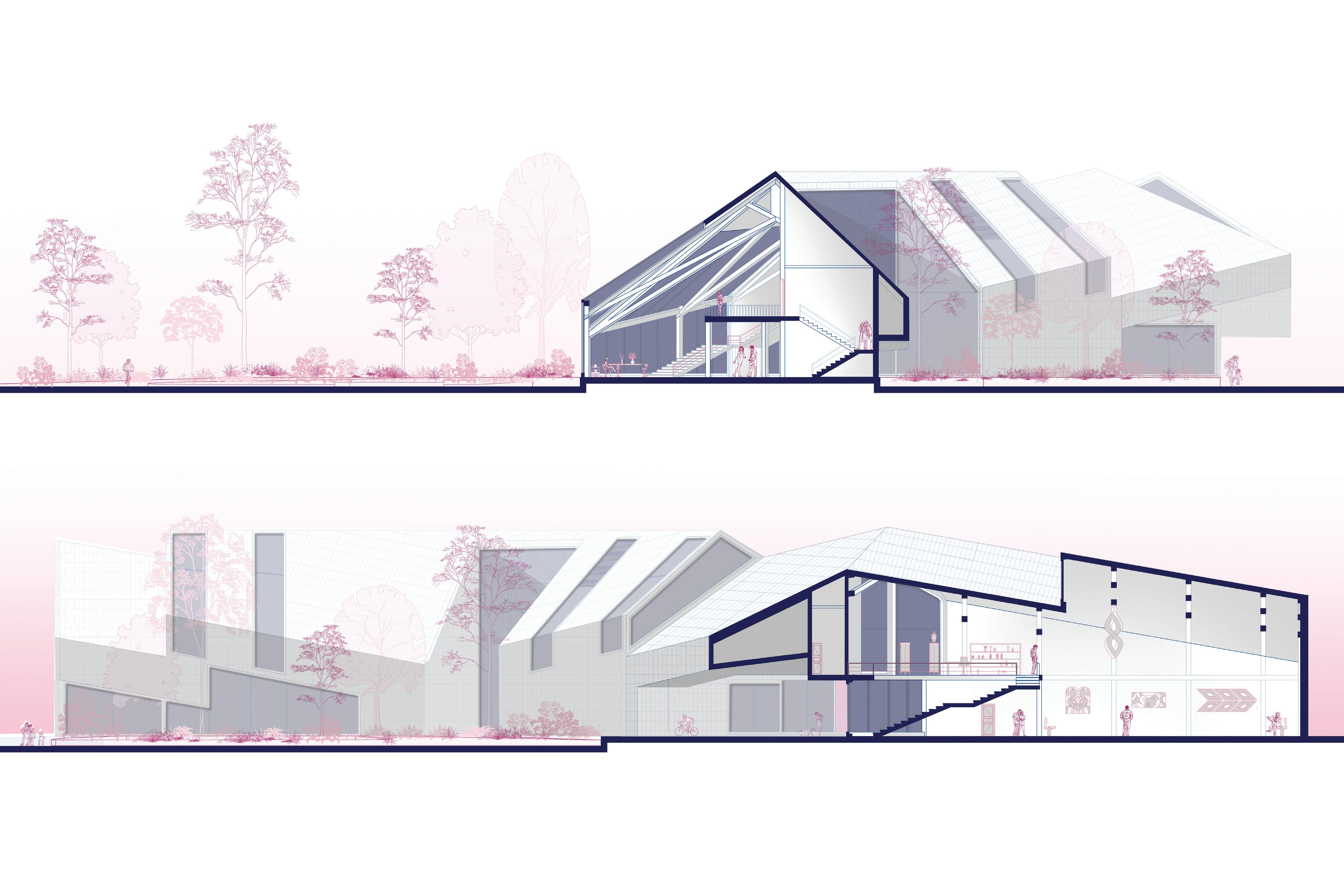

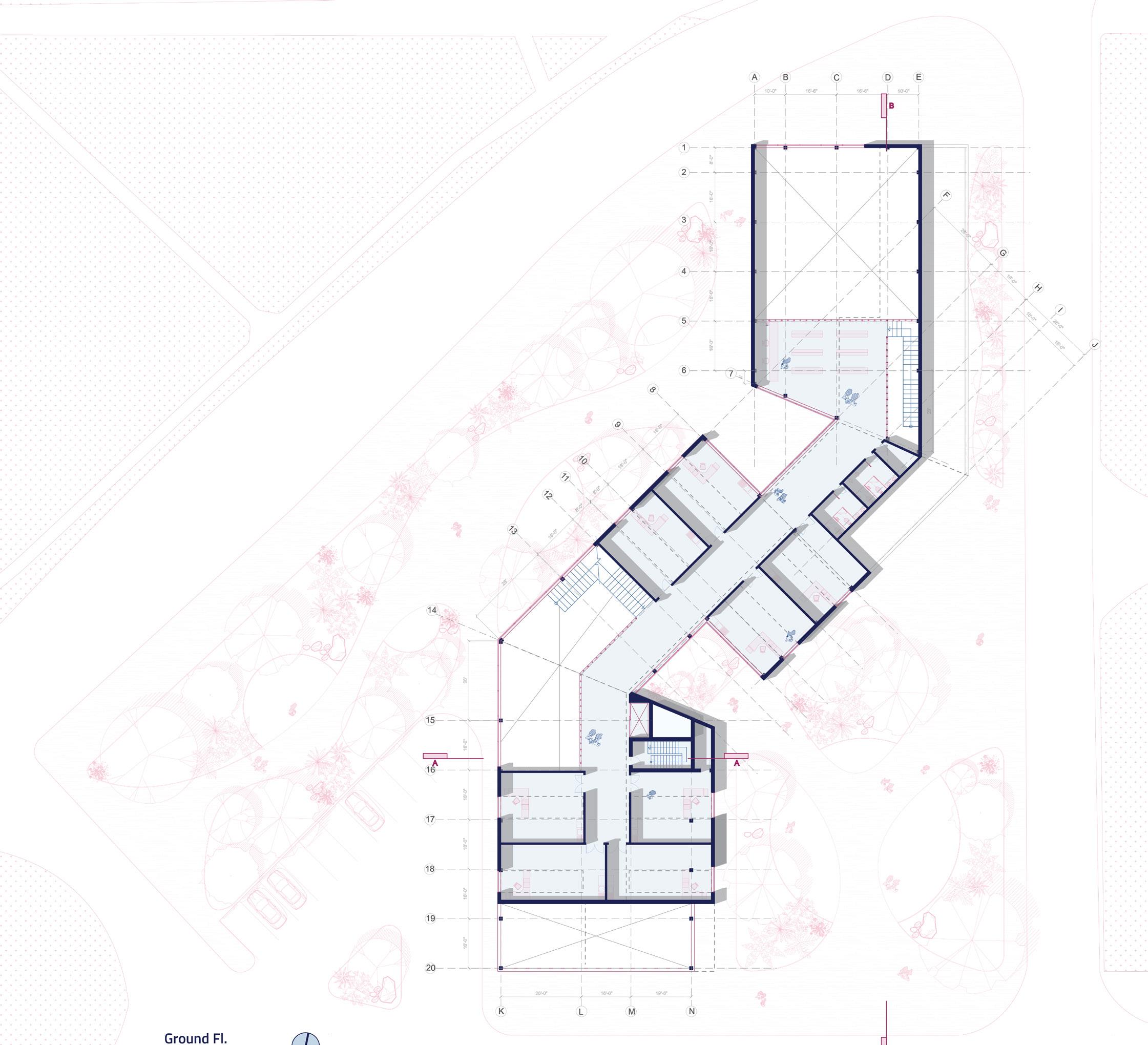

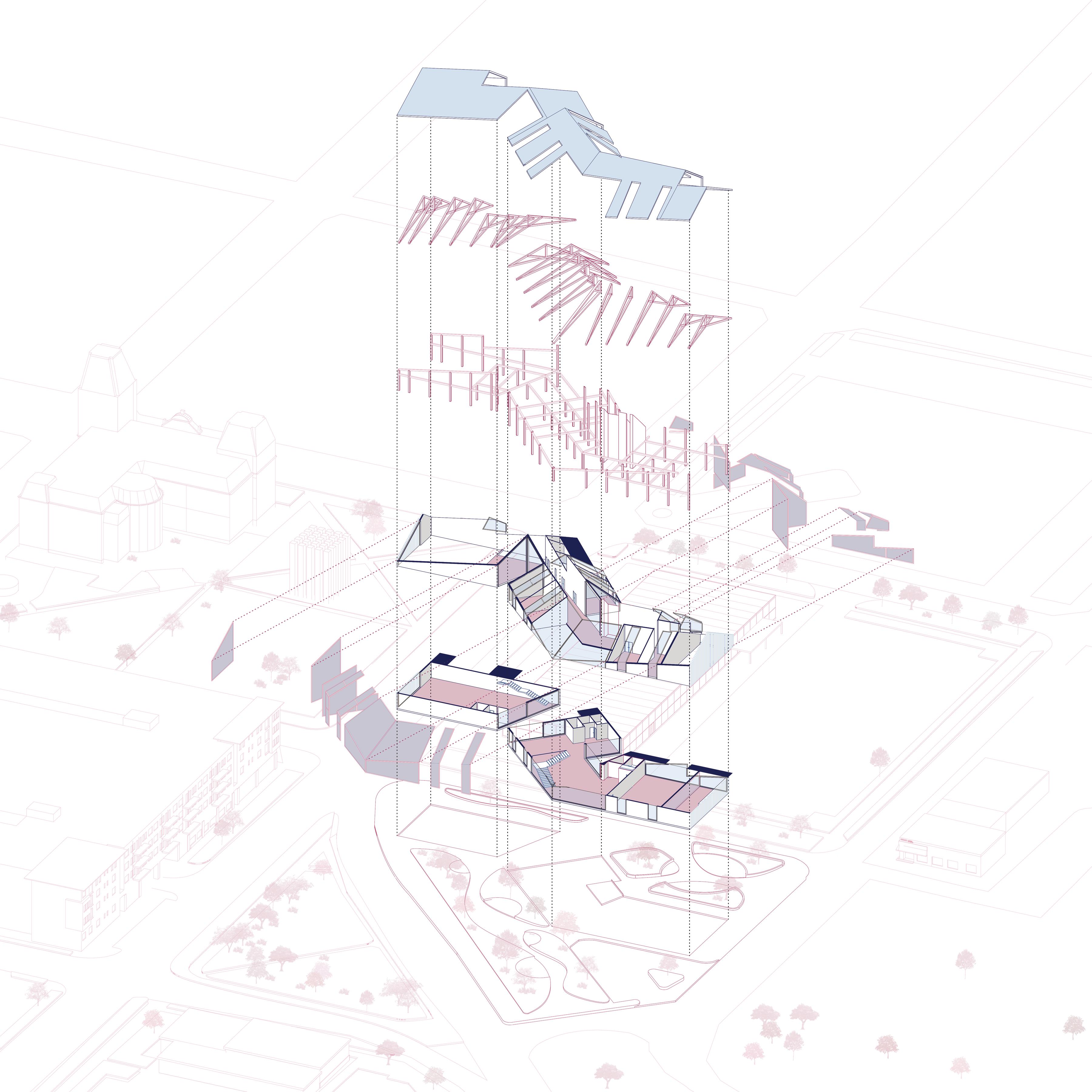

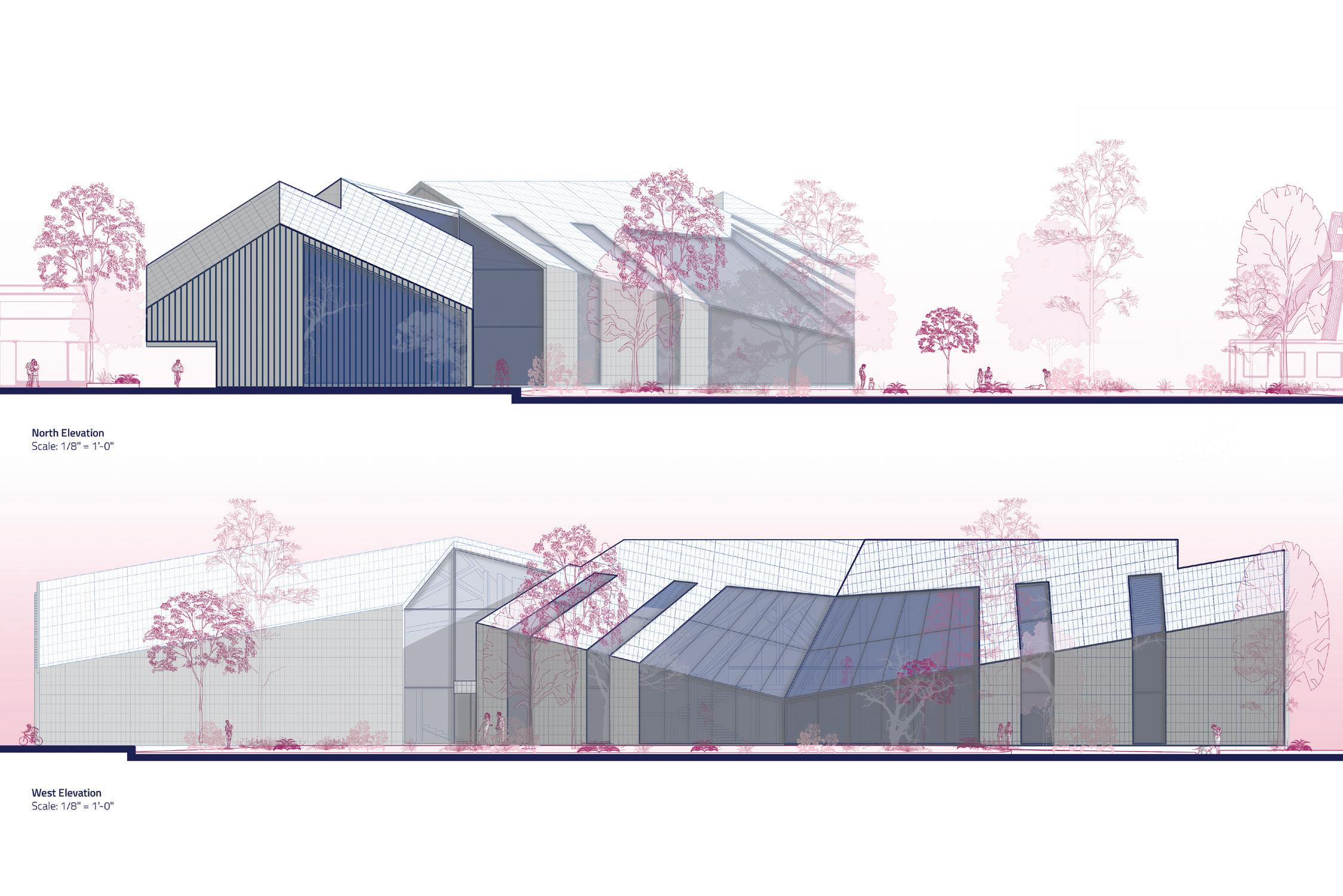

This project, located in Columbus, Indiana, thoughtfully integrates the music community with its surrounding environment through a design emphasizing transparency and smooth transitions. Set on a highly constrained site, the design navigates three distinct flood zones and complex egress requirements, demonstrating a careful consideration of site challenges.

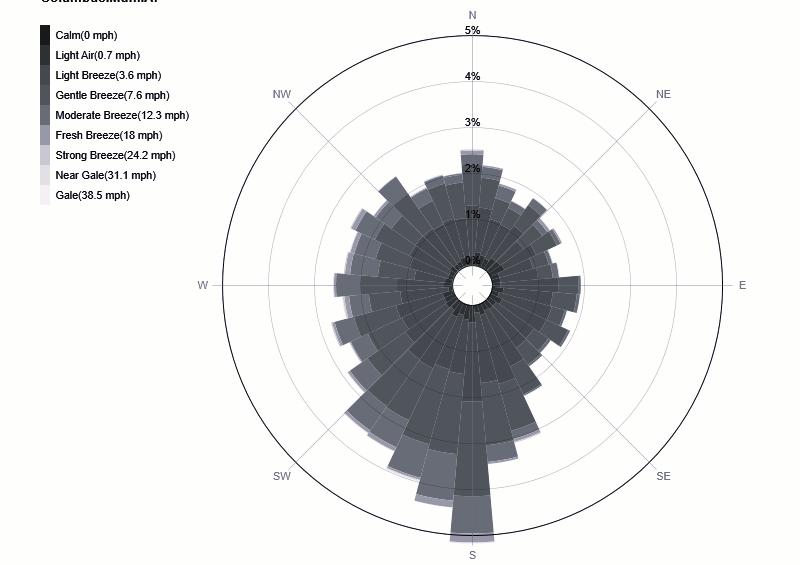

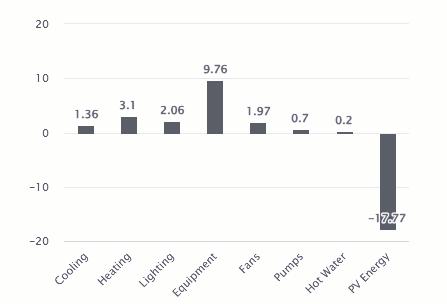

Inspired by repetition and rhythm, the structure fosters a balanced interaction between built spaces and the natural setting, enhancing the experience of music within Noblitt Park. Sustainability and environmental responsiveness are key priorities: the building incorporates shading devices, optimized solar insolation, and solar panels to reduce energy consumption and earn LEED credits.

Constructed primarily from heavy timber, the structure emphasizes material honesty and warmth, while landscaping efforts focus on utilizing local plant species to strengthen the connection between architecture and nature. Overall, the project seeks to harmonize community, music, and environment, creating a dynamic yet sensitive addition to the park.

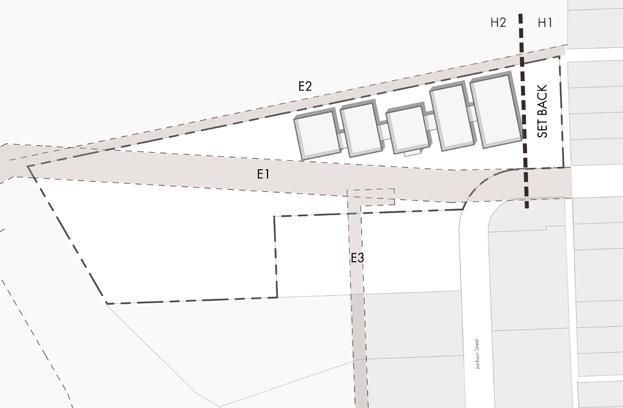

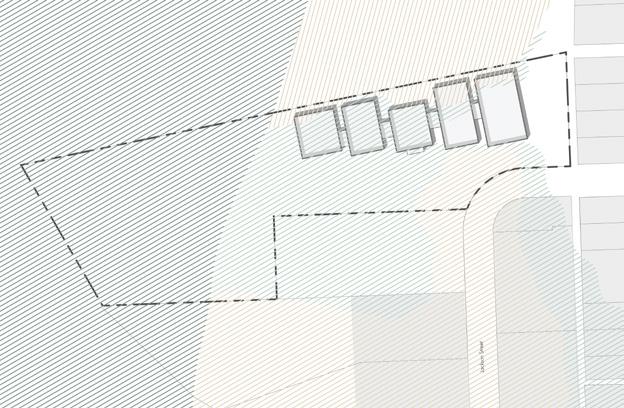

Easement and Setback

Setback= 60’ Height 2= 50’

Honey Locust Tree Ink berry Holly River Birch Boxwood

Switch Grass Liriope Black-eyed Susan Red Maple

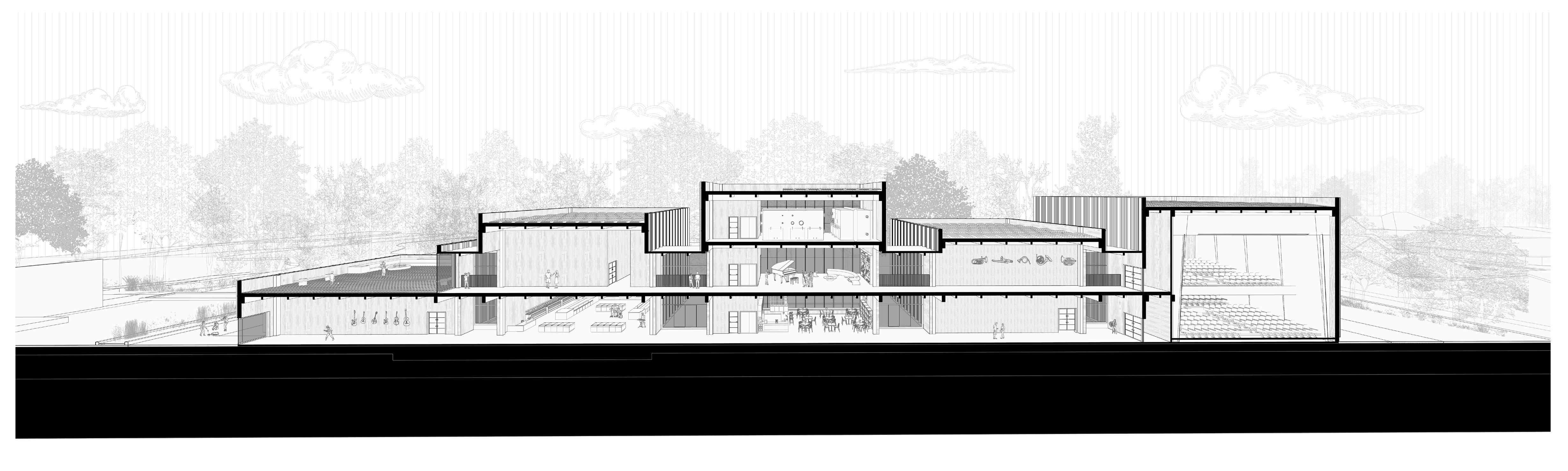

Section B-B

Extensive Green Roof

1. Lobby 2. Cafe’ 3. Music Playground 4. Library 5. Control room 6. Live Recording Room

7. Isolation and Production

8. Black Box

9. Storage.

10. Greenroom

Planels

11. Lounge

12. Classroom

13. Music Practice Room

14. Roof Garden

15. Office

16. Control Room

1. Wall To Roof Detail 1/A-502 3. Raised Floor System Detail 3/A-501

1. BEVELED PLATE

2. ROOF COPING

3. SPRAY POLYURETHANE FOAM

4.PLYWOOD SHEATHING

5. 4” POLYISOCYANURATE BLACK FLUID APPLIED

6. SCULPTFORM 25x100MM NORTHERN SPOTTED GUM

FINISH ALUMINIUM CLICK-ON SCREEN SYSTEM

7. SIMPSON HUC6 5/8-13 1/2 BEAM TO COLUMN

CONNECTOR

8. 6 3/4” x 13.5” GLUE LAMINATED BEAMS

9. 5 3/4” x 36” GLUE LAMINATED BEAM

10. CANT

11. FULLY ADHERED EPDM MEMBRANE

13. COVER BOARD

14. 2” POLYISOCYANURATE

15. 60 3PLY TL CLT PANELS

2. Wall To Floor Detail 2/A-501

1. NATURAL WOOD ACOUSTIC PANELS

2. GYPSUM BOARD

3. SPRAY POLYURETHANE FOAM

4. PLYWOOD SHEATHING

5. 4”POLYISOCYANURATE

6. FLUID APPLIED MOISTURE BARRIER

7. TYPE N MORTAR

8. SLATE STONE EXTERIOR FINISH

9. 4” EXTRUDED POLYSTYRENE

10. SLOPE GRADE AWAY FROM BUILDING 1.5%

11. #4 PLND REBAR @ 24” O.C.

12. DRAINAGE MAT

13. #8 GRAVEL BACKFILL

14. SIMPSON ABU121212Z POST BASE

15. MAPLE HARDWOOD FLOORING WITH BONA TRAFFIC HD FINISH

16. 4” CONCRETE SLAB

17. 6 MIL VAPOR BARRIER

18. 2” POLYISOCYANURATE

1. 3/4” MAPLE HARDWOOD FLOORING WITH A SATIN POLYURETHANE FINISH

2. STEP KIT PEDESTAL

3. 2x6 LUMBER

4. Sliding Window Head Detail 4/A-502

1. NATURAL WOOD ACOUSTIC PANELS

2. GYPSUM BOARD

3. SPRAY POLYURETHANE FOAM

4. PLYWOOD SHEATHING

5. 4” POLYISOCYANURATE

6. BLACK FLUID APPLIED MOISTURE BARRIER

7. SCULPTFORM 25x100MM NORTHERN SPOTTED GUM FINISH ALUMINIUM CLICK-ON SCREEN SYSTEM

8. BUTYL FLASHING TAPE

9. WESTERN WINDOW SERIES 7600 MULTI-SLIDE STACKING DOOR

10. SLATE STONE EXTERIOR FINISH

11. SLOPE GRADE AWAY FROM BUILDING 1.5%

12. 4” EXTRUDED POLYSTYRENE

13. #4 PLND REBAR @ 24” O.C.

14. DRAINAGE MAT

15. #8 GRAVEL BACKFILL

16. MAPLE HARDWOOD FLOORING WITH BONA TRAFFIC HD FINISH

17. SELF-LEVELING COMPOUND

18. 6 MIL VAPOR BARRIER

19. 4” CONCRETE SLAB

20. 6 MIL VAPOR BARRIER

21. 2” EXTRUDED POLYSTYRENE

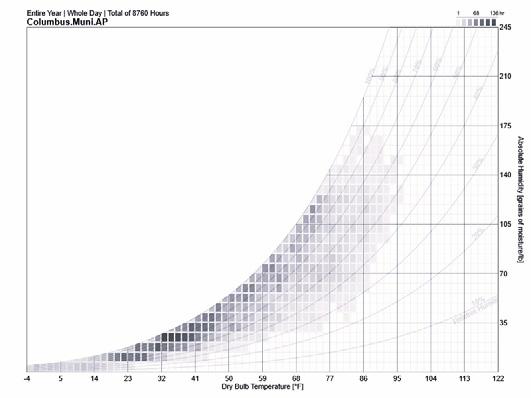

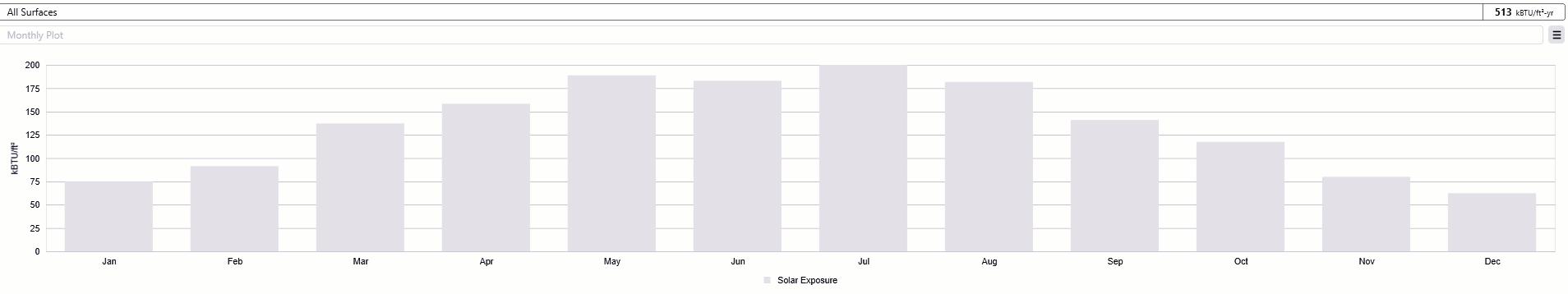

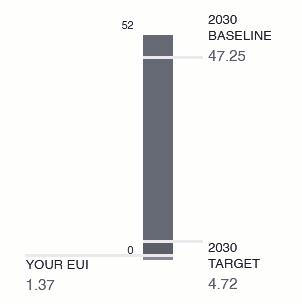

Site Energy Analysis

Based on the total annual solar radiation received in Columbus, the photovoltaic (PV) system, with a total panel area of 10,857 ft², is expected to generate approximately 282,073.2 kWh per year for this building.

Baseline Energy

In The Fold

Architecture Studio IV | May 2025

Category: Design-Build

Teammates: Ana Gaither, Zane Johnson, Erina Jahan, Carolina Zapata Bustamante, Ruviendel Isenia

Instructor: Lucas Allen Brown

Duration: One Semester

A place between places, built for everyone

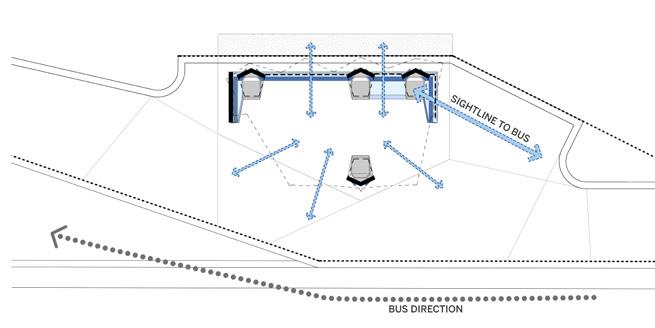

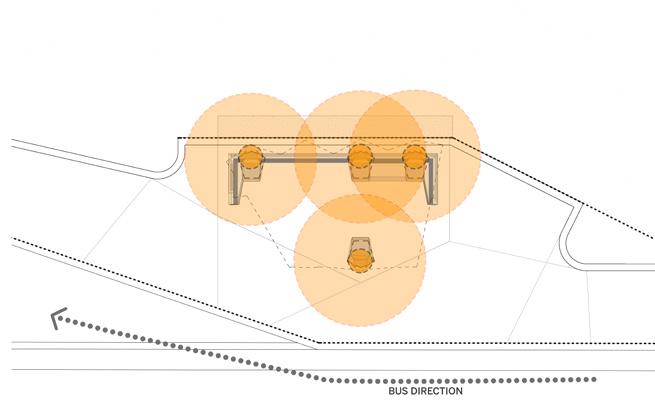

How might we create a bus stop experience that reflects and engages the community for the citizens of Bartholomew County?

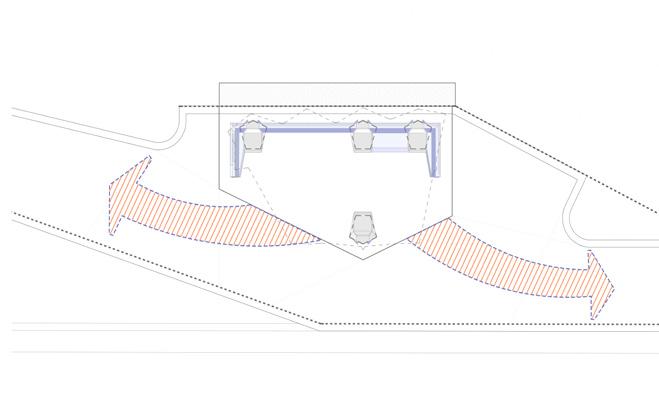

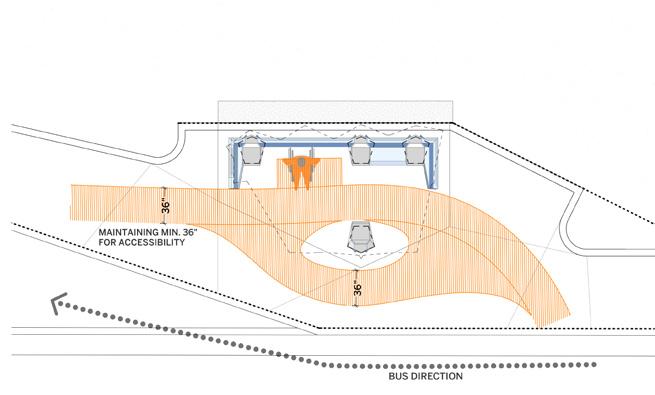

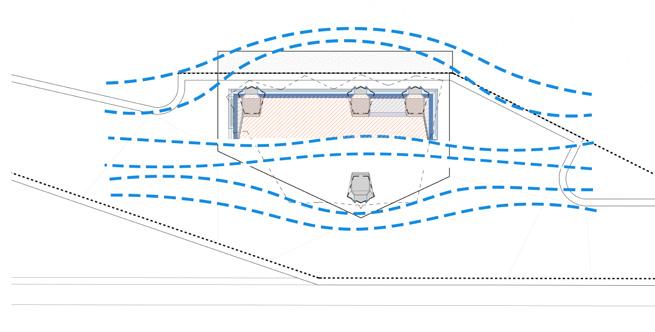

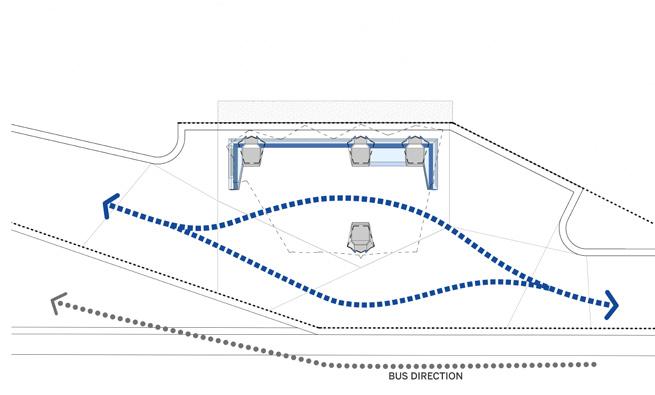

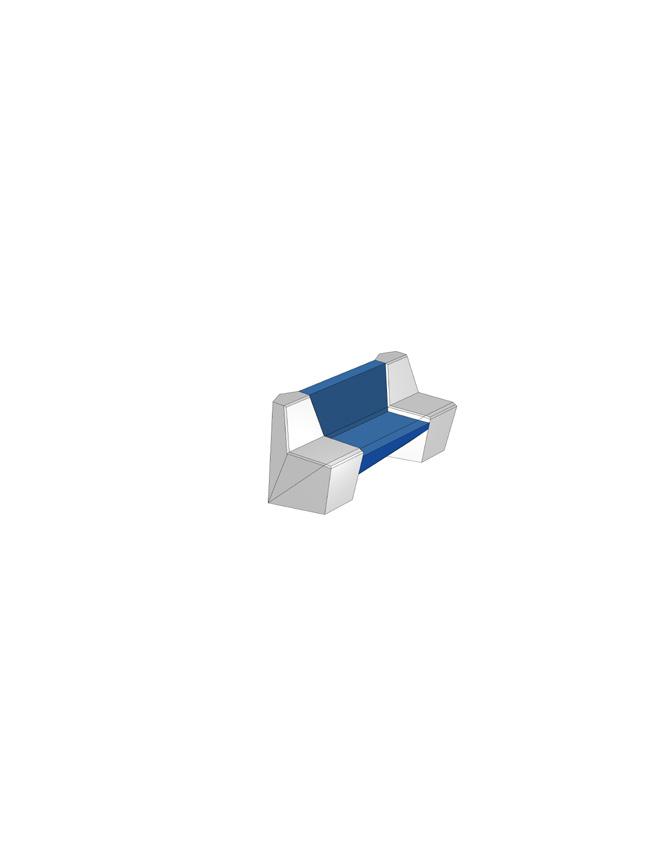

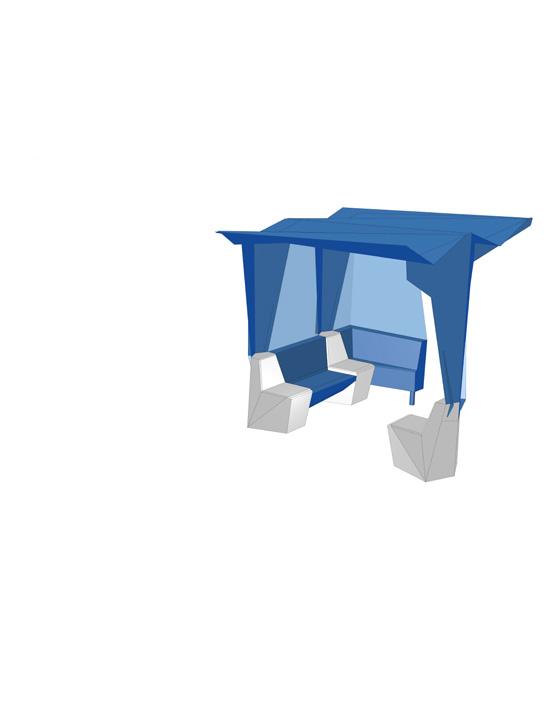

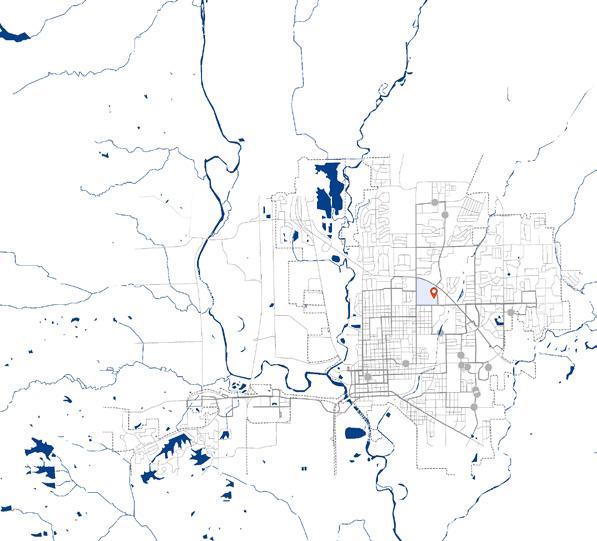

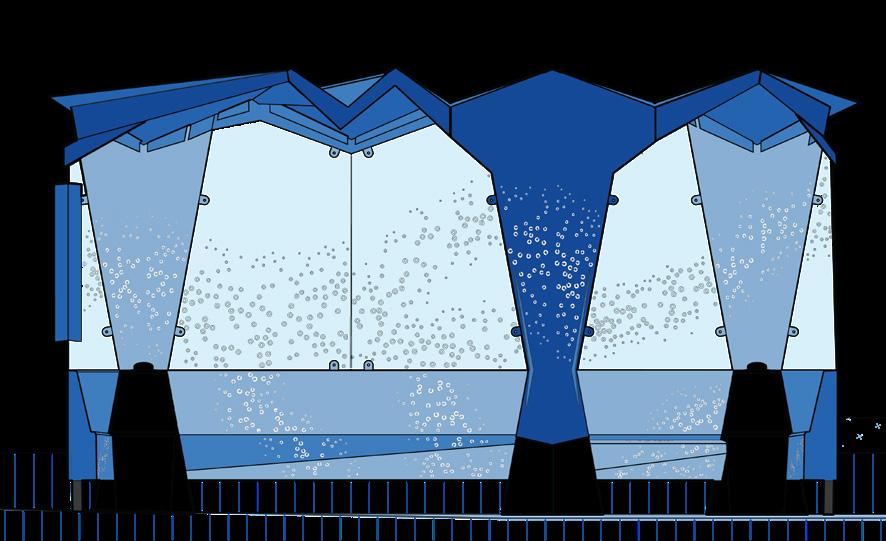

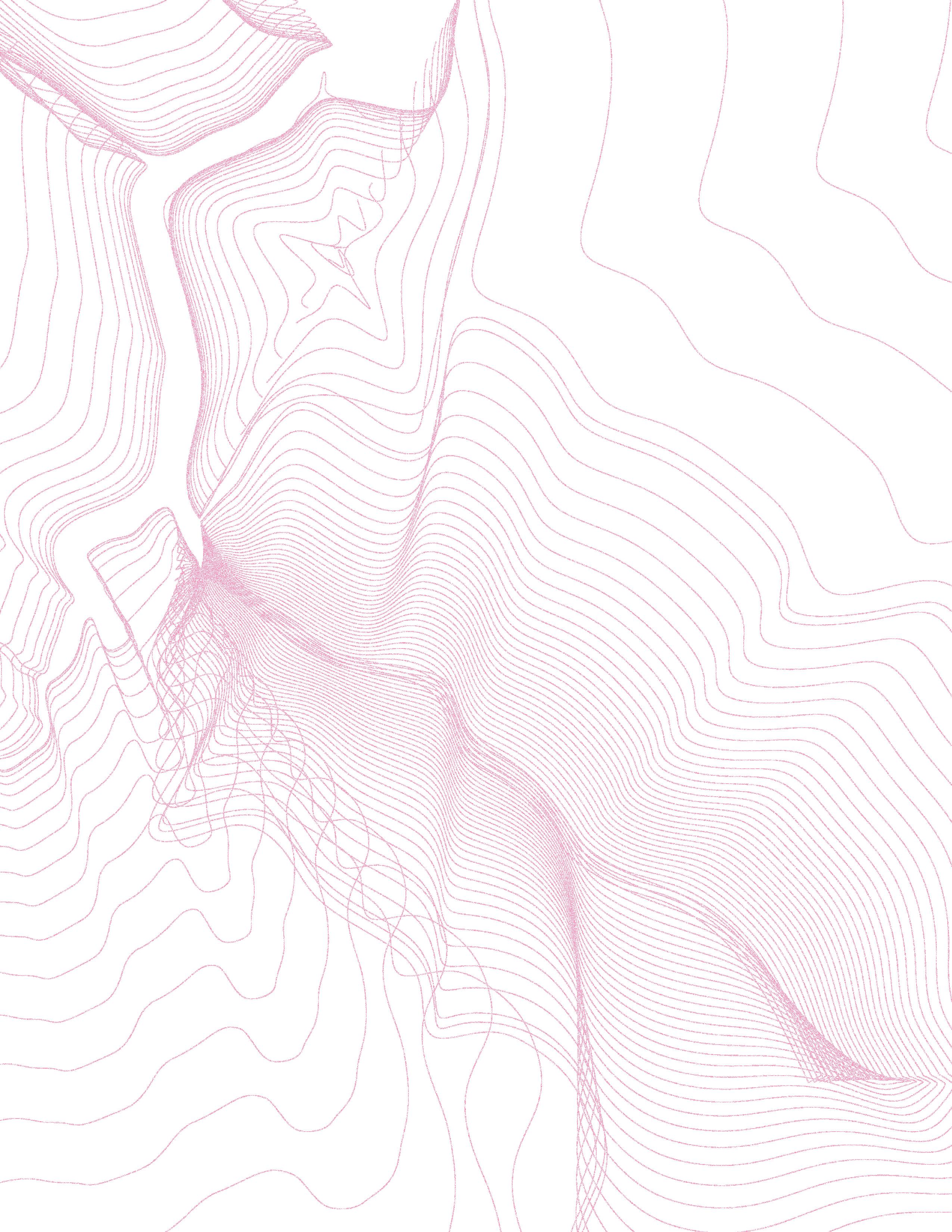

This bus shelter in Columbus, Indiana, folds sleek steel into a welcoming space for gathering. Modular concrete foundations anchor the structure, while connecting steel benches offer places to lean, rest, and gather - with seating designed for all. Two end caps embrace the shelter, providing protection while maintaining openness and visibility. Perforated steel and fritted glass panels echo the flow of Columbus’s river map, quietly rooting the shelter in its landscape and community. This is a space designed not just to serve, but to embrace and unite.

Gradual Slope To Merge With Pedestrian

Accessibility

HERMAN DARLAGE DR

Inspired by the rivers winding through Columbus, the shelter’s perforations echo their fluid paths. Dancing Cs drift within the current, flowing gracefully through the pattern and wrapping the structure like water embracing land.

This folded plate prototype creates a modular system adaptable to various Columbus, Indiana sites, unifying transit shelters with a consistent, flexible design language.

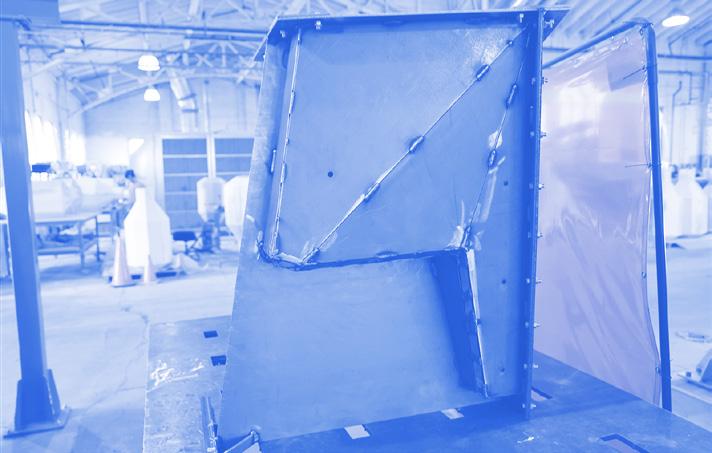

Foundation fabrication: bench mold, welding, & pour

The fabrication of the steel mold for the concrete foundations followed a careful and precise process. We began by 3d modeling the mold, working through the logistics of drafting and ensuring the assembly could be accurately welded together. Once complete, the mold was transported to Precast Solutions, where it was prepared for the concrete pour that would anchor the shelter.

Site Coordination And Installation

Site coordination and communication were critical to the successful installation of the shelter. Staying in close contact with contractors ensured that the most up-to-date drawings were in use and that construction documents were clearly understood. A small error in dimension could have thrown off placement of every bolt and rivet during assembly, so clarity and precision were vital to the process.

Steel Fabrication: Sanding, Bench Press, & Painting

For the steel elements - benches, columns, and roof - fabrication involved a sequence of sanding, press braking components to match shop drawings, and finishing each piece with paint before installation.

We remained deeply involved during installation, observing the transport, scheduling, and on-site coordination that brought the shelter to life. From setting anchor bolts to fastening rivets, each

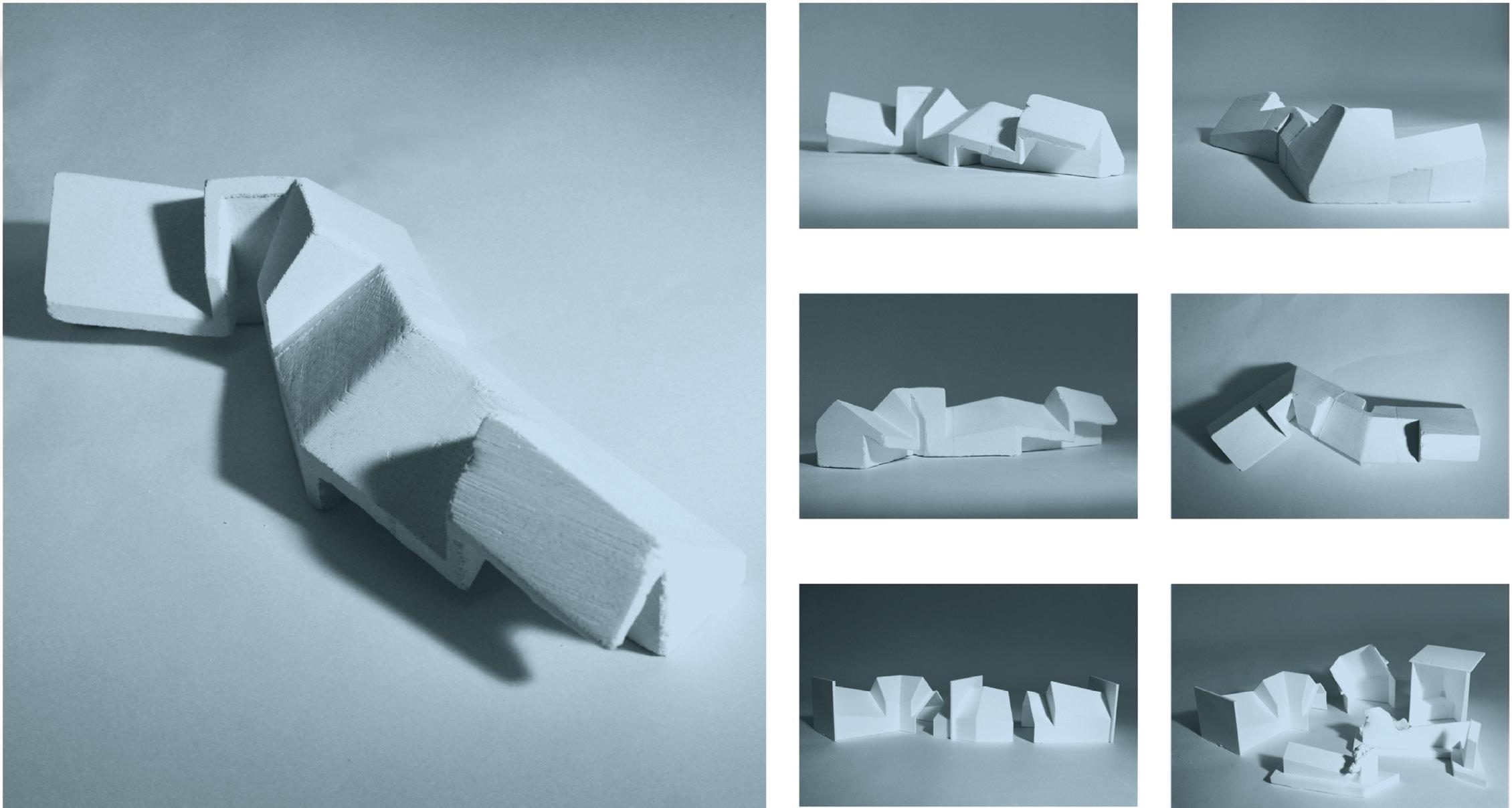

Architecture Studio II|May 2024

Category: Ceramic Community Center

Instructor: Daniel Luis Martinez

Duration: One Semester

Carving whispers the dialogue of light, space, and nature

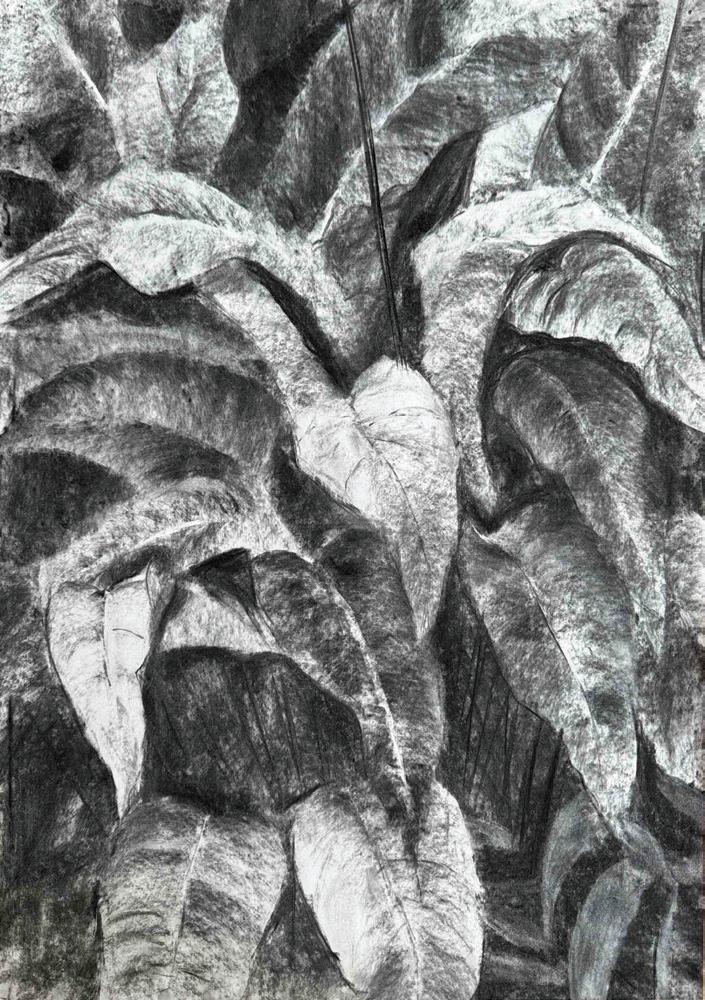

The preliminary design phase of this project focused on developing skills in casting architectural forms with concrete through an integrated digital and analog workflow. Utilizing Rhino 3D, initial geometries were modeled and subsequently 3D-printed as negative molds for casting. As the design process evolved, formal explorations increased in complexity, with each iteration refining spatial and structural qualities. In addition to studying conventional roof typologies, I focused on engraving and carving the form to enhance material expression and surface articulation.

Moreover, we studied clay and plaster casting techniques, incorporating kiln firing and experimenting with color applications to develop glazed ceramic for facade treatments. Investigating how surface texture and glazing could contribute to architectural expression.

With the site and program being introduced, the architectural design project aimed to blend the building with its landscape surroundings, creating a harmonious connection between nature and the community and use carving as a method to reach that goal. By Carving out the building, the form defines public and private areas, the design not only tries to make the spaces practical but also encourages interaction between indoor and outdoor spaces. This approach aims to create an inviting environment that welcomes community engagement and enhances overall functionality.

Concrete Model and 3D printed Mold

Glazed Tile Studies

Farmers Market

City Down Town

City Main Entrance

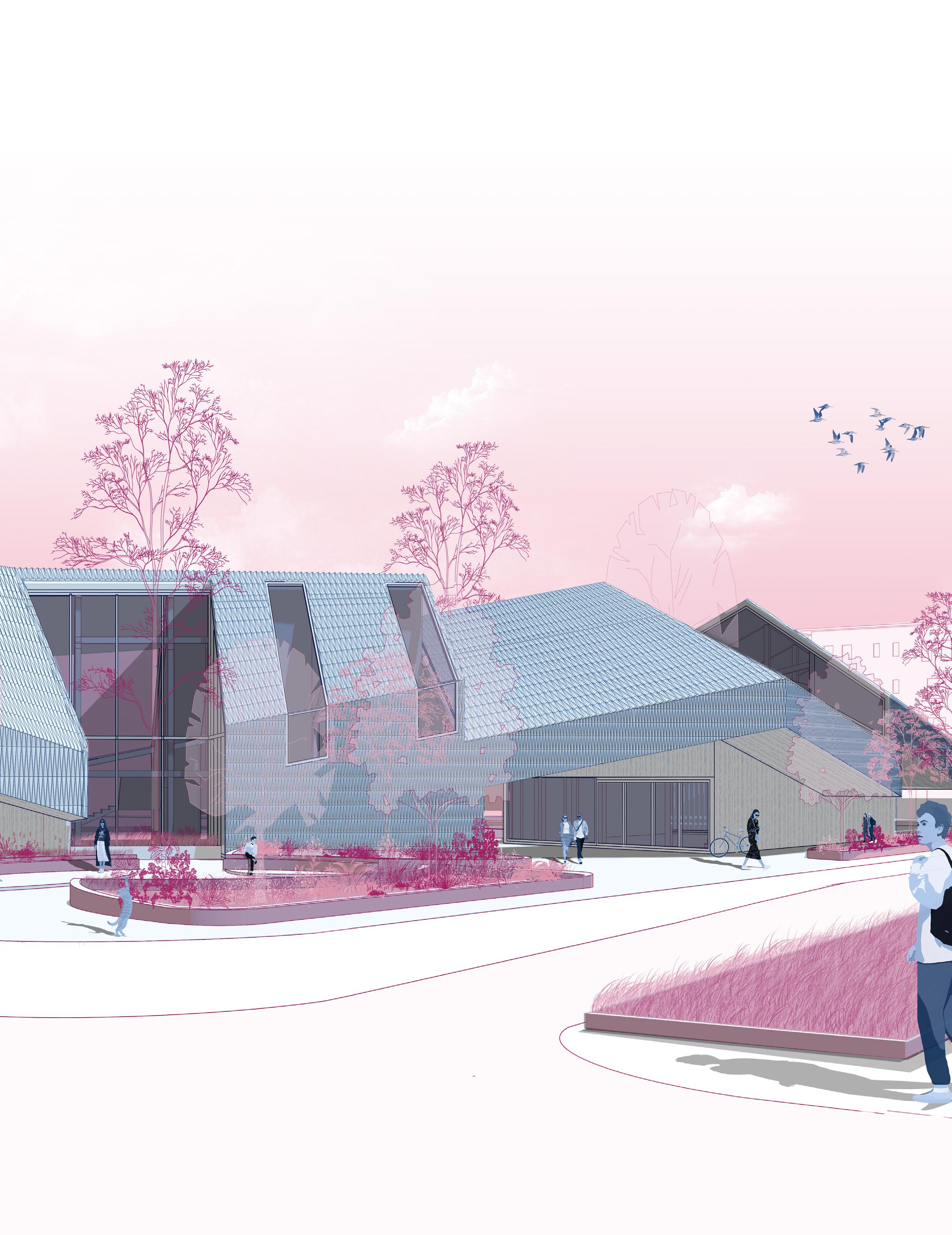

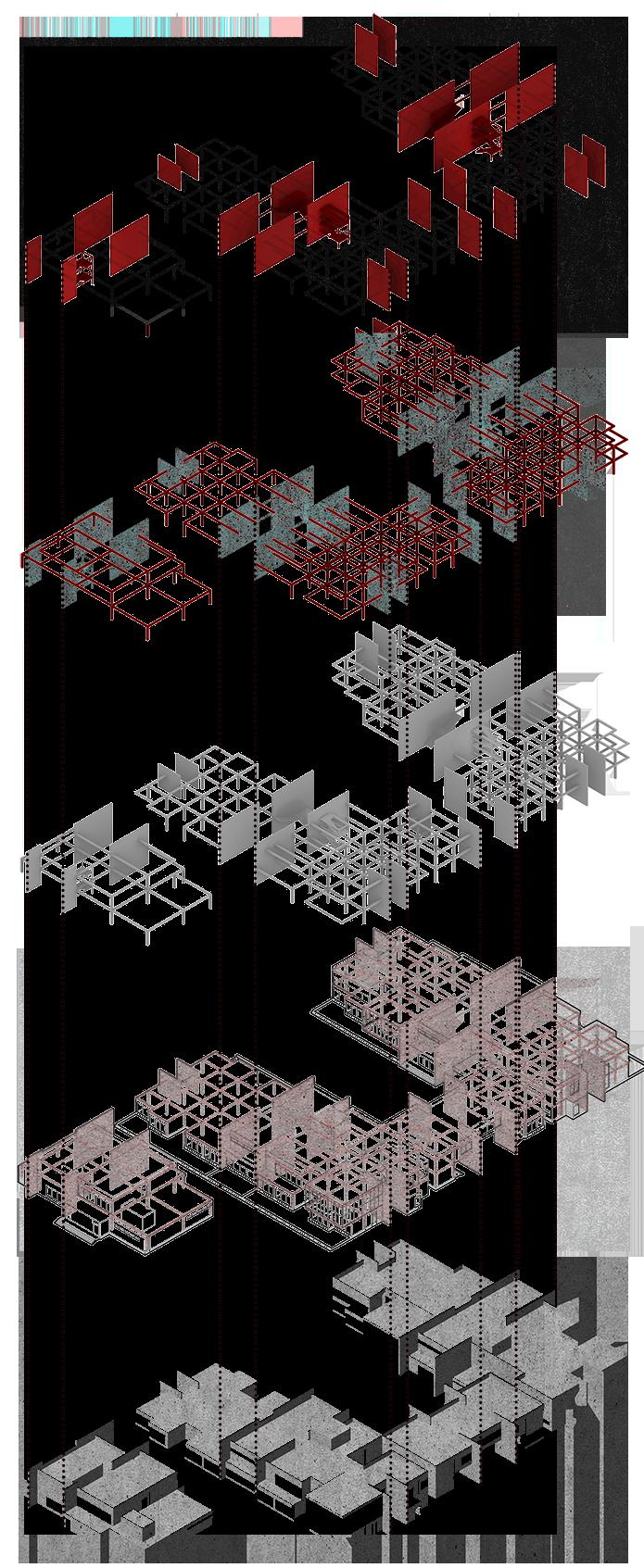

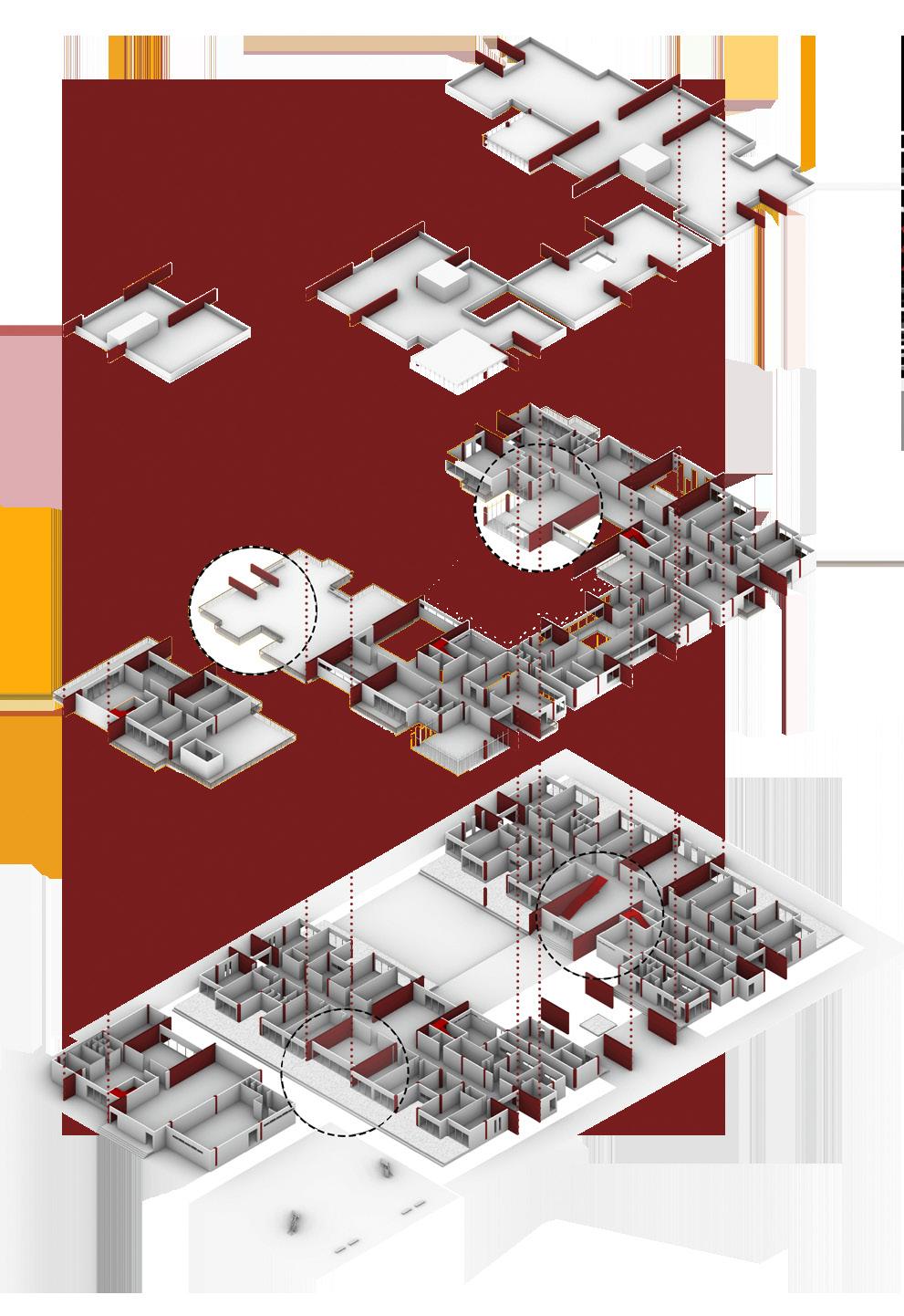

04 Autism Thrive Academy

Final Design Thesis| January 2021

Category: Educational and Rehabilitation Center

Instructor: Shirin Azhdehfar

Duration: One Semester

what goes around comes back around

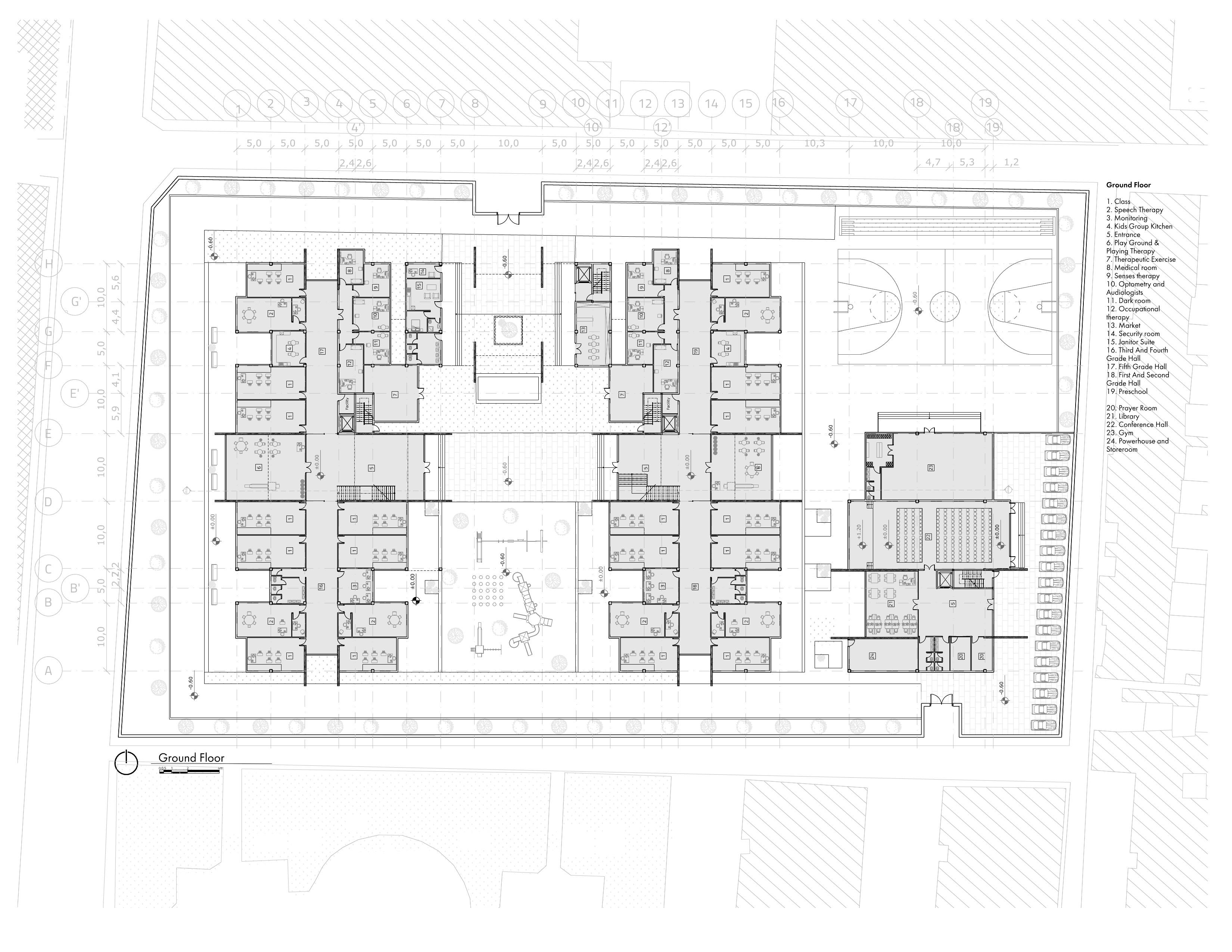

In the last century, the knowledge of autism and its treatment methods have developed and efforts have been made to provide a better educational condition for these children, although in Iran it is not going at the same pace. After research in this field, it was found out that one of the best ways to educate and treat children with autism is to provide them with a dedicated learning environment so that they can benefit from up-to-date methods in small groups for more focus on individual students. The main purpose of designing this school is to create a suitable space for autistic children that follows the principles of a suitable environment for their comfort and greater productivity according to the research result.

Due to the lack of specialized personnel in the field of treatment and education of autistic children, a portion of the complex was dedicated to specialized training for teachers. The educational section was also divided into two groups to maximize the focus of care and education, creating an environment more suitable for each age group. The well-being of the children remained the main focus throughout the design, with features such as a greenhouse for interaction with nature, seamless indoor–outdoor classroom spaces, abundant natural light, and thoughtfully designed group hubs to foster comfort, engagement, and social connection.

Site Location

In Tehran, schools for autistic children often have limited accessibility in deprived areas. Therefore, after careful research, the site for the new school was selected in one of the southern districts of the city, providing both convenient access and the necessary facilities.

Structure and Facade

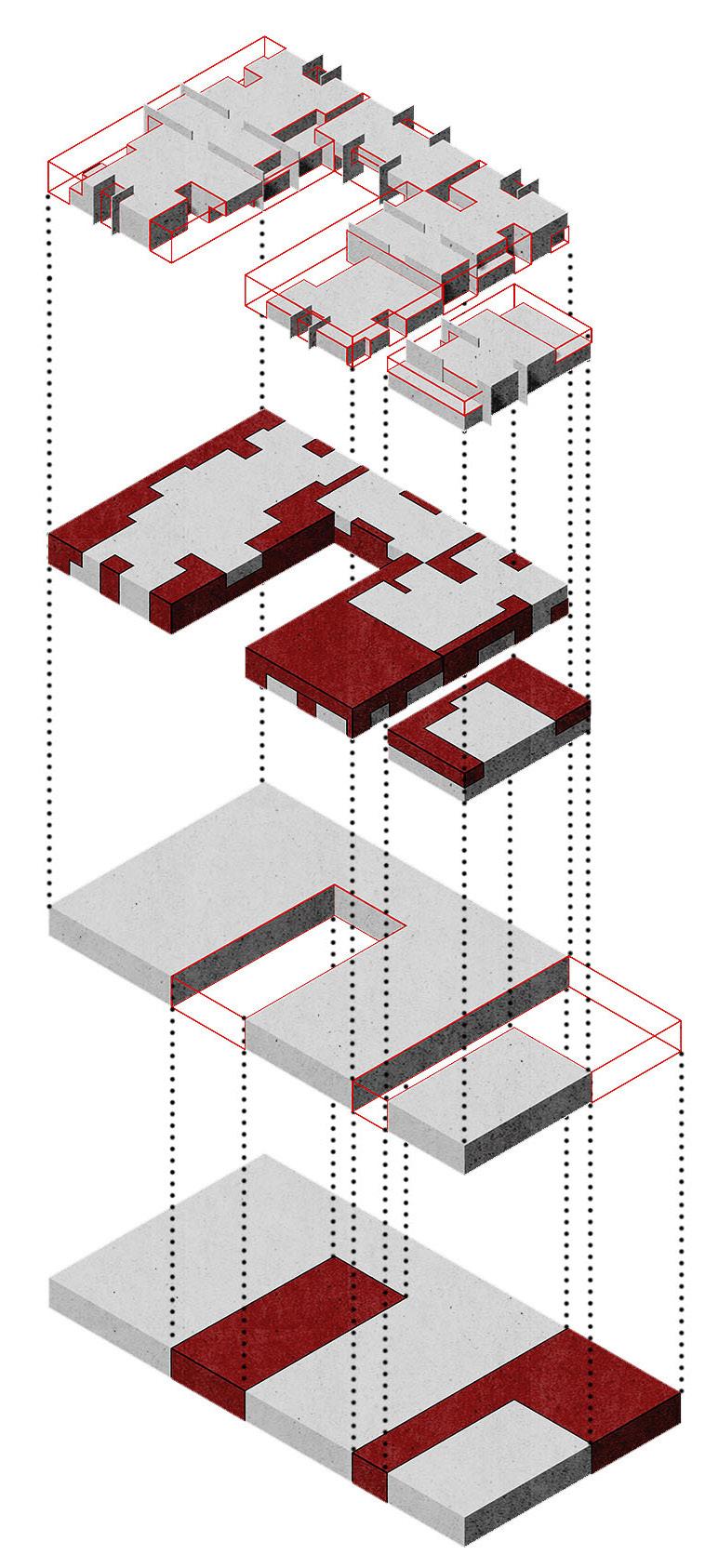

Form Finding Process

4. Eventually, an effort was made to make each part of the building recognizable to children from the exterior view, which can be significantly helpful for the kids.

3. Reduction in each section was done to create terraces and more lighting.

2. Each age groups building, as well as the teachers' department, would have its individual yard.

1. The initial stain was excavated to create yards that are sunny all year round and volumes that can be divided functionally.

1. Use of shear wall for larger openings.

2. Beams and columns connection.

3. Connecting escape and decorative stairs to the structure.

4. The utilization of shear walls in the facade of the building inspired by the works of Tadao Ando.

5. Consuming white concrete and not using too many colors that make autistic children distracted.

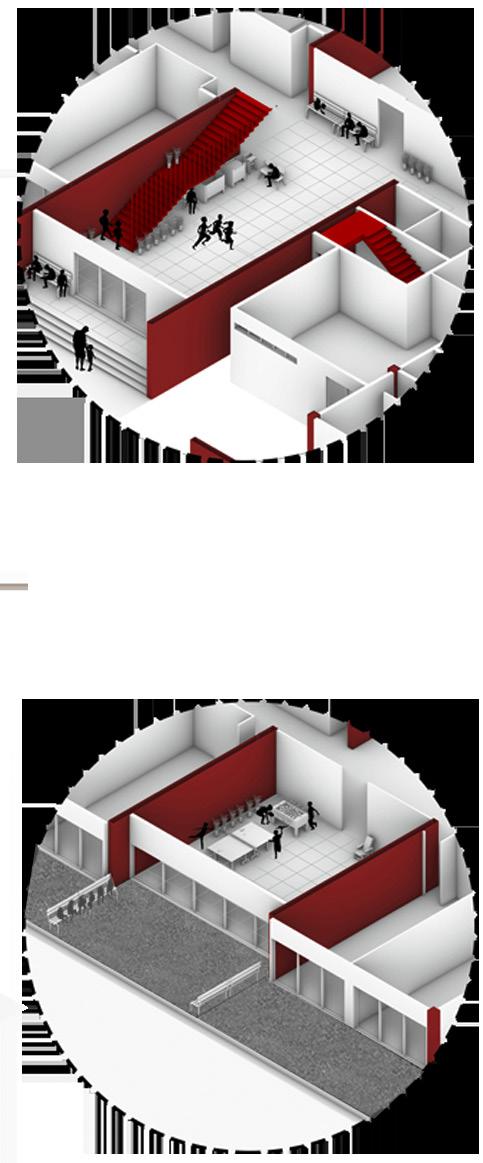

Greenhouses placed in each building regarding their efficiency for kids' treatment.

Each class has its own yard, along with indoor playrooms in each building.

Playground Roof

School Entrance

05 Metal Batwing

Practice| December 2019

Category: Computational Design and Fabrication

Teammates: Alireza Alikaei, Mahshid Amani, Sina Rezaeifar, Samar Yazdanfar

Position: Responsible for all tasks

Duration: Two Months

Dance of math and architecture

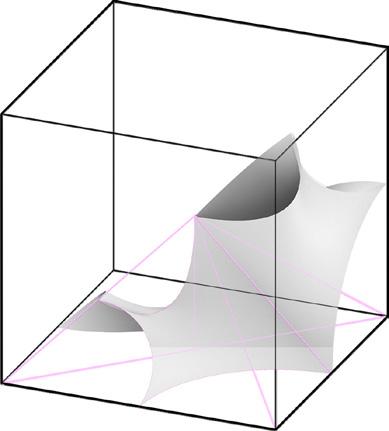

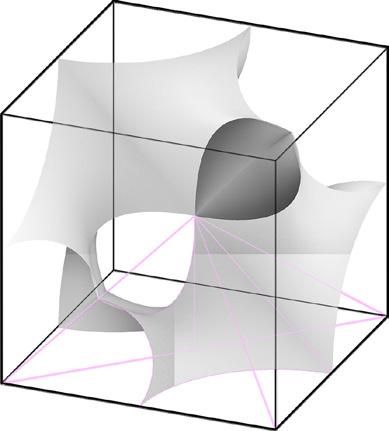

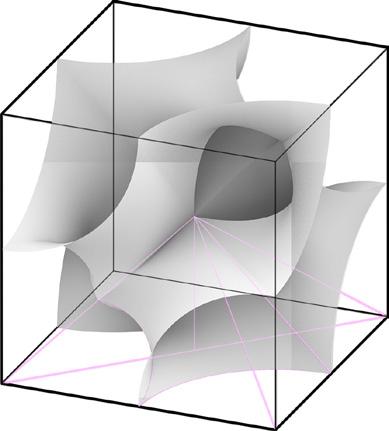

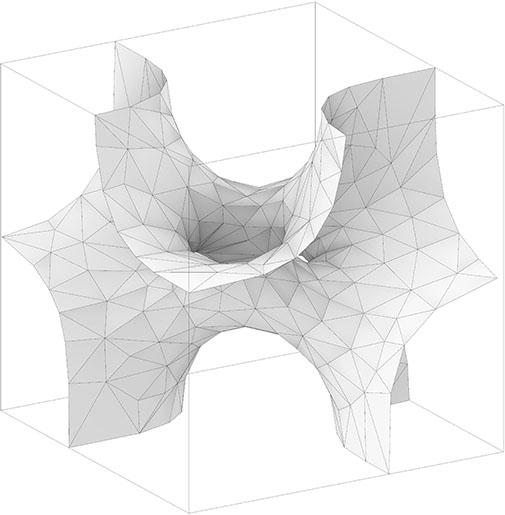

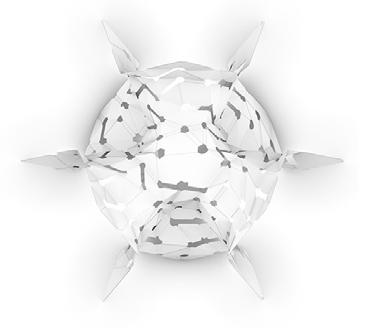

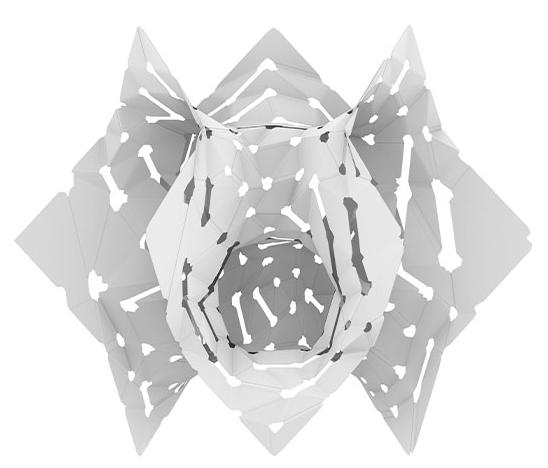

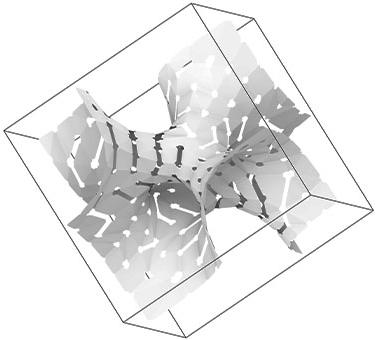

The project centers on the design and fabrication of a Batwing Minimal Surface, a triply periodic minimal surface discovered by Alan Chosen, known for its elegant geometry and zero mean curvature. The surface was mathematically defined and trigonometric approximations were used to generate its complex threedimensional form. After extracting the two-dimensional components from the digital shell, metal was selected as the primary material for its strength, precision, and suitability for laser cutting. The fabrication process began with detailed 2D plans prepared for metal laser cutting, followed by the application of a Bridge-Building technique at the joint points, developed in collaboration with a mechanical engineer to ensure structural stability. The components were then assembled through argon welding, resulting in a construction of striking accuracy. This precision was especially impressive considering it was the team’s first experiment with metal fabrication and laser-cutting technology, producing a refined and technically sophisticated architectural prototype.

In mathematics, a minimal surface is a surface that locally minimizes its area. This is equivalent to having a mean curvature of zero. Minimal surfaces can be defined in several equivalent ways in R3. The design of this project is basically a Batwing Minimal surface. The Batwing is a type of triply periodic minimal surface that was discovered by Alan Chosen. It can be trigonometrical approximated by a short equation:

Cos(x) sin(y) + cos(y) sin(z) + cos(z) sin(x) = 0

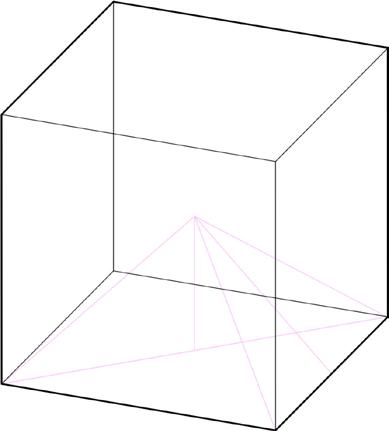

Form-Finding by Grasshopper & Kangaroo

First, a mesh plate with the logic of batwing minimal surface was modeled in the form of a sharp corner. Then, supportive lines and effective points were extracted from the initial mesh, and after that by the kangaroo plug-in and the extracted data, the tensile shell was created. In the end, the surface was manipulated to conform to the fabrication.

Evolution of a Schoen Batwing Minimal surface

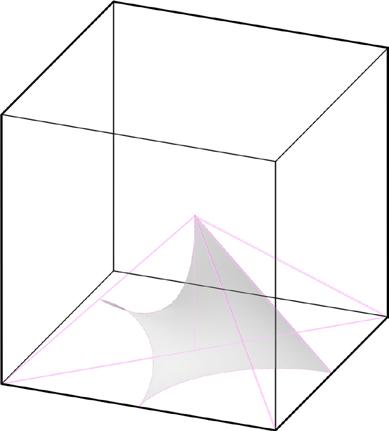

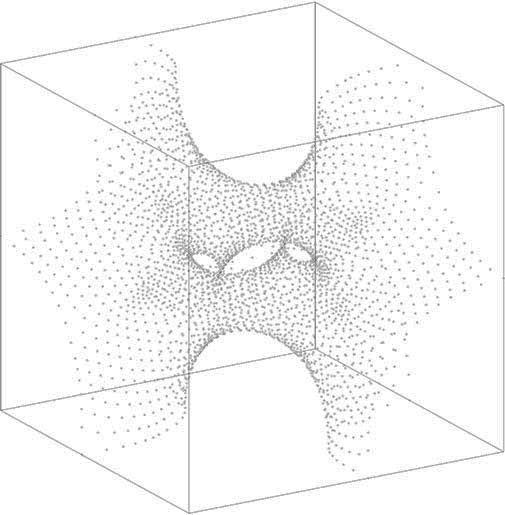

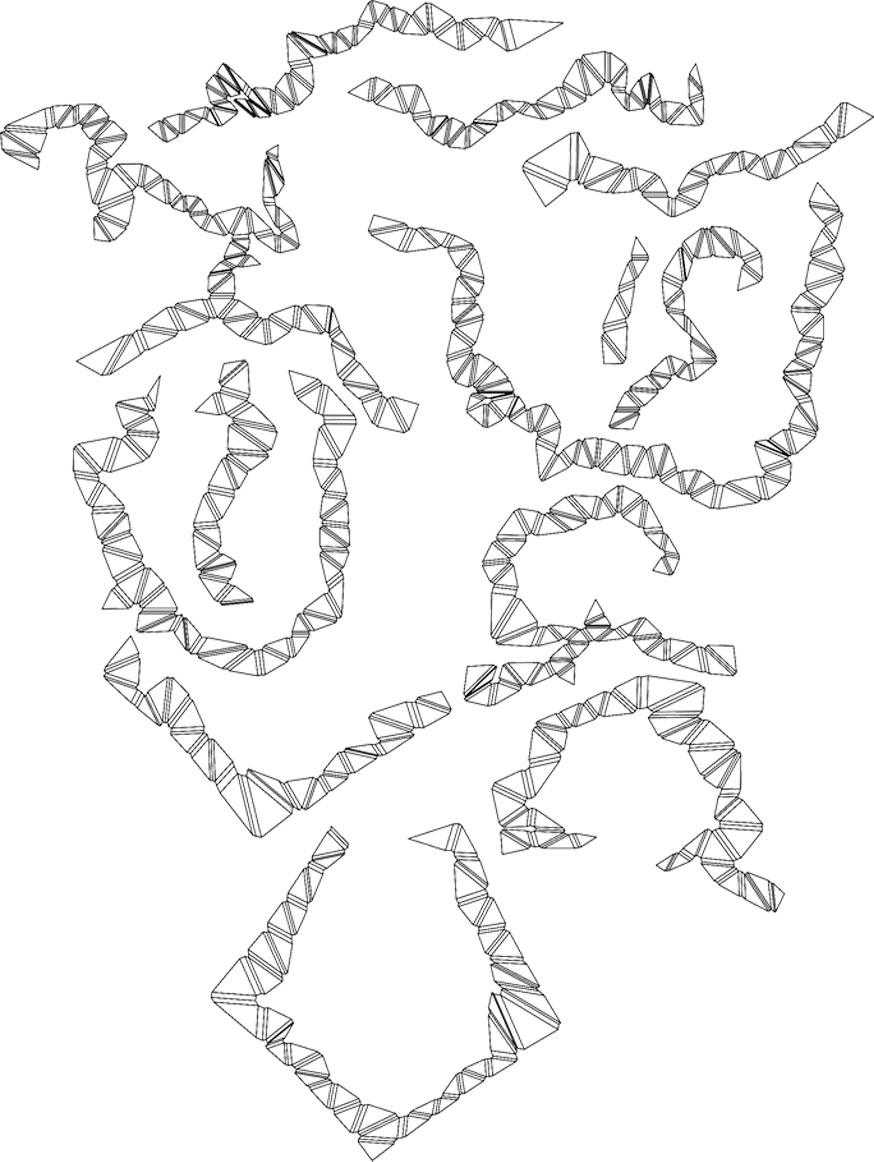

Subdivision by Ivy

At this stage, the shell was subdivided by the utilization of the Ivy, a Grasshopper plug-in, and the developed algorithm. These created pieces were required to be fabricated by the use of the folding method with bendable and shatterproof material.

Subdivision Step 2

Subdivision Step 1

After extraction of the two-dimensional pieces from the shell, it was decided to utilize iron material for making the segments.

Firstly, 2D plans were presented for using iron laser cut. Secondly, a method called Bridge-Building was utilized in the joint points. (This was done after a consultation with a mechanical engineer). In the final step with the use of argon welding, the point was assembled.

Final

Result

After the assemblage, it was observed that the work was done with surprisingly high accuracy, the word surprise is used because this project was our first practice (experiment) of working with iron metal and laser-cut, which were strikingly precise.

CNC Segments

Folding Joint Details