- ALBERT KAHN FORD FACTORY

ALBERT KAHN

Albert Kahn (born 21 March, 1869) in Prussia (current day Germany) was an from a family of immigrants who moved to Detroit.

Known as the ‘Architect of Detroit’ he was one of the most prolific architects in US history. With over 60 buildings listed on the National Register of Historic Places, he worked with various Typologies and Styles.

In his early years he worked with a Detroit firm Mason and Rice. In 1895, Kahn opened his firm, “Albert Kahn & Associates”. He worked on Office Buildings, Factories, Homes for the wealthy Detroit businessmen and a chruch.

Kahn’s factories for Ford and Packard Motors helped to establish the industrial aesthetic of Detroit (it stood in contrast to the Bauhaus movement in Germany).

He fully integrated the work of specialists in architecture and engineering, utilized a team approach to design, and rationalized office operations.

Albert Kahn was an innovator and inventor. With the rise of factory architecture and the rapid rate of growth in the industrial sector, research for new solutions for production space was required.

The traditional factory plans “proved inadequate in providing the flexibility and safety needed for the new management of labor”

(Albert Kahn: Architect of Ford (1993)

Although his work revolutionized industrial architecture, historians of American industry and technology have not adequately recognized his contributions.

In contrast to more renowned architects like Frank Lloyd Wright, Kahn did not establish a design studio and produce scores of young disciples to spread his design gospel.

DOMORE WITHLESS

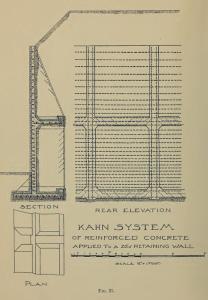

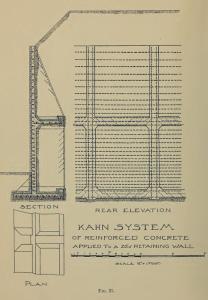

Sketch showing the Kahn System of Reinforced concrete.

This method of construction was developed by Albert Kahn and Julius Kahn ( brother and a structural engineer).

Sketch showing the Kahn System of Trussed Concrete Steel.

The trussed bar was characterized by a horizontal main bar with flanges, combined with rigidly-connected shear members set at a 45 degree diagonal, all formed from one piece of steel.

2

With no loose stirrups, the bars were laid in moulds into which concrete was poured to form precast elements.

TIMELINE

Albert Kahn’s industrial architecture ranges between 1903 to 1941, a period in the U.S. animated by advanced labor struggles, activism, sabotages and mass demonstrations for higher wages, better working conditions and freedom of assembly.

The two extremes of this progressive typological rarefaction of the industrial layout were:

1.The daylight factory

2. The formulated layout

His designs provided for a radical change in the thought process, materiality and style of industrial architecture.

1870 1880 1890 1900 1910 1920 1930 1940

Moved to Detroit,Michigan with his family, 1880

Started working with a Detroit firm Mason and Rice, 1884

Started Albert Kahn & Associates, 1895

Palms Apartment House Detroid, Michigan, 1902

Ford Motor Company Highland Park, 1909

Ford Motor Company Glass Plant, 1924

Packard Motor Plant Detroid, Michigan 1903

General Motors Building Detroid, Michigan, 1919

3

Dodge Chicago Plant Chicago, Illinois, 1941

FACTORY : A NEW TYPOLOGY

Prior to the Industrial Revolution, most of the workforce was employed in agriculture, either a self-employed farmers as land owners or tenants, or as landless agricultural laborers.

The factory system was a new way of organizing labor made necessary by the development of machines, which were too large to house in a worker’s cottage and much too expensive to be owned by the worker.

As these industries were small scale and practised within the family or the village. Prior to this there was no typology which was for industries and factories which would aid to the production of goods in the new era of the Industrial Revolution.

The workspaces created by these structures were often dark, gritty, cramped, and dangerous because the oil-soaked wood floors posed a fire hazard. The lack of natural light over a wide footprint meant that production had to be conducted on multiple floors.

This made the assembly lines inefficient because the multiple floors would cause interruptions in the assembly process.

This new form of industrial architecture was characterized by the exact opposite of the traditional mill construction; long beam spans, the ability to place heavy machinery on the top floor, modern day lit factories, and the speed of construction.

These changes served to accomplish two main functions for the factory owners:

1. The production processes of the time (i.e. the assembly line) could easily be laid out on the factory floor with plenty of space to reconfigure if necessary.

2. Then along with the increased production from the assembly line, an increase in the productivity of the workers was achieved through “good lighting and ventilation”.

Specifically Albert Kahn transitioned the factory designs from traditional mill construction which was characterized by short beam spans, very dark interiors, and generally heavy timber construction which required at least some skilled labor to industrial architecture and the modern factory as we know it today.

These soon became the norms in the field of industrial factory design as the technological advancements of the industrial revolution brought machinery which needed larger spaces to be accomodated.

A typical section through the old factory building before Kahn. The factory life in the early 1900s was not an adequate working environment and issues with health were very high

A typical section through the old factory building before Kahn. The factory life in the early 1900s was not an adequate working environment and issues with health were very high

4

The Truscon Steel company set up by Albert Kahn and his brother

FORD MOTOR CO.

Henry Ford’s first vehicle rode on four bicycle wheels and was powered by a four-horsepower engine. Building his first experimental car in a workshop behind his home in Detroit in 1896, got him recognition in the Automobile world.

In 1899, he joined a group that founds ‘The Detroit Automobile Company’. The investors who quickly began to lose confidence as the felt the vehicles produced were unsatisfactory. By 1901 the company runs out of business.

1903, Ford Motor Company is incorporated. The company had 12 partners who put together the company’s first car : The Model A. With its quick success, Ford setup its first international plant was built in Ontario,Canada, right across the Detroit River from Ford’s existing facilities.

Henry Ford’s Model T in 1908 put the world on wheels with a simple, affordable, durable automobile. Ford sold 15 million Model Ts before ceasing production in May 1927, making it one of the best-selling vehicles of all time, and arguably the most famous car in the world.

“ Our focus on the freedom of movement helped create the middle class with the $5 wage, revolutionized manufacturing with the moving assembly line and got the whole world moving with the first vehicles built for everyone. ”

- Henry Ford

Fordism

The manufacturing of process of the cars at the factories of Ford was coined the term “Assembly line Production”.

An assembly line is a production process that divides up the labor process. It breaks up the manufacture of a good into steps that are completed in a pre-defined sequence. So instead of a linear process of a Production Line, the new Assembly line part and components of the finished producted were added at a particular sub-station.

Henry Ford took that idea and implemented the conveyor belt system used in other industries to mass-produce the Ford Model T on the very first iteration of the modern assembly line in 1913.

Ford’s innovation eventually reduced the Model T’s chassis assembly line from 12.5 to 1.5 hours, and in doing so precipitated a revolution in manufacturing. The accelerating speed with which Ford could produce cars helped him continue to lower the price of the Model T.

5

1907: Introduction of the scripted typeface of its trademark, becoming the company’s logo

1908: Founder, Henry Ford with the Ford Model T. The car’s chassis was the first to be mass produced as a part o ‘Ford Production Line’.

Poster of the famous Model T car

HIGHLAND PARK, FORD PLANT

“ A plan to mass-produce factory buidings. ”

- Albert Kahn

Albert Kahn with his brother had began developing a new construction technique which utilized reinforced concrete instead of wood for walls, roofs, and support beams. This practice made buildings less susceptible to fire and also allowed for large cavities of unobstructed space.

The construction of the Packard Plant attracted the attention of Henry Ford, who hired Kahn to design Ford Motor Company’s Highland Park plant in 1908.

‘It’s all about the Column’

In the part plan below, the arragment of Columns is visible. These reinforced columns helped Kahn achieve the desired spans and openings for the New industrial buildings.

The Columns became the Load bearing members of the structure. Along with this, Kahn used lighter materials like Steel to make Roofs and Windows. Roofs of the buildings started bringing in skylight using the different forms made by the steel truss members.

Plan : Ford Motor Co. Highland Park Plant (done by Albert Kahn)

Tracks around the factory for the movement of raw materials and finished parts

The building blocks facing the main roads were either used for showroom/ delivery areas. The raw materials for the factory came from the other side via railways and reached each unit of Assembly through sub-divisions of the main line.

Inside the factory Ford had achieved its goal of having an efficient assembly process, reorganizing materials and workers to minimize the time they spent acquiring material and moving between the various parts of the manufacturing and assembly process.

The moving assembly line immediately brought the time to complete an entire car down from 728 to 93 minutes.

Building AA : The defining character of is its exterior design, industrial character and the three-story craneway with banks of windows on the other side.

Building NN : The building is defined by its exterior design, open interior space and the abundant natural light brought in through the glass roof and clerestory windows. The building is a bridging space between OO and AA part of the Assembly line.

Building OO : The defining features of Building OO include its more ornamental exterior design as a public facade on Woodward Avenue and the primary interior spaces of the entry vestibule, showroom, and monumental central stair all the way to the fourth floor.

6

O N A B C G F E H L M J D JJ NN AA OO 2 1 R K S 5 3 4 Y Z X W

Part of the Ground Floor Plan showing different building blocks of the Assembly line

AA NN OO

Architecture of the Assembly line

The large floor area with groups of workers assigned specific tasks as a part of the assembly line.

The volume of this area allowed for the conveyor beltsystem to bring in parts from all around the factory to the main assembly.

This area was used as the delivery area for the final touch -ups and additions to the car before handing it over to the customers.

7

Ford Motor Company Highland Park Rendering: bird’s eye view in 1924

Building AA :

Building NN :

Building OO :

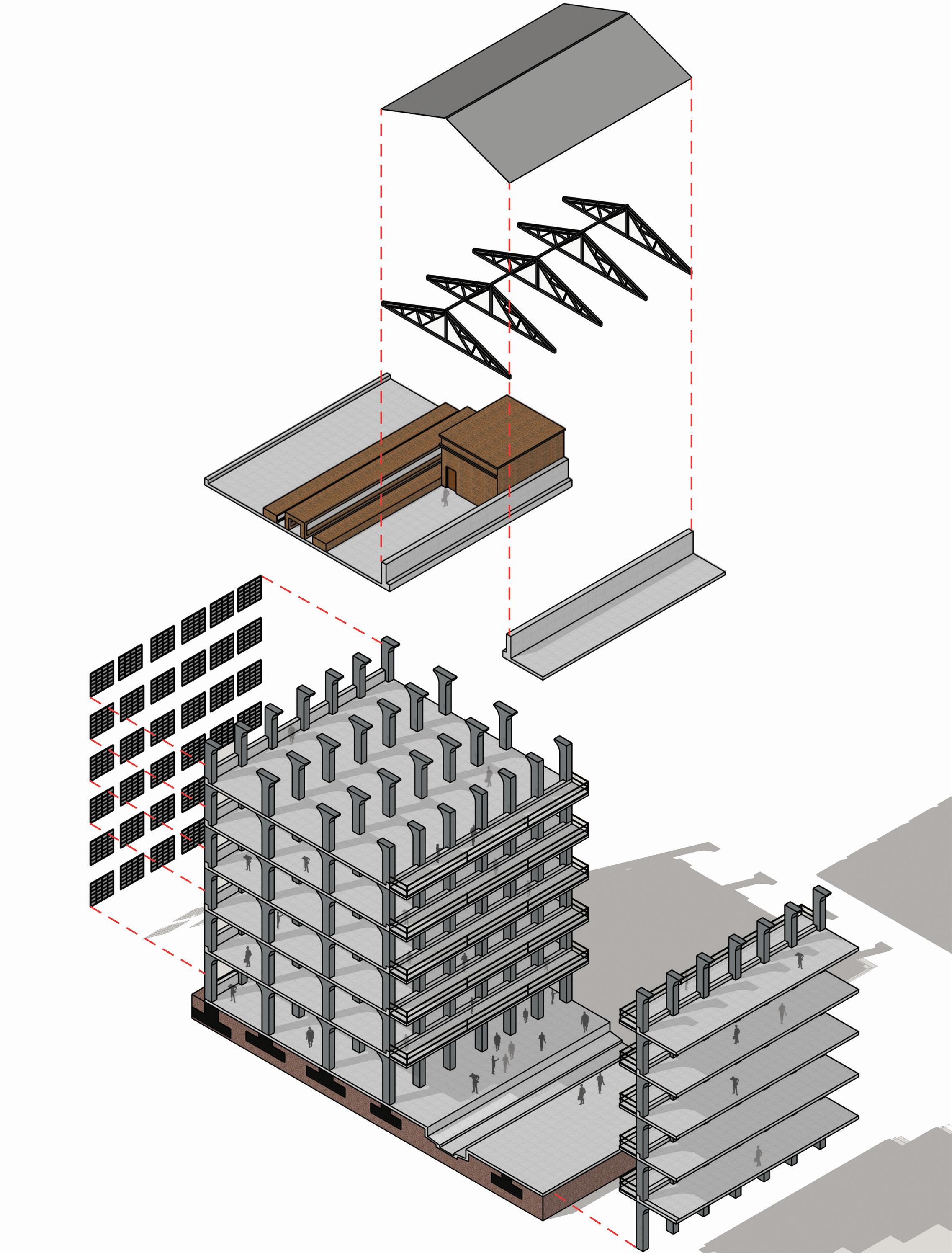

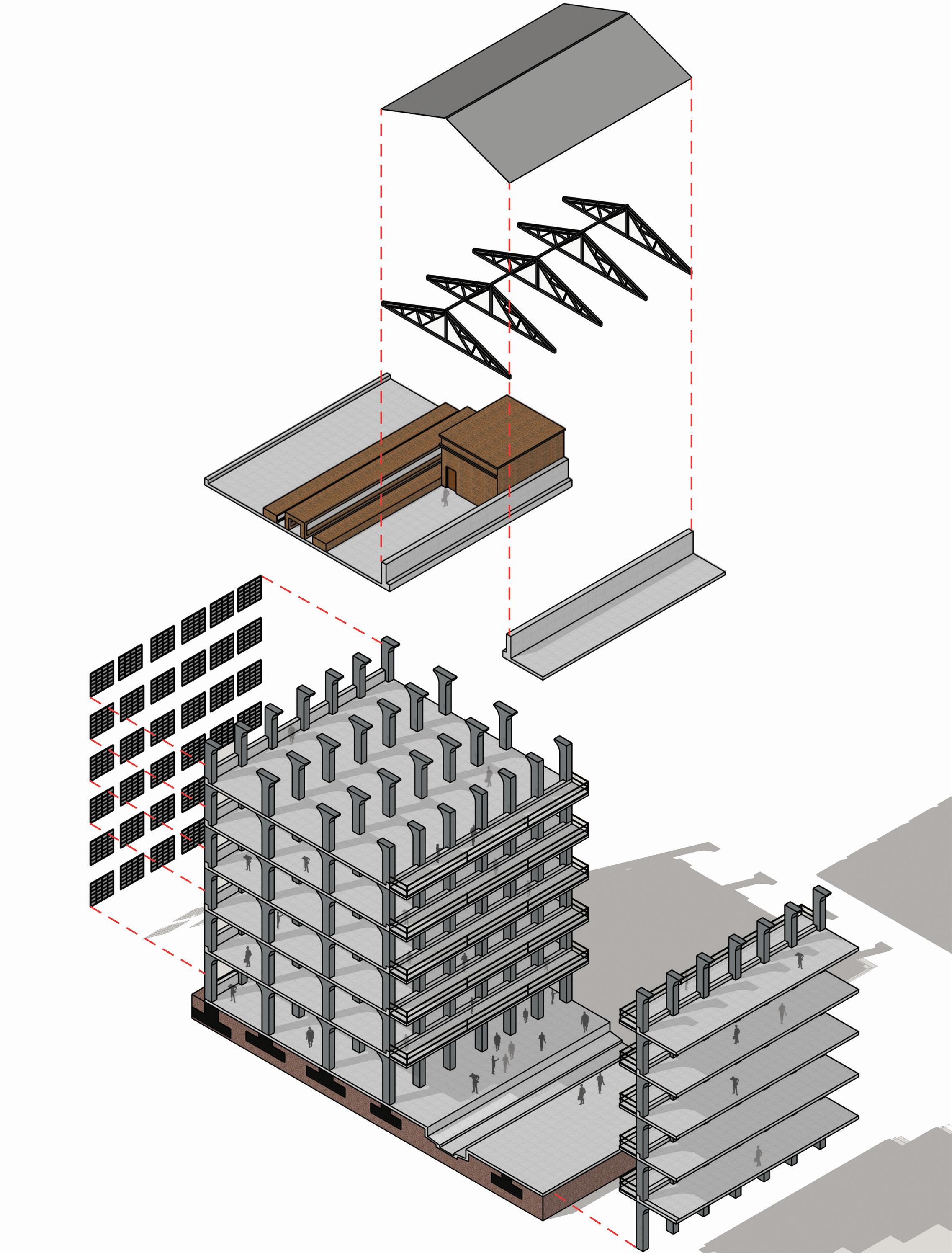

DECODING LAYERS

Glass as roofing material

Layers of the Assembly Line Production in the factory :

1. Raw materials arrive at the factory via Railway

2. Monorail taking workers to different workstations

3. Final Assembly shop, finished car departs

Material distribution lines setup within the Ford Highland Factory

Truss System for supporting the roof

Road networks and the outer framework of the factory

Movement of raw materials and finished products at different levels ; Assembling with Gravity

8

1 3 2

Ducts for Heat and Smoke

Grid of R.C.C. Columns

Glass and Steel windows

Structural Layers of the Factory

PROJECTS FOR FORD

Henry Ford had purchased a 60-acre of land in the Detroit suburb of Highland Park. Plants in Detroit had become inadequate. Ford’s idea was to have an entire plant under one roof, with no open court or dividing walls.

This was in contrast to his old system which had various manufacturing functions in separate buildings arranged in sequential order. Because of Kahn’s growing reputation in industrial architecture, Ford sought out the firm.

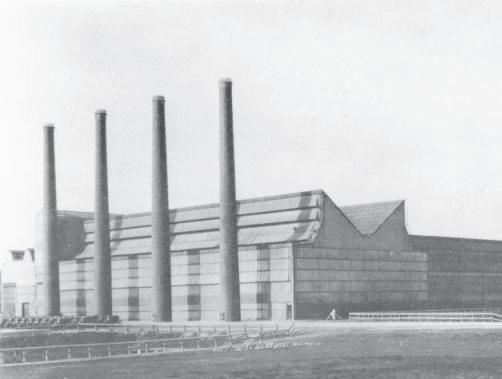

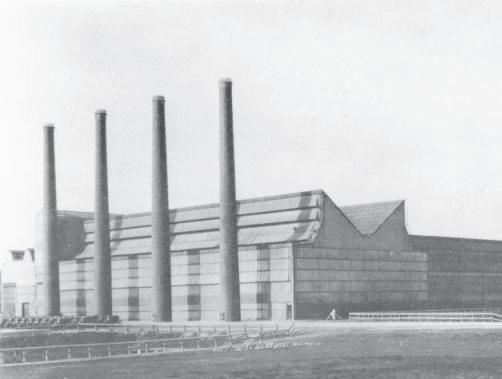

Albert Kahn developed the daylight system in two advanced articulations. On one hand, the multistory building, with concrete frame able to contain the vertical assembling processes all under one roof. On the other hand, the horizontal workshop over one floor, a one story, roof lighted unobstructed working space.

For the first time, industrial steelsash windows we re used in conjunction with concrete framing which gave the butterfly roofs and clerestory monitors as seen in the factory

Ford commissioned a new pavilion for the 1933-34 Chicago World’s Fair. It was 130 feet high and designed to look like a stack of gears surrounding a 92-foot-wide courtyard. The Rotunda was supervised by Albert Kahn. The dome over its courtyard was the first real-world application of inventor Buckminster Fuller’s lightweight geodesic dome.

By late 1934, following the Fair, the Rotunda would be re-located to Dearborn. It was recorded at the time that over 61,000 visitors went through its doors in the first week, and 16 million guests from around the world visited over its 26-year history.

Visitors were able to see how a car was designed, how steel was made, and how an assembly plant worked. Industrial shows and custom car shows were also held within the Rotunda’s walls. The most anticipated event of the Rotunda was the annual Christmas Fantasy drawing in large crowds around the holidays.

On November 9, 1962, as the Rotunda was preparing for the Christmas Fantasy, a fire started on the roof of the building where workers were making repairs. The fire quickly burned through destroying the Routunda.

9

Ford Motor Company Glass Plant, 1924

The Ford Rotunda, 1962

REFRENCES

1. http://www.we-aggregate.org/piece/the-labor-of-albert-kahn

2. https://njitarch382.wordpress.com/2012/03/08/gasworks-and-ford-motor-company-elizabeth-opper-tyler-tourville/

3. https://www.northernarchitecture.us/american-architecture/kahn-becomes-a-popular-concrete-system-for-export-c-19051914.html

4. https://jerubbel.wordpress.com/2013/05/06/albert-kahn-and-his-kahn-crete-the-revolutionization-of-factory-architecture/

5. https://jbjoslin.com/PATH-OF-KAHN

6. https://corporate.ford.com/home.html

7. https://detroitisit.com/the-ford-rotunda-a-lost-albert-kahn-building/

8. https://www.thehenryford.org/

9. https://detroithistorical.org/learn/encyclopedia-of-detroit/ford-highland-park-plant

10. https://sah-archipedia.org/buildings/MI-01-WN126

11. http://tylertopics.com/wp-content/uploads/2015/09/Tyler-HighlandPark-APT2015.pdf

12. https://issuu.com/a1579/docs/albert_kahn_factory/2

13. https://learningenglish.voanews.com/a/henry-ford-1863-1947-he-made-the-automobile-industry-oneof-the-great-industries-in-the-world-137393828/113290.html

14. https://jerubbel.wordpress.com/2013/05/06/albert-kahn-and-his-kahn-crete-the-revolutionization-of-factory-architecture/

15. https://www.alexandriava.gov/uploadedFiles/historic/info/archaeology/SiteReportCulinane1988FordPlantAX119.pdf

16. https://medium.com/the-omnivore/albert-kahns-journey-to-become-the-architect-of-detroite9e7c57f5690

17. https://www.aia.org/articles/6352703-albert-kahn-legacy-projects

18. https://www.youtube.com/watch?v=JkCJkdcl8mw&t=308s

19. https://www.youtube.com/watch?v=PZnGWJ_6BwU

20. https://www.youtube.com/watch?v=LtXJdm08djY

10

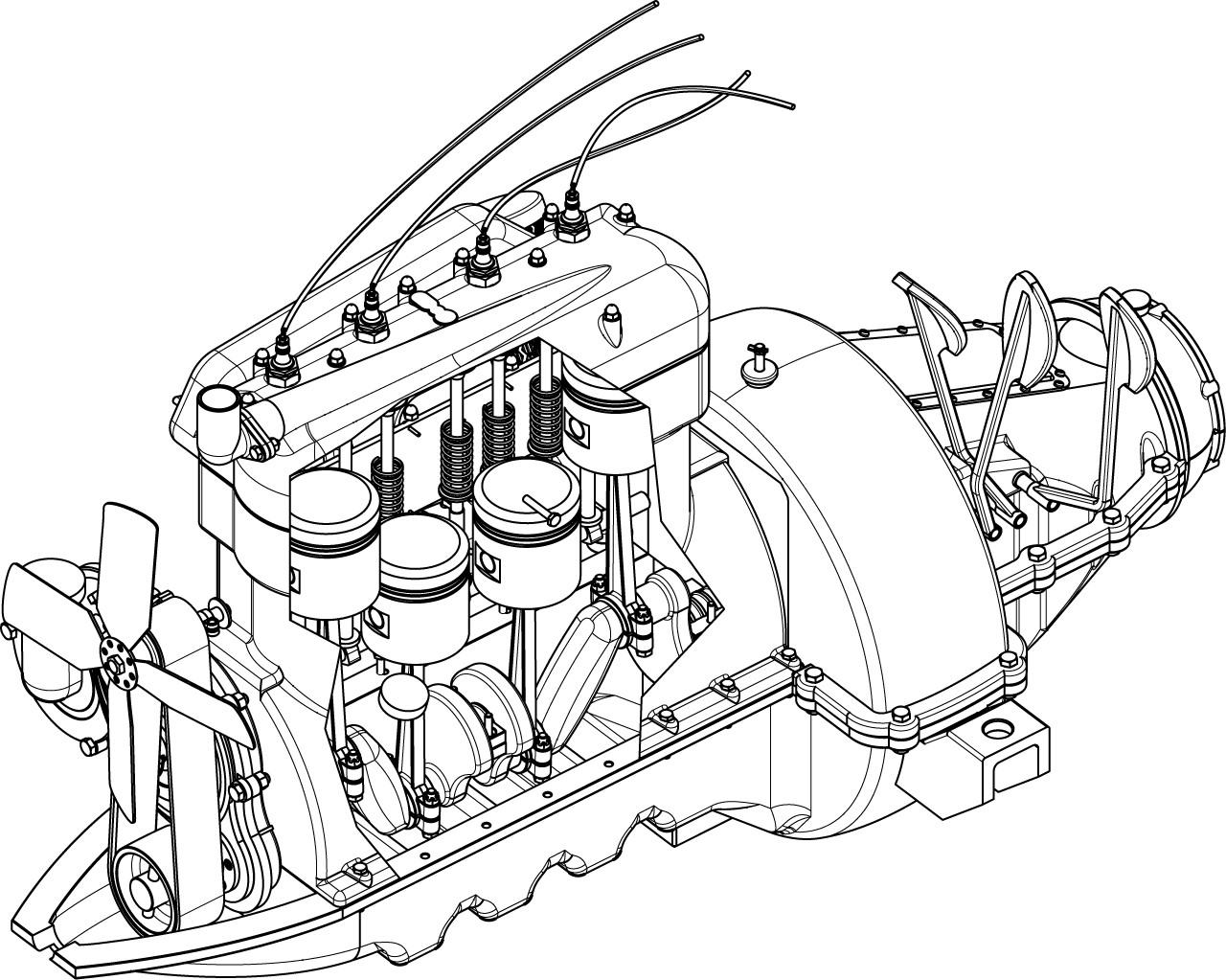

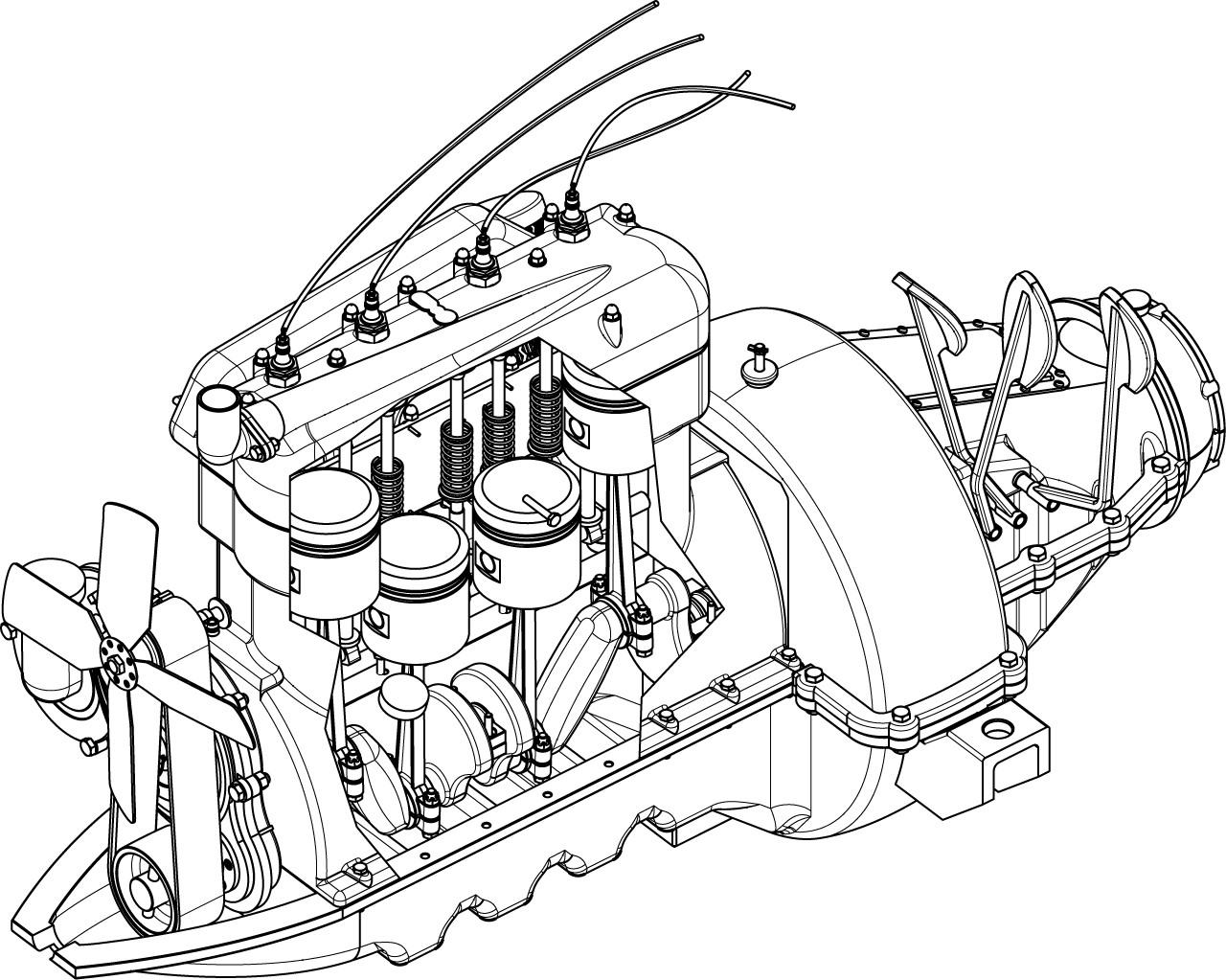

Expoded view : Ford Model T

Email : neelnaregal@gmail.com

Contact : +91 9825168108

Instagram : @nnaregal

Neel Naregal

A typical section through the old factory building before Kahn. The factory life in the early 1900s was not an adequate working environment and issues with health were very high

A typical section through the old factory building before Kahn. The factory life in the early 1900s was not an adequate working environment and issues with health were very high