TaskMaster Tools and Dies

TaskMaster Tools and Dies

NECA TAS BRANCH

1300 361 099

memberservices@neca.asn.au

NECA SA/NT BRANCH

213 Greenhill Road, Eastwood SA 5063 PO Box 47, Fullarton SA 5063

(08) 8272 2966

neca@necasa.asn.au

NECA QLD BRANCH

1.5 Ian Barclay Building, 460-492 Beaudesert Road, Salisbury QLD 4107

1300 361 099 memberservices@neca.asn.au

NECA NSW BRANCH 122 Hume Highway, Chullora NSW 2190 1300 361 099

memberservices@neca.asn.au

1300 361 099 memberservices@neca.asn.au

AUSTRALIAN CABLER REGISTRATION SERVICE

1300 667 771

enquiries@acrs.com.au

www.acrs.com.au

WITH THE GROWING DEMAND FOR ENERGY, AND AMBITIOUS RENEWABLE AND ELECTRIFICATION TARGETS BEING SET BY GOVERNMENTS AROUND THE WORLD, THERE’S NEVER BEEN A MORE IMPORTANT TIME TO ASSESS AUSTRALIA’S ENERGY SUPPLY AND INFRASTRUCTURE.

In this edition of NECA News, we take a look at what’s driving electricity demand to record levels, what’s happening in the world of renewables, and some of the newest and most innovative ideas that might just allow us to keep the lights on.

NECA’s Director of Policy, Technical and Safety, Neil Roberts, shares his thoughts on the current state of Australia’s energy security, future generation forecasts, and the risks associated with the evolving energy mix, while Powering Skills Organisations General Manager of Projects, Steve Hall, delves into the role Artificial

Intelligence is having on reshaping the country’s data centres.

There’s no denying that the electrical and communications industry is at the forefront of a new era for Australia, and it’s imperative we have the skills and the infrastructure in place to support it.

If you have something to share from your corner of the country, don’t hesitate to reach out. We’d love to hear from you.

The NECA News team

Share your feedback via email necanews@neca.asn.au

Share your ideas for content via email necanews@neca.asn.au

We’re looking to showcase NECA member stories in each issue. Reach out to your NECA Branch or email necanews@neca.asn.au

If you’d like to join more than 30,000 of your industry peers and receive a digital version of NECA News, sign up at www.neca.asn.au/necanews

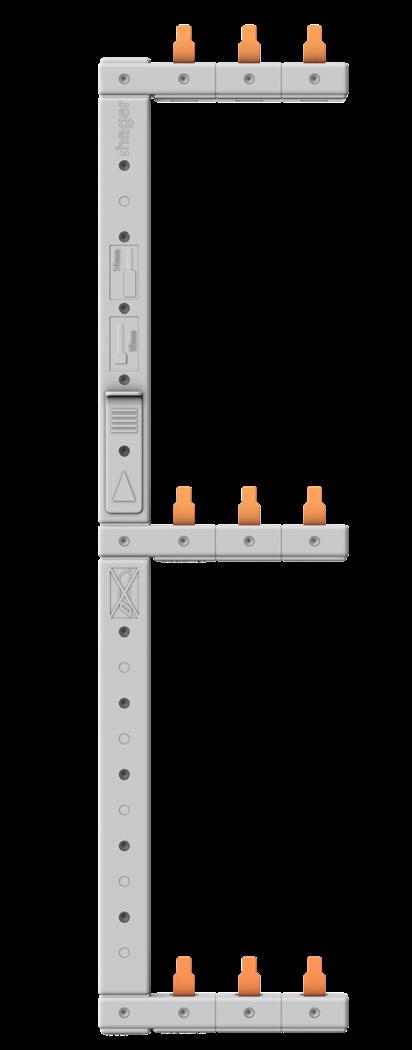

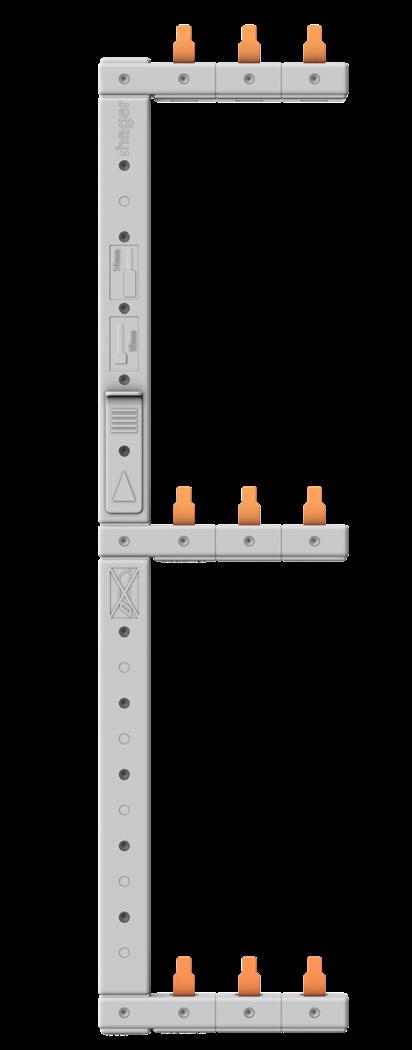

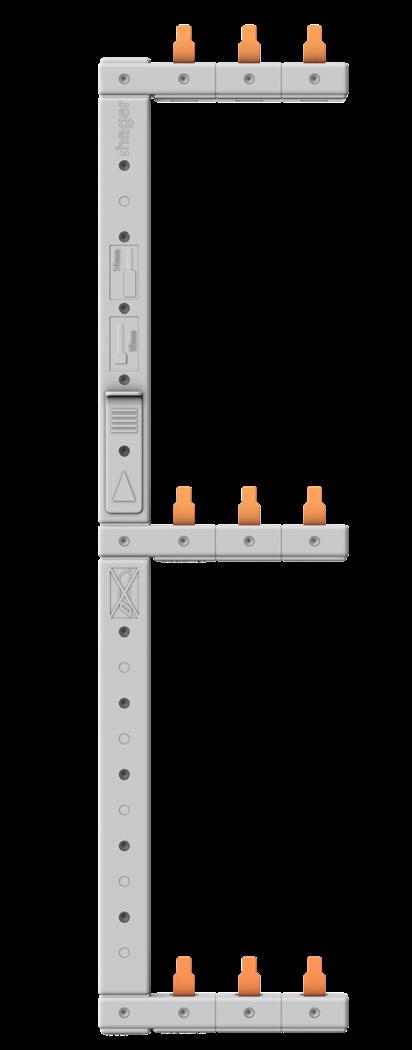

Hager’s onekonekt system offers the most versatile and flexible solutions to electricians on the market today.

Hager’s onekonekt system offers the most versatile and flexible solutions to electricians on the market today.

Hager’s onekonekt system offers the most versatile and flexible solutions to electricians on the market today.

This system consists of a large and evolving range of compact protection devices for both single phase and three phase installations that connect flexibly via a common busbar arrangement.

This system consists of a large and evolving range of compact protection devices for both single phase and three phase installations that connect flexibly via a common busbar arrangement.

This system consists of a large and evolving range of compact protection devices for both single phase and three phase installations that connect flexibly via a common busbar arrangement.

Ultimately, the Hager onekonekt system makes wiring easier, increases safety, and significantly reduces installation time vs traditional cabling.

Ultimately, the Hager onekonekt system makes wiring easier, increases safety, and significantly reduces installation time traditional cabling.

Ultimately, the Hager onekonekt system makes wiring easier, increases safety, and significantly reduces installation time vs traditional cabling.

Hager’s KCL36xL Vertical Busbars are three-phase cable replacement devices that save space and time and offers a solution to minimise concerns over conductor stress and bend radius.

Hager’s KCL36xL Vertical Busbars are three-phase cable replacement devices that save space and time and offers a solution to minimise concerns over conductor stress and bend radius.

Hager’s KCL36xL Vertical Busbars are three-phase cable replacement devices that save space and time and offers a solution to minimise concerns over conductor stress and bend radius.

As Australia navigates the growing demands of a changing energy landscape, energy security remains one of the most pressing issues facing our nation. The role of electricians and communication contractors has never been more vital, and their contributions will shape not only the future of Australia’s energy system, but also the prosperity of local communities.

Energy security refers to the ability of a nation to ensure that its energy needs are met reliably, affordably, and sustainably. As we transition from traditional fossil fuel reliance to renewable energy, this challenge becomes increasingly complex. Australia’s energy needs are evolving rapidly, driven by increasing population demands, the rise of electric vehicles (EVs), and the expansion of renewable energy infrastructure, such as solar, wind, and battery storage.

Electricians and communication contractors are at the forefront of this transition. From installing the infrastructure that supports the electricity grid, to ensuring that renewable energy systems are reliable and efficient, this workforce is critical to securing Australia’s energy future.

The challenges, however, are immense. Energy security does not simply mean generating enough power; it involves ensuring that power is delivered efficiently, that systems are resilient to disruptions, and that the energy supply can support the growing needs of households and businesses.

The electrification of our economy and the transition to renewable energy are inextricably linked. Skilled electricians are essential to ensuring that the infrastructure needed for this transition is built, maintained, and upgraded to meet new demands. Whether it’s upgrading electricity networks to accommodate renewable energy or installing electric vehicle chargers to support the shift to EVs, electricians are integral to securing a reliable energy future.

One of the key roles electricians play is in supporting demand response and energy storage systems. As we increasingly rely on intermittent renewable sources like solar and wind, the ability to store and efficiently manage energy is crucial. Electricians install and maintain battery storage systems and help integrate renewable energy into the grid, allowing households and businesses to store excess energy during periods of low demand for use during peak periods.

The rapid growth of data centres across Australia is driving a significant demand for electricity. As digital transformation accelerates, and industries move further into the online and cloud-based spaces, the power consumption of data centres is set to rise dramatically. These facilities are integral to supporting Australia’s technological infrastructure and digital economy.

This surge in power requirements presents a long-term opportunity for our

sector. The construction and ongoing maintenance of data centres represent a substantial source of work for electrical contractors, from the initial build through to ongoing operations. The need for skilled professionals to install, upgrade, and maintain the systems that keep these centres running smoothly will continue to grow, creating lasting employment and business opportunities in the electrical and communications sectors.

A critical aspect of accommodating the demands of data centres will be ensuring sufficient base load capacity. While renewable energy sources are crucial, they are often intermittent. To support the continuous operations of data centres, reliable, steady power supply is essential. This means base load capacity, that can be provided reliably and without interruption, will be a key factor. This capacity will be needed to complement renewable generation and ensure the stability and reliability of the grid, particularly during periods when solar and wind energy are impacted.

As with many sectors, the growing demand for skilled electricians is not without its challenges. Labour shortages are already a significant issue, with a lack of local training opportunities and the difficulty of attracting workers to rural and remote areas exacerbating the problem. Additionally, the complexity of new technologies, including solar power systems, energy storage, EV charging infrastructure, and the unique requirements of data centres, means that electricians must continually upgrade their skills to remain competitive and capable. NECA will continue to champion workforce development, from world class apprenticeships to ongoing post trade training.

To ensure that the transition to a clean energy future is both successful and sustainable, it is essential that government policies prioritise energy security. This includes continued investment in training and apprenticeships,

particularly in the renewable energy and electrification sectors, and ensuring fair commercial contract terms for electricians working across Australia. Moreover, NECA continues to advocate for the implementation of industry-wide standards and regulations that will simplify compliance and reduce administrative burdens, enabling electricians to focus on delivering the vital work that will ensure Australia’s energy security.

electricians, to support the growing demands of electrification and renewable energy. NECA continues to push for policies that support the workforce and address the regulatory barriers faced by the sector. Our ongoing advocacy ensures that the crucial role electricians play in achieving energy security is recognised at the highest levels of government.

<Record Keeping & Repor ting <Touch Screen <

Recently, NECA appeared before the Senate Economics References Committee’s inquiry into residential electrification. During the inquiry, NECA represented our industry and provided valuable insights into the challenges and opportunities presented by the transition to a clean energy future. Our submissions addressed critical areas, such as the need for skilled labour, the integration of consumer energy resources, and the regulatory frameworks that will support a secure energy system.

In response, the Senate Committee’s report acknowledged the importance of investing in the workforce, particularly

Australia’s energy future is bright, but it will require a concerted effort from all stakeholders, from government to industry, to secure our energy needs. Electricians, with their expertise and skills, will play a crucial role in this transition. It is up to all of us to ensure that they are given the resources, training, and support needed to succeed.

At NECA, we are committed to supporting this workforce and advocating for the policies and reforms needed to maintain energy security for all Australians. A robust, skilled workforce is crucial, but so is ensuring a fair, competitive playing field. Without fair competition and equitable contract terms, the full economic and environmental benefits of the clean energy transition will remain unrealised. We continue to champion policies that promote both workforce development and a fair, transparent marketplace, ensuring that all stakeholders can thrive in a competitive and sustainable energy future.

The future of Australia’s energy security lies in the hands of electricians, and together, we will build a stronger, more sustainable energy future for generations to come.

< Installation Verification & Compliance Testing Pass/Fail limits and “Auto Sequences” set to AS/NZS3017 and AS/NZS3019.

< Single Test Functions Voltage, Mohm & Ohms, RCD, Loop Impedance, Line Impedance, Earth Resistance, Power & Harmonics, Light, Wire Tracing.

< Site Schematics & Installation Reports

Save test results to the Site Schematic or Tree Structure. Start with Site Name and Address. Test reports output to PDF or Excel.

< High Volume RCD Testing System

< Single Test Functions

Complete high volume RCD testing & logging solution with bar-code scanner input of RCD IDs and logging of RCD push button tests.

Voltage, Mohm & Ohms, RCD, Loop Impedance, Line Impedance, Earth Resistance, Power & Harmonics, Light, Wire Tracing

< Installation Verification & Compliance Testing

< Site Schematics &

Pass/Fail limits and “Auto Sequences” set to AS/NZS3017 and AS/NZS3019.

< High Volume RCD Testing System

< Single Test Functions

Complete high volume RCD testing & logging solution with bar-code scanner input of RCD IDs and logging of RCD push button tests

Voltage, Mohm & Ohms, RCD, Loop Impedance, Line Impedance, Earth Resistance, Power & Harmonics, Light, Wire Tracing

< Site Schematics & Installation Reports

Save test results to the Site Schematic or Tree Structure. Start with Site Name and Address. Test reports output to PDF or Excel

AS THE WORLD MOVES CLOSER AND CLOSER TOWARDS THE DEADLINES OF THE AMBITIOUS RENEWABLE ENERGY TARGETS THAT VARIOUS GOVERNMENTS HAVE SET, WE’RE ALREADY BEGINNING TO SEE THE EFFECTS ON AGEING INFRASTRUCTURE, FOR BOTH ELECTRICITY GENERATION AND TRANSMISSION, AND OF EXPENSIVE AND INADEQUATE ENERGY STORAGE SOLUTIONS.

Growing populations and expanding regional centres are always going to drive up the demands on our networks; however, with increased attention being turned to the reduction of CO2, governments are adding even more pressures and incentives to accelerate the switch to electric power.

Further fuelling this demand, are changing lifestyles, the growing number of connected devices, the mass adoption of streaming services and artificial intelligence, and the staged phase-out of combustion engine vehicle sales.

The Australian Energy Market Operator (AEMO) released the annual consumption forecast (below) and we’ve taken a look at some of the drivers for this.

The amount of electricity used around the world is a number that changes every single year, almost always going up. In Australia, the increase per year is about 1-2% per year, a number which seems small, until compounded over 20 years. By 2050, the global electricity demand is projected to more than double, compared to current consumption levels. Internationally, the amount of people who are going to need electricity is projected to go up by three billion, with one billion existing people being connected and the world’s population growing by a further two billion. This, combined with the addition of new technology, has humanity on track to have six times as many internet-using devices in 2030 as we did in 2020, all of which are contributing to increased electricity demand.

While the global electricity usage grows as the world produces new technologies, it also grows as old systems are migrated from a fossil fuel system over to an electrical function. Two of the most notable changes of this kind are transport and heating. The European Union plans to ban new combustion engine vehicles by 2035, which is already driving the transition to electric vehicles there. In Australia, we already have the ‘Driving the Nation Fund,’ which supports transformative infrastructure, including our first national vehicle charging network, which aims to install chargers on our major highways at intervals averaging 150km apart. Electric cars are estimated to save Australians up to three thousand dollars every year on fuel and maintenance costs. Nearly one in 10 new cars sold in Australia is now an EV, a change that has come around rapidly in the last few

years. Tasmania has even introduced $20,000 grants for small businesses purchasing electric delivery vehicles.

One major factor driving the increase of electrical components is our concern for the environment. It is estimated that existing technologies have the capacity to eliminate around 70% of our CO2 production. While these capabilities exist, they’re not built to anywhere near the extent needed to achieve such a high margin of emission reduction. This is changing though, with the Australian Energy Market Operator (AMEO) forecasting a shut-down of all coal power stations by 2038. Gas powered stovetops are being slowly phased out in favour of electric and induction stoves, and domestic gas hot water systems will continue to be the most expensive domestic water heating systems over alternatives, including heat pumps and electric resistance heaters.

The ACT and Victoria are taking leading roles in Australia’s transition to electrification and switch to EV’s, with multiple commitments and targets already being set in place. The ACT government is planning to achieve 80-90% of all vehicle sales to be zero emissions vehicles (ZEVs) by 2030, with incentives including two years free registration, and zero interest loans on ZEV’s and charging infrastructure. From 1 July 2024, the registration fees for ACT vehicles have been gradually transitioning from a weight-based system to an emissions-based system, further encouraging the transition to electric vehicles. In the field of infrastructure, the ACT and Victorian Governments have prohibited the installation of gas connections to new homes in most areas, with the ACT Government setting a goal of being completely fossil fuel free by 2045.

Data centres are some of the largest consumers of energy in today’s world. Data centres are dedicated physical facilities that house computers, servers, network infrastructure, and other general technology of this type. As of 2023, data centres alone were contributing to two percent of the world’s electricity consumption, and with the increase of power-hungry AI technology, that number is rapidly growing. In 2023, data centres across the world used more electricity (approximately 290TWh) than the whole of Australia (188TWh)– a truly baffling thought. 40% of this energy goes into cooling the data centres, since they need to be kept within a range of 18-27 degrees celsius to optimise reliability, longevity, and performance of the equipment within the centre. AI is becoming increasingly more energy dependent, as it continues to become more powerful and widespread. In 2024, the amount of energy required to generate a single image was equivalent to a full smartphone’s battery charge.

With AI continuing to be incorporated in more and more industries, and being used to produce more and more images, videos, and audio-based content, electricity generation is going to have little choice but to grow with it.

The world may have set some ambitious goals for electrification and carbon neutrality over fifteen to thirty years, but while that seems a long time away, it is important that we as an industry and a species are doing everything we can to make sure we’re prepared to keep up with these targets. Whether or not the goals are met, they can act as a guideline and an objective to make sure the world is prepared for an electric tomorrow. It will take a long time to truly phase out all carbon emissions, but it will take just as long to build sufficient electricity generation in its place, and it is our industry that is front and centre in delivering this change.

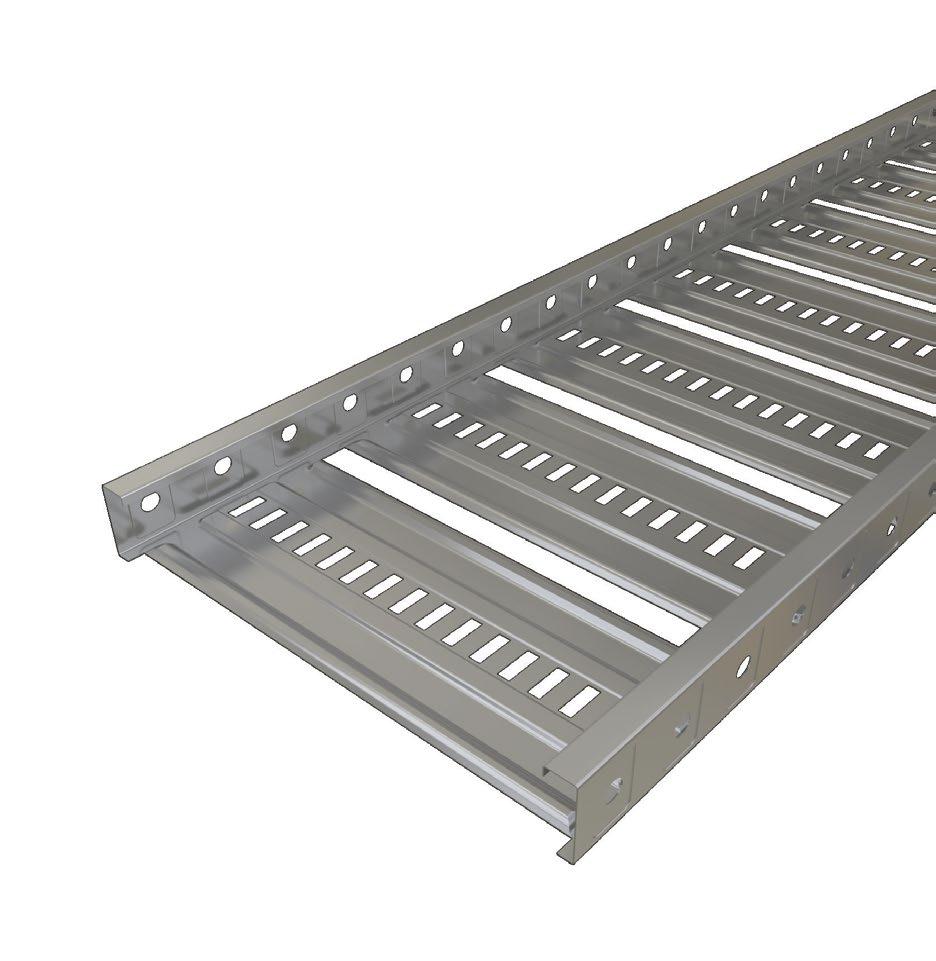

TrueGalv® the effective alternative to traditional hot dipped galvanised products

TrueGalv® the effective alternative to traditional hot dipped galvanised products

► Available in Strut and CableTray Products

► Available in Strut and CableTray Products

Self Healing

Self Healing

Consistent Finish

Consistent Finish

No Dags

No Dags

Cost Effective

Cost Effective

Suitability for all Applications

Suitability for all Applications

RENEWABLE ENERGY IS, WITHOUT DOUBT, THE FUTURE OF INTERNATIONAL POWER GRIDS. WHETHER IT’S PRODUCED LOCALLY OR OVERSEAS, THE POWER WE USE IN AUSTRALIA IS TRANSITIONING SLOWLY BUT SURELY AWAY FROM FOSSIL FUELS AND TOWARDS CLEAN ENERGY SOURCES, SUCH AS WIND, SOLAR, HYDRO AND GEOTHERMAL. SUCH A TRANSITION DOESN’T COME EASILY THOUGH; THERE ARE MANY OBSTACLES OFTEN STANDING IN THE WAY.

When put to work, renewable energy generators rely on natural energy sources to operate, therefore making them ‘free,’ excluding infrastructure and maintenance costs. This is a major difference from fossil fuels, which require mining, transportation, and other preparation processes. Capital costs, however, can be prohibitive. The cost of a typical commercial wind turbine in Australia ranges between four and six million dollars, as well as land purchase costs. Solar farms cost one to one and a half million dollars per mega-watt (MW) of installed capacity, and other renewable energy farms and plants can cost well into the billions of dollars. These are all initial costs, with even more money being spent each year on research, development, and maintenance. However this is not to say that fossil fuels do not have start-up costs. Since coal is not a renewable resource, capital costs apply to it as well, when new coal mines need to be set up. The costs of these mines, depending on the size, can exceed $200 million, and even more when the costs of treatment and transport are factored in.

One of renewable energy productions most notable inefficiencies is how much space it takes up. The largest solar farm in Australia today

sits across a 2,000-hectare site in Northeast NSW, with plans to build an even larger one in the future. Sun Cable, a solar energy company, has proposed and begun working on, a solar farm six times this size, planning to share power all the way through Southeast Asia. Currently, the majority of Australian solar panels are on residential rooftops, but there is only as much roof space as there are houses, and soon the focus will have to shift to these large-scale farms. In situations where there isn’t enough space, these farms are often built in a decentralised manner, with lots of smaller stations, scattered around in available space. As a result, there is a lot more surface area to cover, should a problem arise, adding extra risk and delays that a centralised system wouldn’t have. Furthermore, with these farms requiring large plots of land, they are often built in the more remote regions of the country. This introduces the problem of moving the power from remote farms all the way to residential areas, where it can be used. Cables traveling long distance are more susceptible to energy loss due to resistance, adding to the overall inefficiencies.

As per the law of conservation of energy, energy cannot be created or destroyed, it must be converted from

one form to another. Power generators are machines that take energy in different forms and convert it into electrical energy. Fossil fuel energy plants take the chemical energy from coal and turn it into electrical energy, via heat, steam and a turbine. Coal, while a limited resource, is controllable by humans – we can choose where and when to burn it. This is not the case for renewable energies. We can’t control when the sun will shine on our solar panels, nor can we choose when the wind will blow through our wind turbines. The reliance on favourable weather conditions is something that limits the efficiency of these models. Hydro power is a little different, because generally the river or dam it’s built on will continue to flow, regardless of weather. But even with hydro, one of the major obstacles in building these kinds of power plants – outside of environmental concerns – is the availability of suitable sites.

Most renewable power solutions produce more power than is being used at the time it is generated. This extra power needs to be stored in batteries, to be used at times when the generation isn’t meeting consumption demands. Currently, battery development and installation is an expensive process. However, there is a new technology that helps combat this problem for EV (Electric Vehicles)

owners, in bidirectional charging. Bidirectional charging is something that allows an electric vehicle to act as a battery for a house, effectively making the stored power in the vehicle available for use within the household.

Despite the concerns and expenses required to make the transition, plans are well underway for Australia to push ahead. The Federal Government has set a goal of being 82% renewable by 2030. Whilst this aligns with nations like Colombia, Japan, and the United States, it still lags behind countries such as Estonia, New Zealand, Austria, and Denmark, who have all set 100% renewable energy targets. Renewable energy isn’t just something to replace coal when we inevitably run out; it’s to keep the planet in a sustainable condition, and to put a stop to any further irreversible damage done by the carbon outputs. It also creates opportunities for energy independence, particularly with private solar panels on the roofs of residential structures, creating alternatives for managing power outages, and lowering energy prices. Furthermore, the continuous planning and development of new renewable energy technology creates thousands of extra jobs, which is a massive boost for the economy and the industry. The pressure is on to keep the planet healthy, and to begin implementing more sustainable solutions.

ONE OF THE BEST WAYS TO ADAPT TO OUR GROWING ENERGY SECURITY NEEDS IS TO DEVELOP NEW TECHNOLOGIES, TO EITHER REDUCE POWER CONSUMPTION, OR TO HELP PRODUCE AND STORE IT MORE EFFICIENTLY.

International energy consumption is steadily growing, and with it, different means of production, transition, and storage are being developed. Integrating new technologies for these purposes doesn’t necessarily mean a whole new invention, it can be as simple as introducing modifications to components, or improving techniques within existing technologies.

The recent energy rush caused by the push to switch to renewables, plus a booming population, has caused an incredibly high demand for the development of new storage systems, and one piece of breakout technology comes in the form of gravity batteries. Renewable energy sources are not always available, with wind speeds and overcast weather impacting the generation of wind and solar energy, resulting in the need for better electricity storage technology. Gravity batteries are possibly the next big thing in the energy storage world and are able to meet almost all environmental concerns.

At peak production times, the renewable sources will be able to produce a surplus of energy, which will be used to power a motor that pulls weights located in the battery upwards. These weights are then suspended there until the power is needed, at which point the motor becomes a generator, as the weights are lowered, effectively turning gravitational energy into electrical energy.

At the end of 2024, a Chinese company called Energy Vault opened the world’s first commercial-scale gravity energy storage system (GESS) near Shanghai, China. The system is built over 120 meters tall, and uses 25 tonne weights, made of soil, sand and other recycled materials. The entire building is AI powered, has a round-trip efficiency of 80%, and is capable of channelling 100 megawatts per hour, enough to power several hundred homes and businesses. While the long-term goal is to build a battery that can power a city for hours at a time, this megastructure has been a big step forward.

Gravity batteries don’t necessarily need to be their own new structures. Anywhere there is a straight path of

elevation can be the new home of a gravity battery. This includes underground as well, with several organisations digging chambers straight down to make space for the weights. One idea that is being thrown around is the construction of these batteries in old, decommissioned mines. Some of these old tunnels go as deep as three kilometres below the surface, offering huge potential for storage capacity. Using these holes would not only save money on the cost of digging a new one, but would also repurpose unused land, which could be vital in the long term.

The increase in solar panels across Australian residential rooftops does not just provide a cheaper alternative for property owners, it acts as a widespread power system, functioning as a collective energy source and taking considerable stress off the grid. Australia is a great example of this, with over 37% of residential households having solar panels installed on their roofs. This means over four million Australian homes and small businesses have the ability to generate their own power. This has two main advantages for the overall electrical grid:

½ every single building that is being powered by their own rooftop solar systems is one more building drawing less power from the grid, freeing up the load placed on our existing public power plants;

½ during peak times, these collective private solar systems have the potential to be producing more electricity than they will be consuming, meaning residents can virtually sell their power back into the grid, assisting with powering the rest of the city.

As more and more houses and businesses continue to generate their own solar energy, the load on the main grid will become less and less, freeing up power to build more infrastructure and backup storages.

Systems like this, where grid users produce more power than they are consuming at any given time, and the correct infrastructure is in place, can feed this power back into the grid, creating a VPP.

Renewable hydrogen power is a concept that continues to be developed every day. The technology works by using existing renewables like solar or wind to produce hydrogen, through a process called electrolysis, and then combusting that hydrogen to generate electricity. The only bi-product of this process is water, which makes it a zero-emissions power source. Commercial electrolysis power plants have water-to-hydrogen conversion efficiencies of 70-95%, depending on the type of electrolyser used.

Hydrogen fuelled cars use a similar process, implementing fuel cells to facilitate a reaction between hydrogen gas and oxygen, producing electricity to power the electric motor in the car. The benefits of using fuel cells instead of batteries include being lighter than batteries, and a much shorter time to refuel. A number of Australian governments have announced plans to construct electrolysers as part of a hydrogen fuel cell vehicle project.

The concept of hydrogen seems promising; however, it is still in the early stages of development, as the production of hydrogen through electrolysis still requires electricity in the first place, which today still comes largely from fossil fuels. Although the technology is still somewhat in the development stages, it continues to remain a window into our future, until renewable energy sources become more dominant.

Electric Vehicle (EV) technology is rapidly evolving, with larger batteries, faster chargers and other major advantages being developed consistently. One of the most interesting features of this new technology is bidirectional charging. Bidirectional charging advances past the one-way charging capabilities of older EV’s and allows power to move out of the vehicle as well. Some cars already have this feature; however it has remained largely experimental since its international debut in 2013.

There are three main advantages of bidirectional charging:

½ backup power – using your car as a battery to power your house during an outage;

½ portable power source – use your EV battery to power things on the go, such as a campsite, or even another car;

½ save money – use your car to store energy generated during off peak times and then sell it back to the grid for a little bit of extra money.

As this technology becomes more available and more reliable, many EV manufacturers will start to make it a standard feature in their newer models, with some manufacturers aiming to achieve this as early as next year.

WHAT DOES THE RISING DEMAND FOR ELECTRICITY MEAN FOR AUSTRALIAN BUSINESSES, ESPECIALLY IN THE ELECTROTECHNOLOGY SECTOR? IT’S A CLEAR SIGNAL THAT THE SHIFT TO A LOW-EMISSIONS ECONOMY IS WELL UNDERWAY AND GAINING PACE. FOR THOSE BUSINESSES READY TO ACT, IT IS AN OPPORTUNITY TO LEAD, GROW AND HELP SHAPE THE ENERGY SYSTEMS OF TOMORROW.

We are entering a decade defined by energy transformation. From homes installing rooftop solar panels, to manufacturers investing in energy storage systems, smart grid technologies and electrified fleets, energy consumption across the country is intensifying. This surge is an incentive for further investment and innovation, and for the kind of economic growth that supports businesses of every size.

I see this transition through a pragmatic and optimistic lens. Energy demand is increasing because technology is advancing, expectations are shifting, and sustainability is no longer a side conversation; it is the conversation. What we are witnessing now is the amplification of action. Businesses across Australia are moving beyond intent and into implementation, accelerating the shift toward electrified, low-emissions operations, with urgency and scale.

Global

The United Nations Sustainable Development Goal 7 (SDG 7) calls on countries to ensure access to affordable, reliable, sustainable and

modern energy for all. It is an active framework, shaping policy, investment, and procurement decisions globally.

Australia has the resources, skills, and systems to turn SDG 7 into a national strength. However, it requires action across every business size, from small enterprises electrifying their operations, to large-scale developments integrating solar and battery systems from day one. Each plays a role in reducing reliance on fossil fuels, while creating demand for the products, skills and services offered by the electrotechnology sector.

This is where the opportunity lies. Demand for cleaner power is already embedded in planning approvals, supply chain expectations and ESG targets. Businesses that are adapting now are not reacting; they are positioning themselves to lead, and for this sector, it is exciting times.

Sustainability and profitability are no longer at odds. Businesses that integrate energy-efficient technologies are cutting costs, reducing exposure to volatile energy markets and unlocking new value. From smart lighting and HVAC controls in retail, to large-scale solar and battery solutions in manufacturing, the examples are multiplying across the economy.

Even for smaller operators, access to clean energy is no longer a capitalheavy endeavour. With leasing options, government incentives and smart financing tools, energy upgrades are not only feasible, but they are commercially sound.

With every installation, the demand for electrotechnology professionals rises. The industry is delivering the technical backbone of Australia’s clean energy shift.

What makes this moment particularly powerful is alignment. We have policy momentum at the federal and state levels. We have a growing national awareness that energy security and sustainability go hand in hand. Critically, we have a workforce ready to deliver, but only if we continue to invest in it.

Electrotechnology is no longer a backof-house function. It is a frontline driver of energy resilience, grid stability and emissions reduction. For Australia to keep pace with its energy transition goals, this sector must be supported, with training, innovation funding, and visibility, especially among young people choosing careers.

A future powered by clean energy is not possible without the hands and minds that make it work. Every battery, inverter, control panel and cable installed is part of a larger story, one where trades and technology combine to build something enduring.

We often speak of a sustainable future. However, sustainability is not a destination, it is a daily decision. Every business that reviews its energy use, upgrades its systems, or considers electrification, is contributing to national resilience and growth, for today and for the generations beyond.

When matched with smart supply and skilled labour, rising energy demand becomes an economic advantage – creating jobs, boosting productivity and opening export markets for Australian capability.

We have an opportunity to turn today’s energy pressures into longterm strengths; to not only power our devices, homes and industries, but our global competitiveness. This is the time to act, to invest and to embrace the opportunities.

Lina Altarifi Executive Director of Business Solutions Hub (an initiative of NECA Victoria)

Nataisha Martin NECA ACT & Southern NSW Member Manager

AS WE REACH THE HALFWAY POINT OF THE YEAR, I’D LIKE TO TAKE A LOOK BACK AT WHAT WE’VE ACHIEVED SO FAR.

It’s been a fast-paced, and at times hectic ride, but we sure have accomplished a lot. I look forward to recognising some of these accomplishments at our upcoming awards nights, and hearing about others at our events and catch-ups throughout the remainder of the year. Keep an eye on your inbox for more details about what’s coming up.

NECA technical has received an increased number of enquiries asking about the requirements and risks of installing TPS (ThermoplasticSheathed) cabling around thermal insulation, in particular polystyrene or polyurethane insulation.

Installing TPS cabling touching these types of insulation will cause the plastic outer sheath of TPS cable to deteriorate at an increased rate, leading to a potential risk of fire and electric shock. AS/NZS3001 calls out these risks, stating:

4.7.4.2 Cables in contact with polystyrene or polyurethane insulation

½ cable insulation or sheathing may be compromised by a chemical reaction if it is in contact with polystyrene or polyurethane;

½ cables shall be installed so there is no direct contact between the cable and polystyrene or between the cable and polyurethane;

½ exception: a cable that is manufactured and identified as being suitable for installation in contact with polystyrene or polyurethane is permissible.

Ensure when installing cables touching this type of insulation that you use a TPS cable that has been specifically manufactured to avoid this chemical reaction.

For more information, visit the NECA member portal, or contact NECA technical, on 1300 361 099.

NECA warmly welcomes the Albanese Government’s announcement of a national licensing scheme for electrical trades. This is a major win for our industry, and one that NECA’s National Executive specifically identified as a policy priority. Our association has worked tirelessly, advocating at the highest levels for this reform, to remove unnecessary barriers, reduce red tape, and support a more mobile, responsive, electrical workforce.

National licensing will allow electrical professionals to move across state and territory borders without duplicative licensing processes and fees. This will not only strengthen the industry but also directly address workforce shortages impacting housing construction and clean energy projects – areas where our members are critical contributors.

We commend the Treasurer’s office and the Albanese Government for recognising the value of the electrical industry and for including this reform in the 2025-26 Budget. By working together, we are building a stronger, more productive economy and supporting the skilled tradespeople who power Australia’s future.

NECA made submissions this month (March 2025) in strong support of changes to the definition of a ‘small business employer’ in the Fair Work Act 2009 (Cth) (the Act), which is currently defined as an employer who employs 14 or fewer employees (including regular and systematic casual employees).

NECA has proposed several changes to the Act, in relation to the definition of a small business, which would benefit many NECA members. These are outlined below.

Amend the Act to define a small business employer as one with fewer than 25 employees. This adjustment acknowledges that businesses with up to 25 workers still function as small enterprises, often without dedicated HR or legal resources. Increasing the threshold will extend modest regulatory flexibilities to more businesses, improving compliance and operational efficiency.

Preserve Clarity and Consistency in Definition

Ensure the definition remains simple and does not include unnecessary inclusions, such as non-regular casuals or contractors. Maintaining a straightforward, headcount-based

approach will prevent confusion, and ensure businesses can accurately determine their status.

a

While expanding the small business definition to fewer than 25 employees is a vital first step, the Act should also acknowledge the special circumstances of medium-sized businesses just above that threshold. A graduated approach should extend some small business regulatory reliefs to businesses with up to 75 employees. This could include lower penalty units for certain breaches, slightly extended compliance timeframes, or modified procedural requirements.

Beyond legislative changes, government agencies should increase guidance, education, and advisory services targeted at small businesses. Expanding the Fair Work Ombudsman’s small business helpline, providing tailored checklists, and developing industry-specific resources in consultation with business associations, will help improve compliance outcomes.

NECA supports a balanced approach, that ensures core employee rights remain intact. Expanding the small business definition will not erode essential protections, such as minimum wage entitlements, leave provisions, and protection from unfair treatment. Instead, it will allow small employers to manage compliance more efficiently, while continuing to uphold fair employment practices.

These proposed changes will extend existing small business concessions to a greater number of NECA members’ businesses, providing much-needed relief to those that, despite having 15–24 employees, operate with limited resources, akin to smaller enterprises.

The Fair Work Commission will be reviewing all submissions and will make any changes as they see fit. NECA will keep you up to date on their decisions.

For more information contact NECA Member Services, on 1300 361 099.

Julia Cassar NECA Sydney Metro and Northern NSW Member Manager Nataisha Martin NECA ACT and Southern NSW Member Manager

WELCOME TO THE JUNE 2025 EDITION OF NECA NEWS. IT’S HARD TO BELIEVE WE’VE ALREADY REACHED THE MIDDLE OF THE YEAR!

With the 2025 NECA conference all wrapped up, we’re now busy planning loads of new and exciting events to round out the year. Make sure to keep an eye on your emails to ensure you don’t miss any details of great events, including our upcoming industry dinners and NECA awards nights.

We’re also excited to announce an upgrade to our Chullora Centre of Excellence. This will allow us to increase our training capacity, which we are hoping to take full advantage of in the coming months!

We have recently been advised that Baxters Viatemis ADR Battery Switches (DPS Series) are susceptible to water ingress, causing the product to potentially fail. This product is installed

Makita DGP180ZBK 18V Grease Gun

on prime movers, especially vehicles transporting dangerous goods. If this recalled product fails whilst the vehicle is in motion, it may cause an accident risk to the vehicle, occupants and other road users. Please review the details of the recall and follow the recall instructions for affected vehicles.

Please also note that the Makita DGP180ZBK 18V Grease Gun with 1200mm flexible hose, and the 600mm flexible hose accessory for Makita DGP180ZBK 18V Grease Gun, have been recalled, as repeated bending of the hose tip can create a hole, causing the hose to burst. If this bursts during use, it can cause serious lacerations. Consumers should immediately stop using the grease gun, remove the battery from the gun (and any grease from the barrel), and return the entire tool to a local authorised dealer for a free repair

Baxters Viatemis ADR Battery Switches (DPS Series)

There are two ways an apprentice can progress during their apprenticeship, namely, time-based progression, and competency-based progression. Which way is relevant to your apprentice will depend on the provisions of the applicable award.

Competency-based progression is where an apprentice will only progress once they have demonstrated a certain level of skills and training, as set out in the Award. This method is used for any apprentices covered under the Building and Construction General On-site Award 2020.

Time-based progression focuses on the period of work, with an apprentice advancing to the next level after a period of continuous work (usually 12 months) regardless of any skills and training undertaken. For example, a full-time

apprentice will generally move up a level on the anniversary of their apprenticeship (not the anniversary of their employment with an employer). This method is used for any apprentices covered under the Electrical, Electronics, and Communications Contracting Award 2020.

To ensure you are paying apprentices correctly, check your applicable award to determine if your apprentice’s progression is based on time or competency, and ensure you understand when each apprentice moves levels.

NECA warmly welcomes the Albanese Government’s announcement of a national licensing scheme for electrical trades.

This is a major win for our industry, and one that NECA’s National Executive specifically identified as a policy priority. Our association

has worked tirelessly, advocating at the highest levels for this reform, to remove unnecessary barriers, reduce red tape, and support a more mobile, responsive, electrical workforce. National licensing will allow electrical professionals to move across state and territory borders without duplicative licensing processes and fees. This will not only strengthen the industry, but also directly address workforce shortages impacting housing construction and clean energy projects — areas where our members are critical contributors. We commend the Treasurer’s office and the Albanese Government for recognising the value of the electrical industry and for including this reform in the 2025-26 Budget. By working together, we are building a stronger, more productive economy and supporting the skilled tradespeople who power Australia’s future.

TPS wiring installed around polystyrene or polyurethane insulation

NECA technical has received an increased number of enquiries asking about the requirements and risks of installing Thermoplastic-Sheathed (TPS) cabling around thermal insulation, in particular polystyrene or polyurethane insulation.

Installing TPS cabling touching these types of insulation will cause the plastic outer sheath of TPS cable to deteriorate at an increased rate, leading to a potential risk of fire and electric shock. AS/NZS3001 calls out these risks, stating:

4.7.4.2 Cables in contact with polystyrene or polyurethane insulation

½ cable insulation or sheathing may be compromised by a chemical reaction if it is in contact with polystyrene or polyurethane;

½ cables shall be installed so there is no direct contact between the cable and polystyrene or between the cable and polyurethane;

½ exception: a cable that is manufactured and identified as being suitable for installation in contact with polystyrene or polyurethane is permissible.

Ensure when installing cables touching this type of insulation that you use a TPS cable that has been specifically manufactured to avoid this chemical reaction.

For more information, visit the NECA member portal, or contact NECA technical on 1300 361 099.

While conducting Member Health Checks it’s come to our attention that there are still concerns on completing the Building Commission’s regulated Certificate of Compliance for Electrical Work (CCEW). With more inspectors currently being employed by the Building Commission, they will be investigating electrical contractors’ compliance with the requirements to submit completed CCEWs, and it will be much easier to track, regulate, enforce and fine for non-compliance.

Inspectors recently carried out investigations on regional NSW Contractors, requesting three months’ worth of CCEWs. The amount of electrical work conducted in

a three-month period will differ between contractors. Fines currently sit at $1000 per missing CCEW.

It is a requirement that a CCEW must be provided to the appropriate parties within seven days of the mandatory safety and compliance tests conducted at the completion of electrical work. In all cases, the customer and the building commissioner are to receive a copy, and the local supply authority should also receive one, in specific circumstances.

de-energised for 6+ months

An electrical installation safety inspection must be completed by a qualified electrician on all premises prior to remote re-energisation.

To ensure the premises is safe to re-energise, and for remote connection to proceed, customers will require a copy of the Electrical Installation Safety Inspection Certificate to provide to their retailer.

For more information, contact a NECA technical specialist, on 1300 361 099.

THE HIGH COURT HAS CONFIRMED THAT BUILDERS CANNOT APPORTION LIABILITY UNDER THE DESIGN AND BUILDING PRACTITIONERS ACT 2020.

Anyone working in the construction industry in NSW will be familiar with the ‘statutory duty of care’ imposed by the Design and Building Practitioners Act 2020 (the DBP Act). The Act imposes a duty of care on anyone who carries out construction work to take reasonable care not to cause economic loss. The duty is imposed on head contractors, subcontractors, companies and individuals (including directors of companies in their personal capacity) who carry out construction work. The duty is owed to owners of land and subsequent owners of land, regardless of whether a contract is (or was) in place between those persons.

The Act already made it clear that the duty was non-delegable, but it was readily accepted that the proportionate liability regime under the Civil Liability Act 2002 (the CLA Act) applied to the duty. That is, if you had contracted a subcontractor to carry out works, and that subcontractor caused economic loss, you would only be liable for the portion of the loss which you caused – and if you did little to no work, then this ‘portion’ may be little, to zero. Parties could be forgiven for thinking that this was how the law operated, because section 41 of the DBP Act said so –specifically saying that the part of the Act governing the duty of care was “subject to the Civil Liability Act 2002.”

Nevertheless, the High Court, in Pafburn Pty Limited v The Owners – Strata Plan No 84674 [2024] HCA 49, had other ideas. The High Court held that developers and builders in NSW cannot apportion blame for a breach of the statutory duty.

If you engaged a subcontractor whose works are defective and likely a breach of the statutory duty of care, you will have to bring a cross claim, meaning a greater litigation cost burden, along with you being the party who takes the insolvency risk should that subcontractor be unable to meet judgment should it be found liable. In other words, if the subcontractor breached its duty of care, so did you so if the subcontractor cannot pay, you pay. You also bear the risk of being limitation barred. Claims for breach of contract need to be brought within two years of when the contribution action accrued under s26 of the Limitation Act.

All of this is in circumstances where the DBP Act specifically says that the duty is only owed to owners of land; meaning that subcontractors do not even owe a duty to head contractors under the DBP Act.

Subcontractors owe the statutory duty of care to owners of land as defined in the DBP Act, so an owner of land is within its rights to sue you direct for a breach of the statutory duty of care, even if you had no direct contract with the owner.

Nevertheless, subcontractors enjoy a practical layer of protection from head contractors in this regard. If you contracted with a head contractor and the plaintiff

elects to just sue the head contractor (and not you), the head contractor must pursue you directly for the losses.

If you caused the loss, you will still be responsible, but you enjoy the benefit of the head contractor having to join you to the proceedings and if there are any issues with the head contractor’s claim (including limitation issues), you may be protected from liability to the owner altogether. Further, if the head contractor was involved in your works, including supervision, they will likely absorb some of the liability for that involvement. In circumstances where subcontractors may only have a smaller role in a project, the works, and even the contract itself, may be less well-documented and all of this makes it harder for the contractor to prove a case against you.

Note that all of this relates to the statutory duty of care under the DBP Act. The head contractor may still have a very strong claim against you via its contract.

This serves as yet another reminder of the importance of carefully reviewing and negotiating your contracts, to ensure that roles and responsibilities are clearly defined and risks managed – particularly with regards to any liability which cannot be passed on.

Because you do not want the buck stopping with you, or returning to you uninvited.

For further information on this matter, please contact NECA Legal on 1300 361 099.

Our new online training platform, NECALearn, is now live and has been well received by our industry. The online SafeWorkNSW-compliant silica course has been very popular, with a wide variety of companies now accessing this training, from majors, purchasing hundreds of ‘seats,’ to micro businesses, purchasing just one or two.

The system can accommodate a wide range of users and their inherent demands, with new courses being continually added to the platform.

A ‘Manual Handling’ course was added shortly after the release of the program, and was well received, with over 60 seats booked in the first week. We have also submitted an application to CBOS Tasmania for funding to support the development of three more NECALearn courses.

The Centre of Excellence in Chullora has now exceeded its original capacity for 30 apprentice classes each week, following strong industry demand for our apprentices and training places. A refurbishment is planned for later this year, which will relocate the canteen to the ground floor, freeing up its current location for three new classrooms. This will enhance our capacity for teaching, and take our Chullora centre to full utilisation.

NECA Training NSW continues to make strong progress across apprentice training, post-trade delivery, and content development. Operational improvements, facility upgrades, and engagement with industry partners position us well to meet our 2025 targets and future-proof our programs.

Our ACT team continues to provide a mix of day-release and block training for apprentices, supporting the needs of NECA’s regional members. This year we commenced two new electrical day release classes, one electrical block release class, and one electricity supply industry block release class at our ACT campus. We also commenced a third class at our South Coast training centre.

In addition to their training commitments, our Certificate III trainers have been heavily involved in the re-development of the Certificate III Electrician qualification training, delivery, and assessment materials.

Despite the ACT Government deciding not to continue the ‘Future Skills for Future Jobs’ initiative, which previously funded our Certificate II Pre-Apprenticeship program delivery, the program continues to be very popular amongst secondary school students and provides a stream of potential candidates for our apprenticeship positions. NECA believes it’s important for this program to continue, and have consequently remodelled the syllabus into a shorter (one week), more economically viable, course. We have recently submitted an application to the NSW Government for additional funding to support five pre-apprenticeship courses, two of which will be delivered in regional NSW, at Queanbeyan and Moruya.

Following the success of our 2023 and 2024 programs, the NSW Government has funded an expanded schedule of this program, which targets students in year 10-12 by providing pre-apprenticeship training and industry work experience. Students completing the program are then encouraged to apply for apprenticeships with NECA. In 2025, our coverage has been extended to include the NSW South Coast, where we will build relationships with local schools and encourage suitable students to consider a career in our industry, commencing with a NECA apprenticeship.

NECA Electrical Apprenticeships employ quality apprentices and place them with host companies for any amount of time from 3 months to 4 years.

Becoming a host company means that you pay a fixed charge out rate, whilst we take on all the added costs, responsibilities and risk.

Build your future: 97% of our graduating apprentices are employed by their host on completion.

NECA ELECTRICAL APPRENTICESHIPS PROVIDE Advertising

Recruitment

Interviews and selection

Medicals including colour blindness test

Payroll

On-going monitoring and mentoring by licensed electrical field staff

All administration and paperwork

TAFE (monitoring results)

COSTS INCLUDED IN THE CHARGE OUT RATE

Annual Leave days

Sick days

Public holidays

TAFE days (36/yr)

TAFE fees

Superannuation

Uniforms and PPE

Workers Compensation

Connect with your local NECA centre

ACT (02) 6280 5580

NSW (02) 9744 2754

QLD (07) 3276 7950

WA (08) 6117 3017 necatraining.com.au

With a looming skills shortage of 30,000+ electricians in Australia, skilled migration will be part of the solution. Whilst NECA will continue to lead the way with recruitment and training of young Australians to support our future workforce needs, we can also assist NECA members considering adding a skilled migrant to their team.

NECA Training supports the skilled migration pathway for international electricians, as we now offer the Australian Context Gap training required for licencing overseas-trained electricians.

Around the world, there is a broad range of electrical training standards; however, to work as a practicing electrician in Australia, you must be properly trained in Australia’s wiring rules and Codes of Practice. Australia has a formal pathway for skilled migrants to have their skills recognised, governed by the Federal Agency, Trade Recognition Australia (TRA). Full details are available on the TRA website, but, to summarise, the pathway follows three broad steps:

1. Aspiring migrants complete an Overseas Trade Skills Recognition (OTSR) process in their home country before coming to Australia. These OTSR’s must be delivered by a TRA approved Registered Training

Organisation (RTO) in the applicant’s home country. Approved OTSR providers for electricians already exist in a number of countries around the world, notably in the United Kingdom and Ireland.

2. Having acquired an OTSR certificate, the individual will then need to apply for a visa to come to Australia and work – a process greatly assisted by having the OTSR.

3. When they arrive in Australia, they will need to complete ‘Australian Context Gap Training,’ which teaches and assesses Australia’s wiring rules and local work practices. NECA Training is licenced to deliver this training and is currently offering it in Sydney and Canberra. While doing this training, the new migrant is allowed to work under the supervision of a licensed electrician, similar to a fourthyear apprentice. All workplace experience is recorded through the ‘Exemplar’ profiling system, again, similar to Australian apprentices.

This is the official pathway for skilled migrants to achieve an Australian Electrical licence. NECA continues to defend the high bar set for electrical licensing in Australia, as our standards underpin quality work and the safety of our workers, infrastructure, and customers.

There are several training providers offering alternate pathways to have skills recognised in Australia. These operators often overuse what is called ‘Recognition of Prior Learning’ (RPL) to issue Australian Certificate III trade qualifications. Sometimes, these providers issue the Certificate III after only days or weeks, via a superficial RPL process, or in some instances from submitted videos, in exchange for up-front payments by the applicant. These Certificate IIIs alone do not entitle the applicant to work, as they still require an Australian license. License applicants coming through a non-apprenticeship pathway are required to apply to an industry-led panel to ensure they have the right skills. Following the RPL pathway in this way most often leaves the applicant several thousand dollars worse off, and still in need of training to qualify for a license.

Reach out to NECA Training in Sydney or Canberra.

ACT & Regional NSW 02 6280 6533 courses-act@necatraining.com.au

Sydney 02 9188 4424 skills@necatraining.com.au

NECA Training has purpose built state-of-the-art facilities in Fyshwick (ACT) and Chullora (Sydney) providing the latest digital IP equipment and HANDS-ON training with high end technical resources.

If you wish to gain the ACMA registration, by choosing to train with NECA you’ll have access to our holistic facility. Experienced trainers deliver the courses so you can be up to date in this exciting and ever evolving industry. Learn best practices, improve your productivity, expand your knowledge and grow your career.

NECA TELECOMMUNICATIONS PROVIDE

Nationally recognised training

Specialists in the telecommunications and electrical industries

Train with professionals, someone you can trust NECA provides training for the industry by the industry

Anyone can enrol (including non-members)

TELECOMMUNICATIONS COURSES AVAILABLE

Open Registration Courses

Structured Cabling (Cat 5-7)

Coaxial Cabling

Optic Fibre Terminations

Open Registration Exam for Electricians

Working Near Electricity Network – Initial

Working New Electricity Network – Refresher

More courses available WE ARE NOT-FOR-PROFIT | PASSING THE BENEFITS ON TO YOU

Visit our website for more details, course times and costs.

course times and costs.

ONLINE necatraining.com.au

NSW (02) 9188 4424 skills@necatraining.com.au

Online necatraining.com.au

NSW (02) 9188 4424

ACT (02) 6280 5580 act@necatraining.com.au

ACT (02) 6280 5580

Nicole Fietz NECA QLD Membership and Partnership Officer

WELCOME TO THE JUNE 2025 EDITION OF NECA NEWS. AT THIS TIME OF THE YEAR, WE’D LIKE TO TAKE THE OPPORTUNITY TO REFLECT ON HOW FAR WE’VE COME, AND TO SET OUR BAR HIGH FOR WHAT WE WILL ACHIEVE BY THE END OF THE YEAR.

NECA is pleased to announce our new Membership and Partnerships Officer for Queensland, Nicole Fietz. Nicole brings a wealth of experience to our industry, and we couldn’t be more excited to have her as part of the team. Read on to find out more!

Our Member Knowledge Base has just received an upgrade as well, with a new look, simpler navigation and more information than ever before. Head to our website now to explore what we have prepared for you.

Welcome Nicole

NECA QLD would like to officially welcome Nicole Fietz, our new Membership and Partnerships Officer. Nicole spent over 15 years building her career in the mining, manufacturing, industrial safety, and electrical wholesale industries. She was formerly the National Sales Manager at Cirlock Pty Ltd, a Queensland-based Australian manufacturer of lockout/ tagout equipment, where she played a key role in driving business growth and development, managing client

relationships both here in Australia and internationally. Her work helped position Cirlock products in marketplaces all over the world.

Nicole joined the NECA QLD team in April 2025, to focus on building strong industry connections, growing partnerships, and supporting the electrical community throughout Queensland.

An electrical contractor has been penalised after failing to follow proper safety regulations during electrical testing at a power station, resulting in a worker receiving an electric shock from an exposed, energised conductor. The contractor breached sections 14 and 16 of the Electrical Safety Regulations Act 2013, by not ensuring that equipment was properly de-energised, and not preventing inadvertent re-energisation during the job.

As a result, the Electrical Licensing Committee has imposed conditions on the contractor’s license, including mandatory safety training and an independent safety audit. The contractor was fined $1,000, in addition to receiving a $3,600 infringement notice from the Electrical Safety Office (ESO).

This incident underscores the critical importance of following safety protocols when working with electrical systems. Electricians are reminded to always ensure equipment is fully de-energised and safeguarded against accidental re-energisation, to prevent accidents and ensure a safe working environment.

For safety information, please contact a NECA Safe specialist on 1300 361 099.

NECA QLD would like to inform all members that copper prices have recently increased by up to 5% subject to supplier and cable type. This rise in raw material costs could significantly impact project budgets, supplier pricing, and contract margins. It’s critical that contractors and businesses factor

this into upcoming quotes and review their terms and conditions to ensure adequate coverage for potential cost fluctuations. Helping to set appropriate terms and conditions is just one way NECA Legal can help you keep your margins profitable.

½ check pricing with your suppliers regularly;

½ include rise and fall clauses in contracts where possible;

½ communicate with clients early to avoid disputes or unexpected variations;

½ ensure wording of variation clauses allow for market rates in valuation of the variation works.

Staying informed and proactive will help safeguard your business during these shifts. For support or advice, reach out to the NECA QLD team on 1300 361 099 — we’re here to help you stay ahead.

In the electrical industry, managing hazards effectively is key to ensuring worker safety and compliance with regulations. Under the Work Health and Safety Regulations 2022, certain highrisk activities require the preparation of a Safe Work Method Statement (SWMS). A SWMS outlines the hazards associated with a specific task, and how they will be controlled, ensuring workers are safe and the contractor is compliant with regulations.

The WHS Regulations mandate that a SWMS be developed before starting any high-risk construction work. This includes the below activities:

½ working at heights;

½ work on a telecommunication tower;

½ wemolition of an element of a structure that is load-bearing;

½ works likely to involve disturbing asbestos;

½ works involving structural alterations or repairs that require temporary support;

½ work in or near a confined space;

½ working in or near a shaft or trench deeper than 1.5m or a tunnel;

½ use of explosives;

½ work on or near pressurised gas mains or piping;

½ work on or near chemical, fuel or refrigerant lines;

½ work on or near energised electrical installations or services;

½ work in an area that may have a contaminated or flammable atmosphere;

½ work involving tilt-up or precast concrete elements;

½ work on, in, or adjacent to, a road, railway, shipping lane, or other traffic corridor in use by traffic other than pedestrians;

½ work in an area with movement of powered mobile plant;

½ work in areas with artificial extremes of temperature;

½ work in or near water, or other liquid, that involves a risk of drowning;

½ diving work.

For all other construction tasks that don’t meet these high-risk criteria, while a SWMS is not mandatory, PCBUs

must still manage risks by eliminating or minimising hazards where possible. Developing and using a SWMS for non-high-risk activities is a proactive approach that ensures workplace safety and regulatory compliance.

SWMS are available on MKB, and for additional SWMS, you can access the NECASafe Generator via subscription, which provides full access to NECA’s comprehensive safety document library. Alternatively, these resources can also be purchased via the NECA Online Store.

If you are aiming for ISO certification in Quality (ISO 9001:2015), Environment (ISO 14001:2015), or OH&S (ISO 45001:2018), NECASafe is here to guide you through the process. We’ll work closely with your business, setting up a comprehensive safety management system, to ensure you’re fully prepared for a successful audit and certification!

With our NECASafe Empower platform, we’ll create a tailored safety management system designed specifically for your needs. Plus, we’ll help you build an Integrated Management System (IMS) document that aligns with certification standards.

Ready to take your business to the next level? Let NECASafe help you get ISO-certified!

Please contact NECA Safe on 1300 361 099 for additional information.

NECA technical has received an increased number of enquiries asking about the requirements and risks of installing TPS (Thermoplastic-Sheathed) cabling around thermal insulation, in particular polystyrene or polyurethane insulation.

Installing TPS cabling touching these types of insulation will cause the plastic outer sheath of TPS cable to deteriorate at an increased rate, leading to a potential risk of fire and electric shock. AS/NZS3001 calls out these risks, stating:

4.7.4.2 Cables in contact with polystyrene or polyurethane insulation

½ cable insulation or sheathing may be compromised by a chemical reaction if it is in contact with polystyrene or polyurethane;

½ cables shall be installed so there is no direct contact between the cable and polystyrene or between the cable and polyurethane;

½ exception: a cable that is manufactured and identified as being suitable for installation in contact with polystyrene or polyurethane is permissible.

Ensure when installing cables touching this type of insulation that you use a TPS cable that has been specifically manufactured to avoid this chemical reaction.

For more information, visit the NECA member portal, or contact NECA technical on 1300 361 099.

A confined space and a restricted space differ primarily in their level of hazard and accessibility. A confined space is an area that is not designed for continuous occupancy, and it typically poses significant safety risks. Working in confined spaces likely involves entry permits, appropriate isolations, lock outs and tag outs, emergency procedures, ventilation prior to entry, appropriate gas monitors, and entry and exit procedures. These spaces may contain hazardous gases, a lack of oxygen, or other dangerous conditions, such as toxic fumes. Examples of confined spaces include tanks, manholes, tunnels, pipelines and other similar enclosed areas. The key characteristic of a confined space is the potential for serious health hazards or life-threatening conditions, making special precautions, such as atmospheric testing and proper ventilation, necessary before entry.

On the other hand, a restricted space refers to an area that is difficult to access, or requires specific entry protocols, but does not necessarily involve hazardous atmospheric

conditions. Examples of restricted spaces include roof spaces, attics, or crawl spaces. These areas are typically cramped, or have limited access points, but they do not pose the same immediate danger as confined spaces, unless specific hazards exist, such as poor ventilation or structural risks.

While both types of spaces require safety precautions, confined spaces generally require more stringent control measures, due to the potential for life-threatening conditions.

For more information, please contact a NECASafe Specialist on 1300 361 099.

From 1 April 2025, water equipment is prescribed electrical equipment under Queensland’s Electrical Safety Regulation 2013.

This means extra low voltage water equipment – such as pool lights and pumps, to be installed in pools, spas, baths and paddling pools – will be subject to the same requirements

as other electrical equipment under Queensland’s electrical safety framework. Water equipment means any apparatus, appliance, cable, conductor, fitting, insulator, material, meter or wire that:

½ is operated or used for controlling, generating, supplying, transforming or transmitting electricity at extra low voltage;

½ can only be operated or used when connected (whether permanently or by plug) to an external source of electricity (such as 230v supply);

½ is designed for use in the interior of the container of a swimming pool, paddling pool, spa or bathtub.

Water equipment includes equipment such as pool lights and pumps, but does not include portable battery powered toys, battery powered pool cleaners, submersible phones and waterproof camera devices.

For more information, please contact a NECA specialist on 1300 361 099.

Larry Moore NECA SA/NT Executive Director

WE ARE ALREADY HALFWAY THROUGH THE YEAR, AND IT IS SHAPING UP TO BE ANOTHER VERY BUSY ONE! IT IS FANTASTIC TO HEAR THAT SO MANY OF OUR MEMBERS ARE FLOODED WITH WORK – IT APPEARS THAT THE INDUSTRY IS BOOMING, WHICH IS FANTASTIC FOR BUSINESSES, SMALL AND LARGE.

On Wednesday 9 April 2025, the Specialist Contractors Association (of which NECA SA/NT is a member and provides the secretariat) held their Women in Construction Annual Networking Event at the Kent Town Hotel, with the theme, ‘female engagement in the construction industry.’ The event saw 125 attendees come together to celebrate the fantastic women who are a crucial part of the businesses they work for within the South Australian building and construction industry.

The guest speakers – Senator Marielle Smith, South Australian Skills Commissioner, Cameron Baker, and the Honourable Connie Bonaros, MLC – gave insightful presentations regarding the importance of attracting, retaining, and empowering women to work in the construction industry, to ultimately create

a broader, more inclusive, more innovative, and more successful workforce.

The panel session that followed, facilitated by NECA SA/NT’s Jamie Phillips and NFIA’s Stephanie Hansen, featured:

Cameron Baker

South Australian Skills Commissioner

Holly Willcox

CEO of the Construction Industry and Training Board SA

Emily Quinton

Construction Services

Manager at Lendlease

Emma Bradshaw

Electrician at RNW Fire Services

Elizabeth O’Connor

Contracts Manager at O’Connors

Bridget Dunkin

Field Officer at Electro Careers & Apprenticeships

This interactive panel session was extremely informative for the audience, discussing the event’s theme from each panellist’s unique perspective and experience. The conversations between these individuals prompted attendees to consider alternative methods, such as providing primary school aged children the opportunity to safely engage with tools and construction materials, and educating highschool teachers about the benefits of an apprenticeship and becoming a tradesperson, to promote female engagement in the industry.

The event was an outstanding success, with all attendees providing great feedback on the quality of the content and the fantastic networking opportunities available. We thank those who attended for taking the time to be there, and we sincerely thank our presenters and panel for their invaluable input.

The NECA National Conference made its international return this year, with 200 delegates converging on the picturesque town of Kyoto from 7-10 May. Over the course of the four days, Australia’s electrical and communications contractors engaged in some thought-provoking debates, workshops, discussion panels, keynote presentations, and fireside chats, but also had the opportunity to discuss the various challenges and trends that continue to emerge within the sector.

Attendees also had the opportunity to visit a selection of Kyoto’s incredible landmarks, including the Fushimi Inari Shrine and the Kiyomizu Temple, and enjoy a taste of Japanese culture, by dressing in traditional Happi coats for the closing night party and experiencing traditional Geiko and Maiko singing and dancing performances.

Stay tuned for more information about NECA’s 2026 National Conference! We have a sneaky suspicion it is going to be epic!

Our Excellence and Small Business Awards nominations for 2025 have now closed, with Apprentice Awards nominations open until Friday 4 July. We are currently working through the extensive judging process and are thoroughly enjoying reading your submissions.

The Excellence, Small Business, and Apprentice Awards celebrations will be held at our Industry Gala Dinner on Friday 12 September, in the beautiful Halls CD at the Adelaide Convention Centre. We certainly hope our members, sponsors, and industry representatives will join us for this excellent event, that showcases some of the brilliant work being completed in our industry, as well as our fabulous small businesses and high-achieving apprentices. It also provides a great opportunity to enjoy some fantastic food, wine and live entertainment with your peers.

Our group training organisation, Electro Careers & Apprenticeships (Electro CA), has recently clocked over 200 apprentices – a huge achievement for Craig, Brett, and the team!

Electro CA employs new apprentices every 6-8 weeks, depending on industry requirements. NECA SA/NT members receive a discounted rate on apprentices employed through Electro CA!

If you are looking to hire a new apprentice, or would like further information about how Electro CA can assist you and your business, please contact Brett Taylor, Business Development Manager at Electro CA, via brett@electroca.com.au.

For further information or assistance with any of the above, please contact the NECA SA/NT office on (08) 8272 2966.

The NECA SA/NT Roadshow Seminar Series is back in 2025! We will be visiting 17 locations across South Australia from February to May!