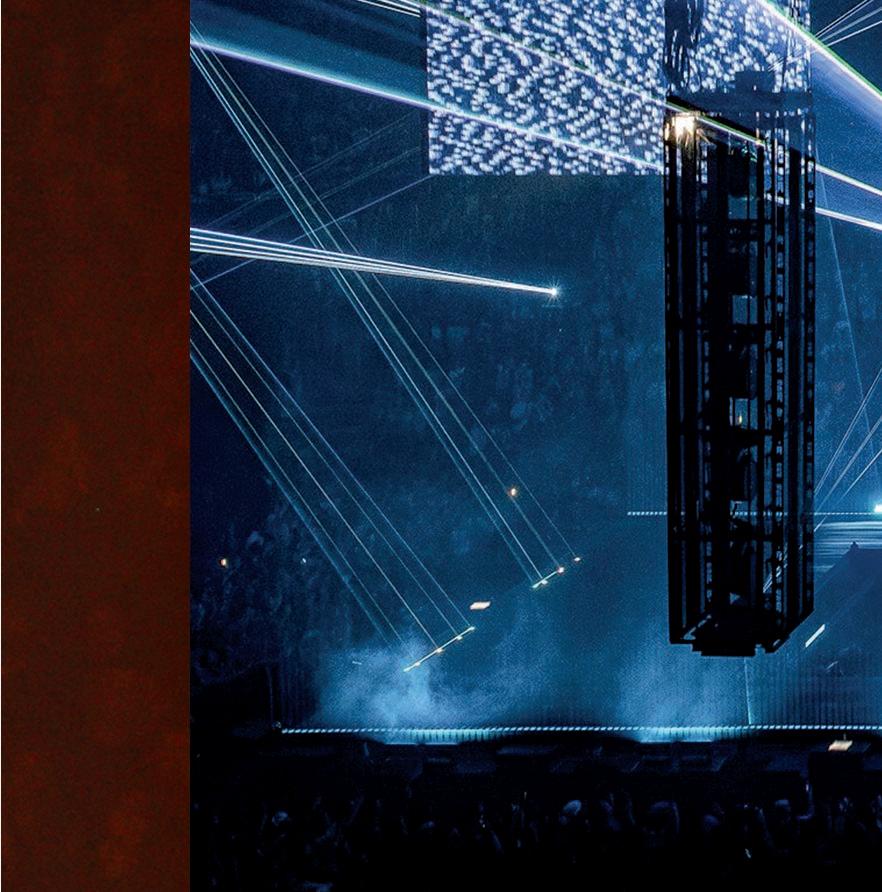

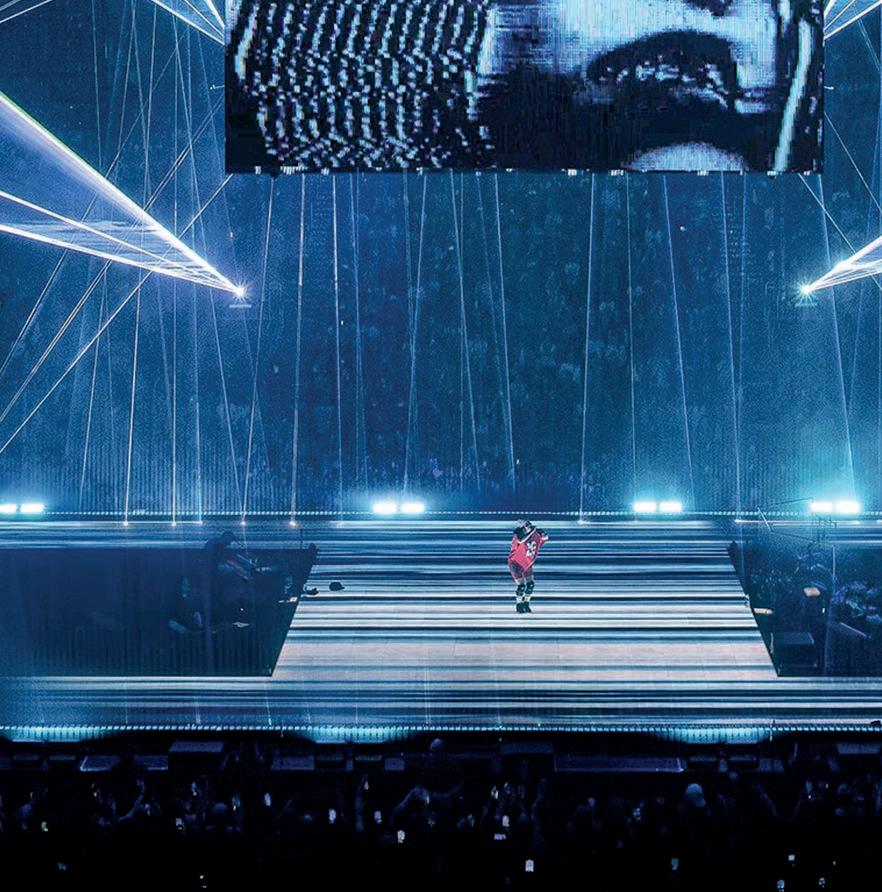

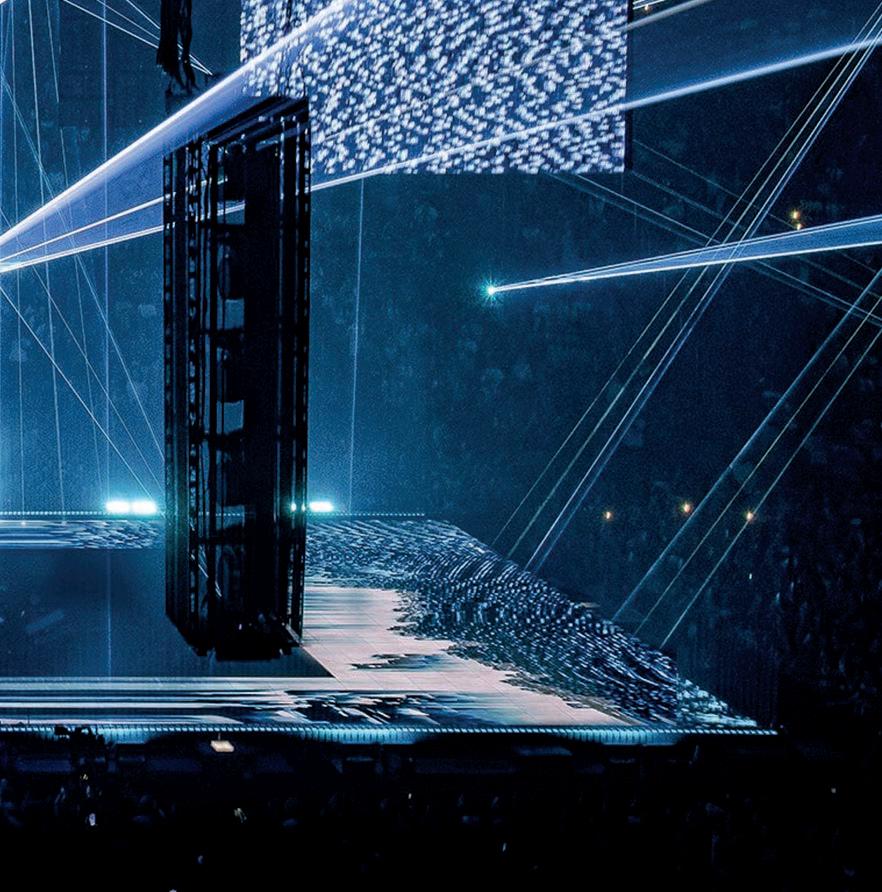

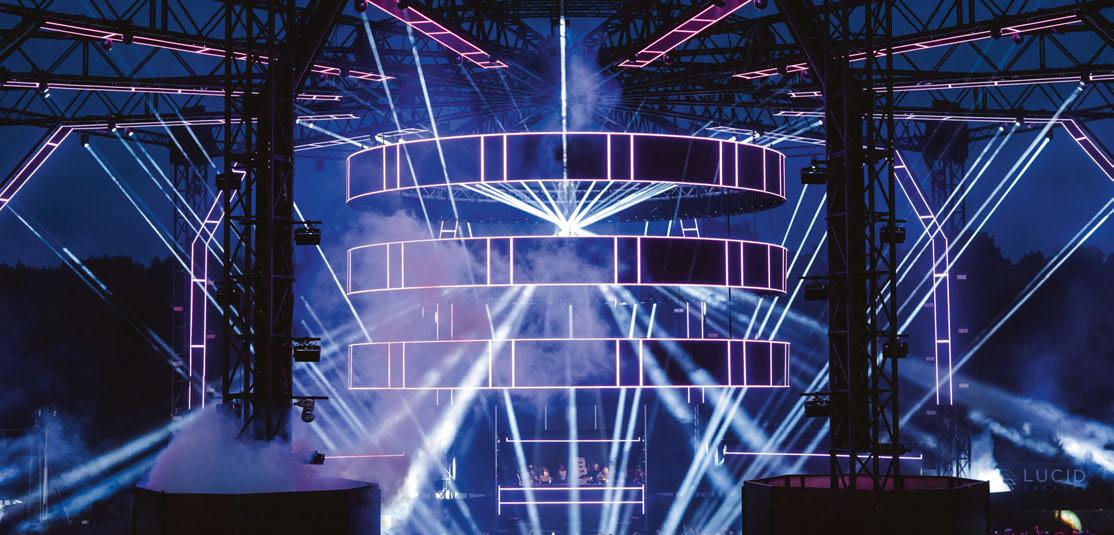

NINE INCH NAILS

A contemporary show design befitting the band’s revered back catalogue

NINE INCH NAILS

A contemporary show design befitting the band’s revered back catalogue

An in-the-round spectacle with production prowess on display from every angle

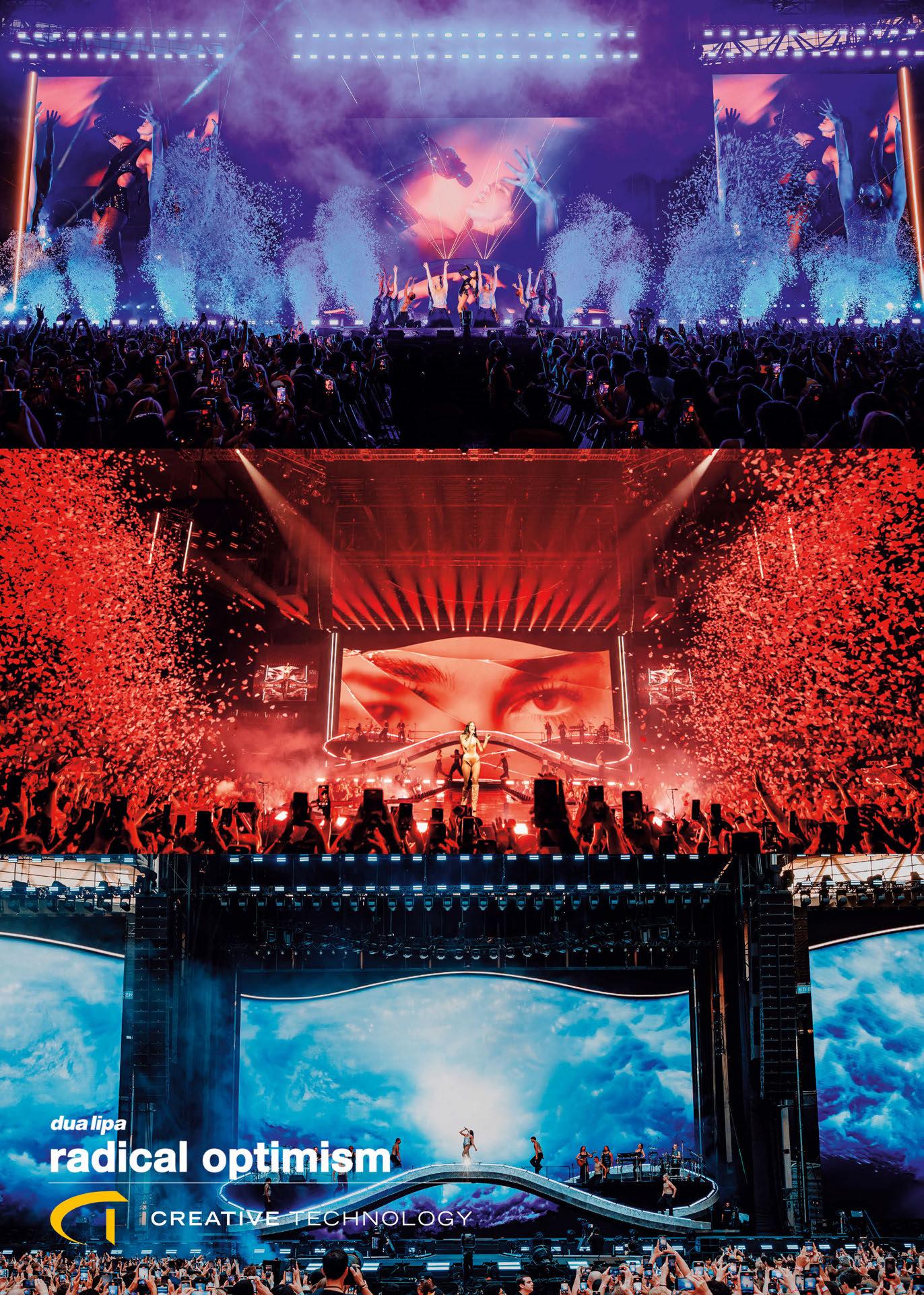

DUA LIPA Crew welfare, inclusivity and innnovation combine on this world-class production

The singer entertains stadiums and arenas, backed by a loyal crew

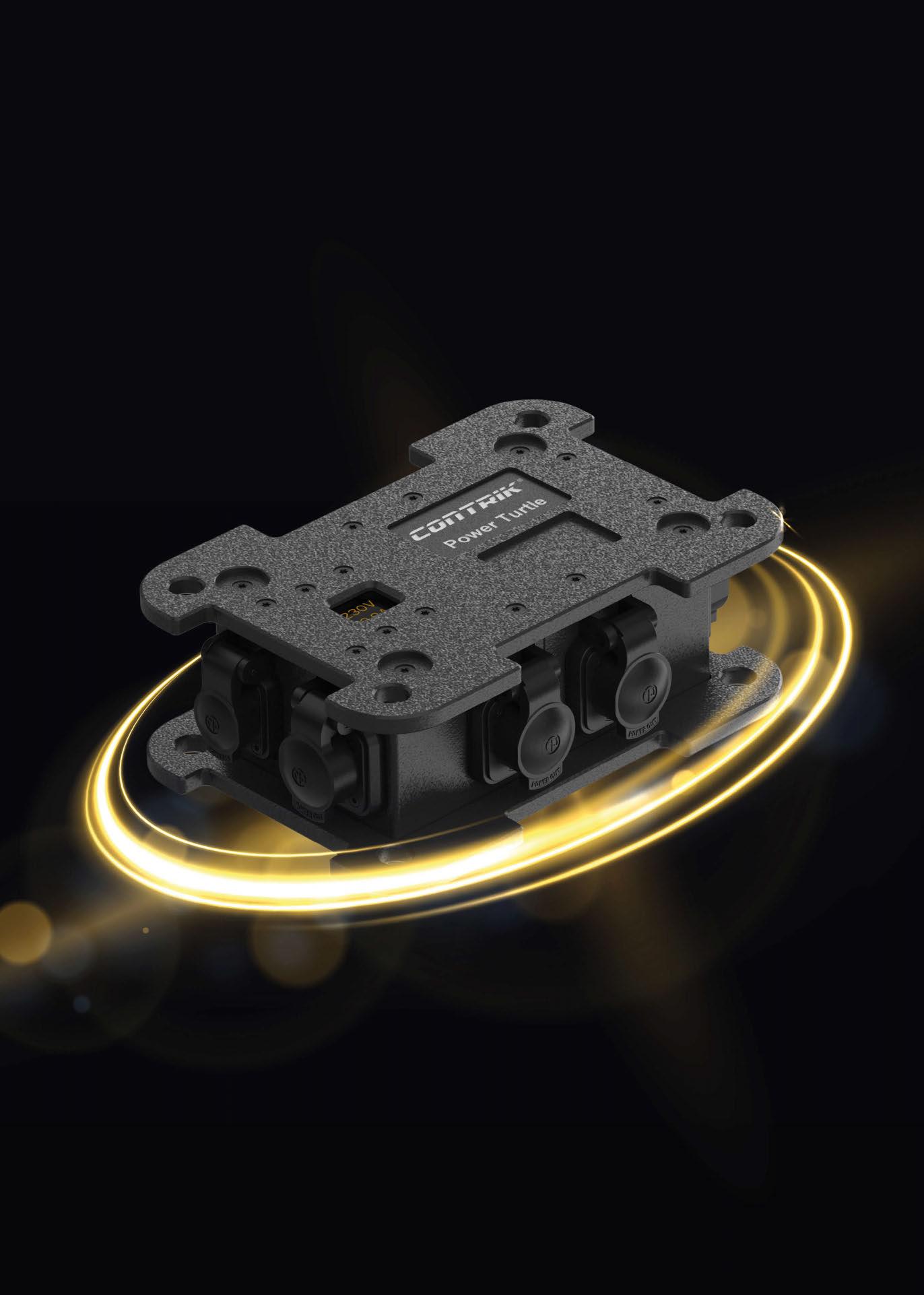

SolaBulb, the new addition to Astera’s Bulb Family, is a zoomable bulb with a 15º–50º adjustable beam, the refined look of a classic Fresnel, power equivalent to a 50 W PAR bulb, and silent, fan-free operation.

As some may have seen in our recent newsletter and LinkedIn posts, we’ve made some changes here at the TPi editorial table. I’m very pleased to say that our own Jacob Waite will henceforth be taking up the mantle of Editor of TPi Magazine. Having been with us since 2017, he has firmly established himself within the industry, bringing a ‘no stone left unturned’ attitude to every assignment he undertakes. Armed with his trusty notebook, he’s more than ready to jump into the driving seat of the magazine, and I’m sure he will make the title stronger than ever.

Meanwhile, I’ll be taking on the role of Managing Editor of TPi and its associated brands. I’ll be looking at the strategic direction of the title and our associated events as we aim to expand the offering that we provide to the sector.

Finally, Alicia Pollitt, who has been with TPi for over two years, has been promoted to Assistant Editor. With an unquestionable passion for the industry, in her new role, she will be aiding more in the production elements of both the magazine and our online platforms.

Elsewhere, Peter Iantorno remains as Editorial Director, heading up TPiMEA Magazine and ensuring editorial standards are maintained across the group. And Jack Needham – our newest member of the editorial family – is getting his feet under the table as Head of Content for Festival Insights | UK Festival Awards.

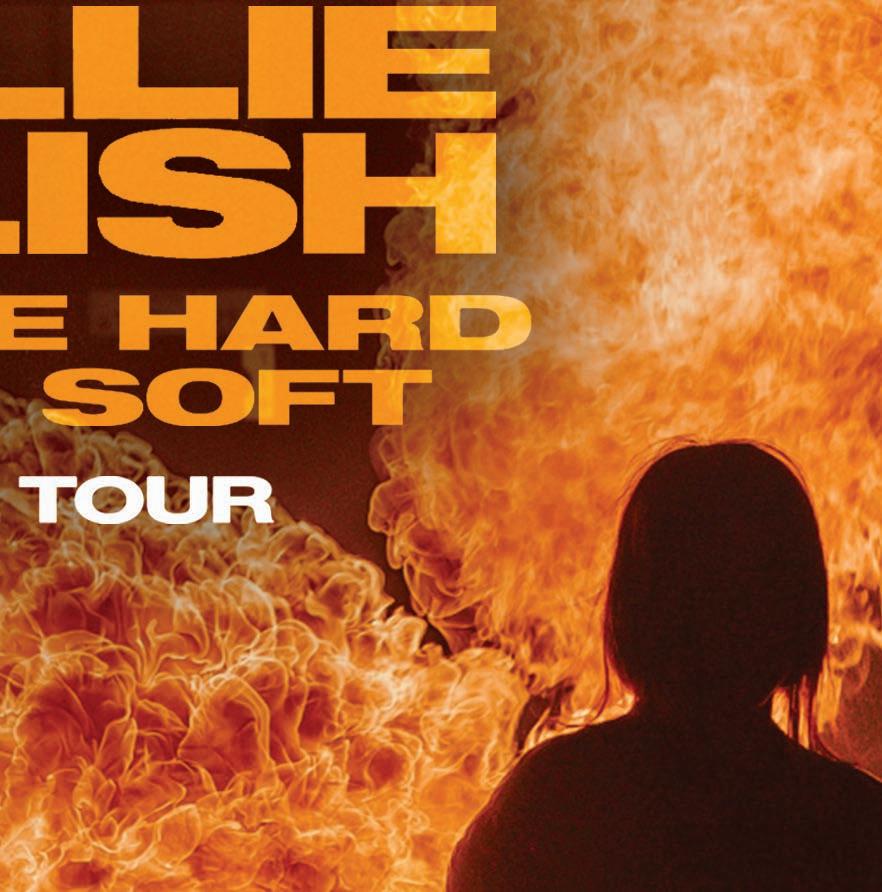

Despite the staff shuffle, we’ve still managed to keep pace with this very busy summer season. I paid a visit to London to witness Billie Eilish’s HIT ME HARD AND SOFT: THE TOUR. From the production’s dedication to sustainable practices to deploying cutting-edge video technology, the tour is more than worthy of this issue’s cover.

From one previous Glasto headliner to another, Jacob got to document Dua Lipa’s Radical Optimism Tour as it made its way through arenas and stadiums throughout the UK. As well as keeping pace with the artist’s growing cultural capital; the production maintained a ‘paying it forward’ ethos, with crew welfare and shadowing opportunities all baked into the touring practices.

Meanwhile, Alicia served up a cocktail of industrial metal and pop as she caught up with the production teams behind Nine Inch Nails and Robbie Williams. She also spoke to sound engineer, Jon Burton about the Healthy Ears, Limited Annoyance (HELA) Certification and why more in the industry should be taking notice of hearing health.

In addition, we check-in with several industry insiders about some of the notable trends from this year’s festival season, while profiling the sustainable steps taken by Unusual Rigging.

As t he leaves begin to change, we are set for the next few months of trade shows, company visits and, of course, the arena touring season kicks into gear.

We’re also busy working on our own events. GTL Sessions 2026 will be hosted in a brand-new location in Málaga on 28 April to 1 May. Autumn ‘26 will also see us take the event to the other side of the pond with GTL Sessions: The Americas. More details to be announced soon.

Before I forget, tickets are now on sale for TPi Awards 2026. This will be our 25th anniversary, so get your glad rags at the ready, this will be one you’ll not want to miss.

Until next time...

Stew Hume Managing Editor

Issue #289

September / October 2025

Managing Editor Stew Hume Tel: +44 (0)161 476 8360

Mobile: +44 (0)7702 054344 e-mail: s.hume@mondiale.co.uk

Editor Jacob Waite

Tel: +44 (0)161 476 8360

Mobile: +44 (0)7592 679612 e-mail: j.waite@mondiale.co.uk

Assistant Editor Alicia Pollitt Tel: +44 (0)161 476 8360 Mobile: +44 (0)7508 441986 e-mail: a.pollitt@mondiale.co.uk

Commercial Director Fran Begaj Tel: +44 (0)161 476 8360

Mobile: +44 (0)7852 336728 e-mail: f.begaj@mondiale.co.uk

Senior Account Manager Matilda Matthews Tel: +44 (0)161 476 8360 Mobile: +44 (0)7413 555978 e-mail: m.matthews@mondiale.co.uk

Account Manager Tom Dyson Tel: +44 (0)161 476 8360 Mobile: +44 (0) 7306505230 e-mail: t.dyson@mondiale.co.uk

Account Manager Sophie Edwards Tel: +44 (0)161 476 8360 e-mail: s.edwards@mondiale.co.uk

Digital Content Manager

James Robertson Tel: +44 (0)161 476 8360 Mobile: +44 (0)7725 475819 e-mail: j.robertson@mondiale.co.uk

Marketing and Events Manager Alice Clarke Tel: +44 (0)161 476 8360 Mobile: +44 (0)7752 392465 e-mail: a.clarke@mondiale.co.uk

Marketing and Events Assistant Charlie Moore Tel: +44 (0)161 476 8360 c.moore@mondiale.co.uk

Editorial Director Peter Iantorno Tel: +44 (0)161 476 8360 Mobile: +44 (0)7763 233637 e-mail: p.iantorno@mondiale.co.uk

Chief Executive Justin Gawne Tel: +44 (0)161 476 8360 Mobile: +44 (0)7768 850767 e-mail: j.gawne@mondiale.co.uk

Accounts Lynette Levi / Sarah Healey: ar@mondiale.co.uk Mondiale Group Chairman Damian Walsh

Graphic Design and Production Dan Seaton: d.seaton@mondiale.co.uk

Jez Reid: j.reid@mondiale.co.uk

Cover Billie Eilish by Henry Hwu

Printed By Buxton Press • www.buxpress.co.uk

Annual subscriptions (including P&P): £42 (UK), £60 (Europe), £78/$125 (RoW).

Subscription enquiries to:

Subscriptions, Mondiale Media Limited, Strawberry Studios, Watson Square, Stockport, SK1 3AZ, UK. Tel: +44 (0)161 476 5580 e-mail: subscriptions@mondiale.co.uk www.tpimagazine.com www.tpiawards.com www.gtlsessions.com

Total Production International (TPi)

The artist’s latest production blends cinematic style and awe-inspiring automation, ensuring the focus remains on the performance.

OBITUARY

12 Remembering Craig Sherwood.

EVENT FOCUS

14 Martin Professional hosts the ColorLab: Innovation Panel.

16 Pulp and their crew celebrate the band’s legacy while pushing creative boundaries.

22 Behind DI-RECT’s farewell shows, assembled by local talent.

28 Bill Sheppell discusses his approach to mixing Shakira.

PRODUCTION PROFILE

54 NINE INCH NAILS

An innovative tour befitting the band’s back catalogue.

64 DUA LIPA

The well-travelled crew champion a culture of innovation and care.

82 ROBBIE WILLIAMS

The singer’s 80-strong crew stage an ambitious show across varying venues.

FESTIVAL FOCUS

92 Creamfields, Glastonbury Festival, Rock Am Ring and more.

98 Lotje Horvers reflects on Bloc Par ty’s latest touring campaign.

102 Jason Ahn pens the book

Neu roaesthetic Stage Lighting

Design: What Makes Good Light

IN PROFILE

106 Unusual Rigging unveils its new HQ, with sustainability at its heart.

PRODUCTION FUTURES

110 Holly van der Rest reflects on her first tour.

GEAR HEADS

112 SIXTY82 unveils the Olympion Roof System.

113 Lifting the lid on Laserworld’s improved Purelight Series.

FEEDBACK

114 PSA looks back fondly on the busy summer season.

116 Jon Burton provides an insight into the HELA initiative.

118 Touring and Mental Health: The Mu sic Industry Manual goes audible with guest contributors.

BACK CHAT

122 Backup Tech’s new Chair, Lee Dennison takes the hot seat.

Craig Sherwood, a much-loved husband, father and respected production manager, passed away on 16th June, after a short and courageous battle with cancer.

Born in Australia and later making his home in the UK, Craig lived a life full of travel, music, and adventure. Affectionately nicknamed ‘Vlad the Impaler’, he was known for his fierce organisation, sharp wit and ability to keep even the most chaotic tours running on time.

Over the years, he worked with bands including Siouxsie and the Banshees, Depeche Mode, Foreigner, Spear of Destiny, and many more, leaving his mark on festivals and events.

Craig was to see out his career with Hurts and Louis Tomlinson, with whom he worked for more than a decade.

To his colleagues who became his friends, he was more than a manager - he was a steady hand, a wise guide, and a kind friend who made people feel safe and supported wherever they were in the world. Away from the stage lights,

Craig was a man of habits and passions that made him unmistakably himself. A double espresso in hand, dressed in his signature black with square-toed boots, he carried both style and presence wherever he went.

A lover of history, he held a deep fascination with Tamerlane, the 14th Century Medieval Mongol Conqueror, and filled his shelves with books that fed his ever-restless mind. Though he travelled widely, one journey he dreamed of was to Samarkand in Uzbekistan, to visit Tamerlane’s tomb, but sadly, never made it.

Craig leaves behind his wife Dawn, his stepdaughter Naomi, and his children Rosie and Kim Sherwood.

Friends and colleagues from across the world remember him as a legend in his field, a generous companion, and a man whose presence always lifted those around him. His light will be missed though one imagines somewhere, he’s still keeping everything (and everyone) running to time.

TPi heads to Norway to discover how industry trends are influencing Martin Professional and witness HARMAN products in action at ‘Scandinavia’s biggest beach party’.

Industry professionals descended on the Norwegian city of Kristiansand in July to attend a panel theorising on the future of live production and current industry trends, and see the deployment of HARMAN branded products over several stages as part of Palmesus 2025 – a two-day music event like no other.

The Martin Color Lab Innovation panel was moderated by Director of Global Corporate Communications at HARMAN, David Glaubke, and featured guests Mark Buss, Global Product Line Manager at HARMAN International; Henrik Kristensen, Product Manager, Stage Lighting at HARMAN International and Kevin Wetzels, Creative Director at TWOFIFTYK Media.

Wetzels began the discussion by delving into the move to digital for the events industry, and how different aspects such as sound, special effects and visuals stand within their own disciplines but that a move into an amalgamated would push the audience experience further. “For years, professional lighting has been the race for more lumens, but I think the race for the most output in a product is over,” Wetzels said. “We’re looking for products that are more flexible, hybrid, and can be everything at once.”

Speaking from a manufacturer’s perspective, and with an impressive product portfolio to cite from, Buss shared insights on what Martin Professional and the wider

HARMAN banner have learned from endusers, having spent decades developing new technologies.“It’s not about a lighting solution’s feature set, but how the industry wants to be able to control and access them,” Buss said.

“We are more open now as a company, its forms like this that allow us to feed into our own engineering teams, figuring what the trends are, pain points and what the future is.”

Kr istensen cited the innovation of the MAC One as a testament of creative output and functionality. He further highlighted the development of Martin Professional’s patented XIP Technology, which allows fixtures to be used in any setting.

“T he development of XIP Technology disrupted the market and went further than expected. It put pressure on our engineering team to create a product that fits demanding applications,” Kristensen said. “It showed that experimentation and innovation pays off.”

Glaubke pivoted the conversation to discuss budgets in the industry and how productions and creatives can adapt to changing circumstances. Kristensen unveiled that the company were now working on products with planned releases in 2028/9 that have a much longer lifespan. “From a sustainability and ROI point of view, we want our products to have more than five years of market relevance – from the materials they are created with through to how we service products already in the market,”

Opposite: Kevin Wetzels, Creative Director at TWOFIFTYK Media, Henrik Kristensen, Product Manager, Mark Buss, Global Product Line Manager and David Glaubke, Director of Global Corporate Communications.

Kristensen explained. “We do everything to make our service quick, but we also ensure we have parts to fixtures that haven’t existed in our market for 20 years but are still being utilised, to ensure everyone gets the same service, no matter how old the product has been out of production for.”

Gi ven the advance in technology and rising costs of tickets, Wetzels believes that audiences demand more. “It’s probably our biggest headache as production managers, our job is to look at the future and be fortune tellers for what the users want to bring to their audiences. A way in which we’re collaborating with the industry is running technology programmes where we work directly with end users to see what the industry looks like for them whether it be light engine, motor control, or lens technology. We know that customers want something new and exciting that looks amazing, so we discuss with end users, tap into our own knowledge as product managers to come up with cool ideas to bring to the market.”

On t he subject on data, Kristensen added: “We haven’t seen a big push on data in our industry, we have a strong strategy going forward, and our customers are going to see a further push for customers and ourselves,” he shared. “Right now, we design solid products, but the question is are we sometimes overdesigning? This request for information is going to change things going forward.”

Buss concurred: “We used to have more products in a line that would cover all bases, but now we put everything into one product, so it would be interesting to know how it is being used to mitigate risk.”

The panel wrapped up with questions from the audience before a communal march over to the Palmesus Festival site, where attendees got a sneak peek of the main and Cupra stages as well as FOH before the doors opened to thousands of festival revellers.

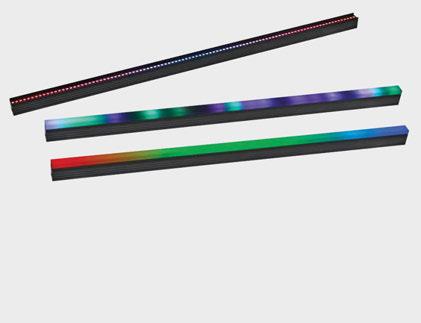

The main stage featured 40 MAC Viper XIPs, 34 MAC Aura XIPs, 32 MAC Aura Raven XIPs, and a pair of P3-275 System Controllers while FOH included 155 VDO Sceptron 20s, 40 VDO Sceptron 10s and a P3-300 System Controller.

The Cupra stage featured 54 Martin VDO Atomic Dot WRMs, 36 VDO Atomic Dot CLDs, six MAC Aura XIPs and a P3-150 System Controller. The HARMAN Professional involvement didn’t stop at lights, the Cupra stage was equipped with JBL VTX-A12 and its VTX-G28 line array systems.

Nordic Rentals was at the heart of the technical package, ensuring visiting production teams – including the likes of Kygo, Fisher, Stormzy and Chase & Status – all had adequate kit.

Nordic Rentals Production Manager, Oscar Olsson has been involved in the technical

delivery of the festival for six years, previously assuming the role of Head of Light and Video at the festival. “It’s my first year doing production at this site,” he stated, proudly. “In Denmark, we like to work together and share our roles – if any department needs help we will always be there, with a helping hand.”

Reflecting on the rig, Olsson waxed lyrical about the legacy of Martin Professional fixtures: “Our house lighting at Palmesus has always included Martin Professional fixtures, they are workhorses and it’s important to have a lamp that works every time. The lamps are so bright, we tend to use lots of haze to help us through the battle of the midnight sun in Norway, but the quality of the fixtures mean that they always cut through.”

As t he sun set on the jam-packed weekend at Palmesus, and dozens of flight cases were rolled out of the festival, the words of Production Futures invitee, Abigail Skelton, who shared her sentiments with Martin Professional in the build-up to the festival were poignant: “I’ve worked with many Martin Professional fixtures at different venues, but there’s always been a degree of separation, so it’s been amazing to spend time with the company and discover the hard work, innovation and guiding principles behind their products.” www.martin.com pro.harman.com www.palmesus.com

In a moment where the thirst for nostalgia tours is unquenchable, eschewing convention for experimentation and presenting something fresh is a neverending pursuit of Pulp and their creative production crew.

On the Summer Solstice, Pulp’s latest arena tour had its curtain call at Manchester’s Co-op Live with a bold, visually rich show that fuses nostalgia with innovation. Featuring bespoke lighting, wacky-waving arm-flailing inflatable tube men, AI-enhanced visuals, an orchestra, and sentiment-rich design, the production celebrates the band’s legacy while pushing creative boundaries.

In keeping with the title of the band’s new album, the aim was the addition of more production and originality.

“T he creative direction from the band is more about what’s artistically interesting and tells the stories in the songs,” Production Designer, Douglas Green said, recalling the project’s creative origins.

The iconic staircase, first seen during Pulp’s legendary 1995 Brixton Academy show, became the creative starting point. A bespoke curved drape, custom-dyed by Blackout, created an intimate, stripped-back setting for the final t rack, A Sunset, following the chaos of unofficial national anthem, Common People

Ahead of the tour, Michael Harpur at Drawn to the Light created technical drawings, which James Sturdy developed into a Syncronorm Depence file for previsualisation. “Collaborating with the team at Drawn to the Light allows

me to work at a speed and scale that’s just unachievable individually. They’re invaluable.” Green s aid. “ Each song looks entirely different because t hey all sound different. Pulp’s music is f ull of pastiche and cultural references, so we approach each song on it’s own terms, and then locate it in the wider arc of the show, scaling it up or down as the moment requires.”

This duality of old and new extended into the visuals. The show opened with black-and-white cutouts of t he band, Jarvis Cocker appearing in silhouette via a lift, before exploding into colour during the track, Spike Island

The visuals were based on a 30-year-old Dazed & Confused magazine shoot by Rankin, and a photograph Jarvis took of a mountain range in Iceland, digitised and animated by More Eyes using an AI Image Upscaler.

Fo r Di sco 2000, vintage Optikinetics Solar 250s were filmed at Insight Lighting and merged w ith modern effects, including AI and Notch. Acrylic Afternoons, a new addition to the set, featured “fizzy, amber-y” hues evoking the lyrics ‘lemonade light’, using pixel-mapped ACME Super Dotlines built into t he floor. “ We replaced t he ROE V isual CB5 LED r iser fascias with bespoke perspex-fronted light boxes w ith ACME Lighting Super Dotlines inside. T he different t ype of light engines on t he

lights g ave us incredible flexibility – t hey could resemble an old disco floor or be t ilted upwards to create light curtains, or even used for video playback,” Green explained. “Big thanks to Production Manager, Jerry Hough and Ox Event House for making these happen.”

In addition to truss and hoists, highlights of the lighting package included 74 Martin MAC Ultra Performances and 22 MAC Ones; 56 ACME Super Dotlines; 21 t wo-light blinders; 13 GLP JDC1s; fi ve Robe iFORTE LTXs w ith Robe FollowSpot base stations and a Mole Richardson Type 245.

“It’s a simple kit list, which makes replication easier across continents,” Green noted, praising support f rom Christie Lites’ Mathew Illot, Lighting Operator, Rob Gawler and the wider lighting crew.

“It is always great to work w ith Christie Lites and Rob is calm and meticulous. We have programmed about 52 songs so far between Lighting Programmers, Ben Cash and Jamie Trant,” he added. “The aim is to have the detail of a t imecoded show w ithout t he actual code –Pulp don’t play to track, so Rob and I have had to memorise every detail of every song. He has been fantastic.”

Alongside the lighting crew chiefs and four lighting technicians on the road, over 50

Attention seekers scan here:

Representing a dramatic leap forward in power and connectivity within a remarkably compact format, Quantum 338 Pulse follows the Quantum 7 in defining the future of audio mixing. Boasting a wealth of new design features and enhancements to create ultimate flexibility of use plus the speed of operation that only Quantum can deliver, Quantum 338 Pulse is based on seventh generation FPGAs with an entirely new system architecture.

• 156 Input Channels

• 72 Aux / Sub -Group Busses

• LR/LCR/LCRS/5.1 Master Buss

• 24 x 24 Full Processing Matrix

• 330 Dynamic Equalizers

• 48/96 kHz Sample Rate

Christie Lites staff – including preparation crew, technicians, warehouse staff, project managers, cross-rental team members and transport coordinators – were involved in assembling the package. “It is always a huge pleasure to collaborate with Dougie – he always has a clear vision of what he wants to achieve. The lighting was a mix of retro and modern styles – a nod to previous Pulp tours,” added Christie Lites’ Mathew Ilott. “It was a massive privilege to support the team.”

Around 200 specific colour presets were used within the show, chosen more through emotion than science. “Pulp’s colour palette often comes from real-world inspiration – each song requiring its own set of colours to create its world,” Green explained.

A major visual highlight was The Sunlight – a custom rig featuring a central Mole Richardson Type 245 5KW Skypan surrounded by ETC Source Four PAR XWFLs and 2-lite moles.

Inspired by a photo sent by frontman, Jarvis Cocker, referencing the song A Sunrise, Green’s bespoke structure delivered an eye-catching moment before the curtain closed for an interval as Cocker danced within its blinding glow – an astonishing commitment to sartorial elegance with the frontman donning corduroy on one of the UK’s hottest days of the year thus far, coinciding with the Summer Solstice. “It is a powerful and unifying moment – the whole

audience and band bathed in the same light and heat,” Green commented.

ER Productions added further spectacle, supplying an EX25 laser, six BB4 lasers, six Stadium Shots, six Stadium Blasters, Viper and Unique hazers, and pyrotechnics, controlled via Galaxis. Additional confetti enhanced The O2 arena performance. Touring crew included Colin Clarke, Ed Chiswell Jones and Amber Forbes. ER Productions’ Managing Director, Marc Webber even operated the green laser during Sorted for E’s & Wizz back in 2011, evidencing the longstanding relationship with Pulp.

“Doug always brings fresh ideas, and his shows look fantastic,” ER Productions Project Manager, Ben Couch commented. “From project coordination to warehouse staff, everyone plays a key part. Working with Pulp is a pleasure.”

The team also handled Pulp’s secret Glastonbury Festival set. To preserve the surprise, even flight case labels were removed. “It was probably the worst-kept secret in Somerset this summer,” Green laughed. “But it worked. Jarvis wanted to reference Charli XCX’ promise of a ‘PULP SUMMER’ back at Coachella so we tweaked some video content, re-lit everything and made it bold for that moment.”

Poncho-clad crew on Glastonbury Festival’s Pyramid Stage, led by Emma Reynolds-Taylor, doubled as extras to hide the band during their entrance, stepping aside for the dramatic

ER Productions Laser Operator, Colin Clarke; Lighting Operator, Rob Gawler; Production Designer, Douglas Green; Lighting Programmer, Jamie Trant.

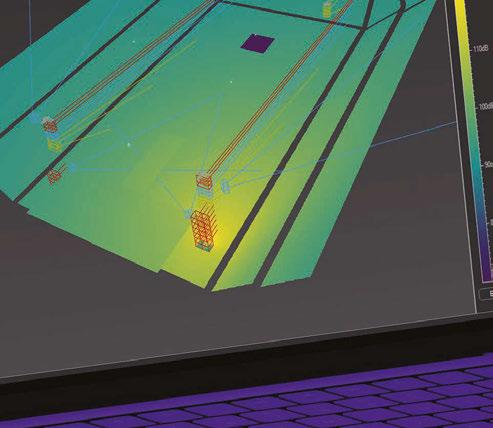

Funktion-One’s Projection system design software introduces a fast, wave based low frequency model. This breakthrough technology fully predicts the complex wave behaviour of bass arrays, including the effects of the physical presence of enclosures on directivity and wave propagation. funktion-one.com

reveal. “We felt so welcomed by the Pyramid stage crew,” Green commented. “It was a special day – 30 years to the weekend after their first appearance on that stage – the reaction blew us all away.”

‘A NEW ERA OF PULP’ Screens Producers, Pete Thornton and Matt Sharp of More Eyes were tasked with transforming existing video content –reassessing, reprogramming, rescaling, and creating new material from the band’s avalanche of ideas.

Visual artist Julian House provided iconography, while Garth Jennings offered creative oversight. An existing Disguise show file, linked tightly with cues, provided a base. “We built upon it – a lot of filming, custom animation and Notch was involved,” said Thornton.

A notable development was the enhanced use of IMAG overlays. “This time, we had more video surface to play with. The IMAGs now carried content, not just live feed,” Green noted. Each song had a unique delivery format. “We previewed everything with the band. Not all visuals were ours – we also used analogue techniques like gel overlays on lenses, paired with digital Notch effects,” said Thornton. “It was controlled evolution,” Sharp added. “Each song had space for happy accidents.”

With only five weeks lead time, the biggest challenge was centralising all the visuals. From scanning hundreds of Rankin’s 1995 archive shots to sourcing a specific sunset image from

a book requested by Jarvis for A Sunset, every element was curated meticulously. “I reverse image-searched it, found the highest resolution online, ran it through an AI Image Upscaler, then animated four images to fade into each other –simple, but it took days,” recalled Thornton.

The band’s freeform style also created technical challenges. “With no click track, we had to build in leeway and buffers. We needed full-length visuals with enough overhang to adjust in real time,” said Sharp, crediting Media Server Programmer, Ben Gittos and Notch Programmer, Dan Williams for their “precision”.

“It’s low-fi creatively, but high-tech in delivery,” said Sharp, noting the use of Disguise GX 3 media servers and real-time Notch effects.

“I love Acrylic Afternoons – dark, sinister, but beautiful. Syncing those moments without code was very satisfying,” added Thornton.

For the interval section, More Eyes dug through 25 VHS tapes supplied by Rough Trade Records to create a five-minute montage superbly edited by Chris Allen. “It felt more like curiosity than nostalgia,” Green noted.

A retro-styled vote between two songs added an interactive layer. As Common People reached its extended chorus, and once the Pulp-branded teabags, fingers of fudge and handfuls of grapes were launched into the crowd, Jarvis used a spy camera on a stick – first used in the 2011/12 shows.

Notch Designer, Dan Williams created a filter that multiplied audience members on screen, turning them into “common people” – a symbolic

blurring of boundaries between artist and audience. “This band’s history predates me, and their style isn’t necessarily my own personal one, so it’s important that I do my research and deliver confidently,” Green said.

“E xperimentation is very Pulp and they’re all about taking risks on ideas. Tour Manager, Liam Rippon knows this all too well and has fostered a supportive environment for us to collaborate in, while also ensuring that the ideas that make it to the stage are delivered to a militarily high standard. Watching him guide this process is a real lesson in management.”

Asked about the responsibility of handling visuals for culturally significant songs, Sharp admitted: “The pressure was on – these are tracks we grew up with. You feel a duty to honour the band and the fans. It felt like a new era, not a nostalgia trip.”

Green concluded: “Two sold-out nights at The O2, a rammed Pyramid Stage and their new album going to number one in the charts. It’s been an extraordinary year and I think proves that resisting convention and taking creative risks can really pay off.” www.welovepulp.info www.douglasgreen.studio www.christielites.com www.moreeyes.co.uk www.er-productions.com www.drawntothelight.design www.insightlighting.co.uk www.lightsurgeons.com www.oxevents.co.uk

The Dutch rock band celebrate their 25th anniversary with three sold-out shows, performing to more than 145,000 fans with an impressive production assembled by local talent.

Stageco steel and ROE Visual LED screens played a pivotal role in one of the most significant live music events in Dutch history – DI-RECT’s farewell concerts at Rotterdam’s De Kuip stadium, home of Feyenoord. Tasked with delivering this historic production, Sightline Productions engaged Stageco to provide staging infrastructure and the build while Creative Technology (CT) Netherlands selected ROE Visual’s Black Quartz LED panels to create an impressive production for 145,000 fans.

The concerts marked the final chapter in De Kuip’s legacy as a live music venue. Over nearly five decades, the stadium has evolved into one of the Netherlands’ most revered concert stages. However, due to upcoming residential developments and increasing concerns over noise pollution, the City of Rotterdam has decided to discontinue large-scale performances at the venue.

DI -RECT embraced the emotional gravity of the moment. As the band paid tribute

to decades of musical history at De Kuip – following in the footsteps of Bob Dylan, U2, Madonna, and The Rolling Stones. CT Netherlands was entrusted with the execution of the LED installation, selecting ROE Visual’s Black Quartz Series. The final setup featured 966 sq m of ROE BQ6 and 56 sq m of BQ4, integrated into a striking 27m-tall LED canvas.

“T he specific requirements of the client naturally led us to high-end products like the ROE BQ series,” said Jeroen Boere, Project Director at CT Netherlands.

“We’ve deployed this product at many high-profile events, and the DI-RECT show once again confirms it was the right choice. Combined with the Megapixel Helios processing platform, it allows us to control each pixel perfectly – natively across 8K resolution canvases.”

With video content driven by Megapixel HELIOS LED processors and Disguise GX 3 media servers, the system operated across a dual 8K configuration, delivering precise colour

reproduction, high refresh rates, and real-time content synchronisation.

A st andout feature was its ability to handle full white brightness levels from 1% to 100%, offering creative flexibility for both subtle transitions and powerful visual moments.

One of the most striking elements of the show’s design featured two massive LED structures flanking the stage, representing a stylised hand (over 24m tall) and a profiled head of Spike, the stage name of DI-RECT’s Frans van Zoest.

These sculptural elements required a custom-engineered rear support structure, specially developed to handle the complex rigging loads and outdoor conditions. The 24m-tall shaped LED surfaces demanded bespoke steelwork and precise structural calculations to ensure safety and stability throughout the performances.

“T his was the highest video screen structure that I have ever built,” experienced Stageco Project Manager, Henkjan Luesink

XPRESSION 2000S

SPOT

- 12-facet circular and 10-facet linear rotating prisms with overlay

- 6 bi-rotational gobos + open

- 7 colours + open

- Frost lter and motorised focus

- GDTF xture les available

- 8 and 48-facet circular prisms with overlay

- 13 gobos + open

- 14 colours + open

- Endless tilt, motorised focus, and frost lter

- GDTF xture les available

- Motorised zoom from 3.8° to 35°

- 16-bit pan and endless tilt for smooth and precise movements

- Adjustable PWM from 1,200 to 15,000 Hz

- GDTF xture les available

said, reflecting on the tonnes of black steel gear supplied for DI-RECT and two support acts on the bill, The Indien and Son Mieux. “We built an elevator within the system to enable quick changeovers.”

The entire stage set fit into 30 trailers. In total, Stageco lifted 17 tonnes of material, including additional wind bracing, making for a heavy system.

“Our knowledge of De Kuip helped a lot. It’s a historic, tight space, not built for live events. It took a week and half to prepare how to transport the equipment and build different sections, in collaboration with the vendors.”

In addition to collaboration, the order of the unload was vital to the success of the project. Stageco deployed in-house constructor Paul Schijfsma to assess windloads, bracing and preparing the build within Eurocode regulation.

“T he most difficult part was actually centralising all the equipment as opposed to weight loads,” Luesink remarked. To this end, an experienced 36-strong team of Stageco staff, as well as some additional freelancers and production crew – making up approximately 450 people in total – were

With over 25 years of warehouse experience within the music -and theatre industry, we offer tailored storage solutions to meet both long-term and short-term requirements, we provide comprehensive storage solutions for all your storage needs—from securely storing band equipment in lock-up cages to housing larger sets in our fully climate-controlled 39,500 sq. ft warehouse . Our highly trained warehouse team are available seven days a week, always ensuring the safe handling of your equipment. For your peace of mind, every item is carefully photographed and logged upon arrival.

involved in the overall build, including 50 crew members assembling the smaller stage.

This project also coincided with multiple projects for the staging company, meaning equipment was allocated in advance and sourced from Stageco’s Tildonk warehouse in Belgium with further scaffolding infrastructure coming from across the Netherlands.

“95% of the gear was off the shelf with 5% custom made specials, which have since been recycled on projects,” Luesink reported, drawing paralell’s between Stageco’s material and the ease of implementation of Lego.

“Everything comes in varying sizes and configurations,” he continued. “In this case, we provided additional roller beams to lift the video screens into place, once they were built on the stage floor.”

Timing, in addition to collaboration and creative problem solving, was paramount. “The timeline was tight. We had several meetings with R&D departments and project leaders in the build-up to the show, and all those hours, ensured the smooth and safe implementation of the system,” he concluded.

“Fundamentally, we are a company that makes people happy, so we were proud to be

involved and collaborate with fellow companies on this momentous project.”

In addition to Sightline Productions, Stageco and CT Netherlands, the vendor roster featured stagebrothers (set construction), The Powershop (power generators), Ampco Flashlight Rental (lighting and audio), MisterBeam (visual content), and Production World (production). As De Kuip closes its gates to live music, DI-RECT and the entire production team leave behind a momentous farewell – one that seamlessly blends music, history, and world-class visual technology.

“T his wasn’t just a concert – it was the final chapter in De Kuip’s storied music history,” concluded CT Project Manager, Jordy Mulders. “We are incredibly proud to have contributed to this legacy and been able to deliver uncompromised visual excellence.”

www.di-rectindekuip.nl

www.ampco-flashlight.com

www.ct-group.com

www.roevisual.com

www.sightline.nl

www.stageco.com

www.stagebrothers.nl www.thepowershop.eu

FOH Engineer, Bill Sheppell shares his approach to mixing the singer’s latest run, and how plugins play into his workflow.

Words: Stew Hume

Photos: Nathan Peterson

With an esteemed career behind the faders, Bill Sheppell has mixed for the likes of Beyoncé and Bon Jovi over the years. This year, he lent his talents to Shakira, mixing for her Las Mujeres Ya No Lloran World Tour Sheppell sat down with TPi to discuss his workflow for the tour, which included the Universal Audio Apollo X16D.

“I started with Shakira in June, mixing the 2024 Copa América final halftime show,” began Sheppell. “Tour rehearsals started in October and went through to January 2025 with the first show taking place in early February in Brazil.”

When it came to his mixing approach, he stated how his main goal was to “keep her vocal out front, no matter what the song style”. He continued: “This went from thumping club stuff, to straight ahead rock, or a delicate ballad.”

For the South and North American tour, Sheppell and the audio team was supported by Eighth Day Sound and Clair Global.

“I work with them all the time, so it was fairly straight forward once we hammered out some details,” commented the engineer, outlining the d&b audiotechnik GSL system that he selected for the tour. “I had used a very similar rig on Beyonce’s Renaissance World Tour and had very good results. Shakira came to that show in Miami, and I was contacted to do the tour the next day. So, I brought the product I had used that helped me get the gig. I have also used d&b systems on many other tours with great results, so it was a no-brainer – especially with the advantage of ArrayProcessing.”

The system design was one of the biggest challenges for Sheppell and the audio team due

to the large thrust as well as some stadiums where sound was “challenging”. He explained: “The main tools for these problems were proper PA placement, ringing out the vocal mics and using ArrayProcessing to clean up the room as much as possible.”

Sheppell selected the DiGiCo Quantum 852 mixing console for control. “It has been working out well and sounds great,” he enthused, explaining how he’s used various versions of the Quantum series for some time including the 852, the 338 or SD7.

Keeping the conversation on control, Sheppell described how he utilised the Universal Audio Apollo X16D within his outboard set. “I’m using the X16D for the reverbs as I really like the ones that UA has including the Lexicon 224, EMT 140 and AMS

RMX16. The quality of the plugins compared to the analogue pieces that I am used to made me want to use the unit. They sound great and all the UA gear I have been using has been holding up well on the road.”

Although the X16D was a newer addition to Sheppell’s spice rack, he was familiar with the Universal Audio brand. “I started using an Apollo 16 unit early on, as I like the plugins available. I went to the Live Rack as soon as it came out. The optical MADI allowed me to have it go with the Optocore DD2/4 and show up as a rack in DiGiCo world that cut down latency. It also could be used in the redundant engines of an SD7 easily, being on the Optocore loop.” He expressed his excitement to further explore the capabilities of the system, adding that he planned to explore the e1x Dante preamp when he gets some time.

“T he tour has been tough but rewarding,” he concluded. “The schedule and moving this stadium show around the world is hard, but the shows have been good with great reviews, so it makes it worth it. We are doing a second run of Mexico now and will be going back to South America to finish 2025.” www.shakira.com www.8thdaysound.com www.clairglobal.com

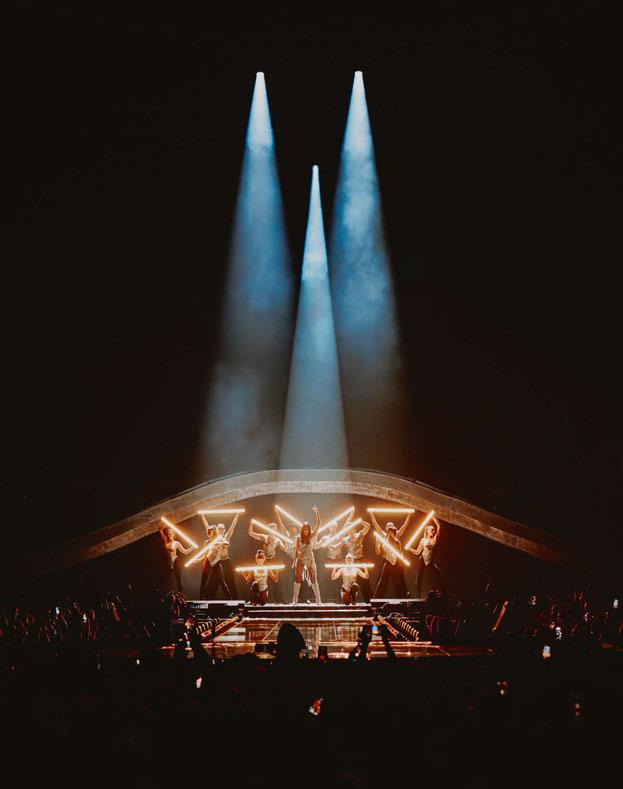

Taking the in-the-round format to the next level, the artist’s latest production brings cinematic style and awe-inspiring automation, ensuring the focus remains on the performance.

Whenever I’m asked my thoughts on a show I’ve covered, I’ll admit that nine times out of 10, I’ll dive straight into ‘production talk’. However, when it came to Billie Eilish, my predominant memory was the sheer control that the 23-year-old singer exerted over her audience. Her mere presence on the stage, sometimes without even uttering a word, was enough to enrapture her fans. Few singers would be able to silence The O2 like she did when performing an a capella looped vocal for her song When the Party’s Over. What was evident from this show was how Billie was placed at the centre of the production with a fully automated set that metamorphosed with moving LED screens, lighting towers and a cinematic live video capture that only worked to enhance the artist’s ability to keep the crowd in the palm of her hand.

Having caught the show on the opening night of the run of six performances in the capital, the next day I headed to meet up with the production to learn the innerworkings of the HIT ME HARD AND SOFT: THE TOUR Our first stop was long-time Production Manager, and 2025 TPi Award w inner, Nicole Massey. Having been with Billie Eilish since 2019, Massey has become the linchpin in the camp as the singer’s production continues to grow. Following the release of HIT ME HARD AND SOFT in early 2024, the wheels started turning at Moment Factory, with the team drawing up the show’s design.

There were certainly a few changes from previous tours. Not only would t his be t he first t ime t hat Eilish toured in-the-round, but she would be w ithout her brother and cowriter Finneas O’Connell. Instead, a group of

musicians joined the singer, adding more of a live d ynamic to her back c atalogue. Performing from two band pits built into the stage, the performance area took up 5,824ft on the show floor w ith an overlapping, giant automated LED st ructure hung above.

“T here is no doubt that the show is massive,” Massey laughed. “That said, it still feels intimate. There’s so much dynamic movement in the songs that even though I’ve seen the show many t imes, I still find it exciting.”

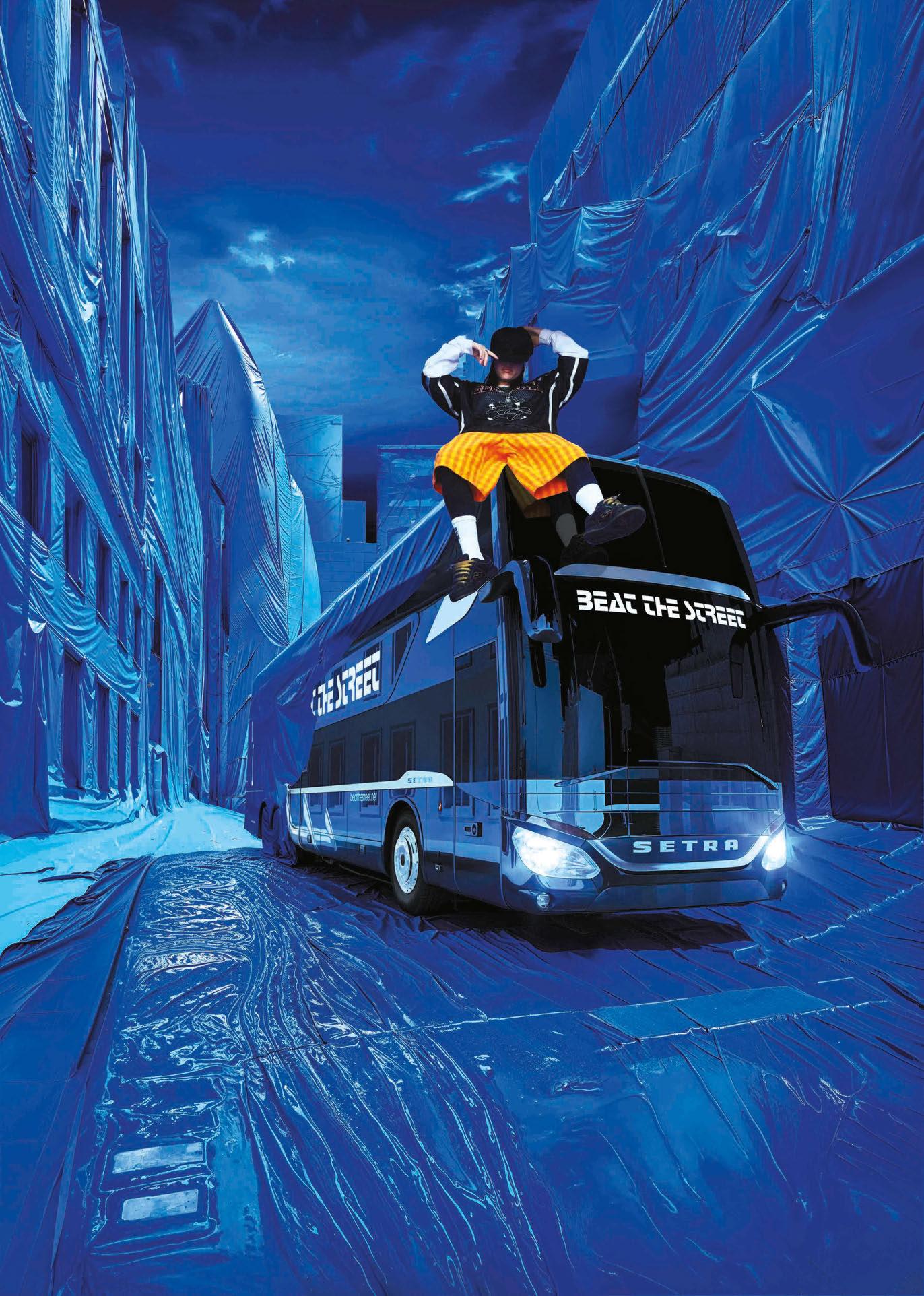

Massey brought in several trusted suppliers including Clair Global (audio), Upstaging (lighting and US motors), Strictly FX (pyro, confetti and lasers) and TAIT (staging and automation). There were three video suppliers including V is-A-Vis (cameras and media servers), LED Shed (flown LED) and PRG (floor and automation tower LED) w ith CES (t ransformers), Actus Motors (rigging in EU/ UK), Eat Your Hearts Out ( plant-based c atering), Dutch B arrier Services (barriers), Beat T he St reet (artist and crew travel) and Stagetruck (logistics) adding to the roster.

Due to t he size of t he production, t he PM spoke of the importance of ensuring each department was crewed appropriately. “We didn’t expect the show to be as big, and once we started, we realised we were going to need some help,” she recalled. “I added eight people after t he first leg.”

T he production office was staffed appropriately for a tour t his size w ith

Production Coordinators, Dick Massey and Brad Kline supporting t he PM. “A lot of tours would not have extra Production Coordinators, piling more and more work onto the production office rather t han hiring more help,” noted Dick.

St age Manager, Jayy Jutting, aided the team with t he d ay-to-day load-in and - outs. “ Due to the scale, I also brought in Craig Finley, who I knew from my time on Coldplay,” explained Massey. “He’s really helped Jayy and I. We’ve even got a Dock Master – PJ A rmellino – on t his tour, who doubles as our Show Caller.”

Sustainability was another subject that was brought up quickly within the production office. “ It’s a huge driving factor for Billie and we have to think about it constantly,” Massey stated, highlighting actions including the use of HVO fuel and the tour’s collaboration with REVERB. As well as working w ith t he team –especially the catering department to provide plant-based meals – REVERB set up stands in t he foyer with activations to engage with fans in some of the tour’s pledges including a reduction of single-use plastics.

“From the beginning, Billie and her team made sustainability a central part of touring,” stated REVERB’s Melissa Jun Rowley. “On the Happier Than Ever, The World Tour, we eliminated more t han 117,000 single-use bottles, served plant-based meals t hat s aved 8. 8 million g allons of water, and offset over 15,000 tonnes of CO2 equivalent through certified climate projects.”

REVERB continued t hese incentives for t his run along with optimising waste management through recycling and composting while making efficiencies in crew and artist t ravel and tr ucking. “More sustainable design choices and donation programmes help eliminate waste,” said Rowley. “ The entire production team is involved and t ruly buys into t hese efforts.”

This mission also extended to the fan experience. Every show, REVERB’s Eco-Action

Village became a hub for action where fans took over 133,500 steps in support of people and the planet. Support+Feed, founded by Eilish’s mother Maggie Baird encourage fans to take a pledge to eat one plant-based meal a day. “More than 88,000 single-use bottles were avoided through refill stations, and 56 nonprofits were featured in Eco-Action Villages across three continents, resulting in over 15,000 direct fan engagement actions. Billie’s touring model is changing the industry. In addition to reducing emissions, we’re reimagining what a concert can contribute to the world, and we look forward to seeing the impact data from HMHAS,” stated Rowley.

“Finding that balance of doing a big show and lowering our impact is a constant conversation for us,” stated Massey, expressing her hope for more incentives in the industry to make an impact such as the use of batteries to partially power Lollapolloza, which Eilish played on her Happier Than Ever, The World Tour festival run.

With multiple moving parts, Stage Manager, Jayy Jutting explained what it was like to keep the train on the tracks for this high-octane show. He cited the moment when Eilish had to get from the main stage to a B-stage for a toaster reveal during the song Guess as one of his interesting daily challenges. “Every venue is different and no matter the advance calls, it’s not really until I get into the venue that I can plan.” This highly choreographed move involved getting the singer off stage, then via scooters getting her in place on the B-stage toaster to be launched into the air to then sing her verse. During the show, Jutting and his

Assistant, Kurt Wagner had other marks they had to hit including getting the wireless selfiecamera on and off stage.

During the build, the team were supported by 120 local crew. “It’s been much easier to ask for these numbers – especially compared to the post-COVID years,” stated Jutting. “We come into these buildings, and we want everyone to be happy to be there. The show wouldn’t happen without these local hands!” While discussing the build, Massey was keen to highlight the hard work of Head Rigger, Matt Rynes and his department – especially due to the sheer weight of equipment being hung above the audience each night.

To learn about the design origins of the show, TPi spoke to Moment Factory’s Tarik Mikouthe tour’s Show and Creative Director, along with Live Video Producer and Director, Stuart Merser. Having provided equipment for Eilish since 2017, Merser has had a front row seat for the singer’s ascension on the live stage.

“I ’ve been involved before there was even really a need for a director,” explained Merser, emphasising how the medium of video has always been important to Eilish. This led to what Merser described as a “great collaboration” with Mikou when it came to the show design to ensure that the video was applied correctly. The four-sided video arrangement hung above the main stage expanded and contracted into various configurations during the show. There was an internal LED automated cube comprising blow through LED and containing and internal performance platform

Above: Production Manager, Nicole Massey surrounded by Dockmaster / Showcaller, PJ Armellino, Second Stage Manager, Kurt Wagner, Secret Weapon, Craig Finley and Stage Manager,Jayy Jutting; Production Assistant, Lauren McCarthy, Tour Dog, Reggie Massey, Production Coordinators, Dick Massey and Brad Kline with Tour Accountant, Jeff Mauss; Video Director, Stu Merser; Jack Sexton, Chris Griffin, Geoff Massey, Olivia McGahan, Crew Chief, Benji Meserole, Lighting Director, Will Flavin, Lexi Rose, Gavin White, Kyle Rutkowski, Erin Grace, Rizzo Mulholland and Bishop Sforza. Opposite: Finn Rankin, Connor Dexter, Freddie Hamlin, Jay Golder, Vendor Rep and Tech Tom Levitt, James Miles, Duncan Stinson, Crew Chief Luke Levitt, Ben Renschen and Luis ‘Bong’ Buno; Wardrobe Supervisor, Trish Forde and Backstage Coordinator, Judy Won; Screens Director Lorenzo Loche, Teddy Corrales, Landon Cable, Brandon Isbell, Crew Chief, Cam Dixon and Cole Peterson; Riggers, Jorge Machado, Brittany Kiefer, Matt Rynes, and Bobby Wright.

used to reveal Eilish, who began the set from within the cube.

“We’ve had the privilege of designing a few Billie Eilish tours and this one was a natural evolution of her as an artist moving into 360°,” stated Mikou, admitting that in-the-round shows can often be tricky from a design perspective. “We’ve done a lot of research and had many conversations with Billie to ensure she was the focus. Sometimes it’s confusing for audiences when there are lots of elements and obstacles that distract from the performance.”

Another goal for Mikou was to break up the room with the use of automation. “Arenas are big, and we wanted to make sure the experience felt intimate. The automated towers that hung around the stage really break up the room and each time they come in musically they make the experience more intimate. When they drop in you feel like you’re in a smaller room and ‘in the music’ with her,” he said.

“I love the fact that Mikou brought me in from the beginning,” said Merser, explaining that these early discussions meant he and his team from Vis-A-Vis were able to ensure they had the right camera positions in place. The camera package was a cut above the ‘standard’ touring package with the team opting for a setup more akin to a film shoot. “They are all PL mount camera and all Super 35 rather than B4, which is the standard touring camera lens. They’ve all got a Cinichip in there for starters and the lenses are all Fuji Duvo,” said Merser. “At Vis-A-Vis, we’ve invested $3m in those lenses this year. They’re not cheap, which is why they look so good. Let’s bring cinema technology into the live world!” This high-level package meant the video

team could live colour grade during the show resulting in “cleaner” IMAG looks.

Some of the highlights of the camera package included the Blackmagic URSA Broadcast G2s, L3 towerCams and Micro Studio G2 with Olympus 7-14mm lenses. There were four Canon CR-N500 PTZ used as spy cameras on each side of stage and two Motion Impossible Agitos with Mag Trax. “No one really tours with Agitos,” stated Merser. “It’s very much a cinematic setup, each with an ARRI SRH 360 Stabilised heads and both of which on a Vislink Hcam Systems.”

As well as quality the Agitos were able to achieve with their moving shots, the system used a magnetic strip rather than a track. “Not only was there no room in the pit to build a track, but the fact it uses a magnetic strip meant that it was very quick to set up and took up very little trucking space. We’re a very environmentally conscious tour and try and do everything we can to make it more environmentally friendly.”

The level in which the video department went to ensure the quality of the shots was impressive, all the way down to having a base on the long lenses containing nitrogen gas to compensate for the vibrations caused by the heavy bass mix of Eilish’s music.

One video element that was front and centre during the show was the incorporation of the camera used by Eilish to film her and the band. “The Billie-cam,” chuckled Merser, who explained that since its debut he’s had many others from the industry asking what he’d been using for those moments. “The idea came during a listening party we did for the album where Billie’s brother Finneas had a camera on

stage, which Billie grabbed and started filming herself with.”

This sparked the idea to incorporate this ‘selfie cam’ shot into the show. “We brought a new version of the camera to rehearsals and started looking at how long her arm was to get the right focal length on the lens so that if she was holding it at arm’s length, it was always going to be nicely framed and in focus.”

The camera in question for that look was a Blackmagic Micro Studio Gen 2. “It’s still a super 35 film sensor with a prime lens on it – a very particular prime lens with a wireless links. The wireless link was the bane of my life trying to find something that works in every region.” It was this wireless setup, however, which Merser was keen to keep under his hat – he won’t be revealing all his tricks.

Merser cut the show manually each night on a Blackmagic 4 m/e vision mixer alongside Screens Director, Lorenzo Loche and Engineer and Colourist, Ben Renschen. Tom and Luke Levitt of LED Shed provided all the flown LED, supported by PRG Crew Chief, Cameron Dixon.

“It’s been the first tour with this setup but since rehearsals it’s been nothing but easy going,” stated Dixon, whose team at PRG provided the large floor LED – comprising YesTech 4.8mm and powered by NovaStar processors. “The LED panels on the floor all fit into a 2x2 TAIT deck which is bolted together by the carp departments then we come in after it’s built to wire everything.” PRG also looked after the automated video towers which used ROE Visual Vanish LED panels.

“We’ve been supporting Billie and her team since the debut album run, and it’s been

impressive to see the creative vision evolve at every stage,” added PRG Account Executive, John Wiseman.

“T his tour was no exception. The in-theround setup with that striking video cube put the visuals front and centre, but the overall design was clean and minimal – no distractions, nowhere to hide. It takes a real artist to hold an arena like that. We were proud to deliver a rock-solid video system that supported Nicole’s production leadership and Moment Factory’s interpretation of Billie’s vision.”

LED Shed’s Tom Levitt emphasised the sheer amount of product the team were dealing with each day: “We’ve got around 800 sq ft of LED and there are few arena tours that have this much video surface, not to mention these types of cameras from Vis-A-Vis.”

Luke Levitt concurred: “Each part of the video delivery is so complex that it needed good people and dedicated teams to get it done.”

The fact that Luke as the Director of the LED Shed was out on the tour personally as well as Merser as Vis-A-Vis Director made a statement of the investment both companies were making with this project. “We’ve worked with Stuart for many years and between all of us I think we’ve really pushed the boundaries of resolution on this tour,” enthused Luke.

The flown screen selected by LED Shed was ROE Visual V4ST for the main surface.

“It’s t he company’s new fl agship product and it clips together fast making it quick to deploy. Importantly it’s as light as you can get while still having t he features and benefits of a touring LED screen.”

As for the centre automated cube, ROE Visual V8 was selected. Processing for the hung LED came from Brompton Technology processors. “We are running it 10bit,” stated Tom.

“Usually tours come in as 8bit, which compresses the image. In our mind there is no point going to all the trouble with deploying high-end cameras and lenses to then going onto a generic LED setup.”

Due to the quantity of screens and content, there was a collection of eight Disguise GX 3 media servers.

The video crew also featured SRH Head Op and Head of Cameras Jay Golder; SRH Head Operator, Finn Rankin; Agito Operators, Duncan Stinson and Bong Buno, with LED processing handled by Brandon Isbell, supported by crew members Connor Dexter, Roger Nelson, Cole Peterson, Anthony ‘Teddy’ Corrales, Landon Cable, James Miles and Freddie Hamlin.

Brought in to add to the visual appeal of the show were Lighting Designers, Ben Dalgleish and Kasper Iseger from creative studio Human Person. The latter was onsite at The O2 to speak about the duo’s lighting goals. “Once we were brought in by the team at Moment Factory, we got to see the main direction and stage design and they outlined some of the looks stating that they wanted some big beam,” Iseger said.

On t he stage, the length of each side was lined with the CHAUVET Professional COLORado PXL Curve 12 solutions. “We got to use them on a shoot we did for the The Late Show With Stephen Colbert during the album

The Automation crew of Will Anglin, Ben Hammett, Monica Walker, Becki Oorbeck, Crew Chief Brian Benauer, Bob Fitts and Operator, Eamon Keane.

WE ARE PROUD TO BE INVOLVED

Headoffice Austria: joerg@beatthestreet.net | hannes@beatthestreet.net | lee@beatthestreet.net | dominic@beatthestreet.net

Office UK: garry@beatthestreet.net | dan@beatthestreet.net

Office Spain & France: tristan@beatthestreet.net

Office UK Groundtransport: ian@beatthestreet.net | mark@beatthestreet.net | courtney@beatthestreet.net Office USA: tim.king@beatthestreet.us | alex.mistry@beatthestreet.us | john.aikin@beatthestreet.us www.beatthestreet.net | www.beatthestreet.us

cycle – which got nominated for an EMMY,” commented Iseger. “So, when I saw the look of the set, I really liked the idea of having a whole line of them stage.”

Although the PXL Curve were very visible on the stage, there were several fixtures that the lighting team were keen to keep hidden and only bring into view for certain moment.

“We’ve utilised the Wahlberg Motion Design lifting columns to bring in the ACME LEO to back light the singer for certain songs. We also have Wahlbergs in the band pit that bring in the Martin MAC Aura XIP to backlight her when she’s sat on the stage. We got very creative hiding and moving fixtures in and out.”

Iseger shared his fondness for pan and tilt fixtures and his excitement when he saw that Upstaging had taken stock of Elation Pulse Panels. “I knew they would work well for the songs ilomilo and bad guy which we have used on the towers. I’m in love with the GLP impression X5s. They are so powerful.”

CHAUVET Professional PXL Strike Ms, ACME LEO, Elation Pulse Bar S, PROTEUS, SŌL I BLINDER, Robe iForte and TMB Solaris Flare XL120 solutions also featured on the lighting rig. The show was operated by Lighting Director Will Flavin via an MA Lighting grandMA3.

“T his is my first run with Billie, joining the camp six months ago,” began Flavin. “The show is fully timecoded but there are several ‘special

moments’ that are a bit more complex,” To aid in key lighting, the visual team utilised FollowMe’s Track-iT system with Eilish always having a tracker on her as well as the company’s manual tracking system as a backup solution.

“We have over 20 beacons around the stage to track her movement,” explained Lighting Crew Chief, Benji Meserole. “The biggest concern on this show is time as we need time to calibrate the system, but at this point, we are very dialled in.”

Key to the integration of the tracking system was Head of Wardrobe, Tricia Forde. Put forward by Go For Wardrobe, Forde worked with the sound and lighting team to incorporate the IEM packs and the tracking system within the singer’s stage outfits.

“Commercially available holders and belts are rarely a good fit for most artists as they tend to be bulky, uncomfortable to wear, limited in colour and in the positions, they can be worn on the body. I created several configurations at the start of tour to ensure the trackers and IEM packs were as comfortable and as invisible as possible while also maintaining function for the artist, sound, and lighting department.”

Forde considers her main role as “supporting for the artist, ensuring her wardrobe is something she’s not thinking about on stage.” She added: “I’m one of the last people to see her before she goes on

stage and creating an environment of calm confidence is chief among my responsibilities.”

Back to the lighting team, helping to ensure that everything was built in time was a team of 13 crew members. “It’s a pretty big team,” admitted Meserole. “We have multiple departments working on top of each other so in that case it’s good to have this many people.”

The entire visual department, including video, lighting, automation and SFX operators, were all situated in the same spot in the upper ring of seating ensuring easy of communication as well as a clear view of the whole stage.

“We’re in a good routine. A large part of my role is working closely with Eamon Keane from our automation department to ensure they have everything they need,” Flavin said.

“We have been involved with Billie Eilish for the past several tours and the production led by Nicole Erin Massey is a great team to work with,” added Upstaging’s Dan Curley. “Ben and Kasper were great to work with and were open to suggestions on gear recommendations. There were a lot of newer lighting products that were coming in from the factories right up until two days before it had to leave our shop.”

He g ave a particular shout out to the CHAUVET PXL Curve 12 and the Elation Professional Pulse Panel FX and Pulse BAR S and L. He also commented that this was the “perfect show” for using Follow-Me’s Track-iT

system. “Track-it allows moving lights to know when the LED wall is in the way and it will fade it out, so you don’t get that big white circle shining on the screen when she goes too far to the opposite edge of the stage,” he commented.

PYRO AND MANY, MANY LASERS

HIT ME HARD AND SOFT: THE TOUR was certainly not short of big SFX moments with a jaw-dropping 54 laser fixtures, pyro hits and custom confetti hit to close out the show. Walking TPi through the various elements were Crew Chief, John Lyons and Laser Operator, Maxime Rocher.

“We have lasers everywhere,” enthused Rocher, while pointing out the various fixtures he and the team deployed each day. “In total, we have 32, 30W, eight 80W, and 12 10W lasers. Each of the automated towers has two lasers with another six on both the left and right of the truss. There two other lasers up and down stage with three 60W for the band.”

The B-stage featured two 80W fixtures flanking the performance area. “All the lasers on the truss are aimed down on the stage with the bigger fixtures on the stage shooting to a safe location in the ceiling.”

Shooting from the automated towers, the fixtures helped create a laser cage moment at the start of the show. “We have physical blocks on each of the towers,” commented Lyons, explaining the safety protocol for his part of the show. “Once the towers are moved into place, we make sure everything is aligned and safe. We

check all the fixtures a few times during the day to ensure everything is where it should be.”

The lasers were operated by Pangolin BEYOND via two computers due to the size of the system. “We have one computer running the lasers in the air and another for the floor lasers.”

To launch the pyrotechnics, the team utilised an MA Lighting grandMA3 console with six Galaxis G-Flames located upstage, and six downstage used for four songs on the set list. “From the outset, Billie wanted an aggressive flame effect, so we’ve gone for a very natural organic look for these moments,” said Lyons.

The band that was out on the road had not really been exposed to pyro before and with all the fixtures being placed in the pit behind the musicians, Lyons stated how he and the wider team worked with them to ensure they were comfortable. “We want things to be as safe as possible and for them to be comfortable in line with the creative. I always say there is ‘concept’ and ‘reality’ with SFX, and our job is to find where these two elements meet.”

During the show, there were two spotters in the stage – one in each musician pit overseeing the Galaxis G-Flames.

“T hey are closer to the effect than anyone else and each have an e-stop as well as fire extinguishers and fire blankets,” commented Lyons. “Amid the show, I’m down on the floor watching everything and giving Rocher – who’s operating each of the looks – a verbal clear. Mainly making sure we are clear of the LED video screen which is constantly opening and closing.”

Head Carpenter, Jack Deitering and Carpenters, Robby Floyd, Pat Boyd, Dave Johnson, Dana Vanella, Trevor White and Stu Farnell; The SFX crew of Natalie Frew, Crew Chief, John Lyons, Kyle Omar, John Arrowsmith and SFX Operator, Maxime Roche missing Xavion Johnson; Playback Technician and Crew Chief, Kyle Fournier, Steeve Hennessy, and Mike Poorman, missing Trevor Jackson; FOH Engineer, Adam Stuart, Audio Crew Chief, Katie Hughes, Systems Engineer, Alex McCormack, Chris Hazelton, Monitor Engineer, Salim Akram, Jony Santoja Martinez, Bree Bradley, Acho Martinez Soler, Hugo Gudino, Julia Hom and Isaac Gennheimer; Power guy Matt Murphy and barricades, Rolf Van Elten.

The last effect was the confetti hit at the end of the show where thousands of initial logos of the current album cycle were fired into the crowd.

“People love the litter,” Lyons said, commenting on all the fans that were often filling their pockets hoping to take a memento home. “We have cannons around the perimeter of the stage in the barricade and the truss,” he continued. “Each day we have to bring in a lift to reload the flown rig.”

He went on to explain that the look had expanded throughout the run: “After the Sydney show, Billie decided she wanted more confetti. Since then, we now carry manual confetti blowers, which are operated by local hands each night who start firing their units after the first hit.” The effect was a continuous confetti drop as the artist closed the show during the outro for BIRDS OF A FEATHER

Scott ‘Bull’ Allen of Strictly FX gave his thoughts on the company’s involvement with the tour: “Working with Billie and her team is a great combination of pushing creativity and boundaries along with old-school rock effects. Collaborating with all the departments, the Strictly crew ensures the safety of artist, band, other crew and fans while integrating into this show with all its moving parts. Working on this tour is like being in a big family and is a great mix of veterans and young talent.”

Walking around the stage, the first thing that stood out was how low the stage was, ensuring

Eilish was as close to the audience as possible. This certainly created a challenge for the crew working in the underworld. “We did move it up slightly in the early stage and added AC systems in Europe because most of the European venues aren’t sitting on ice like in America,” said Head Carpenter, Jack Deitering. “The low stage is amazing for the crowd.”

The Head Carp and some of his team of six start early with rigging starting at 2.30am most mornings. The stage is split into five different parts, which are built around when the flown mother grid is being put into place.

Overseeing the fabrication of the stage as well as all the automated elements of the show was TAIT. Shannon Nickerson, Senior Project Manager for TAIT, spoke to TPi about the various considerations during the build: “First, the weight in the roof and around the scoreboards was under careful consideration,” began Nickerson. “Second, the tour was already on sale, which meant sight lines and footprint for GA were going to be a driving factor. Finally, being in the round, there had to be somewhere for the technicians to be during the show.”

Going deeper into the issue of weight, Nickerson explained how TAIT determined a 58ft span for four tracking trusses and a 68ft span for two static trusses under the scoreboard.

“T hese spans were determined by the proximity of the truss systems to each other, the load each one carried, and the use case of the gear they held. The tracking systems were going to hold a three-sided video screen on each

side of the arena. Along with the video screens, there were going to be light trusses that hung and tracked behind the screens as well as a four-sided video cube that moved vertically throughout the show.”

The static trusses each held another video screen and took the load of the performer flying platform at the centre. “The concept was that the tracking screens would come together around the other gear, so that from the start of the show, the audience would only see a foursided video wall.”

During the performance, the tracking screens opened to reveal the inner video walls and then continued to track to the ends of the arena. The tracking screens came back together and opened several times throughout the show.

To oversee this choreography of screens in the sky, the team deployed TAIT Mother Grid Truss. “It was created not only as a way to house motors over larger spans, but has the ability to house a track and trolley system,” stated Nickerson. “We used this heavy-duty truss to make the spans under the scoreboards, and as the loads transferred to the main arena floor, we made a transfer connection to a slightly lighter truss. This was the first time we had done a transfer across these tracking systems, but by doing this, we were able to reduce some of the load in the roof.”

The smaller video cube and platform also presented a challenge – especially on the American run as it was hung under the scoreboard. “In order to get enough capacity in

www.novastar.tech

tony@novastar.tech

the trusses to fly the artist safely, we had to span over the fully loaded tracking truss system and into the static screen system where there was a little capacity to be found,” stated Nickerson.

“The trick in this aspect was not having to span the 50ft across all the other trusses; it was making sure we were high enough that the four tracking trusses didn’t see any of the load and the profile was low enough that we didn’t change any trim heights.”

Nickerson closed by described what it was like working with production on the tour. “I always enjoy working with the production team for Billie Eilish. The atmosphere is fun, and everyone is playing on the same team.”

On t he road the automation was handled by Automation Crew Chief, Brian Benauer and Automation Operator, Eamon Keane. “It’s a very complex layered mother grid with the performer fly beams spanning across the inside two VTT or Video Tracking Truss tracks,” stated Benauer, while explaining the complex nature of the build and the “carefully coordinated dance between departments working together”.

He added: “While our mother grid takes up the entire arena floor, which blocks access to a lot of other work, we complete our entire safety over looks performed by multiple crew members including our touring rigging team. This adds a little time to the load-in but contributes to the team’s successful and safe shows every night. Four hours in, the towers on the stage left of the arena would have already started their build cycle with one of our team members driving the

TAIT Nav Hoist for PRG and Upstaging teams to construct all four towers. The LED Shed team starts building the static screens on the mother grid as soon as it’s at trim and I give the go ahead, while starting the build of one side of the tracking screens while the stage is being built.”

Keane described safety as the “number one concern”. He commented: “For the performer flying platform, we are fortunate as most of the positions, if we were to lose power for example, we can perform a rescue from a ladder. For the toaster, there are interlocks that prevent the lift from moving if the door is open and plexiglass on the inside to eliminate pinch points. This is the only effect that is controlled locally. Instead of a cue being fired by me at the console, one of our excellent techs, Becki Oorbeck, is firing the toaster from an interface right at the lift.”

Keane explained the benefits of being based at the FOH position along with the lighting and video departments for the tour. “It’s especially helpful when dealing with SFX,” he continued. “Automation and SFX are the two most inherently dangerous departments of a touring production and when they are tied together, as we are with the lasers in the towers, being next to one another is immeasurably helpful to prevent an unsafe situation. As far the other departments go, it is very helpful during load-in to expedite things like lighting focus and aligning the tracking screens.”

He closed by describing how, “full cooperation from all departments is 100% necessary for its success”. He added: “With

everyone’s gear being interconnected, working together is the only option. To see that sort of teamwork daily is incredibly inspiring. When you pair that with an artist who is exceptionally talented and has a strong moral compass, it makes it very easy to come to work every day.”

Handling the barricades for the tour was Dutch Barriers. The company’s US arm, Guardian Barrier Service handled the American leg before handing over to its European partners this side of the Atlantic.

“T here are a lot of barriers, but it’s not a difficult setup,” commented Stanley Jilesen of Dutch Barriers, describing the deployment. “The only challenge is the area where Billie starts her show, and her entrance is a bit different every city. The system we provided has floorplate infills, so there are no gaps in the floorplate at all, taking away all tripping hazards.”

To close out the day, TPi walked over to audio FOH by the B-stage to meet up with FOH Engineer, Adam Stuart; Monitor Engineer, Salim Akram; Systems Engineer, Alex McCormack and Audio Crew Chief, Katie Hughes.

Throughout the entire run, the team carried a full Cohesion PA provided by supplier Clair Global. “The vertical coverage was the biggest initial hurdle,” mused McCormack, while describing the challenge of creating the in-theround setup for the tour. “We always wanted to keep the experience equal for everyone from the back to the front but having such a low stage

in the middle was quite tricky to find a front fill setup that would work.”

For front fills there were a total of 28 CO8s all around spaced on shelves and speaker stands. “They’ve got a lot of horsepower for such a little box,” enthused McCormack.

The rest of the rig was mainly made up of the CO10 with eight main hangs of 20 around centre stage, plus a hang of eight on either end to cover extended floor seating. “I think we’ve got a lot of the inventory of CO10,” joked McCormack. “If it was a larger format box, the weight would have been an issue so the CO10 proved to be the best solution. Adam also prefers the sound of the box, which works better for Billie’s material.”

Also on the rig were 60 CP218 II+ with 24 flown in four hangs of six in end-fire arrays, with an additional 36 on the ground in 12 stacks of three in cardioid configuration FOH.

McCormack harnessed Clair Global’s new modelling software for this run. “It’s really good –especially while making sure all areas are getting equal coverage,” he enthused.

From behind his DiGiCo Quantum 7, Stuart spoke about what he likes about the Cohesion system. “The PA has a great low-end curve and the point between the subs and the highfrequency boxes is very smooth, meaning you get a good ‘sub-bump’ without having any weird interaction between the two.”

The fact that this was the first time that Eilish was touring with a full band opened some new opportunities for Stuart to work with the mix of her back catalogue. “Even the things you would not expect to be live on this show, are

live,” enthused the FOH Engineer, commending the work of the band and Musical Director, Aron Forbes. “It adds a real energy to the show off the back of a tonne of time in the studio working out the various parts.

“T he DiGiCo Quantum 7 has been my desk of choice for many years due to its flexibility and the audio ins and outs are almost limitless,” continued Stuart. “I’ve got a whole lot of Waves with some outboard elements including Rupert Neve Shelford Channel for her vocals, distressors for the snare and a master bus processor on my master group and a couple of Bricastis for vocals, guitar and piano depending on the song.”

While the mix for the room was paramount, Stuart explained that the audio captured by fans’ phones was a consideration. “We spent a lot of time making sure that hangs reached down to the front and we had a few hangs on the far end for better coverage of the floor area. We want to give as much direct sound as possible. Intelligibility is the number one factor – if you don’t have that, you don’t have anything. Thankfully, phones have come a long way and are able to pick up much more, so having a nice low end always feels good.”

A st andout moment of the show was during When The Party’s Over, when Eilish silenced the audience and created a multi loop harmony of her voice to accompany the start of the song. “It’s real!” asserted Stuart when the topic was brought up at FOH. “I was sceptical when it was discussed in rehearsals if it would work live.” The team were “on the edge” of their seats on the

first night of the tour, according to McCormack, but were “so impressed” by Eilish’s ability to silence the audience.

Having been with the singer for the past seven years, Monitor Engineer, Salim Akram is one of the longest standing members of the production crew. “Although there are many new elements on the show this time, her mix really hasn’t changed too much. I just try to make her mix as full as possible,” he stated, discussing his process using an Allen & Heath dLive S7000.

For her vocal microphone, Eilish once again used the Sennheiser MD 445 capsule with all wireless coming via Shure.

“We are still on the PSM 1000s as that is what the artist has used for a long time and when we first were putting this one together, the new Shure products were not quite ready,” commented RF Technician, Hugo Gudino.

All microphones were on Axient Digital with Gudino using Workbench to master the rather challenging setup. “The show has been a challenge especially as the band is lower on the stage, which has LED – essentially, they are ‘inside’ a video wall.”