Chua C and Fadeyi MO (2020). The use of dynamo to automate the process needed to prepare building information modelling (BIM) models for facility management. Built Environment Applied Research Sharing #01, ISSUU Digital Publishing Platform.

BEARS#01 1

©BEARSreservestherighttothisappliedresearcharticle

Camille Chua and Moshood Olawale

Fadeyi,*

Sustainable Infrastructure Engineering (Building Services) Programme, Singapore Institute of Technology, 10, Dover Drive, Singapore 138683, Singapore

*Corresponding author’s email: fadeyi.moshood@singaporetech.edu.sg

ABSTRACT

Building Information Modelling (BIM) is a process that allows multiple project stakeholders to collaborate from the planning and design stage to the construction of the building within a 3D model. In turn, the information can then be extended to be used for facility operations and management. However, the effective operational benefits inherent in BIM models are not usually realised at the facility management (FM) stage. There are two main circumstances to consider; inaccurate as-built BIM models received from the contractors and the lack of BIM skills by facility owners and managers to check BIM models received for accuracy, completeness, and other problems. Additionally, they are unsure about how to transform the 3D as-built BIM models to 6D BIM FM models, which will be more suitable for operational use. Thus, the BIM models are usually untouched, unused, and neglected throughout the building’s operations stages. This, in turn, wastes the efforts placed into creating as-built BIM models in the first place. There is a need to provide a solution to these problems to improve productivity in the FM sector. A solution that could potentially help address the concerns was developed. The potential benefits inherent in the developed solution were tested. There was a noticeable reduction in the time taken to identify errors and inaccuracy in as-built models and transforming as-built 3D models to 6D FM models. This study is important because it provides the knowledge needed to streamline and improve productivity in the facility management sector.

Keywords: Facility management, Building Information modelling, Computational BIM, Productivity

BEARS#01 2

The use of dynamo to automate the process needed to prepare building information modelling (BIM) models for facility management

1. INTRODUCTION

Without an accurate as-built BIM model, the development of 6D BIM models for facility management (FM) and operations will be futile (Lin et al. 2018). For example, if a technician referredtoaBIMmodelontheIntegratedWorkplaceManagementSystems(IWMS)inwhich thelocationofthechillerisincorrect,thetechnicianwillspendtimelookingatthewrongplace for the equipment, thereby increasingin the response time. IWMSor Computer-aided Facility Management (CAFM) are platforms that integrate multiple business processes with its resources and information, which will be shared across many stakeholders. However, owners and their facility managers are usually notequipped with the skills or knowledge to checkthe as-built BIM models received from the contractors. If they are unable to validate the models received,theywillnotbesureofitsquality.

It is not safe to use a BIM model without assurance on its accuracy and quality because if operations staff were to rely on it unknowingly, it would result in unwanted implications. For example, if the information of an asset is missing in the as-built BIM model, and it was only found out many years later, accurate information about that equipment would be difficult to obtain. Trying to retrieve the information from stacks of hardcopy documents may not be feasible, as well. This was a common problem faced by many facility owners and managers. After facility owners receive their as-built BIM models from contractors, it is usually left untouched or checked for appropriateness and completeness. Only through an assessment of theBIMmodelslaterwould theyfoundouttheproblemsinthemodels.

Commonproblemsfoundinas-builtBIMmodelsareinaccurate buildingsystemsinformation, interferencesorclashes,missingorextrabuildingsystemcomponents,incorrectcolourcoding of systems, thewronglevel of details, and noproper connection ofmechanical, electrical, and plumbingsystems.Correctingtheseproblems,albeitnecessary,beforeBIMmodelscanbeused forfacilitymanagementandoperationshavetimeandfinancialimplicationsforfacilityowners. The consequences can be reduced or avoided if the problems are identified before project closeoutascontractorsarestillobligedtomakethenecessarycorrections.

Subsequently, the heavy 3D as-built BIM model will have to be transformed into a 6D lightweight BIM FM model by removing irrelevant information. A 6D BIM FM model will

BEARS#01 3

help to reduce the amount of manual data entry required to transfer the information into any facilitymanagementplatform,whichnotonlysavestimebutalsoreduceanyhumanerror.Itis also said to have possibly up to 80%-time savings for operation and maintenance works (Naghshbandi, 2017). However, owners and facilities managers are not necessarily trained to edittheBIMmodeltoconverttheheavy3Das-builtBIMmodeltoalightweight6DBIMmodel forFMoperationpurposes. The lackof suchskillswillimpede the process ofintegratingBIM models into IWMS, other Internet of Things (IoT) solutions, and any other use of the BIM models. This also results in the BIM models not being able to be put to good use despite the amountofeffortputintothecreationoftheBIMmodelsfromdesigntoconstructionphase.

This study aimsto streamline the processofconverting 3D as-builtBIMmodels to6D models for effective and productive facility management and operations. The first objective of this study is to examine the effectivenessof the developed solution in providing a higheraccuracy of BIM modelsforoperation purposes. Thenumber ofproblemsand taskscompleted withina limited time will be used as measures for determining the effectiveness. If the solution can detecta moresignificantamountofissuesthanthecurrenttraditionalmethod,higheraccuracy of the BIM models willbe achieved. If the solution can complete more tasks correctly, higher accuracyoftheBIMmodelcanbeachieved.Thesecondobjectiveistoexaminetheefficiency of the solution in streamlining the work processes needed to prepare BIM models for facility managementand operation purposes. If the solutioncan reducethetime taken tochecktheasbuiltBIMmodelsforproblemsthanthetraditionalmethod,theprocesswillbeconsideredmore efficient.If thesolutioncanreducethetimetakentotransformtheas-builtBIMmodeltoa6D BIMFMmodelthanthetraditionalmethod,theprocesswillbeconsideredmoreefficient.

2. DEVELOPMENTOFSOLUTION

Thesolutioninvolvedthedevelopmentofaprogrammetoautomatetheworkprocessesneeded to prepare the BIM model for facility management and operations use. The first component involvedtheautomationoftheworkprocessesrequiredtocheckthequalityoftheas-builtBIM models. This is an important step to ensure the quality and integrity of the model that will be usedforfacilitymanagementandoperationpurposessubsequently.Additionally,mistakesthat canbefoundquicklyandaccuratelyduringtheperiod oftakingoverfromthecontractorswill still be the contractor’s responsibility to fix. It is essential to eradicate errors and ensure the

BEARS#01 4

deliveryofBIMmodelswithintegritythatmeetstherequirementsoftheclient.

The second component is to automate the work processes needed to transform the 3D dense as-builtBIM modelto anoperationallyready6DlightweightBIM FM model. This isanother important step to prepare the BIM model for facility management and operation purposes. A heavyweight,complicatedmodelwithinformationmorethanrequiredcaneasilymisleadusers. Moreover, as the amount of unnecessary information and details increases, more time will be taken to retrieve needed information among the rest of the details. Also, facility owners and managersmaynotnecessarilybeequippedwiththeskillstomakechangestothemodelonthe BIMauthoringtool.Throughautomation,alotoftheworkrequiredcanbesimplifiedandmade lesscomplicatedforthefacilityownersandmanagers.

If the solution can help to increase the amount of work completed correctly, higher accuracy canbe attained. The second component willalso help to meet this study's secondobjective of increasingtheefficiencyofworkprocessesbecauseautomationcanreducethetimeneededto complete the same amount of work. It is envisaged that both components will help simplify work processes in preparing the BIM models for operation purposes. By making the work processessimplerfortheusers,itwillhelptoreducethetimerequiredandincreasethequality oftheoverallworkdoneastheycanspendtimemoreproductively.

After much research on possible solutions as well as looking into currently available applications, it was decided to use Dynamo for Revit to develop the solution. A visual programmingsoftwarewaschosen overdevelopingandwritingwritten scripts duetothelack of a strong programming background. We also decided against other possible solutions such asSolibriforcheckingofmodelsbecauseDynamoisanin-builtsoftwareinRevit(Commonly usedBIM AuthoringTool), whichreducesthe need foradditionalsoftwareandconversion of filetypestocatertoanothersoftware.Sinceitisalreadyin-builtintoRevit,italsoreducesthe need to obtain another software. All in all, using Dynamo is a more convenient and costefficientsolutionontopofthemultiplelevelsoffunctionalityandbenefitsitalreadyprovides.

It would be challenging to develop an Application Programming Interface (API) that can interactwithRevitwithoutthehelpofanexpertforintegrationifothersolutionswerechosen. Dynamoisanapplicationthathelpsuserstocreateprogrammesalsoknownasscripts,tosolve

BEARS#01 5

certain problems in Revit. It is an in-built tool included in all versions of Autodesk Revit software. It replaces the typical way of writing codes to create programmes for architects, designers, and engineers, who are more visually oriented or users who are not very knowledgeablewiththeprogramminglanguage,usinggraphicelementsknownasnodes.

Each node will perform a specific task and “wires” are used to connectall the modes to form the programme. Additionally, customized packages of nodes written by online users can be used to create more complicated programs. If the nodes are insufficient, it is also possible to writeascriptforthenodefortherequiredfunction.Thissolutionveryversatileformanyuses. SomeoftheusesorbenefitsofDynamoincludesautomationofrepetitivetasks,creatingaccess to the dataaswellasdoingacomputationalsimulationtosimulatedifferentdesigns.

2.1 ListofFunctions

Based on the two main components for the designed solution, as explained above, a list of functionsforeachofthecomponentswouldbeexplained.Eachcomponentwillbemadeupof multiple functions to complete the different necessary tasks to meet the needs and objectives for each component. The lists are non-exhaustive, and what is listed below are the critical functions thatare required to meetthe objectivesandthe basic needsfor facilitymanagement andoperationpurposes.EachofthechosenfunctionwillbedevelopedusingDynamoandwill gothroughteststodetermineitseffectivenessinmeetingtheobjectives.Thechosenfunction’s scriptdesignwillalsobediscussedbelow.

Inthiscomponent,the functions weresplitinto two maindisciplines. Due to the difference in theparameters,similarfunctionsweresplitintothetwolistsdespitetheprogrammedesignand methodology is the same. See Table 1 for details. In this component, the functions for the Architectural and MEP BIM models share the same list of functions. The purpose of this component is for facility owners and managers to prepare their BIM models and create a lightweight and more efficient BIM model for facility management and operation use. See Table2fordetails.

2.2 Prototype:DynamoScripts

Thefinalscriptswrittenfortheselectedfunctionsareexplainedinthissection.Foreachofthe

BEARS#01 6

scripts,eachstepisgroupedintoboxesofgreenororange.Theboxhighlightedinorangerefers toastepthatthe userwill requiretoinputdatafortheprogrammetorun.

2.2.1 Part 1: Check as-built BIM Models

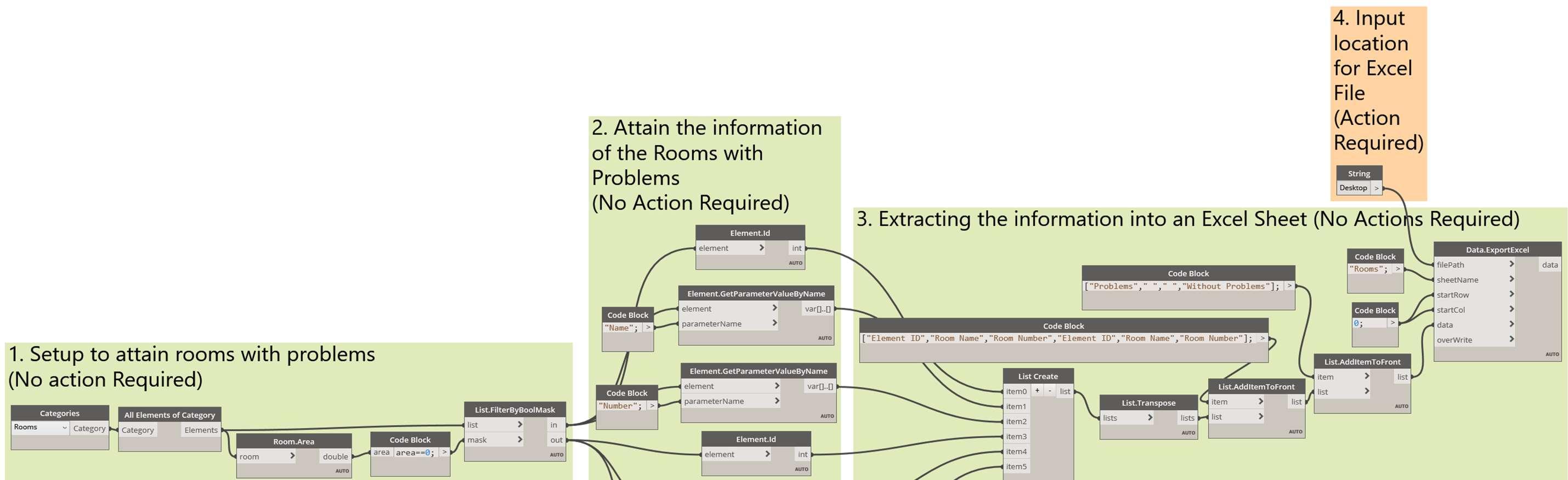

In Figure 1, the Dynamo script was developed to check the architectural BIM model’s room boundaries.Therearefourmainstepsrequiredtofulfillthisfunction.Inthefirststep,thenodes placedareusedtoattainalltheroomsintheBIMmodelandsubsequentlyfilterouttherooms withanundefinedarea.FortheroomswithproblemsintheBIMmodel,Revitwillnotbeable to define the area of the room correctly, and hence when the room is equaled to 0, the programme will be able to filter out all the rooms with problems. Then, the rooms were categorised into two lists; rooms with problems and rooms without problems. In the second step, the nodes are placed to attain the corresponding information of the rooms, which are essential to identify the correct room. The required information includes name, number, and elementIDoftheroom.ByattainingtheelementID, anyusercansearchthisIDinRevit,and theelementwillautomaticallybeprompted.

The third step is to export all the informationattained into a report by using Microsoft Excel. Lastly, before running the programme, the fourth step is to key in the location that the excel fileshallbesaved.AnexampleoftheexportedExcelreportisshowninTable3a,whichwould match the number of problems in the Revit Schedule, as shown in Table 3b. Without this function, users would have to check for the issues manually by creating a room schedule in Revit to look for the issues before extracting the element ID of each room with problems to createthereportandgive tothecontractorstorectifythe problems.

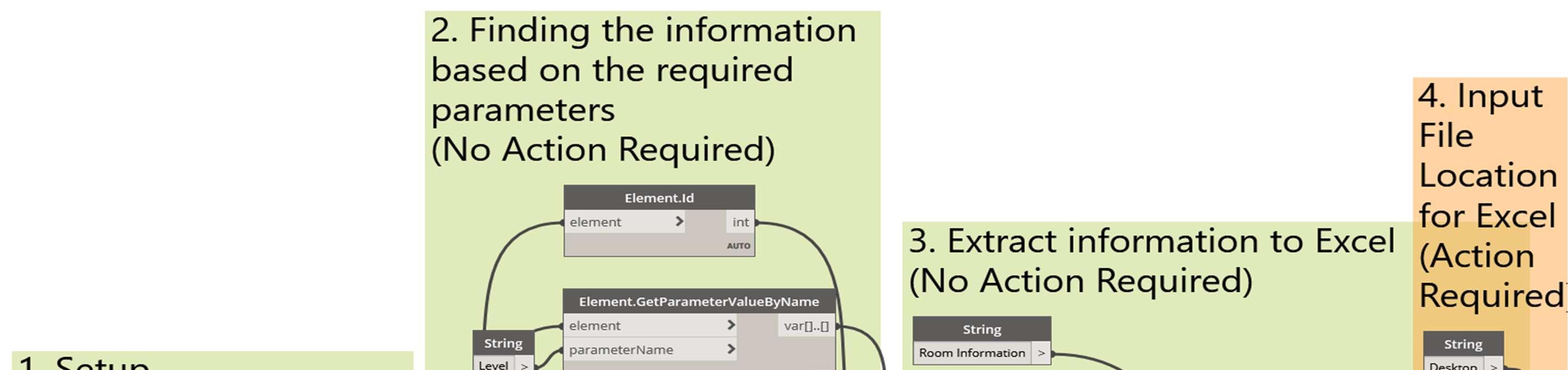

Figure 2 shows the Dynamo script written to check the information fields of the MEP BIM model. The purpose is tocheckall the required fieldsforeachmechanicalequipment thathas beenfilled up. This script can be duplicated for any other equipment in the model. The script ismadeupoffourmainstepstocomplete. Inthefirst step,theprogrammerunstoretrievethe mechanical equipment in the BIM model. In the second step, for each parameter, Mark (also EquipmentLabel),Comments(alsoLocalMotorControlPanel),Brand,EquipmentModeland Capacity, the programme will filter out all the entire list of equipment and check each of the corresponding fields that do not have any information input and filter them into a list by

BEARS#01 7

extractingeachequipment’suniqueelementID.

Inthethirdstep,theprogrammewillexporttheinformationgatheredintoanExcelsheetreport. The last step is a step for the user to input the location that the excel sheet shall be saved. An example of the exported Excel sheet report is shown in Table 4a. Without this programme, users would have to manually look for the missing fields by creating equipment schedules to check each equipment’s information fields for the different parameters before extracting the elementIDforeachequipmentwithmissinginformationtocreateareport.Table4bshowsan example ofthemissingfieldsintheRevitMEPschedule.

Table1:Listoffunctionsforsolution's1st component

Function Description ArchitecturalDiscipline

1 CheckRoom Boundaries

Thepurposeofthisfunctionistoensurethatallroomsareenclosedproperly bycheckingitsroomboundaries. Thisfunction will identifyanyroomsthat havetheerrors;NotPlaced,NotEnclosedandRedundantRoomsasdefined by Revit. Inaccurate room boundaries will result to complementing informationsuchastheroomareastobeinaccurate.

2 CheckRoomNames

Thepurposeofthisfunctionistocheckthatallroomshavebeennamedand numbered in accordance to a standard naming convention that was defined and decided with the facility owners. This is important to help identify the assets’ location, space and management of tenants during the operation stages.

3 Checkfor DuplicatedRoom Numberings

The purpose of this function is to check for any duplication of room numberings. Unlike room names, room numbers cannot have duplicates as they serve as a unique form of identification of a space that may have the samenameasotherspaces.Forexample,therecanbetwotoiletsonthesame floor where the name of the space will be toilet, but the room numbers will serveastheuniqueIDtoidentifythespecifictoilet.

4 CheckforCritical Interferences

MEPDisciplines

1 CheckforExtraor MissingCritical Equipment

Thepurposeofthisfunctionistocheckforanymajorinterferencestoensure theintegrityofthemodelasperonsiteconditions.

The purpose of this function is to check for any extra equipment that does not exist in the building, e.g. accidental placement of the same asset twice, or missing equipment that was not developed in the BIM model. This will affect theintegrityoftheBIMmodeland willmisleadtheuserswithwrong information.

BEARS#01 8

2 CheckInformation Fields

Thepurposeofthisfunctionistocheckthatalltherequiredinformationfor anequipmenthavebeenfilledupbythecontractors.Theinformationwould have been pre-determined in the Asset Information Requirements (AIR) at the beginning of a project that must be delivered by the contractor. Information about an asset is critical for the efficiency and effectiveness of the day to day work for facilities management. Having accurate and sufficient information at hand for facility managers helps them to make informed and better decisions for the building which includes the maintenance processes. It is very important to attain this information from thebeginningfromtheoriginalmanufacturers,vendorsetc.Thisisbecause, overaperiodoftime,itcangethardertoattaintherequiredinformationafter the building starts its operations. For example, it will become almost impossible to attain the specific equipment serial number of a fan coil unit that is insulated and placed up high in the false ceiling in the building. Moreover,wear andtearastimegoesbycanalsocauseequipmentplatesto bewornofforscratchedwhichresultstotheinformationbecomingilliterate. All in all, the information of the equipment is deemed as one of the most importantinformationtohaveforfacilitymanagementespeciallyforcritical assets.

*Critical assets can refer toassetsthat arecritical to theperformanceof the buildingsoranyhighvalueassetswherereplacementiscostlyandmayhave implicationstootherbusinessprocesses.

3 Checkfor Duplicated EquipmentLabels

The purpose of this function is to ensure that there are no duplicated equipment labels allowing easier identification of the assets. Most importantly, all information about a specific equipment is tagged by the equipment label. For example, it would be difficult to match and tag the correctinformationtothecorrectequipmentwhentheBIMmodelsaretobe integratedtoanIWMSforfacilitymanagementpurposes.

4

Checkfor Complianceto ColourCodefor MEPSystems

Thepurposeof this function isto check if the different systems in the MEP BIMmodelsare complying withthecolour codeas stated bythe Singapore Building Construction Authority (BCA) “Code of Practice for BIM esubmissionMEP.”

5 CheckforCritical Interferences

Thepurposeofthisfunctionistocheckforanymajorinterferencestoensure the integrity of the model as per onsite conditions. As compared to the Architectural discipline BIM model, the MEP disciplines tend to have a higher chanceof clashesdueto largenumber ofpipes,ductsandequipment constraint within the same space. Thus, it is important to check for clashes in these and against the different disciplines to ensure the integrity of the models.

BEARS#01 9

Table 2:Listoffunctionsforsolution's2nd component

S/N Function Description

Architectural&MEPDisciplines

The purpose of this function is for users to update new information into their BIM models such as information that were only obtained after the completionof constructionstages.An example could betheinformation of the new tenants. This function consists of 2 parts; extracting informationandimportinginformationbacktotheBIMmodel.

1 Update Informationinto BIMModels

Extract Information to Excel

Thefirstpartistoallowuserstoextracttheexistinginformationfromthe BIM models into a commonly used format, excel, for the users to make adjustmentsorforanyotheruses.

Import Information from Excel to BIM Models

The second part is to allow users to update the BIM models with the updatedinformationfromtheexcelsheet.

2 Removalof UnwantedItems

Thepurposeofthisfunctionistoremoveanyunnecessaryandunwanted itemsintheBIMmodelthatisirrelevanttotheoperationstage.Keeping unwanted items will cause the BIM models to be huge, heavy and lag. Additionally, it reduces the efficiency of navigating the file and finding the required information. Below is a list of items commonly not needed intheBIMFMModels:

Non-CriticalAssets;E.g.FurnitureasdefinedbyFacilityOwners

ConstructionDrawingSheets,Schedules,Viewsetc.

Referencelines,Planes,ScopeBoxesetc.

The purpose of this function is to further lighten the BIM models and reduce the file size. This function consists of 2 parts; Purging and compacting.

3 LightentheBIM Models

Purge Files to Remove Unwanted Items

The first part is to remove any unused components that were previously loadedintotheBIMmodelsthatwouldtakeupspace.

Compact Files to Reduce File Size

Thesecondpartistocompactandoverwritethelarger filesize.

BEARS#01 10

BEARS#01 11 Figure1:DynamoScriptforcheckingroomboundaries Table3a:Exampleofexportedexcelreportforcheckingofroomboundaries(Left).Table3b:ExampleofroomscheduleintheRevit showingproblems(Right) ProblemsWithoutProblems ElementIDRoomNameRoomNumberElementIDRoomNameRoomNumber 3060380Corridor20-CR-02306030720-OF-06 3085010Room20-CR-033060358Office20-OF-01 308502420-CR-063060365Office20-OF-02 3060368Office20-OF-03 3060371Office20-OF-04 3060374Office20-OF-05

BEARS#01 12

ElementIDofMissingEquipmentLabel:ElementIDofMissingLMCP:ElementIDofMissingBrand:ElementIDofMissingEquipmentModel:ElementIDofMissingCapacity: 39355027861570786157078615707861570 7861613786161378616137861613 7865203786520378652037865203 7865218786521878652187865218 7866616786661678666167866616 788117078811077881107 78811387881138

Figure2:DynamoScripttocheckBIMmodels'informationfields Table4a:Exampleofexportedexcelsheetreportofmissinginformation

Table4b:MissinginformationinRevitMEPschedule

TheDynamoscriptdevelopedtocheckforanyduplicatedequipmentlabelsintheBIMmodel isshowninFigure3.Therearefourmainstepsforthisfunctiontobecarriedout.The programmewouldfirstretrieveallthemechanicalequipmentavailableintheBIMmodel.This scriptcanbeduplicatedtodothesameforanyotherequipment.Inthesecondstep,the programmerunstofindalltheduplicatedmechanicalequipmentlabelsbyusingtheparameter “Mark.”Theprogrammewouldfiltertheentirelistofequipmentlabelstofindthenon-unique items(inotherwords,duplicatednames)andretrievetheelementIDoftheequipment.Inthe thirdstep,theprogrammewouldgatheralltheinformationrequiredandexportthemintoan Excelsheetreport.Thelaststep,step4,isforuserstoinputthelocationtosavetheExcelsheet report.AnexampleoftheextractedExcelReportofthelistofequipmentthathasduplicateis showninTable5a.Thefirstcolumnrepresentsthelistofuniqueequipmentlabelsfound.For anyequipmentlabelsthatareduplicated,itwillbeshowninthesecondcolumnonwards. Withoutthisprogramme,userswouldhavetoconductvisualchecksoneveryequipmentto lookforanyduplicatedinnamesasshowninTable5b.

2.2.2.Part2:Transformas-builtBIMmodelstoBIMFMModels

ThepurposeofthisfunctionistobeabletoupdatenewinformationintotheBIMmodelseasily bybeingabletoextractexistinginformationfromtheBIMmodelsforreferenceandediting beforeimportingthenewsetofinformationbackintotheBIMmodel.Withoutthisprogramme, userswouldfirsthavetomanuallycreateanequipmentschedule,selecttherequiredparameters, andexportthescheduleasatextfilebeforeconvertingittoanExcelsheet.Then,toupdatethe informationbacktotheBIMmodels,userswouldhavetogotoeachequipmentandmanually keyininformationcellbycellthenewinformation.

BEARS#01 13

Figure3:DynamoScriptforcheckingduplicatedequipmentlabels

Table5a:Exampleofexportedexcelreportforduplicatedequipmentlabels(Left);Table5b:MissinginformationfromMEPSchedule(Right) EquipmentElementIDElementIDofDuplicatedEquipmentLabels

AHU-21-0129918083729818

CHWP-21-013516748

CWP-21-013517065

CWP-21-023517127

HWP-21-013517528

CH-21-013741993

CH-21-023742374

HP-21-013935502

EAF-21-016415301

HWP-21-0576392277876093

VAV-20-017861570

VAV-20-037861613

VAV-20-047865203

VAV-20-0278652187866616

HWP-21-027881107

HWP-21-037881138

HWP-21-047881170

BEARS#01 14

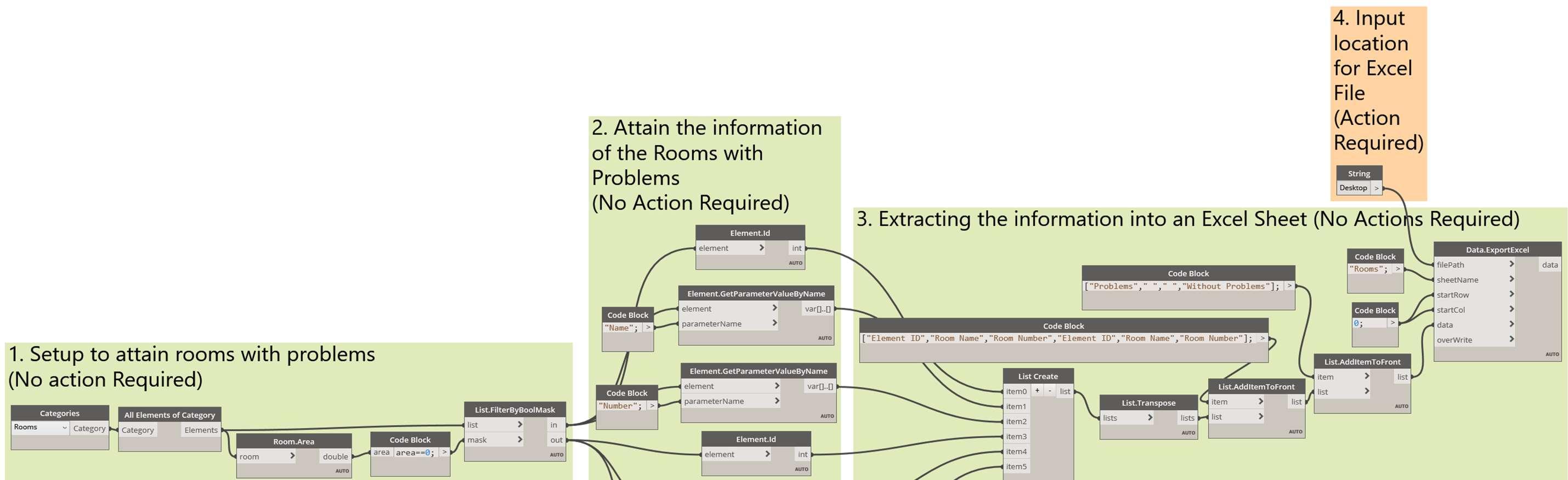

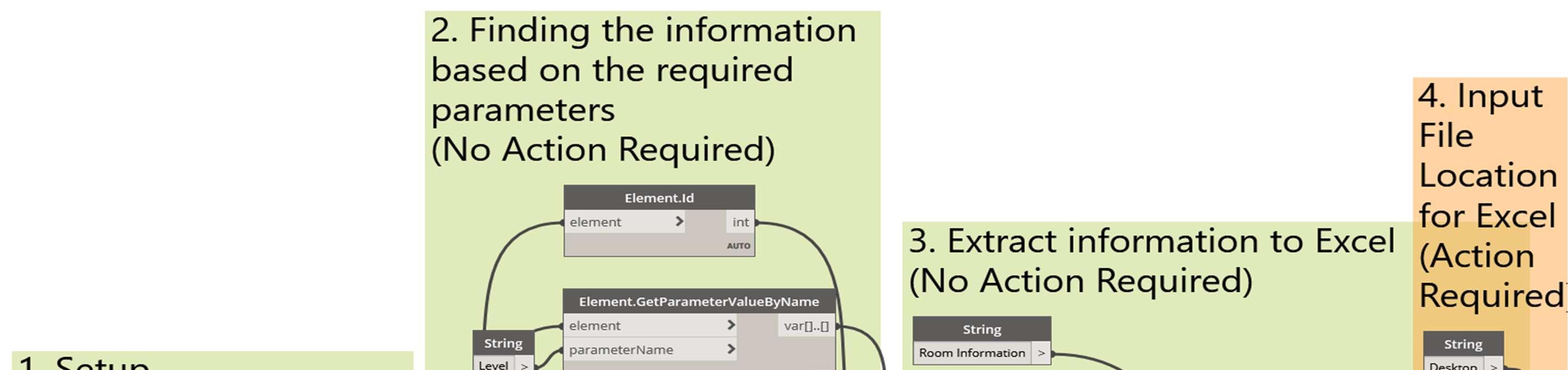

The Dynamo script for exporting information to Excel is shown in Figure 4. An example of extracting existing information about the rooms in the architectural BIM model was used. In this part, thefour mainsteps in the scriptwillrun to extractthe existinginformationfrom the BIM models into an Excel Sheet Report for editing. In the first step, the programme will retrievealltheroomsintheBIMmodel.Inthesecondstep,theprogrammewillextractallthe informationofeachroombyselectingtheparameterstoextract.Inthiscase,theparametersto extractincludetheElementID,level,name,number,area,nameoftenant,andoccupancyrate. Inthethirdstep,theprogrammewillgatheralltheinformationretrievedandextracttheminto an Excel sheet report. The last step is for users to input the location of where the Excel file should be saved. Table 6 is an example of the extracted Excel report with all the information required.

The Dynamo script for importing information to the BIM model is shown in Figure 5. For example, the Excel sheet, as shown in Table 7, is updated with new information that shall be importedbackintotheBIMmodel.Thenameofthetenantsandoccupancyratecolumninthe Excelhavebeenupdated.Inthescript,therearethreemainstepsfortheprogrammetoimport theinformationbacktotheBIMmodel.Inthefirststep,theuserisrequiredtoselecttheExcel filecontainingtheupdatedinformationtobeimportedintotheBIMmodel.Inthesecondstep, the programme will readthe informationfrom the Excelfile into a format for theBIM model to understand and Excel sheet into different columns of information. In the last step, the programme will overwrite the existing information by matching the different columns of informationtotherespectiveparameters.Theprogrammewillidentifytheinformationofeach roomthroughtheelementID.

Table6:Exampleofextractedexcelreportforroominformation

ElementIDLevelNameNumberAreaNameofTenantOccupancyRate

3060307STOREY20CollaborationOffice20-OF-06150.8732516NilNil

3060358STOREY20Office20-OF-0140.2193357NilNil

3060365STOREY20Office20-OF-0240.30419244NilNil 3060368STOREY20Office20-OF-0341.72202394NilNil

3060371STOREY20Office20-OF-0441.01310819NilNil

3060374STOREY20Office20-OF-0541.01310819NilNil

3060380STOREY20Corridor20-CR-0247.18403125NilNil

3060394STOREY20ManagementOffice20-MO-0125.83801766NilNil

3083026STOREY21PlantRoom21-PR-0178.21850707NilNil

BEARS#01 15

BEARS#01 16 Figure4:DynamoScripttoexportinformationfromBIMmodelsintoexcelreport

Table7:ExampleofexcelsheettobeimportedbackintoBIMmodel

ElementIDLevelNameNumberAreaNameofTenantOccupancyRate

3060307STOREY20CollaborationOffice20-OF-06150.8732516SharedSpace30Pax 3060358STOREY20Office20-OF-0140.2193357Untenanted15Pax 3060365STOREY20Office20-OF-0240.30419244Untenanted15Pax 3060368STOREY20Office20-OF-0341.72202394Untenanted15Pax 3060371STOREY20Office20-OF-0441.01310819Untenanted15Pax 3060374STOREY20Office20-OF-0541.01310819Untenanted15Pax 3060380STOREY20Corridor20-CR-0247.18403125Non-TenantedSpaceNoOccupancyRateknown 3060394STOREY20ManagementOffice20-MO-0125.83801766Non-TenantedSpace10Pax 3083026STOREY21PlantRoom21-PR-0178.21850707Non-TenantedSpaceNoOccupancyRateknown

Thescripttodeletetheunwanteditemsfromtheas-builtBIMmodelisshowninFigure6.The script consists of two main steps that do not require any actions by the user. The programme would firstdelete the non-critical assets, e.g., furniture, byselecting components unwantedin thefirststep.ThisstepcanbeeasilyduplicatedtodeleteanyotherunwanteditemsintheBIM model, as well. Then, the programme will delete all unwanted items that were used for construction purposes or drafting purposes, which include scope boxes, reference lines, reference planes, CAD links, elevation views, section views, drawing sheets, and schedules. Without this programme, the user would have to manually select the items in the BIM model to delete off the unwanted items which usually results to careless mistakes by leaving one or twoitemsbehindoraccidentallydeletinganitemthatwasnotmeanttobedeleted.

The Dynamoscript forpurgingandcompactingfilesisshown inFigure 7.The scriptconsists oftwomainstepswhereusers’actionsarenotrequired.Inthefirststep,theprogrammewould first purge the BIM model to remove all the unused items. Then in the second step, the programme would automatically compact the file size and overwrite the existing file to save the smaller sized file as the existing file. Without this programme, users would have to manuallypurgethefilesafewtimestocompletelyremovetheunuseditems,asshowninFigure 8. However, in many cases, the file is not entirely purged to 0 due to carelessness. In the programmedeveloped,thesystemwouldautomaticallyruntopurgeuntilthefigurereaches0, leavingnoerrorsbeforecontinuingtothesecondstep.Forthesecondstep,userswouldusually havetomanuallycompactandoverwritethefile,asshowninFigure9,whereasourprogramme wouldautomaticallydothatfor the user.

BEARS#01 17

BEARS#01 18

Figure5:DynamoScripttoimportinformationfromExceltoBIMmodel

BEARS#01 19 Figure6:DynamoScripttodeleteunwanteditemsofftheBIMModel

Figure7:DynamoScripttopurgeandcompactfile

Figure8:Exampleofstepstomanuallycompletepurgingoffile

BEARS#01 20

Figure9:ExampleofstepstomanuallycompactandoverwritetheFile

3.METHODOLOGYFORTESTINGSOLUTIONEFFECTIVENESS

Testswereconductedtovalidatetheoutcomesfortheimplementationoftheproposedsolution. Twosimilartestswereconductedtovalidatethetwocomponentsoftheproposedsolution–checkingofmodelsandtransformationofmodels.Certainfunctionsareduplicatedfordifferent disciplines;testsforthefunctionswillonlybeconductedononediscipline.Thisisbecausethe conditionsofthetest,thewrittencodeforthatfunction,andtheexpectedresultswillbethe same.Forexample,themethodofcheckingforinterferencesintheArchitecturalandMEP disciplineisthesame.Hence,ascriptandtestweredoneonlyfortheMEPdiscipline.Another exampleisthecheckingofroomnamesforanyduplicateswillbethesameascheckingforany duplicatesforequipmentIDontheMEPdiscipline.

Thepurposeofthefirsttestwastofindalltheproblemsinthegivenas-builtBIMmodelby conductingchecksbasedonalistoftasksgiven.Thepurposeofthesecondtestwastoprepare theBIMmodelforoperationsusesbytransformingthegivenas-builtBIMmodelintoaBIM FMmodelbasedonthegiventasks.Eachparticipantwasgivenasetofinstructionsmanual explainingthedifferenttasksandscopeofworkrequiredofthemforeachtaskandtest specifically.RefertoFigure10“a”to“c”forthetestinstructionstothesubjects.

BEARS#01 21

Figure10a:Testinstructionsforcheckingas-builtBIMmodels

BEARS#01 22

Figure10b:Testinstructionsfortransformingas-builtBIMmodelstoBIMFM6Dmodels

BEARS#01 23

Figure10c:Testinstructionsforupdatingnewinformationforeachroom,removing unnecessaryitems,andpurgingandcompactingfiles.

BEARS#01 24

Thefirstobjectiveforthetwotestswastovalidateifahigheraccuracyratecanbeachievedby comparingthenumberoftasksparticipantscancompletecorrectlywithandwithoutthe proposedsolution.Thesecondobjectivewastovalidateifhigherefficiencycanbeachieved bycomparingthetimetakentocompletethetaskswithandwithouttheproposedsolution. Eachparticipantmadetwoattemptsforeachtest.Onthefirstattempt,theparticipantsusedthe traditionalmanualmethodtocompletetherequiredtasks.Onthesecondattempt,the participantusedtheproposedsolutiontocompletethetasks.Beforethetest,ashortbriefing wasgiventoparticipantstoensuretheyknowtheexpectationsofthetestandwhattheyhave todo.

Usingthemock-upas-builtBIMmodelgiven,theparticipantstriedtocompleteasmanyofthe tasksaspossible.Forthefirsttest,theparticipantstriedtofindalltheproblemsplantedinto theas-builtBIMmodel.Theparticipantsweregivenanexcelsheettorecordtheproblems identifiedforeachtask.Forthesecondtest,participantswererequiredtocompleteasmanyof thetasksaspossibleforthetransformationoftheas-built3DmodeltoaBIMFM6Dmodel. Amaximumof20minutesforeachtest.Figure11showstheBIMmodelsusedforthestudy. ThesizeoftheBIMmodelsadoptedisverysmalltoservetheexperimentalpurpose.Thescale ofbuildingprojectsismuchlarger.

Figure11:BIMmodelsusedforthestudy.

Thefacilitatorforanalysisrecordedthetimeforeachtaskandattempt.Answerswererecorded intheexcelsheet,andcompletedBIMmodelsforthesecondtestwere“marked”bythe facilitatortodeterminethenumberofcompletedtasksforanalysis.Afterthecollectionofthe data,theresultswereanalysedusing:

TimeDifferenceforeachparticipants’results

BEARS#01 25

Percentage oftimesavings

Measureoflocation,mean,andmedianforalltheparticipants’results

The difference in the mean and median to determine if there are very extreme variationintheresults

The same method of analysis was used to evaluate the level of accuracy attained before and aftertheimplementationofthe solution.

3.1 TasksforTest1

Forthefirsttest,participantsdidthefollowingwiththeas-builtBIMmodeltheyweregiven.

Checkthatallroom’sboundariesinthearchitecturalBIMmodelareenclosedwith no“NotEnclose,”“Redundant”,and“NotPlaced”roomsasdefinedbyRevit.

CheckiftheMEPequipmenthavebeennamedanditsinformationhavebeenfilled upintheMEPBIMmodel

Checkthatallequipmenthasauniqueequipmentlabel

3.2 TasksforTest2

For the second test, the aim was to clean up the as-built BIM model to create a BIM FM 6D model. The followingtaskswereperformed.

ToupdatenewinformationintotheBIMmodel

Toremoveunwanteditemsincluding o Sheets/Schedules o Views/Sections/ScopeBoxes o Non-criticalassetssuchasfurniture

Topurgethefilesoffunusedcomponents

Reducethefilesizebycompactingthe file

3.3 TestEnvironment

Six main factors were considered to lower any influences of uncertainty in the results. The selectedfactorsforthisprojectweresummarizedandexplainedinthetablebelow.

BEARS#01 26

Table 8:Environmentalfactorsforthetests

S/N Factor Description

Equipmentusedforthetests:

Thesamecomputer,mouse andmousepadweregiven to theparticipantsto complete the tasks. The purpose is to ensure that the specifications and performanceofthecomputerisconsistenttonotaffectthetimeneeded.

1 Equipment

MeasurementEquipment:

Thesamemobilephonewasusedtorecordthetimetakenfor the participantstocompletethetasksgiven

2 Operator

A facilitator conducted the test and took charge in providing the initial instructions,recordthetimetakenandensurefairnessofthetest.

Thetestwasconductedinaspacethatmeetsthefactorsbelow.

ThermalComfort:

o Thespacewasair conditioned atatemperaturedeemed comfortableby the participant since different individuals will consider different temperatureandhumiditytobesuitableforthem.

IndoorAirQuality:

o Thespacewasdeemedtohavecomfortableairchangelevelstoprevent stuffiness. Participantswere asked whether theyare comfortable or not withthespacebeforecommencingtheactualtest.

Lighting:

3 Environment

o Thespacewasdeemedtohaveenoughlightingfortheparticipants.The screen was placed away from any glare (such as from windows). The computer’sscreenbrightnesswas also adjustedto fittotheparticipants comfortlevelbeforethestartofthetest.

Noise:

o The space where the tests were conducted was an enclosed space with considerablylownoiselevelsfortheparticipanttofocusonthetask.

Stress:

o The space had considerably low amount of distractions such as low humantraffic.Highhumantrafficmaycausestresstotheparticipant.

To garner support from the participants to spend time for the test, the convenienceoftheparticipantswasprioritized.Individualmeetupsatspacesthat meettherequirementswereusedtocatertotheconvenience oftheparticipants. Inordertoensurethatthetestamongalltheparticipantswerefair,theconditions were strictly adhered to. The environmental conditions would be controlled to reduceanypossibilitiesofanxiousnessandstressfromexternalfactors.

4 TestTaker Factors

Factors affecting the participants’ condition of the mind may also indirectly affectthereliabilityoftheresults.Forexample,astressed-outparticipantwitha severe lack of sleep may not produce the same results as compared to when he is in a better state of mind. Thus, a reminder was also given to the participants to ensure that they should have enough sleep the night before the test. All participantswerehealthyduringthetests.

5 Method

Themethodusedbyalltheparticipantwasconsistent.Themethodwasguided bytheinstructionsgiventothesubject–SeeFigure10.

BEARS#01 27

FiveparticipantswithproficiencyintheBIMauthouringtoolandfacilitymanagementindustry took part in the study. It is important to ensure all the participants of the test have a similar level of proficiencyto ensure that the results attained will be ofequalfooting. A smallsize is appropriateforthisstudy becausesubjectshave asimilarlevelofproficiency. Thisisreferred toashomogenoussampling(Bornsteinetal.,2013).

4.RESULTSANDDISCUSSION

4.1 Test1:Checkingoftheas-builtBIMmodels

This sectionprovidesresultsofthetimetakentocompleteandaccuracyofcompletedtasks incheckingas-builtBIMmodelswithandwithouttheproposedsolution.

4.1.1 Time Taken for Tasks

Table 9 shows the time taken for each participant to complete the tasks in Test 1 with and withoutthe proposed solution. Itwasobservedthatallfive participantswere able tocomplete therequiredtasksfasterwiththeuseoftheproposedsolution.Thiswouldmeanthattheywere abletouseashorteramountoftimetocompletethesameamountofwork,whichincreasesthe efficiencyoftheirworkprocesses.

Table9:TimetakentocompleteTest1withandwithouttheproposedsolution

4.1.2 Accuracy of Completed Tasks

Table10showsthecompletionstatusofeachtaskforalltheparticipantswithandwithoutthe proposed solution. The green box means that the participant was able to complete the task correctly and on time as per the requirements of the instruction’s manual. The red box meant thattheparticipantdidnotcompletethetasksrequiredcorrectlyeitherwithmistakesordidnot complete the requirements as per the instruction’s manual. As evident from Table 10, the red boxes only occur for the attempt before the proposed solution was implemented. After the

BEARS#01 28

BeforeAfterBeforeAfterBeforeAfterBeforeAfterBeforeAfter Task1241162237141229150233153263167 Task2432200421213464188416188374181 Task3263176276149273138251128270159 Total936538934503966476900469907507 TimeTakenforEachParticipant(Before&AfterImplementationofSolution)(Secs) TasksParticipant1Participant2Participant3Participant4Participant5 Part1-CheckingofAs-builtBIMModels

implementationofthesolution,allthetaskswerecompletedcorrectlyforallfive participants. This would mean that overall, the accuracy of the results would increase with the use of the proposedsolution.

4.2 Test2:Transformationofas-builtmodelstoBIMFMmodels

This sectionprovidesresultsofthetimetakentocompleteandaccuracyofcompletedtasks incheckingas-builtBIMmodelswithandwithouttheproposedsolution.

Table10:TaskcompletionstatusforTest1withandwithoutthe proposedsolution

4.2.1 Time Taken for Tasks

Table 11 shows the time taken for each participant to complete the tasks in Test 2 with and without the proposed solution. The time was recorded in seconds for each task before adding up the time taken for the participant tocomplete eachattempt. From the data recorded, it was observedthatallfiveparticipantswerealsoabletocompletethesameamountofworkforeach task in a shorter time with the use of the proposed solution. This observation suggests the potentialofourdevelopedsolution.

BEARS#01 29

TimetakenforParticipantstocompleteTest

withandwithoutproposedsolution 4.2.2 Accuracy of Completed Tasks Table 12 shows the completion status of each task for each participant with and without the BeforeAfterBeforeAfterBeforeAfterBeforeAfterBeforeAfter Task1WrongWrong Task2WrongWrongWrong Task3 Legend:CompletedIncomplete Part1-CheckingofAs-builtBIMModels CompletionStatusofEachTask(Before&AfterImplementationofSolution) TasksParticipant1Participant2Participant3Participant4Participant5 BeforeAfterBeforeAfterBeforeAfterBeforeAfterBeforeAfter Task1533323647368545304520287512282 Task2287136285147251126241131217117 Task31377811977183791388112173 Total9575371051592979509899499850472 TimeTakenforEachParticipant(Before&AfterImplementationofSolution)(Secs) TasksParticipant1Participant2Participant3Participant4Participant5 Part2-TransformationofAs-builtBIMModelstoBIMFMModels

Table11:

2

proposedsolution.Itcanbeseenthattheredcolouredboxthatrepresentstheuncompletedtask duetomistakeshappenedonlybeforetheimplementationoftheproposedsolution.Instead,all the participants were able to complete the tasks 100% correctly on the attempt using the proposedsolution.Thiswouldmeanthata higherlevelofaccuracywasachievedwiththeuse oftheproposedsolution.

Table 12:TaskCompletionStatusforEachParticipantforTest2

4.3 Discussion

Afteranalyzingthe datacollectedfrom thetwo testsconductedtodetermine theeffectiveness of the proposed solution, it can be concluded that the proposed solution was effective in meeting the objectivesas wellasthe needs oftheusers. Fromthetests, itcan be seenthat the proposedsolutionwasabletoreducetheamountoftimerequiredtocompletethesameamount ofworkfordifferenttasksmakingtheworkprocessesmoreefficient.However,thedifference is minimal because of the small scale of BIM model used in this study – See Figure 11. We hypothesis the difference will be significant in hours or even days for complex, large or high risebuildingsBIMmodels.Furtherstudywillbeconductedtoverifythehypothesis.

Asforaccuracy,thetestsconductedalsoprovedthattheproposedsolutionhelpedtheusersto identify more problems in the as-built BIM models and complete the required tasks more accurately. The benefit inherent in our proposed solution, as suggested by the results, will be more pronounced in complex and large buildings BIM models. With that, it can be deduced that the proposed solution has effectively helped to solve the problem based on the tests conducted.

Theadoptionofourproposedsolutionwillbenefitfacilityownersandmanagerstomakebetter used on developed BIM models during design and construction stages to improve the productivityoffacilitymanagementandoperations.Ourfindingsimplythatlessermanpower,

BEARS#01 30

BeforeAfterBeforeAfterBeforeAfterBeforeAfterBeforeAfter Task1IncompleteIncompleteIncomplete Task2IncompleteIncomplete Task3IncompleteIncomplete Legend:CompletedIncomplete Part2-TransformationofAs-builtBIMModelstoBIMFMModels CompletionStatusofEachTask(Before&AfterImplementationofSolution) TasksParticipant1Participant2Participant3Participant4Participant5

especiallyforcomplexandlarge buildings,willberequiredinreviewingassubmittedas-built BIMmodelsforerrorsandunwantedinformation.Toreducethetimetakentocheckforerrors while improving accuracy with the non-automatic process will require more manpower. This has financial implications for all parties involved. The higher accuracy our solution provides will help prevent safety problems that may occur due to error in building models used for facilitymanagementandoperations.

5.0 CONCLUSION

As BIM modelsstartto becomemore andmoreused foroperationalpurposes inthe industry, facility owners and managers need to be able to prepare the BIM model efficiently and effectively. The facility owners and managers need to have the proper resources and aids to helpthemensurethattheywillbeabletopreparetheBIMmodelsappropriately.Appropriately in terms of conducting accurate checks after receiving them from the contractors as well as cleaninguptheas-builtBIMmodeltocreateaBIMFMmodelthatismorerelevantforfacility management and operational use. With that, the BIM models will be able to be applied and readyforanypurposewhentheownerdecidestoenhancethedigitalcapabilityoftheirfacility.

Additionally,theBIMmodelswouldbeabletoputtogooduseandthatthetimeandcostspent on developing the models from design to construction would not go to waste. We plan to conduct further studies to verify the potential of our developed solution. Nevertheless, our initial findings show that our developed solution has the potential for improving the productivityoffacilitymanagementandoperations

ACKNOWLEDGEMENT

ThesupportoftheSingaporeInstituteofTechnologyincarryingoutthisappliedresearchstudy is gratefullyacknowledged. Ms. Camille Chua did the work and contentsof thispaperas part of her BEng final year design project in the Sustainable Infrastructure Engineering (Building Services) programme. Dr. Moshood Olawale Fadeyiguidedthedevelopment of theprototype solutionandexperimentaldesigntotesttheeffectivenessofthedevelopedsolution. Dr.Fadeyi alsocontributedtothedevelopmentofthisarticle.

BEARS#01 31