is poised to open its doors, providing unparalleled opportunities for education, research and innovation that will shape the future of dairy in Michigan and across the country.

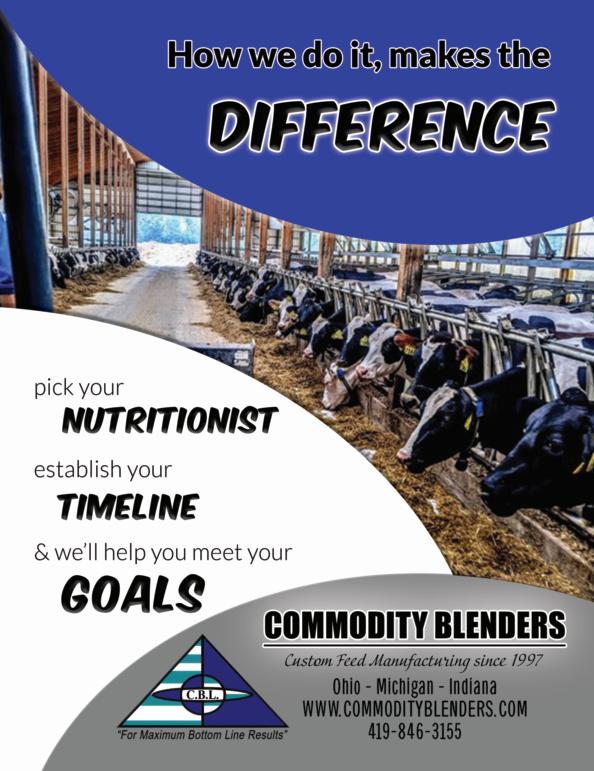

MMPA is committed to cooperative social responsibility and sustainable business practices throughout our entire supply chain. At the farm level, MMPA members are also on a sustainability journey. As an MMPA member, Tom Cook focuses on making the most of every acre on his pasture-based dairy in Pewamo, Michigan.

For more than a century, farmer-owned cooperatives have given dairy producers strength in numbers, stability in uncertain markets and a voice in shaping their own future. The International Year of the Cooperative, as declared by the United Nations, is a chance to reflect on what makes this model so enduring: people coming together not just to market milk, but to build communities, create opportunities and carry forward values that matter as much today as they did generations ago.

SUDEEP JAIN, MMPA DIRECTOR OF QUALITY (PG.

BY MIKAYLA BOWEN

As the leaves turn and harvest season begins, fall reminds us of growth, hard work and new possibilities. Across the dairy industry, innovation and collaboration are helping us build on tradition while shaping a sustainable and successful future for farmers and consumers alike.

In this issue, we highlight the unveiling of Michigan State University’s new Dairy Cattle Teaching and Research Center, a state-of-the-art facility designed to advance research, strengthen hands-on learning and prepare the next generation of dairy leaders. I had the opportunity to tour the new facilities on MSU’s south campus, where cutting-edge design meets practical application to support Michigan’s dairy farmers and the industry at large. It’s inspiring to see partners like MMPA playing a key role in helping MSU pave the way for a more sustainable and innovative future in dairy. (pg. 16)

Sustainability is a common thread throughout this issue. MMPA member Tom Cook shares how he’s putting sustainable practices into action on his pasture-based dairy in Pewamo, Michigan (pg. 20). On page 14, don’t miss the stunning winners of the 2025 MMPA Photo Contest, a visual celebration of our members and their stories. In honor of October’s National Co-op Month and the International Year of Cooperatives, we also take a closer look at the strength and shared purpose behind the cooperative model (pg. 22). And, as the busy harvest season ramps up, we’ve included important safety reminders to help keep you and your team safe around heavy equipment (pg. 29.)

Milk Messenger (USPS # 345-320) is published bimonthly by the Michigan Milk Producers Association, 41310 Bridge Street, Novi, MI 48376-8002. Periodicals postage paid at Novi and additional mailing offices.

POSTMASTER: Send address changes to Milk Messenger, PO Box 8002, Novi, MI 48376-8002.

President and Chief Executive Officer Joe Diglio

Managing Editor

Sheila Burkhardt, Chief Corporate Affairs Officer

Editors

Emily Kittendorf-King, Editor & Advertising Manager

Mikayla Bowen, Editor messenger@mimilk.com

Publication Designer

Stacy Love rezudesign.com

Printing Foresight Group, Stacey Trzeciak staceyt@foresightgroup.net

Publication Office

MMPA Milk Messenger P.O. Box 8002, Novi, MI 48376-8002 p: 248-474-6672 f: 248-474-0924 e: messenger@mimilk.com w: mimilk.com

Established in 1916, MMPA is a member owned and operated dairy cooperative serving dairy farmers in Michigan, Indiana, Wisconsin and Ohio.

An Equal Opportunity Employer – F/M/V/D

Subscriptions: mimilk.com/subscribe

MMPA members - 50¢ per year Non-members - $5 per year

Circulation: 2,600 (ISSN 0026-2315)

SHEILA BURKHARDT, MMPA CHIEF CORPORATE AFFAIRS OFFICER

In this International Year of Cooperatives, it is fitting to take a moment to acknowledge the role cooperatives have played in our industry and communities while working toward common goals that serve as the foundation of a cooperative.

Cooperatives have adapted and changed over the years, but their commitment to cooperative principles has remained. In looking back at MMPA’s history there are a number of initiatives that we are involved in that keep us focused on that common goal of marketing our members’ milk and aligned with cooperative principles.

Cooperatives such as MMPA place a priority on providing opportunities to memberowners to be involved and informed. MMPA will soon be gearing up for its member meeting season which was kicked off with virtual member briefings in August. This December, members will have the opportunity to attend their District Meeting where they will hear an update on industry and association activities and cast their vote on those who represent them at the district and state level. As a member-owner of MMPA, attending your District meeting is key. It not only provides the opportunity to hear updates, but it also provides an opportunity for Board members and staff to hear from members.

Each March, we bring members together for our Annual Meeting and throughout the year, we offer CORE educational programs focused on key topics. Participating in these member information opportunities helps ensure our cooperative’s success by keeping members informed and engaged. If you are an MMPA member and have not participated in a member meeting or CORE program, we encourage you to do so. There a lot of great things taking place at MMPA and we have a shared goal of utilizing these meetings to highlight those activities and answer questions members may have.

Working toward a common goal is also apparent when we join forces with other cooperatives both nationally and internationally. Our strategic partnership with Gujarat Co-operative Milk Marketing Federation Limited (GCMMF), the largest dairy cooperative in the world, highlights the efforts of our two cooperatives working together to bring Amul branded products made with MMPA milk to Americans. This is an excellent example of our two cooperatives working toward a common goal benefiting dairy farmer members of both cooperatives.

Working with National Milk Producers Federation and the National Council of Farmer Cooperatives allows MMPA to join forces on the national level to work toward common goals that benefit all members. Working collectively on issues such as those impacting farm labor, nutrition, animal health, etc. has a much bigger impact through our collective efforts.

One of the principles of a cooperative is concern for community. At MMPA, we are proud of our work with the food bank system, our support of 4-H and FFA programs, and the college scholarships we make available to our members to name a few. Our sustainability initiatives have continued to grow and evolve on both the plant and farm level, all demonstrating our shared commitment to the communities we live and work in.

The theme designated by the United Nations for the International Year of the Cooperative is “cooperatives build a better world.” It is a fitting theme as demonstrated by the collective work of cooperatives, including MMPA, who all work on behalf of their member-owners toward a common goal.

Ben Chapin MMPA MEMBER SERVICES DIRECTOR

MMPA members have a long-storied history of producing top quality milk across the Midwest. I’ve always admired the membership’s dedication towards continuous improvement and progressiveness within the dairy industry. Of course this doesn’t come without challenges. As we work our way out of the summer heat and humidity, I think farmers and cows alike are breathing a sigh of relief.

With much of the focus now shifting to fall harvest, it is important not to lose sight of the quality of the milk coming off the farm. There is a lot of value in what you produce, and it is integral for marketability to our customers. It has been your quality milk that opened the doors to new partners and created sustaining relationships with our customers.

Take the time to schedule preventative maintenance throughout your milking and cooling systems and take advantage of the MMPA services that are accessible to you. Your field staff are available to assist with milking and wash system diagnostics and analysis, herd tests and on-farm milker training schools. The MMPA lab can assist in culturing, running special bacteria counts and trouble shooting. Also, don’t forget the Farm Supply Store carries a wide array of products that help support milk quality.

Christy Dinsmoore MMPA AREA SUPERVISOR

Michigan may not have hit 100°F this summer, but the heat and humidity sure made it feel like we did. Hot weather stresses cows’ immune systems and increases bacteria in their environment, two big reasons Somatic Cell Count tends to rise.

You can’t control the weather, but you can control mastitis management practices on your farm. Lost premiums and deductions are just the beginning of what mastitis costs your farm.

Focus on four key areas:

Identify infected cows: Pre-strip during udder prep to catch clinical cases. Use DHIA data or set up a herd test with your field representative to find subclinical cases. California Mastitis Test (CMT) is easy to add to fresh cow checks. Work with your vet to set up treatment protocols.

Prevent new infections: Keep bedding clean and dry across all cow groups. Refresh your milker team on proper protocols and review dry-off procedures. Start planning facility upgrades for next summer’s heat.

Maintain milking equipment: Regular maintenance matters. Check vacuum regulators, clean pulsators and replace rubber parts on schedule.

Think ahead for winter: Prep facilities and plan for cow comfort now. Consider switching to winter teat dips by October to prevent teat skin chapping.

Steve Lehman

MMPA RAW MILK COMPLIANCE MANAGER

Raw milk quality has been the foundation that has allowed MMPA to build a strong customer base for raw and manufactured products being sold to dairy food companies around the world. High-quality milk has helped retain long-term customers while attracting new ones seeking premium products.

Ensuring top milk quality doesn’t have to be complicated. Regularly clean compressor condensers, especially in hot weather, and flush the plate cooler to remove iron and water scale. Inspect the bulk tank with a light before milking begins. During wash cycles, walk through the parlor to confirm proper water flow, functioning air injectors, no air leaks and no system trapping. Check chemical barrels to ensure adequate supply and usage, and verify that water temperatures are hot enough for effective cleaning.

A valuable tool is a recording thermometer installed downstream from the plate cooler. The data it provides offers key insights into milking and washing performance, helping identify potential issues early. By staying proactive and attentive, producers can uphold the exceptional milk quality that continues to drive MMPA’s growth and reputation.

Three Michigan Milk Producers Association (MMPA) processing facilities earned top scores in their 2025 Safe Quality Food (SQF) audits, underscoring the cooperative’s strong commitment to product safety and quality.

The Canton, Ohio plant received a perfect 100% in food safety and 98% in food quality. The Ovid, Michigan plant achieved 99% in food safety and a perfect 100% in food quality, while the Constantine, Michigan plant earned 100% in both food safety and food quality.

The SQF program, part of the Global Food Safety Initiative, is a globally recognized audit that evaluates infrastructure, practices, policies and behaviors across food production facilities. High scores demonstrate a facility’s ability to consistently deliver safe, high-quality products to the marketplace.

“These achievements are a direct result of the knowledge, focus and teamwork of our plant employees,” said Sudeep Jain, MMPA Director of Quality. “We’re proud of the culture of excellence our teams have built.”

The audits are conducted annually across all MMPA plants, reinforcing a continuous improvement mindset at every level of the organization.

Members of the Michigan Milk Producers Association (MMPA) have the opportunity to nominate their local food pantry to receive the MMPA Food Bank Legacy Award. The recognition, created in honor of past MMPA Board President Ken Nobis, recognizes members for their efforts supporting local food banks and pantries. This annual award gives members the chance to nominate a Michigan food bank or pantry to receive a $1,000 donation toward their hunger relief work. Interested members can contact Jessica Welch at jessica.welch@mimilk.com or at 248-8973400 to receive an application. Deadline to submit nominations is November 1, 2025.

This July, the Michigan Milk Producers Association (MMPA) was honored to welcome Anatoli Didur, a visiting dairy processor from Ukraine to their Ovid, Michigan, plant. His visit was part of the Ukrainian Business Leaders: Promoting Innovation and Entrepreneurship (UBL PIE) program, facilitated through Global Ties Detroit. The program supports international exchange and empowers Ukrainian entrepreneurs with tools to drive innovation and economic development.

Anatoli serves as Head of the Supervisory Board at Kulykivske Moloko, a leading dairy processing company in Northern Ukraine. With over a decade of experience in business management, he oversees strategy, crisis management, shareholder engagement and public communication. His company produces skimmed milk powder, cream butter and cheeses for both retail and commercial use.

During his time in the U.S., Anatoli explored advanced dairy processing techniques, especially in ultra-pasteurized milk, cottage cheese and condensed milk production. His visit to MMPA included discussions on production management, business planning, marketing and branding, key areas he hopes to strengthen within his company and community.

producers scoring 95 percent or higher on Grade A Surveys and Federal Check Ratings

The Michigan Milk Producers Association (MMPA) hosted officials from the U.S. Department of Agriculture (USDA) at its Ovid, Michigan, manufacturing plant for an in-depth discussion on upcoming modifications to the Federal Milk Marketing Order (FMMO) system. The delegation included USDA Market Administrators from throughout the United States and Dana Coale, Deputy Administrator for the USDA Dairy Program.

The visit was initiated by USDA given MMPA's leadership in the marketplace and centered on changes to the FMMO’s mandatory reporting requirements. As part of reforms following last year’s national hearing process, USDA’s Agricultural Marketing Service is launching a new cost survey designed to capture more accurate manufacturing cost data. This information will help USDA set milk pricing formulas that better reflect the true costs of production and processing, ultimately improving price transparency and fairness across the dairy supply chain.

During the tour and discussion, MMPA leaders provided insight into the cooperative’s processing operations, manufacturing costs and ongoing efforts to deliver value to dairy farmers while serving the marketplace. The dialogue was constructive, with both sides exchanging knowledge and identifying opportunities to work together on industrywide issues. MMPA values the opportunity to share its story and partner with USDA on initiatives that will have lasting impacts for dairy producers in the Great Lakes region and across the country.

With smaXtec, you can spot health issues early, enabling quick intervention that reduces treatment costs, boosts milk production, and drives higher profits.

smaXtec’s bolus technology provides precise health data from the cow’s reticulum, measuring internal body temperature (±0.02 °F), water intake, drinking cycles, rumination, and activity. This allows farmers to detect potential diseases long before visible symptoms appear, ensuring better preventive care.

The results speak for themselves. For Amber Horn, who manages over 2,000 cows at Hornsted Dairy Farm, smaXtec’s temperature monitoring has been a game-changer. She explains, “It helps us catch inflammation or metabolic issues in transition cows before they get out of hand.” Sheldon Luehmann from Pine-Vue Farm adds, “We pride ourselves on maintaining a low somatic cell count, usually around 70,000. With the smaXtec system, it has helped us consistently lower it to 55,000 or below.”

Early disease detection plays a crucial role in boosting your farm’s profitability. By identifying health issues before they become visible problems, smaXtec helps reduce diseaserelated expenses while increasing overall milk production, ultimately leading to higher profits. Chad Butts from Willow Breeze Farm explains: “Since switching to smaXtec, our herd health costs have dropped by 40%. We’re treating fewer cows and can quickly assess the effectiveness of treatments.”

Curious? Reach out today at +1 (608) 817-6160 or info@smaxtec.com, or visit smaXtec.com to start transforming your farm’s productivity.

President Trump on July 4 signed into law the “One Big Beautiful Bill Act,” a sweeping tax and spending package that changes farm bill provisions, tax policy and other areas. Parts of the bill will affect dairy farmers and cooperatives. Here’s what’s in it for dairy :

The new law makes permanent the Section 199A tax deduction, which allows certain pass-through agricultural entities, including dairy cooperatives, to deduct up to 20 percent of qualified business income. The deduction, for which NMPF has long advocated, was originally established in the 2017 Tax Cuts and Jobs Act to mirror the benefits of the now-repealed Section 199 and has since become a critical tool for reinvestment in equipment, labor, land and sustainable practices. Cooperatives can choose to reinvest this benefit or pass it on to member-owners.

The legislation also expands the estate and gift tax exemption, increasing it from the current inflation-adjusted $5 million to $15 million per individual and $30 million per couple beginning in 2026. These changes will aid family farms in long-term estate and succession planning.

The law also makes permanent the 100% bonus depreciation that allows farmers to write off the full cost of qualifying equipment and infrastructure investments. The legislation increases the limits for Section 179 expenses, doubling the maximum deduction and raising the phase-out threshold, which will give farmers greater flexibility in managing capital expenses.

The bill extends USDA’s Dairy Margin Coverage (DMC) program through 2031, continuing the 25% discount option for producers who commit to multi-year enrollment. The DMC provision includes an NMPF-supported update to the production history calculation that allows producers to use their highest milk production year from 2021, 2022 or 2023. It also raises the Tier1 coverage threshold from five million to six million pounds of production history.

The legislation provides $9 million for USDA to implement mandatory dairy plant cost and yield surveys to generate data regarding the cost of manufacturing fluid milk into products such as butter and cheese. These surveys, to be conducted every two years, will inform future milk pricing deliberations, specifically regarding manufacturing allowances within the Federal Milk Marketing Order system. Long-term authorization will require congressional action; still, this initial investment marks an important step forward.

The legislation reduces funding for the Supplemental Nutrition Assistance Program by an estimated $186 billion relative to previous projections for the next decade. It imposes stricter work requirements for beneficiaries, including raising the eligible age to 64 from the previous age of 54 and requiring work compliance for parents of children 14 and older. It does not modify the underlying formula for calculating benefits.

The law includes $4 million in annual funding through 2031 for Farm to Food Bank projects under the Emergency Food Assistance Program, which supports efforts to feed food-insecure households using farm-grown produce and dairy.

In response to advocacy by NMPF and the U.S. Dairy Export Council, the new law allocates $285 million annually starting in fiscal year 2027 for the creation of a Supplemental Agricultural Trade Promotion Program. This initiative is modeled after key USDA programs, including the Market Access Program and Foreign Market Development Program, and is designed to enhance the global promotion of U.S. agricultural products. The new law doubles the resources USDA can provide to cooperators like the U.S. Dairy Export Council to expand U.S. dairy promotion efforts globally.

The legislation incorporates remaining Inflation Reduction Act conservation funds into the farm bill baseline, ensuring increased longterm support for the Environmental Quality Incentives Program and the Regional Conservation Partnership Program through 2031. Producers now also will benefit from a new adjusted gross income (AGI) waiver, allowing producers with AGIs above $900,000 to access USDA programs—provided at least 75% of their income comes from farming.

The new law extends the Section 45V Clean Hydrogen Production Tax Credit through 2028. NMPF has been advocating for dairyderived renewable natural gas (RNG) to qualify as a hydrogen feedstock; this extension keeps that opportunity alive, though more work is needed on implementation. The legislation also extends the Section 45Z Clean Fuel Production Credit through 2029. This credit supports the production of low-carbon transportation fuels. It allows the Treasury Department to establish specific emissions rates for different feedstocks, including fuels derived from dairy manure. This will enable more accurate recognition of avoided methane emissions, helping to unlock new revenue streams for dairy farms that invest in anaerobic digestion systems.

The legislation includes mor than $46.5 billion for border wall construction and related infrastructure, $45 billion to expand immigration detention capacity and $30 billion for the hiring, training and support of U.S. Immigration and Customs Enforcement personnel. While these provisions were central to securing the bill’s passage, many lawmakers have cited border security as a precondition for engaging in meaningful negotiations on agricultural labor reform and other visa-related issues. NMPF is hopeful that, with border security now addressed, Congress will shift its focus toward advancing agricultural labor reform that meets dairy’s current and future workforce needs.

SOURCE: National Milk Producers Federation

lelysales@prengersinc.com

lelyna.com/us/centers/prengers

Selected from over 70 entries, the five winning photographs from MMPA’s eighth annual photo contest capture beautiful scenes on dairy farms throughout the Great Lakes region.

In this year’s contest, there were five awards given: first, second and third place judged by a panel of judges, along with a people’s choice award determined by public voting and a staff choice award, the favorite photo among MMPA employees.

Photographer: Julia Troyer

Photo Title: New Morning, New Baby

Hometown: Laotto, Indiana

Photographer: Amanda Story

Photo Title: Harvest Evening

Hometown: Ithaca, Michigan

Photographer: Liam Edwards

Photo Title: Northern Lights, Rural Nights

Hometown: Allegan, Michigan

Photographer: Madeline Frahm

Photo Title: The Best Way to Start Your Day

Hometown: Reese, Michigan

This facility is about positioning MSU, and the state, to meet the challenges ahead. From workforce development to sustainability to cutting-edge research, it’s an investment in the future of our industry.”

For years, the idea of replacing MSU’s aging dairy facility floated around campus and industry conversations, but it never quite gained traction. That changed when the right people, the right funding and the right moment came together.

“When I started at MSU in 1997, the dairy was already old,” Dr. George Smith, Director of Michigan State University AgBioResearch, said with a smile. “People who worked there in the ’70s thought it was outdated back then, and their kids and grandkids came back decades later and said the same thing. But this time, the stars aligned.”

That alignment came from multiple directions; Michigan legislators who understood the economic power of dairy, industry leaders who championed the vision, and university administrators who prioritized making it happen. The result is a state-of-the-art teaching and research center designed to strengthen Michigan’s role as a leader in dairy production and innovation.

“Dairy is Michigan’s number one agricultural sector,” Dr. Smith explained. “This facility is about positioning MSU, and the state, to meet the challenges ahead. From workforce development to sustainability to cutting-edge research, it’s an investment in the future of our industry.”

And that vision shows up in every corner of the new center. Designed to house up to 688 cows and equipped with advanced automation, robotic milking systems and integrated environmental technologies, the facility is built to handle today’s needs while staying nimble enough to adapt for decades to come. Dr. Barry Bradford, the Clinton E. Meadows Endowed Chair in Dairy Management and Nutrition at MSU, explained that flexibility was one of their top priorities during the planning process.

Dr. Bradford described, “Our mantra throughout the project was, ‘Can we build it to do both?’” “We knew the old dairy lasted more than 60 years. This one needs to be able to support research questions we can’t even predict yet.”

From wide, two-way alleys to divided holding pens, every detail is meant to make research easier while also mimicking real-world commercial dairy conditions. The design allows researchers to study cow behavior, feeding strategies and new technologies in ways that reflect exactly what producers face on their own farms.

The new dairy isn’t just bigger, it’s built to answer the questions that matter most to farmers. In the past, MSU researchers often had to wait years to start projects because there simply wasn’t enough space or access to cows.

Now, with room for replicated free-stall pens, robotic systems and advanced sensors throughout the facility, those delays are gone.

“We can finally ask applied questions at a scale that really matters to producers,” Dr. Bradford said. “Take something like cow brushes, producers love them, cows love them, but we’ve never had data showing if they actually pay for themselves. Now we can run controlled trials with five pens using them and five without to measure the impact.”

That ability to replicate pens and isolate variables opens the door for research on everything from feed efficiency to cow comfort to environmental sustainability. And the integration with MSU’s anaerobic digester makes the facility especially unique.

“We want to create circularity in the dairy economy,” Dr. Smith stated. “Farmers shouldn’t just get paid for milk. By exploring renewable energy and nutrient recovery, we’re developing models that could give producers entirely new revenue streams.”

This connection to sustainability runs throughout the dairy’s design. From automated sand separation to waterefficient smart soakers that spray cows only when they’re present at the feed bunk, every system is optimized to conserve resources while improving animal welfare. Researchers will also

collect detailed data on energy, water, methane emissions and other key metrics, giving producers access to realworld numbers that can help inform better on-farm decisions.

And while the technology is impressive, Dr. Bradford emphasized that the goal wasn’t just to build a flashy barn. “We designed this place to look and feel like a commercial dairy,” he explained. “That makes our data more believable, but it also prepares students for real-world work after they leave MSU.”

Perhaps one of the most exciting impacts of the new facility is on education. Built with two classrooms on-site and designed to host hands-on labs, workshops and tours, the dairy is expected to draw students from across the country, and it already has.

“In the past year, we’ve seen students from across the country come visit the dairy program,” Dr. Bradford shared. “The facility gets people’s attention, and once they see the opportunities here, they want to be part of it.”

That attention isn’t just coming from future dairy producers. The center is designed to bring together students and faculty from multiple disciplines, veterinary medicine, agricultural engineering, economics, environmental science and more, to work side by side on complex dairy challenges.

“The dairy industry is interconnected,” Dr. Smith explained. “From feed and animal care to renewable energy and data science, we need experts from

1. It’s One of the Largest University Dairies in the Country

The new facility houses 688 cows, putting MSU in the same league as Cornell and the University of Florida, with the added advantage of being just minutes from campus for easy student access.

2. Cutting-Edge Research Will Happen Here

From cow behavior and feed efficiency to environmental sustainability and renewable energy, researchers can now study real-world, producer-focused challenges at a scale that mirrors commercial dairies.

3. Smarter Systems and Automation

With robotic milkers, smart soakers that spray cows only when they’re at the bunk and advanced automation for lighting, ventilation and manure management, the dairy is one of the most automated research barns in the U.S.

4. A Hub for Hands-On Learning

Two classrooms on-site and a design built for labs and workshops mean more opportunities for students, from future producers to veterinarians, engineers and sustainability experts, to learn on real dairy systems.

5. Innovation Meets Sustainability

The facility connects directly to MSU’s anaerobic digester, turning manure into renewable energy while exploring costeffective nutrient recovery technologies that could open new revenue streams for farmers.

all areas working together. This facility finally gives us the space and tools to make that collaboration possible.”

Outreach is also a priority. The facility includes a visitor center with interactive displays and a glass viewing area where guests can watch cows being milked. Plans are underway to host open houses, school tours and hands-on events, helping connect the public with modern dairy practices.

But at the heart of all of this is MSU’s commitment to Michigan producers.

Dr. Bradford summed it up simply,

“If I could invite every Michigan dairy farmer to walk through, I’d want them to know this: MSU is here to help you find solutions to your real problems. That’s why this facility exists.”

The first cows moved in this summer, and the excitement around the facility is only growing. While operations are still ramping up, the team is already planning a grand opening and ribboncutting ceremony for spring 2026, when producers, legislators and the public will officially celebrate this milestone for Michigan’s dairy community.

“This facility is a testimony to MSU’s commitment to Michigan’s dairy industry,” Dr. Smith said. “It’s a sizable investment, but we’re confident it will pay off for producers, students and the future of dairy in our state.”

Dr. Smith also expressed deep gratitude to the Michigan Milk Producers Association and its members for helping make the vision a reality.

“This project wouldn’t have happened without MMPA’s leadership and support,” he said. “From advocating with elected officials to championing the importance of this investment for Michigan agriculture, MMPA played a critical role in bringing this facility to life.”

With the partnership between MSU and Michigan’s dairy producers stronger than ever, the new MSU Dairy Teaching and Research Center is set to drive innovation, education and opportunity for decades to come.

BY MIKAYLA BOWEN

MMPA IS COMMITTED TO COOPERATIVE SOCIAL RESPONSIBILITY AND SUSTAINABLE BUSINESS PRACTICES THROUGHOUT OUR ENTIRE SUPPLY CHAIN. AT THE FARM LEVEL, MMPA MEMBERS ARE ALSO ON A SUSTAINABILITY JOURNEY. WE’RE CHECKING IN WITH A HANDFUL OF MEMBER FARMERS LEADING THE CHARGE WITH THIS SUSTAINABILITY SPOTLIGHT SERIES.

Fourth-generation dairy farmer Tom Cook doesn’t see sustainability as a trend, it’s a way of life built on decades of hard work, family values and a deep respect for the land. Farming in Pewamo, Michigan, Tom has been operating Cook’s Dairy Farm alongside his wife and three children for the past 27 years. In 1999 after his father fell terminally ill, Tom stepped up to take over the family farm growing the herd from 120 cows milked in a conventional system, into a 300-milking cow pasture-based dairy with seasonal calving.

Tom explains, “I am one of seven children in my family and after my dad told us about his cancer, I had decided to give the opportunity to take over the family dairy business another shot.”

With his children active in agriculture and showing interest in farm life, Tom sees his role as both a caretaker and a mentor, working to create a farm that is resilient, profitable and sustainable.

A key component of Tom’s success has been his innovative cropping system. On his operation, double cropping plays a vital role in maximizing forage production without acquiring additional land. By carefully planning rotations and using every acre to its fullest, Tom ensures a steady feed supply for his herd while maintaining soil health.

“I am pretty aggressive on double cropping and doing cover crops in my rotation to attain more forage without having to acquire more land,” Tom explains. “We grow a mix of crops including cowpeas, sorghumsudangrass, forage oats and winter triticale, strategically rotating them across fields to make the most of each season’s growing potential.”

Another cornerstone of Tom’s operation is his rotational grazing system. His 36 paddocks support a carefully managed schedule wher milk cows and heifers rotate through 230 acres of pasture from mid-April through October.

While grazing requires a unique geographic setup and more daily management than conventional systems, Tom believes the benefits far outweigh the challenges.

“I may not have the same milk production as conventional dairies today,” Tom admits, “but I’d like to

Utilizing a grazing system has allowed my profits to stay positive when other dairies my size have had to either get bigger or sacrifice their margins.”

think I have the profitability, and that’s what matters. Utilizing a grazing system has allowed my profits to stay positive when other dairies my size have had toeither get bigger or sacrifice their margins.”

But the grazing is about more than just feed efficiency for the Cooks, it has also created a safer, more inclusive environment for his family.

“We’ve been grazing for 25 out of the 27 years we’ve farmed here,” Tom says. “Those first two years were conventional, and I think grazing has allowed the family to be more involved. In a confinement system with more mechanical intervention, it may not have been as safe for the kids. But when you’re walking out in the pasture or on the quad/Gator, it’s a much friendlier environment for them to help out.”

Tom’s sustainability philosophy extends well beyond the barn. Over the years, he has partnered with MMPA, the Natural Resources Conservation Service (NRCS) and The Nature Conservancy to implement projects that improve soil, water and pasture management.

With the help of cost-share programs, Tom has installed manure pits, pasture fencing, settling ponds and filtration areas designed to reduce runoff and protect nearby waterways.

“In 2007, I spent over half a million dollars capturing everything and pumping it into a one-and-a-halfmillion-gallon concrete pit,” Tom recalls. “NRCS helped cost-share the project, which made it possible to build a proper storage facility.”

Working with MMPA’s Feed in Focus program and The Nature Conservancy, Tom has also implemented a silage bunker runoff management system that filters and redirects water safely.

“If it weren’t for MMPA and The Nature Conservancy, I wouldn’t have the silage bunker runoff program we have today,” Tom says.

Looking forward, Tom is exploring GPS collars and other grazing technologies to optimize pasture use.

SILAGE BUNKER RUNOFF – ALSO KNOWN AS SILAGE LEACHATE OR EFFLUENT, REFERS TO THE LIQUID THAT DRAINS OR SEEPS FROM SILAGE PILES STORED IN VARIOUS STRUCTURES, INCLUDING BUNKERS, BAGS AND UPRIGHT SILOS.

SETTLING PONDS – A BASIN CONSTRUCTED WITH AN ENGINEERED OUTLET, FORMED BY CONSTRUCTING AN EMBANKMENT, EXCAVATING A DUGOUT, OR A COMBINATION OF BOTH. THE MAIN PURPOSE OF A SETTLING POND IS TO CAPTURE AND DETAIN SEDIMENT-LADEN RUNOFF OR OTHER DEBRIS FOR A SUFFICIENT LENGTH OF TIME TO ALLOW IT TO SETTLE OUT IN THE BASIN.

SOURCE: U.S. DEPARTMENT OF AGRICULTURE

FARM Animal Care and Environmental Stewardship and Comprehensive Nutrient Management Plan

MMPA SUSTAINABILITY MISSION

To continually strive for a more sustainable future for our community, our environment, our economy’s health, and for the lives and world around us.

FOR MORE THAN A CENTURY, FARMER-OWNED COOPERATIVES HAVE GIVEN DAIRY PRODUCERS STRENGTH IN NUMBERS, STABILITY IN UNCERTAIN MARKETS AND A VOICE IN SHAPING THEIR OWN FUTURE. THE INTERNATIONAL YEAR OF THE COOPERATIVE, AS DECLARED BY THE UNITED NATIONS, IS A CHANCE TO REFLECT ON WHAT MAKES THIS MODEL SO ENDURING: PEOPLE COMING TOGETHER NOT JUST TO MARKET MILK, BUT TO BUILD COMMUNITIES, CREATE OPPORTUNITIES AND CARRY FORWARD VALUES THAT MATTER AS MUCH TODAY AS THEY DID GENERATIONS AGO.

Every day across the Great Lakes region, hundreds of dairy farm families wake before dawn to care for their cows, their land and their future. On its own, each farm is a family business rooted in care for animals and land, contributing to the fabric of rural communities. Together, through Michigan Milk Producers Association (MMPA), they form something much larger: a cooperative system built on shared ownership and shared purpose.

Unlike investor-driven businesses, cooperatives exist to serve their members. Profits are returned to the farmers who supply the milk, and major decisions are made democratically. It’s a model that has supported farm families for over a century, giving them stability in volatile markets, access to global customers and a stronger voice than they could have alone.

“It’s not just about selling milk,” said MMPA member-owner James Weber. “It’s about shaping the future of our farms by working together.”

What is a Cooperative?

A business model built for people.

A cooperative is a business owned and controlled by the people who use its services.

The Seven Principles of Co-ops

• Voluntary and open membership

• Democratic member contro

• Member economic participatio

• Autonomy and independenc

• Education and training

• Cooperation among cooperatives

• Concern for community

Once the milk leaves a farm’s bulk tank, the cooperative network takes over. Plant workers, quality assurance teams and the sales experts all play a role in transforming member milk into products that nourish communities.

For Angela Farley, a plant supervisor in Canton, Ohio, the co-op model gives her work deeper meaning. “I know the farmers who own this milk, and I see the families who buy it,” Angela said. “We’re part of the same community.”

That impact is visible everywhere: from gallons of milk in local grocery stores, to innovative dairy drinks fueling athletes in schools, and to dairy ingredients and finished products carrying members’ milk into international markets.

Behind the scenes, the cooperative makes investments no single farm could achieve alone: state-of-the-art processing plants, food safety labs, innovative new dairy products and more.

Why Belong to a Cooperative? Strength in Numbers

In the early 20th century, dairy farmers faced a challenge: milk spoiled quickly, processors held all the bargaining power, and farmers had little control over price. The cooperative model was the answer. By working together, farmers:

• Secured fair prices.

• Built their own infrastructure.

• Guaranteed a market for every load of milk.

Those same reasons hold true today.

the U.S. It provides opportunities that benefit farmers both in the U.S. and India, a reminder that while co-ops operate in different markets, their values are the same.

“Co-ops succeed when they work with one another,” MMPA President & CEO Joe Diglio said. “It’s not about borders, it’s about building strength through cooperation.”

As MMPA looks toward the future, its commitment to youth and leadership development stands out. Preparing the next generation isn’t just an idea, it’s an investment already underway.

Each year, the co-op provides scholarships that help members’ families and employees pursue higher education. Programs like CORE equip members with knowledge about cooperative structure, governance and the dairy industry. The Young Cooperator program offers emerging leaders the chance to build networks, develop leadership skills and represent their farms within the broader dairy community.

During this year’s annual meeting, member-owner Ashley Kennedy reflected on the opportunities these initiatives create. “The MMPA Young Cooperator program has given me the tools I need to take a future leadership role in the co-op. The investments that MMPA makes in young members like me help strengthen the co-op’s future.”

With programs like these, cooperatives ensure that they will continue to embrace innovation, strengthen partnerships and keep members at the heart of every decision for generations to come. Because cooperatives aren’t just a business model. They are a promise that when people work together, everyone wins

set of seven cooperative principles. The shared values connect dairy producers in the Great Lakes region with workers, farmers and communities around the globe.

Engaging with consumers through digital platforms

The retail channel is crucial for dairy farmers, with e-commerce gaining prominence, now representing nearly 20% of total sales. The dairy checkoff is adapting to this trend by engaging with consumers through digital platforms and campaigns like “We Are Family,” partnering with major retailers like Walmart and Costco. The initiative aims to reach 90% of U.S. households, emphasizing dairy’s essential benefits and family nutrition. The strategy includes promotions that will help drive dairy sales.

Learn more: dairycheckoff.com/news/ checkoff-news/driving-dairy-retail-sales

Receive Grants

41 food pantries across Michigan were recently awarded the Food Pantry Grant. United Dairy Industry of Michigan partnered with Blue Cross Blue Sheild of Michigan, Blue Cross Complete of Michigan and BCBS of Michigan Foundation again to provide each pantry with a refrigerator, $250 in dairy matching funds, educational materials and technical assistance.

This grant helps local food pantries provide nutrient-rich dairy foods to their neighbors along with fresh fruits and vegetables. Technical assistance will also be provided to help each pantry figure out what’s working well and where there’s room to grow, so they can keep making a strong impact in their communities.

This year’s Children’s Hospital Cereal Drive was an eight-day event where Gleaners Community Food Bank collected 789,588 servings of cereal and the online donation page in addition to UDIM’s match of funds, raised over $20,000 for milk to go with the cereal donations.

A milk match campaign from Forgotten Harvest Food Bank offered an opportunity for UDIM to match up to $4,000 to help buy fresh milk and dairy essentials for people in need in the Metro Detroit area. UDIM also put together a kit to promote National Dairy Month and encourage people to donate to the campaign in Kroger stores across the area.

In June, UDIM joined the delicious celebration at the Leelanau Cheese Festival, bringing hands-on activities and dairy education to festival-goers of all ages. Attendees tested their knowledge with cheesy trivia, learning fun facts about different types of cheese and the nutritional benefits of dairy foods. One of the highlights was the Cheese Passport Challenge, where participants completed mini dairy-themed activities—including chatting with a local dairy farm family about where their milk comes from and visiting the Hudsonville Ice Cream booth to learn how ice cream is made. To top it all off, UDIM sponsored freshly made, cheese-packed pizza, prepared the morning of the event and served hot to hungry guests. It was a flavorful day full of learning, fun and plenty of dairy!

American Dairy Association Indiana Inc. (ADAI) and the Indiana High School Athletic Association (IHSAA) announce that milk is the official beverage of high school athletics in Indiana. Cow’s milk provides 13 essential nutrients, including calcium, vitamin D, protein, carbohydrates and electrolytes, leading it to be selected as the drink of choice.

“Milk is a science-backed way to refuel, build muscle, hydrate and strengthen bones, making it the perfect choice for athletes to use to recover and gain a competitive edge in their sport,” Jenni Browning, CEO at American Dairy Association Indiana Inc. said. “We are proud to partner with IHSAA to bring education and nutrition to students across Indiana, while also supporting our state’s dairy farmers.”

This partnership will last three years and includes perks like exclusive Winners Drink Milk® display posters in all IHSAA high schools, and celebratory milk presented by an Indiana dairy farmer and family at the conclusion of all State Championships.

For more than 60 years, the American Dairy Association Mideast has sponsored and coordinated the butter cow display at the Ohio State Fair on behalf of Ohio’s dairy farmers.

This year’s display, made from 2,000 pounds of butter, asked fairgoers to “Pardon Our Dust!” as major renovations were underway across the fairgrounds, including in the historic Dairy Products Building, home of the butter cow. Sporting butter hard hats, the butter cow and calf shared the cooler with three life-size butter construction workers: one operating a jackhammer, another studying blueprints, and a third talking into a two-way radio. The construction scene also included scaffolding, sawhorses, safety cones and a “Pardon Our Dust” sign all sculpted in butter!

The butter cow display, which is one of the most popular attractions at the fair, was featured in 875 news stories on TV, radio, online and in print, reaching more than 350 million people. An additional 103+ million people were reached via social media.

The American Dairy (ADA) Mideast works in Ohio and West Virginia to keep dairy relevant and readily available in today’s school lunch experience. One way your dairy checkoff program does this is by providing grants to schools.

ADA Mideast recently provided 77 Fuel Up equipment grants for the 2025-26 school year – totaling $154,000 in equipment – to support school wellness goals and ultimately serve more dairy. Schools were awarded either a Mobile Meals Cart Kit, to help ensure students have access to healthy breakfast, or a Healthy Start Smoothie Kit to start or expand a smoothie program.

Schools that have previously received

The dairy checkoff has also played a leading role in piloting several new and exciting cafeteria program offerings, including hot chocolate milk, lattes, grab-and-go yogurt and other dairy-based menu items and snacks ó all aimed at transforming the school milk experience and making dairy more convenient and accessible than ever.

The Freeliners column is open to current MMPA members who wish to advertise—at no charge— goods or services relating directly to their dairy farm operations.

• An item submitted will be published for no more than two consecutive issues (one issue, unless otherwise requested). After that, it will be withdrawn.

• It will be published again for no more than two consecutive months only if the member resubmits the item by writing or calling the Novi office.

• Reference to a name of a firm or other commercial enterprise with which a member is involved will be deleted, with permission of the member.

• If the member does not wish such deletion, he/ she may choose to have the item published as a Classified Ad at the regular per-line rate.

• Freeliners must be received by the 10th of the

FOR SALE: POLLED HOLSTEIN, JERSEY AND NORWEGIAN RED BULLS. AI bred from very functional dams. Many young bulls to choose from. Hardy and healthy with strong feet and legs, raised on pasture. Competitively priced. Young beef bulls also available. For pictures and pedigrees call or text 906-287-0746.

FOR SALE: DAIRYPLAN C-21 SOFTWARE SYSTEM with computer. Call 810-728-6237.

FOR SALE: JOHN DEERE 348 BALER with number 40 thrower, inoculant applicator, ready to work. $7,900. Call 810-728-6237.

FOR SALE: NEW HOLLAND 890 CHOPPER with 27P hay head. Low use. $6,500. Call 810-728-6237.

FOR SALE: NEW IDEA BALE CONVEYOR, late model 50’, good shape. $3,750. Call 810-728-6237.

FOR SALE: H&S 5126 SIDE SLINGER MANURE SPREADER. Call 989-551-5977.

FOR SALE: LITTLE GIANT HAY ELEVATOR, 45 ft., complete, new condition. $2,500 OBO. Call 616-406-5611.

FOR SALE: GEHL 970 18FT FORAGE WAGON, tandems. $3,500. Call 616-406-5611.

FOR SALE: BOUMATIC OIL-LESS VACUUM PUMP + MOTOR. Stored inside. $3400 OBO. Ag-Bagger, Model G600010ft. tunnel. Owner’s manual. PTO540 includes 1 10x250 ag bag. $9,900.00

Cost for classifieds is $25 for the first 35 words and then $5 for each additional word. Payment due with order. All ads must be received by the 10th of the month preceding desired month of publication. MMPA neither sponsors nor endorses products or services advertised in the Milk Messenger

O PPERMAN GROOVING: We can fix your scabbled floors. Diamond sawed grooves, no hammering or cracking of concrete. No hoof damage. Call Opperman Grooving Inc., Portland. Call 517-647-7381.

DAVIDSON CEMENT GROOVING, INC: No water needed. Wider, rougher grooves for better traction. We also offer texturing for your previously grooved floors. Three operators will travel Michigan and other states. No interest payment terms. Est. since 1987. Call 1-800-365-3361.

CONCRETE GROOVING BY TRI-STATE SCABBLING, home of the 2” wide groove. Best traction, lowest prices. Call 800-554-2288 or visit www.tristatescabbling.com.

A SURE WAY TO KEEP YOUR COWS UPRIGHT! Concrete grooving/texturing provides high quality traction in new and old concrete, fast service. NIENOW GROOVING. Call Cliff at 989-635-1494.

FOR SALE: NEW & USED MILK TANKS. We stock all sizes, makes, models. Special prices to co-op members, corporate & private farms. Contact us anytime, day or night. Special on 2000 gal. Muellers for $13,900 & up. 2700 & 4000 gal. Muellers call 800-558-0112 for quote.

STRAW & DRY HAY (LARGE & SMALL BALES).

Feed Oats, Feed Barley and Corn Silage. Delivery Available. Call 89-723-1886 or 989-277-1414.

ALFALFA HAYLAGE (EXCELLENT & FAIR GRADES) & CORN SILAGE. Call 989-723-1886 or 989-277-1414.

SEED CORN - “Minnesota 13” open pollinated 85-day yellow field corn seed. High protein, High yield, high fat, fast drydown. Great Digestibility! 80,000 graded seeds $100.00. Call 989-284-5052 or visit JanksSeeds.com

OPEN POLLINATED CORN SEED. Early varieties Green Haven Open Pollinated Seed. Hulles Oats, Einkorn Wheat. Call 607-566-9253 or visit openpollinated.com.

As we get into harvest season, it’s important to start thinking about heavy machinery fire prevention. Mechanical malfunction, fuel leakage and flammable materials can all increase the risk of an equipment fire. Here are a few simple reminders to keep you safe this season.

Make sure maintenance is up to date on all harvest equipment and all equipment is inspected before operating. Have a daily checklist to reference, and keep accurate maintenance records and perform an annual inspection for all equipment.

Use best practices when operating such as shutting down equipment when not in use, allowing equipment to cool before refueling and training all operators to identify warning signs such as abnormal noises or smells.

Farm shops and barns should be equipped with working smoke alarms and a proper fire extinguisher should be mounted on heavy equipment such as combines, tractors and trucks. It is important that these fire extinguishers are multi-purpose and equipped to handle both electrical and petroleum fires.

Develop a fire safety and evacuation plan then review with all employees and family members.

Work with your local fire department so they are familiar with the layout of your facility in case of an emergency.

The MMPA Farm Supply Store is now offering Rust-Oleum® Industrial Choice livestock marking paint. It’s a water-based, inverted spray designed for safe, effective marking. This paint provides bright, easy-to-see colors that are fade-resistant for up to 30 days and remain visible even on wet surfaces.

• Safe for livestock—no skin irritation

• Ideal for tail marking, heat detection, and animal identification

• Long-lasting, high-visibility colors

Available in 17 oz spray cans, now stocked in pink, orange, red and green. Additional colors may be special ordered upon request.

$4.83

to Order

Merchandise

Farm

Store Call in your order: Main Line: 989-317-8370 Toll Free: 877-367-6455 Orders (Novi): 800-572-5824 + 2 Fax in your order: 989-317-8372 Email your order: merch@mimilk.com

Sanitizer and Teat Dip Contacts These items are SERVICE personnel only. Order your supplies through your hauler.

Medical Emergency Hotline: 1-800-328-0026 Service Message Center: 1-800-392-3392 Service Representatives:

Pat Mitchell – 517-403-0928 7273 N. Rollin Hwy., Addison, MI 49220

Ben Chapin, Member Services Director

Steve Lehman, Ithaca, Raw Milk Compliance

989-289-0731

989-330-1638

Doug Soehnlen, Member/Superior Supply Representative 330-575-4643

Joe Packard – Area Supervisor

248-520-3481

Logan Archibald, Fowlerville 947-265-0817

Brandon Ewers, Coldwater

Emily Patton, Lansing

Christy Dinsmoore – Area Supervisor

John Lehman, Elsie

Chelsea Smith, Falmouth, MI

Ella Cloud-Schneider, Caro, MI

Cristen Cornell, Remus, MI

Sarah Michalek – Farm Sustainability Manager

Deb Gingrich, Leroy, Animal Care/Sustainability

Main Office

Local line

Toll free

President and Chief Executive Officer

Joe Diglio

Chief Financial Officer

231-414-4539

248-880-3785

248-513-7920

248-444-6775

231-519-2455

269-245-6632

248-826-6294

248-305-0537

248-520-3580

Rachel Rogers, Charlotte, Sustainability Coordinator 248-826-7243

Novi (Monday-Friday, 8 a.m.-4:30 p.m.)

In Michigan

Toll Free

Ovid (Daily, 6 a.m.-10 p.m.)

Constantine (Daily, 7 a.m.-10 p.m.)

800-572-5824

800-233-2405

989-834-2515

800-391-7560

Stephanie Walther, Farm Supply Manager

Jake Riley, Mt. Pleasant

Farm Supply Sales

Main Line

Toll Free

989-824-3321

248-912-5070

989-317-8370

877-367-6455

Orders (Novi) 800-572-5824, then dial 2

Fax 989-317-8372

248-474-6672

800-572-5824

202

Aaron Anticic ext. 277

Chief Corporate Affairs Officer

Sheila Burkhardt

Chief Operating Officer

Brad Parks

Laboratory Supervisor

Teresa Farmer

Quality

208

341

219

Sudeep Jain .................................................................................. ext. 305

Member Services

Emily Keranen

Human Resources

Kelly Kerrigan

Sales

Molly Costaris

Communications

Emily Kittendorf-King

Senior Corporate Controller

Jeannie Strain

Member Relations

203

301

209

234

312

Jessica Welch ext. 303

Matt Rogers, Plant Manager .................................................. 330-477-4515

Constantine, Michigan

Dave Davis, Plant Manager 269-435-2835

Ovid, Michigan

Rodney Gutierrez, Plant Manager 989-834-2221

Middlebury Cheese Company, Middlebury, Indiana

Plant Manager 574-825-9511

If you are unable to reach your assigned member representative, please contact the representatives listed in your area. Your assigned member representative is listed on your quality statements or can be found by visiting mimilk.com/contact/field-staff and searching by your producer number.

Officers

Doug Chapin, Board Chairman

Tony Jandernoa Board Vice Chairman

Eric Frahm, Treasurer

Joe Diglio, President and CEO

Sheila Burkhardt, Secretary

Aaron Anticic, Assistant Treasurer

Brad Parks, Chief Operating Officer

Todd Hoppe, General Counsel

Directors-At-Large

Aaron Gasper, Lowell, MI 616-291-4092

Bruce Benthem, McBain, MI 231-920-1615

Kris Wardin, St. Johns, MI 989-640-9420

District Directors

1 Paul Keener Ashland, OH 330-988-0139

1 Kurt Steiner Creston, OH 330-464-1219

2 Brian DeMann Martin, MI 269-720-7637

2 Brian Preston Quincy, MI 517-376-1350

3 Doug Chapin Remus, MI 231-349-4059

3 Amy Martin LeRoy, MI 231-388-0496

4 Eric Frahm Frankenmuth, MI 989-652-3552

4 Corby Werth Alpena, MI 989-464-5436

5 Tony Jandernoa Fowler, MI 989-593-22245

5 Scott Lamb Jeddo, MI 810-327-6135

A Holstein grazes, calm and slow, her black-and-white coat set aglow. The evening sun sets fields aflame, with amber light that slowly wanes.

A red barn rests beyond the trees, framed by crisp October breeze. Maples drop their fiery rain, while harvest whispers through the grain.

Reduces inflammation for stronger immune response

Boosts health, fertility, and reduces labor needs Rapid + sustained nutrient

Give your cows a stronger start! Ask your CentralStar team for Cow Start Complete.

DONE ONCE. DONE RIGHT. Cow Start™ Complete delivers quick and sustained-release nutrients in just one administration at calving, helping transition cows have less inflammation and stronger immune responses.