DESIGN THE FUTURE

Winter 2025

DESIGN THE FUTURE

Winter 2025

Each Varia Texture panel diverts an equivalent of 3,295 water bottles from the landfill.

Come home to the colors of nature.

Simon Starling’s 2024 solo show Houseboat for Ho (Presented by the Starman) at The Modern Institute in Glasgow featured a cross-cultural installation created with Danish thatchers and Bolivian reed-boat makers.

Now in its

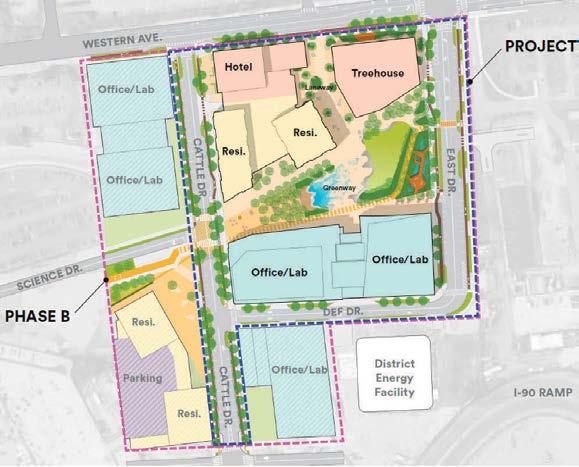

The Enterprise Research Campus draws on the talents of Henning Larsen, Marlon Blackwell Architects,

172 CannonDesign Remakes California’s First LargeScale Sustainable Building

The renovation of a landmark project by Sim Van der Ryn shows what sustainable strategies have stood the test of time—and what ideas have fallen by the wayside.

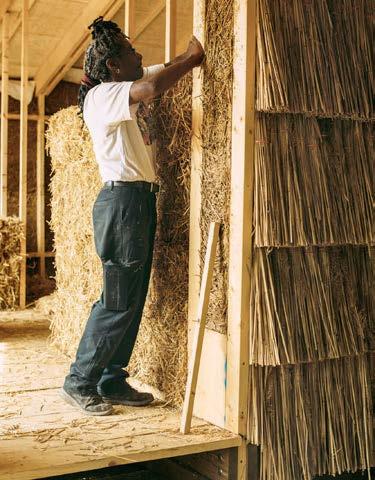

180 Thatch—the Past and Future of Green Building?

Architects are rediscovering the potential of reeds and thatch through projects that sequester carbon—and help restore wetlands.

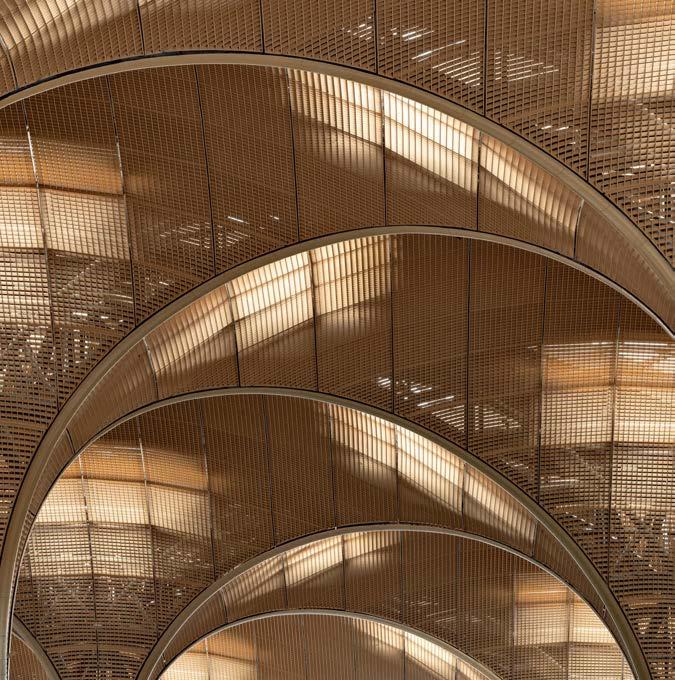

ON THE COVERS: Top: Designed by Studio Gang, Harvard University’s David Rubenstein Treehouse anchors the Enterprise Research Campus with its mass-timber structure.

3XN’s

is

with

Bottom: Inside the Treehouse, exposed beams and glulam columns frame a network of platforms, bridges, and stairs. Photos: © Jason O’Rear courtesy Studio Gang

Trust the Original. Enjoy the Ease.

EDITOR IN CHIEF Avinash Rajagopal

DESIGN DIRECTOR Tr avis M. Ward

SENIOR EDITOR AND PROJECT MANAGER Laur en Volker

SENIOR EDITOR AND ENGAGEMENT MANAGER Fr ancisco Brown

ASSOCIATE EDITOR AND RESEARCHER J axson Stone

DESIGNER Rober t Pracek

PROGRAMS COORDINATOR AND ASSISTANT EDITOR Dinky A srani

COPY EDITOR Don Armstr ong FACT-CHECKER Anna Zappia

EDITORS AT LARGE Ver da Alexander, Sam Lubell

ADVERTISING DIRECTOR

Tamara Stout tstout@sando wdesign.com 917.449 .2845

NATIONAL SALES DIRECTOR Ra chel Pettit

ACCOUNT MANAGERS

Julie Arkin jarkin@sandow design.com 917.837.1344

Meredith Barberich meredith.barberich@sando wdesign.com

Gregory Kammerer gkammer er@sandowdesign.com 646.824.4609

Laury Kissane lkissane@sando wdesign.com 770.791.1976

Julie McCarthy jmccarth y@sandowdesign.com 847-567-7545

Colin Villone colin.villone@sando wdesign.com 917.216 .3690

PRINT OPERATIONS MANAGER Olivia Padilla

DIRECTOR, PROGRAMS & PARTNERSHIPS

Kelly Allen kkriwko@sando wdesign.com

DIRECTOR, CLIENT STRATEGY Kasey Campbell

SENIOR DIRECTOR, MARKETING OPERATIONS Ra chel Senatore

DIRECTOR, CREATIVE SERVICES Carly Colonnese

GR APHIC DESIGNER, CREATIVE SERVICES Paige Miller

METROPOLISMAG.COM @metr opolismag

A MORE SUSTAINABLE METROPOLIS

As part of the SANDOW carbon impact initiative, all publications, including METROPOLIS, are now printed using soy-based inks, which are biobased and derived from renewable sources. This continues SANDOW’s ongoing efforts to address the environmental impact of its operations and media platforms. In addition, through a partnership with Keilhauer, all estimated carbon emissions for the printing and distribution of every print copy of METROPOLIS are offset with verified carbon credits.

CHIEF EXECUTIVE OFFICER Erica Holborn

PRESIDENT Bobby Bonett

CHIEF OPERATING OFFICER Michael Shavalier

CHIEF DESIGN OFFICER Cindy Allen

EXECUTIVE VICE PRESIDENT AND DESIGN FUTURIST AJ Paron

VICE PRESIDENT, DIGITAL Caroline Davis

VICE PRESIDENT, BUSINESS DEVELOPMENT Laura Steele

VICE PRESIDENT, FINANCE Jake Galvin

SENIOR DIRECTOR, VIDEO Steven Wilsey

CHAIRMAN Adam I. Sandow

CONTROLLER Emily Kaitz

VICE PRESIDENT, HUMAN RESOURCES Lisa Silver Faber

DIRECTOR, INFORMATION TECHNOLOGY Joshua Grunstra

METROPOLIS is a publication of SANDOW 3651 FAU Blvd. Boca Raton, FL 33431

info@metropolismag.com 917.934.2800

FOR SUBSCRIPTIONS OR SERVICE

800.344.3046

customerservice@metropolismagazine.net

SANDOW was founded by visionary entrepreneur Adam I. Sandow in 2003, with the goal of reinventing the traditional publishing model. Today, SANDOW powers the design, materials, and luxury industries through innovative content, tools, and integrated solutions. Its diverse portfolio of assets includes LUXE INTERIORS + DESIGN, INTERIOR DESIGN, METROPOLIS, and DESIGNTV by SANDOW; ThinkLab, a research and strategy firm; and content services brands, including The Agency by SANDOW, a full-scale digital marketing agency, The Studio by SANDOW, a video production studio, and SURROUND, a podcast network and production studio. SANDOW is a key supporter and strategic partner to NYCxDESIGN, a not-for-profit organization committed to empowering and promoting the city’s diverse creative community. In 2019, Adam Sandow launched Material Bank, the world’s largest marketplace for searching, sampling, and specifying architecture, design, and construction materials.

THIS MAGAZINE IS RECYCLABLE.

Please recycle when you’re done with it. We’re all in this together.

Rebecca Greenwald is a writer, researcher, and strategist who works with landscape architecture and urban planning studios, artists, nonprofits, and philanthropies. She aims to elevate the work of cities and organizations committed to keeping our urban environments authentic, communal, equitable, and people-oriented amid significant political, economic, and cultural shifts. Greenwald also writes about urban sociology, cultural infrastructure, and public space for outlets including Bloomberg CityLab, METROPOLIS, Fast Company, and Next City. In this issue, Greenwald covers Calder Gardens (p. 110) in Philadelphia, where Piet Oudolf and Herzog & de Meuron’s design brings Alexander Calder’s art into a contemplative, living sanctuary.

Lydia Lee writes about design and sustainability from the San Francisco Bay Area, where she also advocates for more bicycle lanes. She mentors aspiring op-ed writers through the OpEd Project and is the author of The Well-Designed Accessory Dwelling Unit: Fitting Great Architecture Into Small Spaces (Schiffer Publishing). In this issue, Lee revisits California’s first large-scale sustainable building—Sim Van der Ryn’s Gregory Bateson Building (p. 172)—through CannonDesign’s ambitious renovation and its lessons for today’s designers.

Brian Libby has spent the past 25 years as a Portland, Oregon–based architecture and arts journalist. He has contributed to METROPOLIS since 2001 and has also written for nine sections of The New York Times, as well as for The Wall Street Journal, The Atlantic, Dwell, The Architect’s Newspaper, and Oregon ArtsWatch, among others. He has also authored numerous architectural monographs. His forthcoming book, In Search of Portland: Exploring a Transforming City, will be published by Oregon State University Press in 2026. In this issue, Libby explores how LEVER Architecture’s Cascada Hotel and Spa (p. 118) in Portland defines a new era of health-centered, low-carbon hospitality.

STATEMENT OF OWNERSHIP, MANAGEMENT AND CIRCULATION (required by Act of August 12, 1970: Section 3685, Title 39, United States Code).

1. Metropolis

2. (ISSN: 6030-9000)

3. Filing date: 10/1/2025.

4. Issue frequency: 5 times per year.

5. Number of issues published annually: 5.

6. The annual subscription price is $32.95.

7. Complete mailing address of known office of publication: 3651 FAU Boulevard Boca Raton, FL 33431.

8. Complete mailing address of headquarters or general business office of publisher: 3651 FAU Boulevard Boca Raton, FL 33431.

9. Full names and complete mailing addresses of publisher, editor, and managing editor. Publisher, Bobby Bonett, SANDOW, 3651 FAU Boulevard, Boca Raton, FL 33431. Editor, Avinash Rajagopal, SANDOW, 3651 FAU Boulevard, Boca Raton, FL 33431. Managing Editor, Avinash Rajagopal, SANDOW, 3651 FAU Boulevard, Boca Raton, FL 33431.

10. Owner: SANDOW; 3651 FAU Boulevard, Boca Raton, FL 33431.

11. Known bondholders, mortgages, and other security holders owning or holding 1 percent of more of total amount of bonds, mortgages or other securities: NONE.

12. Tax status: Has Not Changed During Preceding 12 Months.

13. Publisher title: Metropolis.

14. Issue date for circulation data below: Sep/Oct 2025.

15. The extent and nature of circulation:

A. Total number of copies printed (Net press run)

B. Paid circulation.

1. Mailed outside-county paid subscriptions.

2. Mailed in-county paid subscriptions.

3. Sales through dealers and carriers, street vendors and counter sales.

4. Paid distribution through other classes mailed through the USPS.

C. Total paid distribution.

D. Free or nominal rate distribution (by mail and outside mail).

1. Free or nominal Outside-County.

2. Free or nominal rate in-county copies.

3. Free or nominal rate copies mailed at other Classes through

RESPONSE

Our bio-based resilient flooring is a heterogeneous, commercial-rated polyurethane made from plant-based oils and naturally occurring minerals. Prioritizing our sustainability commitment, this bio-based resilient collection contains no chlorine, plasticizers, solvents, harmful pollutants, or phthalates.

RESPONSE

JJFL OORING.COM

“UNFORTUNATELY, MODERN SOCIETY has insufficiently supported the human need to affiliate with nature,” Yale University Professor Stephen Kellert wrote for METROPOLIS in 2015. Distilling decades of research into a succinct article titled “What Is and Is Not Biophilic Design,” this pioneering thinker emphasized the value of biophilia to human well-being. “We are just beginning to find that these environmentally impoverished habitats foster fatigue, symptoms of disease, and impaired performance, and the simple introduction of natural lighting, outside views, and vegetation can result in enhanced health and productivity.”

In the decade since he wrote those words, biophilic design has expanded its ambitions. Its promise of reconciling buildings and nature has captured the attention of architects and designers worldwide. And a network of experts in science, sustainability, design, and architecture are urging the adoption of biophilic design not just as a way to make people healthier, but to help other life and planetary systems recuperate and regenerate. “We’re moving beyond buildings that mitigate harm toward architecture that performs like an ecosystem,” writes Erin Rovalo, vice president of community at Living Future and one of the seven leaders who helped us answer the question “What’s Next in Biophilic Design?” (p. 87).

As we begin to consider this larger scope for Kellert’s ideas, we’re also rediscovering that early attempts to make buildings more sustainable ended up looking a lot like biophilic design. When CannonDesign took on the task of renovating California’s first large-scale sustainable building (p. 172) it found that the

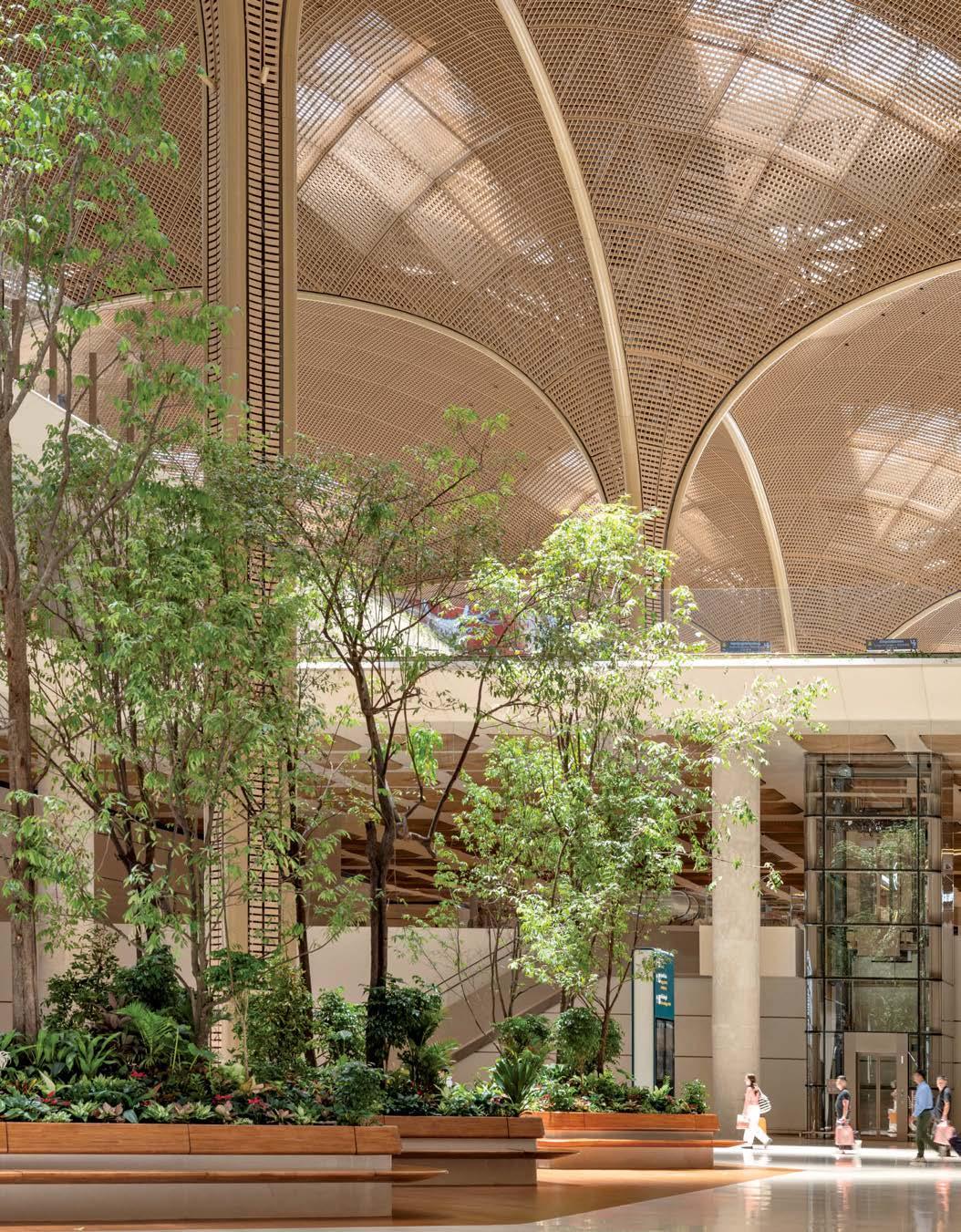

Biophilia informed the design of Google’s Gradient Canopy building in Mountain View, California, which achieved Living Building Challenge Petal certification. Read more about the overlap between biophilic and regenerative design on p. 94

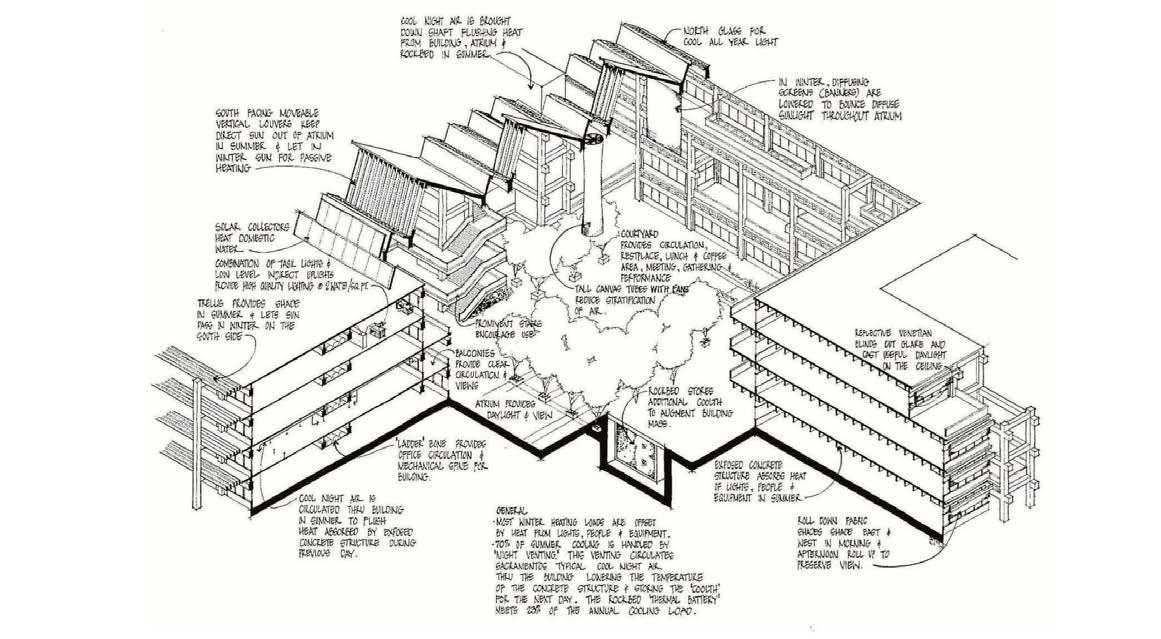

innovative architect Sim Van der Ryn had relied heavily on nature-inspired systems and natural materials in 1981 to help the 330,000-square-foot Gregory Bateson Building perform: a night flush system for heat; operable louvers; and a plant-filled, un-air-conditioned atrium. “In short, more than 40 years ago, the Bateson Building was designed to foster biophilia,” our reporter Lydia Lee writes.

It’s this kind of thinking about both the experience of natural systems and their tangible interactions with buildings that has been finely engineered in 3XN’s design of the new Sydney Fish Market (“A State-of-the-Art Home for Seafood,” p. 164) or harnessed in the form, materiality, and spirit of the Studio Gang–designed David Rubenstein Treehouse at Harvard University (“Harvard's Next Big Urban Experiment,” p. 154) .

In fact, just look at the 42 winners and ten honorable mentions in the 2025 METROPOLIS Planet Positive Awards (p. 127) and you will see how biophilia in fact suffuses all the work architects and interior designers are doing today to make a positive impact in the world.

Ten years after we first had the privilege of publishing Kellert’s ideas, METROPOLIS is gathering all our best reporting and coverage of the design approach he championed in an updated version of “What Is and Is not Biophilic Design.” You can find his original essay as well as project case studies, reporting, and thought leadership at metropolismag.com/biophilic-design.

Inspired by his vision, we can remake the built environment into something more nurturing, sustaining, and organic to this planet’s systems. Happy New Year! —Avinash Rajagopal, editor in chief

Crux combines the natural warmth of wood with the stability of steel, featuring stackable arm and armless café chairs, smooth-rolling casters, bar- and counter-height stools, and matching tables in all three heights.

According to a survey by the research experts at Thinklab, designers are asking for more color and more pattern in performance fabrics. Enter the inventor of the category, Crypton, producer of the industry’s most specified fabric in the toughest commercial environments, and the 30-year-strong guiding force behind the largest and most trusted textile brands, such as Burch, Designtex, Kravet Momentum Textiles & Wallcovering, and Stinson. Whether for hospitality, healthcare, education, senior living, or workplace, designers can go to these brands and ask for Crypton by name to receive durable, stain-resistant, and aspirational indoor performance fabrics made with Crypton’s scientific advances. All Crypton offerings are Greenguard Gold–certified and free of harmful chemicals like PFAS, and many of the new p artner collections are made at Crypton Mills in North Carolina, supporting American-made production and sustainability. Recent highlights include Montage Weaves, a textural and playful series by Kravet Contract; Designtex’s wellness-oriented Biophilia line; and the hospitality-ready and plentiful (more than 180 SKUs!) Anna Elisabeth Crypton Contract collection.

The inaugural event brought industry leaders together under the theme "SYNERGY" to envision a resilient, regenerative built environment.

AT THE NEW SCHOOL IN NEW YORK CITY, the first-ever METROPOLIS Sustainability Lab + Conference brought together more than 200 architects, designers, clients, students, and industry leaders to explore the power of collaboration in shaping a sustainable built environment.

This year’s theme, SYNERGY, highlighted how collective innovation drives meaningful change across sectors—from health care and workplace to education

and development. The program featured dynamic panels, workshops, and keynotes, including Alloy Development CEO Jared Della Valle, alongside the first-ever NYC Sustainability Lab, showcasing 20 partner exhibits (shown on these pages) and an installation by the Healthy Materials Lab at Parsons. Together, the conversations and activations offered a vision for how, through shared purpose and thoughtful design, we can work to create a more resilient and regenerative future. M

ARPER

CATIFA CARTA

Catifa Carta is a reinterpretation of Arper’s original iconic design, the Catifa 53. Its seat is crafted from PaperShell’s revolutionary, namesake material, which ingeniously transforms discarded offcuts of deceased trees into durable craft paper, harnessing the carbon dioxide the tree retained throughout its life, contributing to a more environmentally conscious production cycle. arper.com

AUTEX ACOUSTICS REPET

RePET is Autex Acoustics’ breakthrough pelletizing process, which transforms manufacturing offcuts into homogeneous PET pellets. These pellets then become SpinFix™ mounting clips, Frontier™ End Caps, and Vicinity™ Workstation Clamps. By capturing and reusing in-house waste material, RePET ensures resource recovery, reduces landfill, and minimizes reliance on virgin materials. autexacoustics.com

Borrowed Earth Spaces is a comprehensive solution and sustainability initiative by Borrowed Earth. By carrying a single material palette across the project, the company reduces waste, maximizes value, and creates a cohesive aesthetic. Architects and designers select one or more stone blocks for a project, and Borrowed Earth takes full responsibility for using each block in its entirety as part of its Zero Waste Initiative. From tiles and panels to tubs, vanities, fireplaces, and lighting, every piece of stone is transformed into a purposeful design element. borrowedearthcollaborative.com

Ruchika Grover Founder and CEO, Borrowed Earth

MM: What perspectives or expertise outside your company were critical in shaping the Spaces initiative?

RG: The initiative grew through dialogue with architects, designers, and builders who increasingly sought monolithic pieces—tubs, vanities, large-format panels—that typically left large remnants behind. Their input helped us see the necessity of creating a system where every fragment of stone has a purpose.

Borrowed Earth gives new life to leftover stone with Spaces. Spaces ensures

METROPOLIS Magazine: Tell us about a new product or product line you’re excited to highlight. What need does it address in the built environment?

Ruchika Grover: Borrowed Earth Spaces is an initiative that reimagines how stone is used in projects. Instead of sourcing multiple materials, architects and designers select entire stone blocks, which we then transform holistically into walls, floors, baths, furniture, objects, and even bricks. This ensures zero waste, a unified material palette, and long-term sustainability. It addresses the urgent need for more responsible sourcing in the built environment.

MM: What makes this initiative a sustainability milestone for your company?

RG: It transforms what used to be an inevitable waste problem into a closed-loop system. Instead of letting remnants sit indefinitely, Spaces ensures 100 percent utilization of stone blocks—from monumental installations to the smallest functional objects.

MM: How does it contribute to healthier, more resilient environments?

RG: Natural stone, when responsibly sourced and minimally processed, offers non-toxic, durable, and low-VOC surfaces. By committing to full-block utilization, we reduce extraction cycles and environmental strain, allowing stone to be specified more responsibly in sensitive environments. In health care and education, this translates to longlasting, easy-to-maintain surfaces that minimize replacement cycles. In workplaces, the integration of stone elements can foster biophilic connections to nature, enhancing well-being and resilience.

MM: Can you share an example of how it has been used successfully in a recent project?

RG: In a recent residential project, an entire block of marble was selected under our Spaces program. From this single block, we created a monolithic bath, wall panels, flooring, fireplace surrounds, and a dining table. The approach not only ensured zero waste but also resulted in a spa ce with a remarkable cohesive identity, where every element spoke the same geological language. ■

BIOBASED XOREL

Biobased Xorel is a plant-based, PVC-free textile made from rapidly renewable sugarcane. With up to 91 percent biobased content and a carbon-positive footprint, it delivers durability, cleanability, and aesthetic versatility—without harmful finishes or chemicals. Ideal for wallcoverings, upholstery, and the rPET-based acoustic solution Xorel Artform, Biobased Xorel combines high performance with design flexibility across health care, hospitality, and education environments. carnegiefabrics.com

WINDFALL + CAMBIO

CAMBIO MAGNETIC WALL SYSTEM

Windfall + Cambio crafts wall panels, cladding, stair treads, and furniture from reclaimed, salvaged, and responsibly sourced wood. The company’s cladding products offer three installation methods: Sticks, a linear wood profile; Panels, prefinished architectural surfaces in a wide range of colors and textures; and its latest innovation, Cambio® by Windfall, a patented magnetic wall system designed for circularity—reusable, flexible, and waste conscious. windfall.design

CLARUS

GLASS WHITEBOARDS & DRY ERASE BOARD PRODUCTS

Made in the USA from domestically sourced materials, Clarus products follow responsible manufacturing practices that reduce waste and emissions. Holding more than 43 product certifications, including Indoor Air Advantage Gold and Type III EPDs, Clarus delivers quality, transparency, and flexibility for responsible design. clarus.com

Interface is 'all in' on its goal to be carbon negative by 2040, without offsets

Collaboration fuels Interface’s carbon negative innovations.

Davis Director, Global Market Sustainability

METROPOLIS Magazine: Tell us about a new product or product line you’re excited to highlight. What need does it address in the built environment?

Mikhail Davis: We’re proud to spotlight our carbon negative carpet tile products that store more carbon than they emit. These high-performing products rely on bio-based and recycled content in the supply chain to achieve carbon negativity, and they help us make strides toward our goal of becoming carbon negative by 2040. These innovations address the urgent need for low-impact materials in the built environment and demonstrate how design can actively contribute to climate solutions.

MM: What perspectives or expertise outside your company were critical in shaping these products?

MD: Since the early days of our transformation to becoming a purpose-driven company, we have learned to look to nature for inspiration in design—for our products, our material selection, and our partnerships. Biomimicry taught us that if we wanted to achieve our most ambitious targets, we would need to cooperate as much as we compete, so collaboration with suppliers and partners was essential. Their insights helped us reimagine raw material sourcing and manufacturing processes, enabling us to reduce Scope 3 emissions and expand circular solutions across our portfolio.

MM: What makes these products a sustainability milestone for your company?

MD: They prove that carbon negative is possible—without offsets. This milestone redefines our sustainability strategy and sets a new standard for the industry.

MM: How do they contribute to healthier, more resilient environments?

MD: Experts agree that one of the biggest threats to public health in the 21st century is runaway climate change, so addressing the large-scale ecological challenges we face through our product supply chain benefits not only the building occupant but also the people who interact with our supply chain across the full lifespan of our products. They’re designed for durability, flexibility, and well-being—ideal for high-performance environments like schools, hospitals, and offices.

MM: How do these products represent your company’s larger sustainability journey?

MD: It’s the embodiment of our “All In” strategy— focused on avoiding, reducing, and storing carbon. Our target is to be carbon negative as a company, with no offsets, by 2040. This means storing more carbon in the products we sell than our business emits, and these products leverage over three decades of innovation to help us pursue our commitment to solving the climate crisis through bold, measurable action.

MM: How do you see these innovations contributing to greater collaboration around sustainability in the years ahead?

MD: We learned early on that to go as far as we aspired to, we had to get there together with partners in our supply chain and in our customer community. We’re currently measuring how our product could be carbon negative not only in the cradle-to-gate life stages but also throughout its use phase by partnering with customers to help them commit to renewable energy use and lower their operational impacts overall. By sharing our learnings and challenging others to go carbon negative, we aim to accelerate industrywide progress and inspire new partnerships rooted in climate action. ■

With Stylex, 9to5 Seating, HÅG, and Via Seating, Flokk brings together four distinct brands united by one vision: to design high-performance seating that’s better for people— and better for the planet. A market leader in Europe and now growing across America, Flokk creates furniture that meets the real needs of modern workspaces while actively reducing environmental impact. flokk.com

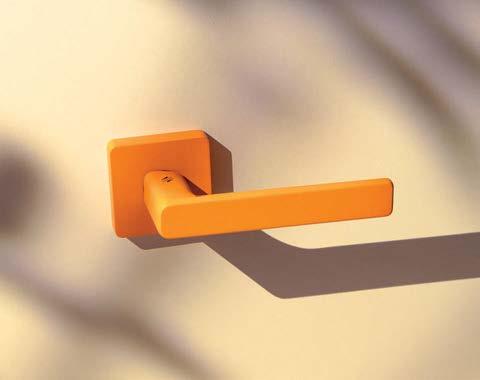

COLOMBO DESIGN

GREEN MADE

Green Made, an initiative by Colombo Design, showcases over 20 years of commitment to conserving nonrenewable resources and advancing eco-compatible production. Through innovations like water recovery systems, solvent-free powder coatings, and a shift from Chromium (VI) to safer Chromium (III), Colombo Design reduces emissions, waste, and environmental impact. colombodesignamerica.com

DUVALTEX

CLEAN IMPACT TEXTILES

Duvaltex’s CLEAN IMPACT TEXTILES® reduce the environmental impact of waste, transforming how products are sourced, manufactured, and disposed of. Gather, made from upcycled ocean waste, is a biodegradable, multiuse style. Its soft-wool-like surface and rich color palette invite tactile exploration, enriching spaces and advancing a more sustainable future. cleanimpacttextiles.com

Colombo Design’s Kombo Box unites seamless aesthetics and sustainability.

Carlo Farina Sales Manager, Colombo Design America

METROPOLIS Magazine: Tell us about a new product or product line you’re excited to highlight. What need does it address in the built environment?

Carlo Farina: The new Colombo Design Kombo Box, developed in collaboration with Krona Koblenz, features a magnetic European mortise case and strike available in all Colombo Design finishes, including the Mood RAL finishes. The magnetic mortise and strike faceplates provide a clean, screwfree appearance and allow for interchangeable options. With no lip on the magnetic strike, the frame maintains a sleek, uninterrupted look. As streamlined, seamless aesthetics continue to gain popularity, complete matching hardware with coordinating accessories has become increasingly in demand.

MM: What perspectives or expertise outside your c ompany were critical in shaping this product?

CF: Innovation thrives through connection, not isolation. Throughout the years, we have listened to our customers and followed the market demand: the Kombo Box stands as a great example of this. At Colombo Design we aim to have customers, architects, designers, and end-users as our best partners.

MM: What makes this initiative a sustainability milestone for your company?

Colombo Design’s water treatment plant recovers 40% of water annually.

CF: Colombo Design partnered with Krona Koblenz to minimize product packaging, energy consumption, and transportation logistics. The key to success lies in combining smart, forward-thinking business ideas with sustainability.

MM: How does it contribute to healthier, more resilient environments?

CF: The sustainable choices Colombo has adop ted under its Green Made initiative reflect our commitment to environmental certifications and values such as UNI ISO 14001 and UNI ISO 9001. These certifications govern our manufacturing processes, including powder coating, trivalent chrome plating, and zero-emission PVD finishes. Additional measures that reduce our environmental impact include the installation of a water treatment plant that recovers 40 percent of water annually, significantly decreasing hazardous waste pollution.

MM: Can you share an example of how it has been used successfully in a recent project?

CF: Although the Kombo Box is brand new to the market, we anticipate a strong launch. Based on research and variations of this product and finishes already available in our range, the Kombo Box expands the possibilities for hardware coordination.

MM: How does it represent your company’s larger sustainability journey?

CF: Reducing packaging, minimizing waste, and lowering energy consumption are all part of Colombo Design’s ongoing commitment to environmental sustainability. In 2026, we plan to culminate a green vision that began 25 years ago by achieving EPD (Environmental Product Declaration) certification.

MM: How do you see this innovation contributing to greater collaboration around sustainability in the years ahead?

CF: Colombo Design continues to welcome collaborations, ideas, and joint projects from all players in the market chain. ■

Formica Corporation is committed to long-term planning and industry-leading environmental stewardship. Formica is committed to becoming carbon neutral by 2030 with a clear road map—including a 25 percent reduction in CO2 emissions and a 10 percent cut in primary energy use by 2026, plus a 5 percent reduction in water footprint. The company also powers its Cincinnati and Saint-Jean-surRichelieu, Quebec, plants with 100 percent renewable electricity. formica.com

INTERFACE

“ALL IN” ON CARBON NEGATIVE

Interface is going “All In” to solve the climate crisis with the bold ambition of becoming a carbon negative enterprise by 2040—without relying on offsets. Building on decades of progress, Interface is scaling innovations in product design, manufacturing, and supply chain engagement to reduce embodied carbon, store carbon in materials, and inspire others to do the same. interface.com

IMPACT ACOUSTIC

BIOBASED PET

Biobased PET plastic relies on crops, fertilizers, and land expansion, increasing biodiversity loss and nutrient pollution. Impact Acoustic’s solution transforms postconsumer PET bottles into high-performance acoustic materials, avoiding farmland use and reducing climate impact. This circular approach keeps resources in use and clearly outperforms biobased PET when assessed against planetary boundaries. Impact Acoustic’s PET solution lowers greenhouse gas emissions up to 60 percent compared with biobased PET. impactacoustic.com

Impact Acoustic's material innovations support ecology and human health.

Erni CEO and Cofounder, Impact Acoustic

METROPOLIS Magazine: Tell us about a new product or product line you’re excited to highlight. What need does it address in the built environment?

Sven Erni: We are developing environmentally friendly, innovative solutions that support bioremediation and advance ecological health and resource efficiency. Our latest material innovation—a product made from nettle fibers—continues this mission. Free of chlorine, hazardous components, and adhesives, the material supports the natural carbon cycle and can help decarbonize buildings, improve indoor air quality, and enable design that aligns with long-term sustainability goals.

MM: What perspectives or expertise outside your company were critical in shaping the final solution?

SE: Developing this product required expertise in bioremediation from environmental and biological engineering perspectives, which our interdisciplinary team was able to provide.

MM: What makes this product a sustainability milestone for your company?

SE: The nettle is a fast-growing, renewable plant, and using it as a fiber source is a sustainability milestone because it leverages the plant’s unique advantages. Nettles do not require specific growing conditions, do not need to be replanted after harvesting, and generally thrive with minimal intervention. This makes them exceptional compared to conventional crops— they can also contribute to bioremediation

while producing our product by absorbing excess nitrogen and phosphorus in the soil.

MM: How does it contribute to healthier, more resilient environments?

SE: The nettle is a natural product that has not been treated with pesticides, fertilizers, or intensive irrigation. This ensures the material is free from harmful chemicals, making it ideal for healthcare and education settings. Additionally, the nettle’s long-lasting properties make it suitable for outdoor environments such as traffic areas.

MM: How does this product represent your company’s larger sustainability journey?

SE: This product exemplifies our innovative approach and commitment to leading the development of circular economy solutions in the acoustic industry. It joins other sustainable materials we use, including mycelium, fungi, algae, cork, wood, and cotton. This is a key step in our process, enabling us to incorporate the biological cycle into our products and help restore carbon to the soil.

We are focused on pr oviding solutions that are both environmentally friendly and innovative. These solutions support bioremediation and demonstrate our commitment to ecological health and resource efficiency. The material contains no chlorine, hazardous components, or adhesives, and supports the natural carbon cycle.

In the built environment, it can be used to decarbonize buildings, improve indoor air quality, and support design that aligns with long-term sustainability goals. ■

Each day, Impact Acoustic turns

10,000+ plastic bottles into acoustic products.

THE REVE™ COLLECTION Bold dreams blossom into breathtaking reality when exquisite craftsmanship and ecological responsibility work in harmony. The Reve™ Collection features Hyphyn™—a revolutionary biodegradable performance vinyl. Engineered with a patented enzyme, Hyphyn™ breaks down by over 90 percent within 24 months in landfill conditions. pallastextiles.com

Formica Corporation delivers durable, long-lasting surfaces with a smaller environmental footprint.

METROPOLIS Magazine: What needs do Formica Corporation products address in the built environment?

Christelle Locat-Rainville: Formica Corporation is committed to long-term planning and industry-leading environmental stewardship. We bring our signature products to market with sustainability built into every stage, while being transparent about our environmental footprint and our goals for reducing it.

MM: What perspectives or expertise outside your company are critical in shaping Formica® Brand family of products?

CL: Our sustainability center of excellence, Nemho, located in Weert, the Netherlands, plays a key role in developing carbon-reduction strategies shared across the Broadview Materials family of companies. Collaboration through Nemho allows us to align sciencebased t argets, implement energy-saving projects across plants worldwide, and transparently report progress each year in our sustainability position paper.

MM: What is a recent sustainability milestone for your company?

CL: Formica Canada reduced greenhouse gas emissions by 5 percent through an innovative heat-recovery system at our St-Jean-surRichelieu, Quebec, plant. Working with engineering and environmental partners, we installed heat exchangers that capture and

reuse hot air from laminate-curing ovens, reducing reliance on natural gas. This project demonstrates how technology and collaboration can meaningfully shrink our carbon footprint while maintaining product quality.

MM: How does your product contribute to healthier, more resilient environments?

CL: By reducing our carbon emissions, we contribute to a healthier en vironment. We provide all related certifications for our products, including EPDs, HPDs, Green Guard Gold, USDA BioPreferred, Declare label, FSC, and more. Formica Group North America also participates in the mindful MATERIALS database and supports product transparency documentation.

MM: How will your products contribute to greater collaboration around sustainability in the years ahead?

CL: Formica Corporation works to reduce waste during manufacturing wherever possible, including by designing beautiful, long-lasting surfaces, as durability and longevity are key sustainability factors.

Our approaches include: manufacturing with renewable energy—our plants in Evendale, Ohio, and St-Jean-sur-Richelieu, Quebec, rely on 100 percent renewable electricity; waste prevention—the extensive Formica® Laminate Collection offers highly durable, timeless patterns that future-proof design; and post-use disposal—our program with TerraCycle enables recycling of sample materials. ■

Formica is working toward a 25% reduction in CO2 emissions by 2026.

Rockfon’s Stone Wool Tiles provide a simple solution for the ceiling—with strong performance attributes that prioritize human health, environmental responsibility, and circular design. The company’s four key foundations are the Natural Power of Stone, Protecting the Outdoors, Fostering Health Indoors, and Enduring Circularity. rockfon.com

Recently, Steelcase doubled the recycled content on average in its top seven task chairs in the Americas and has launched end-of-use services like Circular by Steelcase: Remade to prevent furniture from ending up in landfills. To be remanufactured, or “remade,” a product’s worn elements are disassembled and updated with new parts and finishes, while maintaining the original durability, functionality, and comfort. steelcase.com

Dr. William Chizhovsky Founder & CEO, The Good Plastic Company

The Good Plastic Company makes recycled materials practical and beautiful.

Specifying Growth can save up to 14 lbs of CO2 per square foot compared to the industry average.

METROPOLIS Magazine: Tell us about a new product or product line you’re excited to highlight. What need does it address in the built environment?

Dr. William Chizhovsky: Growth is a collection of eight Polygood® patterns: Cliff, Oyster, Pebble, Midnight, Pumice, Frost, Gossamer, and Haze. Developed with Gensler, the series is inspired by organic textures and natural elements. From the details of bark and leaves to sandy finishes and the luminescence of water, these patterns turn 100 percent recycled plastic into refined surfaces for design-driven projects. Growth answers the demand for circular, specification-grade surfaces in the built environment, providing a sustainable alternative to traditional stone and composite materials.

MM: What perspectives or expertise outside y our company were critical in shaping this product?

WC: Collaboration with Gensler was essential. Their expertise in architecture and design ensured that Growth patterns meet real-world requirements for performance and design flexibility. They guided the balance between visual innovation and application needs, making the collection practical for horizontal uses such as countertops, vanities, and furniture, while maintaining its sustainability focus.

MM: What makes this product a sustainability milestone for your company?

WC: Each Polygood® pattern is made from 100 percent recycled plastic, reducing CO2 footprint and demonstrating true circularity,

yet the collection also proves that sustainable materials can be design-driven, durable, and widely applicable. Specifying Growth can save up to 14 lbs of CO2 per square foot compared to the industry average for surface materials, making Growth not only a design innovation but also a measurable low-carbon solution.

MM: How does it contribute to healthier, more resilient environments?

WC: Growth’s materials are non-toxic, Red List Free, and certified with an A+ VOC rating, ensuring excellent indoor air quality, while our Cradle to Cradle certification confirms that they meet rigorous environmental standards. This makes the collection suitable even for sensitive settings such as health care and education, while its durability reduces replacement needs in high-traffic workplaces and hospitality venues.

MM: Can you share an example of how this product has been used successfully in a recent project?

WC: In the retail sector, WeStore has begun implementing the Pebble design across multiple locations, proving the collection’s scalability and consistency on a global level.

MM: How does this product represent your company’s larger sustainability journey?

WC: With Polygood® and the sophisticated patterns in Growth, we’re showing architects and designers that recycled plastic can go beyond small accents and be used across entire spaces, from walls to furniture to countertops.

MM: How do you see this innovation contributing to greater collaboration around sustainability in the years ahead?

WC: Growth is an invitation for architects and designers to rethink what’s possible with recycled materials. With Polygood®, our goal isn’t just to inspire architects with beautiful materials—we want them to feel confident and comfortable specifying recycled surfaces, knowing they perform reliably like any traditional material in aesthetics, durability, and scalability. ■

Ecoustic Bio is a beautifully crafted acoustic wall tile designed with biophilic principles to connect people to nature for improved well-being. Produced from biobased materials and paired with high-performance acoustic infill, Ecoustic Bio enhances acoustic comfort by reducing sound reverberation, achieving an exceptional NRC rating of 0.85. unikavaev.com

Eloise Rapp Sustainability Manager, Instyle Interior Finishes

With a biobased composition, a minimal carbon footprint, and positive indoor health impacts, Bio Tile exemplifies the transition to renewable, regenerative materials for interior finishes.

MM: How does it contribute to healthier, more resilient environments?

ER: Bio Tile reshapes how we think about human-nature relationships in interior spaces through thoughtful integration of biophilic design principles. With its natural, earthy coloring and visible hemp and flax fibers, it evokes a sensory and emotional link to the natural world. Its sound absorption of NRC 0.85 with Ecoustic® Infill softens spatial noise for calming, inclusive environments.

METROPOLIS Magazine: Tell us about a new product or product line you’re excited to highlight. What need does it address in the built environment?

Eloise Rapp: Bio Tile addresses the urgent need for the built environment to decarbonize and move away from fossil fuel raw materials. With a 100 percent plant-derived, biobased composition, a minimal carbon footprint, and positive indoor health impacts, Bio Tile exemplifies the transition to renewable, regenerative materials for interior finishes.

MM: What perspectives or expertise outside your company were critical in shaping Bio Tile?

ER: The creative insight and expertise of our design collaborators, VANK, were key to shaping an outcome that was fit for purpose. Consultation with the local architecture and design community revealed that there are limited alternatives to fossil fuel–derived acoustic finishes, so we ensured Bio Tile fulfilled the dual need for specifying natural materials and integrating biophilic design for safe, healthy interiors.

MM: What makes this product a sustainability milestone for your company?

Unika Vaev and its partners transform hemp into low-carbon interior finishes. Bio Tile is

ER: Bio Tile is one of the world’s first 100 percent plant-derived, hemp-based acoustic finishes. This climate-positive crop rapidly sequesters carbon, grows with minimal inputs, and, when combined with plant-based polymers, can transform into a high-performance acoustic finish. Its manufacturing process utilizes renewable energy and hemp waste from harvesting, further reducing its climate impact.

MM: Can you share an example of how this product has been used successfully in a recent project?

ER: Bio Tile was a key finish used in the transformation of Bendigo Bank’s Head Office in Melbourne. Over 400 tiles were installed in multiple meeting rooms across three levels, helping transform a plain, cold office shell into a high-functioning and inviting workspace. The project’s material strategy delivered a 28 percent reduction in embodied carbon compared to a standard fitout.

MM: How does this product represent your company’s larger sustainability journey?

ER: Instyle/Unika Vaev’s sustainability focus in the coming years is on environmental stewardship, circular innovation, material transparency, and social impact. Bio Tile embodies this framework as it integrates key goals in this journey: reducing the embodied carbon of our products, progressing our biomaterial R&D, and supporting progressive, renewable agriculture and the communities it benefits.

MM: How do you see this innovation contributing to greater collaboration around sustainability in the years ahead?

ER: Biocomposites such as Bio Tile signal a new era of collabor ation around material sustainability, where agriculture, design, engineering, and academia intersect to accelerate innovation. Hemp is one of nature’s most effective carbon sinks, and it can become a powerful climate solution when adopted at scale by the built environment. ■

THE GOOD PLASTIC COMPANY POLYGOOD

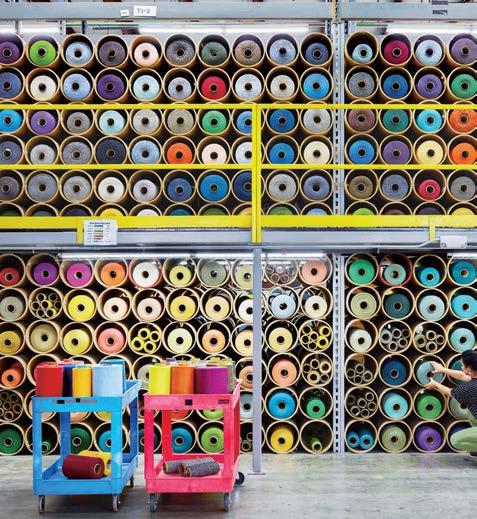

Polygood® is a high-performance, design-forward surface material made from recycled plastics sourced from discarded refrigerators, washing machines, consumer electronics, and industrial spools. The panels are thermo-formable and water-resistant and can be used structurally without additional substrate support, making them ideal for furniture and interior applications. As a mono-material, it can be fully recycled at the end of its life through our take-back program, supporting a circular, Cradle to Cradle® approach to material design. polygood.com

WOOD AND STONE TEXTURES

Turf’s expanded line of Wood and Stone Textures adds to the company’s offering of finishes, providing visionary collections of nature-inspired, digitally printed patterns. Each collection of textures pairs with the exclusive Hues palette, highlighting Turf’s mastery of its 60 percent preconsumer recycled PET felt material. turf.design

Turf combines acoustic comfort with natural aesthetics.

METROPOLIS Magazine: Tell us about a new product or product line you’re excited to highlight. What need does it address in the built environment?

Robert Krejci: Wood Textures invites architects and designers to introduce naturalfeeling surfaces into their spaces, alongside the advanced acoustic performance of our felt. This new collection continues Turf’s pursuit of nature-inspired, tech-enabled material innovation. By pairing the aesthetics of timber with acoustic utility, Turf offers designers a wide range of options for all their design needs to create welcoming spaces through the harmony of nature and sound.

MM: What perspectives or expertise outside your company were critical in shaping this product?

RK: The development process involved extensive research, trend discovery, and a collaborative team effort between Turf’s design team and longtime collaborator Carolyn Ames Noble, to develop a product highlighting both Hues and Textures. As an interior designer and colors, materials, and finishes expert, Noble’s insight on how acoustic solutions function—both visually and aurally—was crucial in ensuring the Wood Textures collection offered designers a tool that is perfect for enhancing the visual appeal of a space while also providing impactful acoustics throughout.

MM: What makes this product a sustainability milestone for your company?

RK: Instead of developing a separate line of specific colors and textures, we were able to celebrate our existing Hues color palette. We experimented with ink density, scale, and patterning to create a functional, versatile new collection of nature-inspired finishes using the power of recycled materials to our advantage. Our VOC-free, water-based printing process also allows us to use the minimum amount of ink to maintain the look and feel of our felt.

MM: Can you share an example of how this product has been used successfully in a recent project?

RK: Even though we recently launched Wood Textures, we have used them extensively in the Turf Design Experience Center at the Merchandise Mart. This allows us to showcase how the different textures and colors can be used to define spaces. With Rift, Rotary, and Flat displayed throughout in varying shades and colors—from bold and stimulating to more subdued and natural—our showroom space offers visitors an immersive experience of the collection.

MM: How does this product represent your company’s larger sustainability journey?

RK: Following the release of our popular Stone Textures, Wood Textures continues Turf’s pursuit of nature-inspired, tech-enabled material innovation. In a natural continuation, we use unique methods to combine procedural textures with parametric products. Wood Textures lean into the material constraints of Turf’s 60 percent pre-consumer recycled PET felt, embracing the heathered look of the recycled product and resulting in a more authentic finish.

MM: How do you see this innovation contributing to greater collaboration around sustainability in the years ahead?

RK: We design our products with timeless and nuanced a esthetics. Good design is sustainable design—our products live a long life by creating quality acoustic solutions. With installations meant to last, we can work with our clients to rehome lightly used, standard products. This is how we all do more with less. ■

NUCOR

FORMAWALL DIMENSION SERIES

With Formawall Dimension Series foam, designers don’t have to choose between visionary design and environmental responsibility. Nucor’s Declare Label–certified, halogen-free foam panels deliver high performance, material transparency, and long-term sustainability, empowering designers to create healthier, more sustainable buildings that inspire generations. centria.com

USG

ENSEMBLE ACOUSTICAL

DRYWALL CEILING

Ensemble® Acoustical

Drywall Ceiling balances superior acoustics with seamless design—combining core USG product technologies to maximize NRC, CAC, and LR performance. It delivers the sleek, monolithic look of drywall, with NRC up to 0.90 and CAC over 40, while enhancing lighting efficiency. usg.com

METROPOLIS Magazine: Tell us about a new product or product line you’re excited to highlight. What need does it address in the built environment?

Stacy Simpson: The Ensemble® Acoustical Drywall System addresses the critical need for enhanced acoustic performance in the built environment. It provides a solution that significantly improves sound control within interior spaces, ensuring a quieter and more comfortable environment.

MM: What makes this product a sustainability milestone for your company?

SS: The Ensemble® Acoustical Drywall System combines high acoustic performance with complete health and environmental transparency. It was the first USG system solution to have complete product transparency: low VOC emitting, Declare Label, HPD, and product specific EPD.

MM: Ho w does it contribute to healthier, more resilient workplaces, health-care, or education environments?

SS: Ensemble® Acoustical Drywall System is a low VOC emitting certified product and LBC Red-List free. This is particularly important in health-care and education settings, where vulnerable populations are present. Ensemble® Acoustical Drywall System can contribute toward the building’s occupants' well-being, providing good acoustics and low VOC emissions. Raw materials selected for use in the Ensemble® Acoustical Drywall System go

through a rigorous process that considers the safest choices for our workers, building occupants, and the environment. Additionally, having full health and environmental transparency documentation available gives project teams the opportunity to make the best choices for their owners/clients.

MM: Can you share an example of how this product has been used successfully in a recent project?

SS: The expansion of Cincinnati Children’s Hospital Medical Center–College Hill was designed to create an environment of comfort, healing, and privacy for its patients. USG collaborated with the project team to help bring the main lobby design from concept to reality, incorporating the Ensemble Acoustical Drywall System as a key feature.

MM: How does this product represent your company’s larger sustainability journey?

SS: In 2022, USG released our 2030 Sustainability Goals with a focus on enhancing customer well-being. Ensemble® Acoustical Drywall System was formulated to consider the sustainability attributes of the entire system from raw materials to acoustics. Additionally, USG has the goal of providing transparency documents for 100 percent of USG’s products. Ensemble® Acoustical Drywall System was the first USG system solution to have complete product transparency: low VOC emitting certification, Declare Label, HPD, and product specific EPD.

MM: How do you see this innovation contributing to greater collaboration around sustainability in the years ahead?

SS: By setting a high standard for acoustic performance and environmental responsibility, the Ensemble® Acoustical Drywall System can serve as a catalyst for innovation focused on sustainable building practices. Understanding the challenges of the indoor environment and product sustainability is essential in developing building materials. Collaboration with our customers allows us to work together on their sustainability projects and get a better understanding of their needs.

The Autodesk Gallery, located at the company’s San Francisco headquarters, showcases the wide range of applications made possible by Autodesk’s software—spanning industries from multimedia to architecture.

Joe Speicher, Autodesk’s chief sustainability officer, discusses how integrating AI and cloud tools can make sustainable design measurable and achievable across the built environment.

By Francisco Brown

IN 2023, AUTODESK, the giant tech company, launched Forma, an integrated, end-to-end platform that leverages artificial intelligence for predesign and schematic design. The cloud software supports a hypercentralized model for architects, engineers, and construction professionals to ensure buildings perform as planned throughout the project cycle.

METROPOLIS sat down with Joe Speicher, Autodesk’s chief sustainability officer, about how the company is aligning these innovations with its sustainability goals—particularly around energy efficiency, workplace design, and corporate commitments.

This interview has been edited for length and clarity.

Francisco Brown: With Autodesk’s rapid growth in cloud computing and AI, how do you reconcile the increased energy demands of data centers that power these technologies with the company’s commitment to environmental impact?

Joe Speicher: We’ve been investing in what would now be considered AI capabilities for over a decade, and we feel well prepared to deal with both the opportunities and challenges this presents. We procure cloud service providers and AI capabilities upstream from our vendors. We subsequently provide those same vendors with

Autodesk technology and tools to design, build, and manage their cloud infrastructure.

We are aware of the energy and emissions associated with the rise of AI, and we are leveraging all of our capabilities to help reduce that overall, by using some of our tools for energy modeling, materials optimization, and data management in these same servers.

FB: You released Autodesk Forma, which features embodied carbon analysis and materials insights. What have you heard from your customers about these new options, and is it changing sustainability practices?

JS: It’s a broad spectrum. We have some customers who are incredibly advanced in their thinking about sustainability and others who are beginning to get their heads around these issues and are starting to address them.

As you mentioned, we created Forma, a platform that connects all phases of project delivery. At the moment, what is designed is not necessarily what gets built. We know this just from change orders alone, right? Now, with this integrated approach—from the architect’s original model, to construction, to the owner, to the [building] operator—they get a live digital twin of the project model to validate performance against the original design and specifications.

As we transition to this datadriven, end-to-end offering, we’re also becoming a platform company, which, by definition, means interoperability of data across the markets we serve, particularly in the built environment, because, for us, sustainability is a data problem. But, yes, we’re getting positive feedback from our customers overall, and interestingly, I will say, over the last few years, our customers are pushing us to do more.

FB: What are the biggest challenges that Autodesk faces in meeting its own sustainability targets on time?

JS: We have three goals that we focus on from a sustainability perspective. The first: Reduce emissions associated with running our own business.

We have an SBTi [Science Based Targets initiative]–validated goal across scopes 1, 2, and 3 by this decade. Second: We subsequently commit to powering our business with 100 percent renewable energy. And thirdly, we address the residual emissions associated with our operations.

We are a technology company, so we don’t own much of anything, and we essentially ship only code. We have a relatively light footprint. We meet all our commitments with our customers in mind. What are the things that the industry needs that our customers need overall? For instance, thinking about reducing carbon emissions, one of the really challenging things is business travel.

Aviation is a hard sector to abate. Therefore, we invest in a couple of sustainable aviation fuel companies and procure sustainable aviation fuel because we think the best thing we can do as a business is to drive the cost curve down so others can participate in this market.

Instead of buying a renewable energy credit, we invest in something called virtual power purchase agreements, which enable us to underwrite the development of renewables on the grid. Bringing more renewables onto the grid helps our industry overall by decarbonizing the grid itself and, lastly, by addressing residual carbon emissions. We invest in a rigorous carbon offsetting program because, again, if we can bring down the cost curve, others—including our customers—can participate in this market.

FB: What are some internal design and workplace strategies that you have implemented that architects and designers might find inspiring in their own offices?

JS: Having an attachment to a workplace and wanting to be in the office are

productivity enhancers for us as a business. One of the best ways we do that is by looking to lease office space that is LEED certified, meets the WELL standard, or meets the BREEAM standard. We know that employees prefer working in office spaces when there’s a sustainability certification. For instance, in our Platinum LEED–certified San Francisco headquarters, we ensured our employees had the best possible experience.

For us, it’s all about the opportunity to move toward outcomes-based thinking, or as we call it, outcome-based BIM [building information modeling]. Rather than just square footage, architecture firms can start thinking about [spatial] utilization and the number of folks in the building in order to improve people’s lives in the future.

FB: That is a fantastic lead to my last question, which is about the future. When we think about the future of design tools, what excites you most about the role Autodesk plays in making sustainable design easier, faster, and more creative?

JS: I’m excited about how AI can let designers focus more on the creative side of their work. We’re using AI to automate repetitive tasks and simplify workflows—the parts no one enjoys doing.

Some worry AI might be threatening, but the reality is there’s far more work than there are people or tools to handle it. Technology like ours helps bridge that gap. I often get asked how much carbon Autodesk has offset with our tools. The truth is, the process has traditionally been very siloed—architects design, builders construct, and data gets lost in between. As we connect those stages through platforms like Autodesk Construction Cloud and Forma, we’ll be able to track a building’s lifecycle, validate its performance, and see measurable carbon reductions. That’s what really excites me—proving that sustainable design isn’t just an ideal but a quantifiable outcome. M

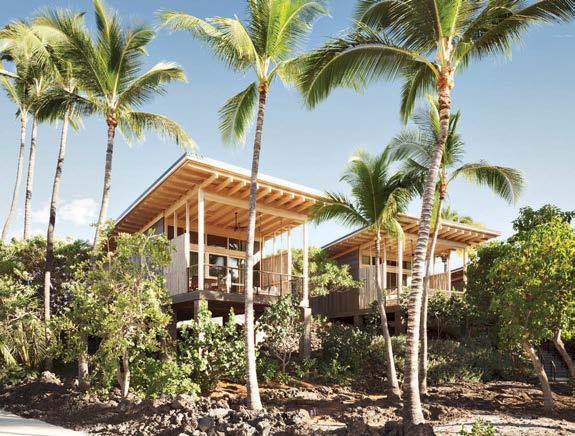

A pavilion at the London Design Festival opens new possibilities for an American hardwood that has long been overlooked.

AT THE INTERSECTION of biophilic design and material innovation stands Vert—a 33-foot-high urban pavilion reimagining an age-old material for sustainable architecture. Conceived by design studio Diez Office and urban greening experts OMC°C, with support from the American Hardwood Export Council (AHEC), Vert integrates living greenery with a renewable structure to show how design can both delight and decarbonize.

Built for the London Design Festival, Vert is a quiet yet radical experiment in circular design thinking. Its framework, constructed from glued-laminated red oak, demonstrates that a native, underutilized U.S. species can perform on par with—if

not better than—its European counterparts. The project, realized in collaboration with timber construction engineers Neue Holzbau, engineering firm Bollinger + Grohmann, and experience designers Forward Studio, is a study in how the built environment can tap local materials to solve global challenges.

Red oak, abundant across American forests, has long been overlooked in structural applications. By engineering this hardwood into glulam form, the Vert team unlocked new potential for strength, stability, and aesthetic warmth—qualities that steel and concrete can’t replicate without heavy environmental costs. The result is a space that feels alive: a porous,

from glue-laminated red oak, an abundant but underutilized American species.

light-filled structure where plants and people live in harmony.

Vert asks what would happen if cities embraced renewable hardwoods as the backbone of their built environment. In testing red oak’s structural limits and showcasing how beauty and performance can coexist, Vert reveals a way that hardwood can fuel the next generation of mass timber construction, offering a tangible pathway toward greener, more biophilic cities. M

The full story of Vert—and many others like it—appears in the inaugural issue of Hardwood & Design, a new publication celebrating the intersection of architecture, design, and the material intelligence of wood. hardwoodanddesign.com

Corgan introduces its mass timber carbon calculator, which measures the embodied emissions of biogenic carbon.

By Justin R. Wolf

Corgan, in partnership with Lake Flato Architects, is designing the new, 900,000-square-foot terminal at San Antonio International Airport. The 17-gate expansion featuring mass timber, which will unify Terminals A and B, is slated for completion in 2028.

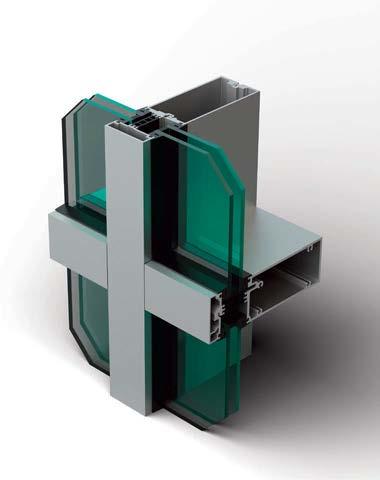

BARELY A DECADE AGO, mass timber was anointed as the sustainable alternative to building with steel or concrete. Those who initially doubted the engineered material’s tensile strength or fire resistance were assuaged by the International Code Council’s significant gesture of recognizing mass timber in the 2015 International Building Code. What’s more, mass timber’s lightness and flexibility make it ideal for fast and lean construction crews.

But when it comes to carbon and its overall emissions impact, mass timber has left a few questions unanswered. As journalist Jim Robbins noted in 2019 for Yale Environment 360: “A lack of understanding of the full CO2 picture has not kept the field from taking off.” Well, now that picture is coming into focus.

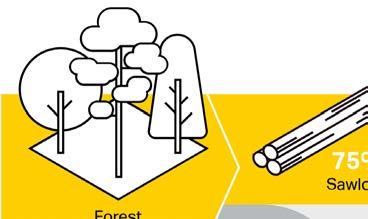

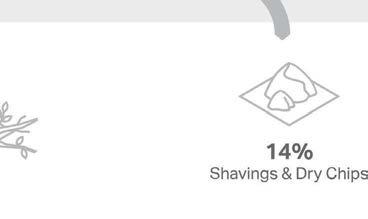

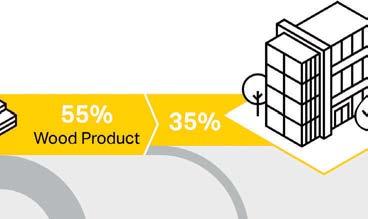

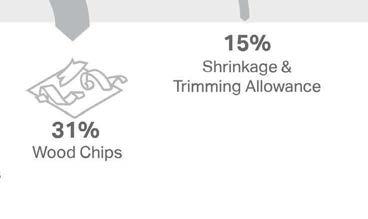

Design firm Corgan recently unveiled its Mass Timber Carbon Calculator. This free and open-source tool allows design teams to more accurately quantify the embodied emissions of specific projects. Typically, mass timber’s climate benefits are framed in terms of the wood’s capacity for carbon storage and lower emissions associated with manufacturing. Corgan has effectively repositioned the goalposts, using slashrelated biogenic carbon and transportation emissions as integral metrics in the larger question of mass timber’s carbon impact.

“Our industry is ignoring the biogenic carbon that’s associated with the extraction and harvesting of timber from forests,” says Varun Kohli, principal and director of sustainability at Corgan. “So we asked, what happens if we include that? Will that mean

mass timber is no longer the solution we thought it was?”

Biogenic carbon is released through the decomposition or combustion of biomass. When excess tree parts like branches, bark, and stumps (collectively known as slash) are invariably left to rot after a harvest, they gradually emit much of the CO2 that the tree sequestered over its life. Harvests also reduce forests’ capacity to act as carbon sinks, meaning there are fewer trees to absorb what’s being released into the atmosphere and therefore further challenge the notion that producing mass timber is a strictly climate-neutral pursuit. “If you leave [slash] in the forest, off-gassing takes time, but nonetheless you’re not taking the entire tree,” Kohli says.

This practice of slash management, or lack thereof, is the crux of Corgan’s exercise. The streamlined tool factors in wood species (e.g., hemlock fir, Southern yellow pine, et al.), harvesting technique, and project location, as well as where regional manufacturing occurs. With these variabilities accounted for, biogenic carbon is the X factor.

The motivation for developing the calculator stems from a 2023 report released by the World Resources Institute, The Global Land Squeeze which concludes that previous assessments of mass timber’s carbon impact were incomplete. “Our accounting approach differs from many others that either fail to account for future forest regrowth or

inappropriately view harvests as carbon neutral so long as forest carbon stocks remain stable on average,” the report reads.

In response, Kohli and his colleagues built a tool that traces impact “back to the forest.” “It’s not enough to go back to the fabrication facility,” he says, noting that this is roughly where the proverbial breadcrumbs have been traced to when project teams conduct a life-cycle assessment (LCA) of their building materials. “We also know that EPD [Environmental Product Declaration] data most likely will not count biogenic carbon,” Kohli adds.

Like its cousins, the Embodied Carbon in Construction Calculator (EC3) and One Click LCA, Corgan’s Mass Timber Carbon Calculator is designed to paint a more complete picture of practices we know are superior to the status quo but that have been compromised by half-finished datasets. Undoubtedly, when timber projects benefit from sustainably managed forests, regional material sourcing and manufacturing, and faster construction schedules, their carbon footprint is significantly lower compared with conventional builds.

"Mass timber is still a good solution for embodied carbon, but we’ve got to pay attention to the nuances,” Kohli says. “You can’t ignore the entire life cycle of mass timber, the piece that existed before fabrication. All told, though, it’s still a better product.” M

Our revolutionary process uses heat and pressure, not acrylic fillers, to create an ultra-dense 100% natural, highly sustainable, hardwood floor that’s ideal for commercial spaces. Armstrong Flooring® TimberTones™ stands up to ustainable, a range of daily demands and ensures that soft, hardwood species are now viable design options for commercial interiors. So, strut, walk, run or jump - we can take it.

Developed by MycoWorks, Reishi is a new leather alternative, grown in South Carolina and finished in Spain. With a supple, natural grain and exceptional durability, it has been crafted into handbags, footwear, furniture, and automotive interiors—offering water-resistant, plastic-free luxury for design industries seeking sustainable, high-performance materials. At ICFF 2025, Reishi was featured in furniture upholstery and interior panels, signaling circular design’s shift. reishi.mycoworks.com

Kasthall’s 2025 Fasad collection, designed with David Chipperfield, reimagines luxury rugs through sustainability. Using 25 percent recycled wool and linen, the woven bouclé designs—Uno and Duo—echo the brick facade of Kasthall’s Swedish mill. The collection blends architectural precision with environmental responsibility, offering tactile pieces crafted for longevity. kasthall.com

XAF Cumulus 3D Cloud

The latest addition to Carnegie’s XAF Clouds collection, the XAF Cumulus 3D Cloud has a sculptural silhouette measuring 55 inches wide, 20 inches high, and 4.75 inches deep. The product is backed with Kirei’s recycled PET and finished in proprietary plant-based Xorel fabric. carnegiefabrics.com

High-performance indoor-outdoor upholstery textile made from sugarcane

The Knit One Chair features a ribbed, dual-tone, 3D-knitted shell that replaces traditional foam, reducing material waste. Its lightweight metal frame enables flat-pack shipping and easy assembly, while optional angled modules, bolt-on wood side tables, and a range of fabric colors allow versatile, customizable configurations. isomi.com

Tumble includes a sculptural side and coffee tables with a round top of shredded, compressed, recycled textiles, giving each piece a unique flecked pattern. Supported by a wood base with a circular cutout, Tumble is offered in two sizes, gray or black tops, and three wood finishes, combining playful geometry with warm, textural contrast. kfistudios.com

MOMENTUM

Muratto Collection

Momentum and Muratto’s Muratto Collection transforms cork into more than 20 tactile, acoustic formats. Crafted from 100 percent natural, recyclable, and biodegradable cork harvested from the bark of cork oak trees, the collection includes two lines—Organic Blocks and PrimeCork. Panels, strips, blocks, and tiles in varied colors combine durability and sound absorption, adapting to bold or minimalist interiors and highlighting cork’s versatility as a sustainable material. momentumtextilesandwalls.com

Turf’s new ceiling product Pantheon is designed to sculpt the ceiling plane and can be supported using a standard tee grid. It features a coffered form that can be configured with open and closed tiles to create graphic patterns and is available in standard 24-by24-inch tiles finished with nine-millimeter PET felt in a range of colors and textures. turf.design

Sourced from underutilized wood, this live sawn red oak veneer paneling is an eco-responsible alternative to white oak. Cut from select at-risk, mature, or diseased trees, the veneer is applied to medium-density fiberboard made with up to 80 percent recycled material. Panels measure two or four feet wide, eight feet tall, and three-quarters of an inch thick. urbanevolutions.com

With the Fern chair as its first product to fully achieve closedloop manufacturing, Haworth is proving that environmental responsibility and ergonomic excellence go hand in hand. The process reuses plastic generated during production stages and from end-of-life chairs to create new Fern models, optimizing existing resources and reducing waste to deliver brand-new products without sacrificing quality or increasing costs. haworth.com

Following the DANA storms that ravaged Valencia, Spain, last fall, Spanish designer Patricia Urquiola partnered with Andreu World, one of the region’s leading furniture manufacturers, to launch this hauntingly beautiful piece. The stool, which is 3D printed using a biodegradable and compostable material, has a trunk-like form that appears as though it were hit by a force, evoking resilience and community with its interwoven texture. All proceeds from its sales benefit the affected communities and individuals. andreuworld.com

Gio LN14-LN15

Inspired by Gio Ponti’s pareddown yet vibrantly hued Muranoglass chandelier and the glass craftsmanship the Venetian island is renowned for, Luca Nichetto created this modern reinterpretation for &Tradition. Gio takes cues from its namesake by stripping away ornamentation to form a minimal three-tiered luminaire with each component powder-coated a different color. As a subtle nod to Murano glassmaking processes, the conical discs making up the tiers are spun aluminum. The design is offered in two sizes and two color schemes. andtradition.com

Utilizing only high-quality, hand-selected fibers, the Premier Collection merges superior acoustics with an astonishingly smooth surface and depth of color. Acoufelt’s soft architecture ceiling and wall solutions deliver on our trademark commitment to sustainability and wellness. Meticulous sourcing and manufacturing plus an exacting approach to blending fibers of varying color tones and thicknesses allows us to maintain strict control of an exceptional finished product.

Sample today on

Arktura’s Tapestra collection features cable-hung acoustic ceiling modules that merge sound absorption with sculptural form. Consisting of four models—Weave, Spool, Lace, and Pleat—the system uses Soft Sound® material with 12-millimeter frames and 3-millimeter curved ribbons. Modules can form continuous arrays or clustered, cloudlike formations, offering flexible, visually striking acoustic solutions. arktura.com

Merenda Wallpaper’s Formation collection reinterprets traditional motifs through geometric and textile-inspired patterns. Tilt features a bold chevron rhythm with vintage undertones, Cleo reimagines a woven check, and Halo was created from a rubbing done on a vintage glass window in Havana, Cuba. The patterns can be printed on PVC-free substrates in smooth and embossed options and contain no olefins, plasticizers, phthalates, formaldehyde, chlorine, halogen, or heavy metals. The line is digitally printed on FSCcertified papers. merendawallpaper.com

Sample today on

Introducing Olive, crafted to balance personal expression with high performance, Olive blends sleek design with practical features. Its soft, natural tones and clean, tailored lines create a workspace that supports focus, calm, and/or relaxation. Olive features an adjustable lumbar pad and optional headrest that delivers comfort and style in every setting.

RARIFY X GANTRI

Cube One

Launched at NYCxDesign 2025, Cube One is the first in-housedesigned product by Rarify—a designer-led ecommerce platform dedicated to vintage and contemporary design—in collaboration with lighting manufacturer Gantri. The modular lamp uses repurposed authentic USM Haller frame elements and a 3D-printed cube lighting unit molded in a sugarcane-derived, biodegradable plant polymer. The modular system supports stacking or clustering multiple cubes to form larger configurations, and the lighting unit is removable at end of life for sustainable disposal. rarify.co

Rooted in heritage yet adapting to the present, generous forms and honest materials define the CH290 Series by Hans J. Wegner, embodying meticulous craftsmanship and relaxed elegance. The collection features 2- and 3-seater sofas, low and high-backed lounge chairs, and a footstool — each bringing lasting warmth, quiet sophistication, and a timeless expression to refined interiors.

Rooted in heritage yet adapting to the present, generous forms and honest materials define the CH290 Series by Hans J. meticulous and relaxed elegance. The collection features 2- and 3-seater sofas, low and chairs, and a footstool — each warmth, quiet sophistication, and a timeless expression to refined interiors.

KEILHAUER Dais

Designed to use as few materials as possible, Dais provides a design-forward, sustainable seating solution that is both relaxed and supportive.

Constructed with FSC® Certified Wood and biobased foam, it pairs a light, airy frame with a generous, oversized cushion to create a unique visual tension. In 2025, the Dais collection expanded to include a side chair. keilhauer.com

Sequels Wood-Look Finish

For those times when a project calls for warmth as well as durability, Armstrong World Industries has added four new wood-look finishes to its MetalWorks ceiling and wall panels. Available in La Jolla Oak, New Haven Walnut, Cape May Cherry, and Montauk Driftwood, the panels feature FASTPeel protective film that is easy to remove for increased productivity on-site. The collection is available to ship in four weeks or less. armstrongceilings.com

New York–based boutique wallcoverings brand Calico is known for its prolific release of collaboration-driven collections, often imagined with conceptual or expressive frameworks.

Stephen Burks’s new Particulaire collection is no different. The offering was conceived based on the idea of keeping souvenirs of one’s travels, in this case, trips to far-flung places like Cambodia. calicowallpaper.com

BILTRITE ABPURE® Infinity

ABPURE® Infinity is a cradle-togate, carbon-neutral rubber flooring in 20 earth-centric colors. Made with renewable natural gas (RNG) from organic waste, it reduces emissions while offsetting its footprint, as verified by its Type III EPD. By investing in local RNG initiatives, American Biltrite is transforming waste into clean energy, reducing reliance on fossil fuels, and creating a more sustainable future for flooring. american-biltrite.com

HBF TEXTILES

Creativo

Mark Grattan’s new Layered collection draws inspiration from three aspects of his persona. Creativo, embodying his identity as “the creative,” features a seductive, checkered velvet motif. The textile alternates between cut and uncut surfaces in a rhythm that is both tactile and visually appealing across eight colorways. hbftextiles.com

Crafted from circular materials and entirely without PVC, the Dimension Collection offers lasting performance, natural beauty, and conscious craftsmanship—setting a new standard for what flooring can achieve.

Designed by Lievore Altherr Molina in 2004, Catifa 46 recently received updates with contemporary materials, resulting in Catifa (RE) 46, which features a distinctive shell made from 100 percent recycled plastic. The shell is available in eight shades and pairs with three base options: four wooden legs, four steel legs, and a sled base. A new seat cushion, also available for outdoor use, is made from Breathair®, an elastomeric polyester. Optional armrests can be added to certain configurations, and Catifa (RE) 46 is also available as a stool in two different heights. arper.com