BEYOND HIGH-STRENGTH CONCRETE: ULTRA-HIGHPERFORMANCE CONCRETE Metna Co. (Email: metnaco@gmail.com)

Concrete:

The Most Widely Used Construction Material

BEYOND HIGH-STRENGTH CONCRETE: ULTRA-HIGHPERFORMANCE CONCRETE Metna Co. (Email: metnaco@gmail.com)

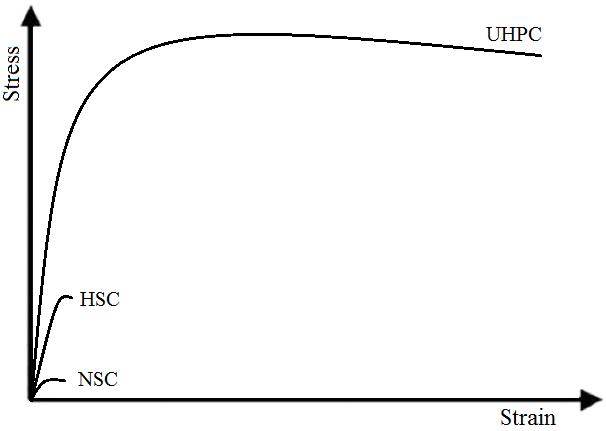

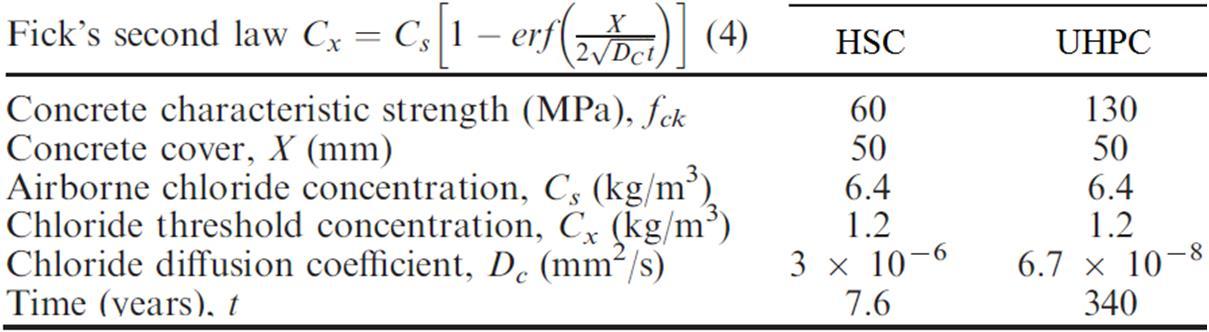

• Distinctly high compressive strength (>20 ksi, 140 MPa), tensile strength (>2.6 ksi, 18 MPa), ductility, toughness, blast and fire resistance, impermeability and durability.

• Some key features include high packing density of particulate matter, very low water/cementitious ratio, and effective use of discrete fibers.

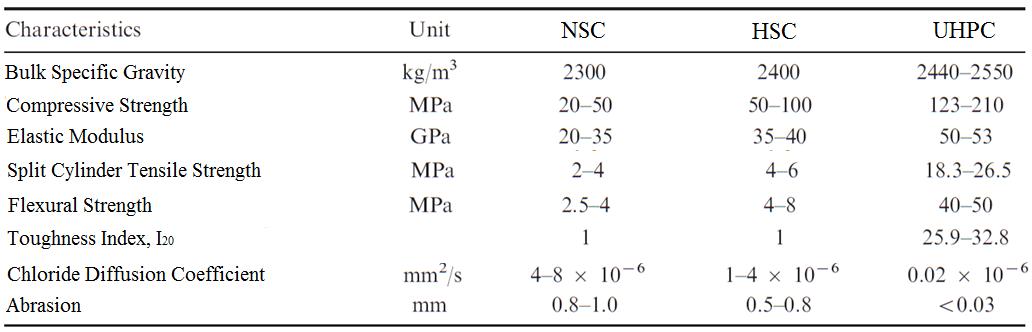

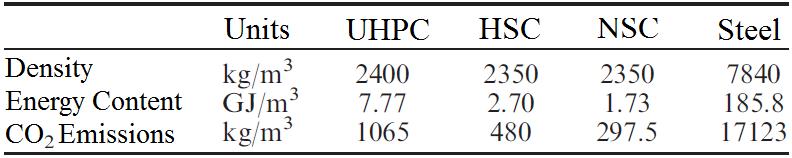

Typical Performance Characteristics of Normal-Strength Concrete (NSC), HighStrength Concrete (HSC), and Ultra-High-Performance Concrete (UHPC)

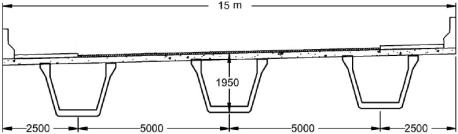

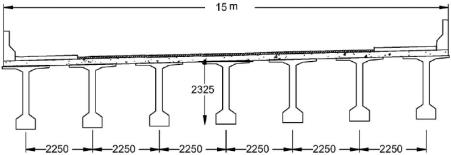

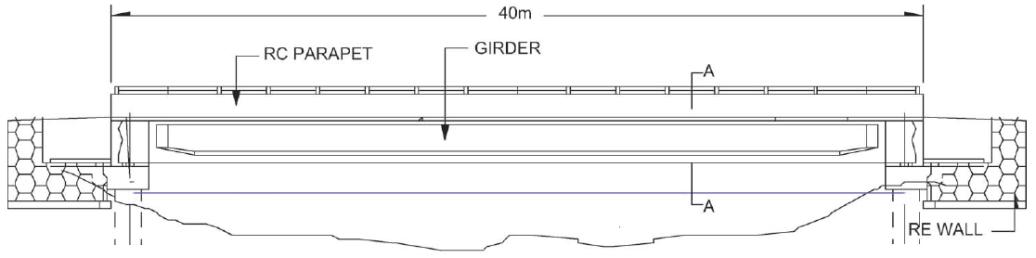

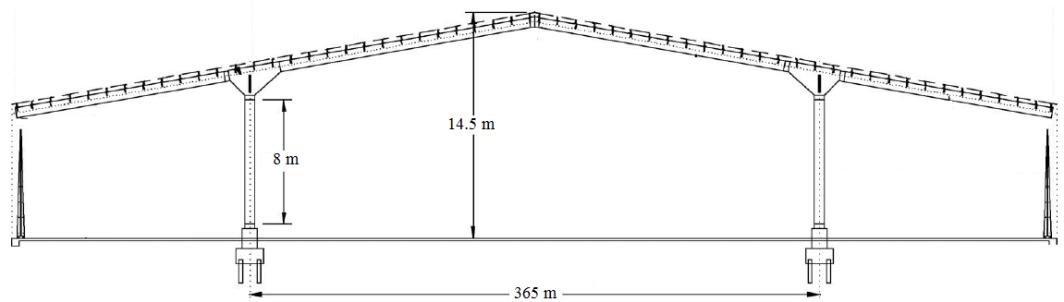

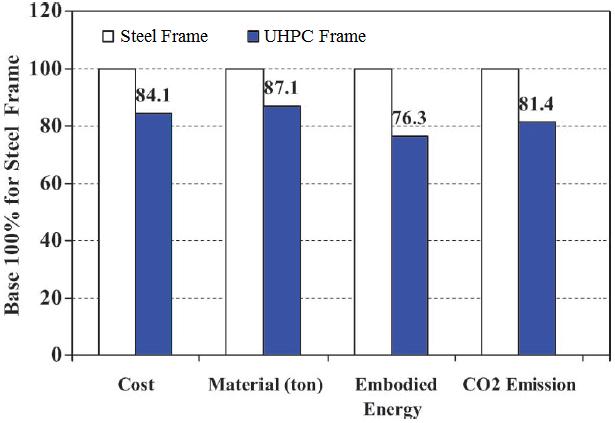

Structural Frame: Steel Replacement

Abrasion-Resistant, Low-Cost Dies for Production of Metal & Polymer Parts

• High Packing Density

• Removal of coarse aggregate

• Use of specially graded fine aggregates

• Optional use of relatively inert powder

• Use of fine pozzolans (silica fume)

• Low Water/Binder Ratio

• Use of Advanced Superplasticizers

• Effective Use of Fibers

• High-Temperature Curing

Typical Mix Designs of Normal-Strength Concrete (NSC), High-Strength Concrete (HSC), and Ultra-HighPerformance Concrete (UHPC)

• Excess Cementitious Contents

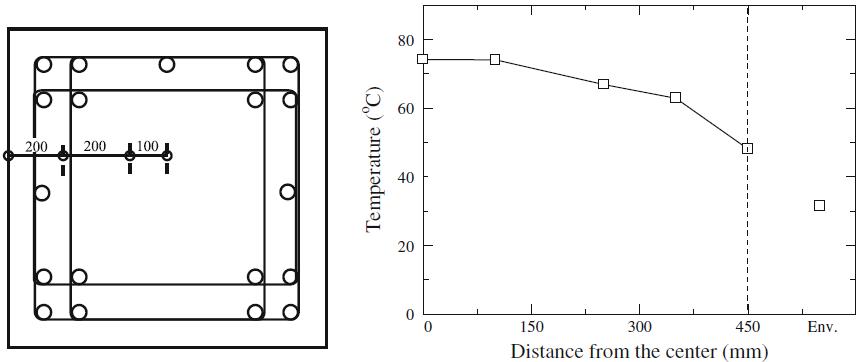

• High Heat of Hydration

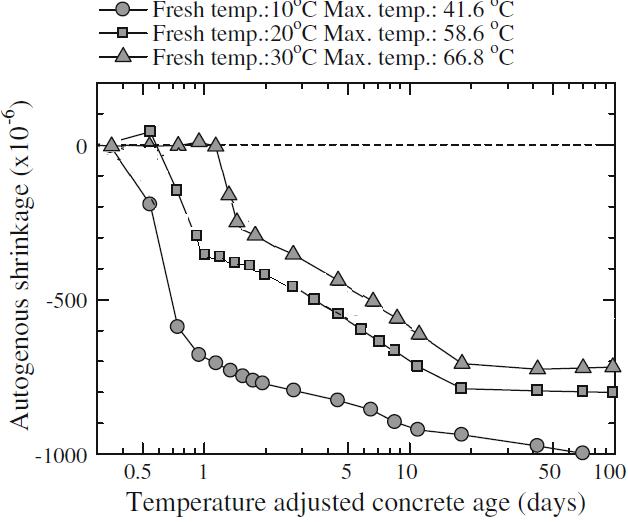

• Large (Autogenous) Shrinkage (correlated with temperature rise)

• Restrained (thermal/autogenous)

Shrinkage Cracking

• Large Creep Deformations

• Need for Thermal Curing

• Specialty Aggregates

• Excess Mixing Time/Effort

• Cost

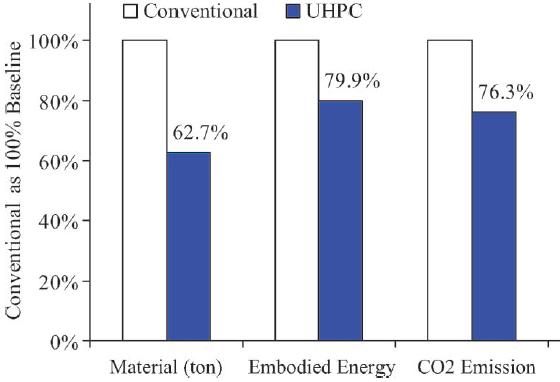

•Future Needs: Develop mix design and production methods for reliable and costeffective construction of UHPC infrastructure systems using commonly available materials and equipment.

•Key Benefit: Enable effective use of UHPC towards enhancement of the safety, structural efficiency, durability, sustainability, and initial and life-cycle economy of concrete-based infrastructure systems.