FUELS & LUBRICATION

LUBRICATION OPTIMISATION KEY TO REDUCING GHG EMISSIONS Rathesan Ravendran, Technology and Innovation Specialist, Hans Jensen Lubricators A/S discusses how cylinder lubrication oil consumption contributes to GHG emissions Annual greenhouse gas emissions from shipping exceeded 1 billion tons in 2018. While this only constitutes 2.9 % of global emissions, it exceeded the annual emissions from Germany, the largest single emitter in the European Union. The current prediction is that significant part of the emission reduction can be achieved by changeover to green fuels such as ammonia, methanol and bio-fuels as well as technologies as wind-assisted propulsion and CO₂ scrubbers. Adapting these measures is however not enough to reach a fully carbon neutral vessels. There are several hidden sources on board vessels contributing indirectly to GHG emissions – and a significant contributor is cylinder lubrication oil. Hans Jensen Lubricators A/S have been working on this topic for many years, and delivered products that reduce lubrication oil consumption and environmental impact for vessels. The products are in continues development in order to meet the needs and requirements from the market. This article highlights the emissions related to cylinder lubrication, and how it is possible to reduce these by efficient lubrication. Emission related to lubricating two-stroke marine diesel engines Cylinder lubrication is essential for the performance of twostroke diesel engines. It is the key component controlling the friction loss and wear on the cylinder liner and piston rings, by providing a thin oil film between the sliding interfaces. Increasing the dosage of lubrication oil does not mean less frictional losses and wear. It is as damaging as low oil dosage, as well as an environmental problem due to engine smoke formation and oil sludge production, which is naturally increased with the lubrication oil consumption. Therefore, balancing lubrication oil becomes important part of an engine when aiming at enhancing lubrication performance and reducing its contribution to exhaust gas emissions. Mechanical efficiency (reduced friction) Proper lubrication has a significant impact on the mechanical efficiency (reduced friction), which have a direct contribution to reduced emissions, including CO₂ emissions. The less engine friction, the less energy is required to propel the vessel, the less fuel is burned. Consequently, fewer emissions are created. Friction losses that occur at liner/ring interface led to loss in propulsion power. Research has shown that this interface contributes to about 20% of the engine’s total mechanical frictional loss. Another source for power loss comes from insufficient gas seal by the lubrication oil between cylinder liner and piston rings, which will lead to reduced compression pressure.

lifetime have an additional impact on CO₂ emissions, which are related to the production and logistics of the components. Wear near the top-dead-center (TDC) is often the limiting factor for the lifetime of engines. High wear rates are caused by abrasive and adhesive wear which is highly influenced by the engine operating conditions of the engine. Today, engines are exposed to tougher conditions with the low-sulphur fuels, since sulphur in the fuel have a beneficial tribological effect due to build-up of a solid lubricating oil film and due to promoting a beneficial mild corrosive wear. The lost lubricity of the low sulphur fuel must be replaced by conventional cylinder lubrication oil, distributed correctly on the cylinder liner.

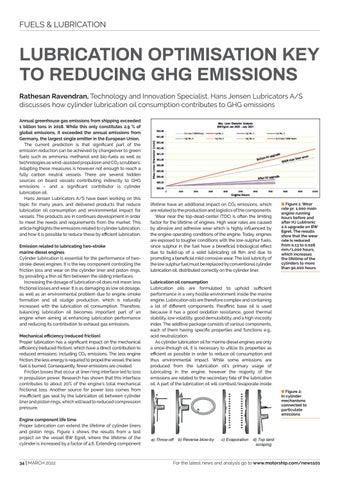

8 Figure 1: Wear rate pr. 1,000 main engine running hours before and after HJ Lubtronic 2.0 upgrade on BW Egret. The results show that the wear rate is reduced from 0.13 to 0.028 mm/1,000 hours, which increases the lifetime of the cylinders to more than 90,000 hours

Lubrication oil consumption Lubrication oils are formulated to uphold sufficient performance in a very hostile environment inside the marine engine. Lubrication oils are therefore complex and containing a lot of different components. Paraffinic base oil is used because it has a good oxidation resistance, good thermal stability, low volatility, good demulsibility, and a high viscosity index. The additive package consists of various components, each of them having specific properties and functions e.g., acid neutralization. As cylinder lubrication oil for marine diesel engines are only a once-through oil, it is necessary to utilize its properties as efficient as possible in order to reduce oil consumption and thus environmental impact. While some emissions are produced from the lubrication oil’s primary usage of lubricating in the engine, however the majority of the emissions are related to the secondary fate of the lubrication oil. A part of the lubrication oil will combust/evaporate inside 8 Figure 2: In cylinder mechanisms connected to particulate emissions

Engine component life time Proper lubrication can extend the lifetime of cylinder liners and piston rings. Figure 1 shows the results from a test project on the vessel BW Egret, where the lifetime of the cylinder is increased by a factor of 4.6. Extending component

34 | MARCH 2022

For the latest news and analysis go to www.motorship.com/news101