www.mehi.fi | Made in FINLAND

2024 English CERTIFIED SO 9001

Mehi Oy | Catalogue

Table of Contents

MEHI OY Metallitie 2 - 4 89600 SUOMUSSALMI FINLAND tel. +358 (0) 207 929 600 sales@mehi.fi www.mehi.fi Special Tools Mehi® Special Tools 4 Special toolholders 6 Adjustable chucks 6 Helical milling cutters 7 Chamfer mills 7 Shrinkfit Holders 7 Step drills 8 Combination boring tools 8 Back face boring tools 9 Stamping tools 9 External boring tools 10 Profile / Disk milling cutters 11 Adjustment tool for tool changer 12 Measuring tools for Spindle 12 AF20 and AF25 Adjustment elements 13 AF50 Adjustment element for finishing boring heads 13 Standard tools Mehi® standard tools 14 Mehi® boring tool system 14 Boring heads TF Boring heads 16 LF Toolholders 17 1TP Boring heads for semi-finishing 18 1LC Toolholders 19 1LC, 75°, CCMT indexable inserts 19 1LC, 90°, CCMT indexable inserts 19 1LC, 95°, CCMT indexable inserts 19 2TP Boring heads for roughing 20 2LC Toolholders 21 2LC Tool holders 75° CCMT-indexable inserts 21 2LC Tool holders 90° CCMT indexable inserts 21 2RF Boring heads for roughing and finishing 22 2RF Toolholders and counterweights 23 AF50 Adjustment elements for finishing boring heads 23 Finishing tools 1TAF Boring heads for finishing 24 Tool holders for 1TAF Finishing boring heads 24 AF50 Adjustment elements for finishing boring heads 25 Adjustment element for VNL 25 A1FL Boring heads for finishing 26 AF50 Adjustment elements for finishing boring heads 27 A2AL Boring heads for finishing 28 Tool holders for A2AL Finishing boring heads 28 AF50 Adjustment elements for finishing boring heads 29 Adjustment element for VNL 29 TVA Boring heads for finishing 30 Adjustment elements for TVA Boring heads 30 1THF Boring heads for finishing 31 Adjustment elements for VNL 31 Back face boring tools Back face boring tools 32 Toolholders Weldon/Whistle toolholders 33 Cylinder arm weldon/whistle chucks - small chucks 33 Extensions Extensions, EB model A and B 34 Reducers, RB model A and B 35

Mehi Oy introduction

Mehi Oy

We design and manufacture high-quality MEHI® special tools and standard tools with cutting inserts for the needs of the machine shop industry. We also make a range of fixation solutions for lathes and machining centres. In addition, demanding subcontracting machining, prototypes and product development projects are part of our range of services. Mehi Oy has a certified ISO 9001 Quality management system.

We have been operating since 1973 and we are supplying MEHI tools not only Finland, but also the Nordic countries, Europe, North America, Canada, Turkey and China. Decades of experience and expertise enable the implementation of demanding tool packages always in a customer-oriented way, enhancing customer production.

We use the latest 3D CAD/CAM software. Our own design, production, heat and surface treatment, as well as grinding departments guarantee extremely fast delivery times. Tools made of different steels are delivered hardened if needed, and aluminium standard tools are coated. Special aluminium tools are coated on a case-by-case basis as required. Tools will be equipped with the desired cutting inserts.

Fast production. A customised product is produced in as little as four weeks. The exact delivery time is always confirmed with the order confirmation. Standard tools can also be customised into special tools with different sizes. We also manufacture vibration-damped mandrels, turning and tool holders, and customised machining fixtures according to customer requirements at our factory in Suomussalmi, Finland.

» Customized Special tools

• Solving your problems, optimizing your production

• With long term knowledge, passion, and new thinking, we generate value to our customers

• More efficient production by less tool changes, increased quality and shorter lead time

• We desing and manufacture the products with a short delivery time, up to four weeks

• High-quality special tools according to the wishes of our clients

» Standard tools

• Roughing Tools (Can be equipped with coolant channel)

• Finishing Tools (Can be equipped with coolant channel)

• Subcontract manufacturing

• Precision machining

• Precision tooling

• Fixtures solutions

• Product development services

Export sales directly from Mehi Oy

Request for quotation sales@mehi.fi

EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 3

Mehi® Special Tools

Mehi® special tools are always designed according to the customer’s needs. The goal is to improve the efficiency of the customer’s production. Mehi® special tools are usually capable of performing multiple machining operations at once, which significantly speeds up the customer’s production lead times.

Our special tools are known for their high quality, reliability, and longevity. They can be modified from Mehi® standard tools or redesigned from scratch. If necessary, special tools can have fluid channels added depending on the material being machined. All special tools are available with customer-selected steel cutting inserts.

Mehi® special tools can consist of e.g. a tool body, a suitable cutting tool holder, and a finishing element such as a replaceable AF50 fine adjustment element. Fine adjustment elements in special tools can also be directly attached to the tool body. The customer’s chosen cutting inserts can also be ordered directly from Mehi Oy’s factory with the tool.

Mehi® special tools are manufactured with the most common tool holder types. All models are manufactured entirely at the factory. Special tools made of steel are surface-hardened, which significantly increases their service life. In demanding machining applications, where the work surface is farther away, the solution often involves a vibration-damped boring bar combined with a special tool or an integrated vibration-damped tool solution. These options ensure accurate quality in demanding machining applications.

Export sales directly from Mehi Oy

We aim to serve customers by listening and finding a comprehensive solution to improve their production.

Standard tools

Please submit a request for quotation to sales@mehi.fi. If the products are in stock, we can deliver them quickly.

Special tools

Please send your request for quotation with the required information to sales@mehi.fi

Required information:

» Image or sketch of the object / tool to be made

» Material requirement

» Tool holder type (DIN, HSK, WELDON, BT, HTS, CAPTO…)

» The desired insert

» Schedule request

If necessary, we will contact the customer for any additional information. For larger tool projects, we hold a separate remote meeting with customers.

We are happy to assist with arranging shipping. The delivery time for freight, for example, from our factory to China, is about seven days.

Special Tools

free to ask us for a quote!

Feel

sales@mehi.fi

EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 5

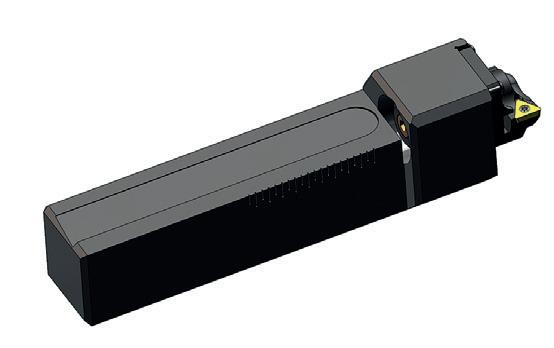

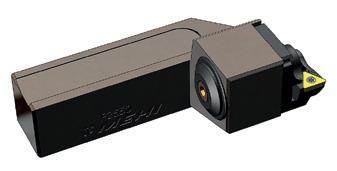

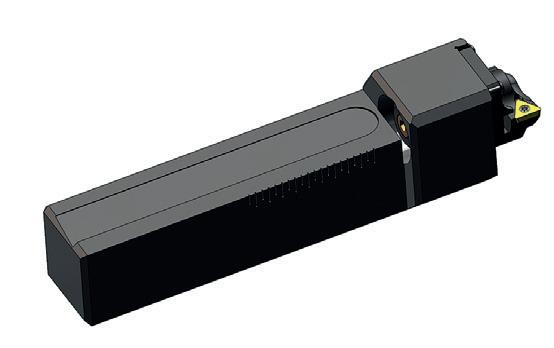

Special toolholders

» Fit all common spindle types (HSK, DIN, BT,..)

» Vibration dampening optinal to some models

» Can be equipped with coolant channel

» Can be equipped with RFID tag

» Lengths up to 1000 mm

Adjustable chucks

» The tool can be adjusted to the desired diameter

» Designed according to the customer’s needs

Special Tools

Helical milling cutters

» Rigid, modular construction

» High material removal rate

» Fit all common spindle types (HSK, DIN, BT...)

» Vibration dampening optinal to some models

» Can be manufactured according to customer insert specification

Shrinkfit Holders

Manufactured according to the customer’s desired A-measurement and attachment for e.g. 4-20mm drill pins.

Chamfer mills

» Designed with the angle (As), height (L) and fastening specified by the customer

» Can be manufactured according to customer insert specification

» Can be equipped with coolant channel

EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 7

Step drills

» Manufactured with the customer’s desired fastening method

» The tools are designed based on the target piece to be worked on

» Can be manufactured according to customer insert specification

» Coolant channels

Combination boring tools

» Manufactured with the customer’s desired fastening method

» The tools are designed based on the target piece to be worked on

» Can be manufactured according to customer insert specification

» Coolant channels

Special Tools

Back face boring tools

» Direction of rotation selectable

» Manufactured with the customer’s desired fastening method

» Can be manufactured according to customer insert specification

» Coolant channels

Stamping tools

» Stamping tool for marking the work piece during the machining

EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 9

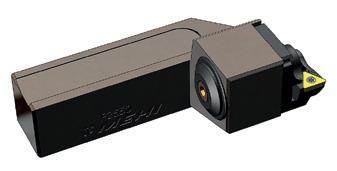

External boring tools

» Manufactured with the customer’s desired fastening method

» The tools are designed based on the target piece to be worked on

» Can be manufactured according to customer insert specification

» Coolant channels

Special Tools

Profile / Disk milling cutters

» Manufactured with the customer’s desired fastening method

» The tools are designed based on the target piece to be worked on

» Can be manufactured according to customer insert specification

» Coolant channels

EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 11

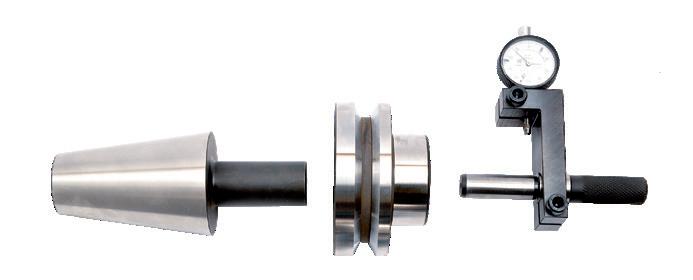

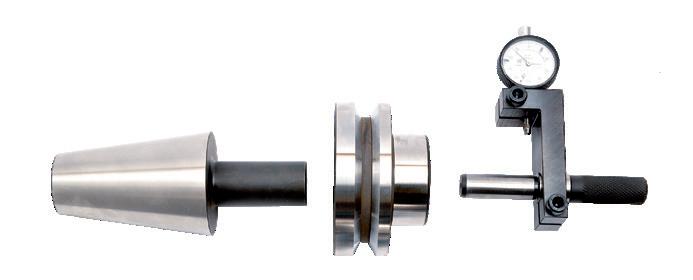

Adjustment tool for tool changer

» Adjustment tool for checking and adjustment of tool changer

» Gauge is not included

» Toolholders: BT, DIN, CAT, HSK…

Measuring tools for Spindle

Special Tools

Model Chuck L+0.5 D-0.2 TTSK50 50 350 40 TTSK40 40 250 30 TTBT50 BT50 350 40 TTBT40 BT40 250 30 TTMK2 MK2 250 20 TTMK3 MK3 250 24 TTMK4 MK4 350 29 TTMK5 MK5 350 34 TTMK6 MK6 350 34

AF20 and AF25 Adjustment elements

» For special tools

AF50 Adjustment element for finishing boring heads

» Adjusment accuracy 0.004mm in diameter

» Possible to use in special tools

» Standard tool, available from stock

Model D min. Dr AS Insert Insert screw AF20CC06 20 0,3 95 CCMT0602.. J901030 AF20CC06R 20 0,3 95 CCMT0602.. J901030 AF25TC11 25 0,3 90 TCMT1102.. J901030 AF25TC11R 25 0,3 90 TCMT1102.. J901030

Model D min. Dr As Insert Incert screw Screw AF5090TC11L 50 3.00 90 TCMT1102.. J901030 K121110 AF5090TC11R 50 3.00 90 TCMT1102.. J901030 K121110 AF5095CC06L 50 3.00 95 CCMT0602.. J901030 K121110 AF5095CC06R 50 3.00 95 CCMT0602.. J901030 K121110 AF50RC0803L 50 3.00 90 RC..0803.. J901085 K121110 AF50RC10T3L 50 3.00 90 RC..10T3MO.. J901085 K121110 EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 13

Mehi® standard tools

Mehi® standard tools are well known for high quality, reliability and longevity.

The Mehi® product range offers a wide range of options to meet the needs of the machine shop industry. For example, in roughing operations, the diameter range of the standard tools is D19.5–D1310, and for finishing operations, D20–D1800. Mehi® standard tools for milling include a very sturdy, modular design shell mill with high cutting capacity, or in smaller cases, e.g. a Weldon end mill holder equipped with a coolant channel and left-hand rotation direction.

Mehi® standard tools include a wide range of different toolholders, which should always be selected according to their intended purpose. Adjustable fine adjustment elements enable precision of up to 0.02 mm.

The Mehi® standard tool consists boring head and of a tool holder with a suitable inserts or precision adjustment elements for finishing.

Feel free to ask us for a quote!

sales@mehi.fi

Mehi® boring tool system

Mehi boring tools can be fixed to DIN-chucks

Mehi boring tool system is suitable for milling and drilling.

Benefits

» Can be attached to face groove chuck

» Sturdy construction

» Adjustable lenght with extensions and reducers

» Wide diameter range D12 - D1800 mm

» Tool holders for ISO standard inserts

» Coolant channels

Standard tools

EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 15

Boring heads

TF Boring heads

» Range D19,5-D65

» Single cutting boring tool

» For roughing or semi-finishing

» Adjustable

Model Range L L 1 d Tool holder Screw 1 Screw 2 TF 195-20 19.5-24 120 70 20 LF 19 K311346 K311346 TF 240-20 24-34 130 80 20 LF 24 K351346 K311346 TF 240-25 24-34 136 80 25 LF 24 K351346 K351346 TF 330-25 33-46 156 100 25 LF 33 K351346 K311426 TF 330-32 33-46 160 100 32 LF 33 K351346 K311426 TF 450-32 45-65 180 120 32 LF 45 K311426 K311426 TF 450-40 45-65 190 120 40 LF 45 K311426 K311426

LF Toolholders

Model Screw 3 Screw 4 Insert LF 19 SE-19 J901030 CCMT-0602… LF 24 SE-24 J901030 CCMT-0602… LF 33 SE-33 J901030 CCMT-0602… LF 45 SE-45 J901070 CCMT-09T3… EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 17

Boring heads

1TP Boring heads for semi-finishing

» Single cutting boring tool

» Mounting to face milling arbor

» Range D50 - D300

» Fine adjustment 0,02 mm

Model Range L d D Toolholder Screw 1 Screw 2 Screw 3 Pin 4 Screw 5 Mounting Screw 1TP050 50-65 65 22 40 1LC. 050... K351582 K351432 AS.650 J251360 K351432 VM-10 1TP065 65-90 70 27 48 1LC. 065... K351582 K351512 AS.665 J251360 K351512 VM-12 1TP090 90-130 75 32 58 1LC. 090... K351660 K311430 AS.690 J251362 K351512 VM-16 1TP130 130-200 90 40 70 1LC. 130... K351666 K351660 AS.813 J251362 K351512 VM-20 1TP200 200-300 90 40 70 1LC. 200.. K351666 K351660 AS.820 J251362 K351512 VM-20

1LC Toolholders

1LC, 75°, CCMT indexable inserts

1LC, 90°, CCMT indexable inserts

1LC, 95°, CCMT indexable inserts

Model b F L Insert Insert screw 1LC.050.75 16 20 32 CCMT09T3.. J901070 1LC.065.75 16 20 44 CCMT09T3.. J901070 1LC.090.75 16 20 64 CCMT09T3.. J901070 1LC.130.75 25 32 98 CCMT1204.. J901115 1LC.200.75 25 32 132 CCMT1204.. J901115

Model b F L Insert Insert screw 1LC.050.90 16 20 32 CCMT09T3.. J901070 1LC.065.90 16 20 44 CCMT09T3.. J901070 1LC.090.90 16 20 64 CCMT09T3.. J901070 1LC.130.90 25 32 98 CCMT1204.. J901115 1LC.200.90 25 32 132 CCMT1204.. J901115

Model b F L Insert Insert screw 1LC.050.95 16 20 32 CCMT09T3.. J901070 1LC.065.95 16 20 44 CCMT09T3.. J901070 1LC.090.95 16 20 64 CCMT09T3.. J901070 1LC.130.95 25 32 98 CCMT1204.. J901135 1LC.200.95 25 32 132 CCMT1204.. J901135 EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 19

Boring heads

2TP Boring heads for roughing

» Range D35 - D620

» Adjustment according to scale

» Coolant channels

» Mounting to face milling arbor

Model Range L d d1 Screw 1 Screw 2 Screw 3 Screw 4 Toolholder 5 Material 2TP 035 35-45 62 32 16 K311430 K311510 K311226 VM-8 2LC.035.. Steel 2TP 045 45-58 62 32 16 K351510 K351510 K311226 VM-8 2LC.045.. Steel 2TP 058 58-70 70 40 22 K351582 K351582 K311430 VM-10 2LC.058.. Steel 2TP 070 70-90 70 48 27 K351512 K351586 K311426 VM-12 2LC.070.. Steel 2TP 090 90-120 74 58 32 K351512 K351656 K311508 VM-16 2LC.090.. Steel 2TP 120 120-180 80 58 32 K351586 K351656 K351508 VM-16 2LC.120.. Steel Model Adjustment Range L d d1 Screw 1 Screw 3 Screw 6 Toolholder 5 Material 2TP 175 175-260 85 88 66,7 K351590 K351586 K121684 2LC.175.. Steel 2TP 260 260-380 87 88 66,7 K351660 K351586 K121684 2LC.260.. Steel 2TP 380 380-460 100 88 66,7 K351660 K351586 K121684 2LC.260.. Steel 2TP 450 460-540 100 88 66,7 K351660 K351586 K121684 2LC.260.. Steel 2TP 500 540-620 100 88 66,7 K351660 K351586 K121684 2LC.260.. Steel

2LC Toolholders 2LC Tool holders

2LC Tool holders

75°

Model b F L Insert Screw 2LC03575 12 16 20,5 CCMT0602.. J901030 2LC04575 12 16 26 CCMT09T3.. J901070 2LC05875 12 16 32 CCMT09T3.. J901070 2LC07075 16 20 39.5 CCMT09T3.. J901070 2LC09075 16 20 52 CCMT09T3.. J901070 2LC12075 20 25 74.5 CCMT1204.. J901115 2LC17575 20 25 104 CCMT1204.. J901115 2LC26075 25 32 153 CCMT1204.. J901115

CCMT-indexable inserts

90°

Model b F L Insert Screw 2LC03590 12 16 20,5 CCMT0602.. J901030 2LC04590 12 16 26 CCMT09T3.. J901070 2LC05890 12 16 32 CCMT09T3.. J901070 2LC07090 16 20 39.5 CCMT09T3.. J901070 2LC09090 16 20 52 CCMT09T3.. J901065 2LC12090 20 25 74.5 CCMT1204.. J901115 2LC17590 20 25 104 CCMT1204.. J901115 2LC26090 25 32 153 CCMT1204.. J901115 EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 21

CCMT indexable inserts

Boring heads

2RF Boring heads for roughing and finishing

» • Range D200 - D1310

» • Possibility to use single or double cutting

» • Roughing and finishing

» • We recommend using the fine adjustment element AF5090TC11L

» • Aluminum frame

Model Range L d d1 Roughing tool holder Finishing tool holder Screw 1 Screw2 2RF200-260 200-260 83/115 88 40 2RF2525 15M F2550/F2550VP K121684 K351593 2RF250-310 250-310 77/115 88 40 2RF2525 15M F2550/F2550VP K121684 K351593 2RF300-360 300-360 76/114,5 88 40 2RF2525 15M F2550/F2550VP K121684 K351593 2RF350-410 350-410 76/114,5 88 40 2RF2525 15M F2550/F2550VP K121684 K351593 2RF400-460 400-460 76/114,5 88 40 2RF2525 15M F2550/F2550VP K121684 K351593 2RF450-510 450-510 94,5/109,5 88 40 2RF3232TL F3250/F3250VP K121684 K351593 2RF500-560 500-560 94,5/109,6 88 40 2RF3232TL F3250/F3250VP K121684 K351593 2RF550-610 550-610 94,5/109,7 88 40 2RF3232TL F3250/F3250VP K121684 K351593 2RF600-660 600-660 94,5/109,8 88 40 2RF3232TL F3250/F3250VP K121684 K351593 2RF650-710 650-710 94,5/109,9 88 40 2RF3232TL F3250/F3250VP K121684 K351593 2RF700-760 700-760 94,5/108,5 88 40 2RF3232TL F3250/F3250VP K121684 K351593 2RF750-810 750-810 134,5/149,5 128 60 2RF3232TL F3250/F3250VP K121793 K351593 2RF800-860 800-860 134,5/149,6 128 60 2RF3232TL F3250/F3250VP K121793 K351593 2RF850-910 850-910 134,5/149,7 128 60 2RF3232TL F3250/F3250VP K121793 K351593 2RF900-960 900-960 134,5/149,8 128 60 2RF3232TL F3250/F3250VP K121793 K351593 2RF950-1010 950-1010 134,5/149,9 128 60 2RF3232TL F3250/F3250VP K121793 K351593 2RF1000-1060 1000-1060 134,5/149,10 128 60 2RF3232TL F3250/F3250VP K121793 K351593 2RF1050-1110 1050-1110 134,5/149,11 128 60 2RF3232TL F3250/F3250VP K121793 K351593 2RF1100-1160 1100-1160 134,5/149,12 221 60 2RF3232TL F3250/F3250VP K121793 K351593 2RF1150-1210 1150-1210 134,5/149,13 221 60 2RF3232TL F3250/F3250VP K121793 K351593 2RF1200-1310 1200-1310 134,5/149,14 221 60 2RF3232TL F3250/F3250VP K121793 K351593

2RF Toolholders and counterweights

AF50 Adjustment elements for finishing boring heads

Model L L1 b Fine tuning element/insert F2550 105 59 25 AF50.90.TC11L / TC11L.. F3250 170 42 32 AF50.90.TC11L / TC11L.. 2RF3232TL 168 32 / SN..190612 F3250VP -2RF3232 P19 168 32 / SN..190612

Model D min. Dr As Insert Incert screw Screw AF5090TC11L 50 3.00 90 TCMT1102.. J901030 K121110 AF5090TC11R 50 3.00 90 TCMT1102.. J901030 K121110 AF5095CC06L 50 3.00 95 CCMT0602.. J901030 K121110 AF5095CC06R 50 3.00 95 CCMT0602.. J901030 K121110 AF50RC0803L 50 3.00 90 RC..0803.. J901085 K121110 AF50RC10T3L 50 3.00 90 RC..10T3MO.. J901085 K121110 EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 23

» Adjusment accuracy 0.004mm in diameter

Finishing tools

1TAF Boring heads for finishing

» Range D70 - D1020

» Single cutting finishing boring head with aluminium frame

» Mounting to standard face milling arbor

» Large adjustment range, separate tool holder with adjustment element

» Version with VNL elements is better suited for bottoming holes

» Version with AF50 element works best for through holes

Tool holders for 1TAF Finishing boring heads

Model Range L d D Toolholder (VNL) Toolholder (AF50) 1TAF 070 70-100 100 27 48 1 LVA.0701TAF 100 100-150 100 32 58 1 LVA.100 F9.50 1TAF 150 150-240 100 40 70 1 LVA.230 F13.50 1TAF 230 230-330 100 40 88 1 LVA.230 F13.50 1TAF 310 310-420 100 40 88 1 LVA.230 F13.50 1TAF 410 410-520 100 40 88 1 LVA.230 F13.50 1TAF 510 510-620 90 40 88 1 LVA.230 F13.50 1TAF 610 610-720 90 40 88 1 LVA.230 F13.50 1TAF 710 710-820 90 60 128 1 LVA.230 F13.50 1TAF 810 810-920 90 60 128 1 LVA.230 F13.50 1TAF 910 910-1020 90 60 128 1 LVA.230 F13.50 Model L L1 L2 b Adjustment element F 09.50 95 65 34 25 AF50.9.. F 13.50 136 65 75 25 AF50.9.. 1 LVA.070 57 - - 25 VNL 123.90.TC11 1 LVA.100 93 - - 25 VNL 123.90.TC11 1 LVA.230 131 - - 25 VNL 123.90.TC11

AF50 Adjustment elements for finishing boring heads

» Adjusment accuracy 0.004mm in diameter

Adjustment element for VNL

Model Dr min. AS Screw Insert Insert screw VNL 123.90TC11 3,5 90 R090008 TCMT1102.. J901030

Model D min. Dr As Insert Incert screw Screw AF5090TC11L 50 3.00 90 TCMT1102.. J901030 K121110 AF5090TC11R 50 3.00 90 TCMT1102.. J901030 K121110 AF5095CC06L 50 3.00 95 CCMT0602.. J901030 K121110 AF5095CC06R 50 3.00 95 CCMT0602.. J901030 K121110 AF50RC0803L 50 3.00 90 RC..0803.. J901085 K121110 AF50RC10T3L 50 3.00 90 RC..10T3MO.. J901085 K121110 EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 25

Finishing tools

A1FL Boring heads for finishing

» Range D50 - D150

» Single cutting finishing boring tool

» Mounting to standard face milling arbor

» Coolant channels

» Fine boring unit is equipped with two elements position on both sides

» Aluminum frames with counterweight

» Open socket screw 3 enables to shift the element between positions settings (by pulling or pressing) and counterweight shifts likewise

» Torque of socket screw 3 20Nm.

» Element adjustment range for diameter 5mm

» Element adjustment range for diameter 5 mm

» Element shift from side to another – adjustment range diameter 5 mm

Model Range d D L Adjustment element Screw 1 Screw 2 Screw 3 Material A1FL50 50-70 22 40 100 AF5090TC11L/ AF5095CC06L K351586 VM10 K121452 Steel A1FL70 70-90 27 48 100 AF5090TC11L/ AF5095CC06L K351660 VM12 K121452 Aluminum A1FL90 90-110 32 58 100 AF5090TC11L/ AF5095CC06L K351660 VM16 K121452 Aluminum A1FL110 110-130 32 58 100 AF5090TC11L/ AF5095CC06L K351660 VM16 K121452 Aluminum A1FL130 130-150 32 58 100 AF5090TC11L/ AF5095CC06L K351586 VM16 K121452 Aluminum

AF50 Adjustment elements for finishing boring heads

» Adjusment accuracy 0.004mm in diameter

Model D min. Dr As Insert Incert screw Screw AF5090TC11L 50 3.00 90 TCMT1102.. J901030 K121110 AF5090TC11R 50 3.00 90 TCMT1102.. J901030 K121110 AF5095CC06L 50 3.00 95 CCMT0602.. J901030 K121110 AF5095CC06R 50 3.00 95 CCMT0602.. J901030 K121110 AF50RC0803L 50 3.00 90 RC..0803.. J901085 K121110 AF50RC10T3L 50 3.00 90 RC..10T3MO.. J901085 K121110 EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 27

Finishing tools

A2AL Boring heads for finishing

» Range D150-D1800

» Double cutting finishing boring tool with aluminum frame

» Mounting to standard face milling arbor

» Large adjustment range, separate tool holder with adjustment element

» Axial adjustment for tool holders

» Coolant channels

» Version with VNL elements is better suited for bottoming holes and version with AF50 element works best for through holes.

Tool holders for A2AL Finishing boring heads

Model Range L d D Toolholder (VNL) Toolholder (AF50) A2AL150 150-200 130 40 70 1LVA1518A2AL200 200-300 130 40 88 1LVA2018 F9.50 A2AL300 300-400 130 40 88 1LVA2318 F13.50 A2AL400 400-500 130 40 88 1LVA2318 F13.50 A2AL500 500-600 130 60 128 1LVA2318 F13.50 A2AL600 600-700 130 60 128 1LVA2318 F13.50 A2AL700 700-800 130 60 128 1LVA2318 F13.50 A2AL1000 1000-1100 160 60 128 1LVA2318 F13.50 A2AL1000 + A2AL Jatko 2 1000-1400 200 60 128 1LVA2318 F13.50 A2AL1000 + A2AL Jatko 3 1400-1800 200 60 128 1LVA2318 F13.50

Model L L1 L2 b Adjustment element F 09.50 95 65 34 25 AF50.9.. F 13.50 136 65 75 25 AF50.9.. 1 LVA.070 57 - - 25 VNL 123.90.TC11 1 LVA.100 93 - - 25 VNL 123.90.TC11 1 LVA.230 131 - - 25 VNL 123.90.TC11

AF50 Adjustment elements for finishing boring heads

» Adjusment accuracy 0.004mm in diameter

Adjustment element for VNL

Model Dr min. AS Screw Insert Insert screw VNL 183.90TC16 7,2 90 R090008 TCMT16T3.. J901050 VNL 183.95CC09 7,2 95 R090008 CCMT09T3 J901070 VNL 183.95CC12 7,2 95 R090008 CCMT1204 J901115 Model D min. Dr As Insert Incert screw Screw AF5090TC11L 50 3.00 90 TCMT1102.. J901030 K121110 AF5090TC11R 50 3.00 90 TCMT1102.. J901030 K121110 AF5095CC06L 50 3.00 95 CCMT0602.. J901030 K121110 AF5095CC06R 50 3.00 95 CCMT0602.. J901030 K121110 AF50RC0803L 50 3.00 90 RC..0803.. J901085 K121110 AF50RC10T3L 50 3.00 90 RC..10T3MO.. J901085 K121110 EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 29

Finishing tools

TVA Boring heads for finishing

» Range D20 - D40

» Single cutting finishing tool

» Adjusment accuracy 0.02mm in diameter

» Mounting to weldon or collet tool holder

Adjustment elements for TVA Boring heads

Model Range d L1 L Adjustment element TVA 20-20 20-24 20 70 120 VALX83.90TC06 TVA 20-25 20-24 25 100 156 VALX83.90TC06 TVA 24-25 24-28 25 100 156 VAL083.90TC06 TVA 28-25 28-32 25 100 156 VAL083.90TC06 TVA 32-32 32-36 32 100 160 VAL083.90TC06 TVA 36-32 36-40 32 100 160 VAL083.90TC06

Model D min. Dr AS Screw Insert Insert screw VAL X83.90TC06 20 2,25 90 R090007 TCGT 06T1.. J901035 VAL 083.90TC06 23,5 2,25 90 R090007 TCGT 06T1.. J901035

1THF Boring heads for finishing

» Single cutting finishing tool

» Mounting to standard arbor

» Adjustment range for diameter 0.02mm

Adjustment elements for VNL

Model Range L d D Adjustment element Screw 1 Screw 2 Material 1THF 036 35-39 80 16 32 VNL.103.90TC11 K351512 K351512 Steel 1THF 040 39-43 80 16 32 VNL.103.90TC11 K351512 K351512 Steel 1THF 043 43-50 100 22 40 VNL.123.90TC11 K351582 K351582 Steel 1THF 050 50-57 100 22 40 VNL.123.90TC11 K351582 K351582 Steel 1THF 057 57-64 100 22 40 VNL.123.90TC11 K351582 K351582 Aluminum 1THF 064 64-71 100 22 40 VNL.123.90TC11 K351582 K351582 Aluminum 1THF 070 70-84 100 27 48 VNL.183.. K351656 K351586 Aluminum 1THF 084 84-98 100 27 48 VNL.183.. K351656 K351586 Aluminum 1THF 098 98-128 100 32 58 VNL.183.. K351656 K351660 Aluminum 1THF 128 128-158 100 32 58 VNL.183.. K351660 K351660 Aluminum

Model Dr min. AS Screw Insert Insert screw VNL 103.90TC11 3,5 90 R090008 TCMT1102.. J901025 VNL 123.90TC11 3,5 90 R090008 TCMT1102.. J901030 VNL 183.90TC16 7,2 90 R090008 TCMT16T3.. J901050 VNL 183.95CC09 7,2 95 R090006 CCMT09T3.. J901050 VNL 183.95CC12 7,2 95 R090006 CCMT09T3.. J901050 EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 31

Back face boring tools

Back face boring tools

» Mounting to weldon or collet tool holder

» Equipped with coolant channel

» Lefthanded rotation direction

» Can be also manufactured according to customer spesific dimensions.

Model D +0.05 D1 min. L1 d h6 L S Insert screw Insert ATW0915 15 9 30 20 97 12 J901030 SPHX060204R ATW1018 18 10 35 25 112 12 J901030 SPHX060204R ATW1220 20 12 40 25 117 12 J901030 SPHX060204R ATW1420 20 14 85 25 161 15 J901030 SPHX060204R ATW1422 22 14 50 25 127 12 J901030 SPHX060204R ATW1424 24 14 50 25 127 12 J901030 SPHX060204R ATW1626 26 16 50 25 130 15 J901085 SPHX090304R ATW1830 30 18 60 25 140 15 J901085 SPHX090304R ATW1832 32 18 55 32 136 16 J901085 SPHX090304R ATW2032 32 20 65 32 145 15 J901085 SPHX090304R ATW2033 33 20 65 32 145 15 J901085 SPHX090304R ATW2236 36 22 70 32 150 15 J901085 SPHX090304R ATW2239 39 22 70 32 150 15 J901085 SPHX090304R ATW2240 40 22 70 32 150 15 J901085 SPHX090304R ATW2337 37 23 50 32 130 15 J901085 SPHX090304R ATW2438 38 24 80 32 160 15 J901085 SPHX090304R ATW2440 40 24 80 32 160 15 J901085 SPHX090304R ATW2645 45 26 60 40 155 20 J901125 SPHX120404R ATW2646 46 26 60 40 155 20 J901125 SPHX120404R ATW2648 48 26 60 40 155 20 J901125 SPHX120404R ATW2743 43 27 85 32 165 15 J901125 SPHX090304R ATW2848 48 28 100 40 195 20 J901125 SPHX120404R ATW3048 48 30 100 40 195 20 J901125 SPHX120404R ATW3055 55 30 105 40 200 20 J901125 SPHX120404R ATW3254 54 32 70 40 170 20 J901125 SPHX120404R ATW3353 53 33 105 40 200 20 J901125 SPHX120404R ATW3657 57 36 115 40 210 20 J901125 SPHX120404R ATW4165 65 41 150 40 250 25 J901100 SPHX150504R

* whitout coolant channel

Weldon/Whistle toolholders

Cylinder arm weldon/whistle chucks - small chucks

» Chuck for milling tools and drills

» 2° angle hole is for clamping drills and milling tools

» At bottom of the placing hole is a screw with hole that coolant goes through

» Always when using 2° hole you have to be sure that the milling tool or drill reach the bottom of hole.

Model D d L1 d1 d2 Top screw Weldon screw 3 WPH200670 20 6 70 36 25 K121356A K901630 WPH200870 20 8 70 36 28 K121436A K901510 WPH201070 20 10 70 36 31 K121516A K901582 WPH201270 20 12 70 36 36 K121516A K911656 WPH201470 20 14 70 40 40 K121590A K911657 WPH201670 20 16 70 40 42 K121590A K901726 WPH202070 20 20 70 40 48 K121590A K901757 WPH250670 25 6 70 40 25 K121356A K901630 WPH250870 25 8 70 40 28 K121356A K901510 WPH251070 25 10 70 40 31 K121516A K901582 WPH251270 25 12 70 40 36 K121590A WPH251470 25 14 70 40 40 K121660A WPH251670 25 16 70 40 42 K121660A WPH251870 25 18 70 40 45 K121660A WPH252070 25 20 70 45 48 K121660A Model D d L1 d1 d2 Top screw WPH320690 32 6 90 48 25 K121356A WPH320890 32 8 90 48 28 K121436A WPH321090 32 10 90 48 31 K121516A WPH321290 32 12 90 48 36 K121590A WPH321490 32 14 90 48 40 K121660A WPH321690 32 16 90 48 42 K121660A WPH321890 32 18 90 48 45 K121660A WPH322090 32 20 90 48 48 K311763A WPH322590 32 25 90 56 61 K311763A WPH323290 32 32 90 56 68 K311763A WPH402090 40 20 90 61 48 K311763A WPH402590 40 25 90 61 61 K311763A WPH403290 40 32 90 68 68 K311763A Toolholders EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 33

Extensions

Extensions, EB model A and B

Model Type L d D Thread M Screw 1 Scrw 3 Wedge 2 Thread 4 Screw 5 EB.16.16.60 A 60 16 32 M8 VPN.8 J301008 K121116 EB.22.22.60 A 60 22 40 M10 VPN.10 J301010 K121232 EB.27.27.60 A 60 27 48 M12 VPN.12 J301012 K121356 EB.32.32.70 A 70 32 58 M16 VPN.16 J301014 K121354 EB.40.40.70 A 70 40 70 M20 VPN.20 J301016 K121436 EB.22.22.100 A 100 22 40 M10 VPN.10 J301010 K121232 EB.27.27.100 A 100 27 48 M10 VPN.11 J301012 K121356 EB.32.32.120 A 120 32 58 M16 VPN.16 J301014 K121354 EB.40.40.120 A 120 40 70 M20 VPN.20 J301016 K121436 EB.88.100 B 100 40 88 M20 K121672 J301016 M12 K121672 EB.128.120 B 120 60 128 M24 K121660 VK-2525 M16 K121672

Reducers, RB model A and B

Model Type L d1 d2 D1 D2 Thread M Screw 1 Wedge 2 Screw 3 Screw 4 RB.22.16.70 A 70 22 16 40 32 M8 J301008 VPN.10 K12116 RB.27.16.100 A 100 27 16 48 32 M8 J301008 VPN.10 K12116 RB.27.22.70 A 70 27 22 48 40 M10 J301010 VPN.12 K12132 RB.32.22.100 A 100 32 22 58 40 M10 J301010 VPN.16-1 K12132 RB.32.27.70 A 70 32 27 58 48 M12 J301012 VPN.16 K121354 RB.40.27.100 A 100 40 27 70 48 M12 J301012 VPN.20-1 K121354 RB.40.32.70 A 70 40 32 70 58 M16 J301014 VPN.20 K121354 RB.40.32.100 VPN.20 K121354 RB.088.70.100 K121436 RB.128.88.100 K121436 EXTENSIONS TOOLHOLDERS BACK FACE BORING TOOLS FINISHING TOOLS BORING HEADS STANDARD TOOLS SPECIAL TOOLS 35

Made in FINLAND www.mehi.fi CERTIFIED by Fine Audit Oy ISO 9001