This work has been produced by a student at York St John University as part of their university work and is intended as an educational output. Where necessary, the student has considered copyright and appropriate credit has been given where reference has been made to the work of others

Rethinking the supply chain of the brand Chanel with

a focus on environmental responsibility with a

Circular supply chain

EXECUTIVE SUMMARY

Chanel is rethinking its Supply Chain to align with being more transparent as although the mission they stand behind, with incorporating social responsibility as its sustainability statement aims to have a more sustainable world by cutting down on emissions (as the emission affect humans and the planet, causing lung and other diseases) by using renewable electrically energy within its operations (Loker, Eckman and Dickson, 2009).

However, as the brand scored 1% on transparency in 2021 in the Fashion Transparency Index it is a contradiction to the statement, other brands in fashion luxury scored much higher as Fendi scored 66% and The North Face scored 84% (Fashion Transparency Index,2021). One of the key topics within this report will be addressing CRS (Corporate Social Responsibility) with a focus on environmental management, approving the transparency and supply chain will increase sales and profits, add to customer loyalty, improve Chanels image and reputation and increase access to capital and markets (Nitin, 2021).

Introduction

Chanel is a part of the luxury sector of fashion and has grown in global popularity since its opening in 1910. The luxury fashion industry has been unfired with its contribution to the threat to the natural environment (Chan et al., 2020).

Luxury fashion has gained a huge market that is now worth over 1 trillion dollars (US) (Campos Franco, Hussain and McColl, 2019). The brand coordinates itself with having a mission of contributing to a positive light on the environment call CHANEL Mission 1.5, as the fashion industry produced 2.1 billion tonnes of emissions, helping the planet's temperatures going up by 1.1 degrees (Berg and Magus,2020).

This is a factor of over-consummation, as it plays a big part in the fashion industry, it is important for brands and retailers to take initiative with sustainability and social change (Burns, 2019). Chanel's mission is not measurable as its transparency was 1% (Fashion Transparency Index,2021).

The key points made within this report will cover; what a supply chain is, the difference between with 2 types of the supply chain (linear model and circular supply chain), customers for a focus supply chain, sourcing, data (looking into blockchains and how the chain can be more transparent (which will help with turning Chanel mission to be measurable) and the recommendation for the brand Chanel when it is rethinking the supply chain with a focus on the environmental responsibility with a circular supply chain.

Triple bottom line Framework

The triple bottom line consists of the three Ps; People (social justice), Planet (environmental quality), and Profit (economic prosperity), with this report the focus is planet by looking at environmental responsibility (water and energy use, carbon footprint, pollution reduction, recycling and reuse of resources) (Fulton and Lee, 2010; Burns, 2019)

The Triple bottom line framework is a part of the business frameworks for sustainable and social change, in this report Chanels focus will be on the Planet side of change. The environmental quality involves; water and energy use, carbon footprint, pollution reduction, recycling and reuse of resources (Burns, 2019). The growing acknowledgment of climate change especially in the fashion manufacturing industry and its impact on the environment is a key driver for change in supply chains (Osland and Zhou, 2013).

WHY 2030

The change for companies to make the decision to take initiative by 2030 to be more focus on Enviromental responsibility. The year 2030 is important when it comes to climate change and the damages become irreversible, with a 1.5-degree Celsius limit (European Commission, 2022). The Paris Agreement set goals for the limit would be well below 2 (see more in appendices regarding The Paris Agreement) (United Nations, 2015).

Supply Chain

Supply chains as a system are one of the world's most important systems (Taqui et al., 2020). The supply chain is the process of goods being from in the design room to being in the customer's hands going through the network of suppliers to the manufacturers then the distributors, dealers and then customers. For the goods to be produced and delivered smoothly all these must work together (Londrigan and Jenkins, 2018).

Supply chains are globally used within Chanel which can be more changing than a domestic supply chain, due to factors including; different languages, cultures, transportation, and material planning (Purvis, 2010). Buying goods and services to sell onwards to customers for money and meeting the demands of customers is an essential part of having a successful working supply chain, whether that is lean or agile (Hines, 2021). Supply chain management is the relationship between suppliers and business customers (Giunipero, Handfield and Eltantawy,2006; Prokop, 2020).

Linear model vs circular supply chain

Companies need and are taking initiatives when it comes to the supply chain and the global challenges it creates (Niedenzu, 2022).

The linear supply chain has an end (make it, use it, dispose of it), which makes the chain not sustainable, this model of the supply chain is characterised by a high level of control and is an agile supply chain (Nasir et al., 2016). With a linear supply chain model most of the clothes will end up in landfill as the fashion industry both produces and throws away millions of tonnes of clothing every year, and instead of using, with less am 1% of old clothing being turned back into new clothing, this has created so much waste that every second a truckload of clothes is being burned or thrown away (Ellen MacArthur Foundation 2021).

A circular supply chain will not only save brands money as the throwing again of clothing cost billions of pounds globally, but also with CSR. Consumption is on the rise as 62 million tonnes are made every year and by 2030 is set to be 102 million tonnes (Niinimäki et al., 2020). Using a circular supply chain will help by reusing instead of binning or burning (Davis, 2020). The drive for change in the supply chain for Chanel is driven by the negative environmental impact and change in laws (Giunipero, Handfield and Eltantawy, 2006). With laws changing to become stricter when it comes to sustainable policies, companies are needing to oblige to this. A circular economy is a step companies can take with it being the best method to reduce negative impacts on the environment (Rodríguez-González et al., 2022).

As the production of the materials used to make clothing is the biggest contributor to the emissions of greenhouse gases (GHG), coming in at 38% (Berg et al., 2020). A circular supply chain can play a role in decreasing this percentage, as when clothes reach the end of life where most of them will go to landfill or burned (Ellen MacArthur Foundation 2021). The clothes will be broken down back to materials and fibbers that can be made into new clothes, ready to be sold again and again. This will not just benefit the environment but also benefit Chanel with its profile as it will not need to use raw materials.

Agile -responsive to customer

Agile supply chain management is identified as responding to high demand as a response to customers (Purvis, 2010). The agile framework mainly focuses on; being particularly appropriate for fashion because of its variation, stock available in terms of demand decreases the risk of surplus stock and is not so dependent on long-term forecasts.

Lean – responsive to costs

A lean supply chain has a focus on a high volume of products, with the concept expanded from the Toyota Production System (TPS), using a lean approach within a supply chain can offer performance improvement (Asmae, En-Nadi and Herrou, 2020).

The lean framework mainly focuses on; being particularly appropriate for fashion because of its variation, Stock available in terms of demand, and decreases the risk of surplus stock, which can mean that products are unavailable and not so dependent on long-term forecasts.

Sourcing

Sourcing is the decision process that takes place within the supply chain, many companies embody social responsibility or corporate social responsibility (CSR) (Burns and Mullet, 2020). With sourcing being a global process, it can be hard to keep track of every step with sourcing the following; knowing how much of said garment, trying to get the best price with negotiating, dealing with a problem that will acre, meeting the demands on due dates, quality control, and scheduling deliveries (Granger and Farnan, 2020). Sustainably will be a drive for the chain for rethinking the supply chain, improving the standards without having a detrimental effect on the planet (Fulton and Lee,2010).

The over-consumption and Postconsumer of textile waste are not only costing the brand but also, back into the landfill. The fashion industry is the second biggest polluting industry, coming second to the oil industry with 60 million tonnes of clothing made every year and by 2030 with statistics set to ride to 100 million tonnes (Moorhouse and Moorhouse, 2018).

When processing the fibbers of raw metals are one of the first steps within the supply chain 90% of clothing made in us is made from cotton or polyester, both of which create a health risk because of the chemical that is used (Aggarwal and More, 2020).

For Chanels supply chain to move into a circular, issues with landfill and the health risk that are involve with processing raw metals would significantly reduce, keeping with focus on environmental responsibility with a Circular supply chain.

Logistics

Logistics management is the combination of data analysis, project planning, technology and general management (Londrigan and Jenkins,2018). Logistics managing three sectors; time, space and location. Every brand/ retailer uses logistics to conduct business. For this to be successful it would have to be on track with the 7 rights; right item, right quantity, right condition, right customer, right time, right location and the right price (Prokop, 2022).

Improving the supply chain will not happen overnight however improvements can start. As logistics involve destitution and transportation, Chanel could use this opportunity to incorporate more sustainable methods. This can be done by using hydrogen lorries, using hydrogen lorries will not only cut emissions but this will improve air quality (linking back to corporate environmental responsibility) (McKinnon, 2018). Improving air quality has a positive effect on people and the planet.

DATA

Data is a virtual power source that is contacted 27/4, the number of bytes that are processed in a day is the quintillions. Data can be collected from anyone, or anything connected to the internet, whether that be by someone using their smartphone or house appliances, it can also be collected from items with a barcode or a radio frequency identification (RFID) tag (Prokop, 2020). Big

Data (BD) is important within the supply chain and has changed the way businesses are run, as information and communication can be done quicker with access to terabytes (Gravili et al., 2018).BD can help Chanel with inventory as it collects data from point of sales, with online purchases (inventory data can help with not over ordering) (Londrigan and Jenkins, 2018).

BD can also help with disruptions, with data to analyse problems the supply chain faces. Disruption to the supply chain affects time and money (both unexpected and expected factors), COVID-19 pandemic caused a huge disruption in all factors of the chain. Some of them include; logistics problems, people's attitude change (panic buying) and workforce limitations (Choi, 2020; Wicaksana et al., 2022). Logistics-servicecapacity, when big scales of logistics services are needed, are needed in advance of manger seasons (Christmas). As there are many factors if just one part gets disrupted by unpredictable events a domino effect would happen (Choi, 2020).

As Big Data Analytics (BDA) is a big part of Supply Chain Management (SCM). As the growth in available data has grown due to the demand with the globalisation economy of supply chain and commotion in the last few years. Because of this factor, the volume of data is doubling every couple of years, set to reach 40 trillion Gigabytes by 2030 (GB) (Roßmann et al., 2018). Technology can help with several things within the supply chain; transparency, reliability and visibility through different technologies these factors will help build a trustworthy supply chain (Taqui et al., 2020). Blockchain is a new technology that will have the capability to help the supply chain to be more resile supply chain currently depends on real-time and reliable data, but through the blockchain, brands can use this technology to help improve both efficiency and transparency (Chaikaew, Osiriphun and Boonchieng; Taqui et al., 2020).

The key to a supply chain is to aggregate big data into a meaningful forecast of the supply chain, with data tracking that can help with being more transparent with using public blockchain (Krasteva et al., 2021). As public blockchains allow anyone with the internet to excess information, brands can use these throughout the tiers to be more transparent in the supply chain.

Value chain

A value chain is a set of input activities that are carried out to create value for the customers, with the value chain consistent with 2 main sectors: primary activates and support activities (Preece, 2005). The primary involved activates are; inbound logistics, operations, outbound logistics, marketing, sales and service (primary activities are the creation and delivery of the product or service). Furthermore, the support activities include; firm infrastructure, human resource management, technology development and finally procurement (Porter, 2001).

Understanding the Value chain can help a brand with; customer value increment, reduce costs in areas and improve efficiency. This can also help identify key areas to work on to have a competitive advantage over competitors.

Customers

The drive for customer focus is essential for a brand to be successful, as meeting their needs whether that be the quality of the clothes or having the product ready on time (Hines, 2018). The customer's buying decision has an influence on the fashion industry, both with the choice of products and how much (Colucci, Tuan, and Visentin, 2020). Customer shopping habits can change with influence to reduce negative environmental impact (Design for Sustainable Behaviour) (Bhamra, Lilley and Tang, 2011). This will help influence Chanel customers when it comes to the recommendations for the brand.

Luxury

Luxury is a huge market with reacting 1 trillion euros in 2019, with access to luxury goods has created an appetite for luxury consumption that motivates customers to adopt a new lifestyle (Brandao, Godinho Filho and da Silva, 2021). The luxury sector of fashion can be an inspiration for other makes as it can trickle down through the different markets and be an inspiration to others (Kaiser, 2019). Chanel can be a part of the leading brands for this and learn how to have a positive impact on the planet and pushing on the Triple bottom line Framework (Fulton and Lee, 2010).

Competitors

After looking into similar high-end brands Fendi, which is a part of LVMH, scored 66% in the traceability section of the Fashion Transparency Index. As Channel only scored 1% Fendi is doing much better, this shows that it is possible for brands (especially brands in the same sector in fashion) (Fashion Transparency Index, 2022). The luxury industry is looking into ways to change the supply chain, Fendi is one of the brands that are looking into blockchain technology with traceability and product originality (Hemantha, 2022).

Chanel could take the opportunity to learn from other brands in the luxury sector of fashion, as Chanel transparency is one of the lowest brands in the Fashion Transparency Index, the brand could adapt blockchain into the supply chain information.

Aftercare

Aftercare of clothes takes 20% of the emissions that are created within its lifetime, taking just second place after the production of the material (Berg et al., 2020). With a linear supply chain, the clothes have an end of life and in 2018 this was 3% overall (63.18 Mn tonnes Co2eq). Chanel could inform the customer of how to take care of the clothes, as unclean and unwashed are different (Ranson, 2021). To provide information for aftercare in ensuring the clothing last for the longest by having a scannable barcode on the tag with advice.

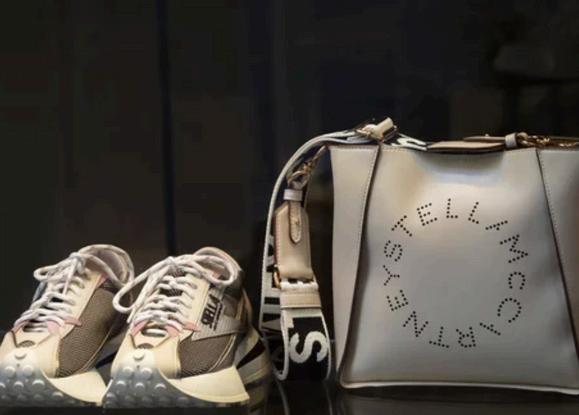

Stella McCartney

Stella McCartney is a pioneer when it comes to taking environmental responsibility, as the brand uses a circular supply chain with using reusing metals and making clothes last (Londrigan and Jenkins, 2018; Stella McCartney, 2022). The brand's sustainably statement reads ‘Our sustainable vision is guided by and accountable to our bold values – making every action count, inspiring trust and celebrating life. We are change agents; we are activists. We stand up and speak up for Mother Earth, our fellow animals, and in solidarity with all humans.’ This is a brand that others should look at when taking influence in improving its environmental responsibility within a supply chain.

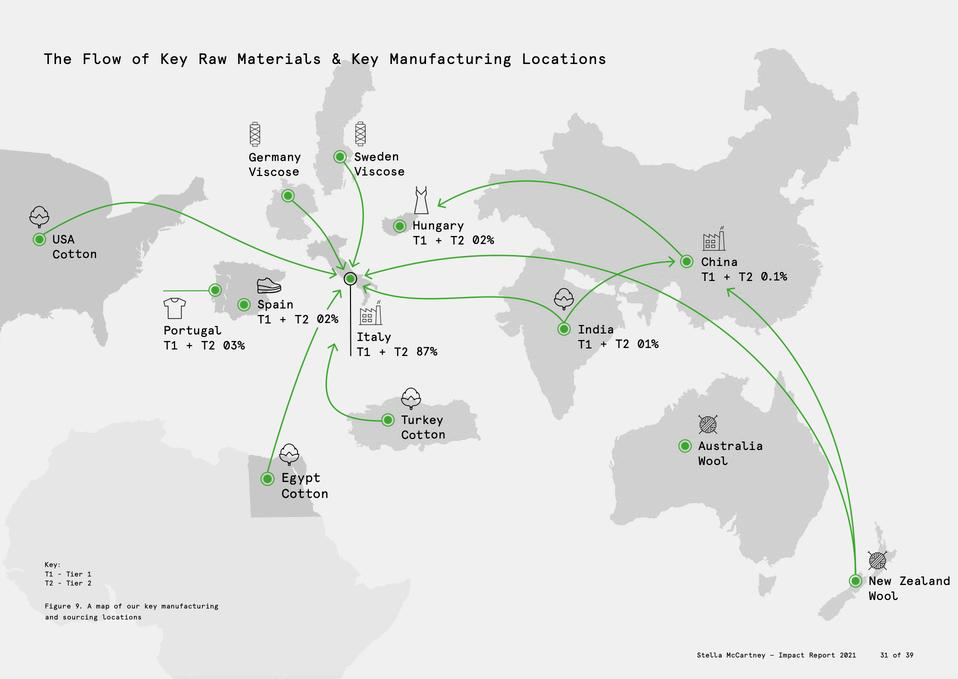

The brand uses The Environmental Profit and Loss (EP&L) to measure the environmental impact from the very start of the supply chain by souring the raw materials, making and distributing to store to sell (which was developed by Kering) (Stella McCartney n.d.). Not will this just help with being able to measure the impact and how it can do better but also help when it comes to transparency across all the tires. Chanel can learn and be inspired by Stella McCartney, where the brand shows it is possible to mark a profit and take environmental responsibility within its supply chain. Stella McCartney's impact report 2021, provides information on productions through Tiers 1, 2, and 3 with a breakdown of the environmental impact. It also has a map of where and what was made (see appendices) (Stella McCartney, 2021).

Recommendation

Linertocircular supplychain

The brand Chanel recommendation is to move from a learner to a circular supply chain, this change will not only help with keeping in line regulation with climate change and global warming crises but also to have a supply chain with a customer focus.

As the process to retrieve the raw materials is the biggest contributor to putting emissions into the environment taking 38% of all emissions a garment produces with its life cycle (Berg et al., 2020).

The consumption of raw and natural resources is also on the rise and the involvement in change not only is a manufacturer/ industries responsibility but also the final customer (Jim and Sethna, 2019). As fashion brands are starting to go beyond price and style and are also involved in corporate environmental responsibility and recognize the negative impact the brand is producing (Colucci, Tuan and Visentin, 2020). Chanel Mission 1.5 incorporates a section of wanting to reduce its carbon emission using the value chain, moving to a circular will help the brand achieve this by cutting down on the production of raw materials, this was the biggest impact on its value chain.

The shift change is not a short-term change, this will change how Chanel runs its business. As the year 2030 is important for climate change, the deadline for this is 2030. For a brand to change from a liner to a circular supply chain is not something that is an overnight process however, steps in order to make this happen can start. By 2030 the aim is to have a running circular supply chain with Chanel and to be transparent throughout the tiers, starting with tier one all way to tier 5, due to this a timeline shows the gaols over the next 7 years.

Transparency and mapping through the tier

The timeline shown is a plan for Channel, it is a plan beginning 2023 – 2030. The year 2030 is important for climate change as the damages are irreversible (European Commission, 2022). The technology of blockchains is a way for Chanel to achieve these goals, as shown by the competitor Fendi, which was one of the highest brands with transparency with 66%, which is using blockchains within its supply chain (Fashion Transparency Index, 2022). The available technology is making it possible for Chanel much higher on the Transparency Index.

Being transparent will help the brand mappable its focus on environmental responsibility by having the proof to back up its claims.

Chanel could use the EP&L to help with being transparent through all the tiers, as a mapping tool and pubic blockchain, this not only will put the data together but also be able to allow customers to view this. This will significantly help with higher itself on the chat.

With using barcodes on clothing tags is one easy a customer can look to see where the clothing was made, just like the aftercare part of the report.

The tier consists of 5 tiers (1-5), 1 bringing the closest to the finished product (main production) and 5 being the start (raw materials).

Timeline Go

als till 2023

2028

Fully mapped

Partially mapped 2030

2029

Fully mapped

By 2024 - tier one

Be fully mapped with the main production sites where the sites finish the garments and ready to be transported to stores

By 2025 – tier two

Be fully mapped with the process integral to production where stitching and quality checks happen

By 2026 – tier three

By fully mapping with enhancements of products where dying and prints happen to the fabric and any embroidery

By 2027 – tier four

Partially mapped with fabrics and components, these are the fabric mills and hardware, and trims are made

By 2028 – tier four

Fully mapped with fabrics and components, these are the fabric mills and hardware, and trims are made

By 2029 - tier five

Partially mapped with raw materials where the textile fibbers and naturals materials are farmed

By 2030 – tire five

Fully mapped with raw materials where the textile fibbers and naturals materials are farmed

Conclusion

In conclusion this report has outlined key factors that will help Chanel rethink its supply chain with a focus on environmental responsibility with a Circular supply chain. With climate change and global warming being the main conversation, industries starting to do its part for the planet to cut down on the negative impact on the environment. As the fashion industry is the second biggest for pollution, after the oil industry, with both emissions and water waste (Berg and Magus,2020)

There are many steps that Chanel can do to improve its environmental responsibility, moving from linear to circular with its supply is a start as the brand will cut down on its emissions output as 38% of the clothing lifecycle emissions go into producing raw materials (Berg et al., 2020). It will also help with landfill and the burning of clothes as they can be made into new clothes (Ellen MacArthur Foundation 2021). The brand can take inspiration from Stella McCarney as the brand is a pioneer when it comes to taking environmental responsibility. To help Chanel improve its traceably on the Fashion Transparency Index blockchain is new technology the brand could use to improve, as one of its competitors (Fendi) is an example to look at and learn from (Fashion Transparency Index,2021; Hemantha, 2022). The Timeline will help the brand to keep on track with the traceable gaols that have been set.

Appendices

(Stella McCartney, 2021)