HEAT PUMP

Arctic Heat Pumps

HEAT PUMP

HYDRONICS

ME AND MY A2W HEAT PUMP

Hot Rod shares design, installation and operation tips after installing an air to water system in his own shop.

Bob “Hot Rod” Rohr

WATER HEATING DECARBONIZATION OF A COMMERCIAL DOMESTIC HOT WATER SYSTEM

Prior to this project, domestic hot water for Vancouver’s Arthur Erickson Place was generated by different gas-fired boilers depending on the season.

ROAD WARRIOR ALEXANDER BRAKE: PASSIONATE ABOUT ENERGY EFFICIENCY

Alexander Brake enjoys working with heat pumps, especially as the technology continues to advance.

Carolyn Cooper

GEOTHERMAL LEADER OF THE PACK

Utilizing the power of the earth and constant underground temperatures makes efficiencies skyrocket, says Reid.

Matthew Reid

Editor’s Note: Be sure to check out Paul Bies’s MARKETING column on pg. 84 of this issue (May/June 2025). Bies discusses how to stand out in the heat pump market.

OTHER FEATURES

53WORTH A LOOK

Report seeks to change the messaging around geothermal energy

Carolyn Cooper

56EVENTS – HEAT PUMP SYMPOSIUM

The Heat Pump Symposium took place on May 6, 2025 at the International Centre in Toronto, ON. Kerry Turner

DEPARTMENTS

46-53PRODUCTS

A showcase of heat pump technology.

58JOBSITE JARGON

Test your knowledge of heat pump terminology for a chance to win a $150 gift card.

Everything you need, anywhere you are – scan to open the digital edition of the Heat Pump Journal.

Cover Photo: Scott Grant, RONiN photo

Me and my A2W heat pump AIR TO WATER HEAT PUMPS

Without a doubt air to water heat pumps (A2WHP) are all the buzz these days. You would be hard pressed to pick up a trade journal (or read the online version) and not see multiple articles and ads regarding this technology. Industry trade shows have been promoting A2WHP systems and offering trainings on sizing and installation.

Many of the big names in the hydronic industry are jumping onboard with product offerings. The long-established boiler manufacturers are starting to offer products and keying into a dual fuel option.

SURGE IN POPULARITY

The technology of pulling, or “pumping,” heat energy from the surrounding air is not new. This technology dates back to the 1960s. At least one manufacturer has been offering residential-sized five ton and under products for almost 20 years now.

Recent enhancements such as newer refrigerants, variable speed compressors, engineered fans, fan blades and enclosures have increased efficiencies. These upgrades also reduce noise levels and provide multi-zone applications. So, what drives the sudden and rampant growth in this technology? Many will point to the electrification movement as a prime driver. The talk of restricting fossil fuel availability is another contributing factor. For those of us involved in the hydronics world, it offers another opportunity to offer customers an option to fossil fuelled heating equipment, including boilers for the most part.

In my area there are a lot of residential photovoltaic solar systems (PV) being installed. So, covering some of the electrical energy needs with site generated power is yet another feature of an electric powered heating/cooling/DHW system.

Tighter than normal tube spacing allows for the lowest supply temperature, optimizing the heat pump efficiency.

Four inch black corrugated drainage piping protects the insulation from harsh UV, which breaks down exposed insulation.

A FIRST-HAND LOOK

I decided to jump in and install a system in my own shop to determine how these systems perform in real life. I got my system up and running in December 2024, so I was able to catch a few months of heating use data.

My system is a simple one zone radiant in slab, over about 800 square feet of shop floor area. When I built the shop in 2022, I made the decision to install the 1/2 in. PEX tube 6 in. on centre. This tighter than normal spacing allows for the lowest supply temperature, which leverages the heat pump (HP) efficiency.

Added bonuses of lower slab operating temperatures include lower downward heat loss and quick recovery. I started the system at a 46°C setpoint, and lowered it to 43°C part way through the season. I have yet to dial in the outdoor reset function. I will get that dialed in before next heating season.

The system I installed is a Viessmann Vitocal AM2V, with 20 MBH heating capacity and 1.5-ton cooling capacity. It includes a 20-gallon buffer. The fit and finish of the unit is top notch. With a single zone system sized close to the HP output, I may reconsider the need for the buffer tank. For redundancy I did keep my Lochinvar Knight boiler piped into the system.

HPJ

By Bob (“Hot Rod”) Rohr

Bob Rohr is a trainer with Caleffi, and was the recipient of the 2020-2022 Carlson-Holohan Industry Award of Excellence. He has 40+ years of experience as a plumbing, radiant heat and renewable energy contractor.

THE END RESULT

I was pleased with the operation this winter. The system never fell behind even at near design conditions of -15°C for this area. My electric bill went up from the previous year about US$100. Some of that was also a price increase for the kWh charge.

Maybe I went a bit overboard on the installation of the outdoor unit (ODU). I poured a concrete foundation, and concrete posts, and built an aluminum mounting frame to support the ODU, the goals being that the structure would be long lasting, maintenance free, and sound deadening. The ODU is extremely quiet when it’s running − much quieter than the AC unit at our nearby home.

I insulated the outdoor piping with 1 in. Armacell Tubolit non-particulating polyethylene foam and covered it with a piece of 4 in. black corrugated drainage piping. This protects the insulation from harsh UV, which breaks down exposed insulation.

ON TO COOLING

My next goal will be to see how much of the cooling load I can cover with chilled water running through the slab. I live in a very arid climate, so I think I have a good shot of covering a good portion if not all the load. Because it is my shop space, anything below the 38°C plus temperature I have experienced the past summers will be a win.

All in all, I feel the market and current product offering has evolved nicely. Inside the ODU and IDU is not a lot different than a modern mod con boiler. Large circuit boards manage the hydronic and refrigerant components. There is ample room to work on any of the parts if needed.

I run a 30 per cent mixture of Fernox Alphi 11 in the system. Inside the shop, I installed a brazed plate heat exchanger (HX) under the indoor unit (IDU), to separate the glycol from the water used in the radiant system. The “isolation” HX saved about 20 gallons of glycol, which I would have used if I had incorporated glycol into the entire system. The manufacturer’s tech support helped me use their online sizing software to select a generously sized HX to keep efficiency loss at a minimum.

The installation and start up was not unlike a hydronic boiler system. A 40 Amp circuit was required, which you do not typically require for a fossil fuelled boiler system. I was able to lock out the electric resistance back up element that is built into the indoor module.

“My electric bill went up from the previous year about US$100.” Some of that was also a price increase for the kWh charge.

PERFORMANCE COMPARISONS

I suggest you dig into the brands and features of A2WHPs. Find the job that matches the capacity of the heat pump. The outdoor temperature and the required SWT need to be considered. The lower the temperature that you run them, the higher the efficiency. Be aware that the output drops off as the outdoor temperature drops. The installation manuals have all the info, so find them online to make performance comparisons between brands and models.

I watched several training and installation videos online before I started the installation. Viessmann had a series of videos and I watched installers talk about their installations online via YouTube.

I really enjoy sharing my home project adventures with you. I imagine you too may experiment with cool heating components for fun, as well as work. Be sure to send me pictures and details of your homegrown heat pump systems!

every home

systems not only reduce your energy bills by transferring heat instead of generating it, but they also provide year-round heating and cooling. Imagine a home that stays consistently comfortable, no matter the season, all while reducing your carbon footprint. With quiet operation and a long lifespan, heat pumps are a smart, eco-friendly investment that pays off in both savings and peace of mind. Choose heat pumps for a greener, more comfortable future.

WATER HEATING

Decarbonization of a commercial domestic hot water system

Prior to this project, domestic hot water (DHW) was generated by different gas-fired boilers depending on the season. In the heating season, two large 3,077 MW (10,500 MBTU/hr) gas-fired boilers, dating from the original construction, were used for DHW production and also provided hot water for hydronic space heating. These large boilers were turned off during the cooling season and three smaller gas-fired boilers, ranging from 88 MW (300 MBTU/hr) to 147 MW (500 MBTU/ hr), were used instead. One of these three smaller boilers provided DHW for the tower and two were dedicated for the fitness centre change rooms. The DHW was stored in two large 1,325 L (350 US gallon) storage tanks, both original to the building.

The copper risers, running vertically through two mechanical shafts beside the elevator shaft, were also original to the building and had begun to leak on occasion. This signalled to Colliers that the risers were approaching the end of their long service life and required replacement.

The carrot

Each year, Kingsett Capital, one of the building owners, holds an Innovation in Sustainability competition for projects at their managed properties. For the 2020 competition, Kingsett indicated they were particularly interested in seeing submissions focused on cutting-edge technologies that have not yet scaled up to mass adoption, or are new to the Canadian or North American market. The award prize was a $50,000 contribution towards the winning project.

For its submission to the competition, Colliers proposed to combine the planned replacement of the aging risers with the electrification of the tower’s DHW system as a means to significantly reduce the building’s GHG emissions. The electrification project included decoupling the large boilers from the DHW systems, replacing the boiler serving the tower with two sets of all-electric, CO2-based heat pumps for year-round DHW generation, and installation of new DHW storage tanks. Electrification of the DHW system for the change rooms was not part of the proposal because the two boilers for this system were less than 10 years old.

The project won the internal competition, and was approved for some additional funding from the CleanBC Better Buildings program, and Colliers was tasked with implementing it.

The 26-storey office tower, Arthur Erickson Place, was constructed in 1968 and has a gross leasable area of approximately 33,445 m2 (360,000 ft2).

The Building

Arthur Erickson Place - 1075 West Georgia Street Vancouver, BC

Building Type: Office tower

Built: 1968

Estimated cost of GHG reduction: $146/tCO2e*

Reduction in GHG footprint: 40 tCO2e/year

The Team

Property manager: Colliers Canada

Mechanical consultant: SES Consulting

Mechanical contractor: Pacific Mechanical Systems Ltd.

Heat pump supplier: Small Planet Supply

Controls provider: ESC Automation

Right-sizing is critical

To begin, the DHW system was assessed by SES Consulting to ensure proper sizing of the new equipment. They began with an audit of all the plumbing fixtures to determine the number of fixtures and their flow rates. SES then used guidelines from the American Society of Plumbing Engineers (ASPE) to approximate the size and number of heat pump water heaters and the number of water storage tanks required for the project. Because the ASPE guidelines can lead to oversizing of equipment, SES refined the sizing calculations with a third party-reviewed, manual calculation which took into account low-flow fixtures and time-of-day usage patterns for certain fixtures. This ensured that the equipment was more appropriately sized for the specific hot water heating demands of the building.

Because the tower’s DHW system is divided into two loops – one serving the upper 16 floors of the building and one serving the floors below, two separate right-sizing exercises had to be undertaken. It was determined that six heat pumps and four 450 L (119 US gallon) storage tanks would be required for the upper system. Four heat pumps and three 450 L storage tanks would be required for the lower system. Because the original boilers were retained to continue to provide space heating for the building, the new all-electric DHW heating plants required a new home. Non-tenanted space on the top floor and parkade level was converted to secondary mechanical rooms to accommodate the new equipment.

An important consideration for many electrification projects is the electrical service to the building and in particular the difference

Putting the plan into action

After receiving several bids for the scope of work, Pacific Mechanical Services (PMS) was selected as the mechanical contractor for the project. Similar to many older office towers, there was enough room in the mechanical chase to install a new riser while the adjacent existing riser was in use. This allowed PMS to install the equipment in the new secondary mechanical rooms and connect it to the new riser without disrupting the water supply to the building. Once the new system was tested and commissioned, it was tied into the existing branch piping outside of regular office hours because this part of the work involved shutting off the water supply to the building or several floors at a time. Because CO2-based heat pump water heaters require low supply water temperatures to maximize efficiency, the temperature of the hot water recirculation loops is maintained using one electric swing tank for each system (instead of the heat pumps). The swing tanks, installed in the secondary mechanical rooms, are equipped with an electric resistance coil to keep the temperature in the recirculation loop at 55°F (131°C).

between the peak demand and the maximum capacity. In this case, the typical peak demand was approximately 1,500 kW, representing less than 40 per cent of the available service. There was more than enough spare capacity for an electrification project that would add no more than 100 kW to the electrical demand. The panelboards to which the heat pumps would be connected also had spare capacity and as a result, did not have to be replaced.

Because the original boilers were retained to continue to provide space heating for the building, the new allelectric DHW heating plants required a new home.

According to PMS, a big advantage of the CO2-based heat pump water heaters is they can be installed by plumbers, rather than specialized refrigeration technicians because the CO2 refrigerant is sealed entirely within the heat pump units. This reduces the installation cost of the system, compared to systems where refrigerant lines are installed in the building.

Original gas-fired boiler.

CO2-based heat pump units.

WATER HEATING

The end result

The project is expected to reduce the building’s GHG footprint by approximately 40 tCO2e/year (at full occupancy). In addition to significantly reducing the building’s operational emissions, the refrigerant used for the heat pump water heater also reduces the risk of contributing to global warming should a leak occur.

Colliers is monitoring the energy consumption of the systems with dedicated submeters. In addition to providing specific energy consumption data for the DHW systems, the submetering should provide a means of detecting most

Hot water storage tanks and electric swing tank.

Ducted and ductless system solutions for every application

Discover the latest innovative HVAC products with LG Air Solutions. LG offers a wide range of electric heating, ventilating, and air conditioning solutions, along with controls, for today’s modern homes.

As the world is working to reduce its reliance on fossil fuels, LG Air Solutions is championing the switch to electric with stylish and dependable electrification solutions. Choose from our ENERGY STAR® certified products, which provide an opportunity to help reduce energy consumption, increase efficiency, and enhance whole-home comfort.

operational issues as they occur. This will allow Colliers to maintain and repair the systems in a timely manner and as a result, maximize the service life of the heat pumps.

Based on an average run time and indoor installation (protected from precipitation and high humidity), the heat pumps are expected to have a service life of 15 to 20 years, with little more than annual or semi-annual maintenance. After the expected service life, it may be possible to simply replace wornout components rather than replace the entire heat pump.

Given how recently the project was completed (2021) and that the year-overyear difference in GHGs and electrical consumption values have been skewed by the pandemic, it is difficult to determine representative results. Assuming full occupancy and an increase in electrical consumption of approximately 60 MWh/ yr, Colliers expects the payback period for the electrification portion of this project to be approximately 15 years. The capital cost portion of the payback period calculation is based on the estimated difference in cost between a new gas-fired DHW system and the installed system, less the financial incentives. The corresponding GHG reduction cost is estimated to be approximately $146/tCO2e (taking into account the incentives but not including any reduction in maintenance costs).

Colliers and SES Consulting are now working with the building owners to develop a netzero carbon retrofit plan for the building as a whole, with the DHW project forming the first step on this journey.

LG ARTCOOLTM Deluxe

LG Cold-Climate Heat Pump LG A-Coil

LG Multi-Position Air Handler

UNLIKE BLENDS, R-32 IS A PURE, SINGLE-COMPONENT REFRIGERANT, MAKING IT EASY TO REUSE, RECYCLE, RECLAIM, AND SERVICE! The easy choice.

Daikin

ROAD WARRIOR

Name: Alexander Brake

Company: Total Energy Solutions

Job title: Owner

Born in: Meadows, NL

Live in: Hughes Brook, NL

Age: 29

Pet: A Labrador/Shepherd mix named Sade

Alexander Brake: Passionate about energy efficiency

Growing up Alexander Brake knew he wanted to work in the skilled trades, but he was unsure which sector he preferred. “I knew I needed to do a hands-on career, something that challenges you, with your mindset as well as the physical aspect, and the trades are certainly where to go for that,” he recalls. It was after finishing high school, when Brake spent a year working with a local HVAC company doing residential ductwork, that he became hooked on the industry. “The first time they installed a heat pump system and I saw the gauges come out, that really piqued my interest,” he laughs.

Brake attended College of the North Atlantic and apprenticed with Dan Spence Refrigeration in Deer Lake, NL, working on “anything you could think of that heated up or cooled down.” He established his own HVAC company, Total Energy Solutions, in 2020 with business partner Roy Moores, at first servicing residential and commercial systems and eventually focusing on “heat pumps and home heating satisfaction,” he says. “When we got into that I kind of got drawn into the reaction of the customer when you put a new system into their home and you see the acknowledgement that they now have an energy efficient home that they can rely on. It’s kind of addicting. So, we kind of left the commercial side to the wayside.” The company also became a subcontractor of Toronto-

based 1Click Heating and Cooling, an electrification service provider operating across seven provinces, and in 2023 became a partner with 1Click. “We developed a shared interest, shared values and what we were trying to produce for the customer base,” says Brake. “1Click started off as a heat pump company, but everything right now is moving more towards electrification, so electrical upgrades, electrical equipment, battery backup systems, monitoring systems, anything to reduce loads in homes and the power grid as well. We’re going that route currently.”

Brake enjoys working with heat pumps, especially as the technology continues to advance, noting that “you’re not able to just stand by and watch this system or this industry develop, you have to be a part of it at all times. It’s a constant engagement with the equipment and with the industry that keeps you engaged all the time.”

Brake has already seen how cold climate heat pump technology is impacting heating and cooling in harsher climates like Newfoundland. “The first time we installed a heat pump system it wasn’t actually designed for our climate, the unit did not have a defrost sequence, so it completely froze solid with no way to defrost that ice or snow build up. It wasn’t designed for the humidity levels or the cold temperatures that we experience here

By Carolyn Cooper

in Newfoundland. Now the technology has improved dramatically, and not only the technology, but the industry itself. The producers of the equipment are listening to the techs in the field, getting proper feedback for certain areas and making adjustments to make sure that their equipment will work in any circumstance.”

With 12 employees, including eight technicians, the company covers much of western Newfoundland, and Brake anticipates expansion into eastern and central parts of the province with support from 1Click. “We do work with subcontractors in the other areas, and we’re basically developing those other regions to mimic the same reputation that we have on the west coast and the same reliability,” he explains.

“We’ve expanded within the last five years exponentially. And I think it all comes down to, again, the reputation and the quality of work that we hold ourselves to. Our work speaks for itself, and we make sure we do everything we possibly can to satisfy our customers.”

In the mechanical industry since: 2014

Schools and programs: College of the North Atlantic, Refrigeration and Air Conditioning

Advice for young people considering entering the trades: Stay curious and remain open to learning. Find a mentor early on, someone who’s been through it and can help guide you. A strong work ethic, a willingness to adapt, and the right support can take you a long way in this field.

The current work ride: 2500 GMC truck

Service area: All of western Newfoundland

If you were granted one wish: I would wish for everyone to switch over to a heat pump. If people truly understood how much they could save, how energy-efficient these systems are, and the overall benefits they offer, more homeowners would make the switch. It would be amazing to see more communities embrace this technology.

Any area you like to get dispatched to, and why: I enjoy getting dispatched to remote areas because I’m able to help people who truly need it. In many of these places, access to reliable HVAC service can be limited, so it feels good knowing my work makes a real difference.

Favourite tool in your toolbox: My refrigeration gauge

The most useful tool in your toolbox: A debugger tool

Favourite parts of the job: Being able to help people, educate homeowners, and constantly learn new things. I take pride in knowing that I’m helping people make their homes more energy efficient, which contributes to a greener, more sustainable future.

Favourite music style: Country music

Favourite sports: Baseball and hockey

Favourite car of all time: 1985 Chevy 1500

Favourite season: Fall

Favourite food: Good pasta

Favourite snack: Flavoured chips

Favourite outdoor activity: Hunting

Hobbies: Hunting, fishing, and playing softball and hockey

Biggest pet peeves: A lack of craftsmanship and cold coffee. There’s nothing more frustrating than seeing work that’s rushed or done without care. And as for cold coffee, it’s just one of those little things that can throw off your day – nothing beats a fresh, hot cup to keep things going.

One place in the world you would like to visit: Alaska

One word or phrase that describes you: Resilient. Whether it’s in work or life, I believe in staying strong, adapting, and never backing down from a challenge.

Do you play an instrument? I play the guitar

Finish these sentences: My rule of thumb is ... work smarter, not harder. Automation and technology should enhance HVAC services, not complicate them.

When I was a kid, I wanted to be a ... garbage truck driver, because my Grandpa was one and I wanted to be just like him. He was hardworking, dependable, and someone I really admired.

GEOTHERMAL

By Matthew Reid

Matthew Reid is technical director – heating division at Enviroair’s Richmond Hill, ON office. He can be reached at mreid@enviroair.ca

Leader of the pack

Aco-worker recently asked me “What type of system is best?” I took that to mean which system is most efficient year-round and it really got me to thinking. Usually, I talk about one type of system at a time during presentations and discuss the features and benefits of that particular system, but the question had me considering what is actually the “best” type of system to heat and cool buildings.

There are numerous options with boilers, chillers, air handlers, heat pumps, and so on. Which system would come out on top if they were all thrown into an arena and had to duke it out? I believe the one that would win for best system for all intents and purposes would be geothermal or geo as it is sometimes referred to.

Geo has an exceptionally long history. The first documented commercial geo system dates back to 14th century France. They used wooden pipes and harnessed the power of hot springs. Perhaps this is not the geo power you are accustomed to with earth bore loops and heat pumps but it is still harnessing earth power to heat. It goes to show that when it comes to not freezing to death humans show great ingenuity when thinking of ways to stay warm.

Geothermal systems can usually be retrofitted for existing structures with the conventional system typically replaced with a geothermal heat pump and other equipment.

So, how does geo get incorporated into the modern world, and especially how does it get introduced to 30-storey towers in our cities? Not every site has hot springs or lava pools to pull heat from. That is where you will see the more traditional geothermal heat pump type systems we know of today. These systems require earth loops and heat pumps to either absorb or reject heat.

How do we get geo to a tower in the middle of a metropolitan city? The answer is an engineering marvel and comes down to one seemingly simple action: Drill baby, drill.

Before I continue, I will note that there are district geothermal utilities in many cities that buildings can tap into. These utilities are great at what they do and if you have the opportunity to partner, that is likely the easiest way to go about utilizing geo energy in a building, but that may not always be available in the area and that’s what I will focus on.

The most economical and simplest way to get a geothermal field incorporated into a tower is to put the geo field in place before the building goes up.

Photo Fleming Steel Erectors

Discover 100% capacity and 100% performance down to -30°C.

The new Orion XLTH+…a star performer in extreme weather.

Like the Orion Constellation brightening the winter night sky, the Fujitsu AIRSTAGE Orion XLTH+ Series stands out as a brilliant star for heating performance...even in the harshest climates. While others fade in extreme cold, Orion shines brighter, delivering more than 100% capacity even at -30°C.

Beyond 100% Performance at -30°C – No derating, just powerful, consistent heating. No Lockout Temperature – Unlike other systems, Orion keeps running in relentless cold.

ProCore™ Corrosion-Resistant Technology – Built to endure and perform.

Advanced Defrost Cycle – Reduces downtime, maximizing comfort and efficiency.

Flexible Installation – Designed for seamless integration into a variety of applications.

Orion XLTH+...the stellar performer in low-temperature heating.

Fujitsu

GEOTHERMAL

DRILLING CONSIDERATIONS

The absolute best way to get a geothermal field incorporated into one of these buildings is to put the geo field in place before the building goes up. It allows the use of giant drilling machines that can go down 600 to 800 ft. to create a well. The number of wells will depend on the building heating and cooling load but it’s not uncommon to have from 50 to 200 holes depending on the building size.

There are a lot of considerations when drilling in any area such as existing underground infrastructure; including unconsolidated overburden sitting on top of bedrock where the boreholes may need to be cased during drilling to prevent collapse; and aquifers.

Adding geothermal wells to existing towers is complex. Drilling wells or ground loops under existing structures such as towers is generally avoided due to potential structural damage and safety concerns. If geothermal systems are needed, alternative solutions such as vertical ground loops or horizontal ground loops outside the immediate tower footprint are usually explored and all of the above drill considerations must still be reviewed. It is difficult to incorporate geo systems in this situation but it’s not impossible. After the holes are drilled and the piping for the geothermal system is run through the wells the more complex part of the system comes in when you have to tie everything together. Geo fields are often referred to as “the source” when talking in terms of geo mechanical designs.

It’s this source that makes geothermal such an efficient system. The source is constant and heat pumps love constants. Calculating heating and cooling outputs with a constant source temperature is a very reliable way to know what output loads can be year-round unlike air source which has a variable source (ambient outdoor air) temperature where the output can vary.

Why doesn’t everyone have GEO?

There is another consideration for a geothermal well. It’s one that we don’t talk about very often: the lifespan of the well and source field. That’s right, fields do come with a best before date and it is long but still finite. Geo wells last from 50 to 100 years. The longevity of the ground loop depends on the quality of materials used, proper installation, and the balance of heat extracted from and added to the ground.

A further drawback of geothermal systems is the upfront capital cost. You have the cost of drilling, which is all over the map

depending on soil make up, depth, and the equipment required. The piping can literally be miles of underground piping. Pumps are required to move the fluid medium through these pipes and through the heat pump. There is of course the heat pump itself. There are also controls and terminal units to consider. There is a tremendous number of components in a geo system and all of these will have a cost associated with them.

Geo is not cheap but it is the embodiment of pay me now or pay me later. Utilizing the power of the earth and the constant temperature of the underground makes efficiencies skyrocket. The higher the efficiency the lower the utility bill will be. Geo is something that should be considered when selecting what type of heating and cooling system to use in a building.

Ground source heat pump types defined

There are three types of ground-source heat pump: closed loop, open loop and direct expansion.

Open loop

This type of heat pump uses a lake, river or another body of water to exchange heat. The unit draws water directly to the heat exchanger, where heat is extracted. The system discharges the water either to an above ground body of water or back underground through a well.

Closed loop

Most closed-loop pumps circulate an antifreeze solution through a closed loop, usually made of plastic tubing, which is buried in the ground or submerged in water. A heat exchanger transfers heat between the refrigerant in the heat pump and the antifreeze solution in the closed loop. The loop can be in a horizontal, vertical, or pond/lake configuration.

Direct exchange

In this system, a refrigerant circulates through a continuous loop of copper tubing placed in the ground. It uses a relatively shorter and smaller set of buried tubing, reducing installation costs.

Source: NRCan

Wolseley

HEAT PUMP PRODUCTS

Side-discharge

The EcoNet-enabled Ruud Endeavor RD17AZ heat pump is compatible with nearly any existing HVAC system or as a universal replacement. As part of the Sound & Space Constraint Solution, it features a compact footprint making it a solution for applications where space is at a premium, with sound as low as 58 dBA.

www.

rheem.ca

Geothermal zone valve

Geothermal Heat Motor zone valves from Taco are made for high-head, open-system zone control, and provide a way to create individual zones or equipment isolation in a hydronic heating system. End switch design allows the valve to control the heat pump, allowing cold water into the coil before the heat pump starts. Twist-off head allows it to be serviced without disturbing system connections. Available in connection sizes 3/4 in. threaded, 3/4- and 1-in. sweat. www. tacocomfort.com

Easy service access

Arctic EVI air-to-water heat pumps are specifically designed for North American weather, with the ability to operate in as low as -22°F (-30°C) temperatures for hydronic heating and cooling. With a mono-block design and multiheat pump staging, the Arctic EVI has a COP of 3.1/3.2, and is available in three models offering 29,000 BTU, 48,000 BTU and 60,000 BTU respectively. The unit is WiFi enabled for full remote control, and offers ultra-quiet DC motor fans, intelligent defrost based on ambient temperature, and Blue Fin technology on evaporator and condenser fins for high corrosion resistance. www. arcticheatpumps.com

Cold temperatures

Designed for Canadian winters, the LG cold climate heat pump operates at temperatures as low as -35°C. It retains full heating capacity down to -25°C and functions at 70 per cent capacity at -35°C. Additionally, the heat pump incorporates a refrigerant cycle that prevents frost accumulation on the outdoor heat exchanger, for enhanced heating performance. The heat pump is also equipped with a high-capacity, highefficiency twin rotary inverter compressor that uses low GWP R-32 refrigerant; COP at -15°C for 9K BTU is 2.04 and 12K BTU is 2.05. www. lghvac.com

Universal heat pumps

The Daikin FIT offers cooling and heating with the energy-efficient power of a heat pump with adaptive inverter technology. It is a quiet, compact, smart and efficient HVAC unit for ducted homes. This all-electric system is designed to provide reliable, yearround performance without the noise or bulk of traditional units. This unit is five times quieter than non-inverter systems and less than 14 in. wide, and delivers up to 19.0 SEER2, 8.8 HSPF2 and 2 to 5 tons.

www. daikincomfort.com

All climate heat pump

The Midea EVOX delivers cooling in temperatures up to 47°C and heating down to -30°C. With dual-fuel compatibility and inverter-driven performance, it suits both new construction and retrofit applications. Enhanced vapour injection technology ensures year-round comfort, while the modular Block-n-Lock air handler simplifies installation in tight spaces. Featuring dualvoltage compatibility, flame-free flair fittings, and wireless Sub-1GHz communication, EVOX uses low-GWP R-454B refrigerant.

www.

midea.com

Cold climate mini split

Fujitsu has launched the AIRSTAGE Orion XLTH+ (Extra Low Temperature Heating Plus) cold climate heat pump as part of its H-Series R-32 heat pump line. The single-zone, wallmounted mini-split system works in temperatures as low as -30°C, with a SEER2 rating of up to 33.5, and 100 per cent capacity heating at -26°C and 90 per cent capacity at -30°C. Featuring a compact design and remote monitoring through the AIRSTAGE app and built-in WiFi connectivity, the system has sound levels as low as 23 dBA indoors and 44 dBA outdoors. Units are available in models with maximum heating capacities of 24,000, 27,300, and 28,000 BTU/hr.

www.

fujitsugeneral.com

Geothermal system

Side discharge

The Goodman SD is a split system, side-discharge air conditioner and heat pump designed to optimize space and performance. The inverterdriven, variable-speed units are a compact, high-efficiency solution for small spaces. With performance as low as 56 dBA and 45 dBA in quiet mode, SD air conditioners deliver up to 17.2 SEER2, with cooling up to 46°C, while heat pumps reach up to 17.5 SEER2 and 8.5 HSPF2, with heating down to -12°C.

www.

goodmanmfg.com

The 5 Series 3D residential system from WaterFurnace provides energyefficient forced air heating, cooling and hydronic heat for radiant floors and domestic hot water heating all in one unit. Units come standard with low GWP refrigerant and Aurora Advanced Controls for operating logic, troubleshooting and two-way communication between components for real-time remote system access. Other features include aluminum PinnaCoil with anti-corrosive properties, variable speed ECM motor, 27.8 EER and 4.7 COP.

www.

waterfurnace.com

Wall mounted unit

The Meridian wall mounted heat pump system from Moovair is now available in a mid-size 15,000 BTU. This A2L unit uses R-454B refrigerant and delivers up to SEER2 22.2 and HSPF2(V) 8.5. It includes a built-in multifunction board for auxiliary heat, a refrigerant leak sensor, and offers stable, high-efficiency heating performance down to -30°C.

www.

moovair.com

HEAT PUMP PRODUCTS

Automated temperature controls

The R-454B-equipped Climate 5000 ductless mini-split heat pump system from Bosch Home Comfort features Intelligent Eye infrared technology. When the room is empty, the Intelligent Eye eases off the compressor speed to conserve energy and control humidity. A factory-installed A2L sensor on the evaporator coil directly connects to the indoor unit’s control base. The condenser powers up to six indoor air handlers, and electrical, refrigerant and condensate drain lines connect outdoor and indoor units via a 3-in. diameter hole. A backwardscompatible universal-wired thermostat is included.

www. bosch-home.ca

Gas heat pump

Anesi’s gas heat pump delivers 80,000 BTU/hr heating capacity, and space heating down to -40°C without the need for backup. The unit is UltraLow Nox compliant, and its 140per cent AFUE lowers gas use and reduces CO₂ emissions. The sealed system contains R-717 refrigerant with zero GWP and no PFAS, and uses existing 120C/15A circuits. Other features include variable speed evaporator fan and 4:1 modulated burner, rear water and gas connections with built-in isolation valves, and remote system monitoring.

www. stonemountaintechnologies.com

Hybrid system

Weil-McLain introduces the ECO HP air to water heat pump, an electric heat pump designed for residential and light commercial applications. As part of the ECO hybrid dual-fuel hydronic system, it pairs high-efficiency heat pump technology with a traditional gas boiler. Made for maximum performance in all climates, the system features efficiencies up to 5.37 COP, R-32 refrigerant, and ultra-quiet operation.

www.

weil-mclain.ca

UNIX SERIES

HIGH-EFFICIENCY CENTRAL HEAT PUMPS WITH CASED COILS

Heat pump combination AHRI Certified for installation with ANY 3rd party furnace.

Eligible to financial incentives in certain provinces, contact us for more detail.

SPARE PARTS

TO FULLY SUPPORT OUR DEALER NETWORK

*GREE Canada is not responsible for warranty on units sold outside GREE Canada’s sales channel.

For more detail, contact our team at proservice@gree.ca.

HEAT PUMP PRODUCTS

Solar system

EcoSolaris hybrid solar air conditioning and heat pump systems cut energy costs while reducing environmental impact. Heat pumps can run on solar, grid, or both, offering flexibility for a range of applications, including residential, commercial, and remote settings. Certified by ENERGY STAR and Intertek, EcoSolaris systems use R-32 refrigerant, and can be controlled via WiFi by a smart phone. Heat pumps are available in 12,000 BTU and 18,000 BTU sizes.

www.

solarcooling.ca

CONFORTO

STAY COOL ALL SUMMER WITH CONFORTO

Conforto heat pumps keep your home refreshingly cool during the hottest days of summer—without compromising on energy efficiency. Choose the Cold Climate Centrally Ducted System for whole-home cooling or the Maximum Ductless Mini-Split for targeted comfort in any space. Both systems are whisper-quiet, ENERGY STAR® certified, and built to perform year-round.

Conforto Granby

Compact footprint

Samsung’s Hylex heat pump is a universal, inverter-driven solution that replaces traditional AC units without requiring a full system overhaul. It is compatible with existing coils and infrastructure, helping reduce waste and lower installation costs. It has a compact footprint (3.34 ft²) making it easier to move using a dolly and to get through gates, and requires less space on the installer’s truck. It is available in capacities from 2 to 5 tons, with SEER2 up to 18.5 and an operating range of -20°C to 51.7°C for cooling and down to -25°C for heating.

www.

samsunghvac.com

Self-cleaning coils

Hitachi airHome features R-32 refrigerant and energy-saving motion sensor technology. The H600 wall mounted indoor unit heat pump has an operating range for heating of -25°C to 24°C, and -18°C to 48°C for cooling. Units have WiFi with AirCloud Go, FrostWash 3.0 self-cleaning coils, and PM2.5 filtration. FrostWash technology freezes dust and dirt, melting it and washing it away.

www.

master.ca

HEAT PUMP PRODUCTS

A2W monobloc

The Versati IV air to water monobloc heat pump from Gree is an all-in-one solution for heating, cooling and domestic hot water production. Featuring inverter technology and Gree’s dual-stage inverter compressor, the unit can produce heat at outdoor ambient temperatures as low as -25°C. The Versati IV has a heating capacity of 54,598 BTU/hr, EER up to 11.8 and COP of up to 4.4, and sound power level of 60 dBA.

www.

gree.ca

Chiller heat pump

York’s YMAE inverter modular chiller and heat pump is engineered for commercial applications, using low-GWP R-454B and offering up to 20.01 IPLV and COPshc 8.1 in simultaneous mode. Modular two- or fourpipe configurations and inverter compressors (575V/3ph/60Hz) ensure installation flexibility, exceptional part-load efficiency, and reliable performance. www. york.com

Mini split series

Convectair introduces Legato, a mini split heat pump series designed for residential or commercial spaces in all seasons. Available in 9,000, 12,000, 18,000 and 24,000 BTU capacities for both indoor and outdoor models, the series offers a high-performance invertor compressor, Golden fin element coating, and 20 dB operation in Silent mode. Operating in temperatures from -29°C to 30°C, the units use R-454B refrigerant and are WiFi enabled using the Convectair Connect app. www.

convectair.glendimplexamericas.com

Ensure your HVAC/R appliances, equipment and components are certified to meet the latest regulatory requirements utilizing low global warming refrigerants. Intertek’s experts will help you gain compliance and certification for flammable refrigerants with speed to market.

Low-GWP R-32 refrigerant

Daikin Rebel Applied packaged rooftop systems are electricity-powered heat pumps, with lowGWP R-32 refrigerant and inverter compressors. An additional outdoor coil surface and a supplemental compressor kick in when temperatures drop. Energy recovery wheels, an optional feature, preheat air before it passes through the heating coil, extending the heat pump’s capacity once again. By using configurable circuitry, and isolating new loads to smaller and separate circuits, the systems eliminate or minimize electrical infrastructure modifications, trimming installation time and associated expenses. www. daikinapplied.com

Rooftop units

Lennox Enlight dual fuel heat pump is powered by the Lennox CORE control system, and offer energy-efficient, environmentally friendly, and serviceable design with the flexibility to configure the product to your exact application. These heat pump and dual fuel configurations are available from 3 to 25 tons and meet a range of applications. The line has SEER rating up to 17 SEER2, and 12.7 EER2 and is available in 575v/460v 3ph and 208/230v 1ph/3ph

www.

lennoxcommercial.com

Multipoise design

The Conforto ducted heat pump offers 100 per cent heating capacity at -20°C and operation down to -30°C. It features advanced inverter technology, side-discharge design, and quiet operation. The heat pump is compatible with most third-party thermostats, and is ENERGY STAR certified.

www.

confortohvac.com

WORTH A LOOK

Air to air heat pump

Viessmann’s air to air ductless heat pump systems are designed for residential and light commercial applications. The systems use inverter technology which continually adjusts the compressor speed as conditions change to maintain consistent comfort while reducing energy consumption. The systems have powerful low ambient heating and cooling down to -30°C and as high as 50°C.

www.

viessmann.ca

HPJ

Report seeks to change the messaging around geothermal energy

Baseload

Capital has released a report highlighting the ways geothermal could transform the energy transition, but calls for unity in communication and collaboration to mobilize the geothermal sector.

“We must reshape the narrative using storytelling and visuals to make geothermal appealing and simplify the message,” says Kristina Hagström-Ilievska, CMO of Baseload Capital, a Stockholm, Sweden-based investment firm that funds the deployment of geothermal power plants worldwide. Hagström-Ilievska says that the global renewable energy capacity will need to triple within five years to power data servers and for other uses, meaning an additional 16,000 gigawatts of geothermal energy will need to come online.

“There is no crowd or competition in this race. There could be 100 more companies working in geothermal, and we could all be successful,” she says. Hagström-Ilievska also notes that like geothermal power, the solar energy sector faced similar challenges in terms of public perception but has been able to overcome them.

“[The solar energy sector] made an exponential leap from being very expensive to being affordable. How can we do that for geothermal? There is a lot to learn; from their business models to how they used advocacy and lobbying to get their voices heard.”

By Carolyn Cooper

She adds that there are “massive learning opportunities by looking at collaborative efforts with other energy sources,” and that communicating with end users will be vital to keep the geothermal sector strong and moving forward.

From 2022 to 2023 Baseload Capital joined with other stakeholders, including Geothermal Rising, the International Geothermal Association, ThinkGeoEnergy, and Ormat Technologies, to establish a foundation for continued work and long-term impact. They also established the Declaration of Communication for geothermal sector participants, which “explains why we need one united voice and offers clear, actionable steps,” says Hagström-Ilievska.

The company is also creating a resource hub at geothermaldoc.com, says Hagström-Ilievska, “where people working with geothermal and communication can access information and get inspired. We’re calling on ambassadors worldwide to join this energy revolution!”

baseloadcap.com

Say hello to the airHome series by Hitachi

Canada’s newest name in high-performance heat pumps.

NOW EXCLUSIVELY AVAILABLE AT MASTER

airHome systems are designed for all-season comfort with the smart features your customers want and the reliability you need.

• R32 refrigerant – low GWP, in use by Hitachi since 2013

• Built-in Wi-Fi with AirCloud Go™ app

• Reliable heating down to -30°C

• Motion sensor for smart energy savings

• FrostWash™ 3.0 self-cleaning coils

• Models: 400, 600, 800 & multi-zone

• PM2.5 active carbon filter – lab -tested for fine particles

EVENT HIGHLIGHTS

Heat Pump Symposium sees impressive growth in just three years

The third Heat Pump Symposium, held May 6 at the International Centre in Toronto, ON, featured 22 educational sessions and 80 exhibitors. Sessions addressed regulatory trends, financial and policy incentives, adoption barriers and opportunities, rebates available in Ontario, and the results of the Bridging the Skills Gap for Heat Pump Proficiency research project.

Case studies a popular draw

Alex Kalopsis, City of Toronto; Joanna Jackson, Minto; and Etienne de Muelenaere of Ecosystem walked attendees through a City of Toronto’s Deep Retrofits Challenge project in Yorkville. Minto’s 61 Yorkville is a mixed-use building combining 181 apartments, amenity spaces, and commercial space. In partnership with Ecosystem, Minto is undergoing a deep energy retrofit that is expected to reduce energy use intensity by 50 per cent and lower greenhouse gas emissions by 80 per cent. The session showcased real-world implementation and lessons learned from the project. A second case study presentation shared insights from Bondi Energy and Dream Unlimited about their latest retrofit of 723 Bloor St. West.

Coming soon

The event, which attracted 1,000 delegates, was hosted by The Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI). The Atlantic symposium will be held September 23 in Halifax, NS following the 2025 HRAI Conference and AGM.

By Kerry Turner

The Atlantic symposium will be held September 23 in Halifax, NS following the 2025 HRAI Conference and AGM.

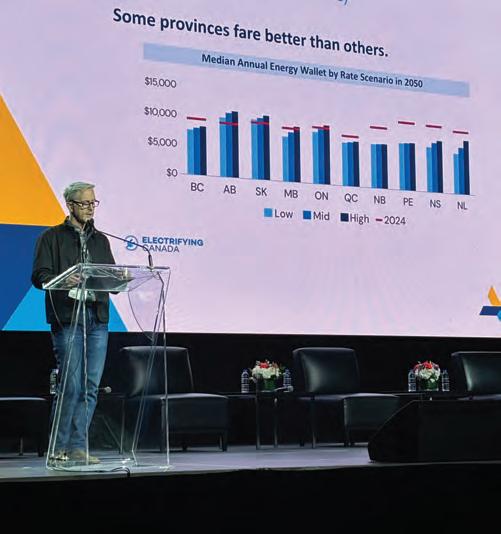

1. Opening keynote speaker Bryan Flannigan talked about the future of heat pump technology and shared specifics about heat pump uptake across Canada. Flannigan is executive director of the Building Decarbonization Alliance.

2. Virtually every heat pump technology was represented at the symposium with 80 exhibitors on the show floor

3. Gord Cooke, president of Building Knowledge Canada, discussed sales strategies for promoting heat pumps in a competitive market. He noted that customers need to be aware of energy efficiency and cost savings. Attendees also learned how to address customer concerns and boost adoption.

4. Closing keynote speaker Mélanie Auvray of the European Heat Pump Association provided insights into supply chain and competitiveness in the heat pump industry. The session highlighted international strategies for market expansion.

A heat pump that heats, cools, and purifies the air…

New model with better purification capabilities now available

R32 Refrigerant

• Higher cooling capacity *

• Reduce energy cost *

Suitable for cold climate

• Room Freeze Protection

• Base Pan Heater

Improved nanoe™ X air purification effectiveness

• 10x more hydroxyl radicals/ second compared to previous ClimaPure™ XE model

* Compared to R410A Refrigerant

5 effects nanoe™ X air purification technology

Inhibits 3 types of pollutants

Deodorizes Odours Hazardous substances Pollen Allergens

Now available!

Scan QR code to learn more

Test your heat pump knowledge!

Match the terminology you hear in the field to the correct definition or function by June 27, 2025 and enter for your chance to win a $150 Visa gift card. This contest is open to Mechanical Business subscribers in Canada. Enter online at mechanicalbusiness.com or send answers to kerry.turner@mechanicalbusiness.com.

JOBSITE JARGON

EXAMPLE: 4) Single-zone K) A single compressor connected to a single air handler

Answer 4,K

Thank you for participating!

A) These indoor units are generally located on the floor or wall of an occupied space, and heat or cool the air in that space directly

B) Allows for a full range of operation, similar to the accelerator in a car, and automatically adjusts output for optimal efficiency

C) Performance testing standard for three phase air-source heat pumps

D) Component of a heat pump’s outdoor compressor unit that receives refrigerant in the form of hot gas from the compressor and cools it into a warm liquid

E) Also called dual-source or multiple-source, these heat pump systems combine multiple geothermal sources, or both geothermal and air source

F) Geothermal heat pump that collects thermal energy from a water source and transfers it either to indoor air (water to air) or to water (water to water)

G) A measure of heat pump capacity equivalent to 3.5 kW or 12,000 BTU/hr

H) Allows cold-climate heat pumps to improve performance in cold temperatures by allowing increased refrigerant flow into the evaporator coil

I) Establishes an electronic connection between all the different heating and cooling system components to optimize overall performance, efficiency and comfort

J) Geothermal heat pump that collects thermal energy from groundwater or water from a source such as a pond, lake, or well, and circulates it through pipe before depositing it back into the source

K) A single compressor connected to a single air handler

Senville